working its way loose. This was a good time to get all new

bearings in the 9.5" 3rd while the engine bay is being stuffed

with a 330 horse power LT1 with auto tranny. As it turns

out, the 411 original gearset would also need replacing

but more on that later.

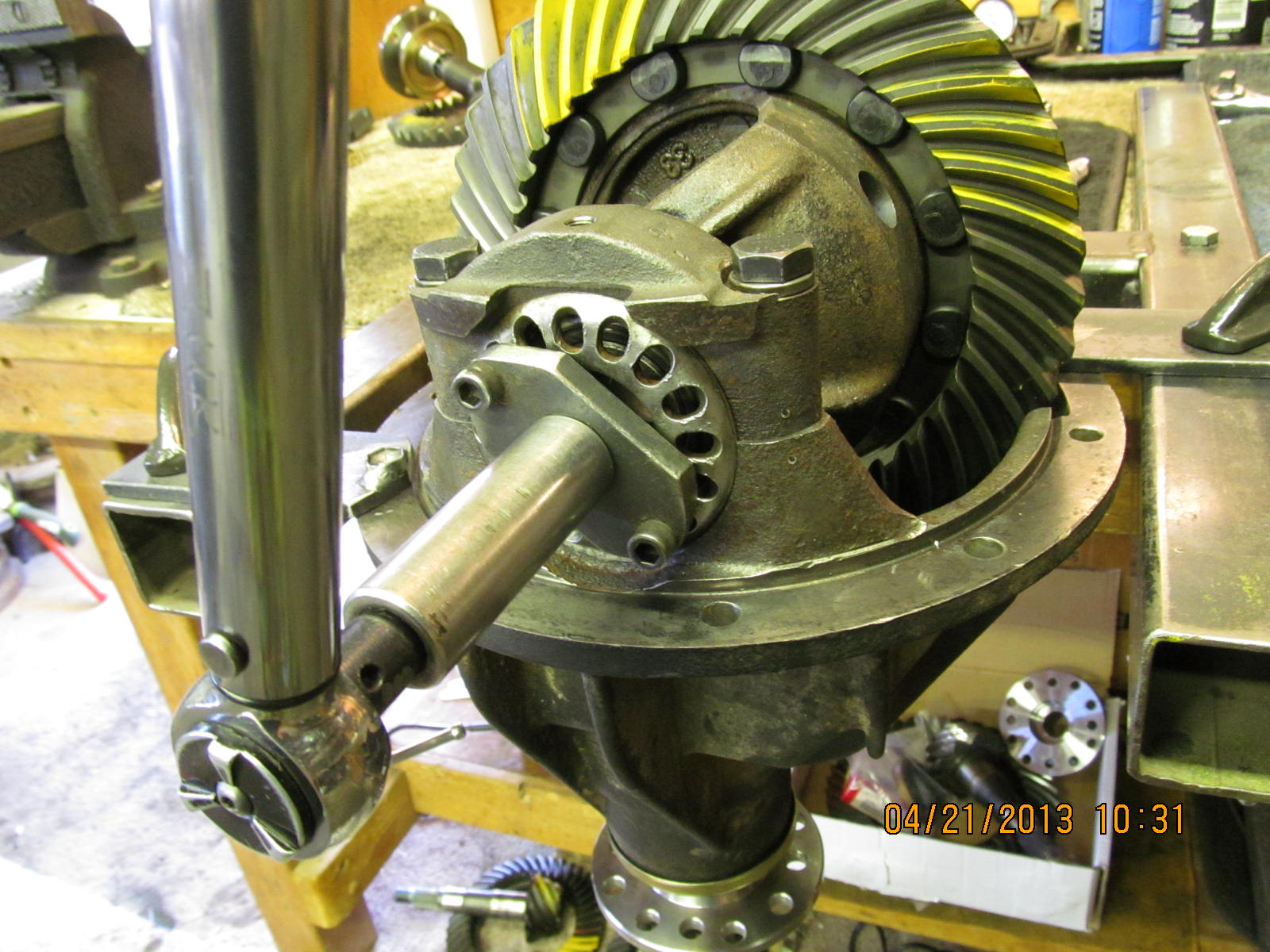

dis-assembled package over to me. By the way, Brad reports

that the Aussie works great. Note the coarse spline pinion

and the brand new coarse spline flange.

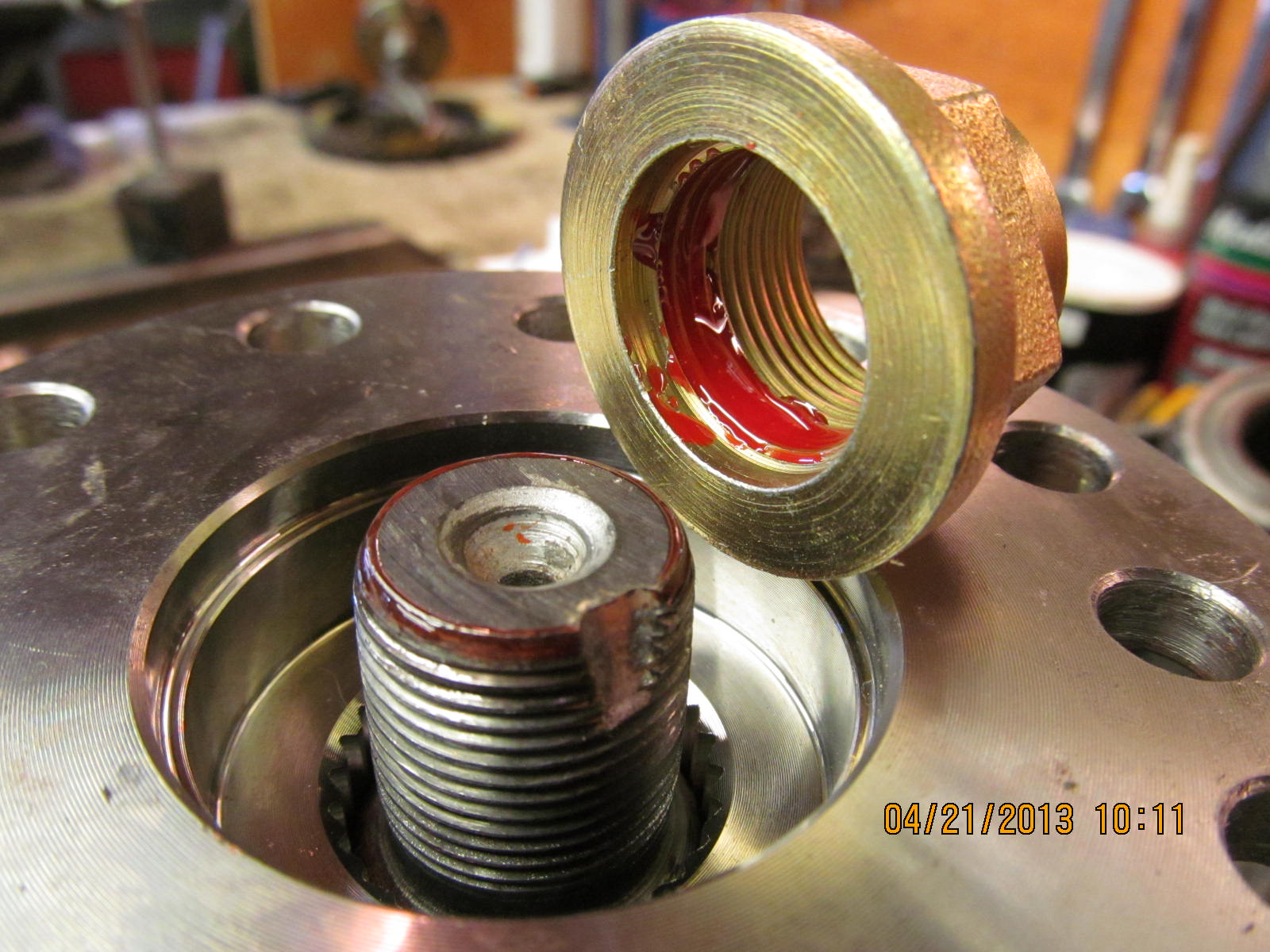

built in 'solid collar'.

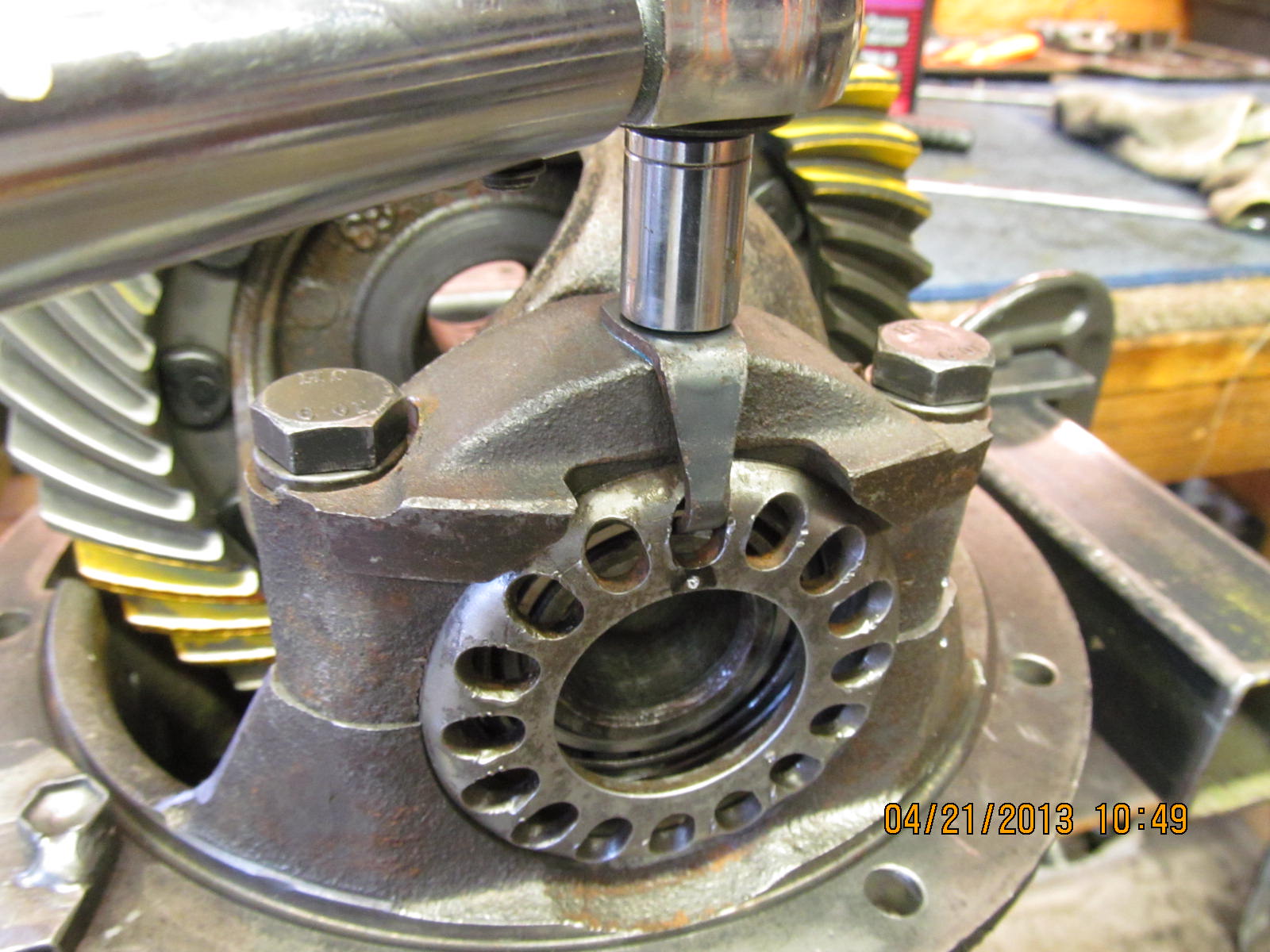

An old race is used to press the new one in all the way.

thoroughly and green sleeve-locking compound will fix that.

12mm x 1.5mm tap chased the threads as good as good gets.

The 2 related metric bolts had to be replaced and, as you

know, Ace is the place. You Russian guys that are running

this page thru the translaters are probably wondering what

the heckski is this American guy talking about :) Ace is

a popular super sized hardware store on the west

coast, at least.

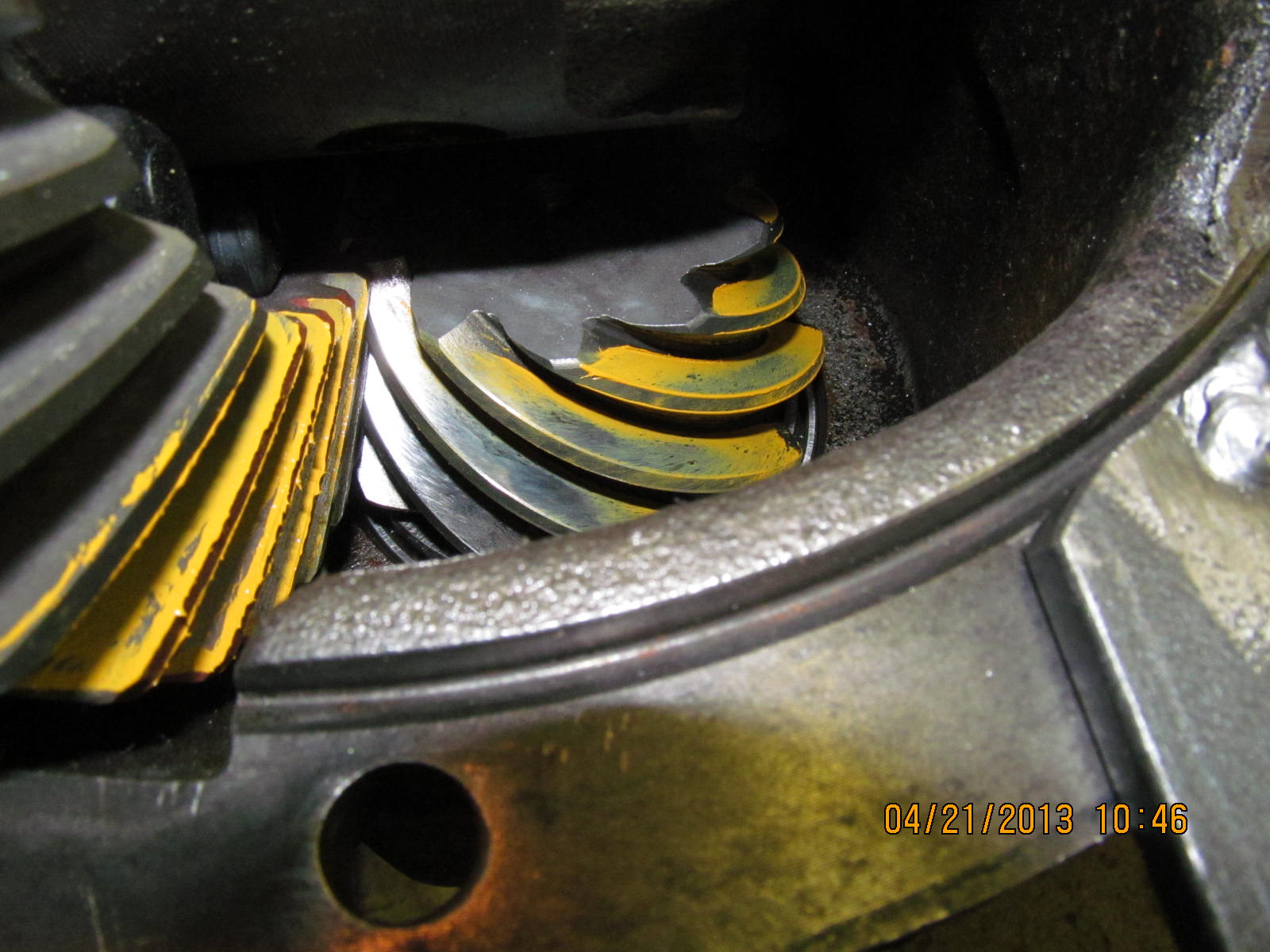

I was using the 19mm wrench to turn the ring gear. Not only could

I feel it in the wrench but I could also hear the rumble noise.

the tooth also.

pattern and rumble.

condition in an attempt to move the drive pattern off

the toe end.

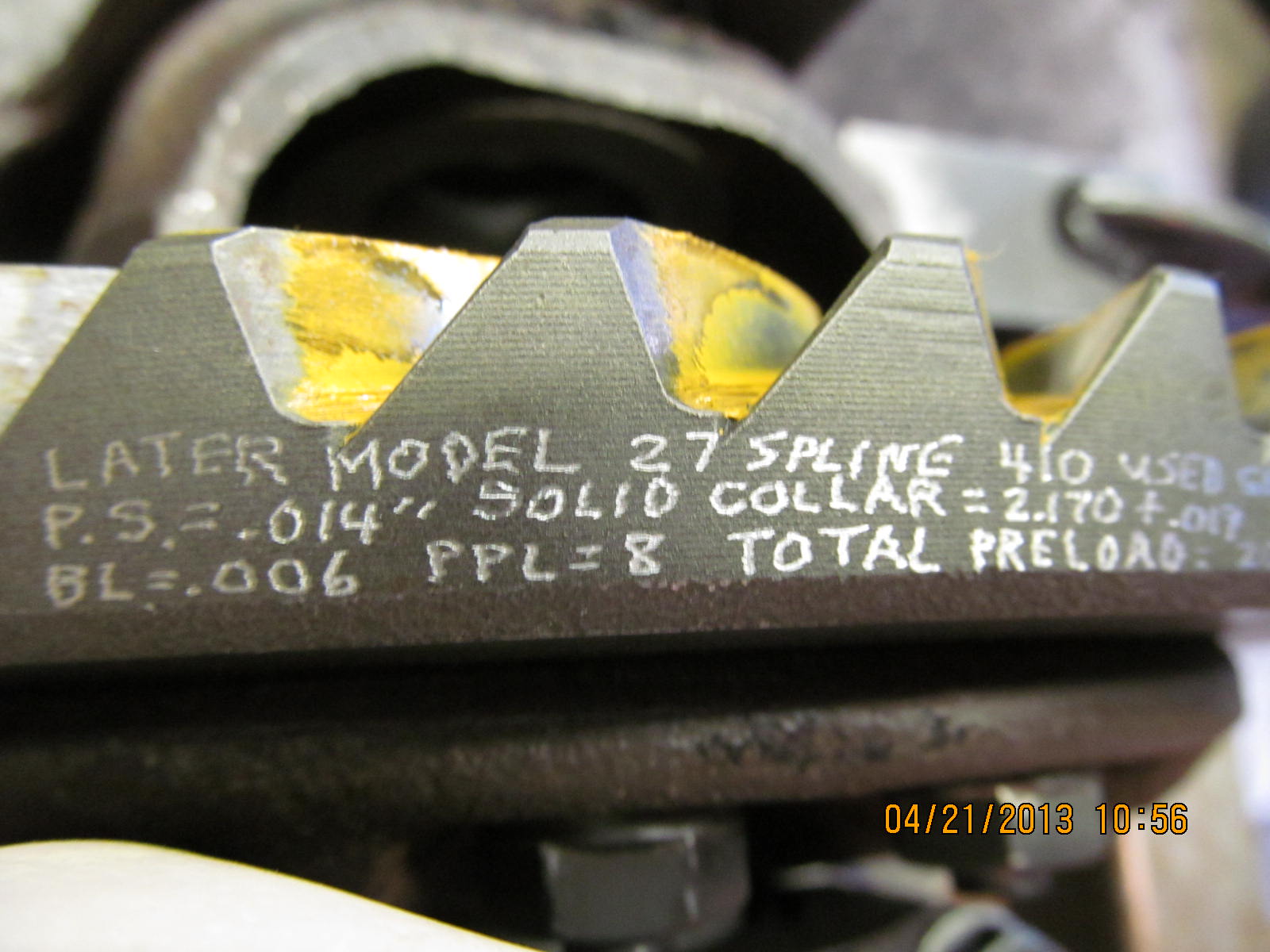

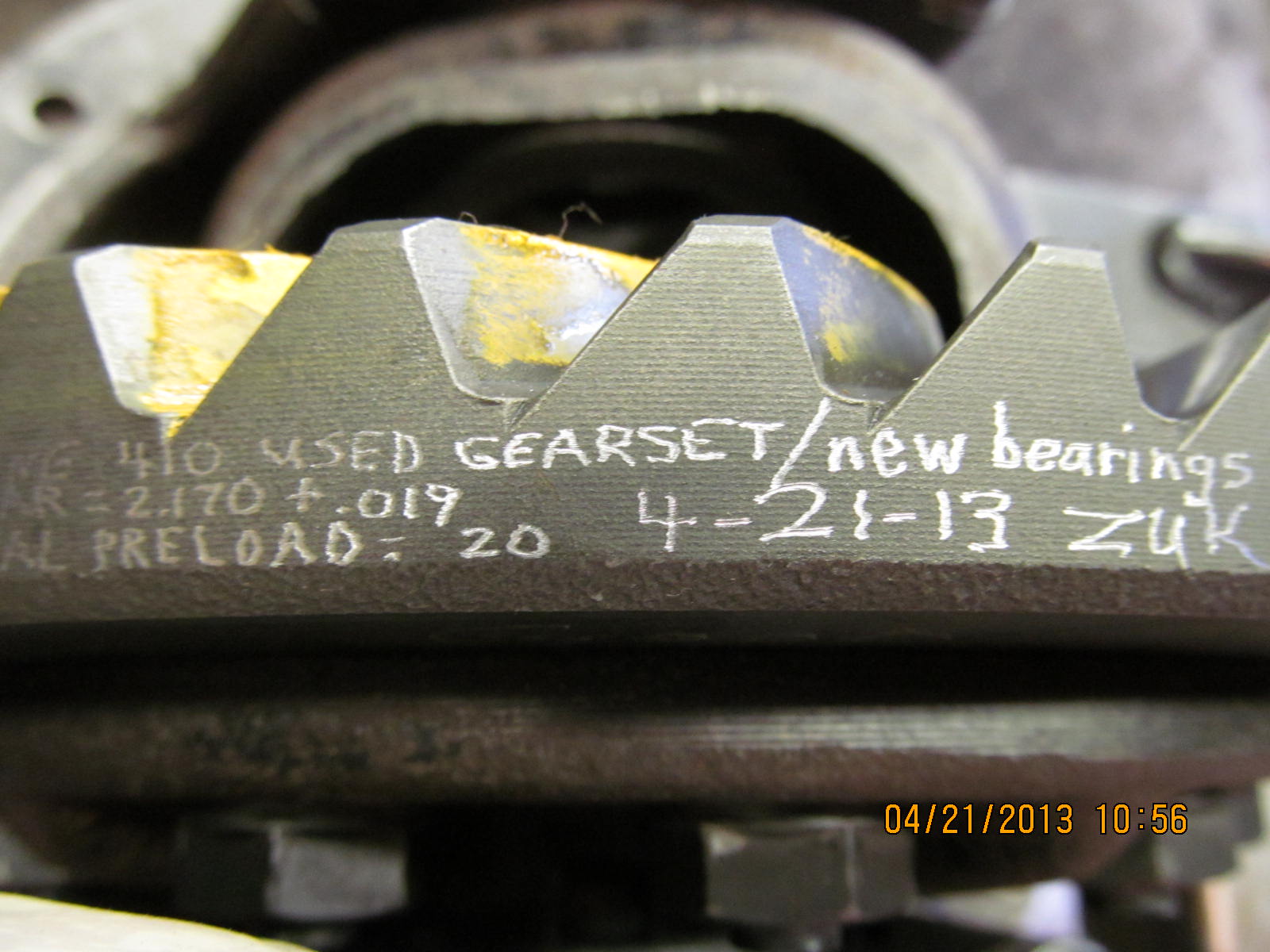

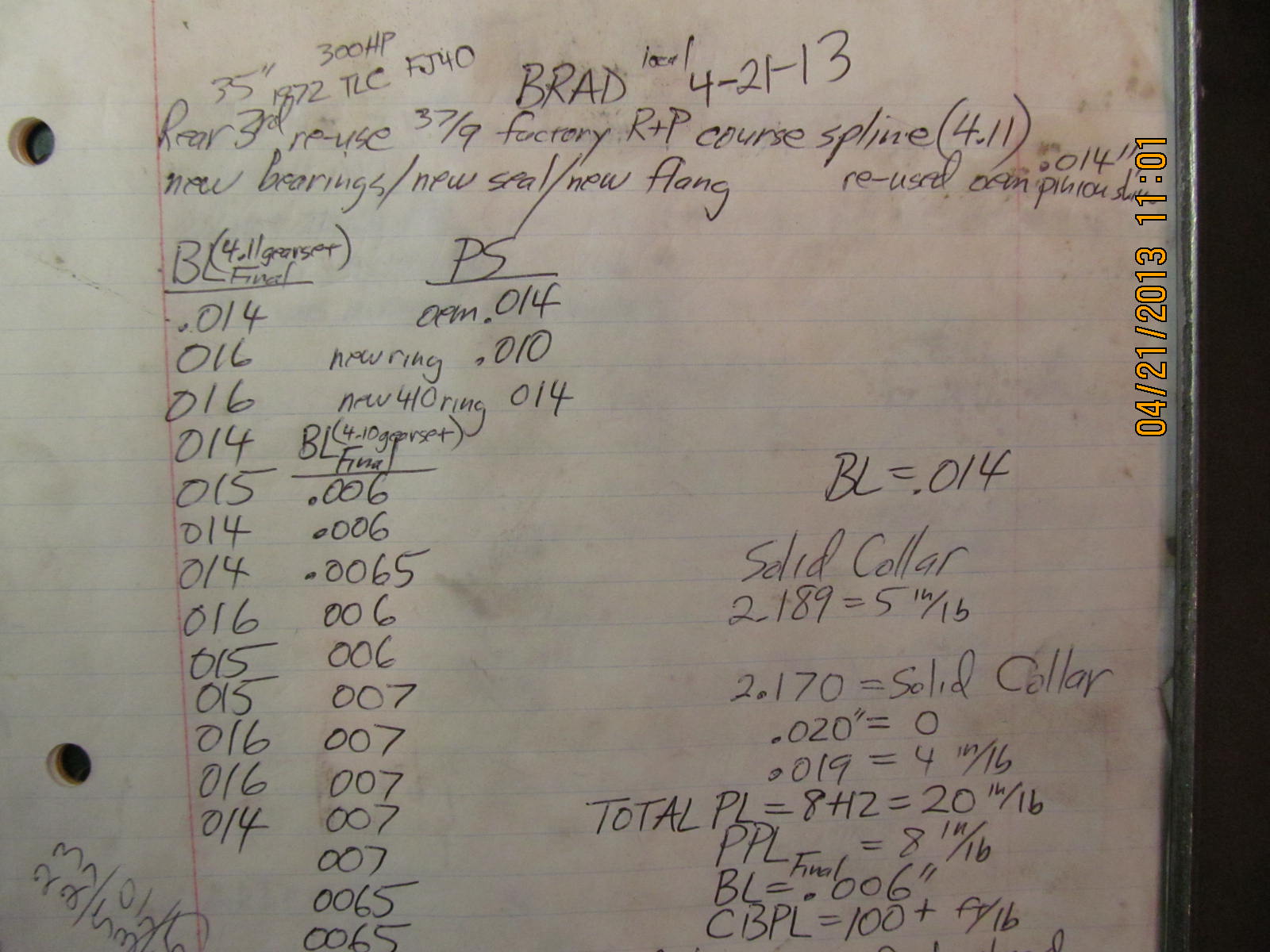

4.11 ring/pinion. I had another used 4.10 later model

ring/pinion that would fit perfectly and do the job very

quietly.

much better results. I like how the contact is deep in the tooth.

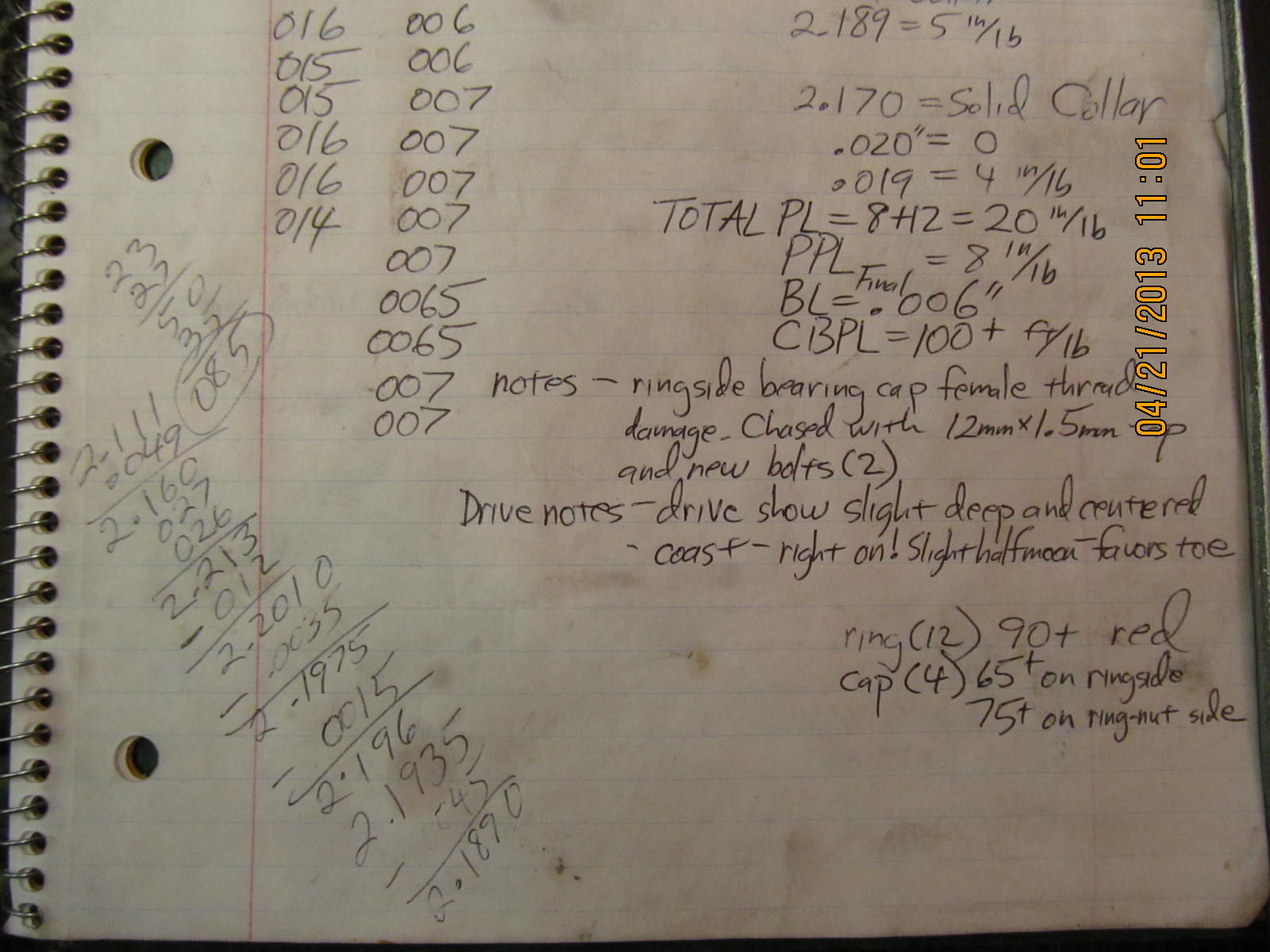

close that gets me to some PPL.

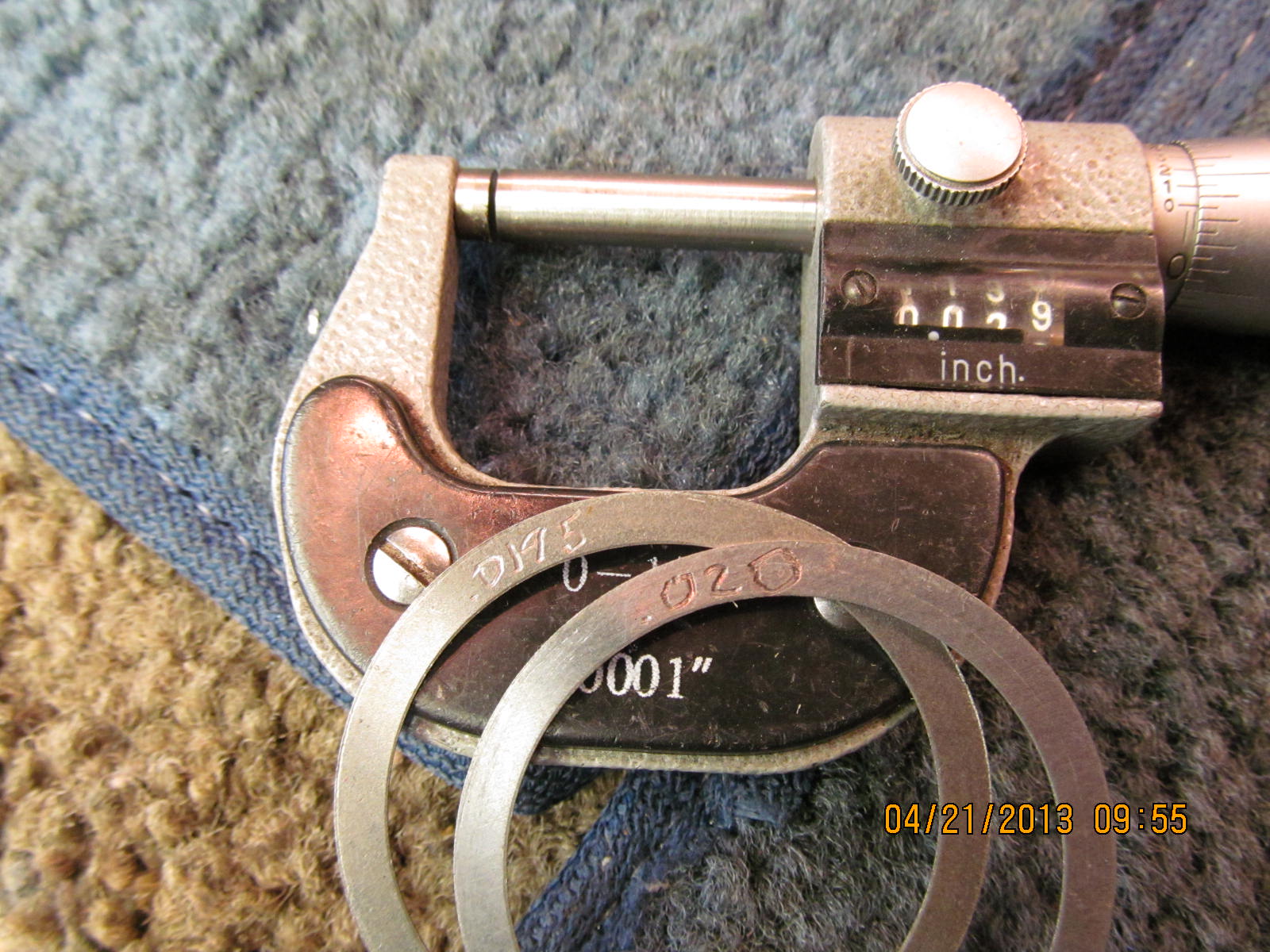

play at all. It will take less than .001" to show some

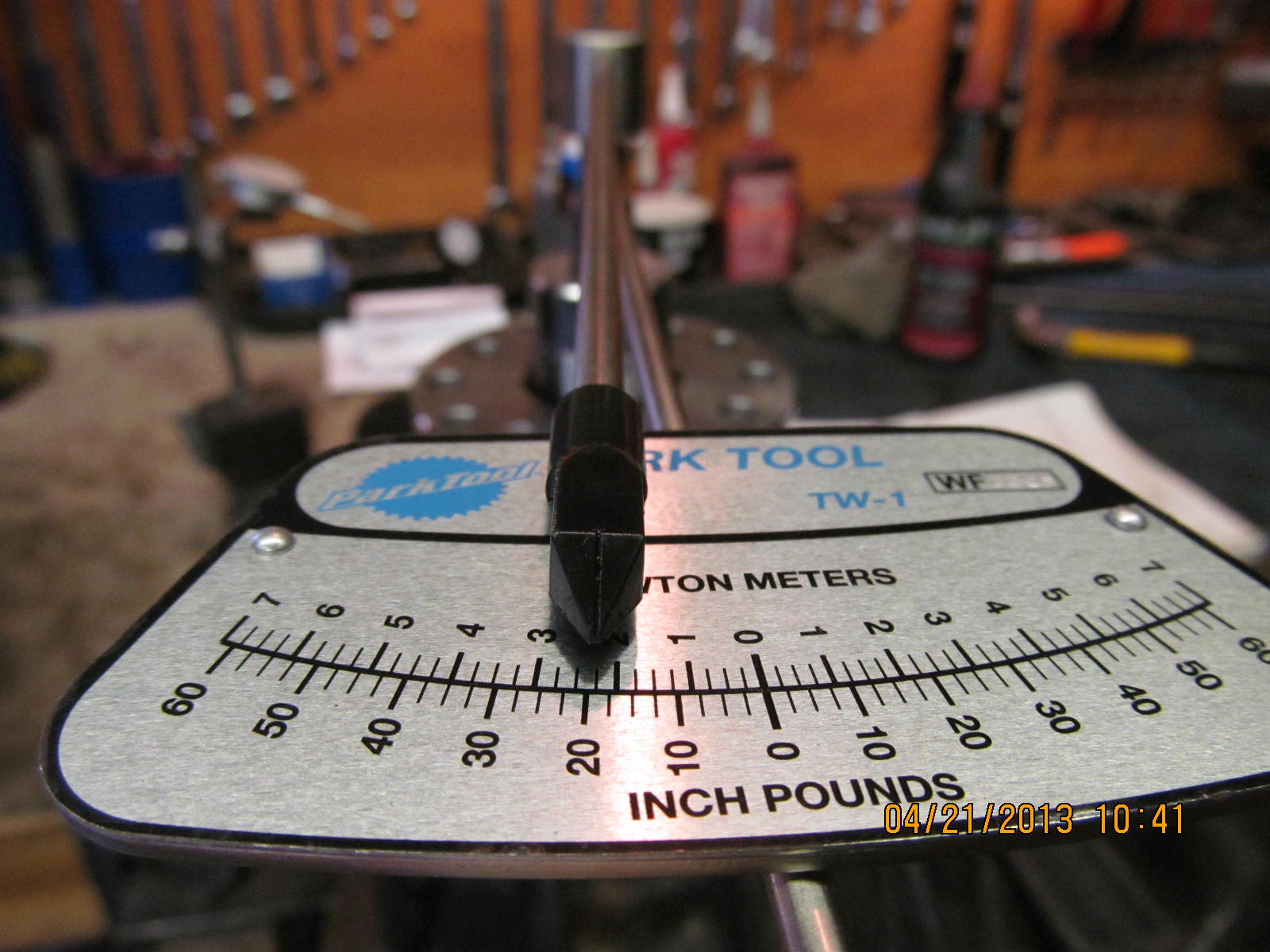

pre-load on the torque wrench.

right tools. All the repetition goes so much faster with the

right tools.

Perfect. Because I can tweak/increase that with the 4 foot cheater

bar. Solid collars do compress a small amount with proper coaxing.

flange on. I like the way Permatex "Ultra-Blue" spreads around

so future gear installs will be more blue.

rubber seal to the max. Trying to eliminate residual drag

contributions from the rubber seals.

staked....but so be it.

than what the electric impact will do.

8 inch/pounds start torq.

up the remaining threads with a tapered tap. I didn't feel

comfortable with a full 75 ft/lb so 65 on this one and the

one to the right of it in the picture.

to get the CBPL to spec and guide the backlash to its target at

the same time.

and recorded on the "data sheet" shown at the end of this link.

pinion AND carrier bearings to start to roll. I measured 20 in/lb

total...plenty of anti-deflection pre-load.

is applied to 3 teeth.

the tooth root. Pattern also appears slightly deep and I'm good

with that knowing Brad is bolting in an LT1.

Reading the depth looks like it is set right where it should be.

his set up should run strong and quiet.