|

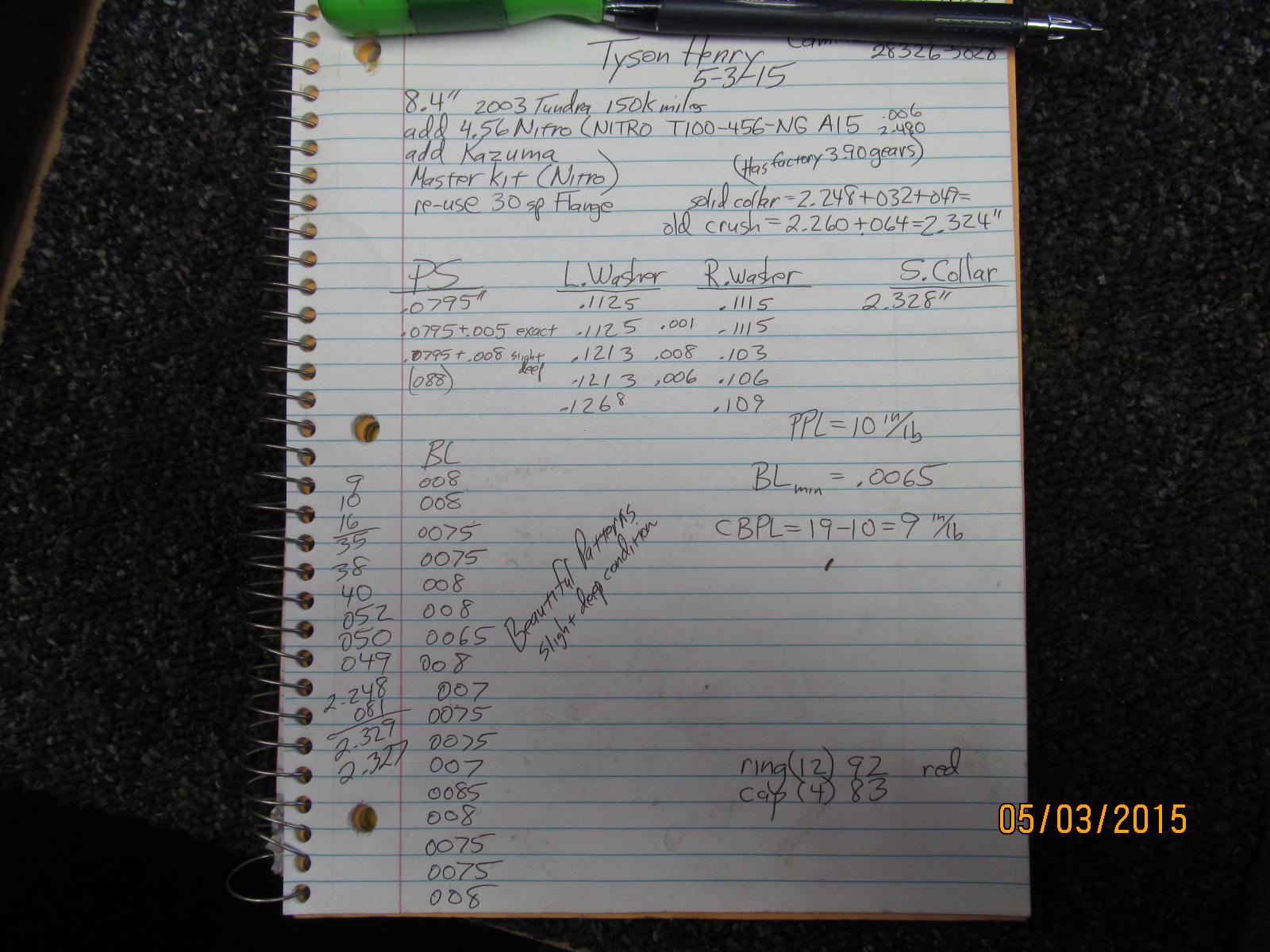

Kazuma LSD and 4.56 Nitro Gears for Tyson's 2003 Tundra

|

|

(38 BIG pics loading)

|

|

May 11 2015

|

|

|

Tyson is in North Carolina and his 03 Tundra is called upon to do some unusual duties....

like pulling a 24' gooseneck trailer with horses inside thru the wet, soggy and sometimes mucky grass.

|

|

|

|

Excellent traction is a must for this useage in this 1st gen 2WD Tundra with 4.7L 245 horsepower V8

with A340E auto tranny. In the differential is a limited slip but it's the weak factory

version and very worn out.

|

|

|

|

As received from Tyson. I've seen these extra heavy duty totes at Home Depot and also

at Lowe's. I think they were priced at about $15.

|

|

|

|

|

115 pounds.

|

|

|

|

The spare open Tundra 3rd, Kazuma LSD, Nitro 456 gears and the master install kit.

JustDifferential 8.4" Nitro Gears

JustDifferential 8.4" master kit

|

|

|

|

Manufactured by Eaton for TRD, this lsd is much better than the OEM version that Toyota sometimes

puts in the Tundras. Here's some of the reasons why.... Kazuma LSD

|

|

|

|

|

Cabe Toyota has them for $299 Cabe Toyota

|

|

|

|

|

=============================

|

|

|

|

|

8.4" master install kit

|

|

|

|

|

4.56 30 spline Nitro Gears...very beefy thick pinion shaft.

|

|

|

|

|

Teardown starts by removing the cross-brace.

|

|

|

|

The 12 ring gear flange style bolts had some sort of oem high strength loctite on them

so the electric impact got a work-out getting them off.

|

|

|

|

|

The ring gear was a very tight fit.

|

|

|

|

|

Red loctite and 92 ft/lb on the 12 bolts.

|

|

|

|

|

Carrier bearings tapped on very tight.

|

|

|

|

|

The "carrier" is now put aside and the pinion end begins.

|

|

|

|

|

New outer and inner bearings are waiting. But first...

|

|

|

|

|

...the old pinion and races have to be purged of the differential.

|

|

|

|

|

Old race comes out.

|

|

|

|

|

Use the same chisel and tap out the old inner race. The pinion sham is behind the race on these 8.4" 3rds.

|

|

|

|

|

The original .0795" washer plate is re-useable if one takes the time to remove the damaged material.

|

|

|

|

|

Notches were ground out such that I can tap the race out in the future to change pinion depth with no damage.

|

|

|

|

I'll add .005 to the oem .0795" plate. I know the Nitros need a little more than the oem value

to dial in the best pattern.

|

|

|

|

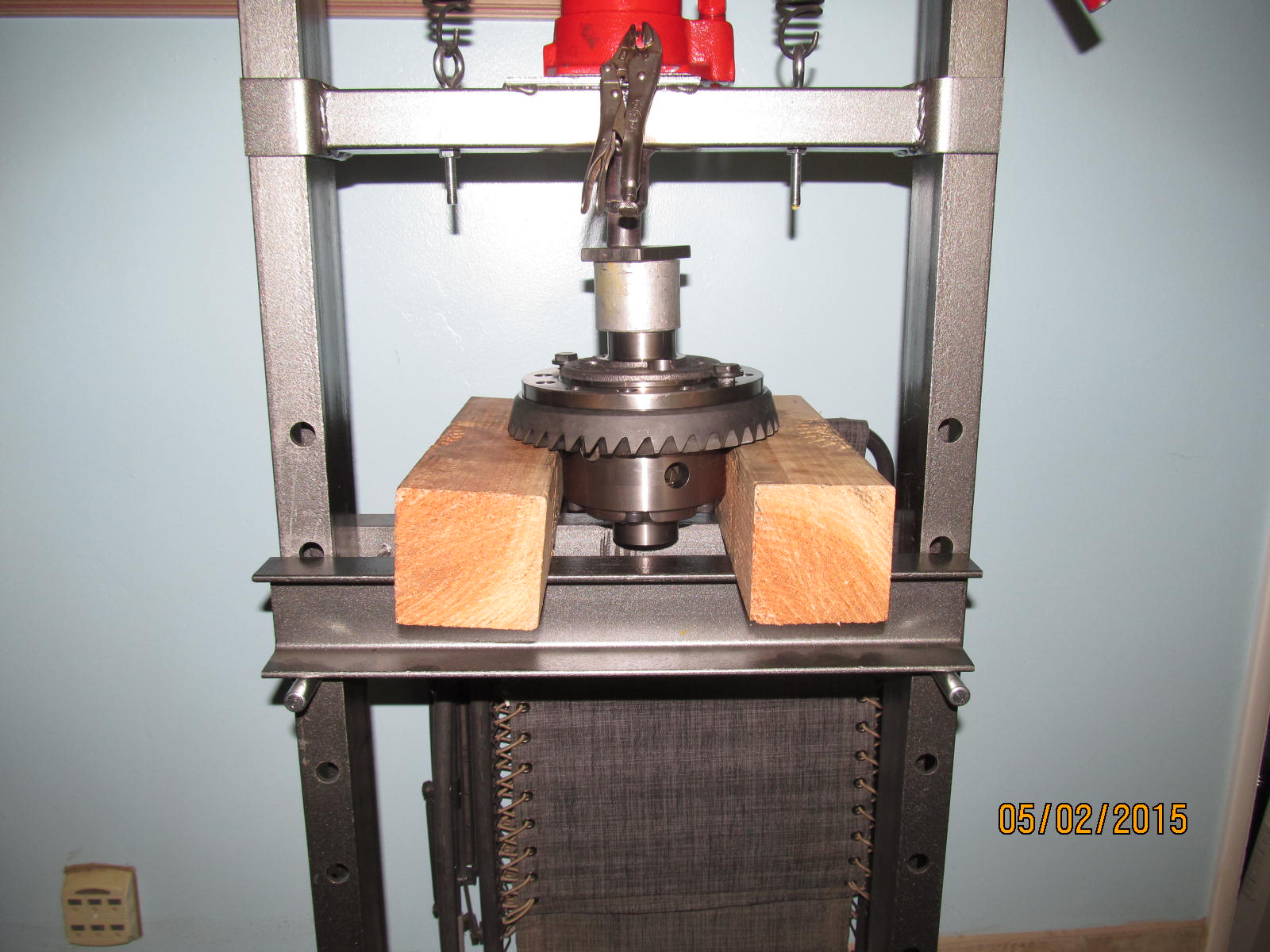

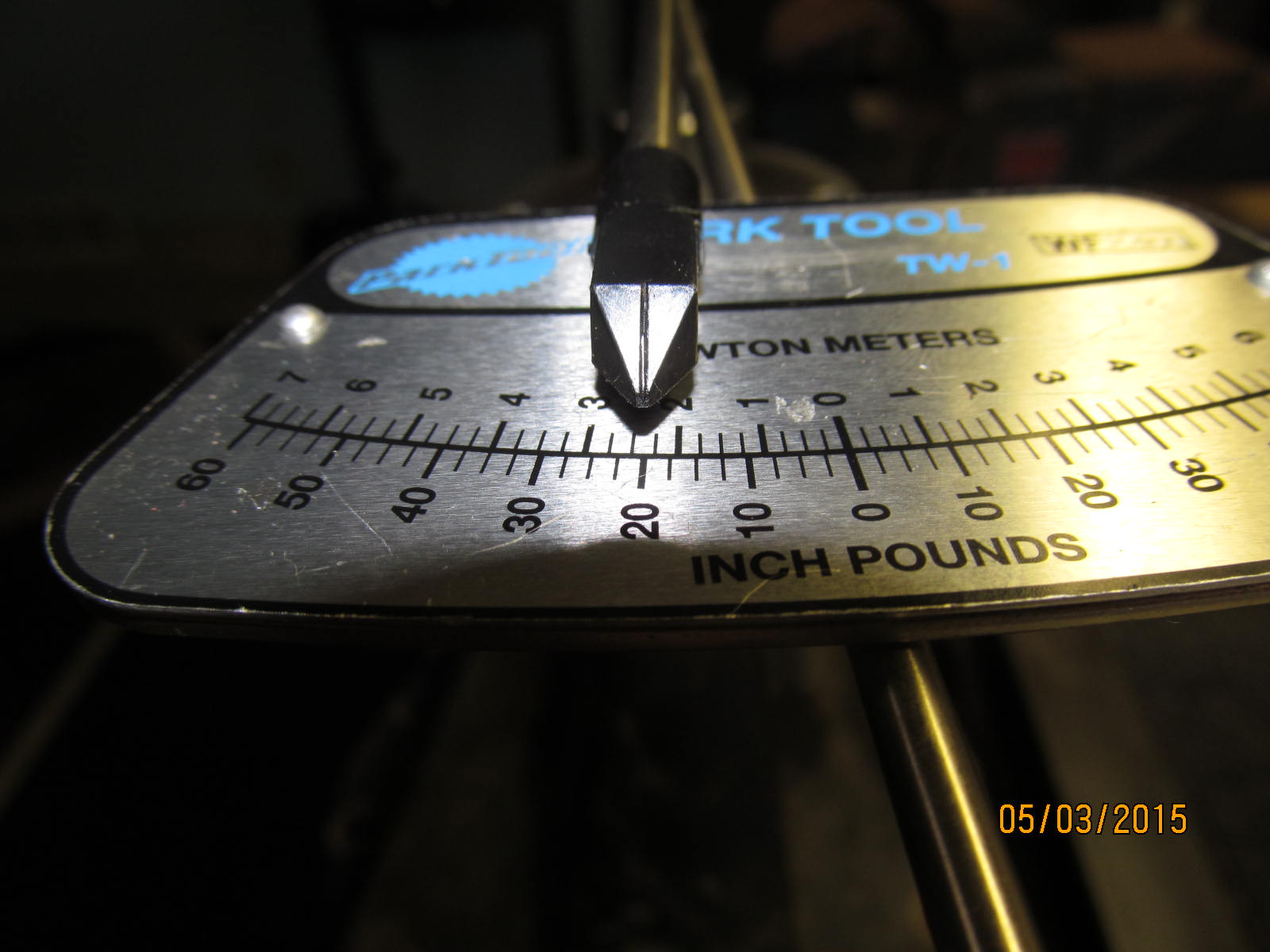

The 30 spline OEM flange is an amazingly tight fit over the pinion splines so I like to

use the press to ease the flange down 95% of the way. Then tighten the pinion

nut with the electric impact until about 20 in/lb of drag is felt.

|

|

|

|

The Kazuma is loaded in place...start with the oem washer plates and see if the backlash is close

enough for a paint check. I observed that it was not. Was only measuring .001" backlash.

|

|

|

|

By adding .008" to one side and taking the same amount off the other side, the backlash

increased by about another .006" giving us the green light for a paint check.

|

|

|

|

|

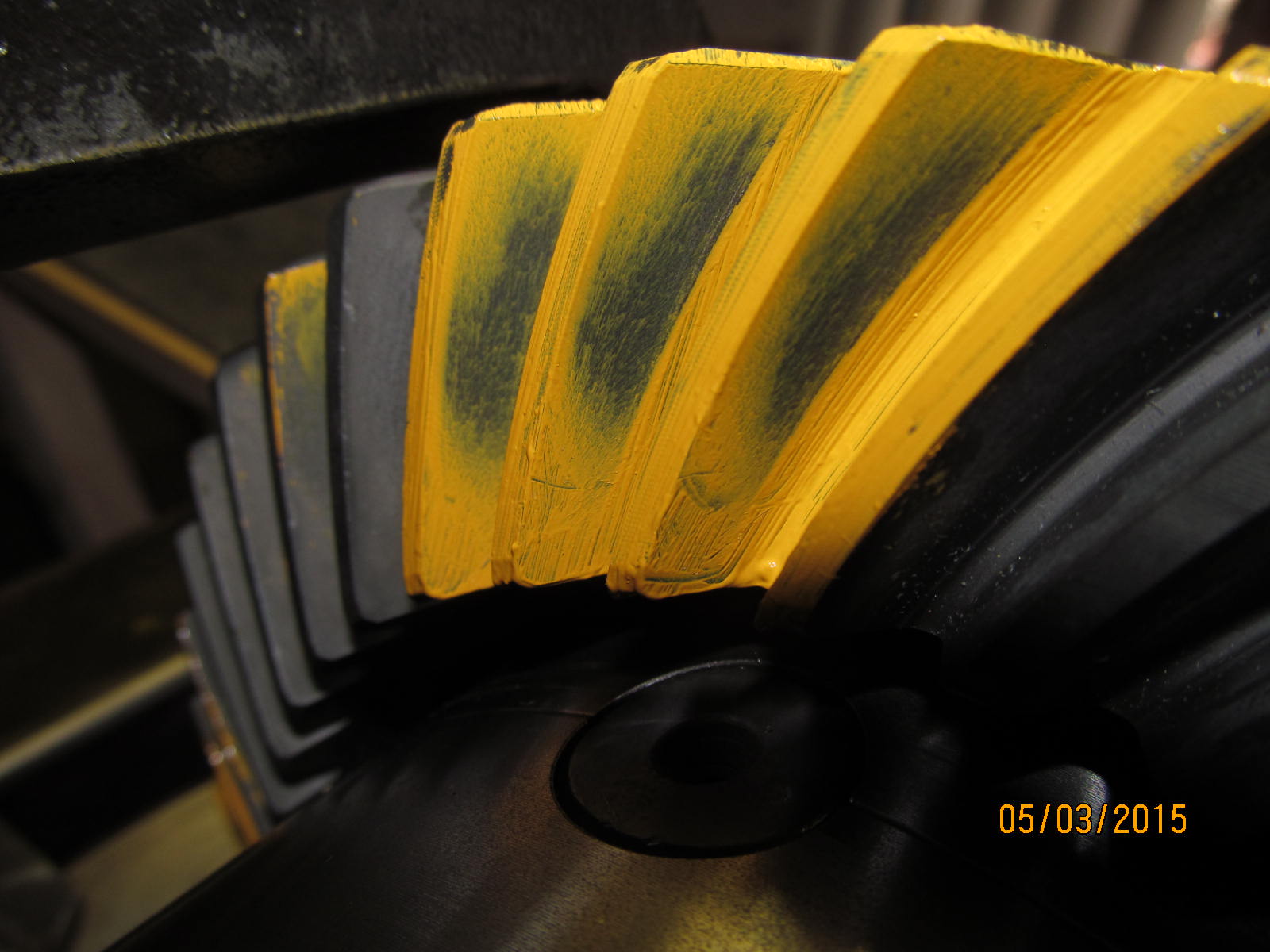

close but could be deeper.

|

|

|

|

|

Right in the center but too soft....could be deeper.

|

|

|

|

|

Teardown time. Take the .005" shim out and replace it with a .008" shim.

|

|

|

|

Now is a good time to check how snug the lip of the pinion seal fits. Nice.

Not shown but a solid collar was also installed.

|

|

|

|

With the thicker pinion shim installed and the solid collar, now it's time to tighten the pinion nut

til about 9 or 10 in/lb of drag is measured.

|

|

|

|

|

I was able to tweak it in to a nice 10 in/lb.

|

|

|

|

|

Ding the nut and done.

|

|

|

|

I added another .005" on this side shown and .003" on the other to increase the backlash

and also the pre-loading.

|

|

|

|

|

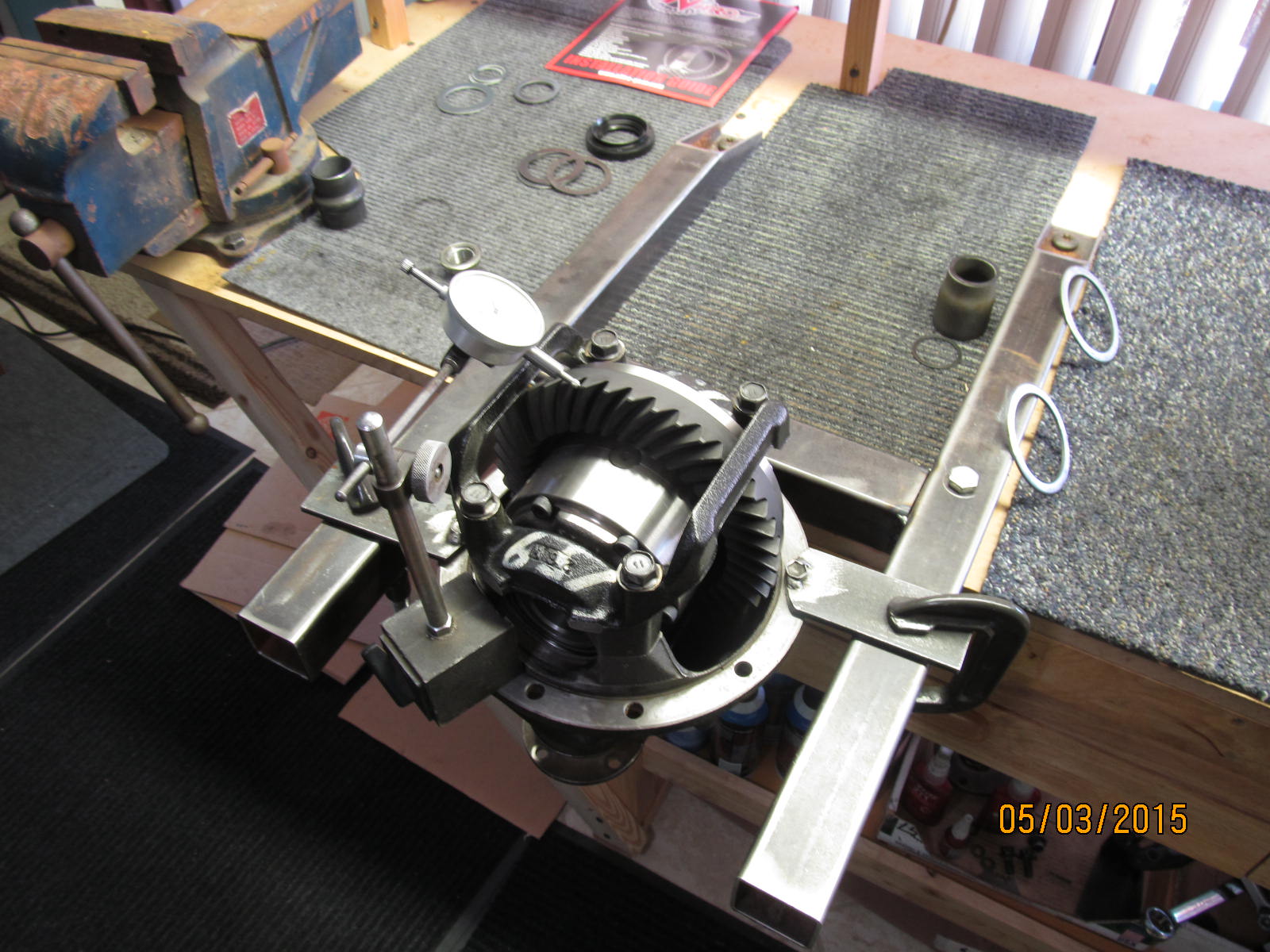

Backlash was measured on every other tooth. The minimum was noted to be .0065"

|

|

|

|

Combined preload was 19 in/lb. Pinion preload was previously measured at 10 so that means

the carrier bearing preload is 19 - 10 = 9 in/lb

|

|

|

|

|

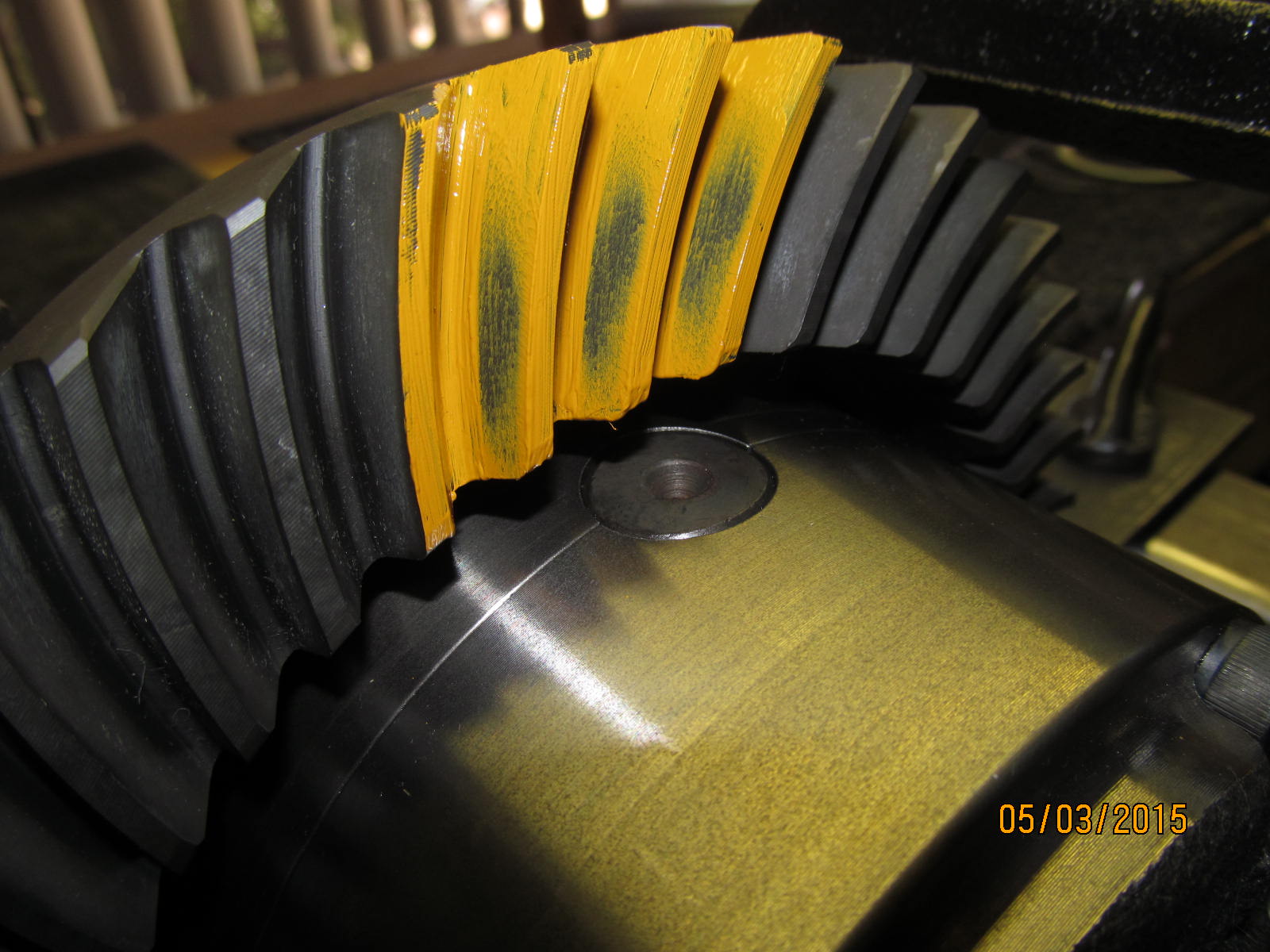

Last paint check and the drive side looks to be my preferred slight deep depth. Well centered too.

|

|

|

|

|

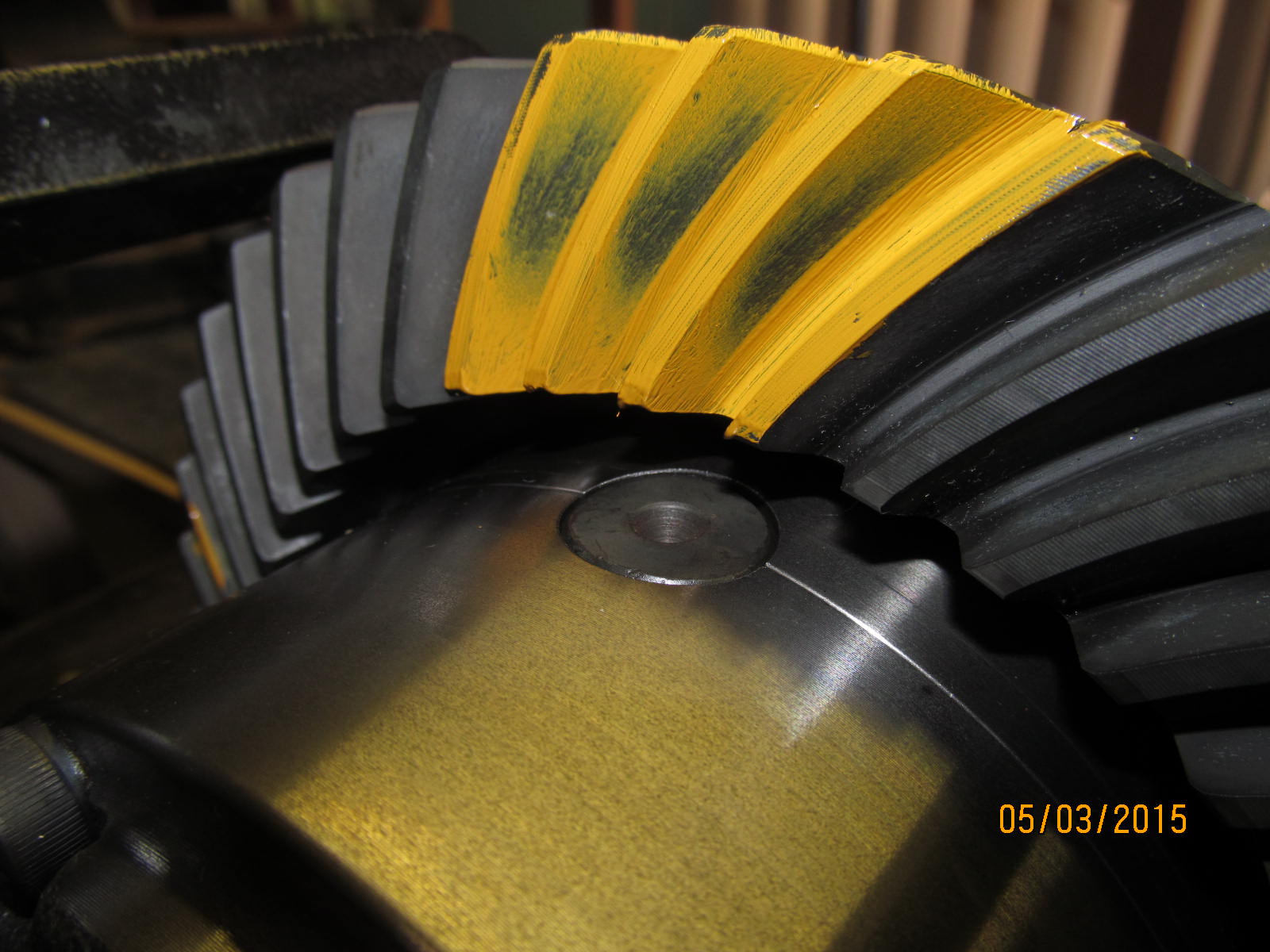

Coast..proper root contact and slightly favoring the heel.

|

|

|

|

|

A double-check...The FSM says 83 ft/lb and I like the sound of that number too :)

|

|

|

|

|

======================

|

|

|

|