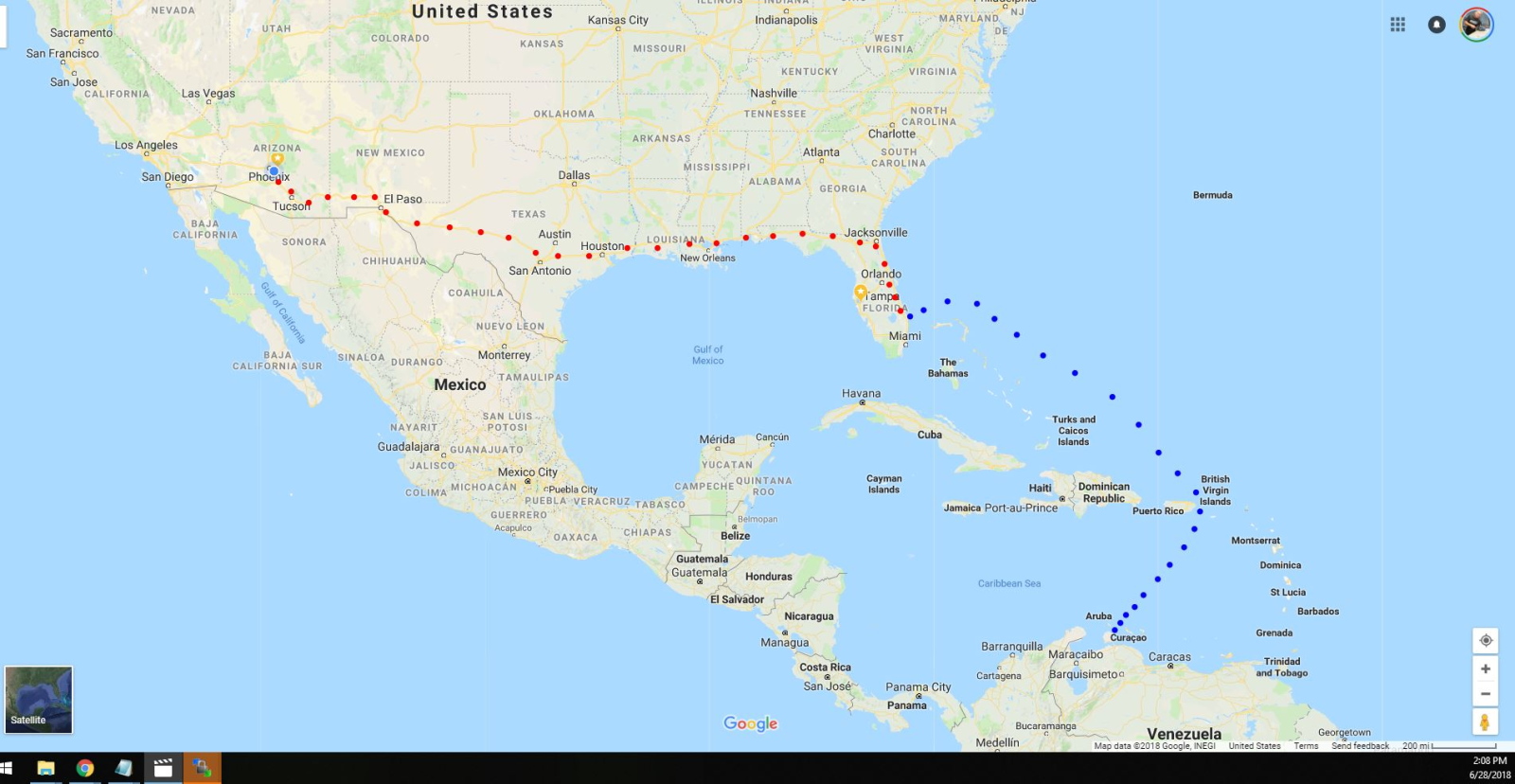

| Ivan's 2000 Tundra rear 8.4" rebuild (from the Island of Curacao) |

|---|

| (42 BIG pics loading) |

|---|

| JUNE 28 2018 |

|---|

|

Ivan's 2000 Tundra had a rear 8.4" that needed rebuilding. Rebuild shops are tough to find on this Island... so he made a box from wood

and Bon Trade forwarded it to me in Arizona. |

|---|

|

|

| As received. It made the trip with no loss of wood panels. :) |

|---|

|

|

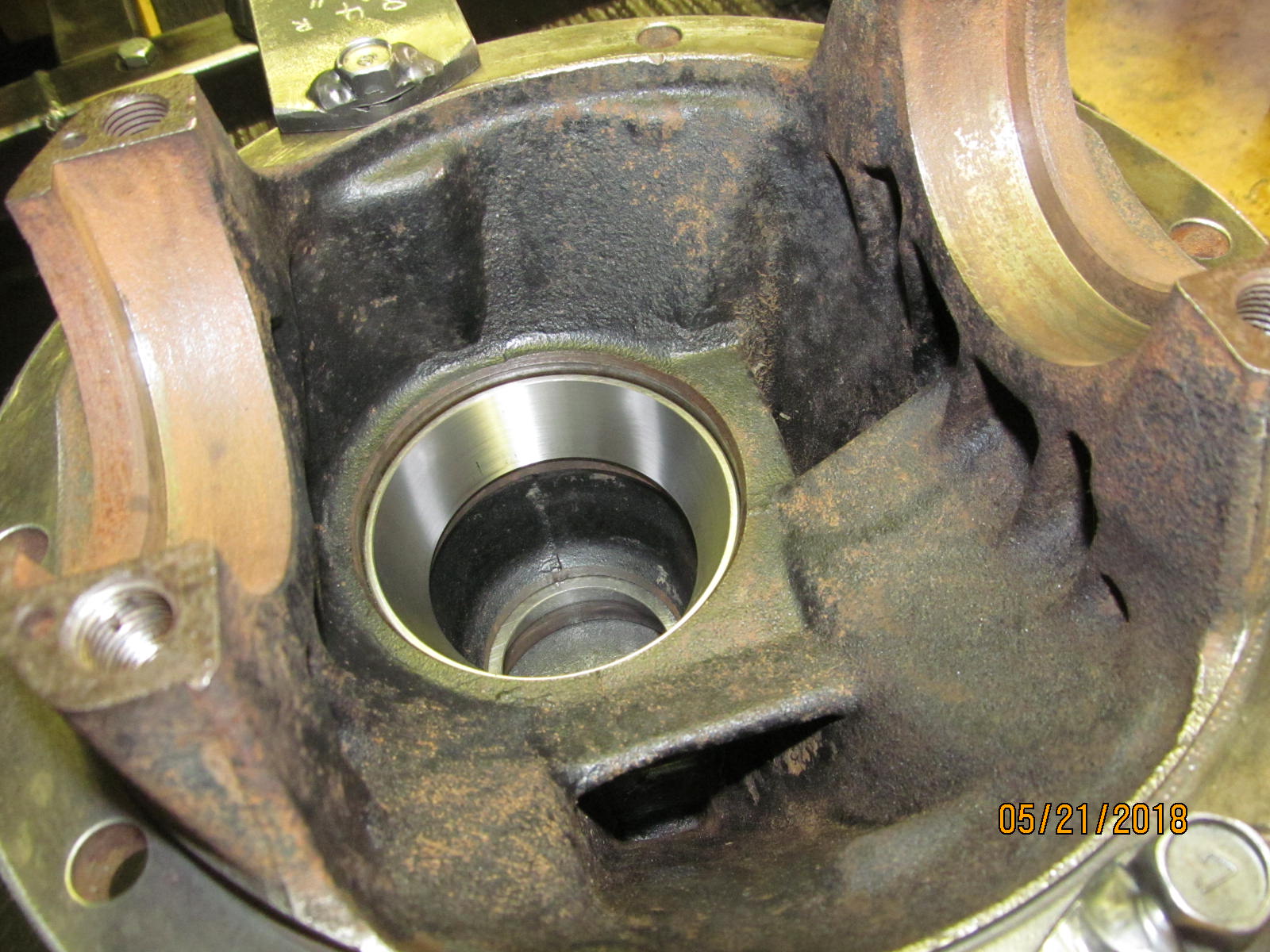

A little bit of surface rust I suspect from the salt in the air on the trip over. Easy enough to clean up though.

Apparently the ring and pinion were also destroyed. |

|---|

|

|

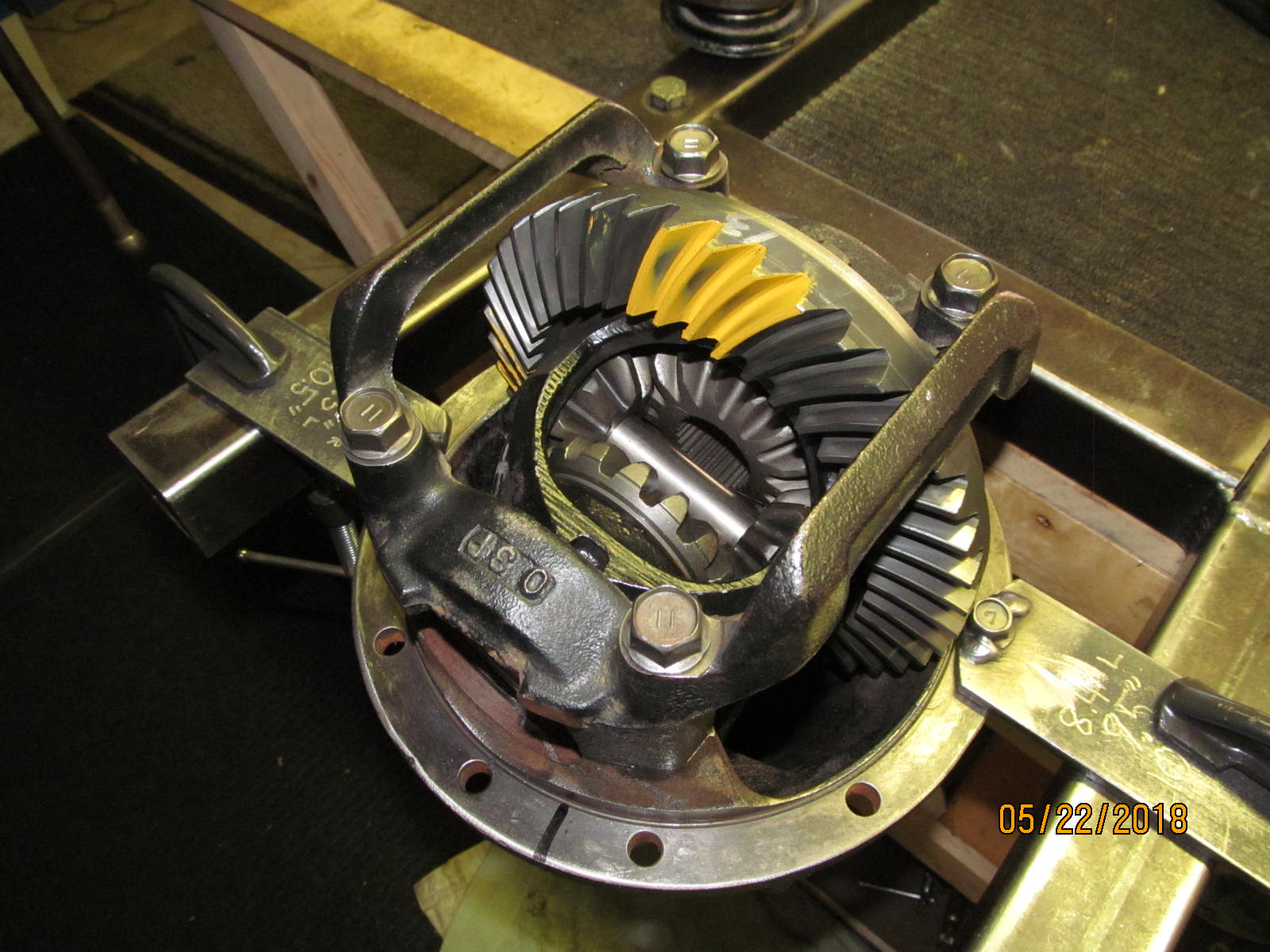

| I'm supplying the 3.91 (43/11) take-offs and new bearings and center carrier assembly. |

|---|

|

|

| 92 ft/lb and red high strength threadlocker on the 12 bolts per fsm. |

|---|

|

|

| New Koyo carrier bearings are tapped on. |

|---|

|

|

| Ring and 2 bearings are on....this end is complete. |

|---|

|

|

| New outer race.............. |

|---|

|

|

| .....is tapped in. |

|---|

|

|

| Fully seated....nice tight fit also. |

|---|

|

|

| Same with the larger inner race. No washer plate under this race. It will be re-located to the pinion head.....like most other traditional Toyota 3rds. |

|---|

|

|

| Let's try .080" shim first and see what it paints like. |

|---|

|

|

| The Harbor Freight 12 ton easily presses on the bearing and shim. |

|---|

|

|

Put the main body of the 3rd over the pinion, tap the pinion flange on, tighten nut to give about 10 inch/pounds of pinion preload,

bolt the ring gear assembly down and set some preload and backlash. |

|---|

|

|

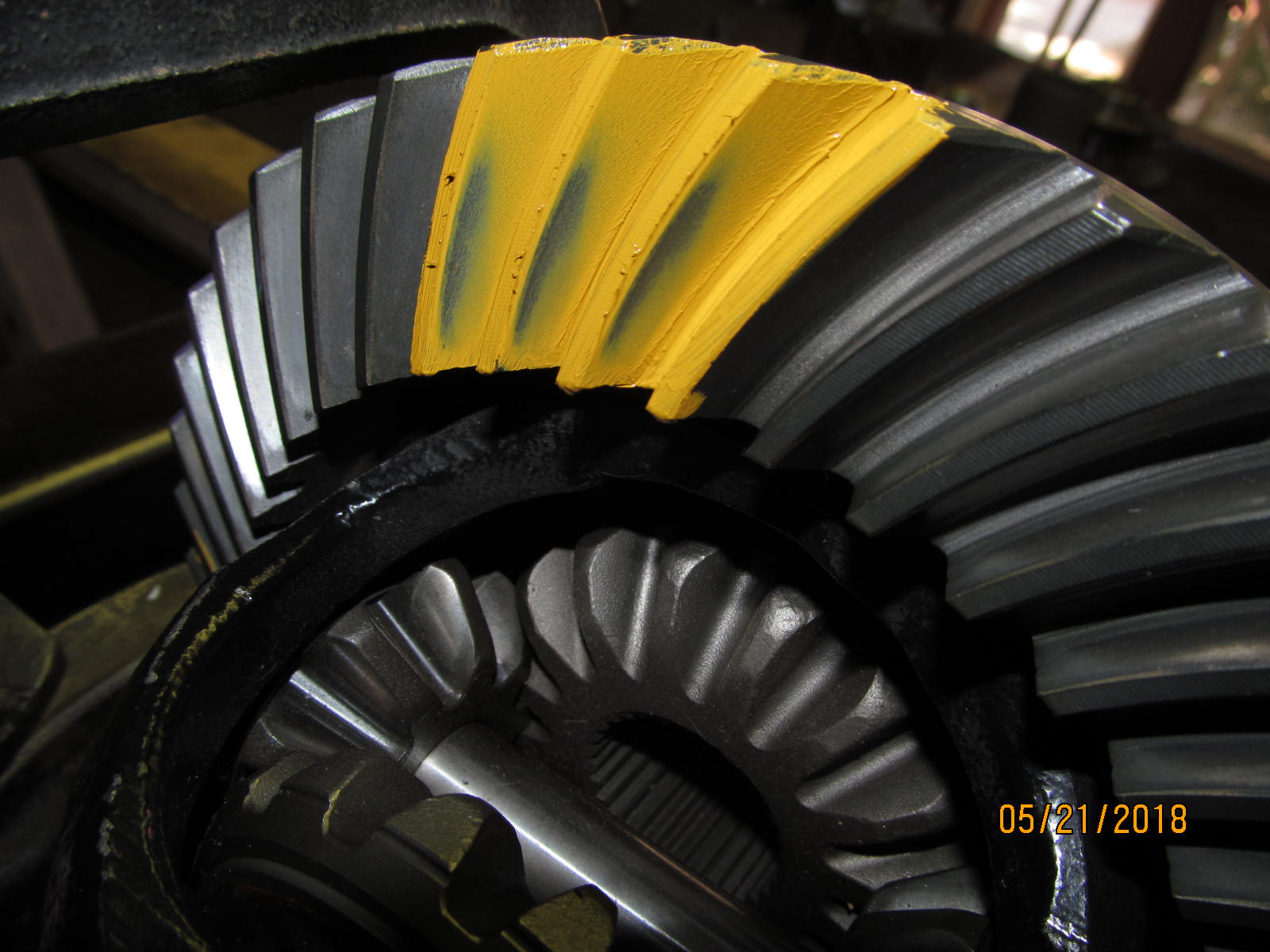

| Drive pattern says way too shallow....needs a thicker pinion shim. |

|---|

|

|

| Coast side agrees. |

|---|

|

|

| Comet tail on the drive side pinion tooth is tucked in too hard....which means that the ring gear is shallow. |

|---|

|

|

Teardown and reshimmed for 6 thou more for a total of .086"

Driveside looks slightly shallow. |

|---|

|

|

| Coast looks nice. |

|---|

|

|

But the comet tail says it all.....says to go deeper with a little more shim.

(Comet tail is severely tucked into the root.) |

|---|

|

|

| So we take it apart once more and slap another .003" on the pinion head for a total of .089" |

|---|

|

|

| press press press |

|---|

|

|

| This time I feel so good about this 089" shim that I will put the new crush sleeve in now. |

|---|

|

|

Tightened up just enough to get an accurate paint test.

Driveside looks beautiful. Even favors the toe a little. |

|---|

|

|

| Coast looks very nice and is centered. |

|---|

|

|

| The comet tail tells the story....comet tail feathering to the center. Perfect. |

|---|

|

|

| In the case of the 8.4", the best seal is the OEM factory seal. 90311-44007 |

|---|

|

|

Last chance to oil up the outer pinion bearing....and apply some thick grease to the inards of the seal to prevent the garter spring

from accidentally popping off. |

|---|

|

|

| This original flange looked kind of "ratty" on the seal surface even after #1500 wet/dry passovers. |

|---|

|

|

| A shiny, new flange is the best guarantee against a drip. |

|---|

|

|

| Aluminum based anti-seize was applied to the pinion threads. |

|---|

|

|

| The pinion nut was tightened until a smooth 10 inch/pounds of pinion start torque was measured. |

|---|

|

|

| DING! and this end is done. |

|---|

|

|

Last chance to tweak the bearing preload and the backlash value....add less than .001" to this side....and also add .002" to the other side.

That has the affect of tightening the bearing preload and closing up the backlash a small amount. |

|---|

|

|

| The 4 bearing cap bolts are torqued to 83 ft/lb per the FSM. |

|---|

|

|

| Total combined preload is measuring about 17 inch/pounds |

|---|

|

|

| ........................ |

|---|

|

|

| Backlash is recorded on every other tooth. |

|---|

|

|

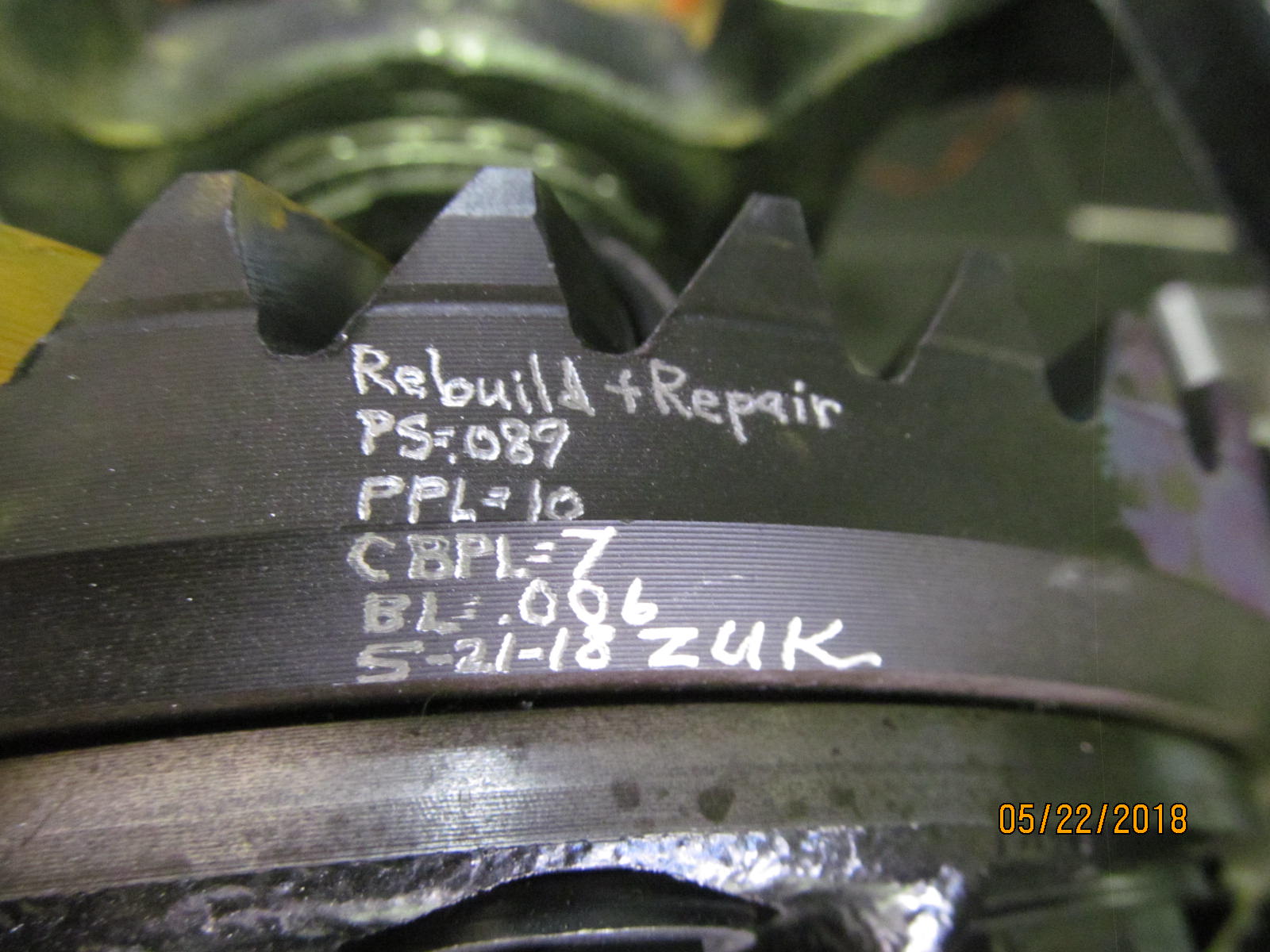

| The ring is inscribed with the basics. |

|---|

|

|

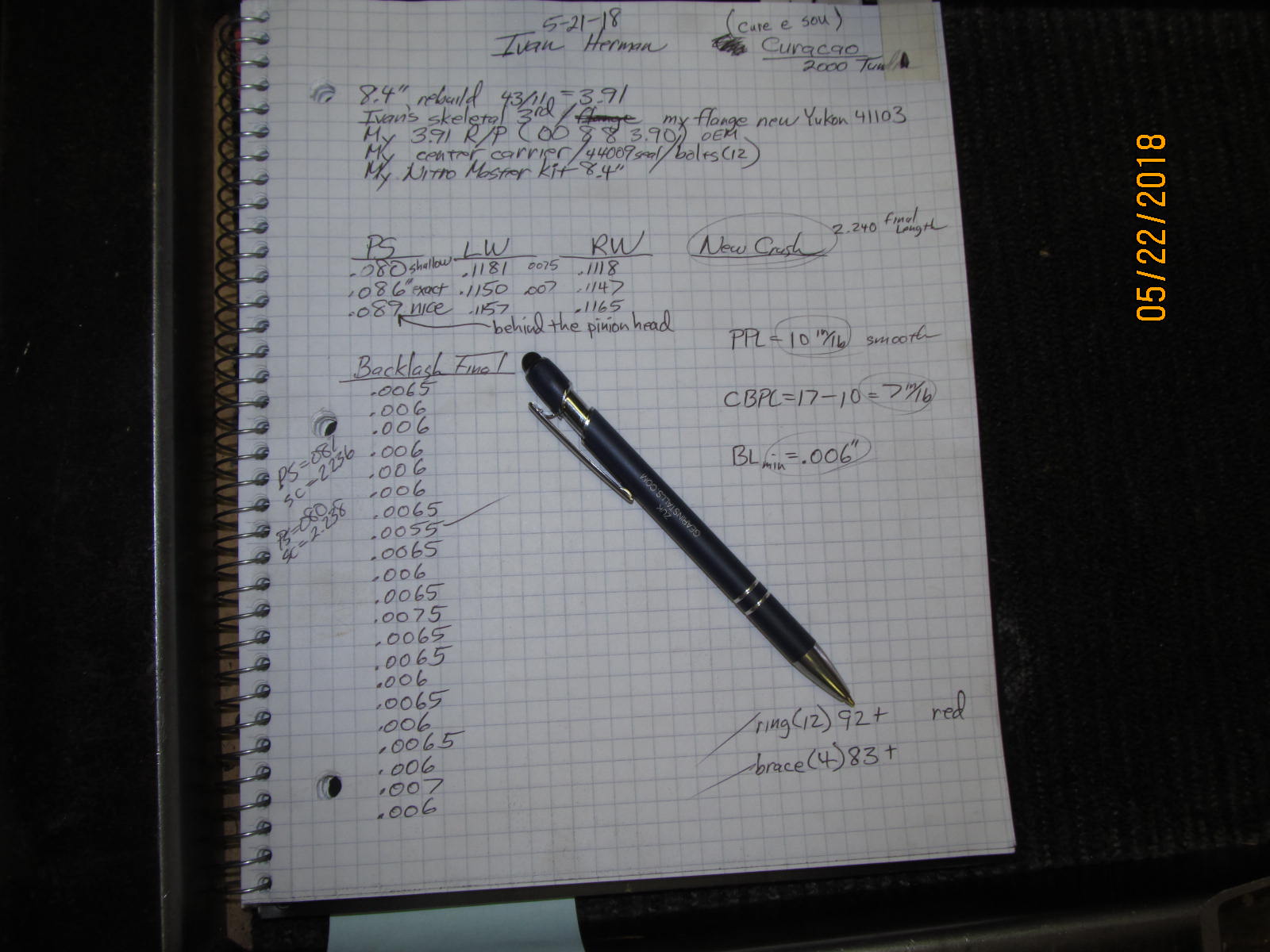

| A shot of the notes for Ivan's rebuild. |

|---|

|

|

This is how Ivan did it.....created an account here. Bon Trade ships it to their Florida USA port and then it's forwarded to me.

Then the rebuilt 3rd I ship it back to the Florida address. |

|---|

|

|

|