| 8" clamshell with Harrop A11110 elocker from Steve's 2012 4Runner needs some real TLC |

|---|

| (47 BIG pics loading) |

|---|

| FEB 1 2022 |

|---|

|

Joe, owner of GMG Fabrications located in Tempe, AZ, had Steve's 2012 4Runner on the lift with a reported issue of an

oil leak. Oil was added to the front 8" clam and then a steady stream

started coming out of the passengerside tube. As can be seen, this seal was hammered

on too too far....like 1/2" too far. Joe's shop was in no way responsible for this 'FUD'....

some other shop in the valley claims that prize. Seal installation was the cause of that issue

but that was only the tip of the subzero waterstack. |

|---|

|

|

| Genuine new axle seals will be going back in. |

|---|

|

|

| A new passengerside axle seal 90311-47013 is fully supported and recessed .222" below the edge. |

|---|

|

|

| This seal complete..... |

|---|

|

|

| Further inspection reveals the rubber grommet for the elocker wires was installed incorrectly. |

|---|

|

|

2 things....there is no steel bushing welded to the hole for actual seal support and the hole was

drilled with a 1/2" drill bit. The proper drill bit will be in the range of .460~.465".

Bending the grommet a little reveals that the oil can easily seep out.

The shell at this location is barely .100" thick. |

|---|

|

|

So, the purple plastic connector is snipped off.....But before I actually open the lid up,

maybe it is a good idea to look at the pinion end of things. |

|---|

|

|

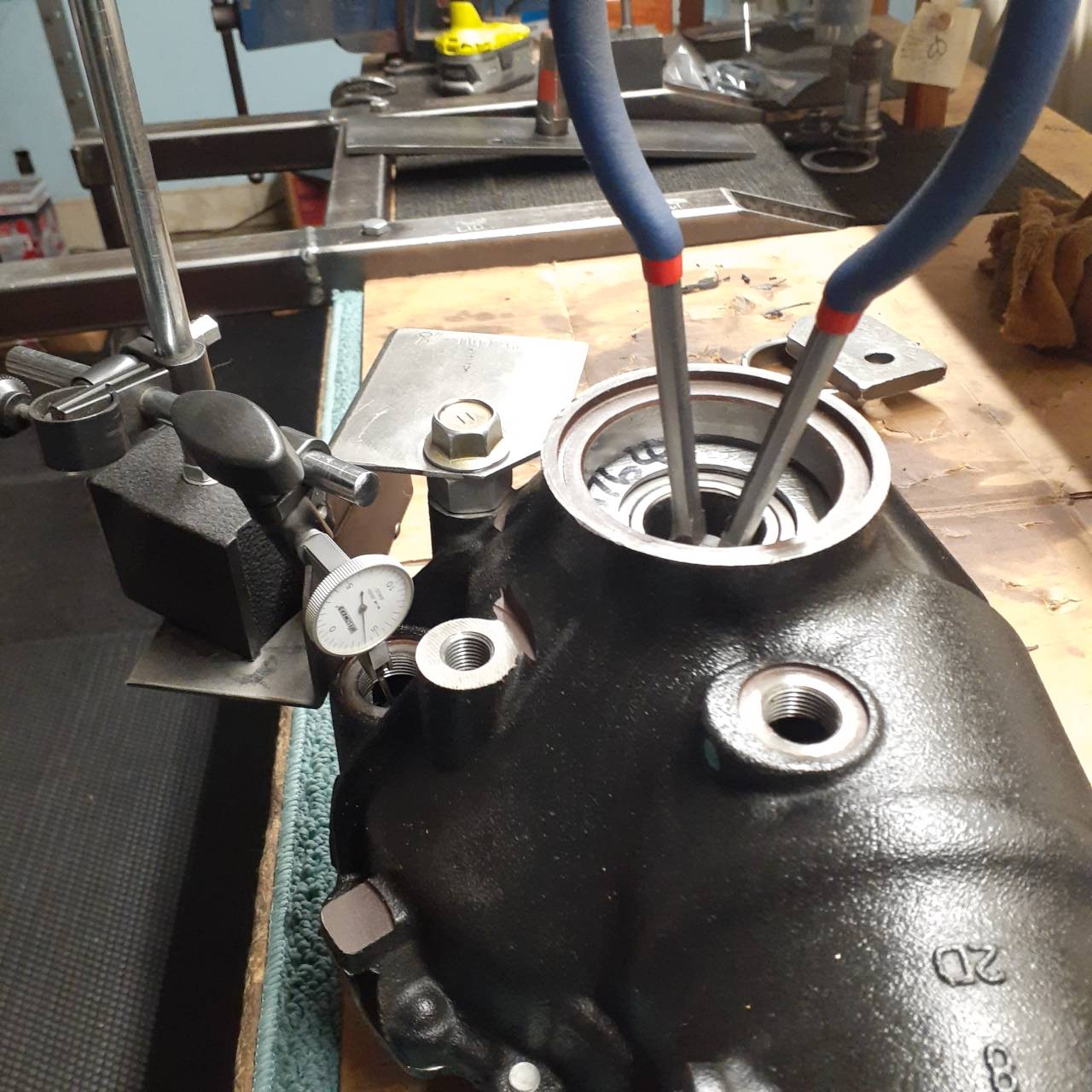

Measured pinion preload is 150 inch/pounds.....about 10 times more than the spec.

Also, this nut is sticking out too far and I am wondering what I will find as the cause of that. |

|---|

|

|

Remove the flange.....the seal was never recessed the proper amount (~.170").

Looks like the underside of the flange has been burning into the seal. |

|---|

|

|

So the seal has been removed and the pinion nut was re-tightened

to a measured PPL of about 10 inch/pounds. |

|---|

|

|

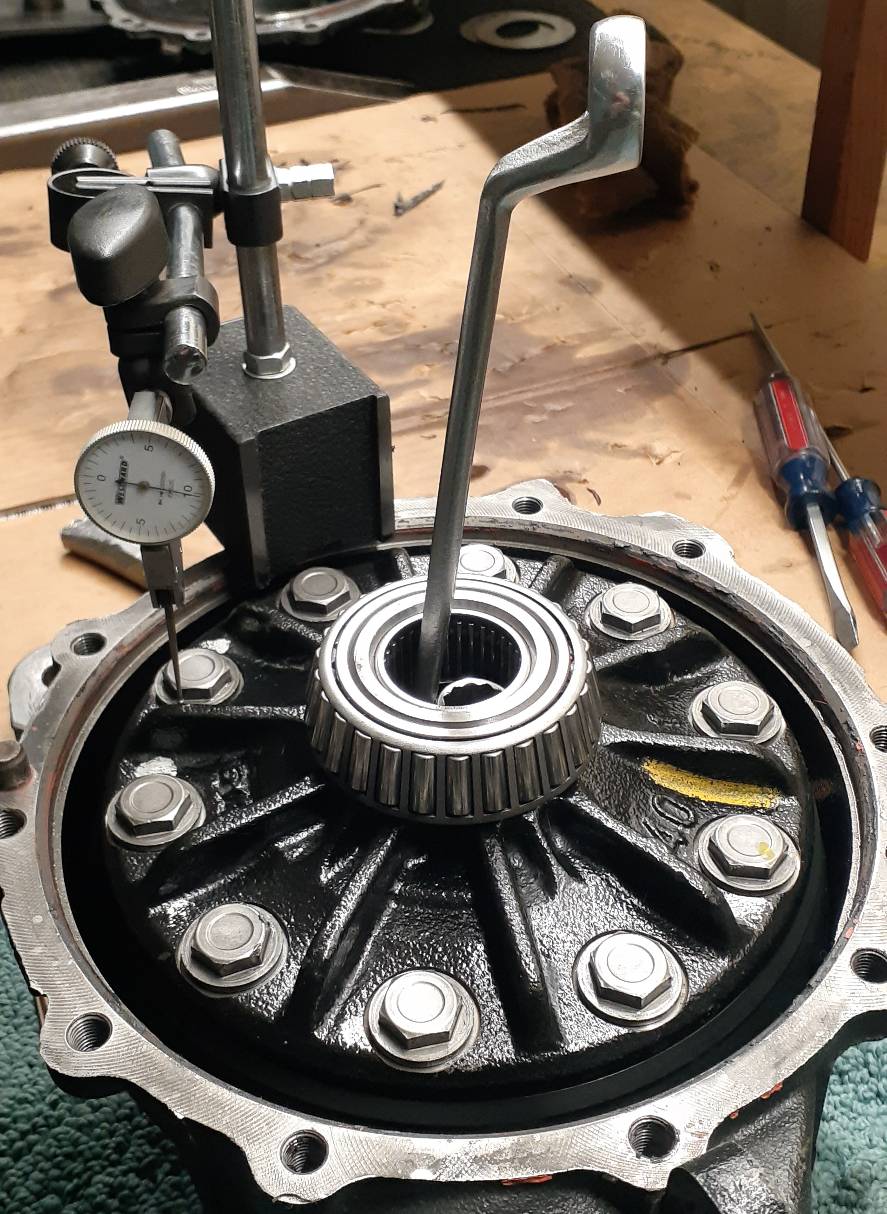

Backlash was measured at .023" ! which is almost 4 times the spec so I have to make

some carrier bearing washer plate adjustments before even thinking about a paint pattern test. |

|---|

|

|

The lid is removed and the 2 wires are found to be ripped off.

This is something I can't fix unless I have a complete magnetic assembly.....

and those are hard to come by. |

|---|

|

|

| The grey magnetic ring is scuffed and dented and pretty sure it's "distorted" also. |

|---|

|

|

| The ripped off wire..... |

|---|

|

|

| The elocker goes in a box and will be returned to Steve. |

|---|

|

|

| The pinched wires.... |

|---|

|

|

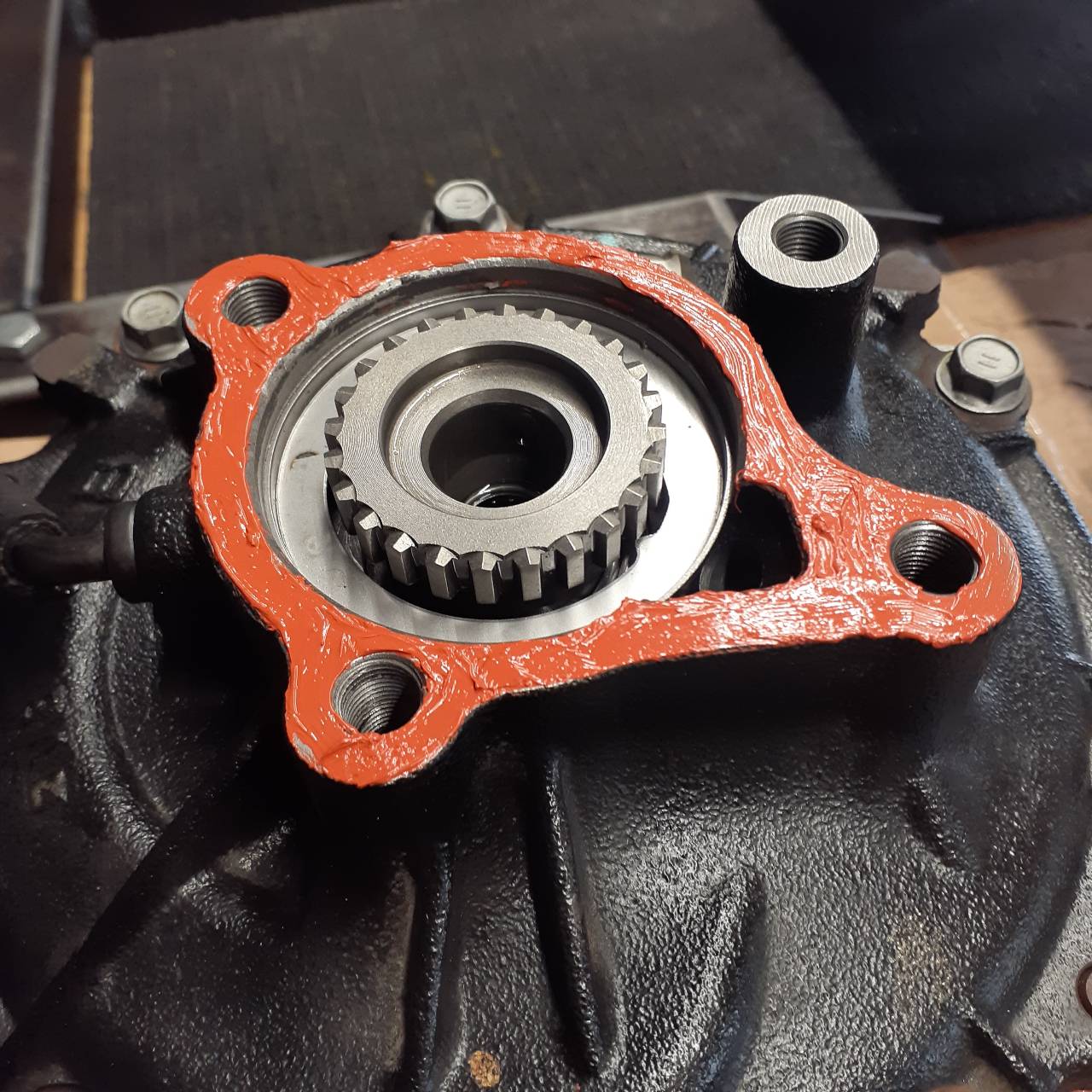

A factory open center carrier will go in for now.

An ECGS bushing in the driver side shown here will

address the wobble that the factory carriers are noted for. |

|---|

|

|

| 85 ft/lb and red Loctite to secure the 488 Nitro gear |

|---|

|

|

The hole was drilled way too low.....

an excellent place is 3" from the lip.

The 1/2" hole will be filled with the MIG machine. |

|---|

|

|

When the lid was bolted and tightened up it caused the delicate magnetic ring to dent the 3 shown ribs.

It's mandatory to clearance them a good 1/4" with a dremel drill or similar. |

|---|

|

|

| Made some washer plate adjustments....... |

|---|

|

|

| A real backlash check shows it is now much better. |

|---|

|

|

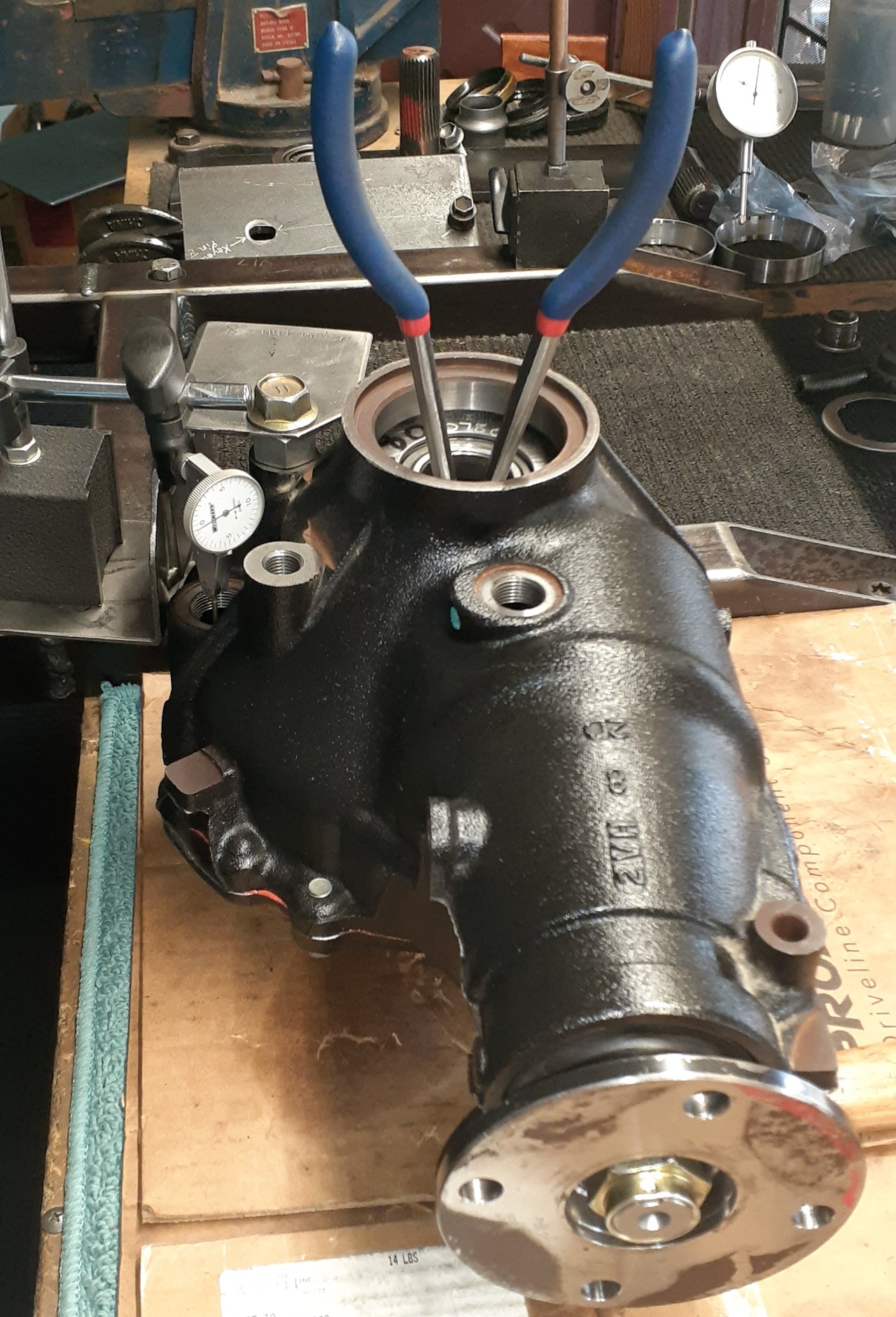

| The jig for running a paint test..... |

|---|

|

|

| Drive.....a bit too deep (too much shim). |

|---|

|

|

| Coast side....really into the root. |

|---|

|

|

| OEM shim was 078 and this 073 should do the trick. |

|---|

|

|

| ................ |

|---|

|

|

The aftermarket crush sleeve is a sloppy fit onto the pinion shaft....it's a piece of junk

and looks like it slipped off the small outer bearing.

The factory crush on the right is a proper fit and does not slip. |

|---|

|

|

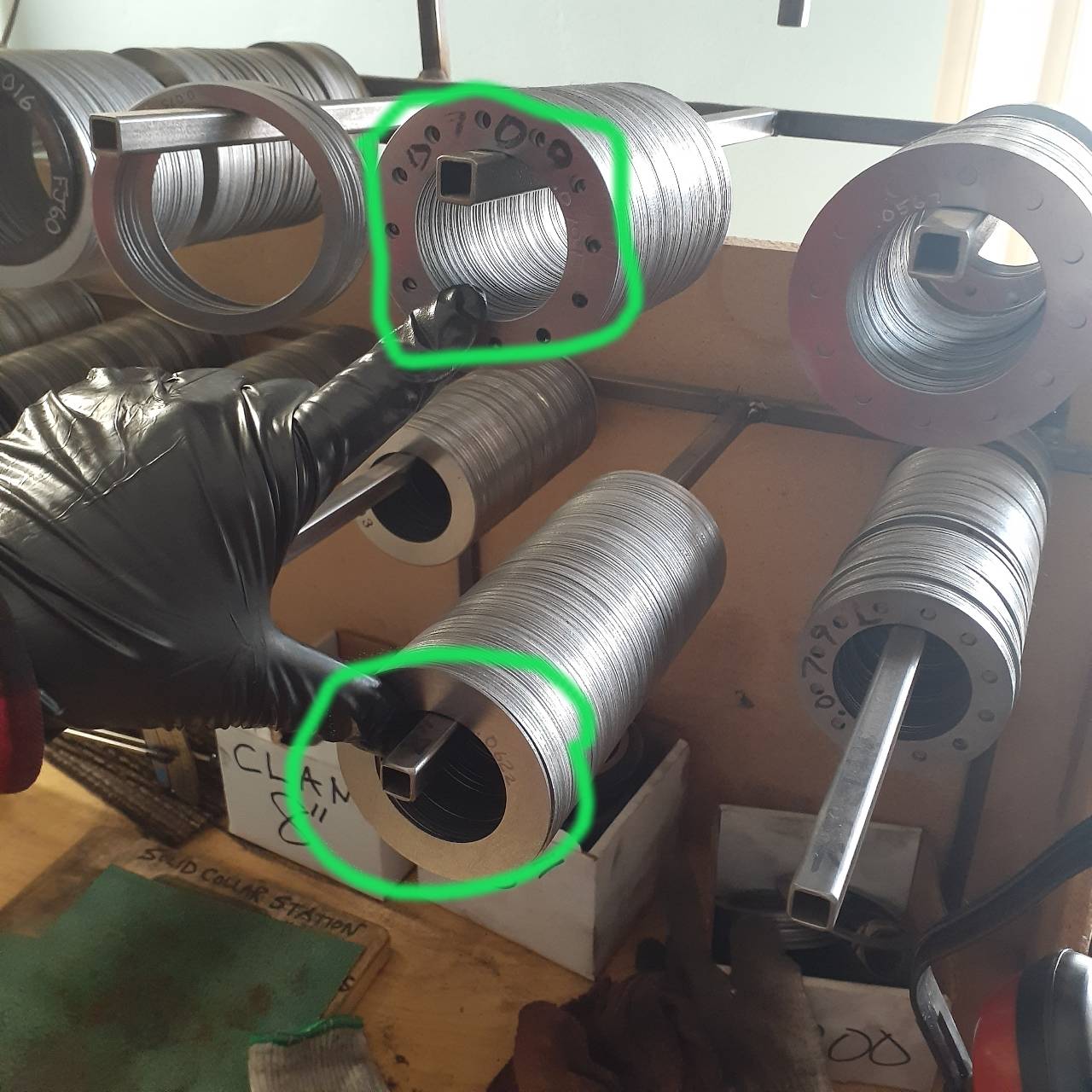

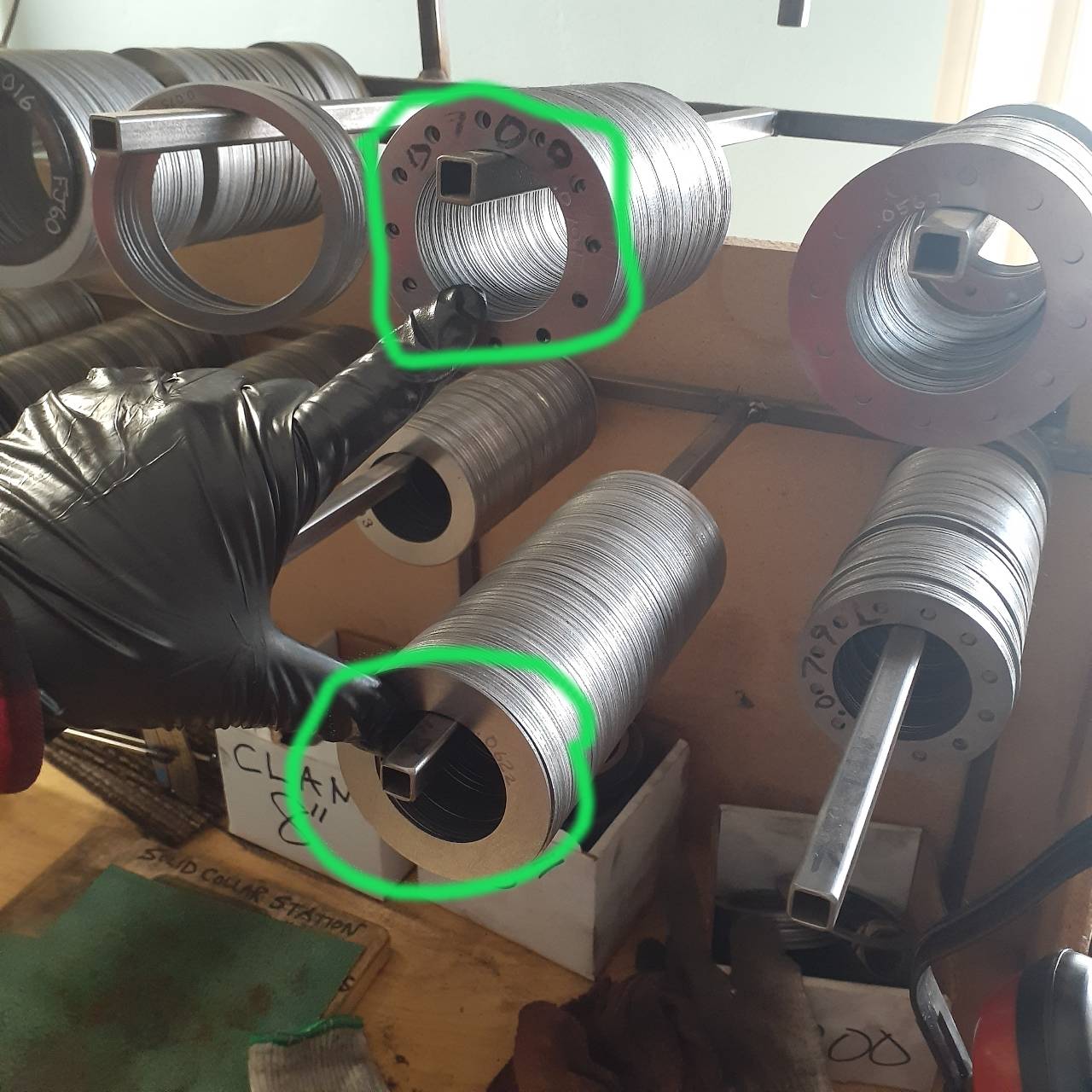

These are the genuine factory washer plates used behind the carrier bearing races to set

backlash and preload. These are a must to do the job right. |

|---|

|

|

| Drive with 073 shim and this is very nice. Centered and good balance face to flank. |

|---|

|

|

| reverse painted drive #2....nice. |

|---|

|

|

| reverse painted drive #3...nice again. |

|---|

|

|

| coast |

|---|

|

|

| coast...reverse painted #2 |

|---|

|

|

| coast...reverse painted #3. |

|---|

|

|

| genuine factory crush..... |

|---|

|

|

Something else was discovered at this point.....the outer pinion bearing and race did not match.

The rollers did not match the race "profile". |

|---|

|

|

| Brand new bearing and race that do match ;) |

|---|

|

|

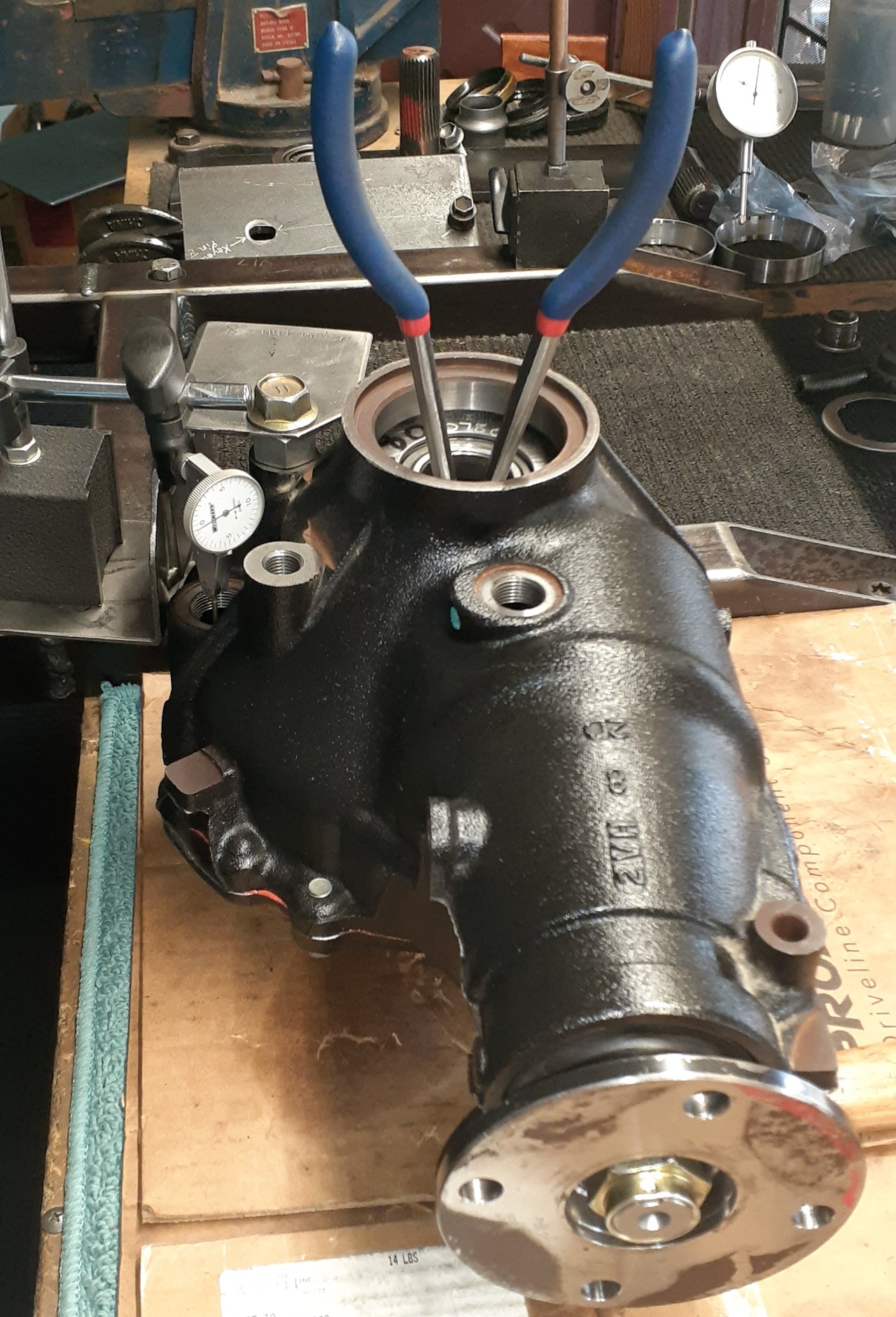

Now all is good.....things are going together as they should.

Genuine 41009 seal going in... |

|---|

|

|

| Seal is recessed to the spec of .176" |

|---|

|

|

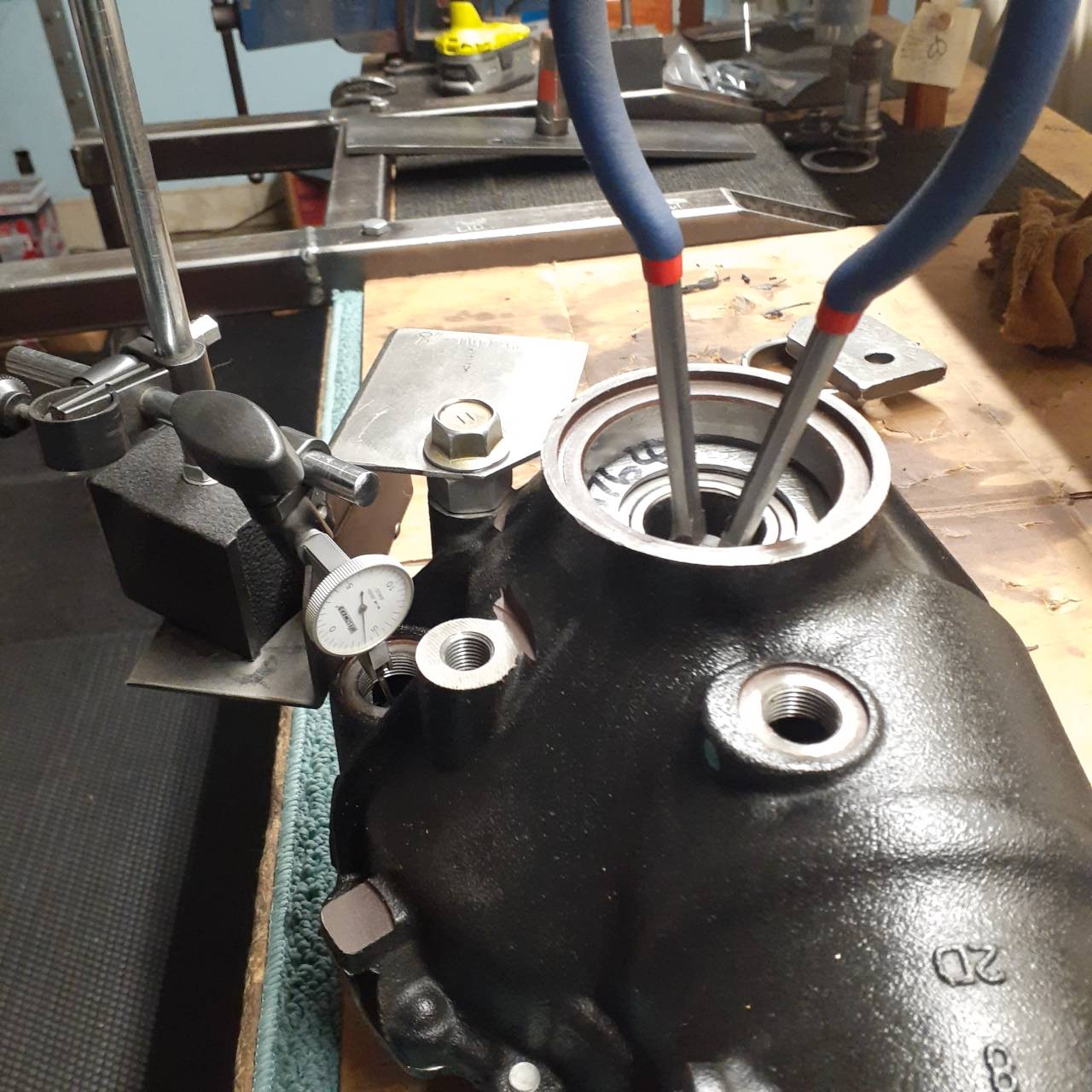

Hmmm...now the same exact nut is seating down onto the pinion threads as it should be.....

must have been that bearing mismatch that threw it off.

11 inch/pounds recorded and DING! and this end done.. |

|---|

|

|

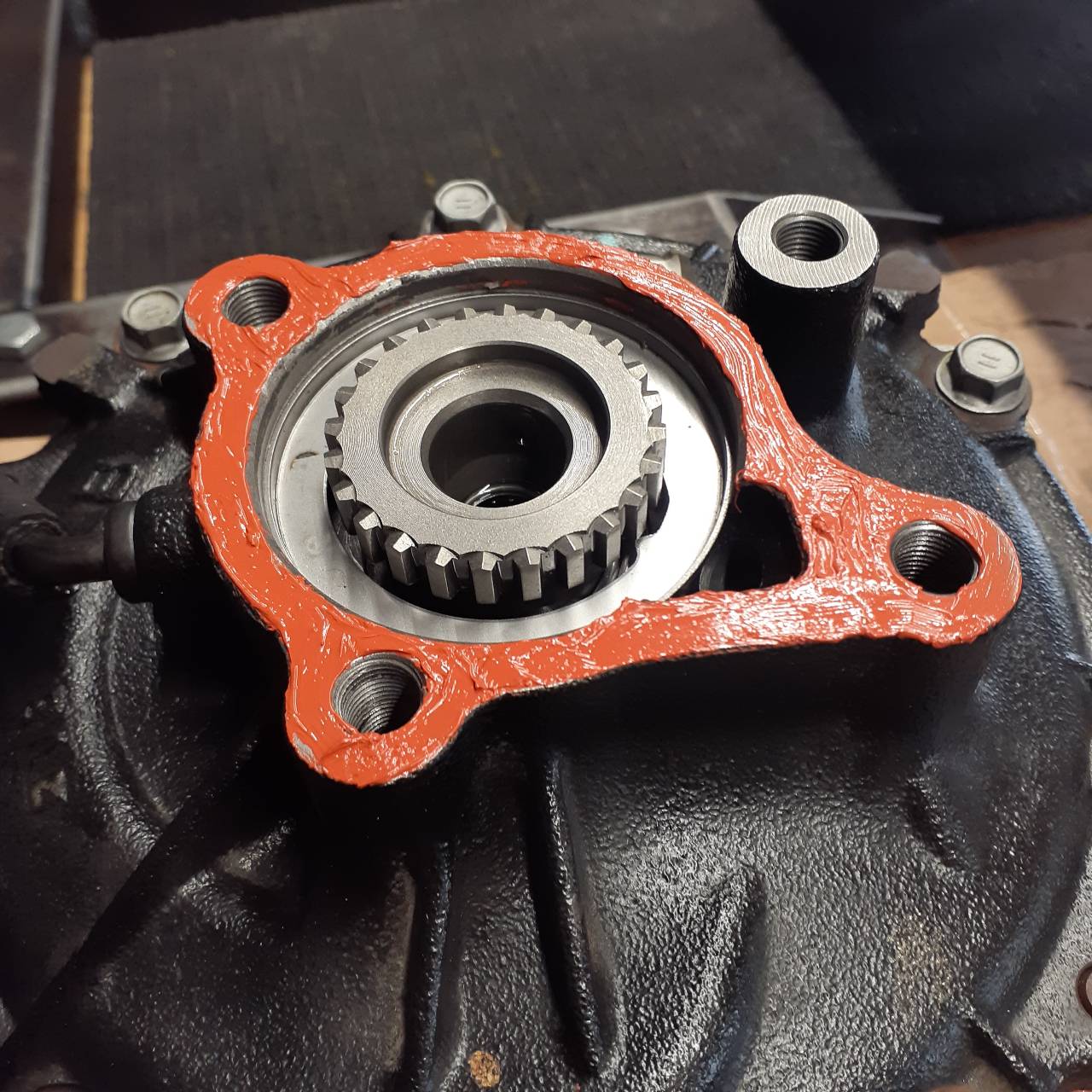

| Orange Toyota FIPG on the lid..... |

|---|

|

|

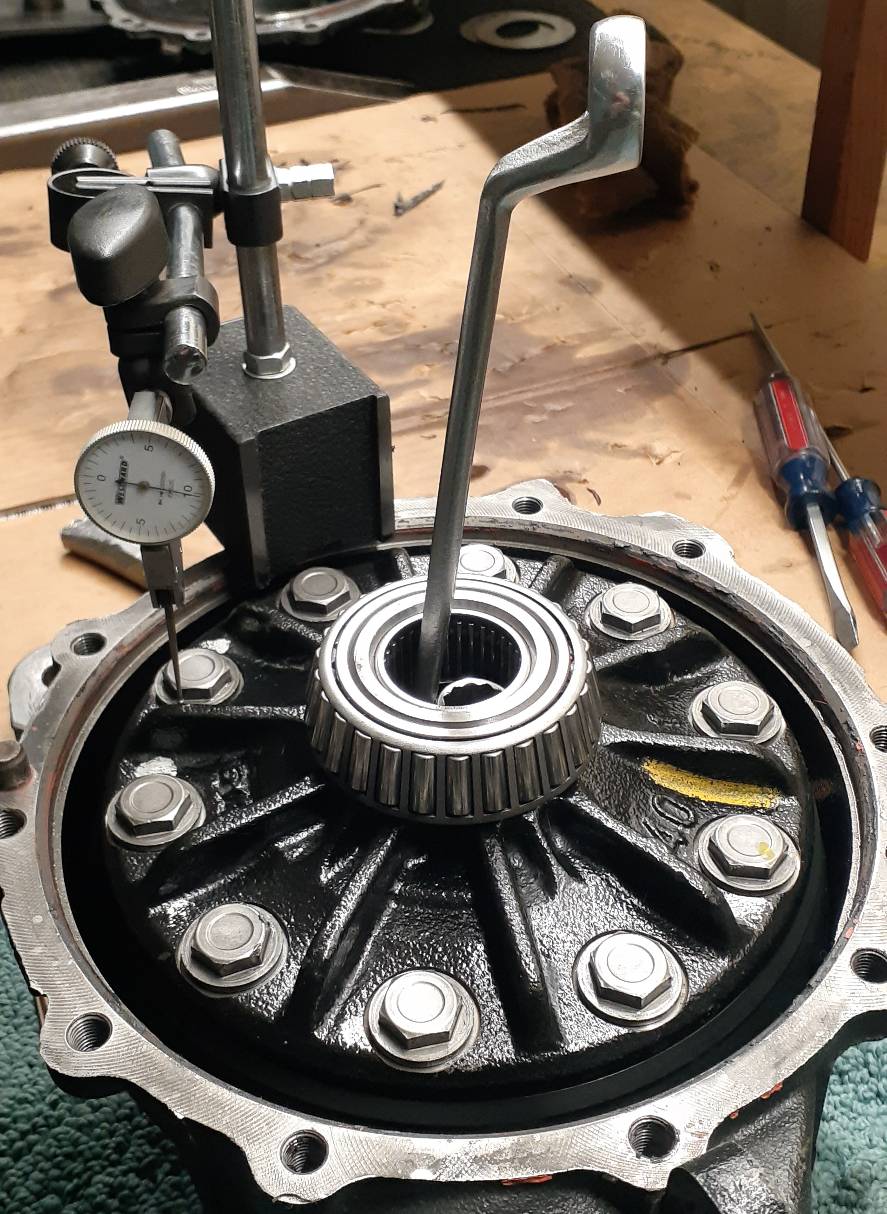

| ....Then to record the backlash readings(every 3rd tooth). |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| FIPG on this end and tighten the 4 axle tube bolts to 81 ft/lb. |

|---|

|

|

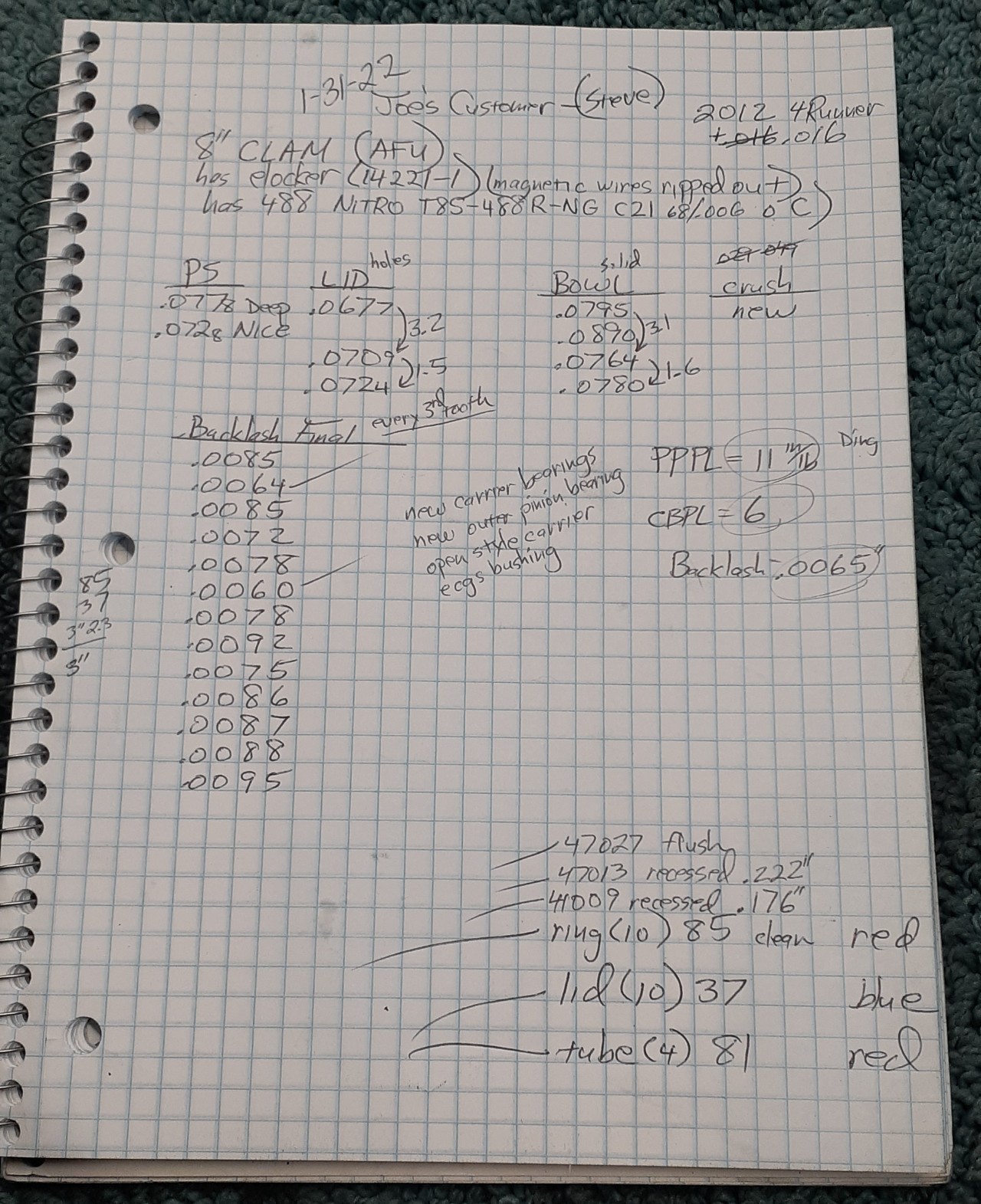

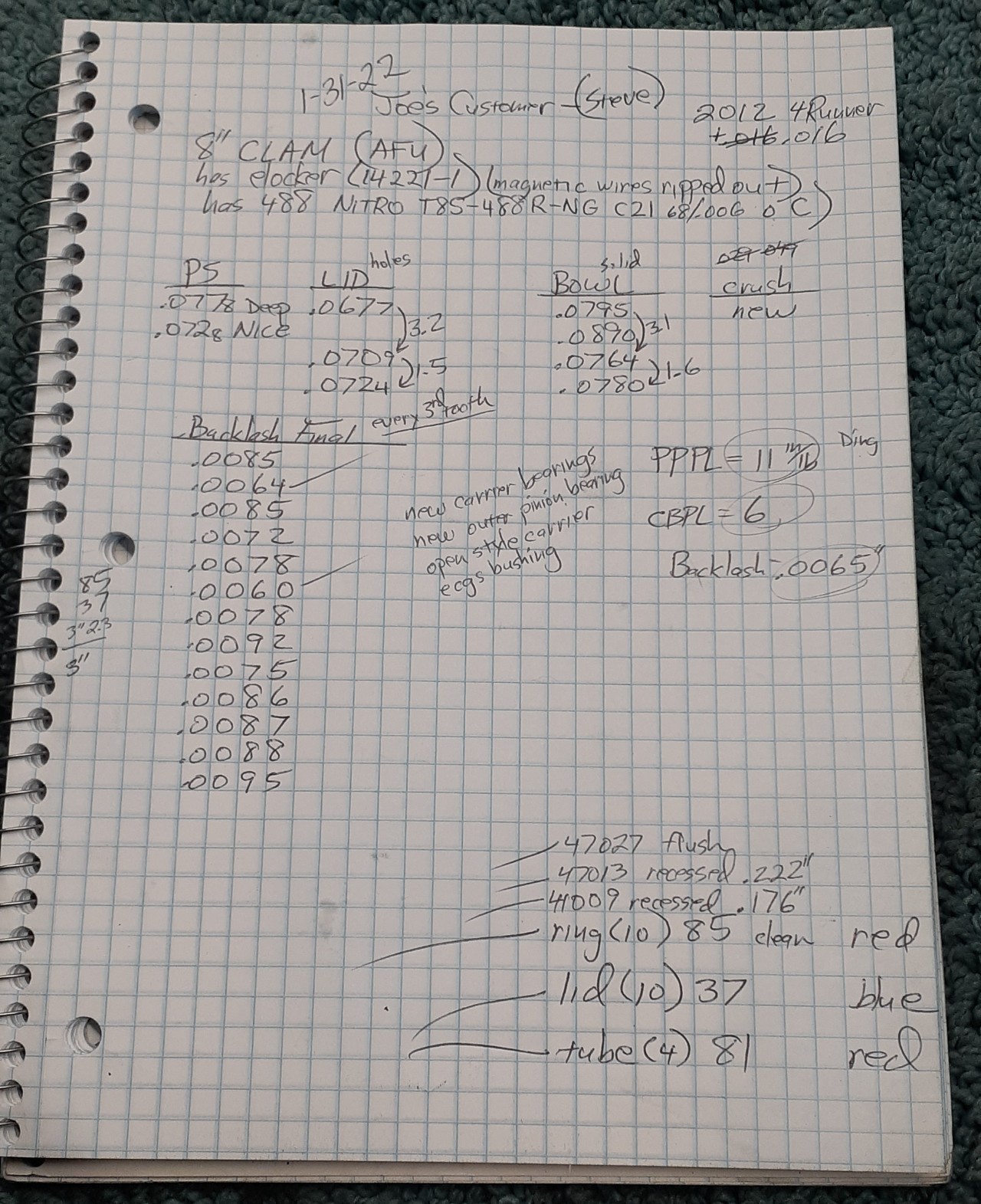

| Notes kept of the rebuild..... |

|---|

|

|

|