| JP's 2017 Tundra Gets a Harrop A13791 with a Regear to REM and CRYO'd Nitro 529's |

|---|

| (73 BIG pics loading) |

|---|

| MAY 3 2020 |

|---|

|

| JP's 2017 Tacoma |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| The 10.5" Nitro 529 rear gears were already "REM treated" locally and now they are at CryogenicsInternational.com |

|---|

|

|

REM makes them look almost like chrome and reduces the friction so no real break-in required.....

whereas Cryo reduces the Austenite content which has the affect of making the metal stronger.

Smoother....shinier ....stronger. |

|---|

|

|

Items are layed out on the bench. The Harrop for the BIG 10.5" is a brand new item for the USA market.

It is not cheap.....retails at $2298.

We just happen to get serial number 001, too! |

|---|

|

|

| Disassembly begins on the 108 pound diff. |

|---|

|

|

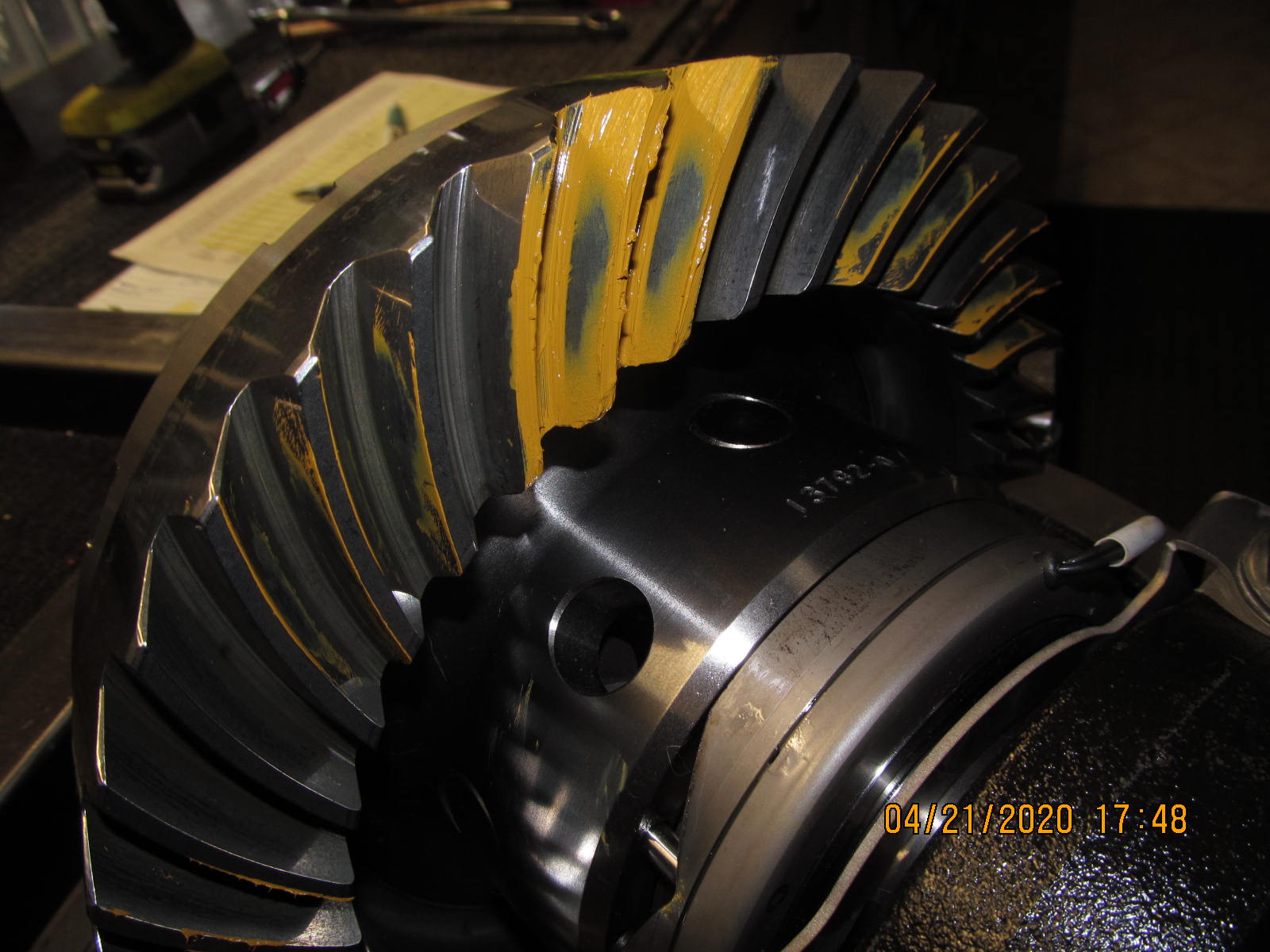

| A paint test was performed on these "2-cut" face hobbed gears. |

|---|

|

|

The 2 cut process is faster and cheaper than the 5-cut process but the 2-cut over time will see more wear

and pitting in the center of the tooth contact. |

|---|

|

|

| Bearing caps are removed. |

|---|

|

|

Carrier bearing washer plates are tapped out.

These plates set backlash and carrier bearing preloads. |

|---|

|

|

| Part of the Nitro master kit.....no crush sleeve is included because the factory already puts a solid collar in. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| The 12 ring gear bolts are removed. |

|---|

|

|

| Pushing the pinion out... |

|---|

|

|

| Massive pinion flange. |

|---|

|

|

| Seal surface is in excellent shape. |

|---|

|

|

| The factory solid collar. |

|---|

|

|

| The factory pinion seal UH5186E |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| ...................................... |

|---|

|

|

| My seal remover made quick work of it. |

|---|

|

|

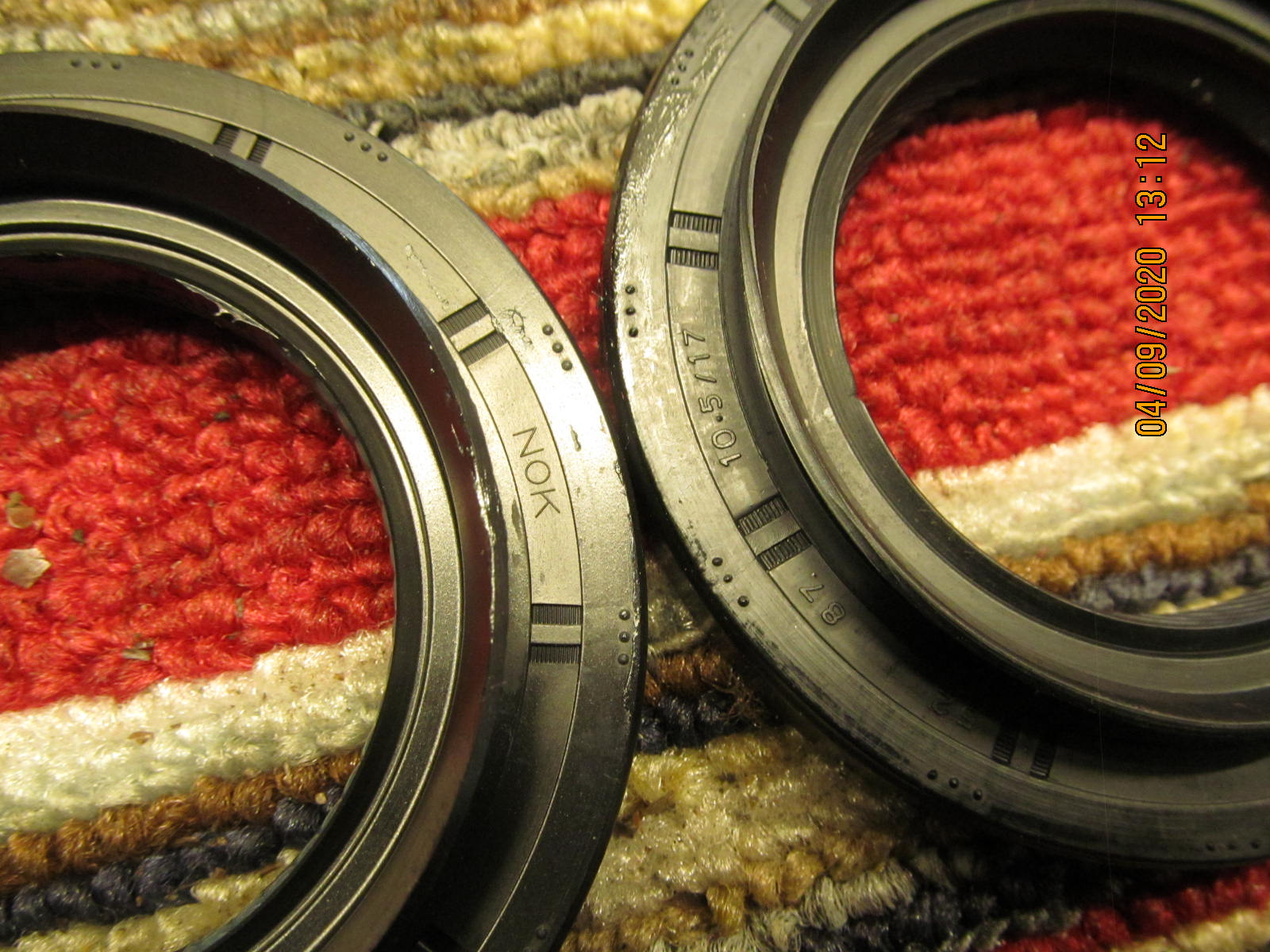

| The Nitro kit supplies a pinion seal but the genuine Toyota seal radiates quality. |

|---|

|

|

| Genuine vs Nitro |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| '''''''''''''''''''''''''''''''''''''''''' |

|---|

|

|

| ////////////////////////////////////////// |

|---|

|

|

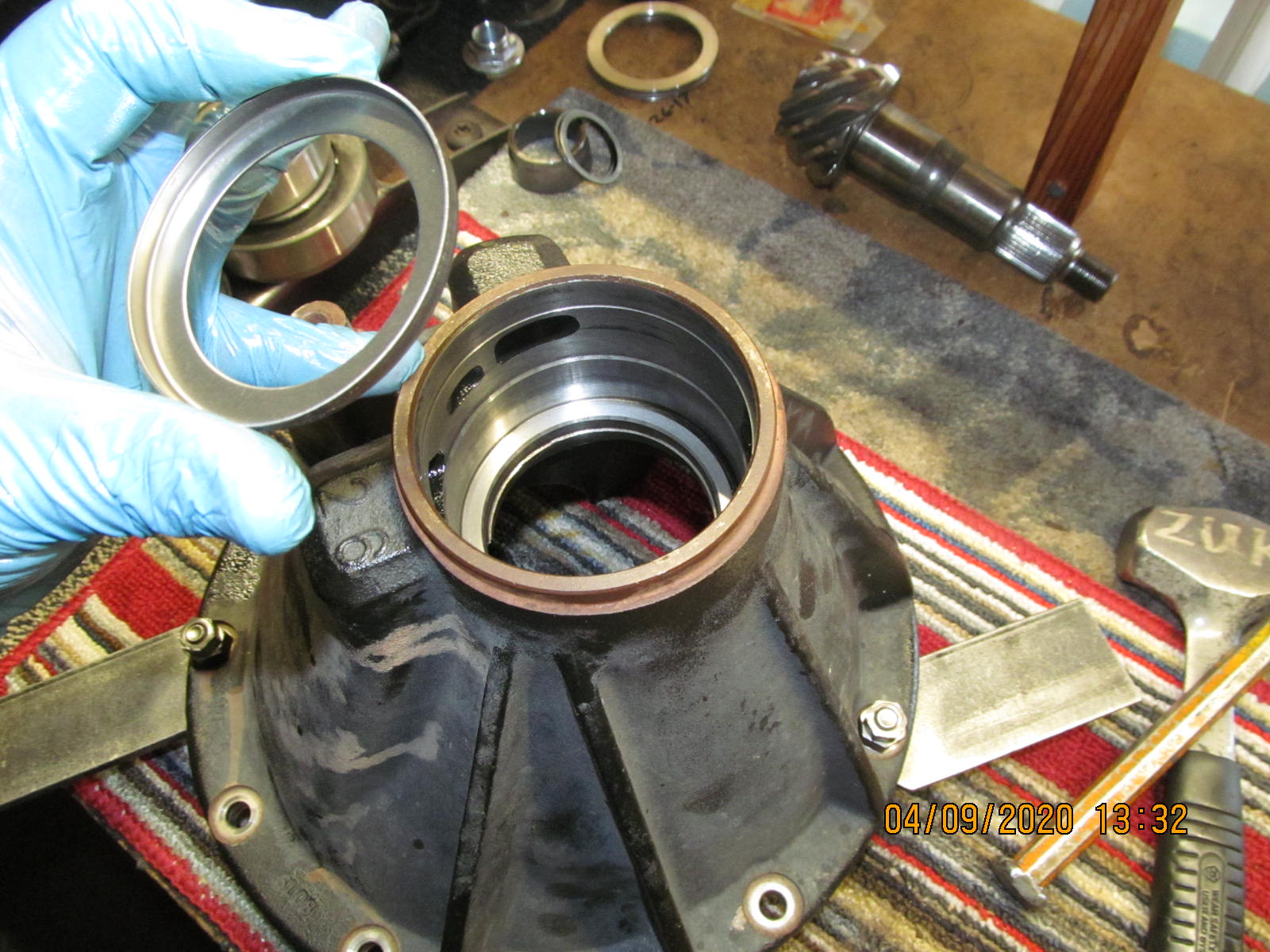

| The massive outer pinion bearing comes out. |

|---|

|

|

| A simple washer cut in half to help push the old race out with no damage to the oil retainer under it. |

|---|

|

|

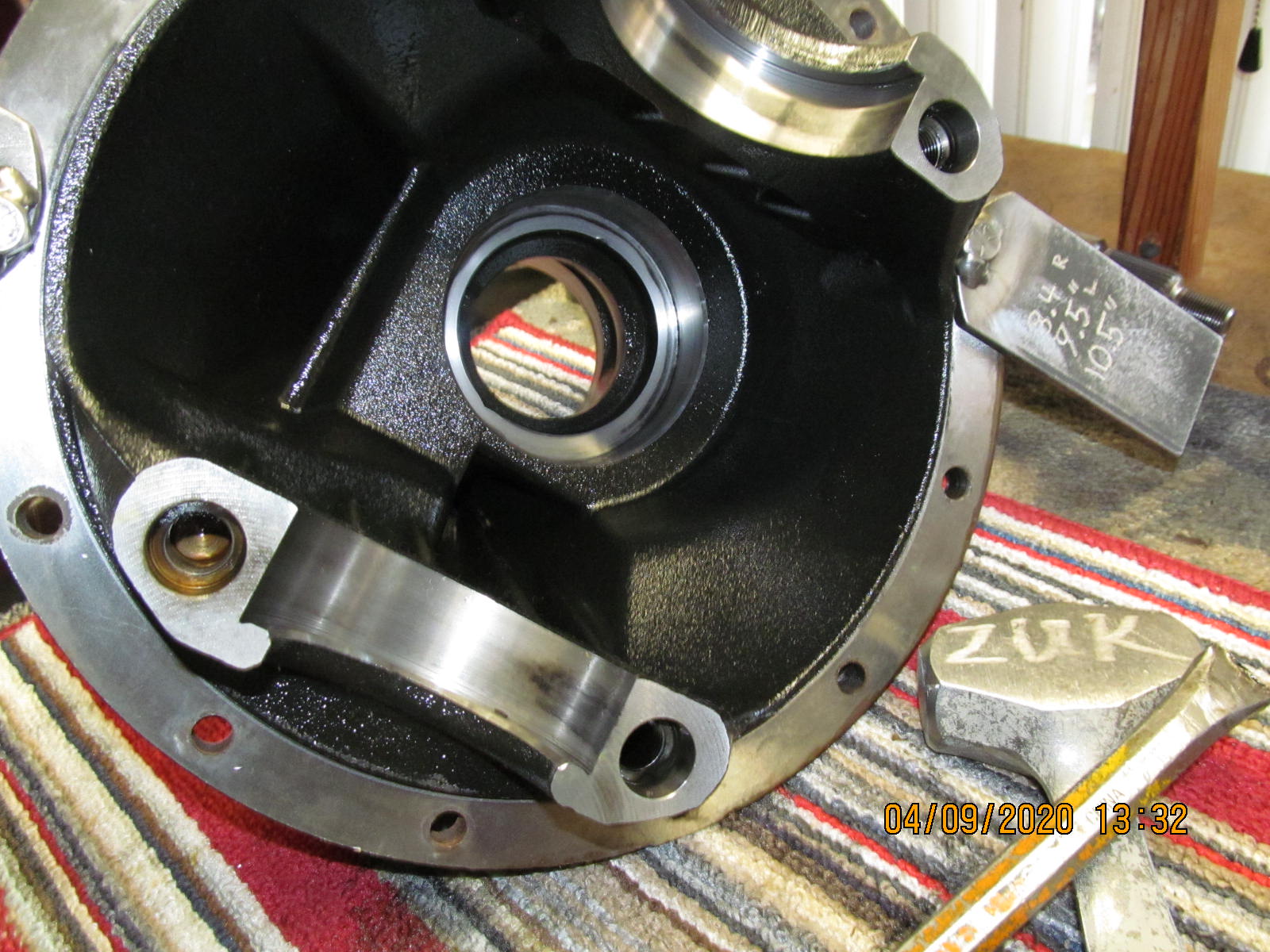

| Both races have been removed. |

|---|

|

|

| No damage to the oil retainer |

|---|

|

|

| New race going in and can use the old race to help tap it down with 360 degree support. |

|---|

|

|

| TAP TAP |

|---|

|

|

| One good looking race tapped down 100% with an oil retainer under it. |

|---|

|

|

| The larger inner race takes more patience to get it to tap in straight. |

|---|

|

|

| 100% seated. |

|---|

|

|

| Surfaces checked for burrs/ridges and all is good. |

|---|

|

|

| I didn't have the heart to scratch the REM surface :) |

|---|

|

|

| New ring gear was tapped on. The fit was still very tight. |

|---|

|

|

| Red loctite and 145 ft/lb on all 12 bolts. |

|---|

|

|

The Harrop carrier is ready. Now to select a starter shim for the pinion....start with what was on there before.

No REM'ing of the bearing surfaces on the pinion....they obviously masked it off which was wise to do. |

|---|

|

|

| The new bearing was a nice, tight press fit as it should be. |

|---|

|

|

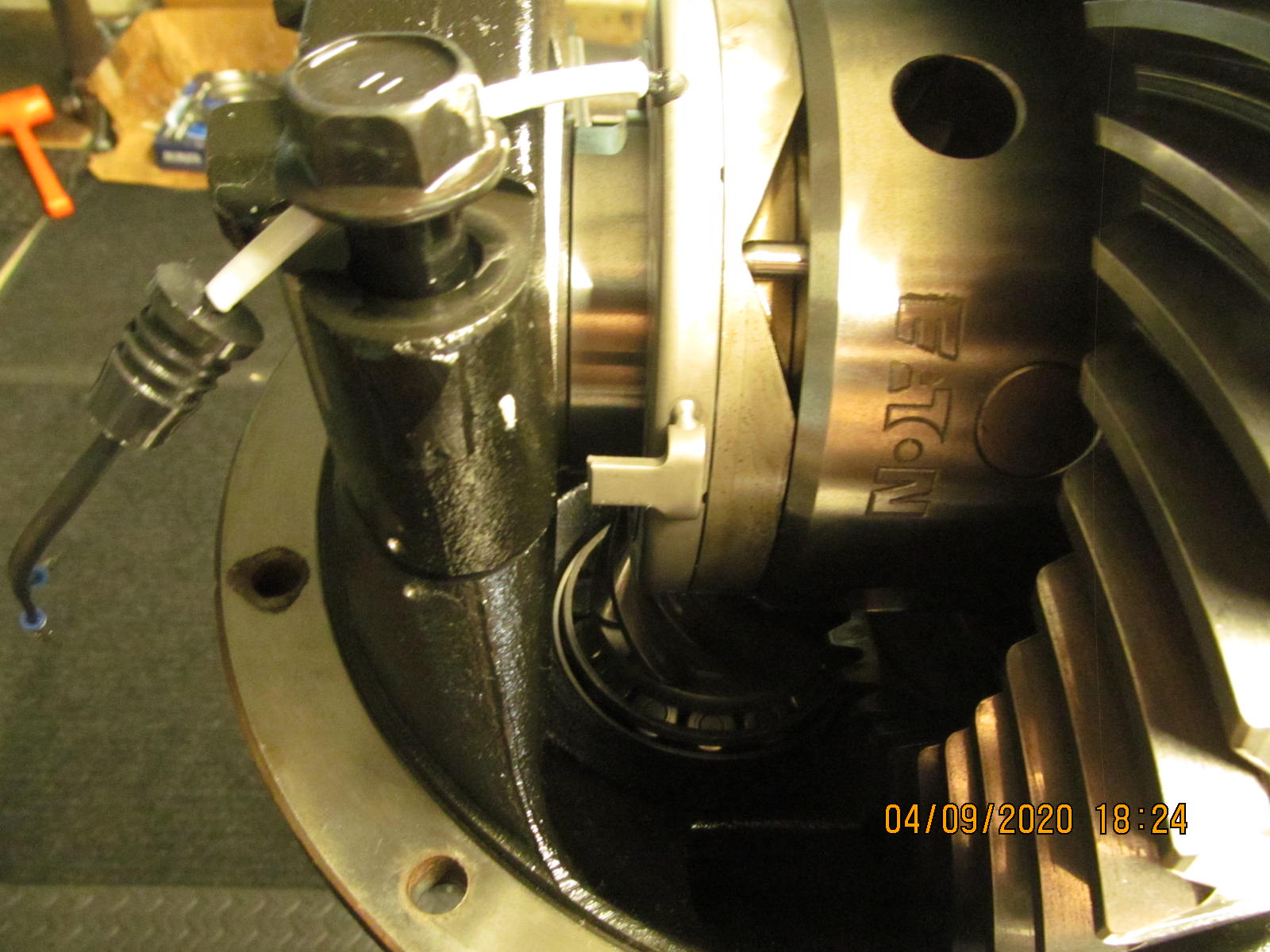

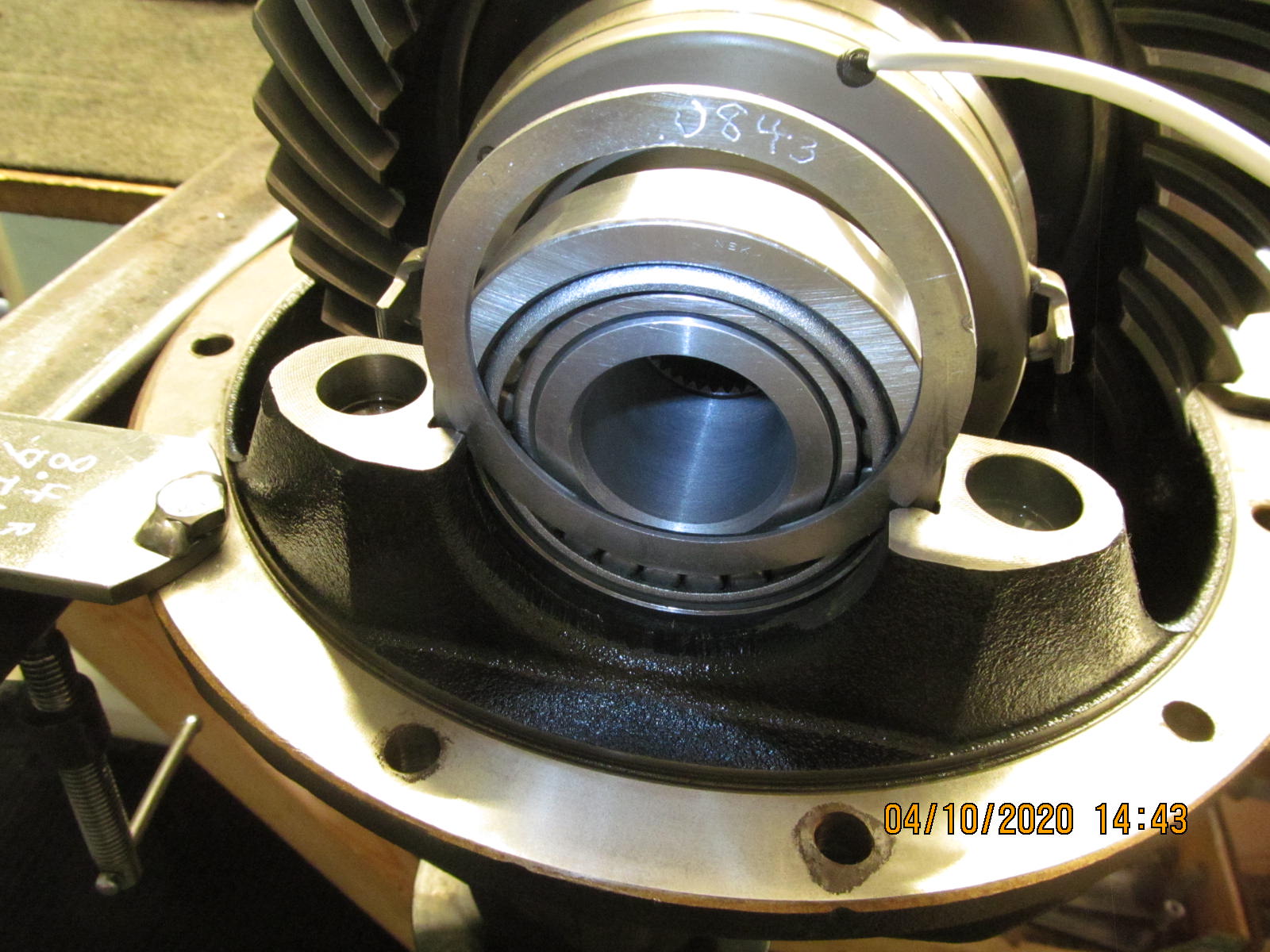

| Now to mount the pinion inside the differential carrier. |

|---|

|

|

| Only tighten the nut enough to develope about 15 inch/pounds of resistance. |

|---|

|

|

| Then mount the Harrop..... |

|---|

|

|

| //////////////////////////////////////////////////// |

|---|

|

|

| First paint test using .0472" shows the drive side to be too deep. |

|---|

|

|

| Coast agrees with that. |

|---|

|

|

| Comet tail is flaring out to the outside and agrees. |

|---|

|

|

| ///////////////////////////////////////////////// |

|---|

|

|

| Process is repeated and this time reducing the shim thickness to .041" |

|---|

|

|

| A slight adjustment to the washer plates..... |

|---|

|

|

| ////////////////////////////////////////////////// |

|---|

|

|

| The softer brass hammer seems to do less damage to the washer plates. |

|---|

|

|

| Drive .041" looks better. |

|---|

|

|

| Coast is favoring the outside Heel. |

|---|

|

|

| Comet tail is more in the center....still says it may be too deep. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| Disassemble again and reset with .039". This is looking good. |

|---|

|

|

| Depth look good but is close to the heel end. Sometimes there is very little to do to correct this. |

|---|

|

|

| I like the comet tail....it's about halfway between center and the root. |

|---|

|

|

| It's a keeper. |

|---|

|

|

| A little anti-seize under the bolt-head flanges keeps them from twisting the supplied bracket out of shape. |

|---|

|

|

| 151 ft/lb per the FSM. |

|---|

|

|

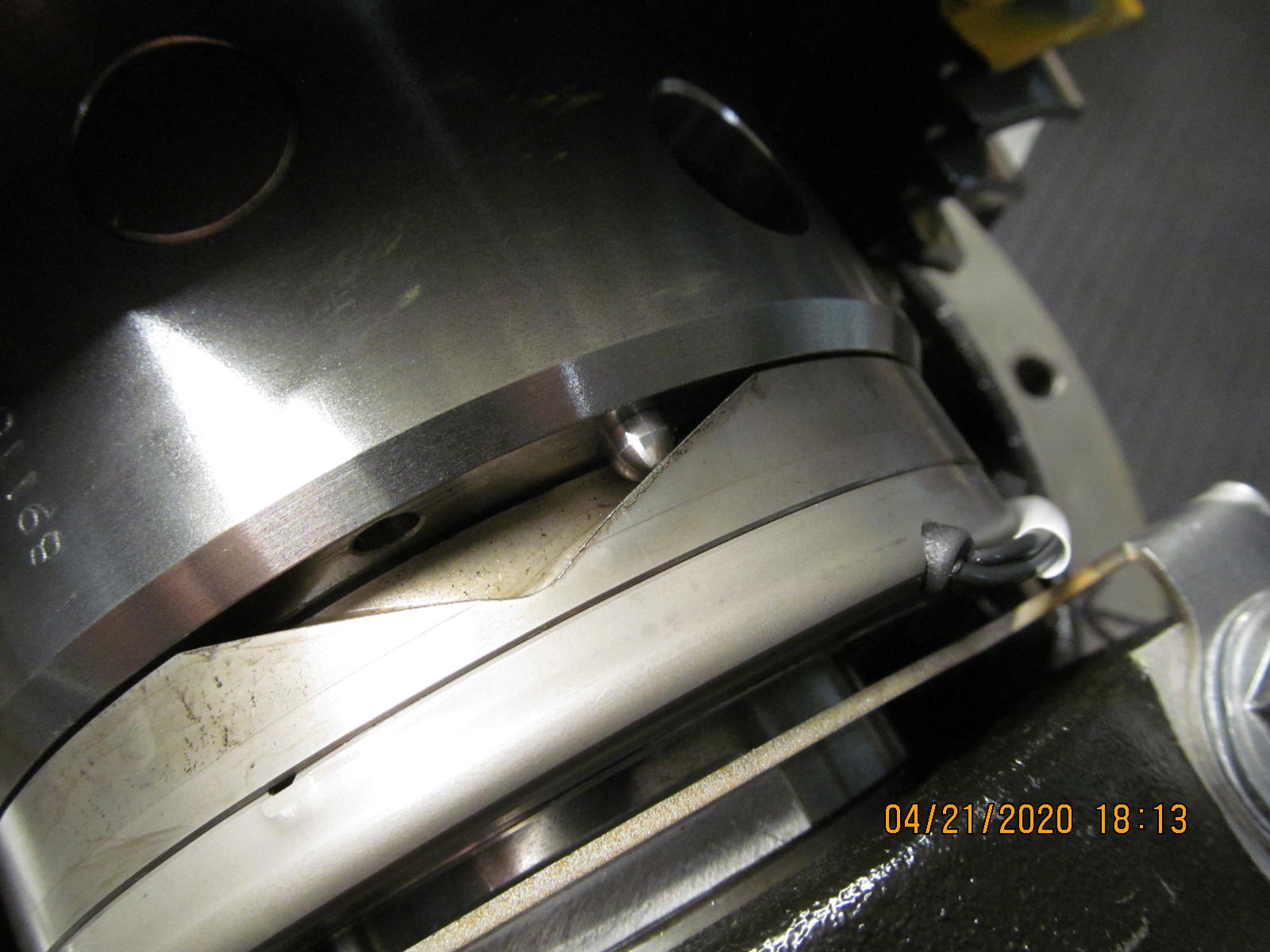

| Backlash is recorded on every other tooth. Minimum backlash checking in at .007" |

|---|

|

|

| A final paint check. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

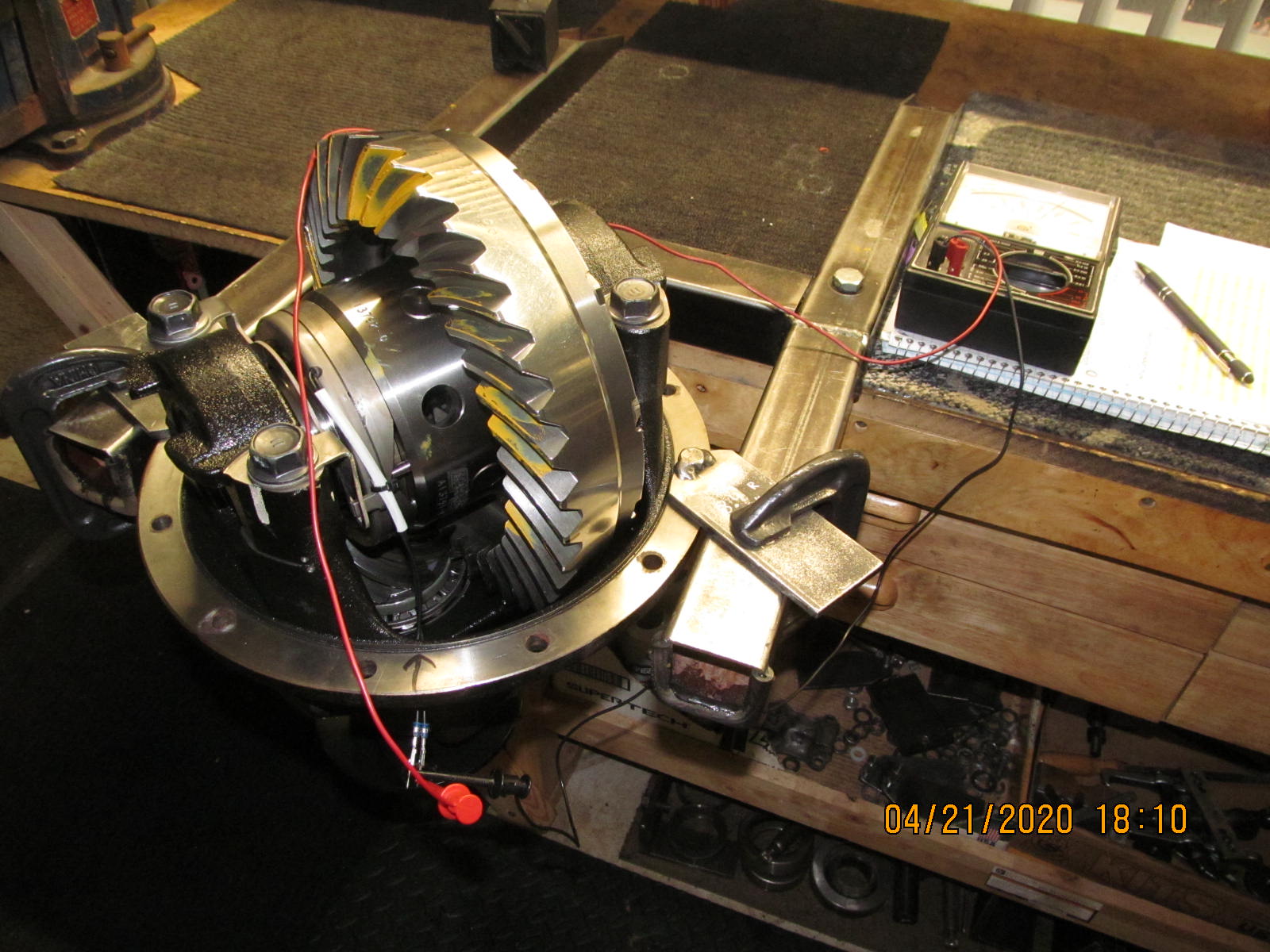

| Harrop coil test......measuring 3.8 ohms. |

|---|

|

|

| Live 12 volt test. |

|---|

|

|

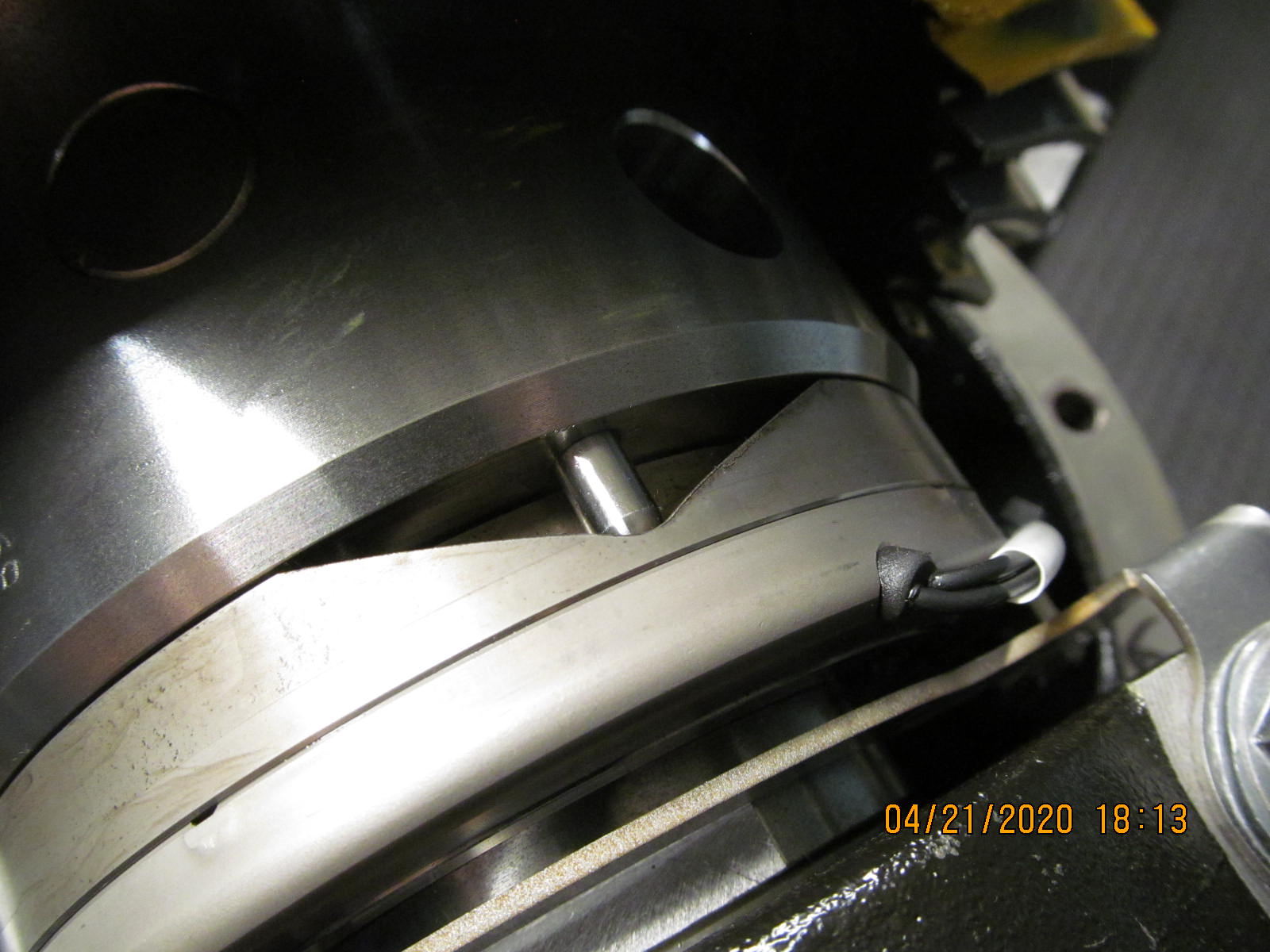

| With 12 volts applied, the ring gear is turned slightly and the pins recess into the case(ramp affect) |

|---|

|

|

| Remove the 12 volts and the pins immediately snap in place. |

|---|

|

|

| The rubber grommet with the 2 wires is routed thru the carrier. |

|---|

|

|

| Hi Australia......Another 3 inches of wire sure would be nice...... |

|---|

|

|

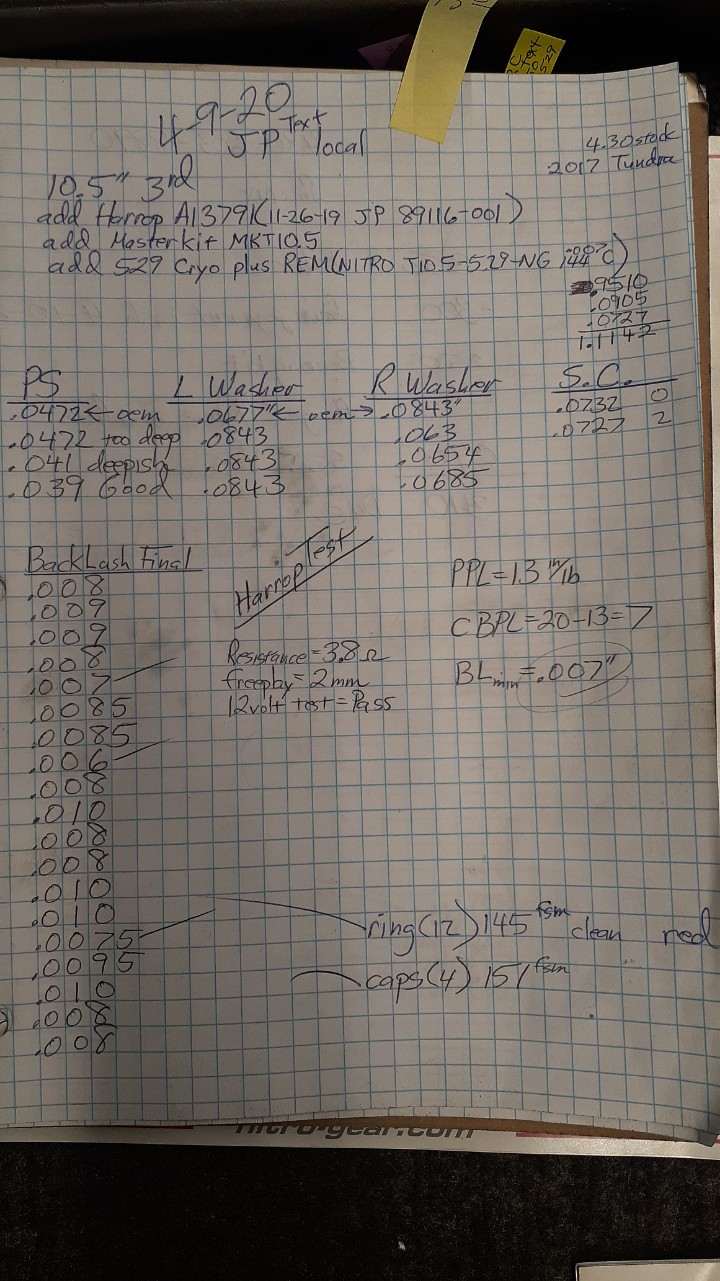

| Notes of the install. |

|---|

|

|

|