| Brian's 1993 FJ80 gets 3.73 gears from Marks4wd.com (imported from Australia) |

|---|

| (90 BIG pics loading) |

|---|

| JULY 26 2017 |

|---|

|

Brian, from Tennessee, expressed an interest in making his stock factory 410 gearing actually taller. Taller because he

is in the process of dropping a diesel in and they work better at about 1600 rpm. OEM 3.70 gears are common in

the 9.5" rear of FJ60's but the front 8" high pinion of the FJ80's is a no-go on a match and the nature

of the typical FJ80's "all wheel drive" means the gears have to be the exact same.

After checking around online, a place was found operating out of Victoria, Australia

named Marks4wd.com. The hotlink should take you directly to the gear page for the FJ80 Landcruisers.

You can even go as tall as 3.54 if you have the extra cash.

Update---11/14/2018---Looks like Marks4wd no longer sells ring/pinions. I was directed to contact Don kyatt.

donkyatt.oc.au |

|---|

|

|

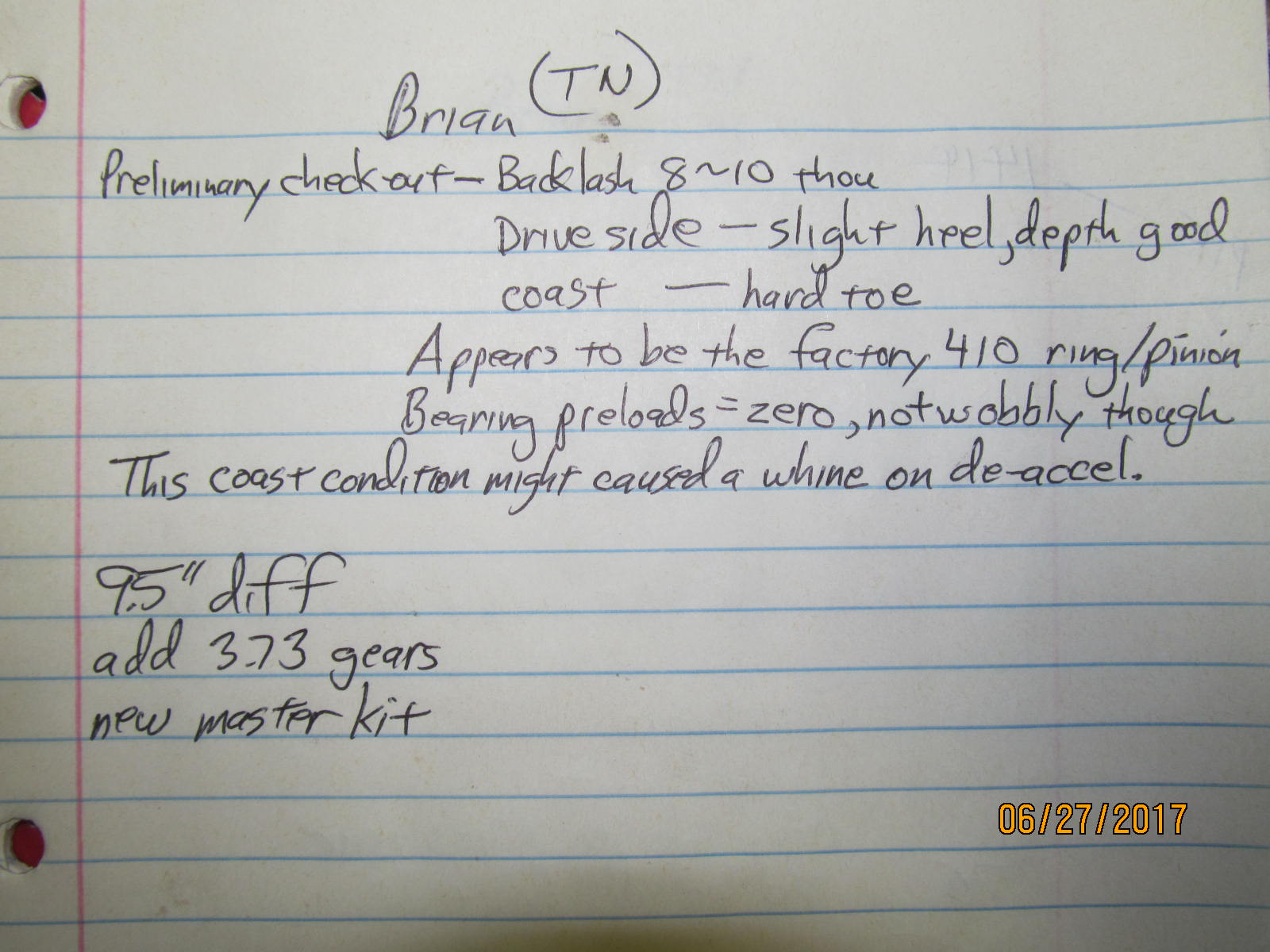

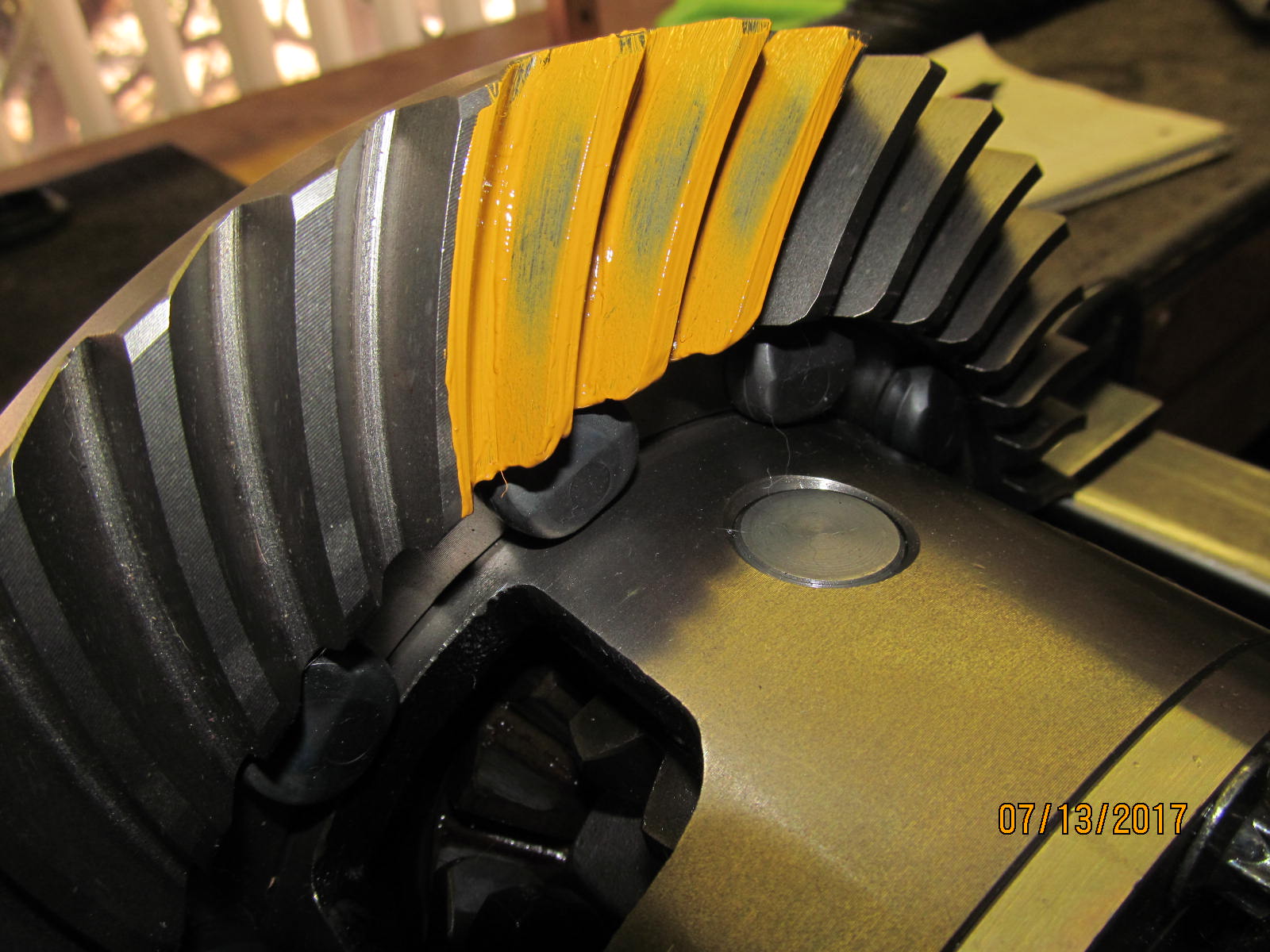

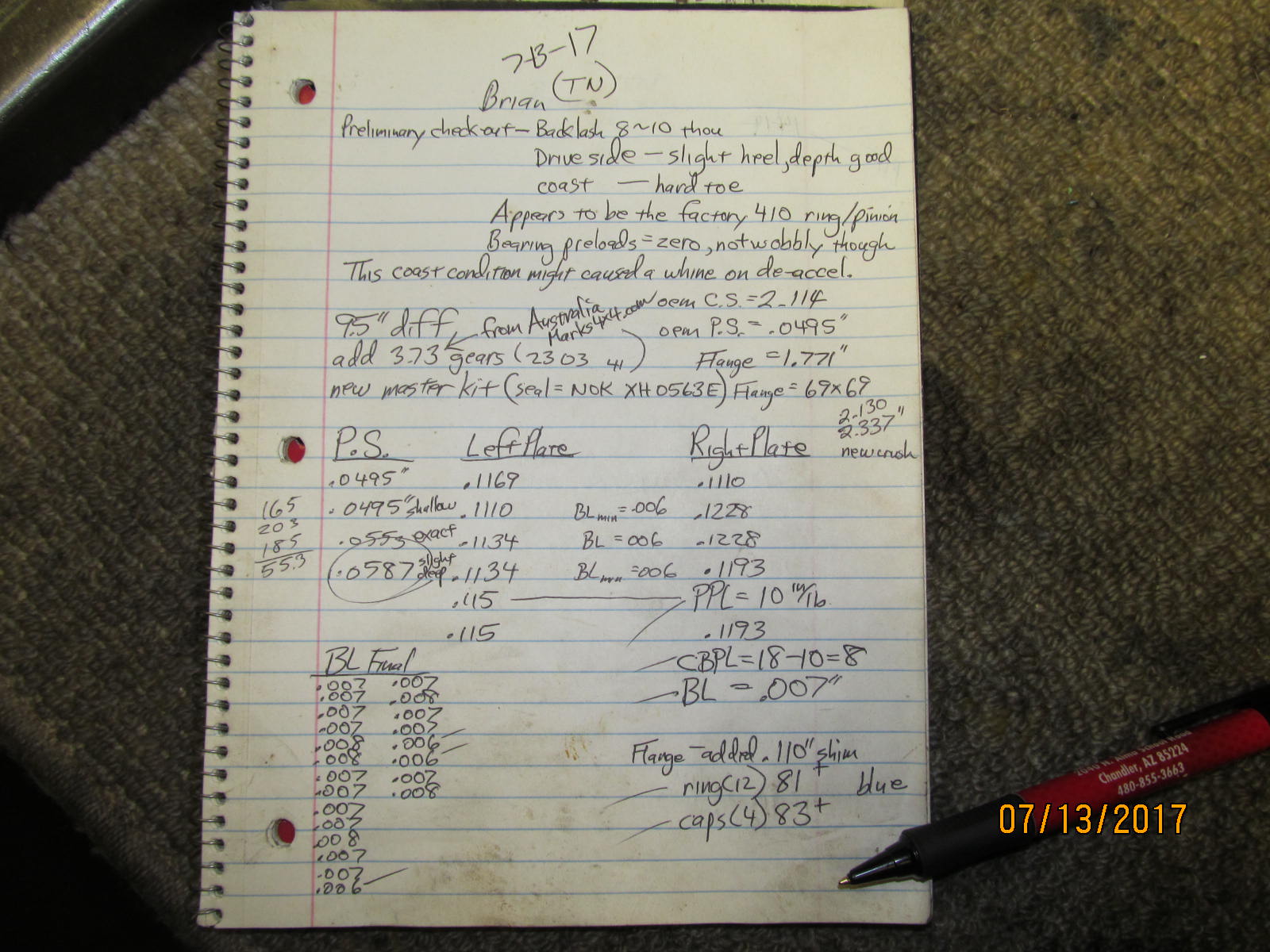

Brian was having a whistling issue from the rearend so a little pre-check of the 9.5" 3rd before I disasssemble it.

Backlash was acceptable in the range of 8~10 thou. |

|---|

|

|

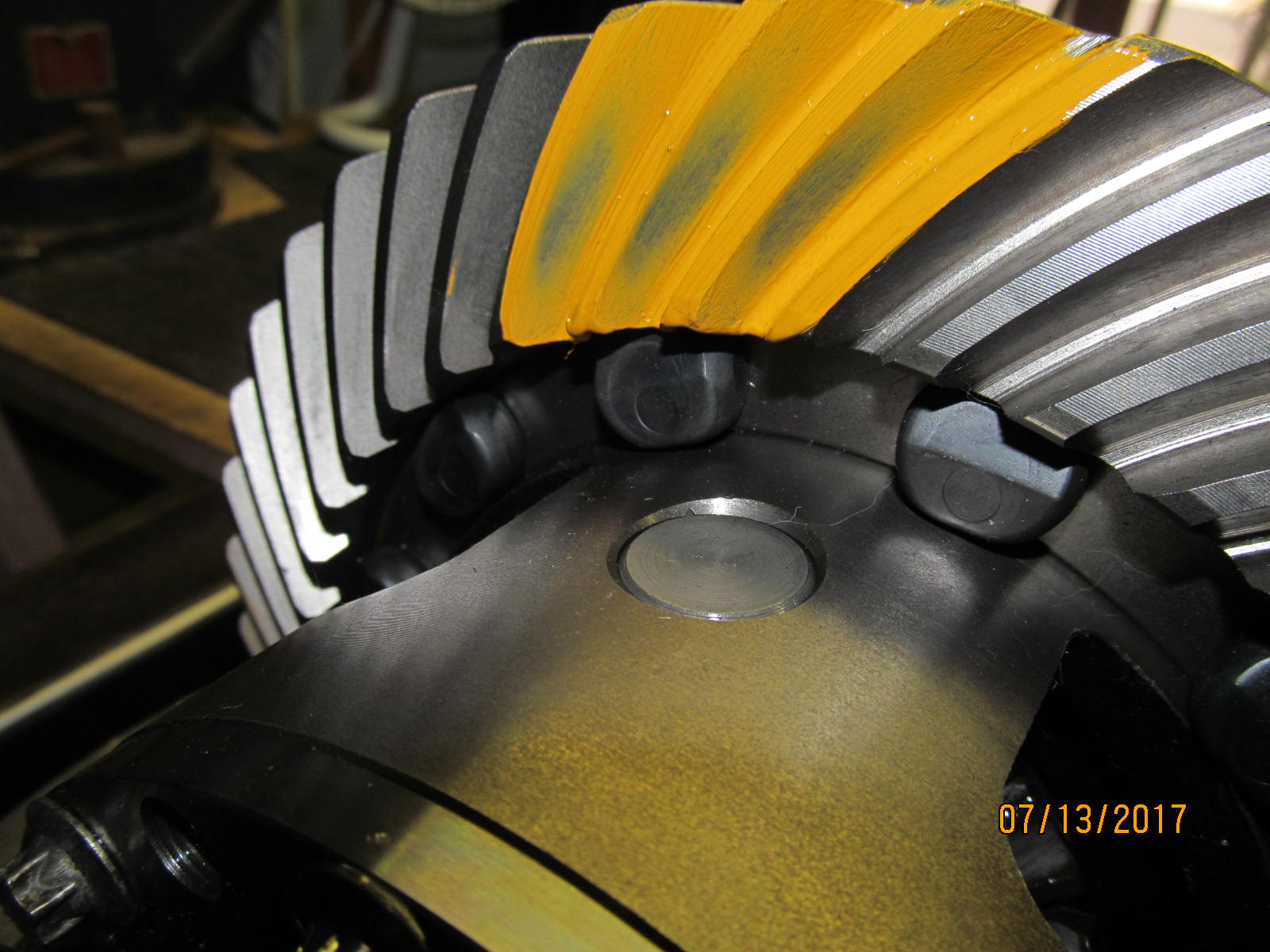

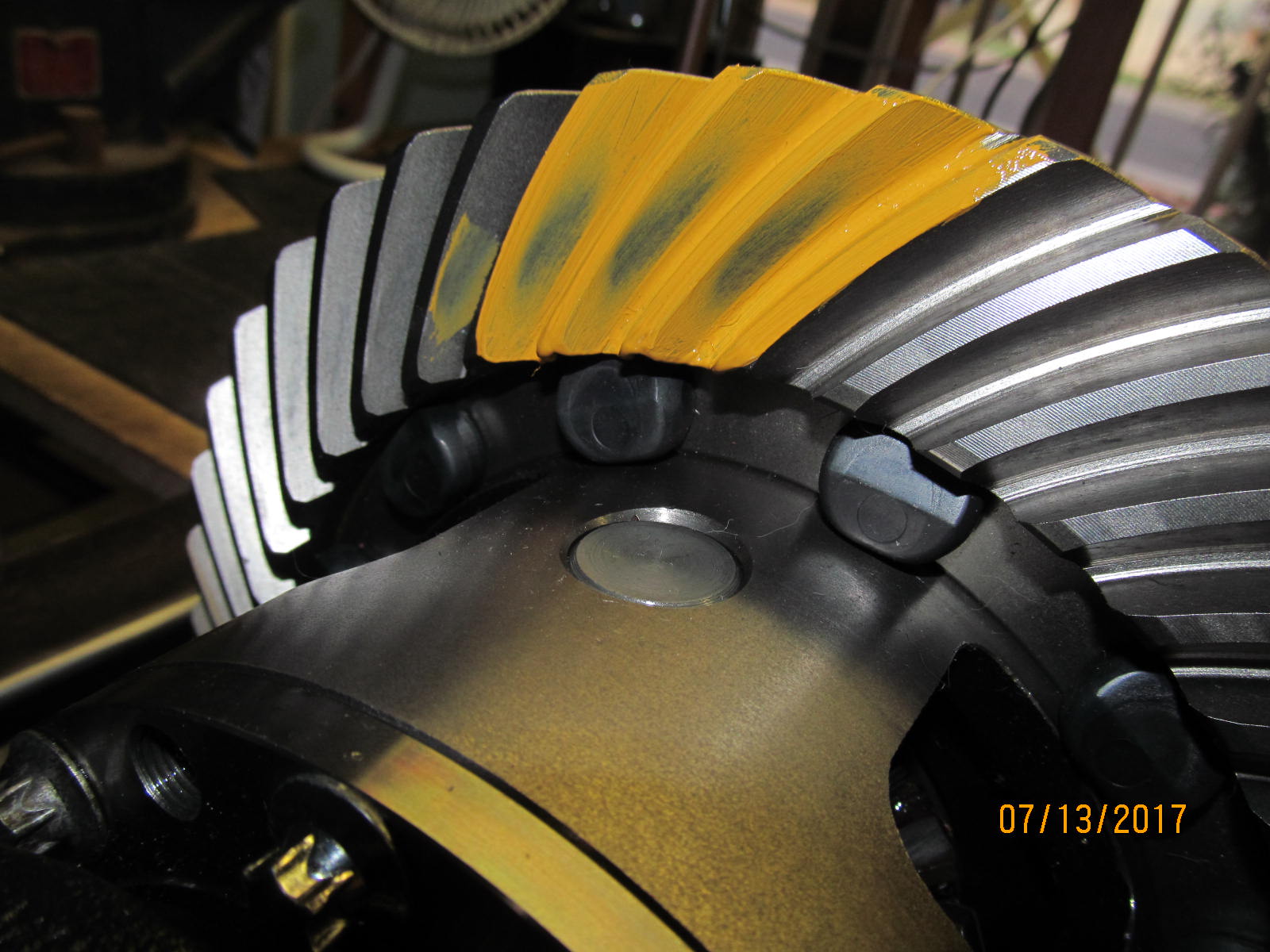

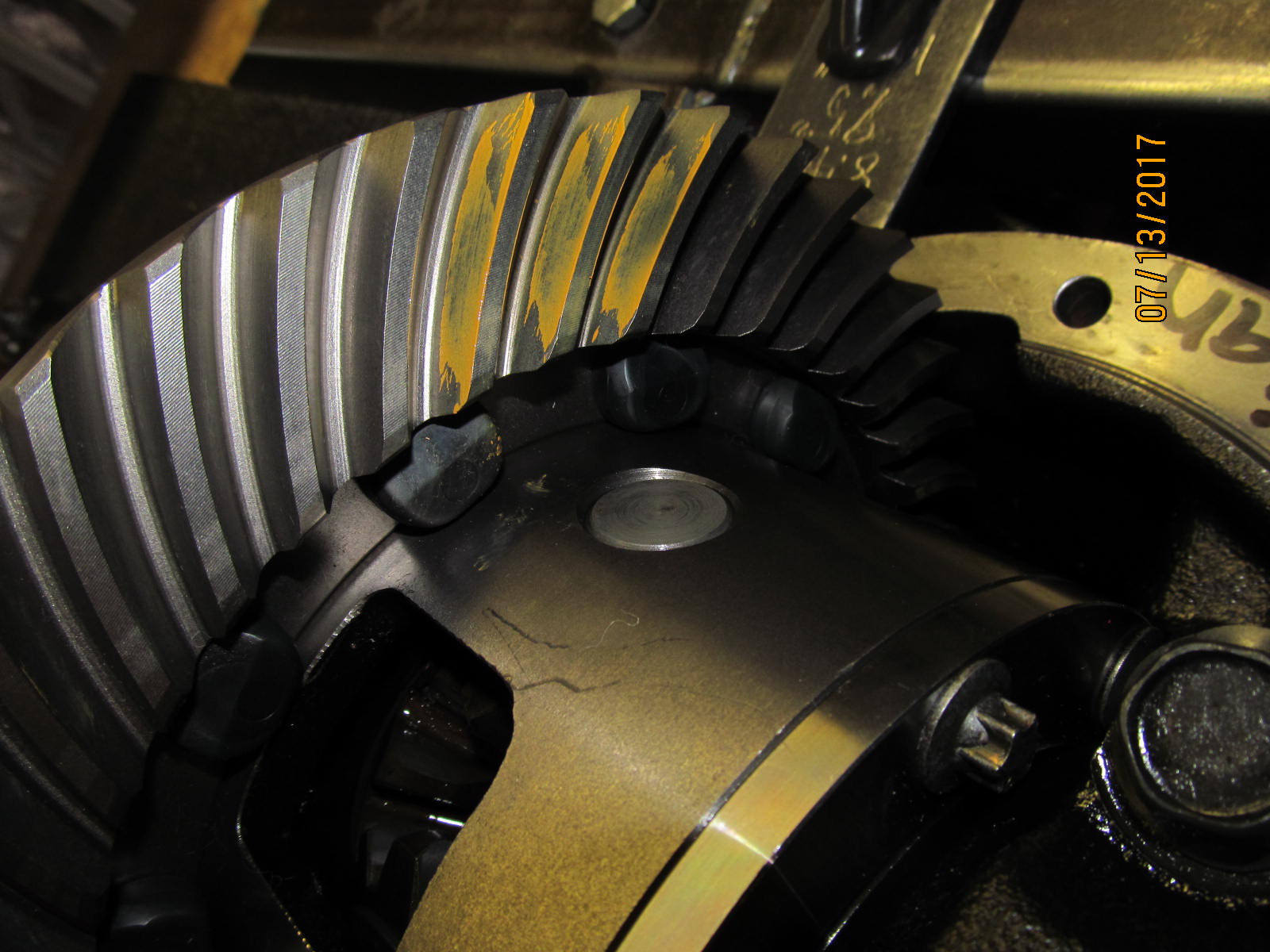

| A paint of the drive side shows a good overall load bearing position. |

|---|

|

|

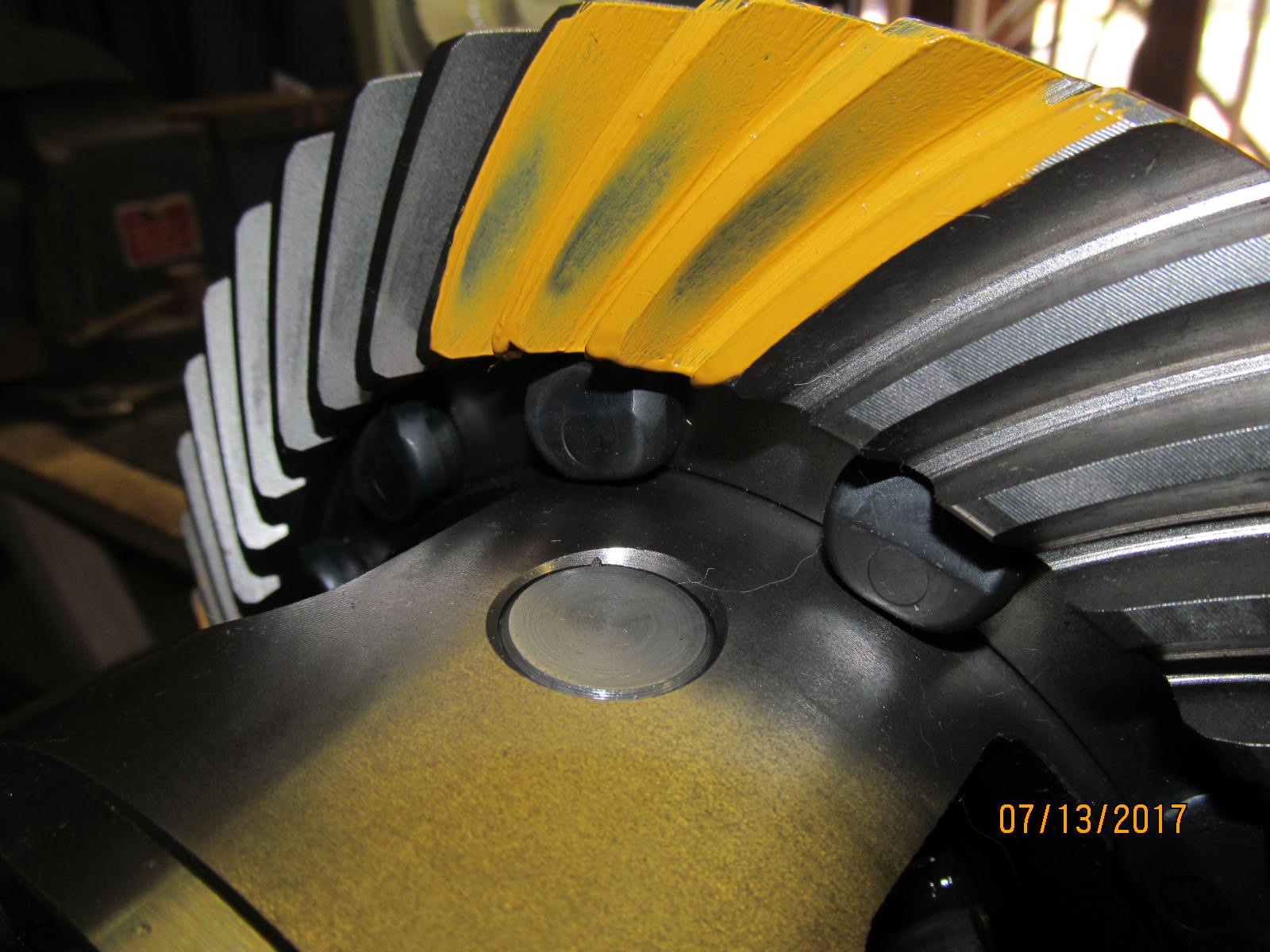

| The coast was leaning on the toe but nothing too unusual. |

|---|

|

|

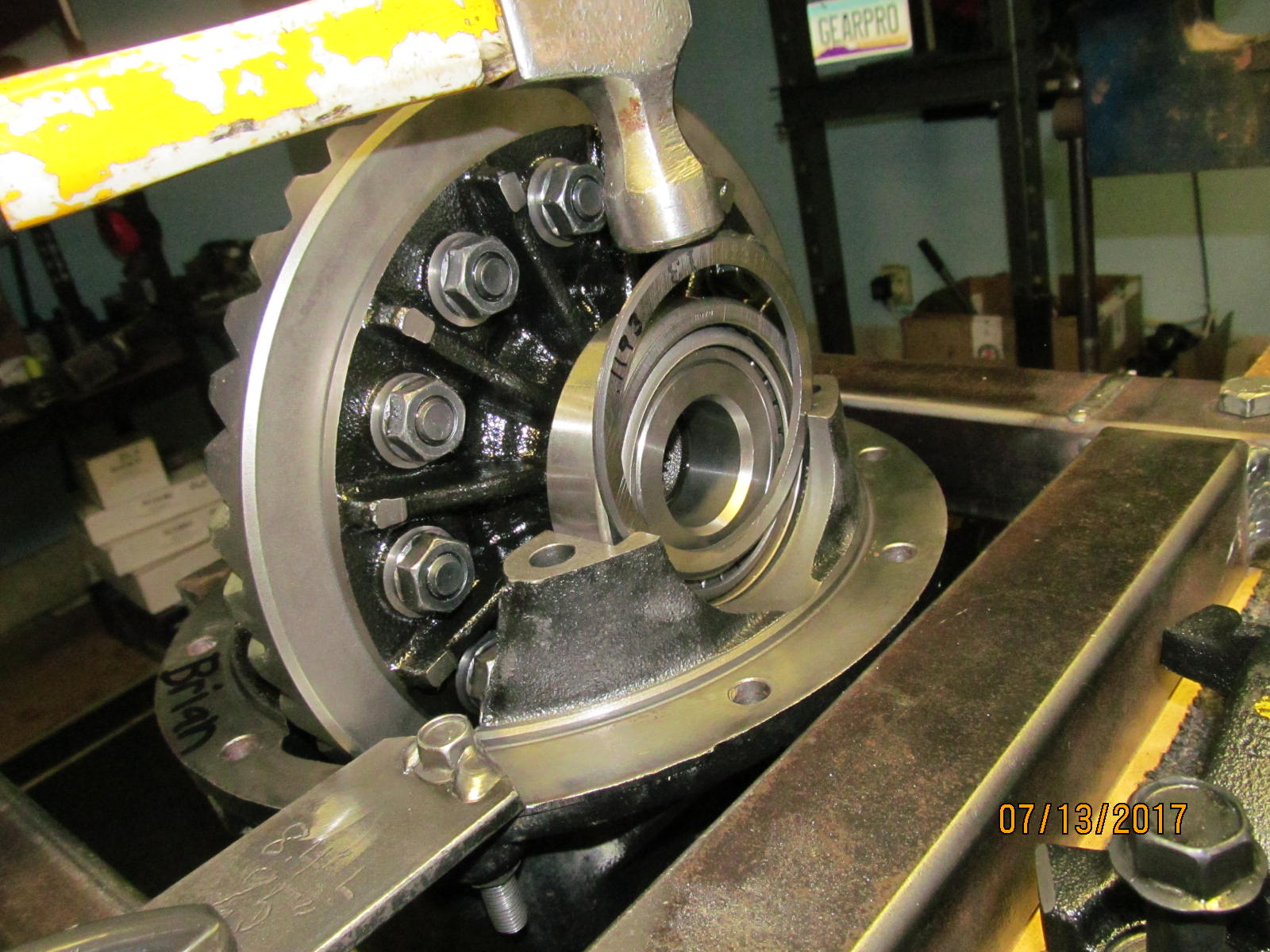

The pinion nut is still factory staked so no one has likely messed with it. Both the carrier bearing preload

and pinion preload were "relaxed" but not loose enough to detect any kind of wobble. |

|---|

|

|

| Conclusion is that Brian has to look elsewhere for the load whine....maybe the transfercase. |

|---|

|

|

| So here's the plan....install the 3.73 oem style gears with all new Koyo bearings. |

|---|

|

|

| Remove with the old 410 ring. |

|---|

|

|

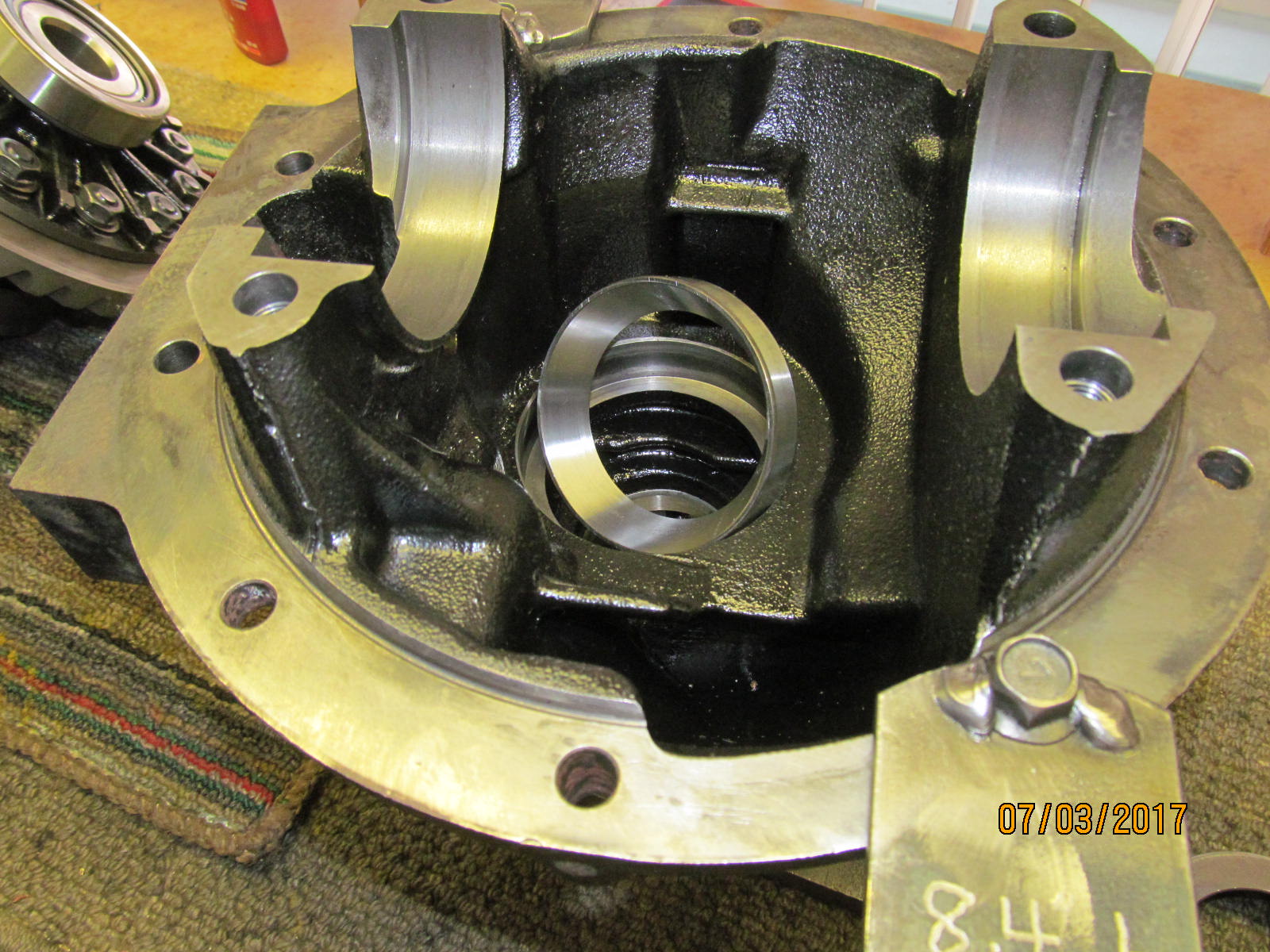

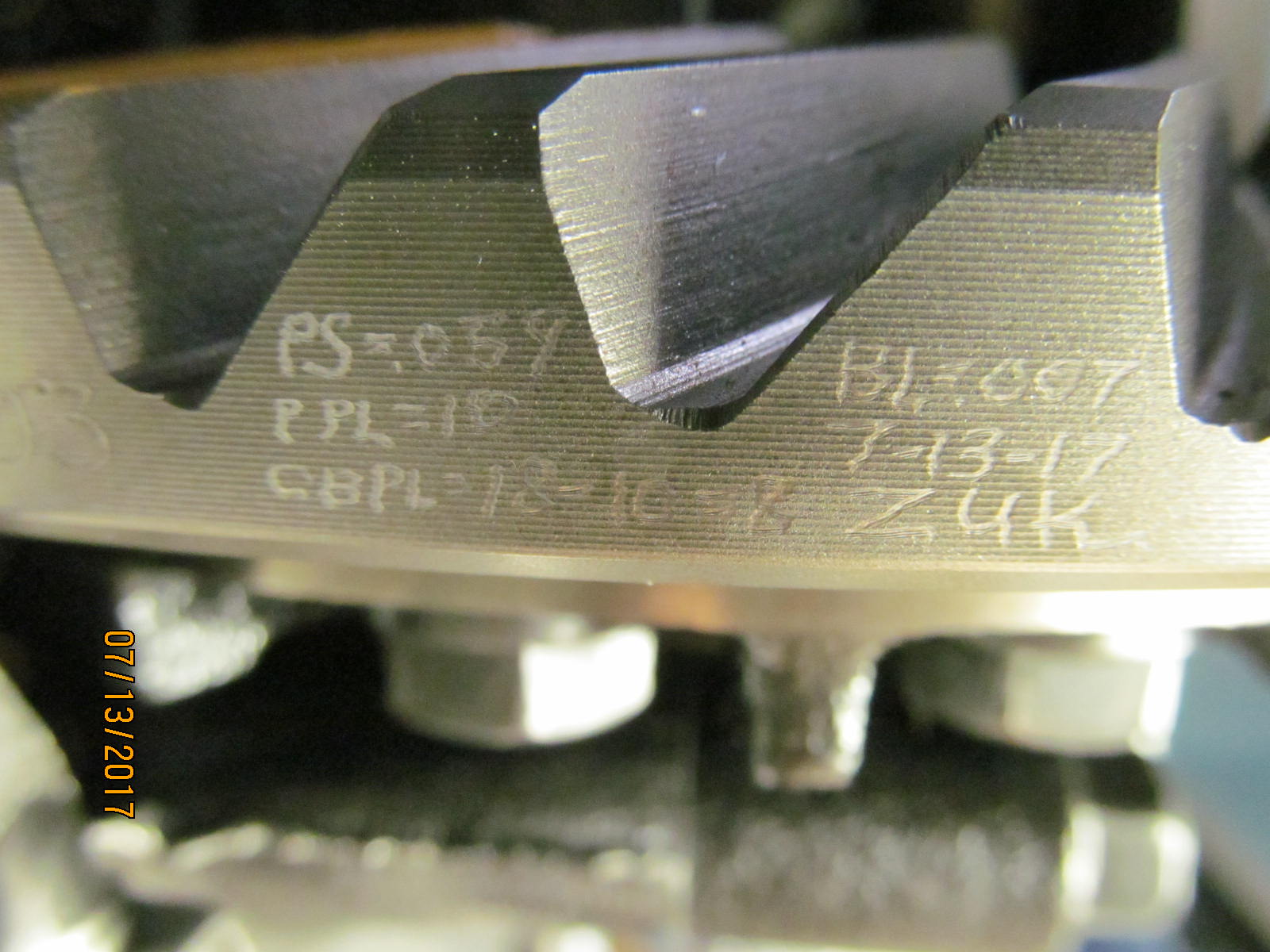

Checking for high spots/burrs on both mating surfaces. Thes 3.73 gears are very nicely machined. The finish was beautiful.

An email to Marks4wd.com confirmed that these are NOT Chinese and they are from Japan. |

|---|

|

|

| The gears were a tight fit....got it started with the plastic lead filled hammer just fine.... |

|---|

|

|

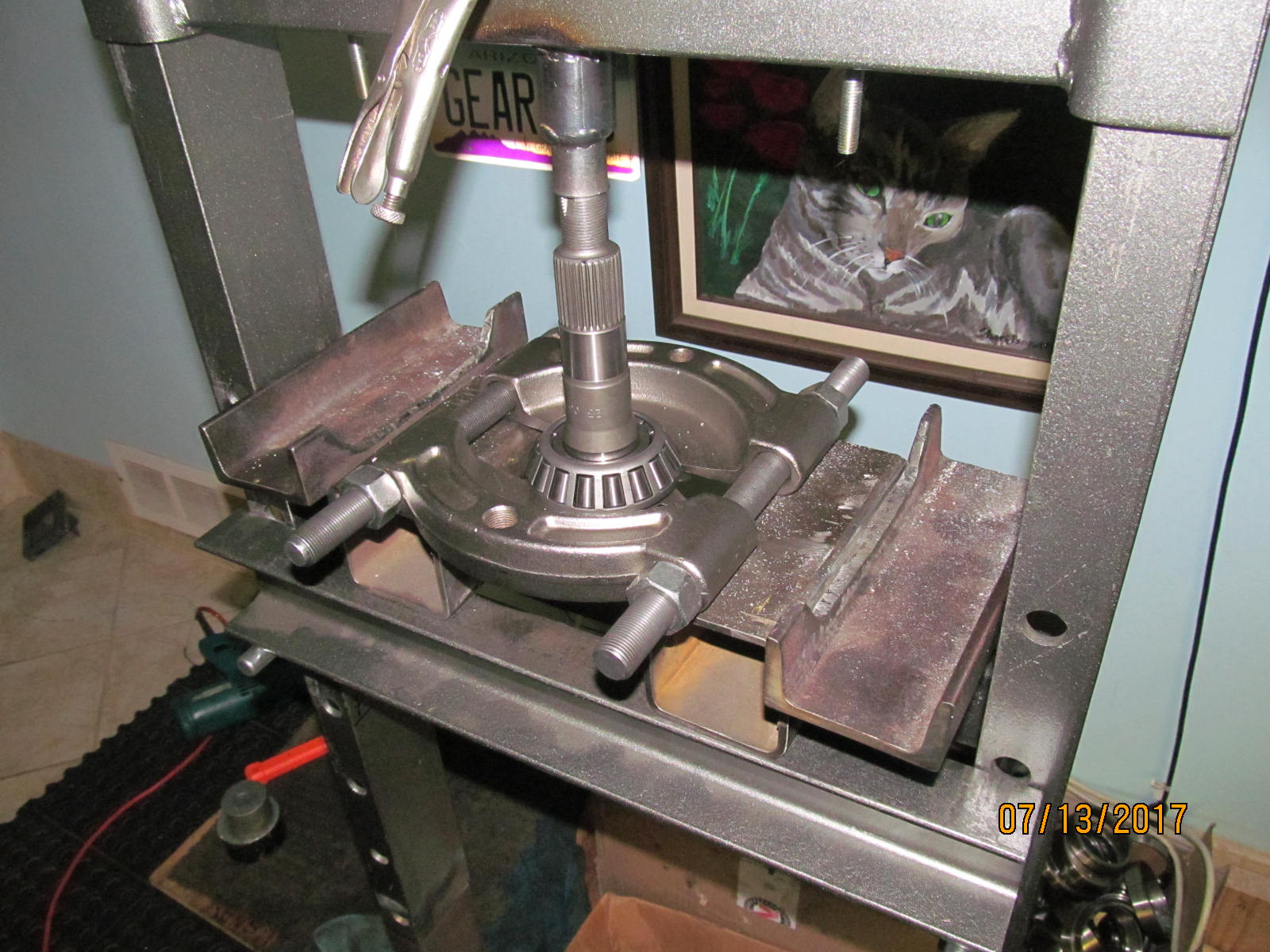

| ...and finished off the last 1/8" with the 12 ton. |

|---|

|

|

| Blue loctite appied to the 12 ring gear bolts. |

|---|

|

|

| 81 ft/lbs. |

|---|

|

|

| New carrier bearings tapped on and very tight they did tap on I might add. |

|---|

|

|

| ........................ |

|---|

|

|

| Same with the other side. |

|---|

|

|

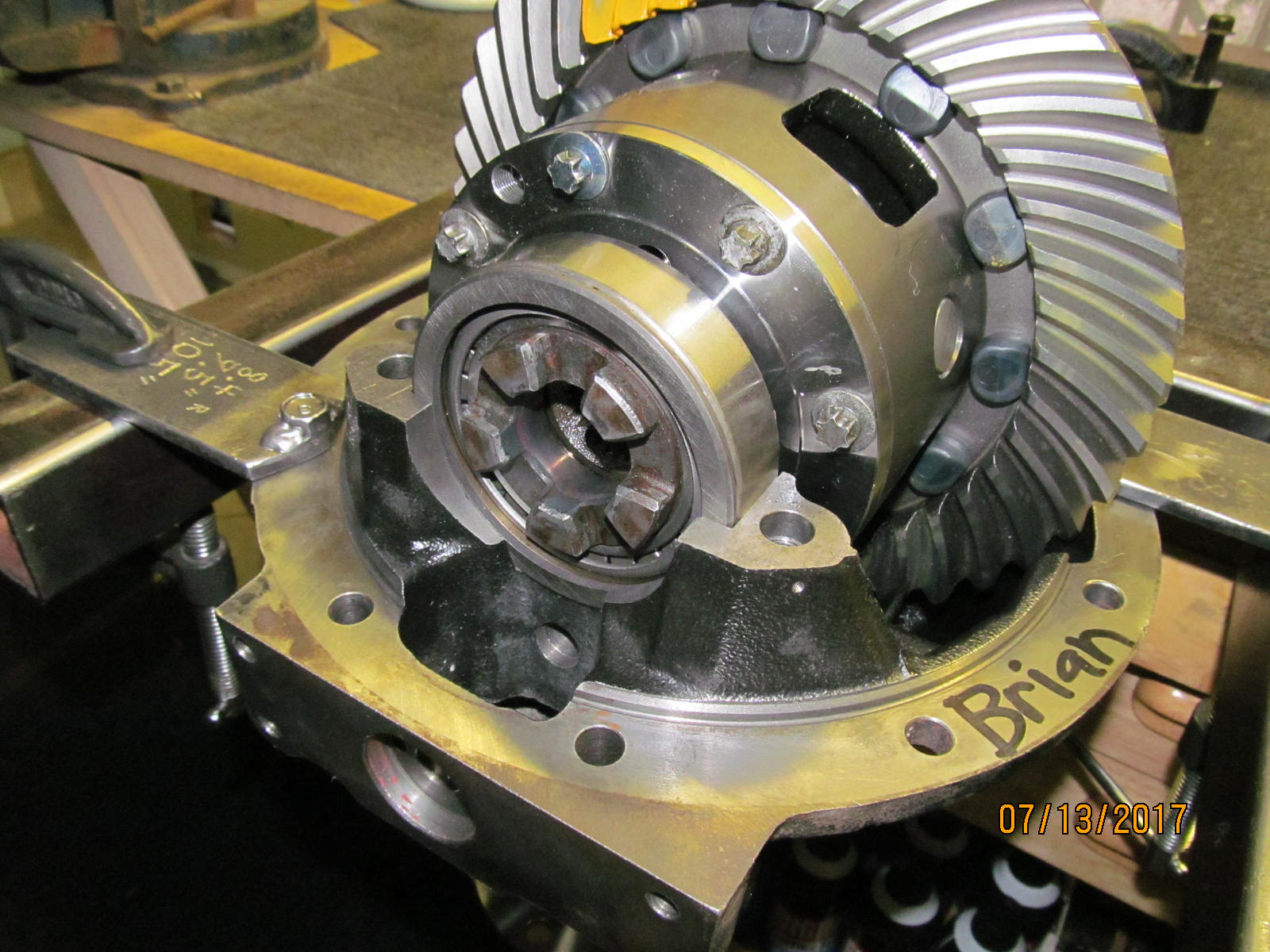

| This center carrier is now complete...onto the other end of things now. |

|---|

|

|

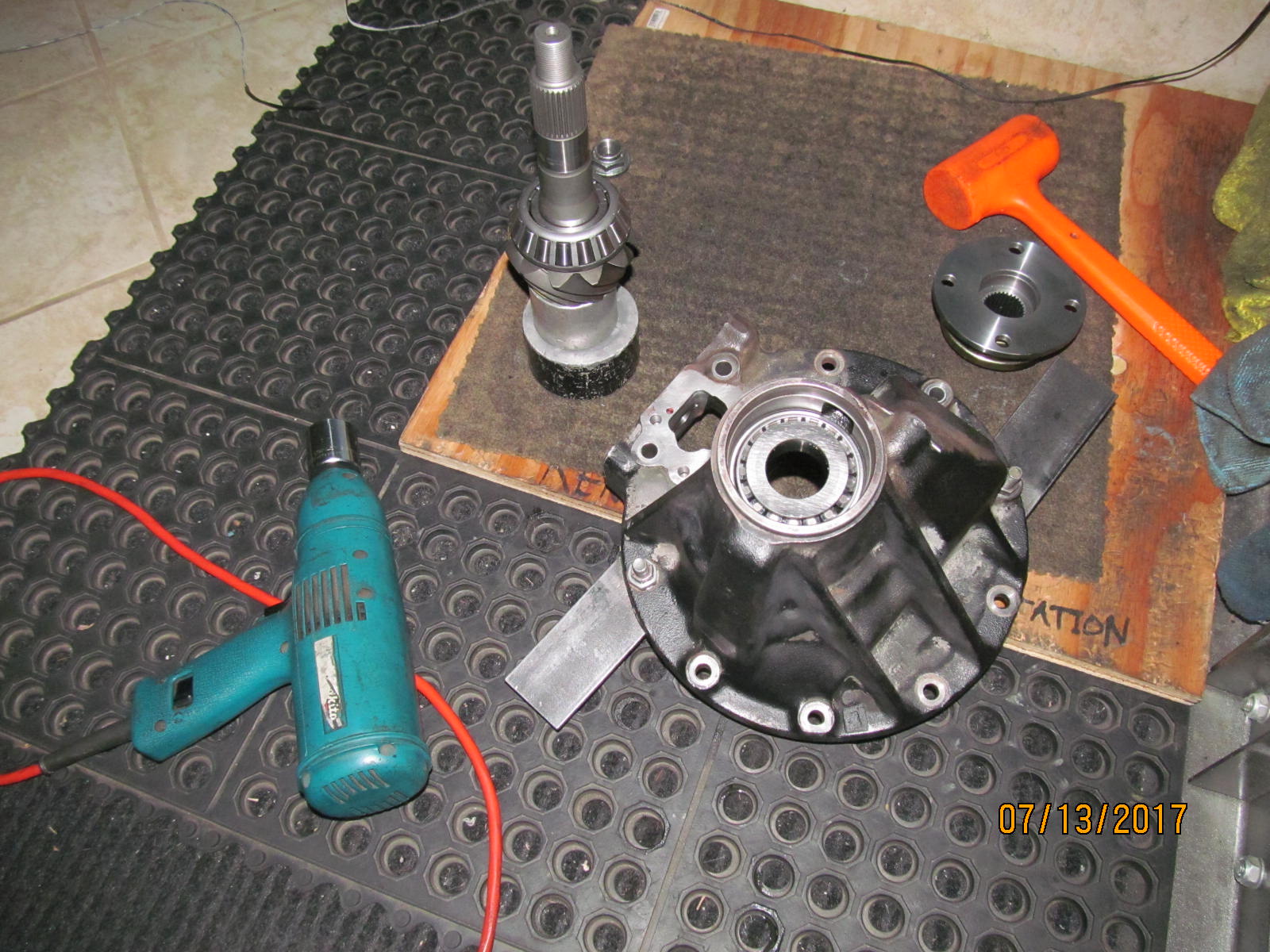

This old Makita 6905H has been helping me with all my gear installs for over 15 years and it still keeps working.

The power cord has already been replaced once. |

|---|

|

|

| Pushing the 410 pinion out. |

|---|

|

|

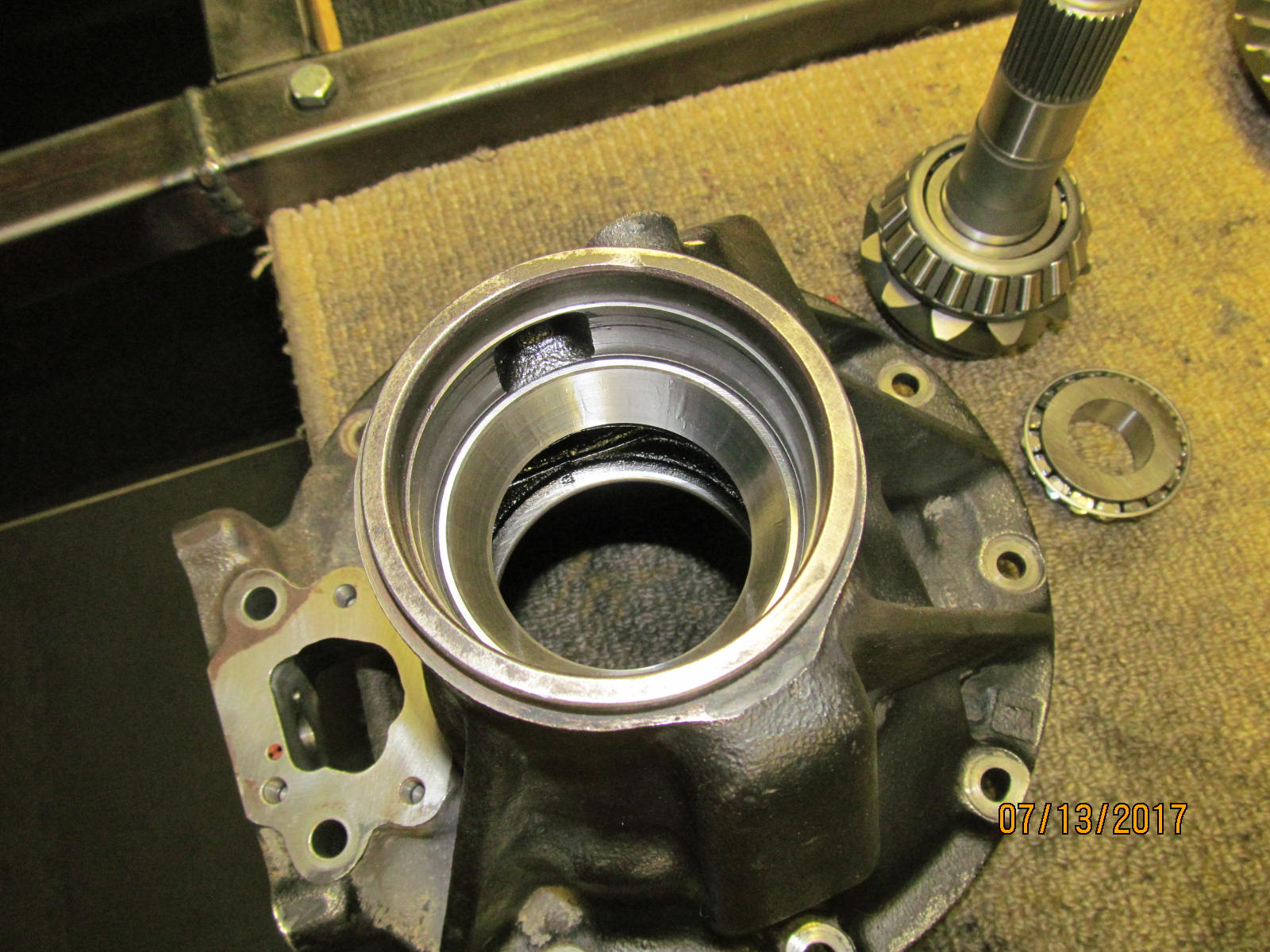

| The seal removing tool made quick work of it. |

|---|

|

|

| After everything was cleaned up, the new outer race can go in. |

|---|

|

|

| Tap tap. |

|---|

|

|

| Fully seated down 100%. |

|---|

|

|

| The larger inner race is next. |

|---|

|

|

| 100% seated. |

|---|

|

|

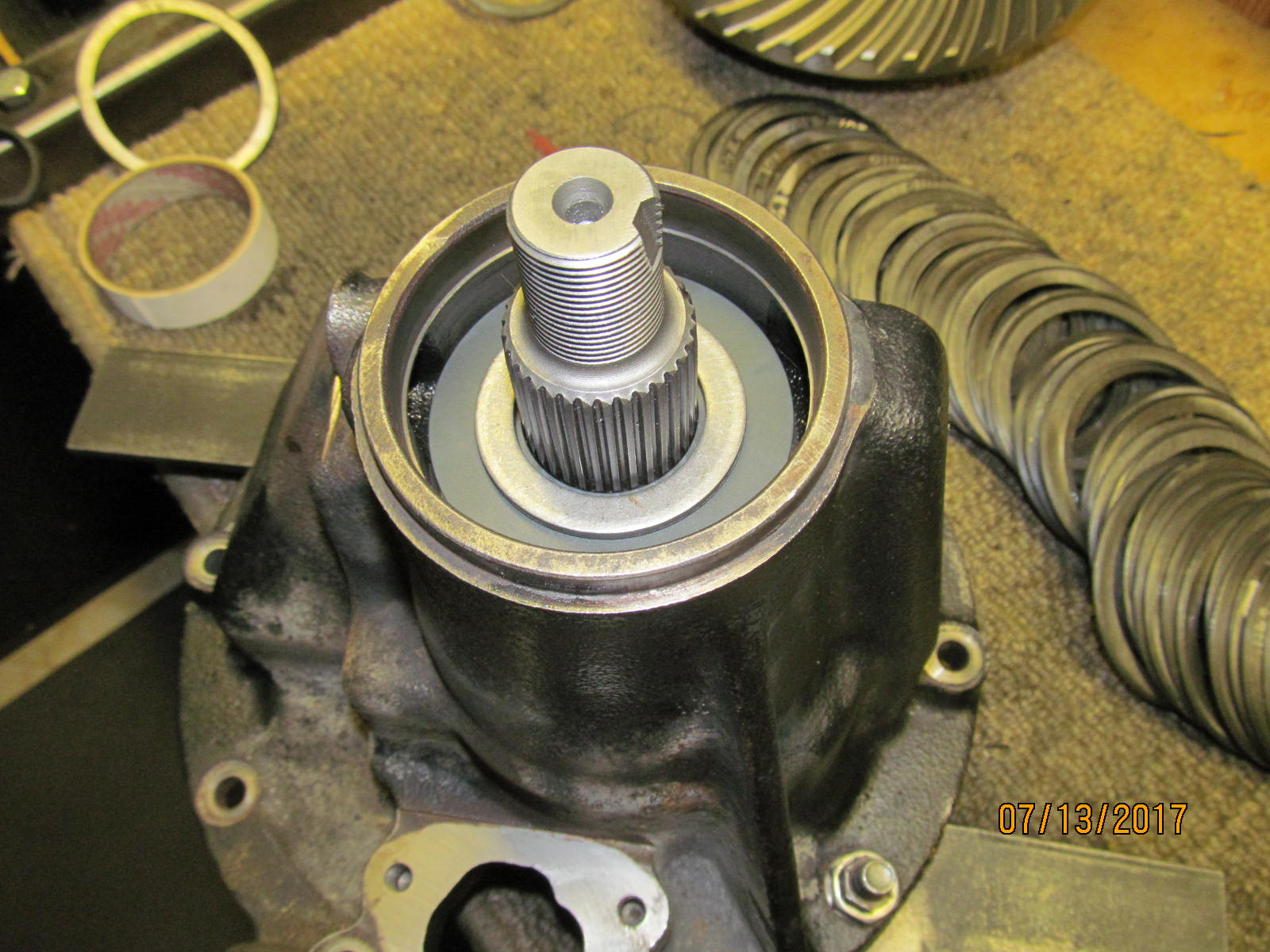

| Onto the pinion end....starting with a pinion shim of .0495" |

|---|

|

|

| Pressing the new Koyo bearing on. |

|---|

|

|

| It was then that I discovered that the usual Koyo 30306 outer bearing would not slip over the massive 32 spline pinion. |

|---|

|

|

| Typical 27 spline on the left and 32 spline on right. |

|---|

|

|

| Some hi-tech research and pick a number. |

|---|

|

|

90366-33006 is the oem Toyota part number but good luck trying to get hold of one.

Both bearings are identical in stamped numbers. |

|---|

|

|

| Much easier to just get it from JustDifferentials.com. |

|---|

|

|

| The 32 spline PB slips right over the big 32 splines but the 30306 does not. |

|---|

|

|

| This is the one I originally ordered from the dealership so this is the one to use I guess. |

|---|

|

|

| .......................... |

|---|

|

|

| Tap down the new race evenly with your favorite widget. |

|---|

|

|

| Another 100% seated race. Jolly good. |

|---|

|

|

| ...................... |

|---|

|

|

| Tighten the pinion nut 'til it's snug and turns with about 10~20 inch/pounds of bearing load. |

|---|

|

|

A lot of thread showing. The outer bearing has a little different deck height but that will be addressed later with an

extra thick splashguard of sorts. |

|---|

|

|

| It's good to have a healthy selection of carrier bearing oem washer plates. |

|---|

|

|

| The washer plates sets not only the backlash but also the carrier bearing preload. |

|---|

|

|

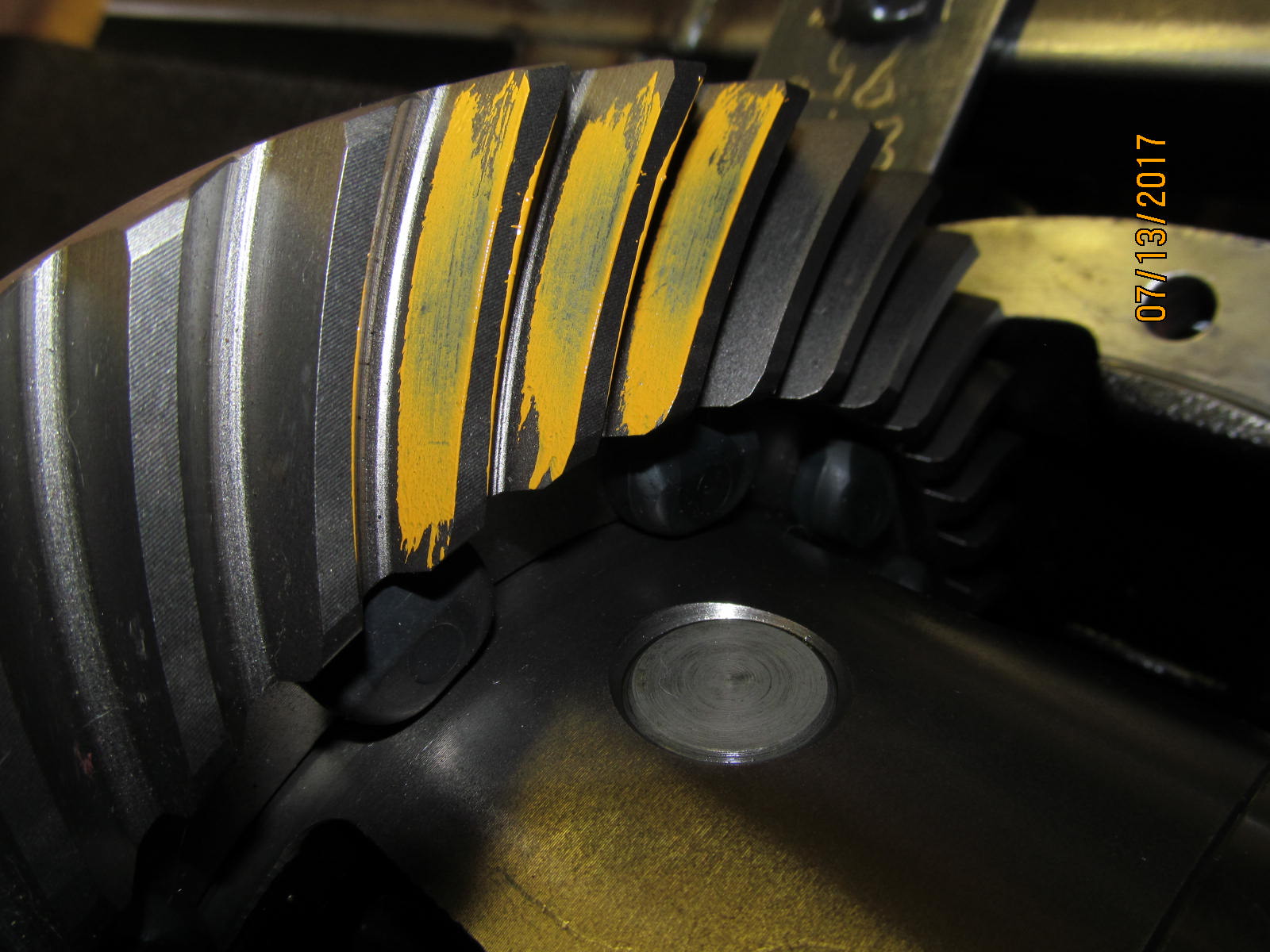

| The resultant paint shows the drive side to be shallow...not enough shim. |

|---|

|

|

| Coast....looks shallow, too. |

|---|

|

|

| Reverse painted driveside. |

|---|

|

|

| The comet tail is deep in the root of the pinion tooth. Deep in the root of the pinion means shallow on the ring. |

|---|

|

|

| ......................... |

|---|

|

|

| Now to tear it all down and add about .005" to the existing .049" shim. |

|---|

|

|

| These 3 shims add up to just over .055". |

|---|

|

|

| Press the big bearing back on. |

|---|

|

|

| Mount the pinion back into the 3rd.... |

|---|

|

|

| Depth appears to be very close to "exact". |

|---|

|

|

| Coast |

|---|

|

|

Pinion shows the comet tail just barely coming off the root. It's so close to my preferred "slight deep" condition that I know

that the next adjustment will be the final one. |

|---|

|

|

| Disassemble and add about 3 thou more. |

|---|

|

|

| Center carrier put back in..... |

|---|

|

|

| Tap in the right side washer plate. |

|---|

|

|

| Drive side. Beautiful. Slight deep condition. |

|---|

|

|

| Coast. Nice. |

|---|

|

|

| Drive. Reverse painted. |

|---|

|

|

| Drive on the pinion tooth....Comet tail is very close to center. |

|---|

|

|

| Yes....tail is swinging in the center. Ideal spot. |

|---|

|

|

| ......................... |

|---|

|

|

| Pinion depth has been established....home stretch |

|---|

|

|

| Press the pinion out..... |

|---|

|

|

| ...add the crush sleeve in.... |

|---|

|

|

Some of the crush sleeves are a sloppy fit onto the pinion. A little trick I do to keep the sleeve as

perfectly centered as possible. White tape. |

|---|

|

|

| The top of the crush sleeve does not have a whole bunch a real estate before it slips off the edge of the outer pinion bearing. |

|---|

|

|

| Not much room for error. |

|---|

|

|

| Just enough raps of tape to take up all the free play in the fit. |

|---|

|

|

| The shop flange is only on long enough to get the pinion pulled up as much as possible. |

|---|

|

|

| Then the slinger and the spacer are dropped in place. |

|---|

|

|

| .................... |

|---|

|

|

| ............................ |

|---|

|

|

| ........................ |

|---|

|

|

| This is a 32 spline pinion so the seal is a bigger inside diameter. Part number 90311-45028 |

|---|

|

|

| ..................... |

|---|

|

|

| ..................... |

|---|

|

|

| Tap it on with 360 degree support. |

|---|

|

|

| Tap it flush. |

|---|

|

|

| Anti-seize liberally applied to the threads. |

|---|

|

|

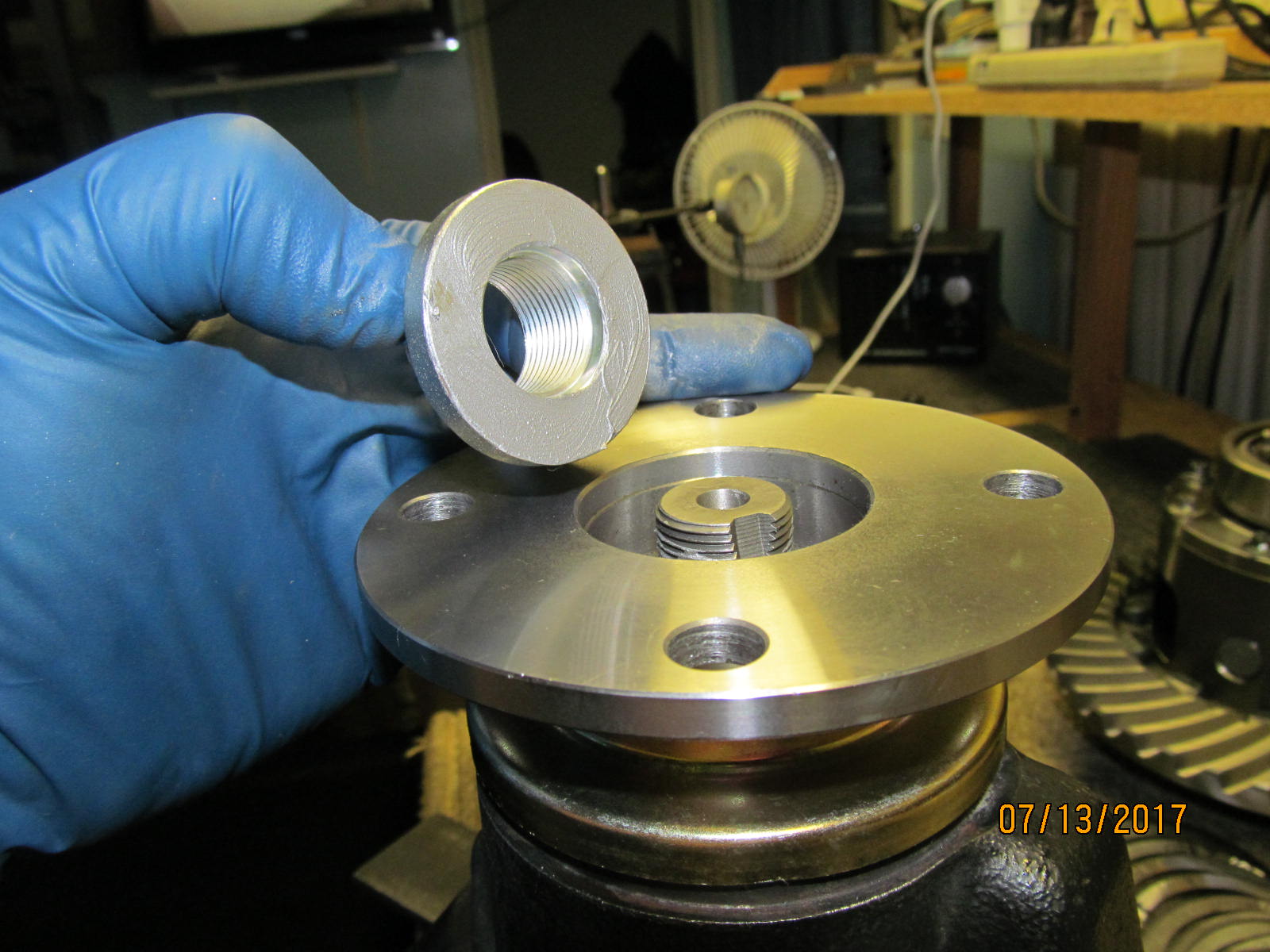

| Even on the bottom of the flange nut. The Toyota part # for the 32 spline flange is 41204-60060. |

|---|

|

|

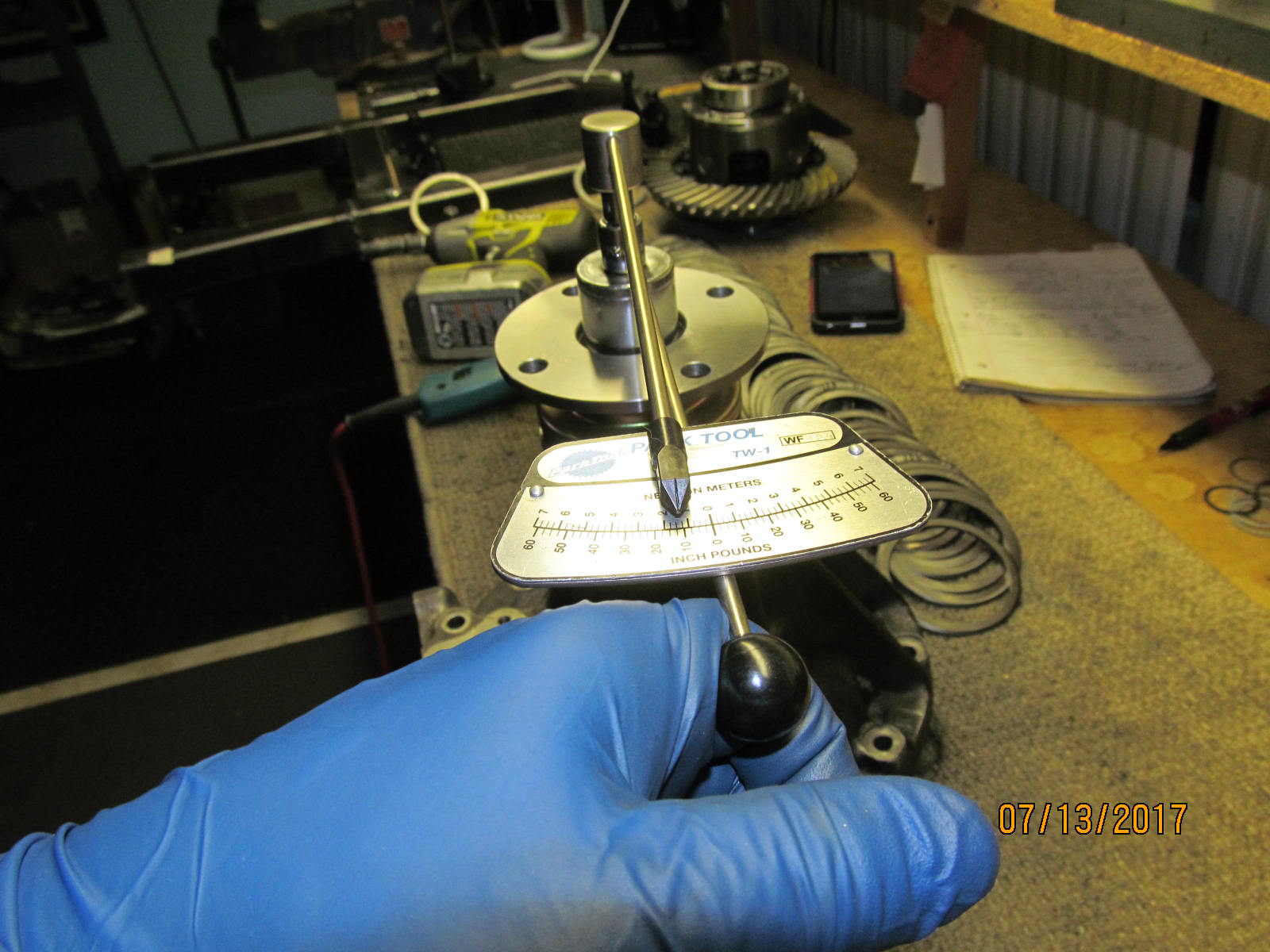

| Tighten the nut until the PPL is 10 in/lb. Stake the nut and done on this end. |

|---|

|

|

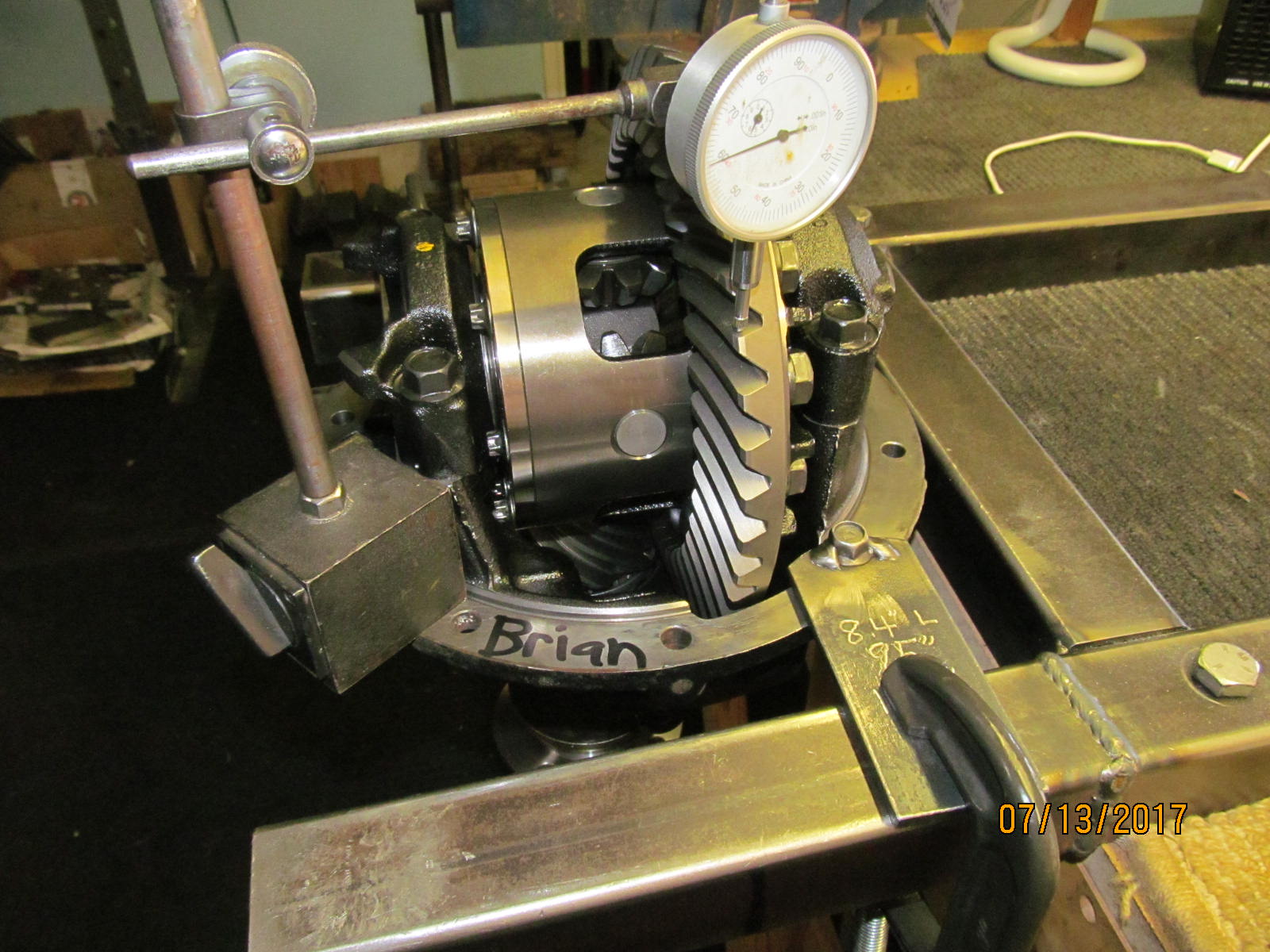

| Last chance to tweak the washer plates. Then measure backlash on every other tooth and record it. |

|---|

|

|

Total bearing pre-load is measured and coming in at 18 in/lb start torque.

18-10=8 which is the start torque of the carrier bearings. |

|---|

|

|

| Bearing caps were already close to the spec but now the final tighening to 70 ft/lb. |

|---|

|

|

| .............. |

|---|

|

|

| Final notes. |

|---|

|

|

| Packing it up getting it ready for the trip back to Tennessee. |

|---|

|

|

| .................... |

|---|

|

|

|