|

Jason's 2006 4runner has a noisy rear diff

|

|

(35 BIG pics loading)

|

|

FEB 18 2017

|

|

|

Jason's 06 4runner has only 135k miles and it already started to develope a resonance

that seemed to be coming from the pinion bearings as determined by some clever

stethoscope work. They have owned it since new and did an oil change at about

100k miles. Jason remembers the oil as being dark but not black yet.

|

|

|

|

The 3rd was removed and sent to me double boxed. Interesting that Toyota elected to integrate

this "harmonic balancer" into the pinion flange. Were the driveshafts that noisy or out of balance?

|

|

|

|

|

The kit was supplied by JustDifferentials Genuine Koyo bearings.

|

|

|

|

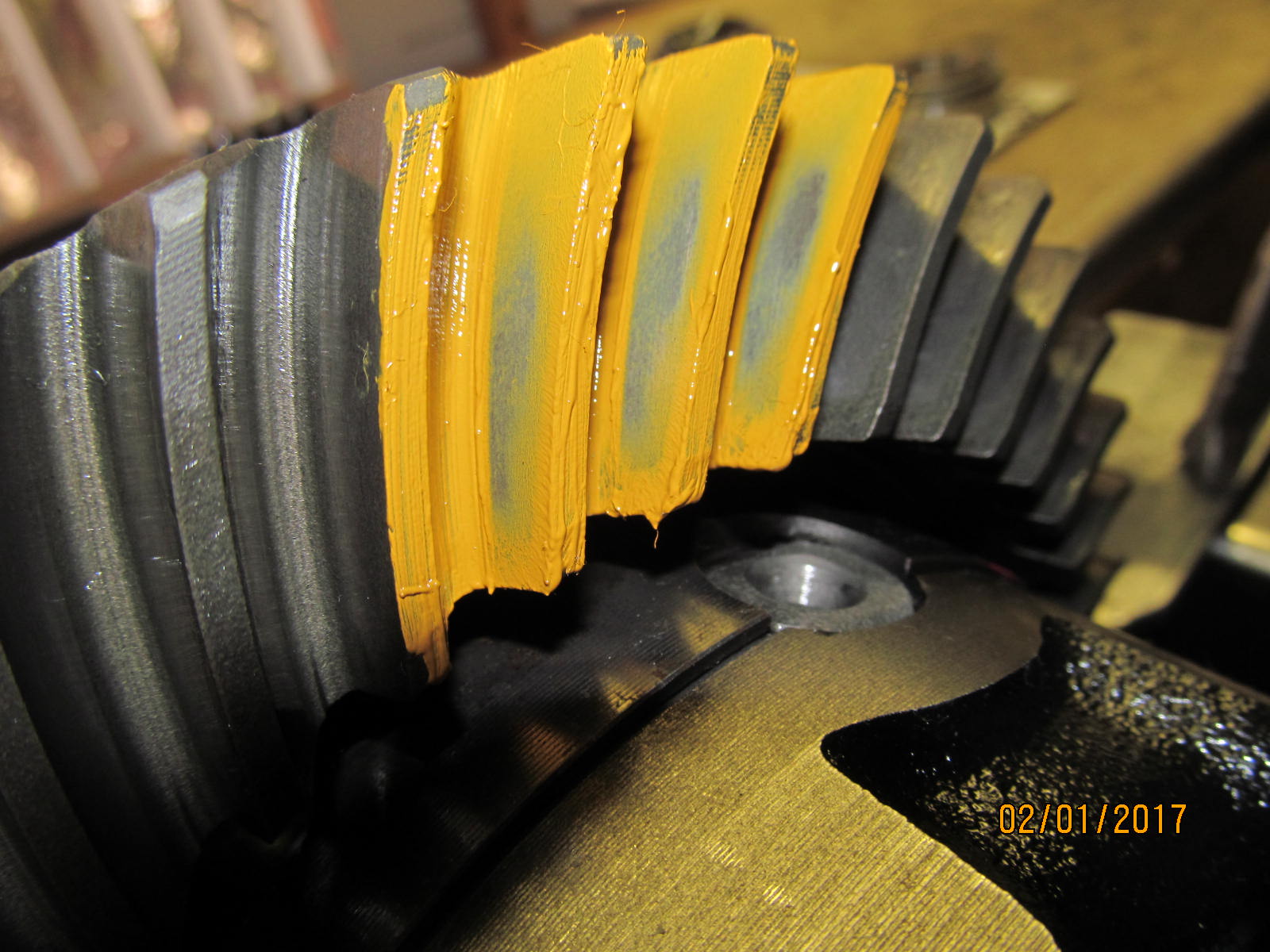

Visual of the ring gear looked ok. But it's also important to run a pre-paint check.

And this drive side paint does look good.

|

|

|

|

|

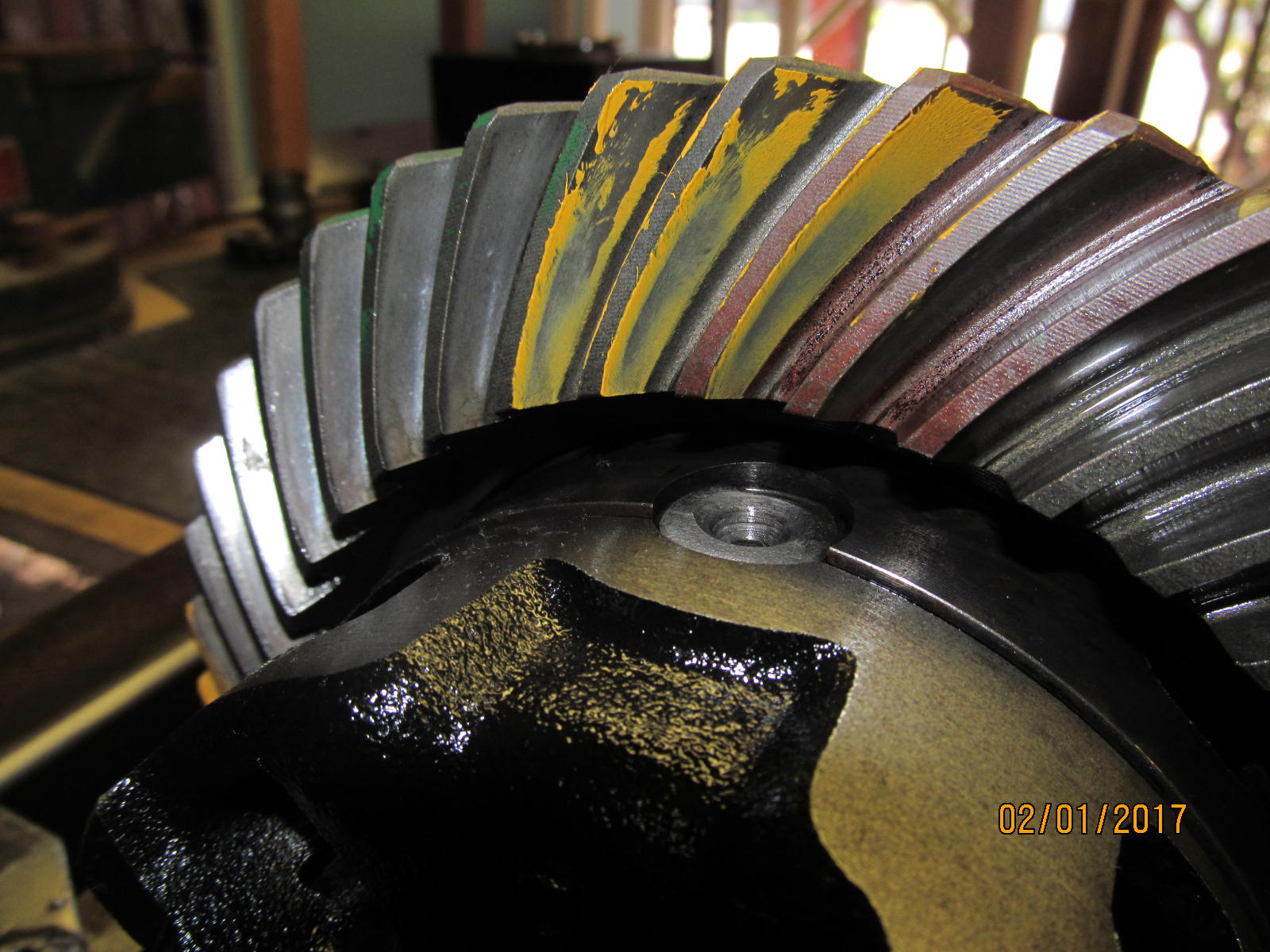

Coast also looks very nice.

|

|

|

|

|

Reverse painted drive side.

|

|

|

|

|

Reverse painted coast.

|

|

|

|

|

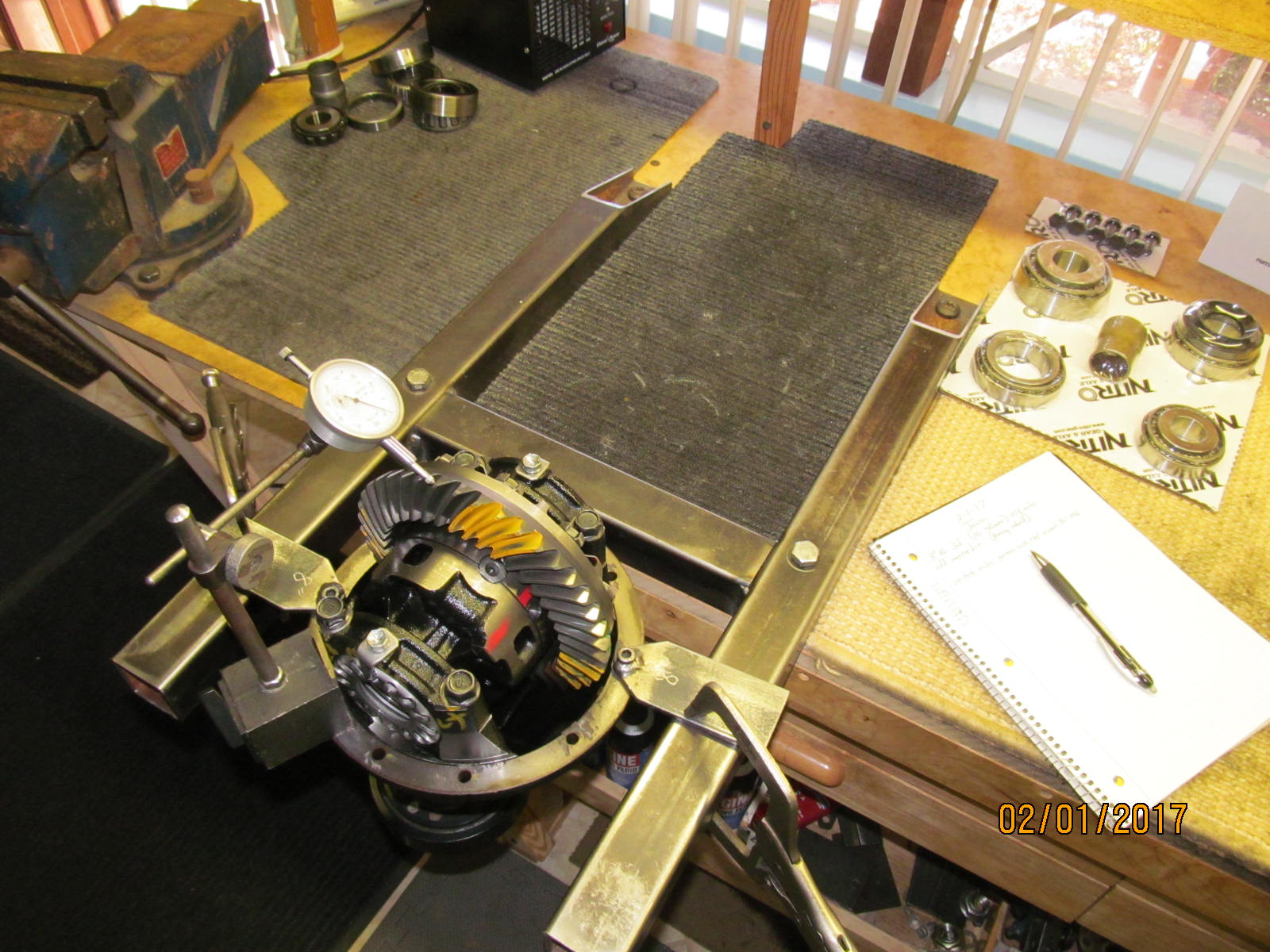

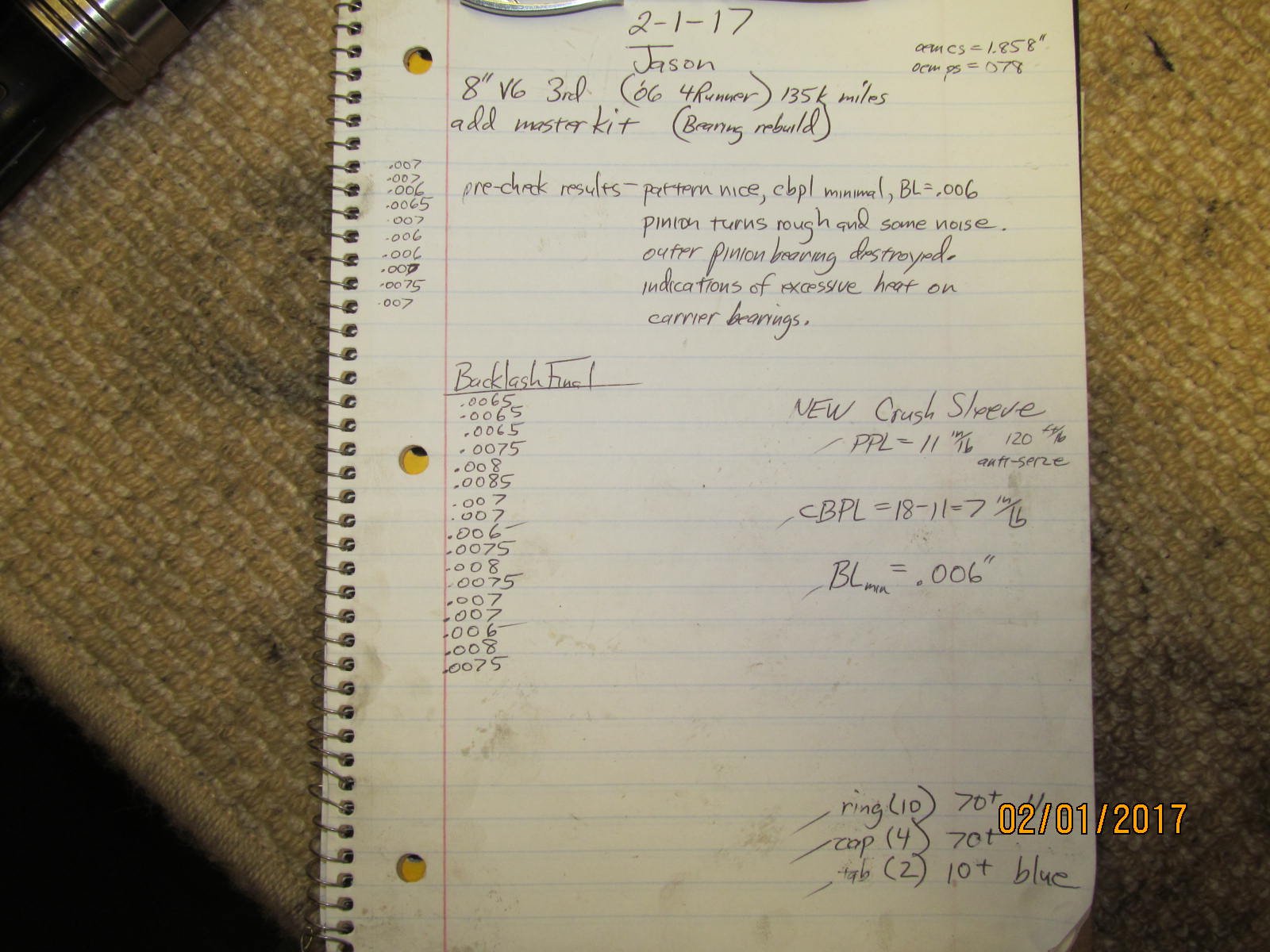

Characterizing the backlash.....this one was in spec and averaged .006". I expected wider.

|

|

|

|

|

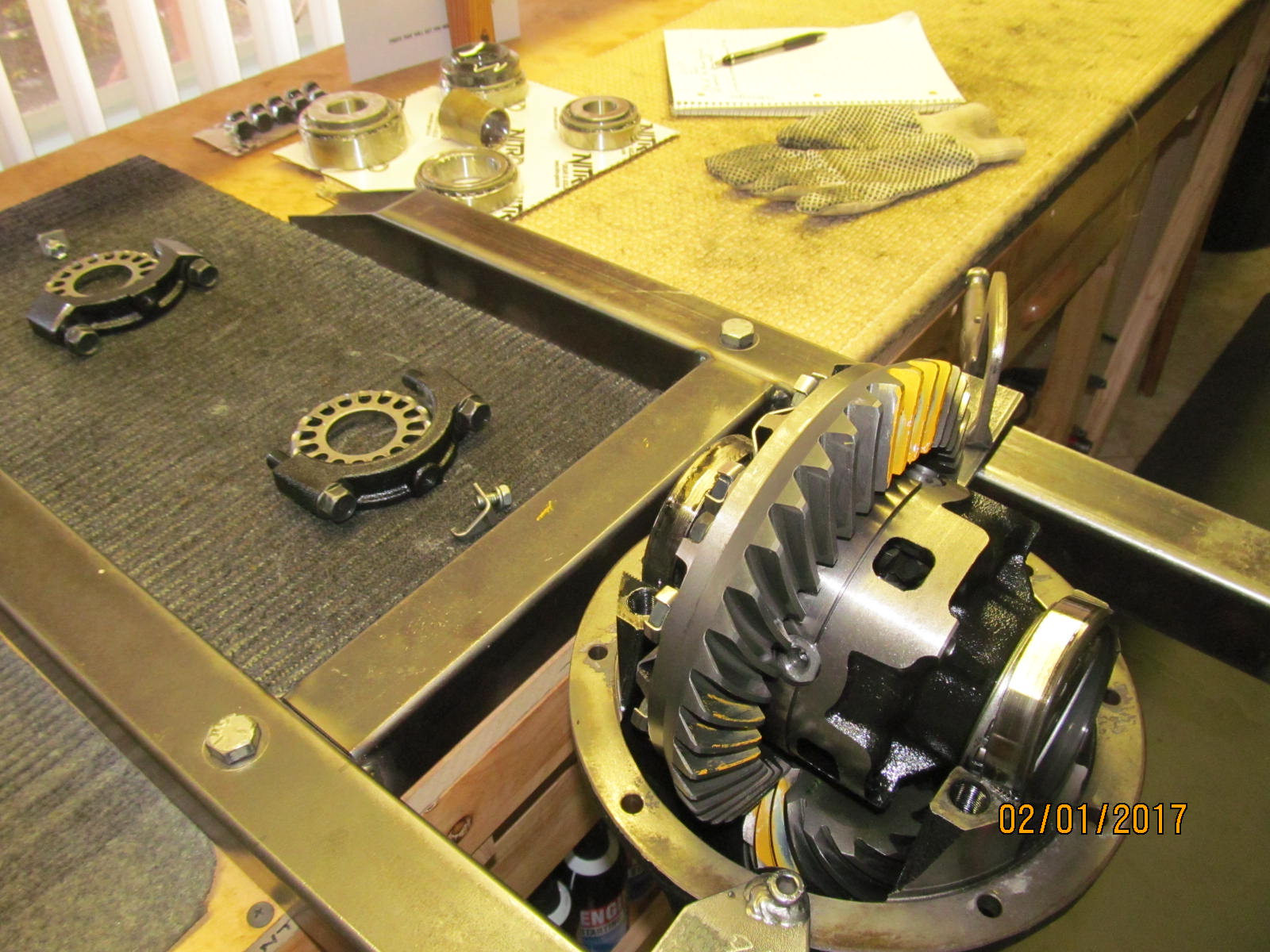

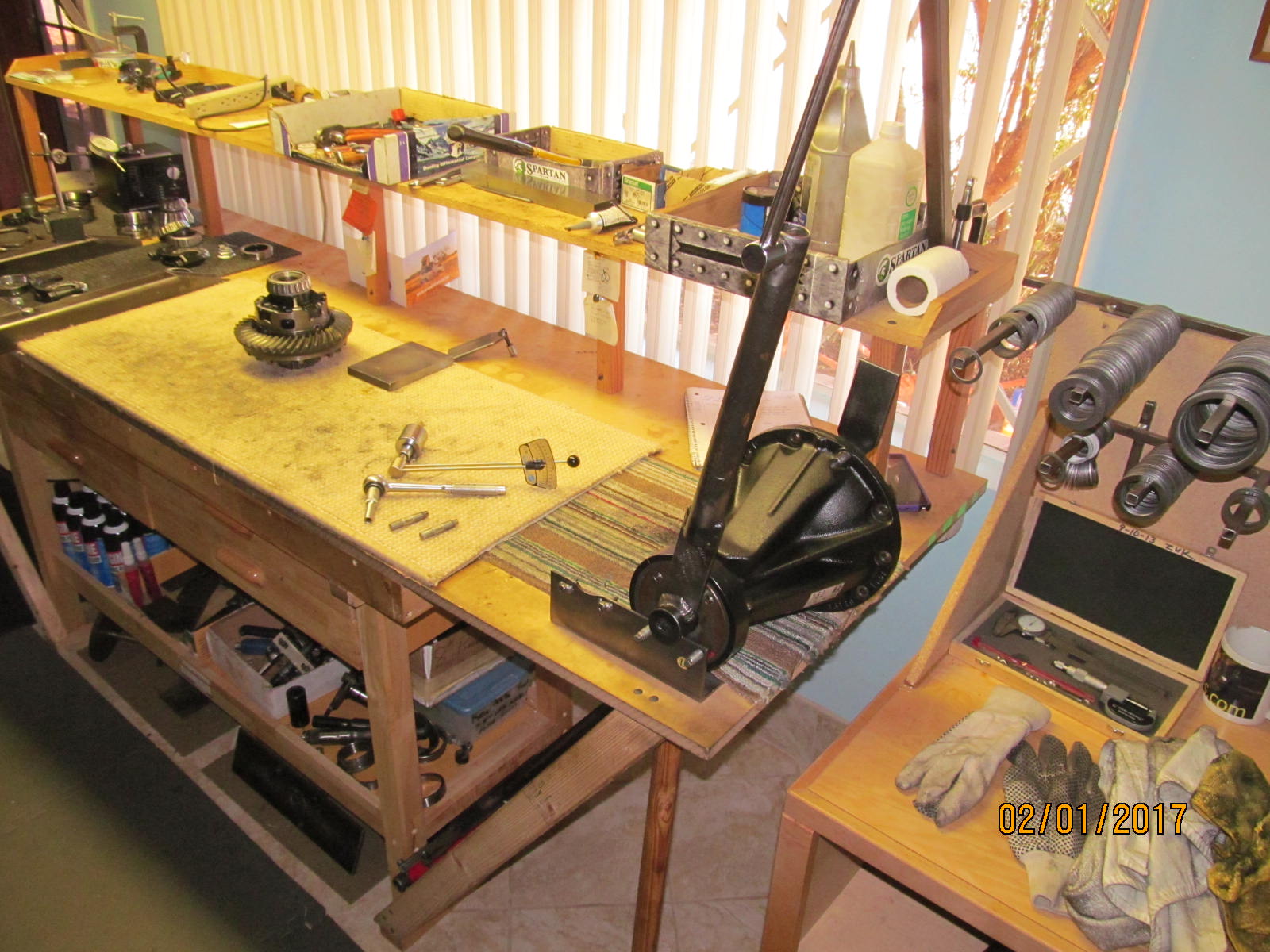

Disassembly begins.

|

|

|

|

With the ring gear out now I could turn the pinion freely and evaluate the preload which did not

exist and any possible roughness or noise. And I did feel some roughness with a slight rumble.

|

|

|

|

|

My 2 fingered grabbers could not wrap around the massive flange assembly so the press made quick work of it.

|

|

|

|

|

......................

|

|

|

|

The flange surface is in nice shape. The digital camera is deceiving. Where the seal was

contacting is more of a polish mark and not a groove.

|

|

|

|

|

Even the massive inner pinion bearing does not look that healthy....like as if it saw heat.

|

|

|

|

|

................

|

|

|

|

Jason reports that there were some tiny metal chunks on the magnetic drain plug so I'm sure some similar

pieces floating around could cause the scarring/streaks seen here.

|

|

|

|

The small outer pinion bearing shown here is the source of the noise that Jason's wife was hearing.

Also, the source of the chunks on the drain plug. Notice the slight color changes....an indication

that a lot of heat was present.

|

|

|

|

|

.......................

|

|

|

|

|

................................

|

|

|

|

Ya, that's a good question. Oil may have worn out prematurely and was not doing its lubrication job.

Even these carrier bearings showed "heat trauma" with its grey colorings. These carrier bearings

need replacing also. If a shop had replaced just the outer pinion bearing then the noise would

have been "fixed".....but this was the next failure waiting to happen.

|

|

|

|

|

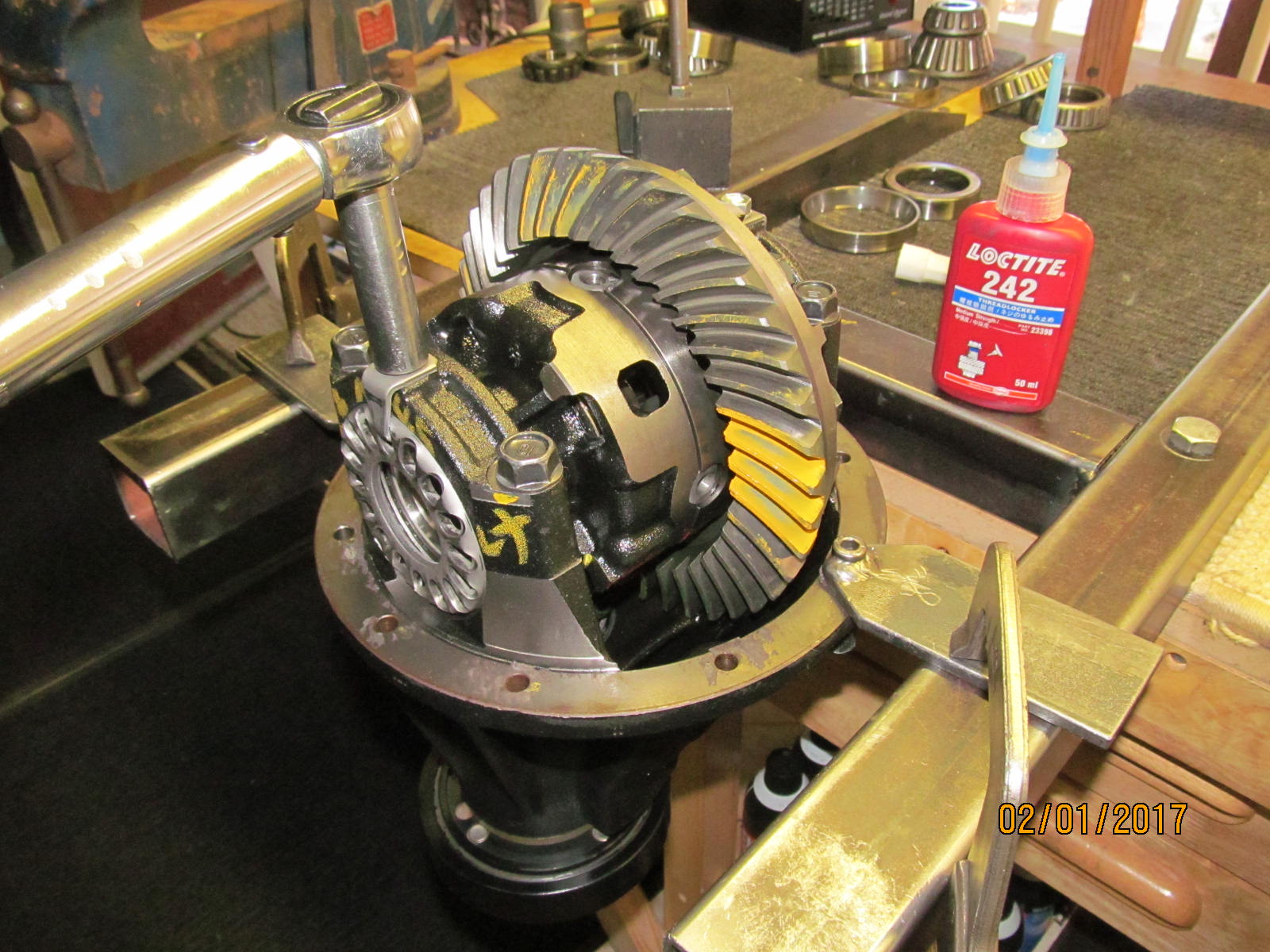

New ring gear bolts (without those nasty safety tabs) with blue loctite and 70 ft/lbs.

|

|

|

|

|

The new koyo carrier bearings tapped on with a good tight fit.

|

|

|

|

|

New inner bearing with the oem 078 shim is pressed on.

|

|

|

|

|

New outer race installed.

|

|

|

|

|

New inner race.

|

|

|

|

|

Time to final assemble the pinion so the new crush sleeve can be slipped in place.

|

|

|

|

Generally, generic seals come with the kits....gear oil is applied to all the

rubber portions that will contact any metal. So, that would be the inside

and outside of the seal.

|

|

|

|

|

.......................

|

|

|

|

The final crushing of the sleeve. Aluminum based anti-seize to the

threads and the bottom of the flange nut. I noted the crush sleeve started to crush

with 180 ft/lb but, after about a full 360 degrees, it only took 120 ft/lb.

It's the nature of a crush sleeve. With no anti-seize it would have taken much

more effort to crush. The nut will never back off with a little DING!

|

|

|

|

|

70 ft/lb on the 4 bolts.

|

|

|

|

18 ft/lb total preload. Total preload is the preload of both the pinion bearings and

the carrier bearings. Since we already know that that the pinion preload is

11 in/lb then that must mean that the carrier bearings are the remaining 7.

|

|

|

|

|

A final pattern check and the drive side looks great.

|

|

|

|

|

Coast.

|

|

|

|

|

Diamond dust on a dremel bit....

|

|

|

|

Only after being certain that the CBPL and BL is correct then the locktabs can be secured.

10 ft/lb and blue loctite.

|

|

|

|

|

Notes of the bearing rebuild. Done.

|

|

|

|