| Joe's 2002 Tacoma gets Sierra 4.56 gears in the rear 8" elocker |

|---|

| (64 BIG pics loading) |

|---|

| AUGUST 8 2017 |

|---|

|

Joe had his front 7.5" clam re-geared by me 2 years ago and still has not put it in......

I can't believe it....somebody that procrastinates more than I do! :) |

|---|

|

|

| Joe supplied all the product which is ok but keep in mind, I can supply all the product (in Nitro Brand) ;) |

|---|

|

|

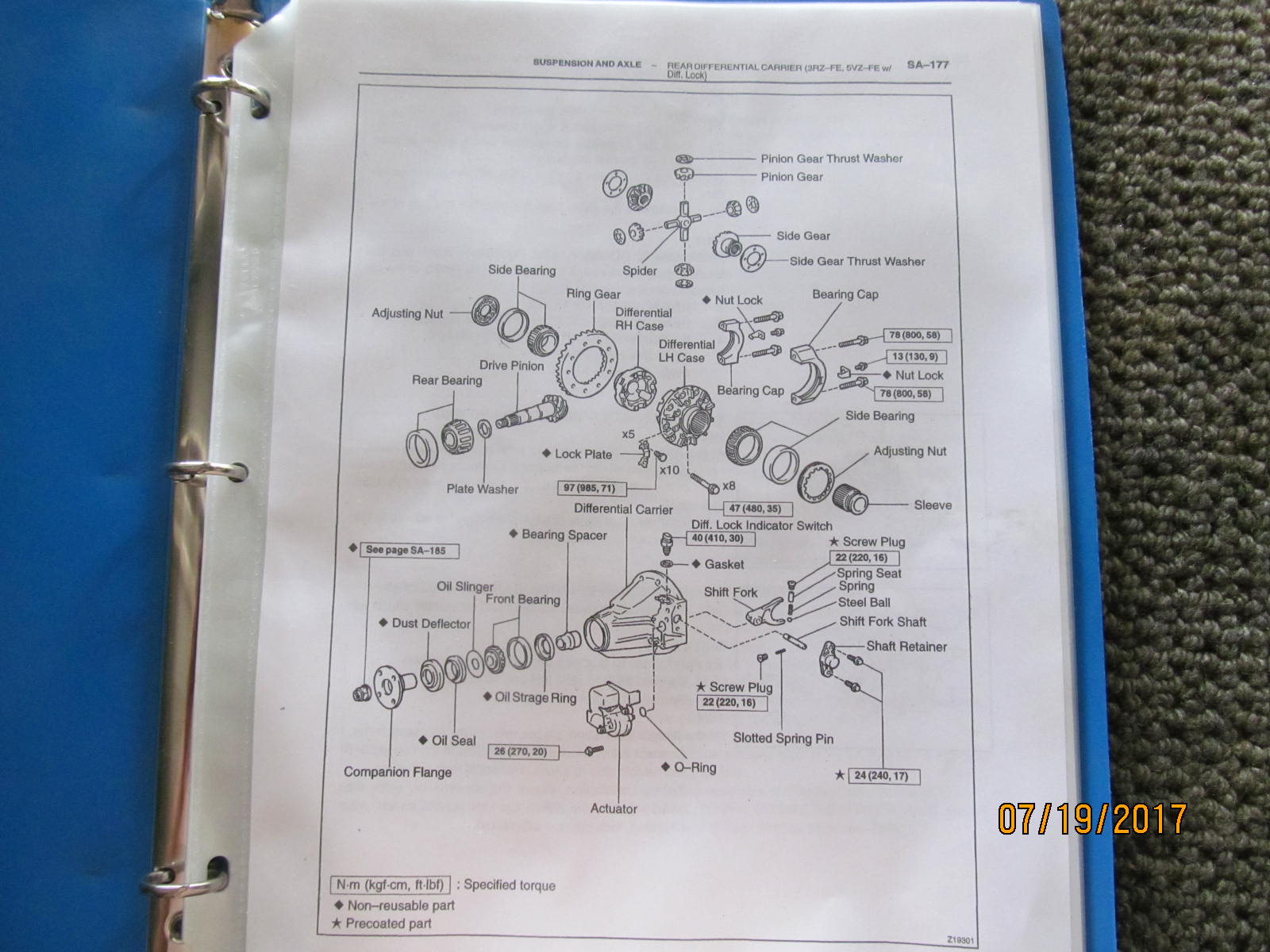

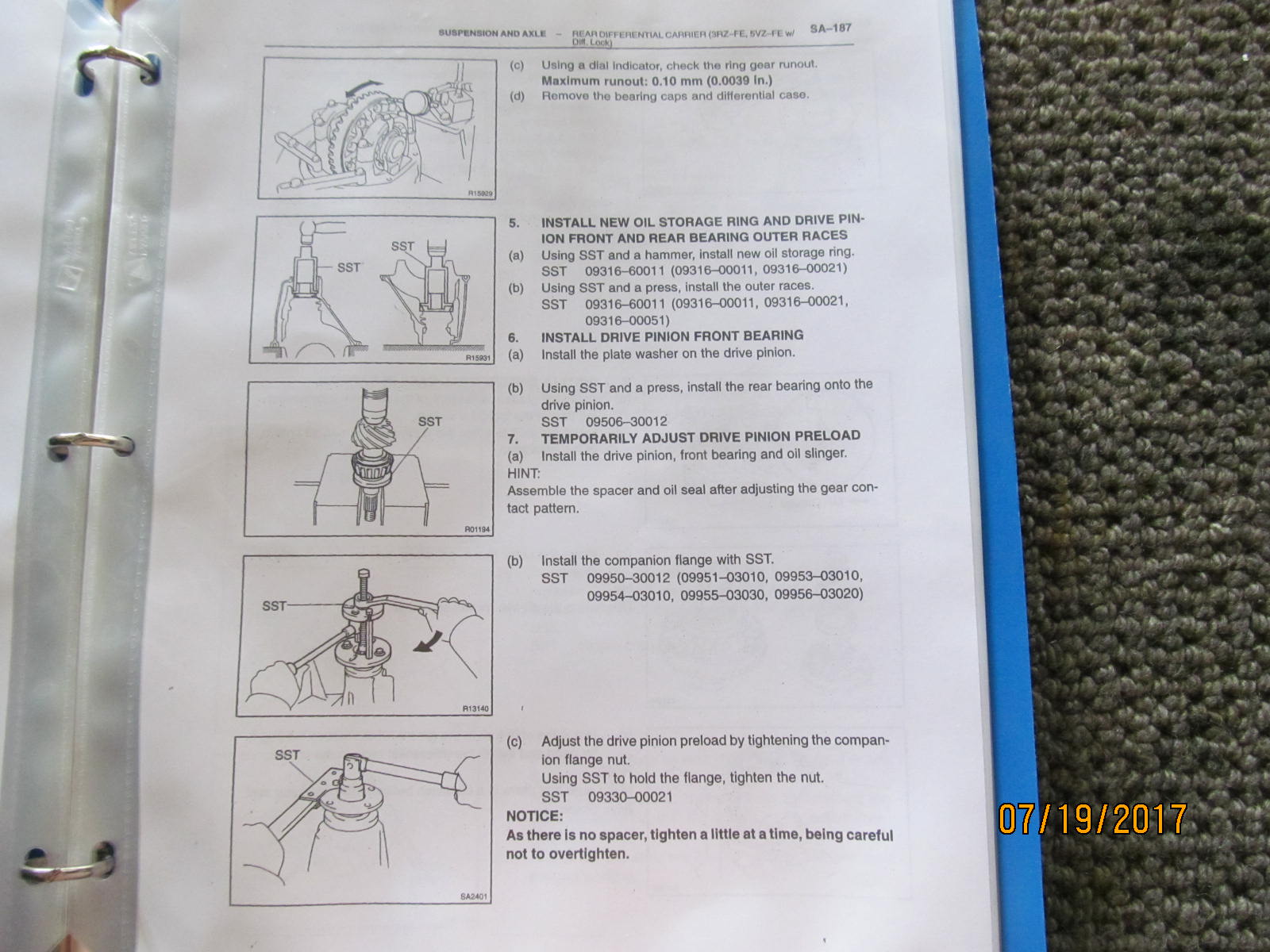

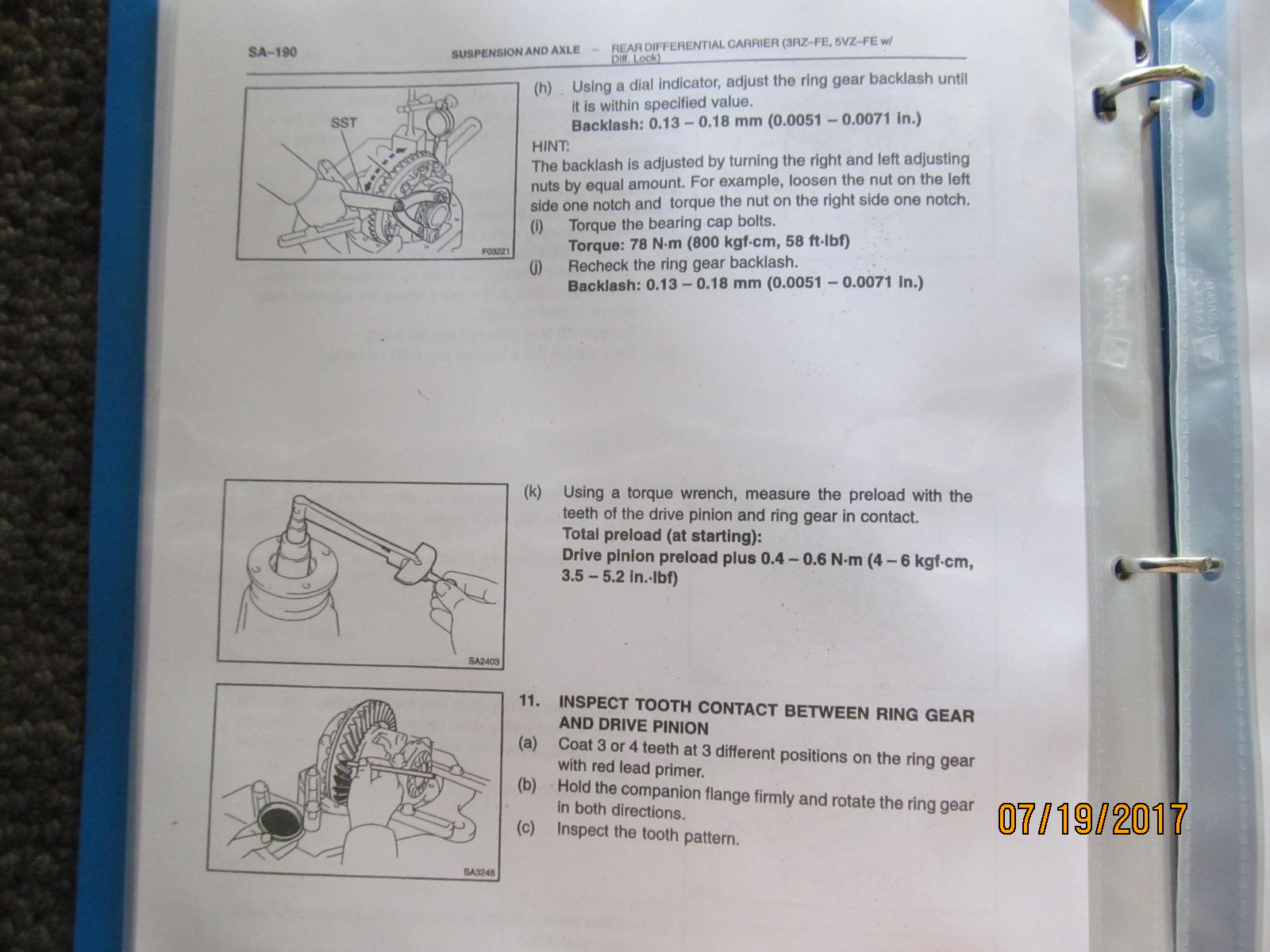

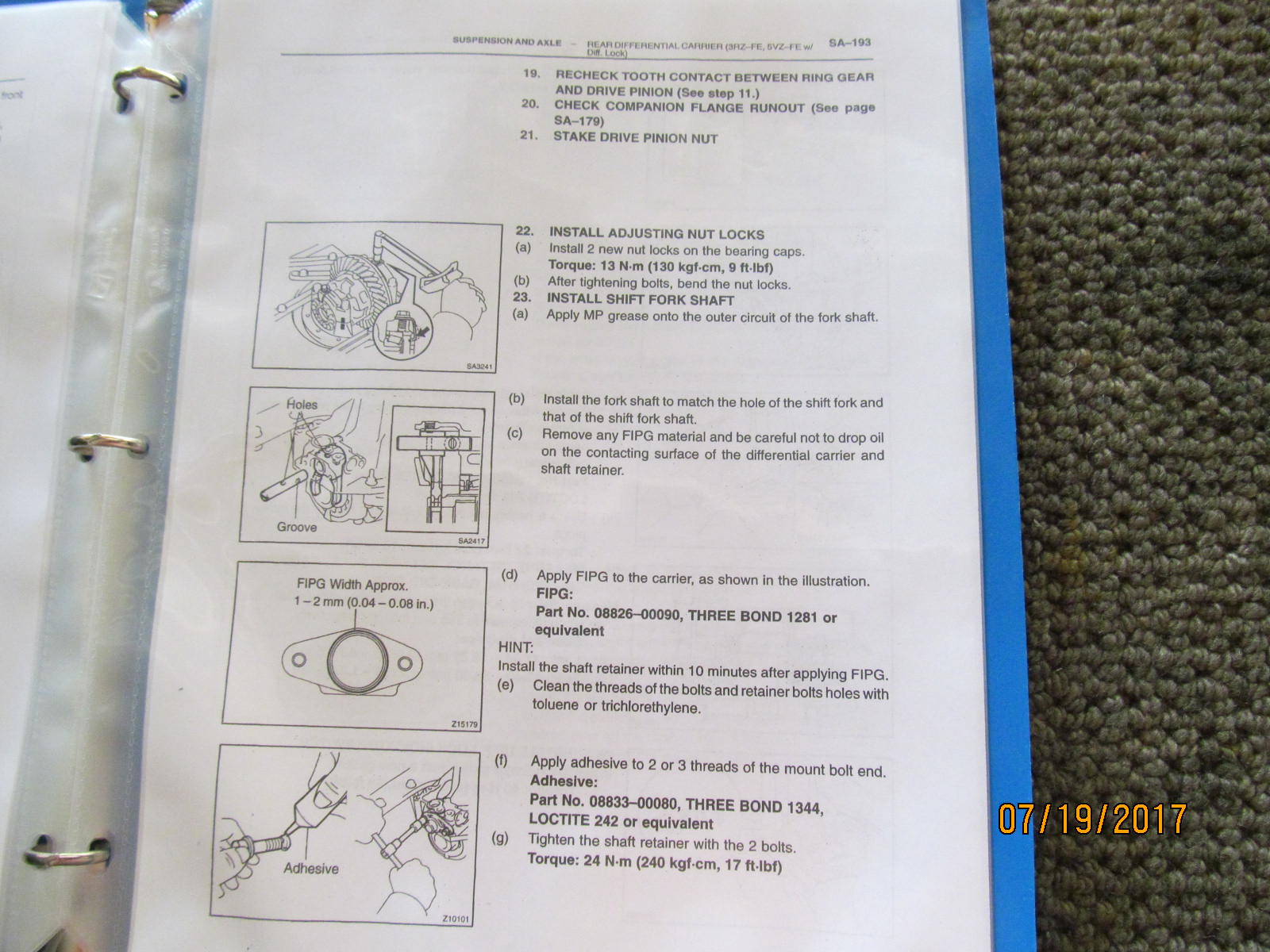

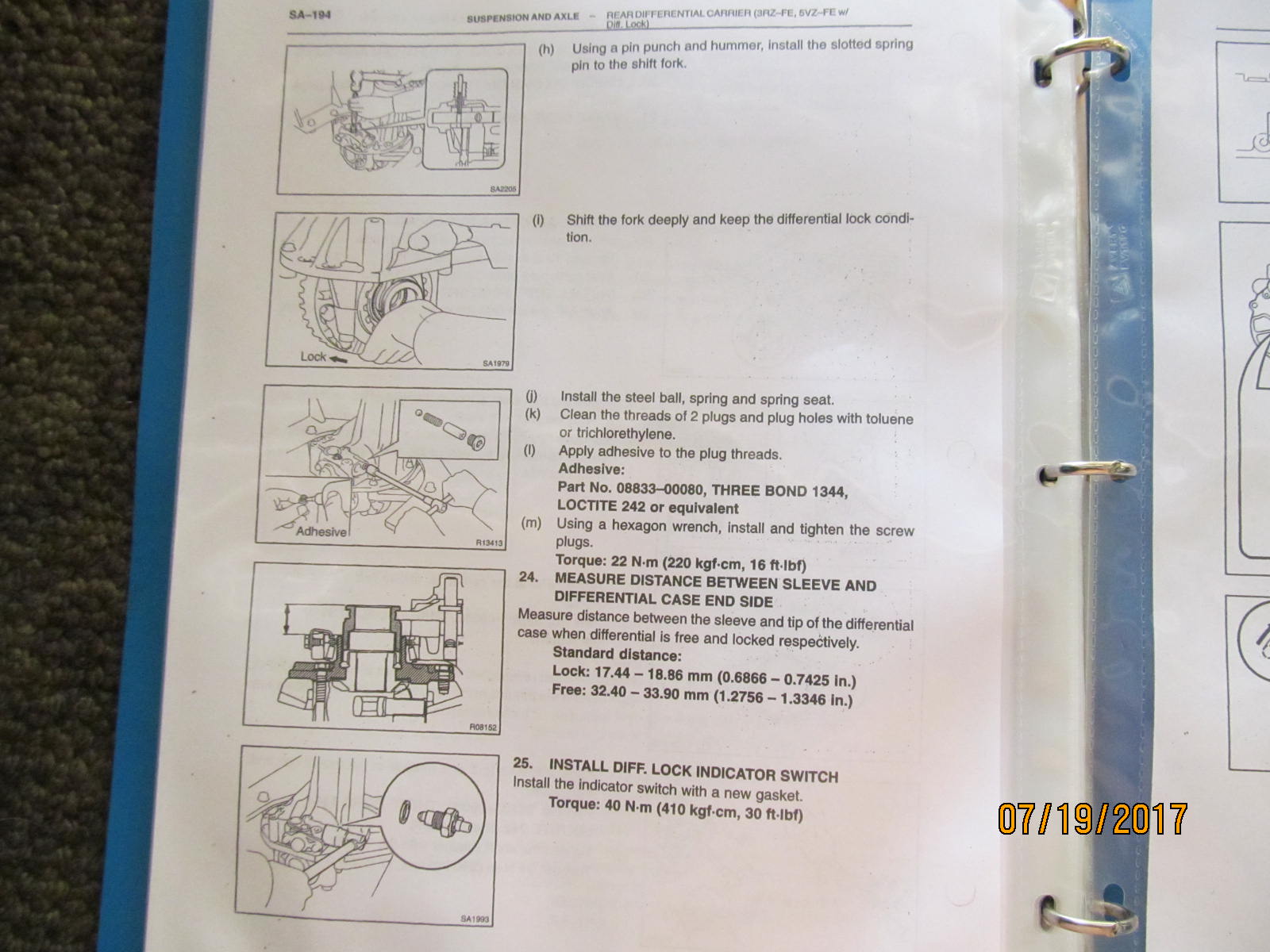

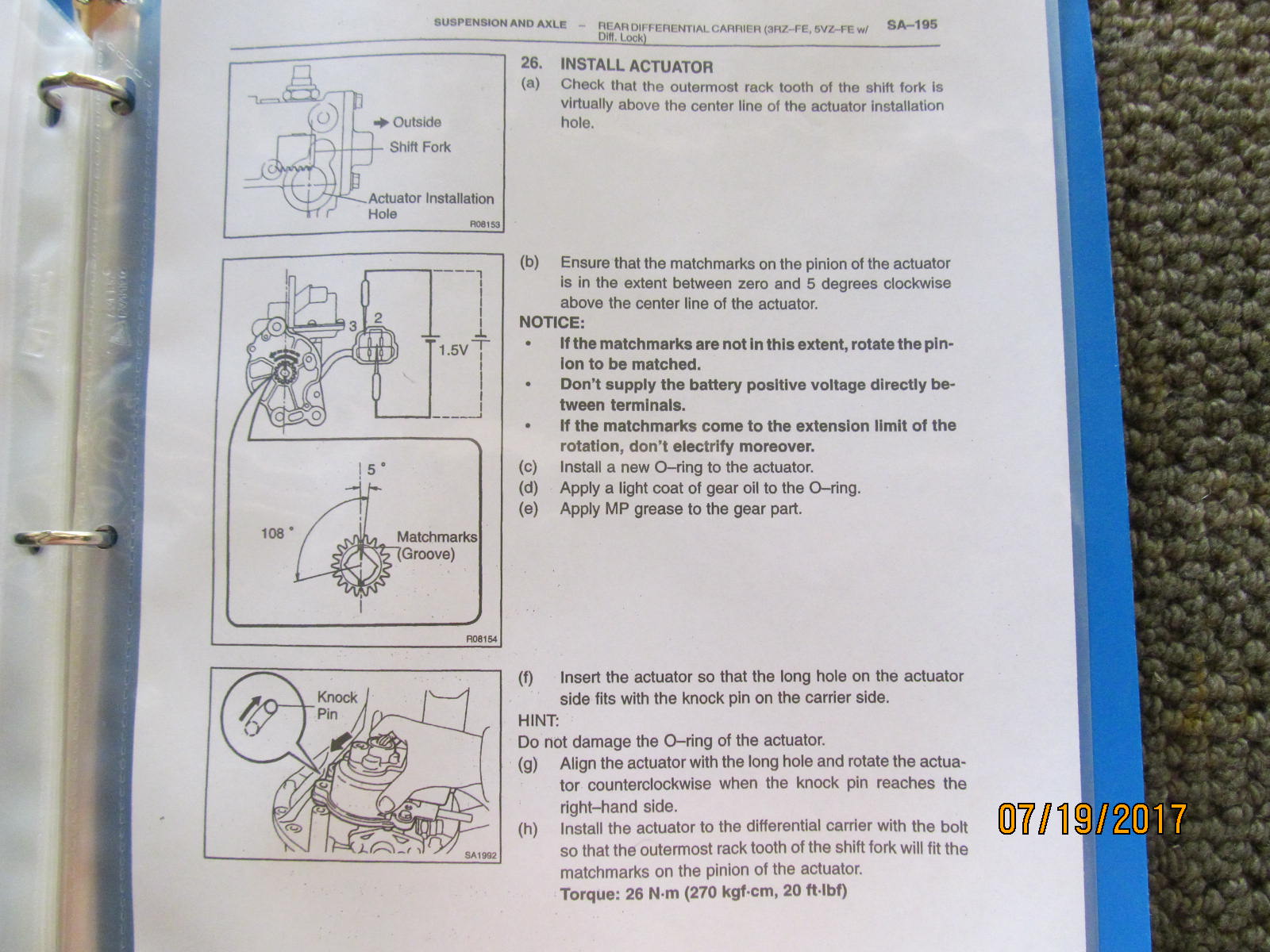

Some useful pages from the FSM worth noting for this rear 8" elocker gear install

Common torque values for the bolts. |

|---|

|

|

| Used bearings....pinion preload range 4~7 in/lb. |

|---|

|

|

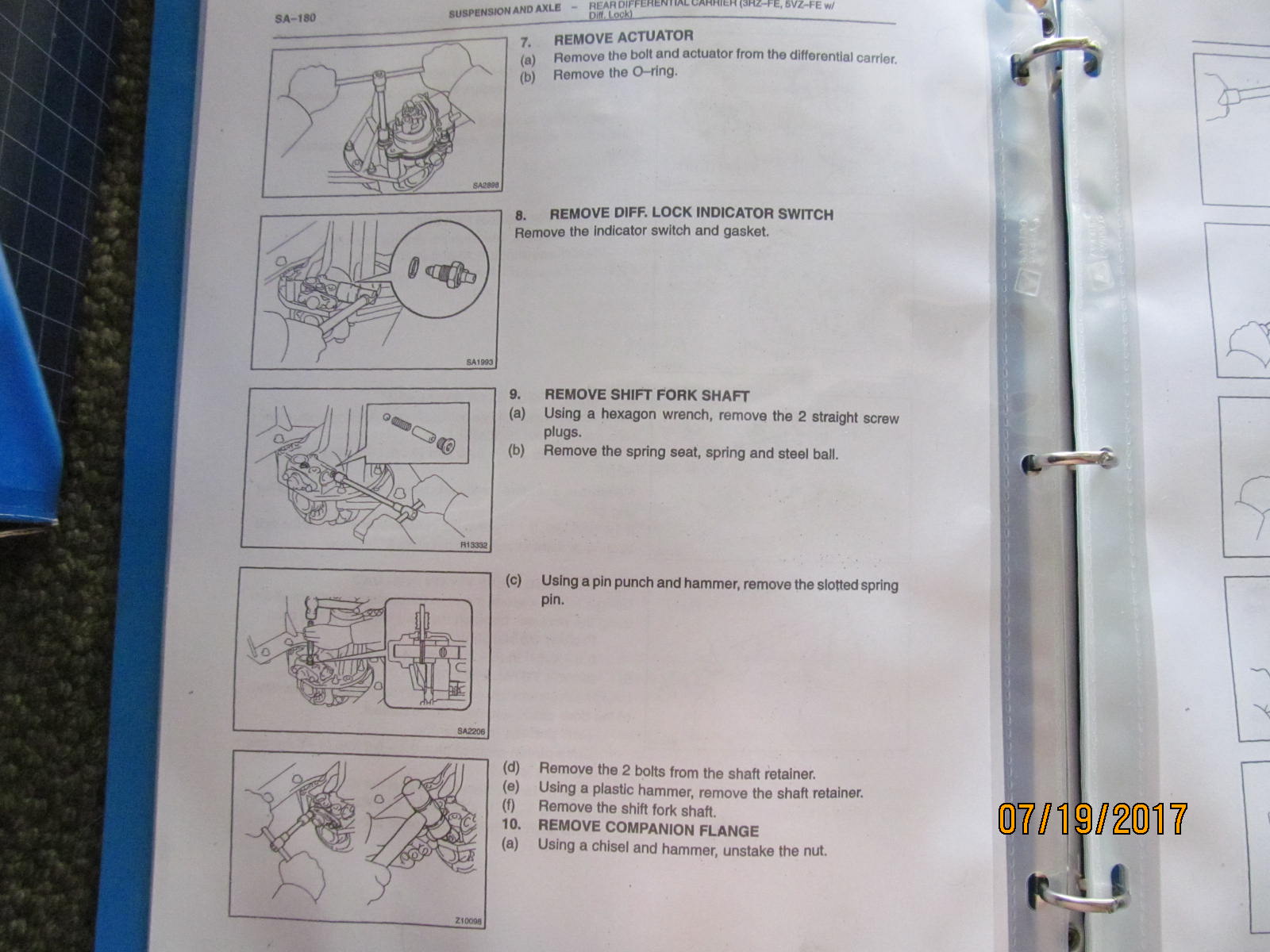

| Not much of interest on this page.... |

|---|

|

|

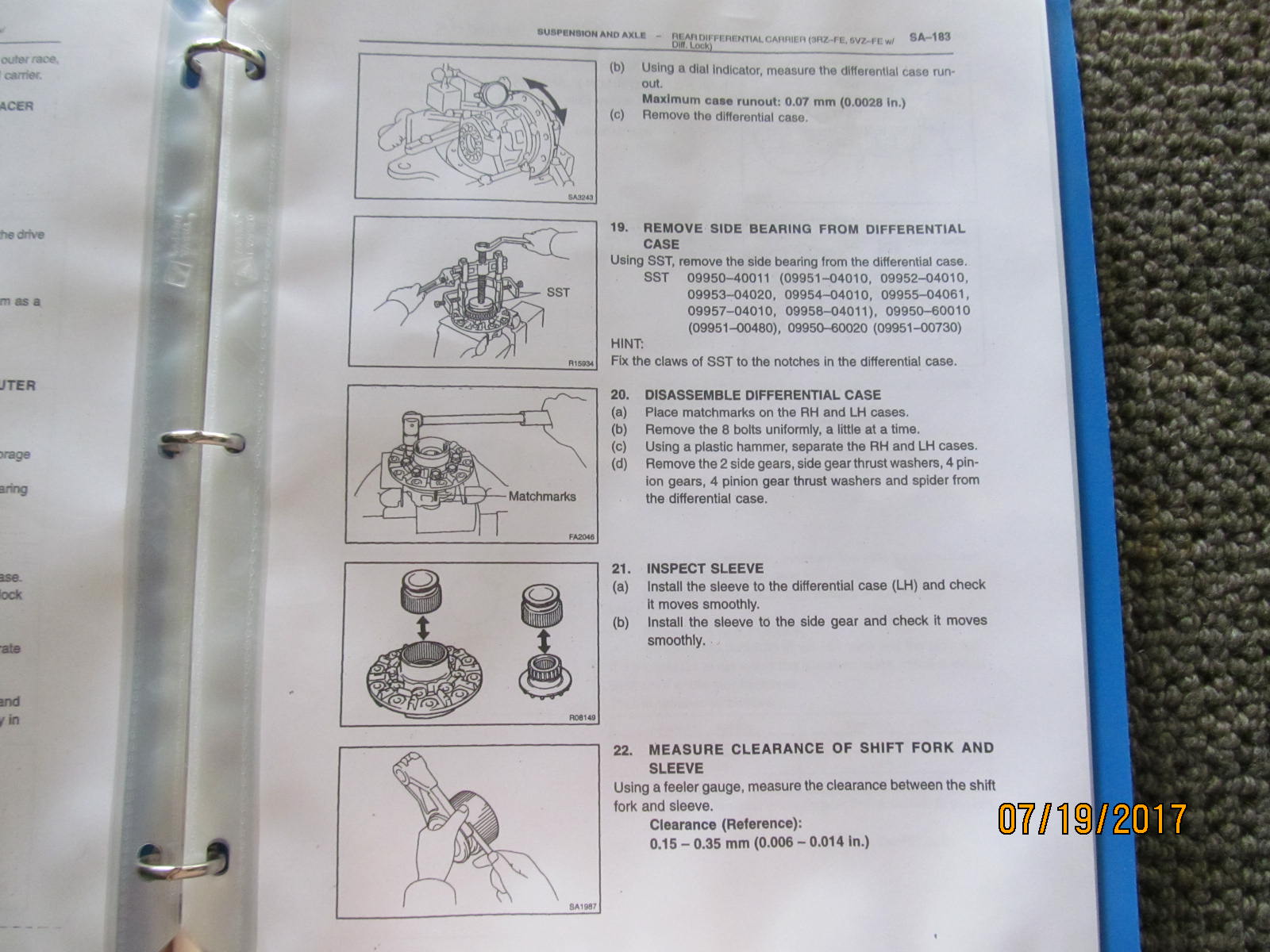

| Max run-out allowed....almost 3 thou. |

|---|

|

|

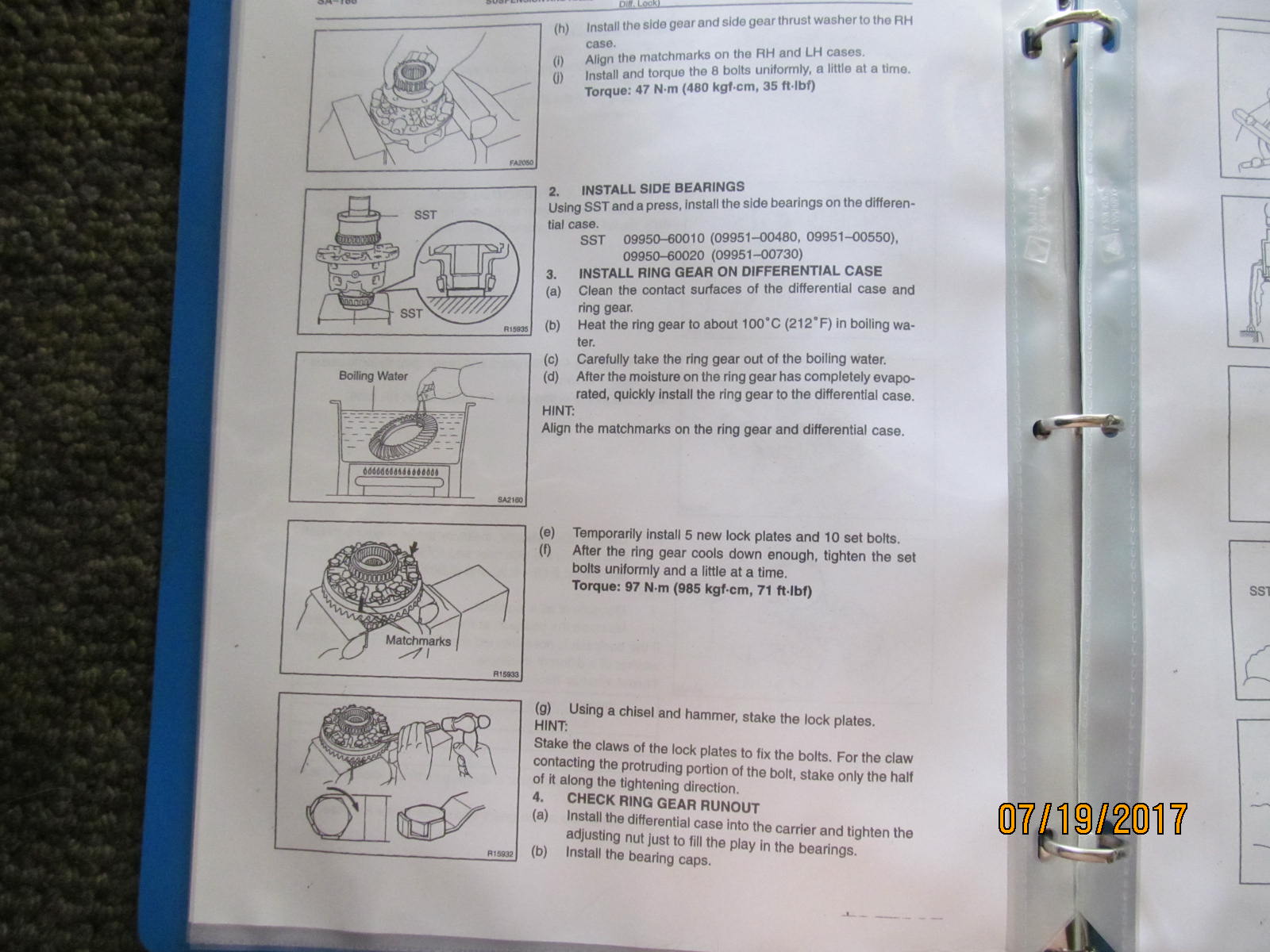

8 case bolts only 35 ft/lb....I use a little closer to 45.

71 ft/lb on the 10 ring gear bolts is what I use. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

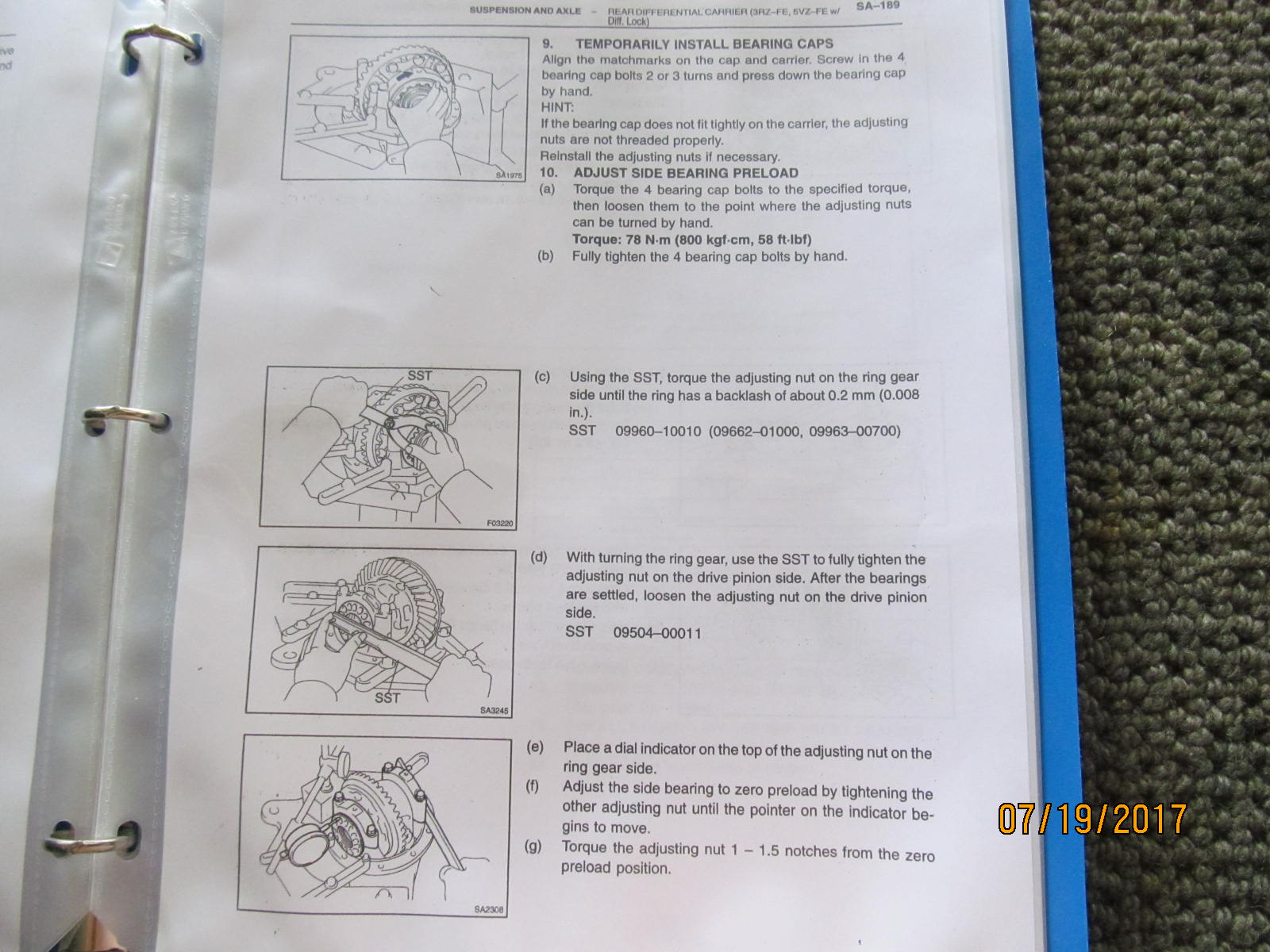

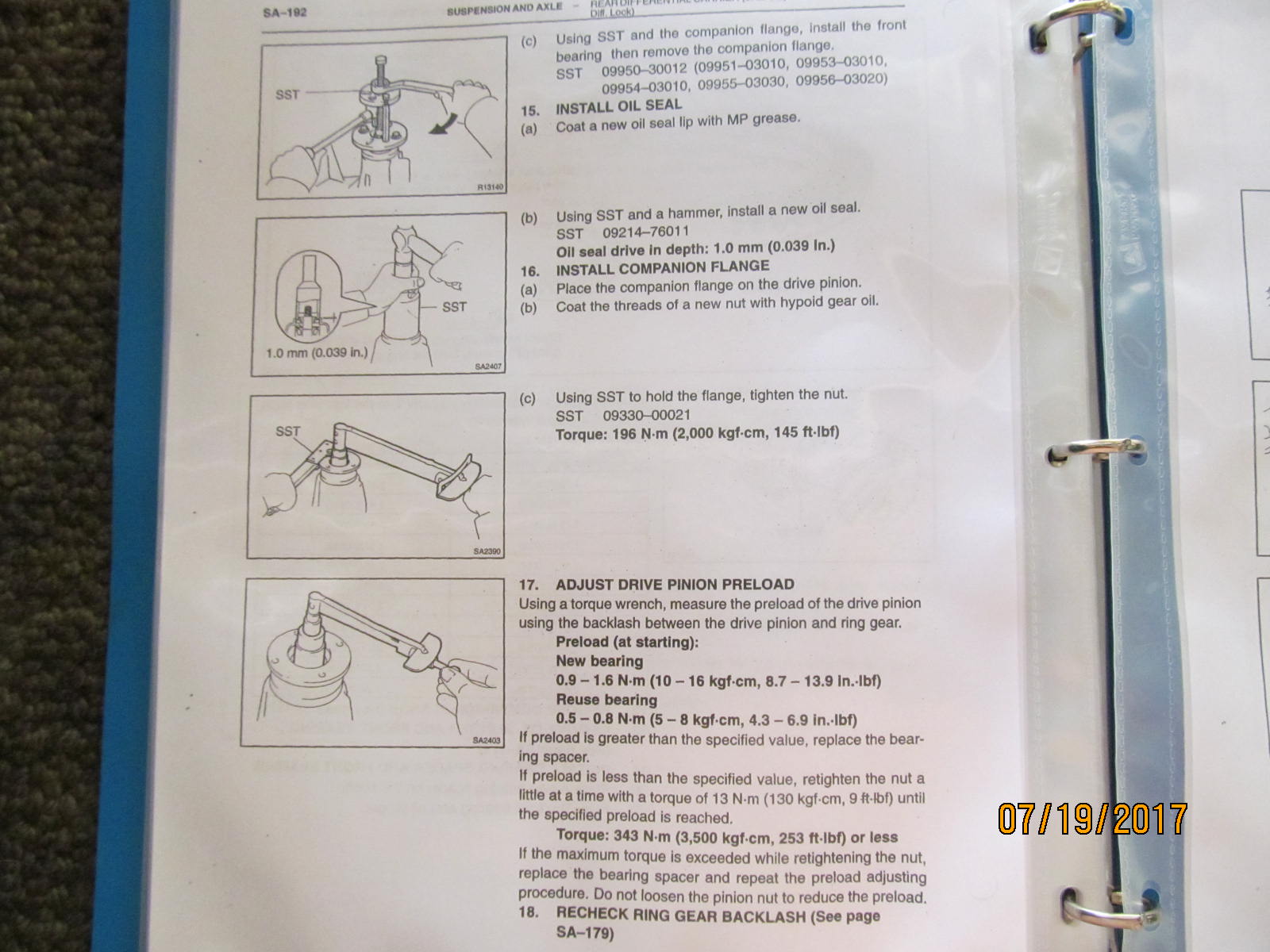

| Interesting....new bearing pinion preload range 9~14 in/lb. |

|---|

|

|

| Bearing caps they spec at 58 ft/lb. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| The pinion nut will crush with the above mentioned 145 ft/lb of torque IF the threads and the bottom of the flange nut have anti-seize on them. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| 30 ft/lb for the diff lock sensor. |

|---|

|

|

| I bet some vaseline on the e-motor o-ring would help it seat down more smoothly and positive. |

|---|

|

|

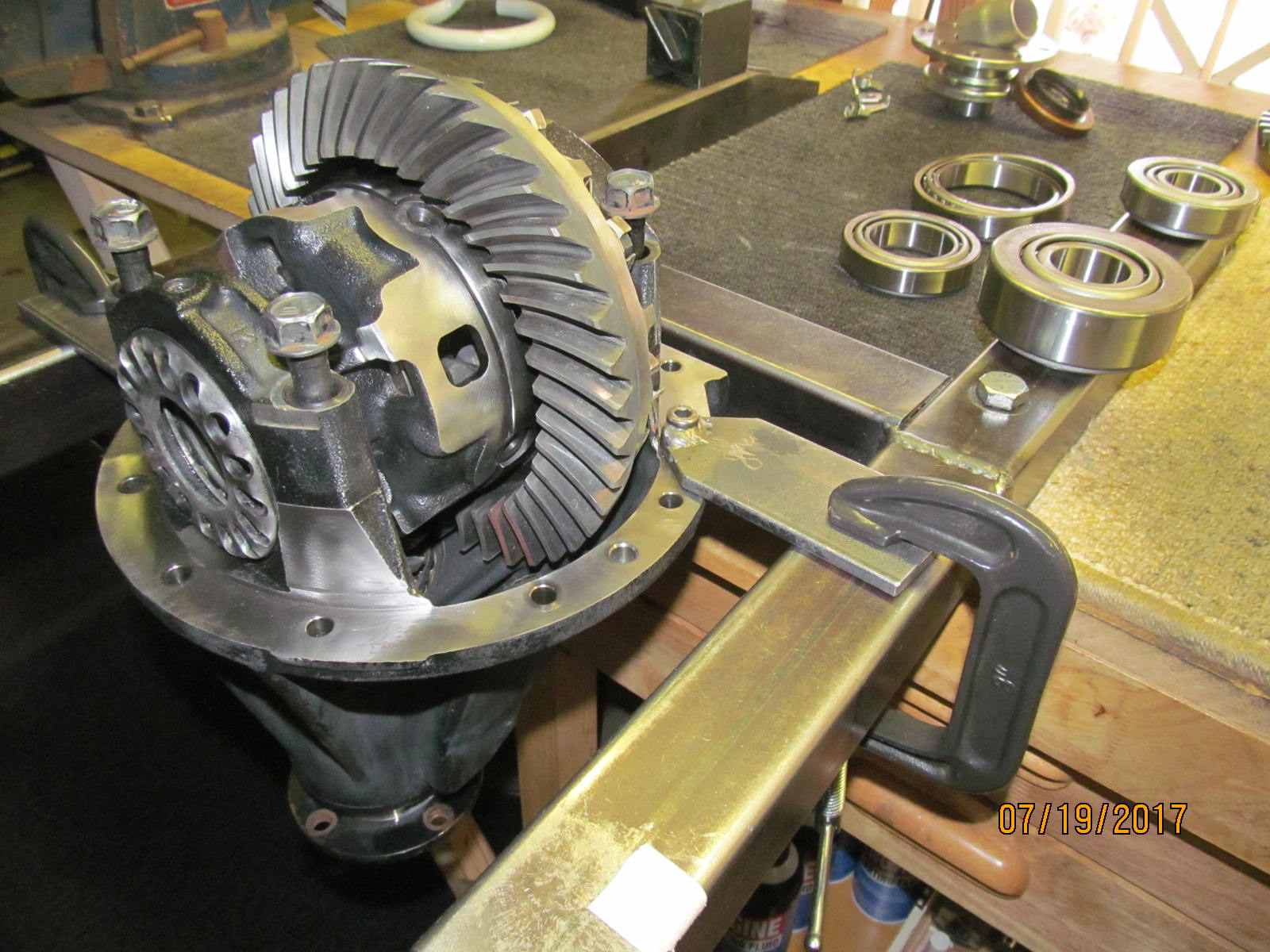

All the "stuff" that Joe supplied. Notice that the Sierra Gear pinion has the "Circle K" stampings. Nothing wrong with the K stamped gears.

They have the quality look and feel....as well as set up well. |

|---|

|

|

| The new 456 ring gear will have to be mounted....and 4 new Koyo bearings. Teardown begins. |

|---|

|

|

| Tap tap. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

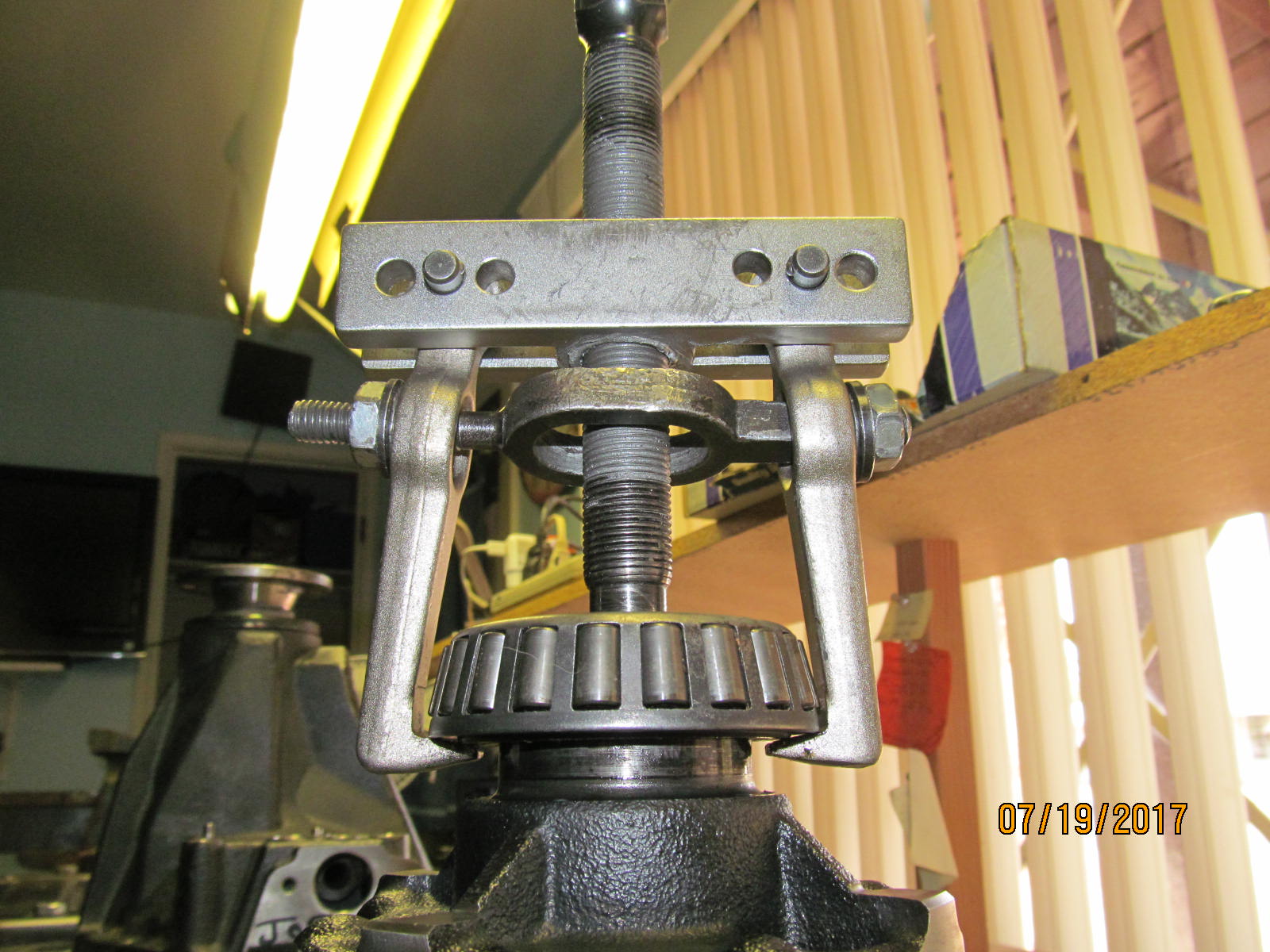

| With the right puller, the old carrier bearings come right off. |

|---|

|

|

| The 8 center carrier bolts are being verified to be about 45 ft/lb and they all were. |

|---|

|

|

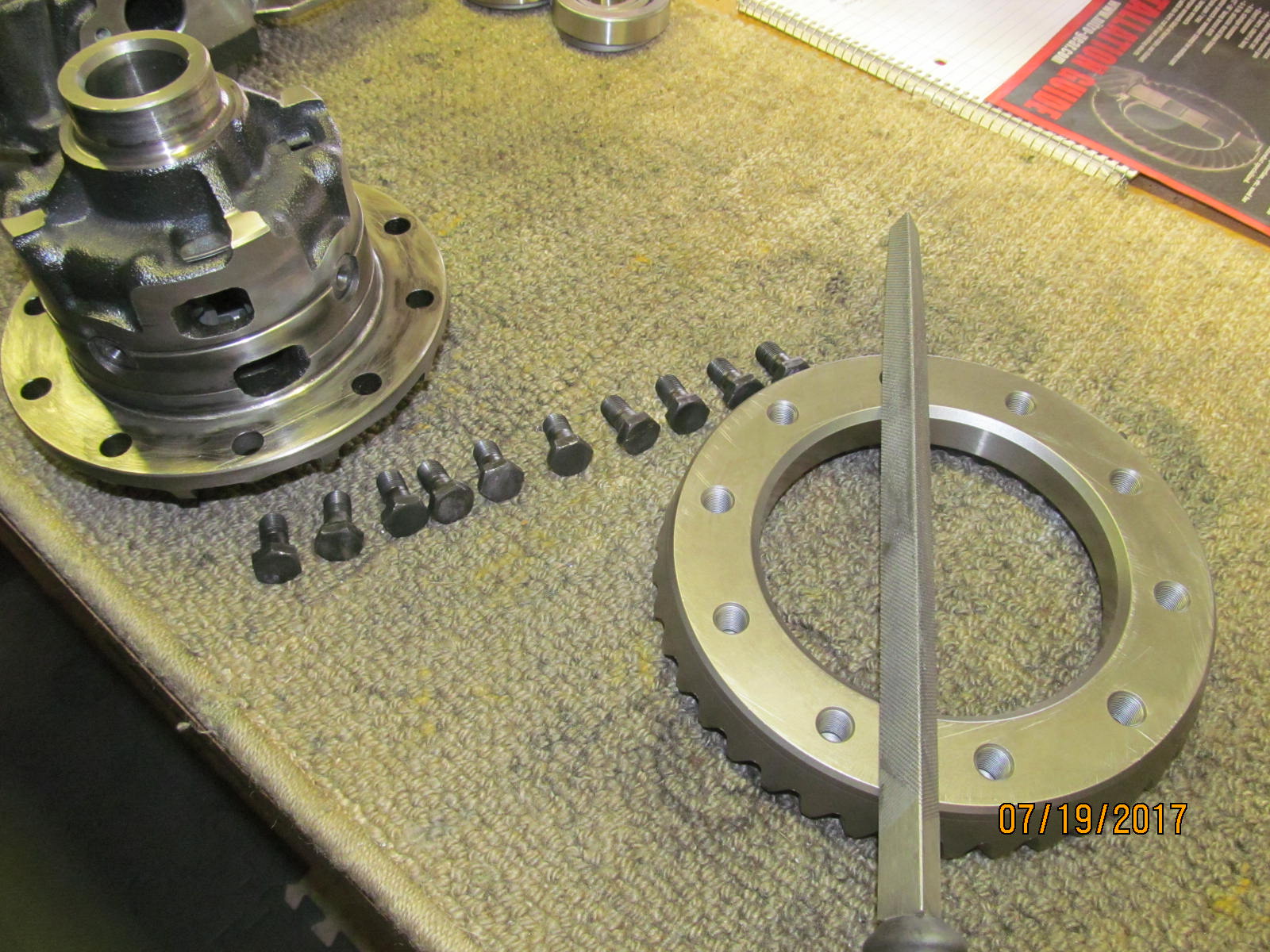

| Both surfaces were checked with a file and no unusual burrs or bumps found. |

|---|

|

|

| This ring gear was a "just right" fit and only took a few dainty taps to drop down. My favorite type. |

|---|

|

|

| A dab of blue Loctite and 71 ft/lb on the ring gear bolts. |

|---|

|

|

| Tapping the new carrier bearing on. |

|---|

|

|

| Same on the other side. |

|---|

|

|

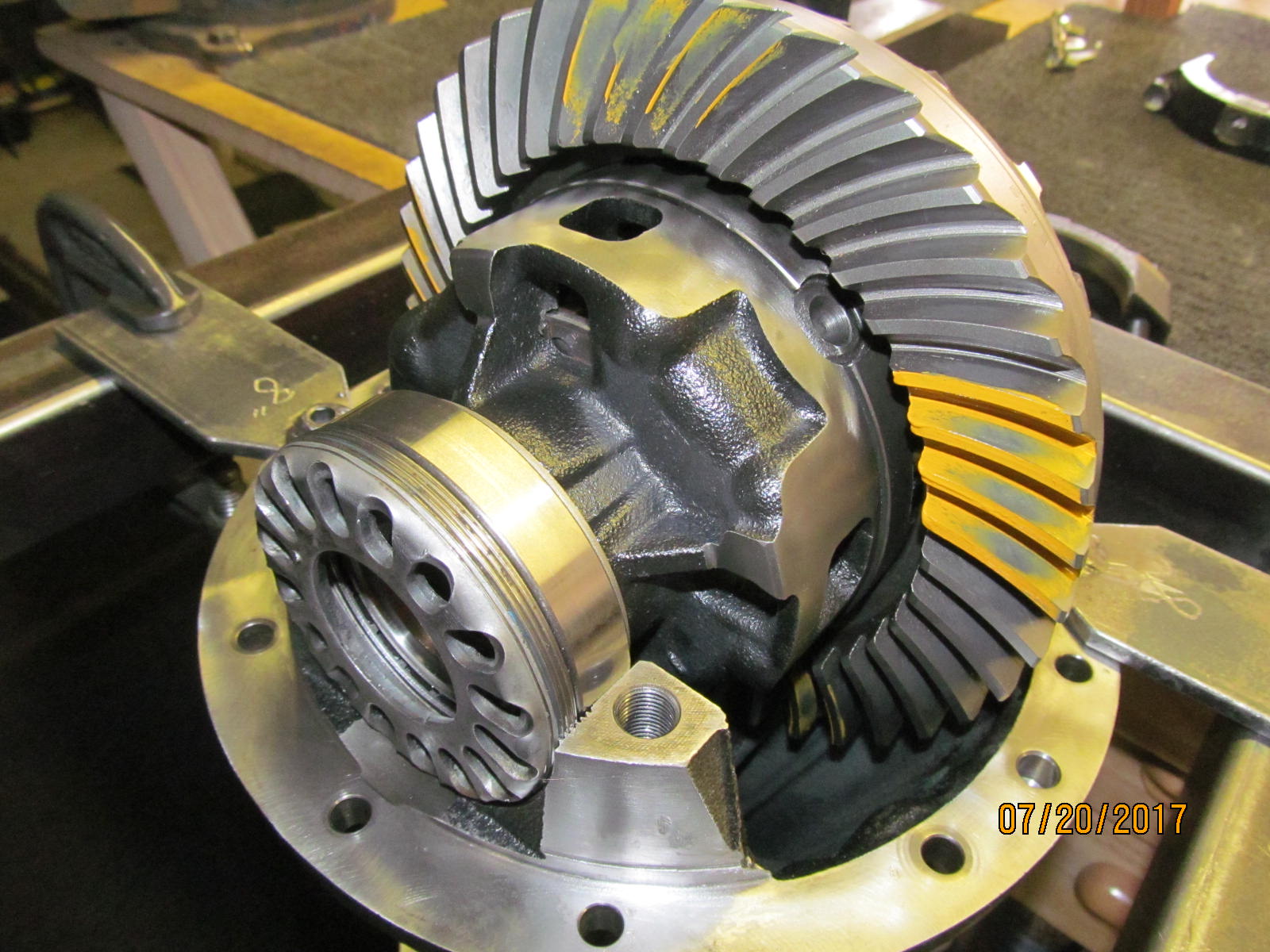

| This assembly is now complete....onto the pinion end of things. |

|---|

|

|

| Pressing the 410 blue pinion out. |

|---|

|

|

| Sure looks pretty. Will try .078" pinion shim on the 456 pinion. |

|---|

|

|

| Pressed on....this portion is now waiting.... |

|---|

|

|

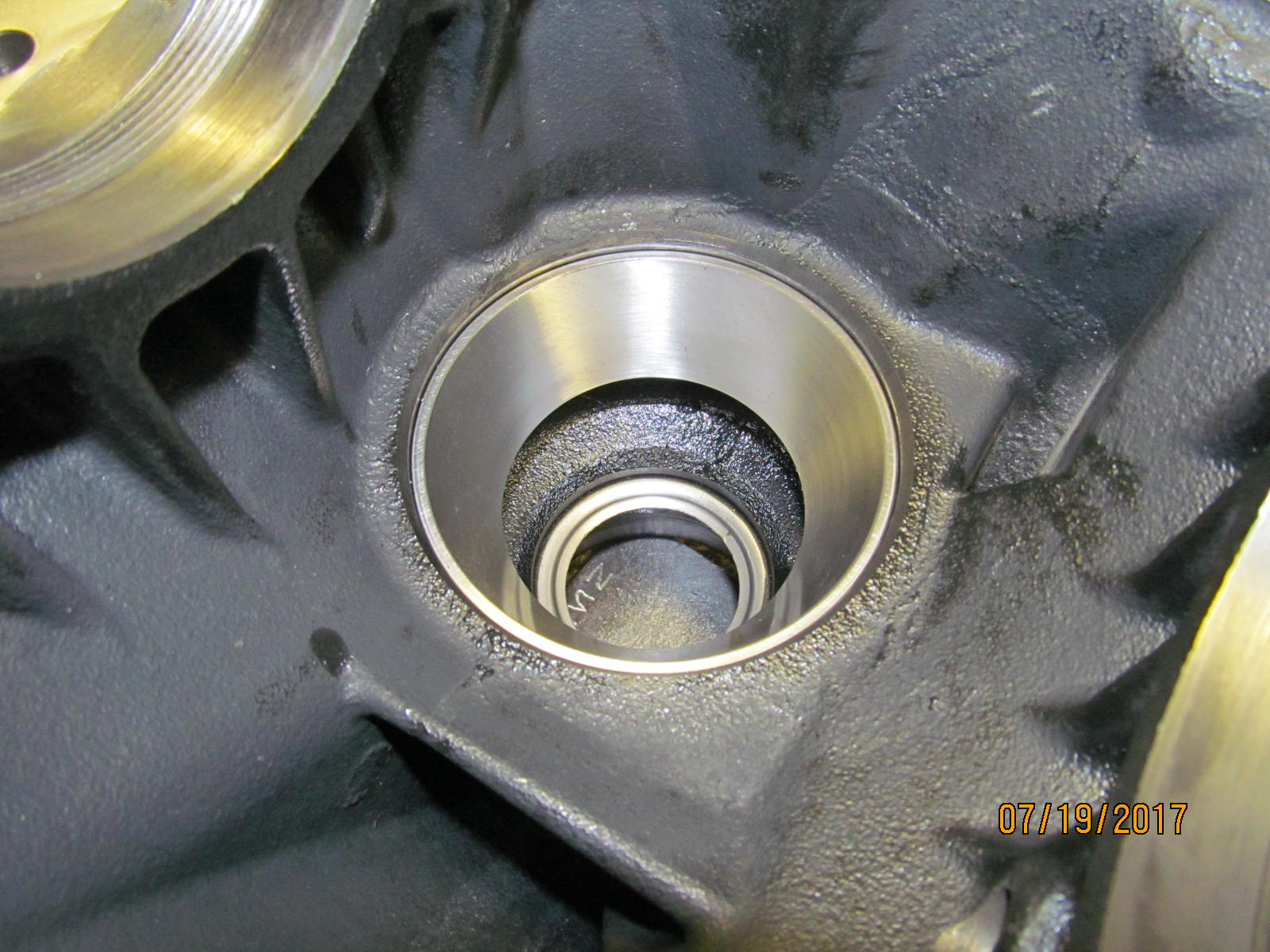

....for this main diff section to get the new races. Notice that the old race was removed with no damage to the oil retainer.

It's entirely possible with the right BIG washer and plastic bottle cap. |

|---|

|

|

| Badda bing, badda boom, new race is in. |

|---|

|

|

| Same with the large inner race. |

|---|

|

|

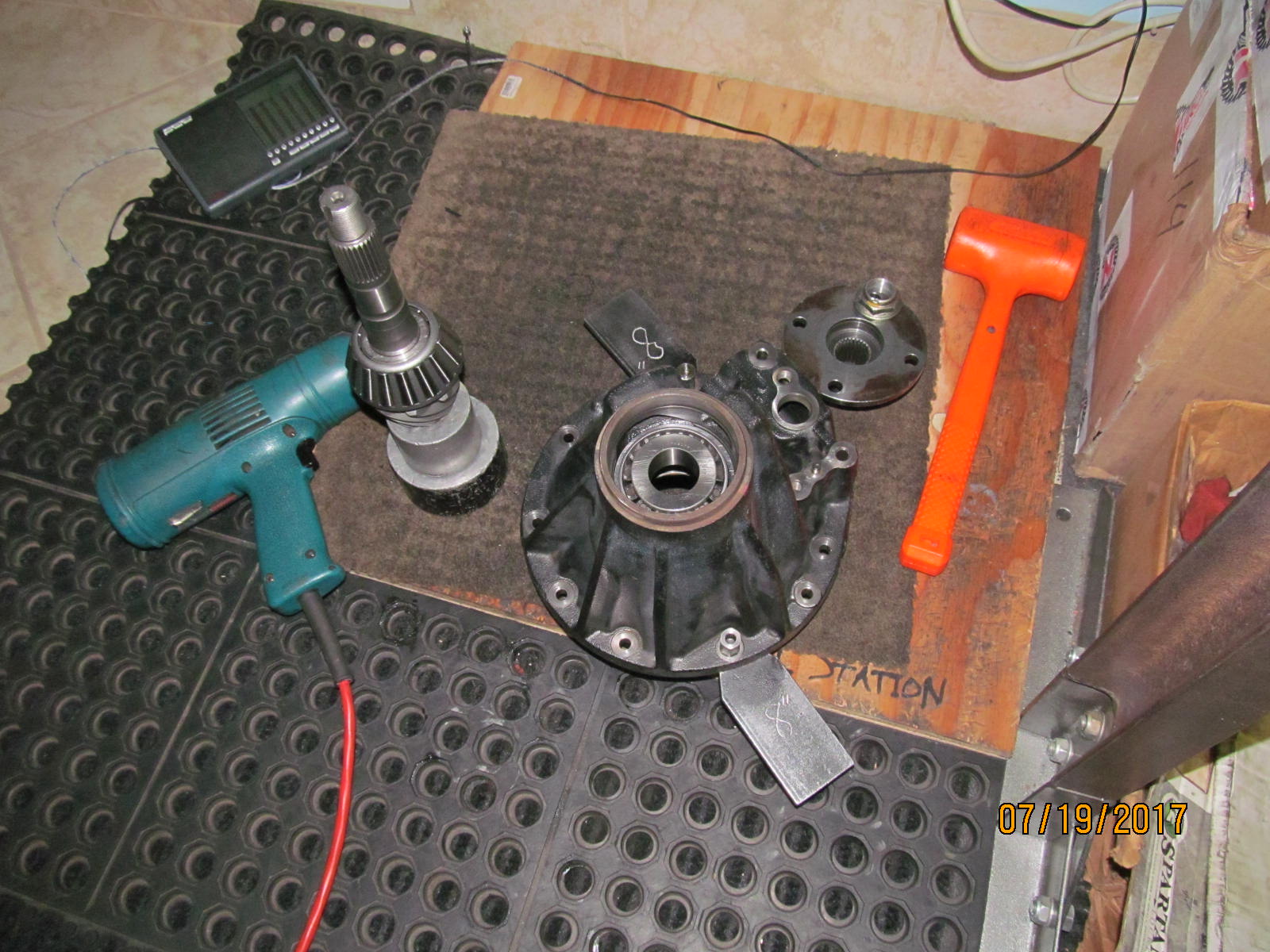

Now to mount the pinion assembly in the main diff. Support the pinion with aluminum blocks....lower the diff onto the pinion...mount the flange....

tap it down with the plastic hammer then tighten with the electric impact and being careful not to overtighten it...

just enough to allow the flange to turn firmly. |

|---|

|

|

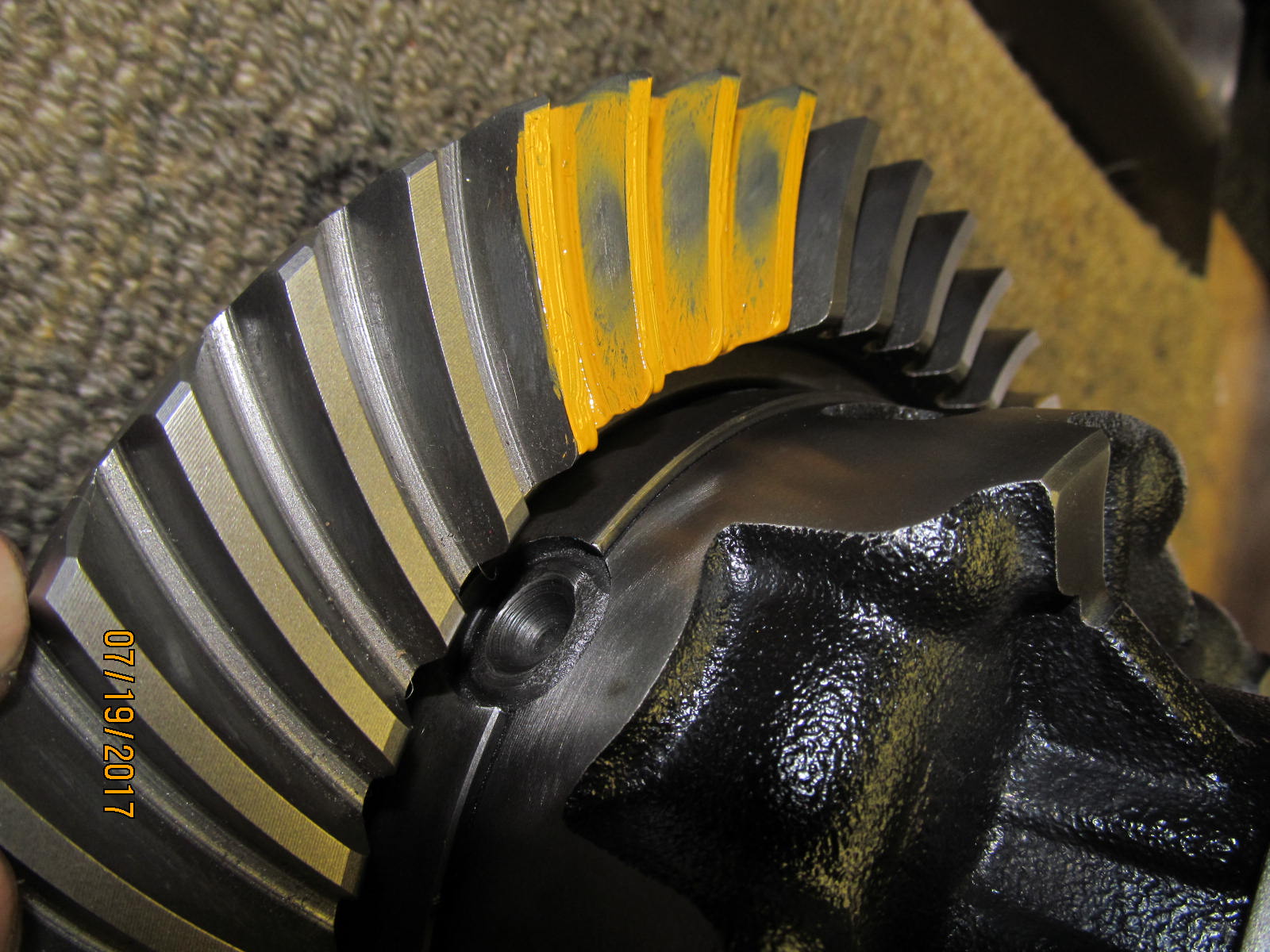

| Mount the center carrier. Tighten the 4 cap bolts. Set the backlash in the ballpark with some bearing preload and apply yellow paint. |

|---|

|

|

| Drive side...I like what I see...looks to be slight deep...or even exact. |

|---|

|

|

| Coast is telling me that it is a slight deep condition so leave it alone. |

|---|

|

|

| Reverse painted DRIVE says exact depth. |

|---|

|

|

| COAST says slight deep. |

|---|

|

|

| Comet tail says slight deep as it is swishing towards the center. |

|---|

|

|

| .078" is a keeper. |

|---|

|

|

| With depth now established, the oem seal can now be mounted. |

|---|

|

|

| Slinger had to be opened up a little for the 29 spline pinion shaft...but that was easy with a 1/4" die grinder. |

|---|

|

|

| Then the seal is installed... |

|---|

|

|

| Nice, clean mounting. |

|---|

|

|

| ,,,,,,,,,,,,,,,,, |

|---|

|

|

| Dang! Forgot the the seal was a little 27 spline one and the larger 29 spline flange is going to require one of the larger 29 spl oem seals to work properly. |

|---|

|

|

| Genuine OEM seal from the dealership... |

|---|

|

|

| BH6832E is for the 29 spline applications. |

|---|

|

|

| Oil and anti-seize applied to all the right places... |

|---|

|

|

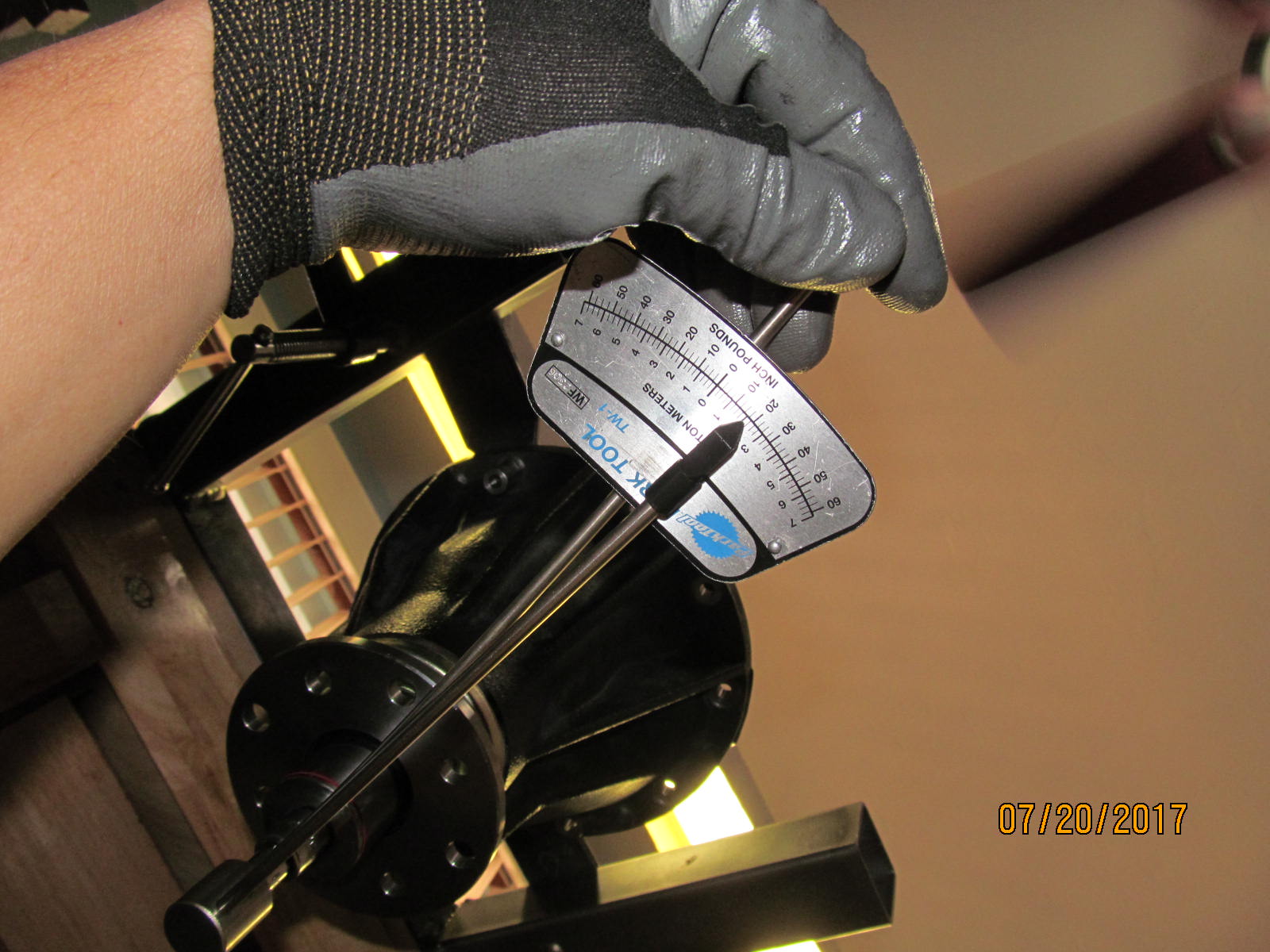

| Pinion preload is measured. |

|---|

|

|

| DING!! and this will not loosen by itself. |

|---|

|

|

| Adjuster wheels are meshing perfectly. |

|---|

|

|

| This wheel is a bit trickier to get it dropped in the proper threads but it's very much doable. |

|---|

|

|

| 70 ft/lb on all 4 bearing caps. |

|---|

|

|

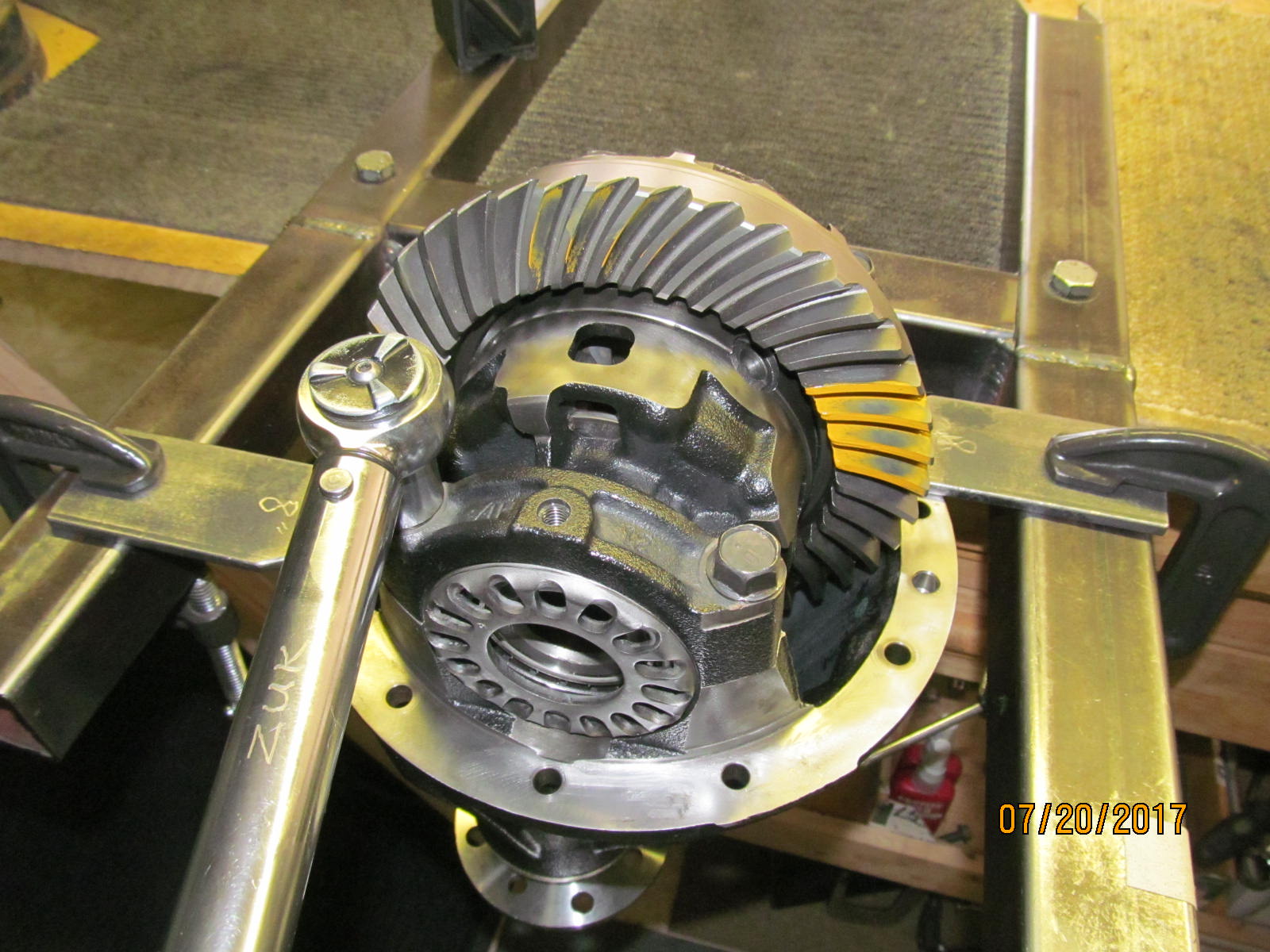

| Turning the pinion will cause the carrier bearings to rotate and hitting the corners like I am in the pic will let the bearings "equalize" in tension. |

|---|

|

|

| Some final tweaking of the wheel adjusters to get the desired backlash and preload. |

|---|

|

|

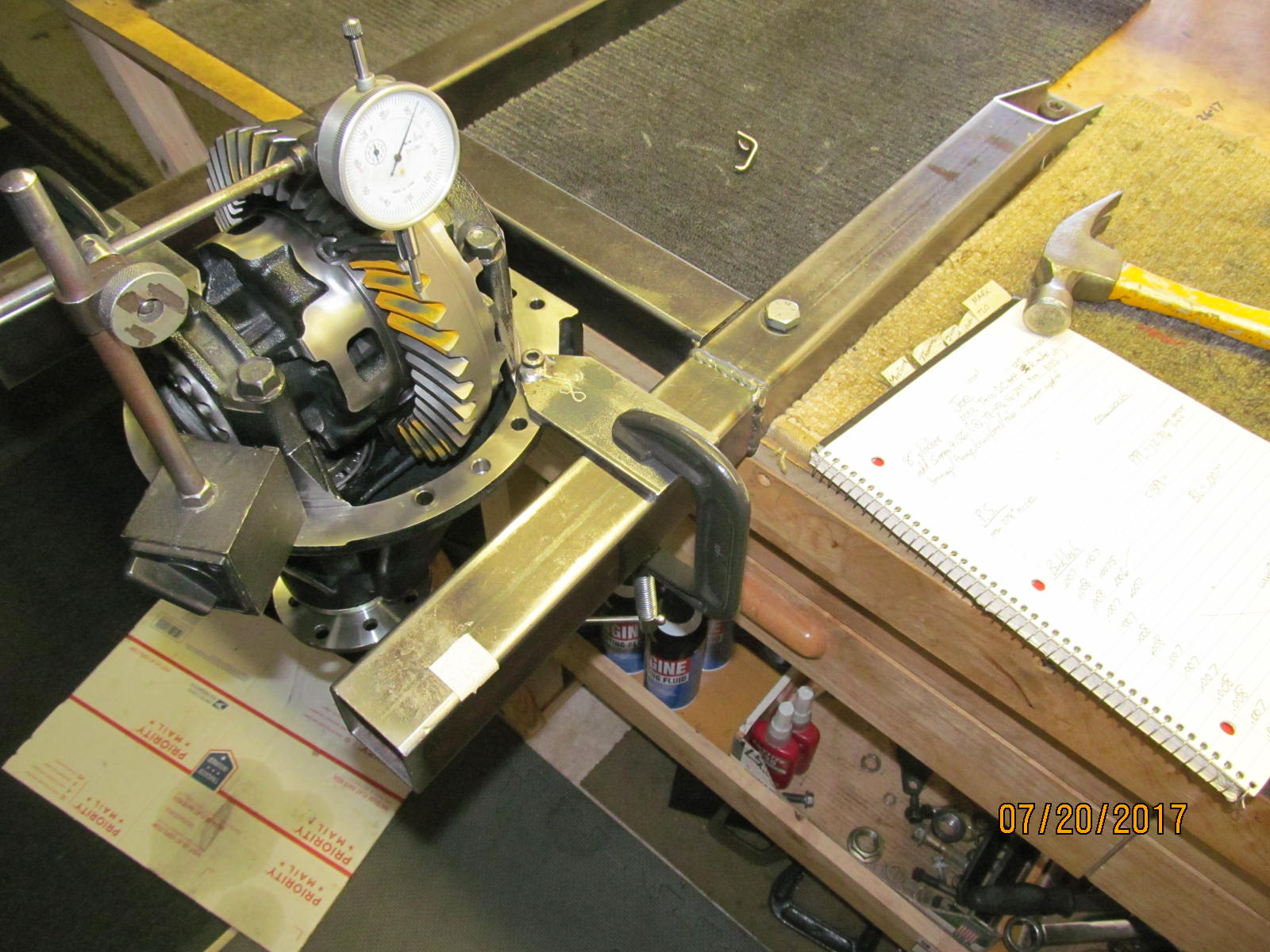

| Backlash was measured on every other tooth for about 20 readings. |

|---|

|

|

| The total preload(turning both the pinion and carrier bearings) checked in at 19 in/lb. |

|---|

|

|

| 10 ft/lb on the lock tabs with blue Loctite. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

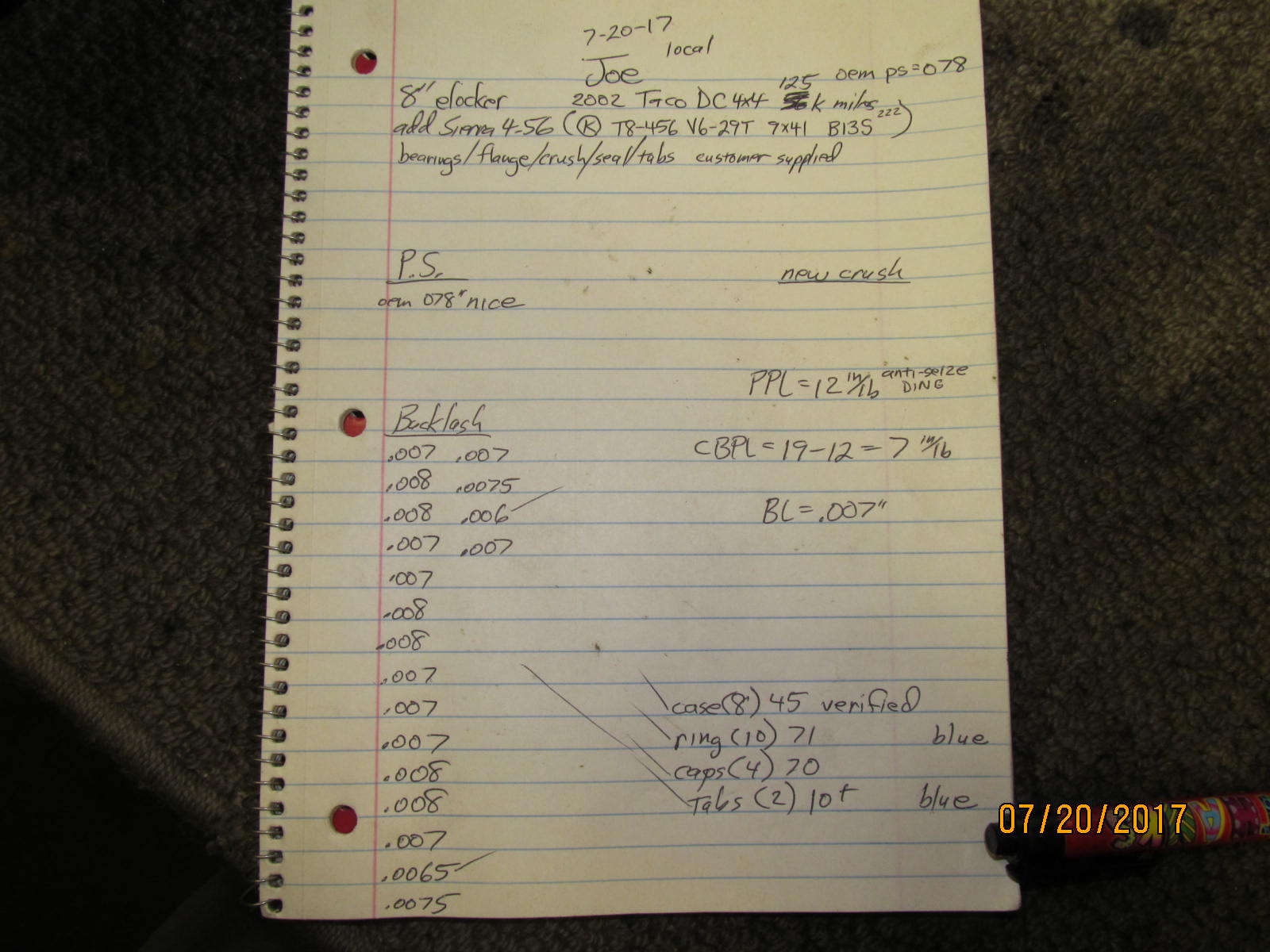

| All the notes on Joe's install ;) |

|---|

|

|

|