| Mike's front 8" high pinion Harrop install for his 97 TLC |

|---|

| (61 BIG pics loading) |

|---|

| NOV 25 2017 |

|---|

|

| This just arrived from the Ebay seller. Apparently, this 3rd came out of a 96. |

|---|

|

|

| I'm trying to cut open the dual boxes....and Cola has to see what's happening.. |

|---|

|

|

| Nice double boxing with good padding inside the box. |

|---|

|

|

| This 3rd will be easy to clean up. |

|---|

|

|

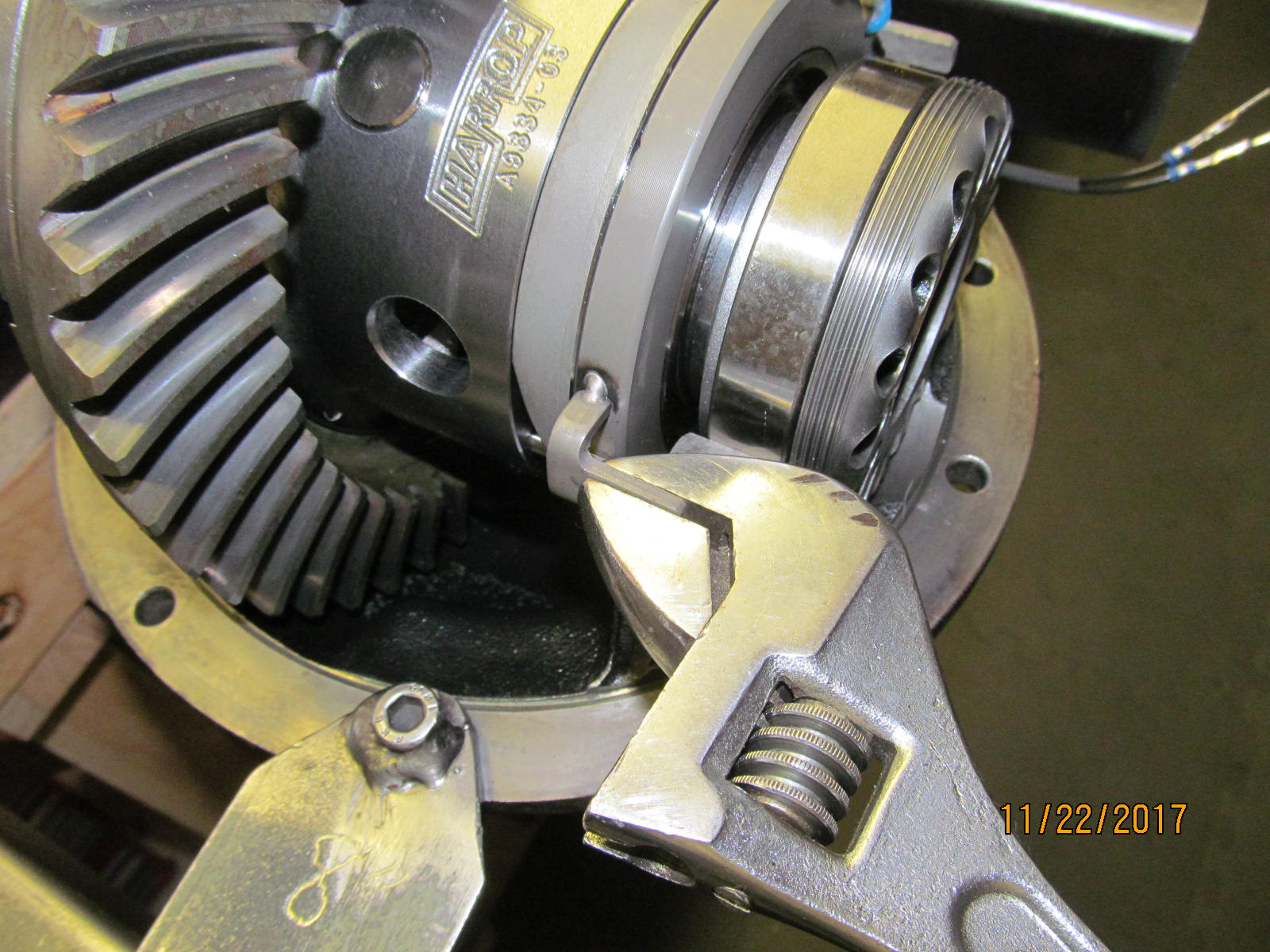

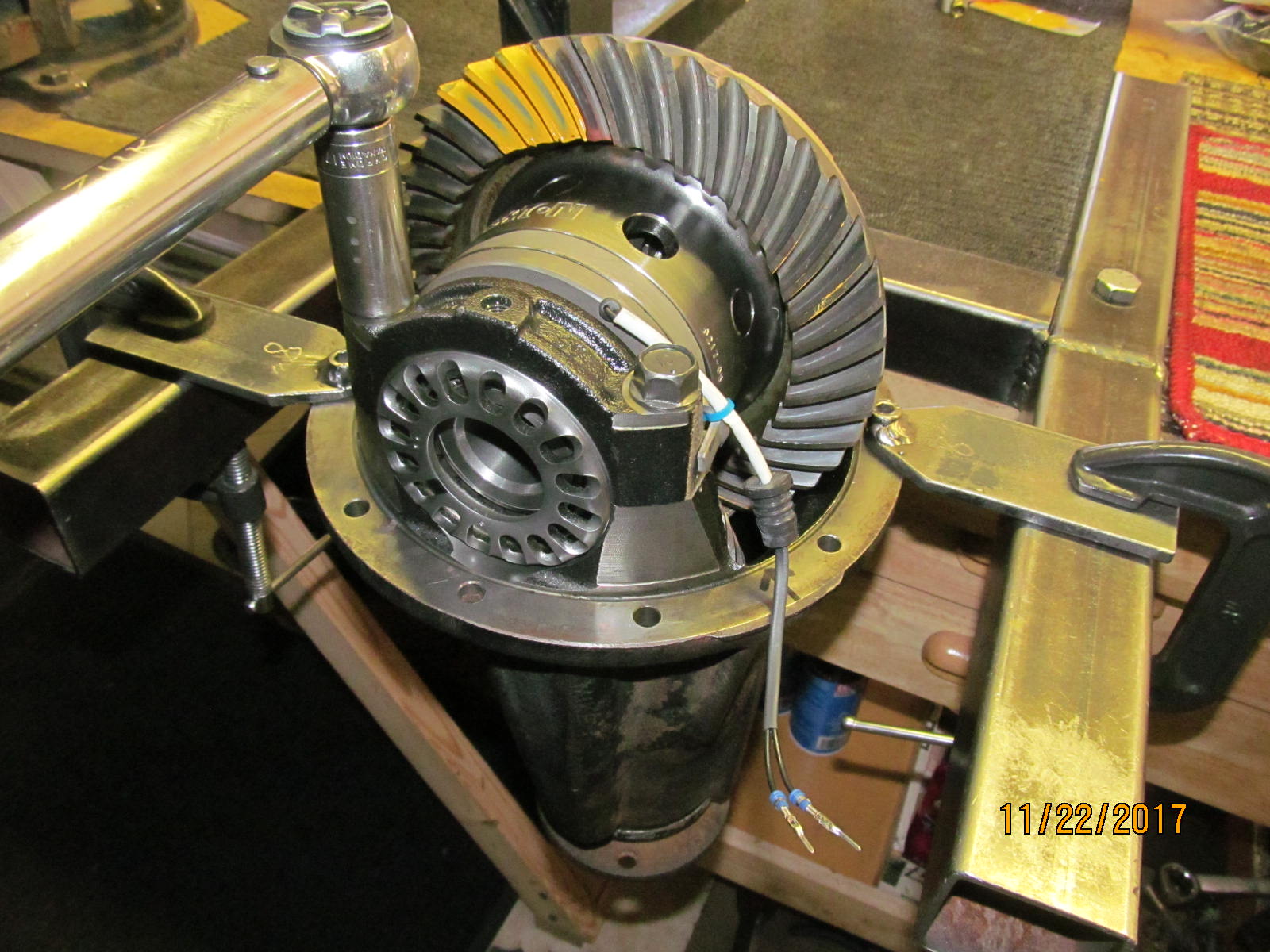

| This #9334 Harrop elocker will be installed. |

|---|

|

|

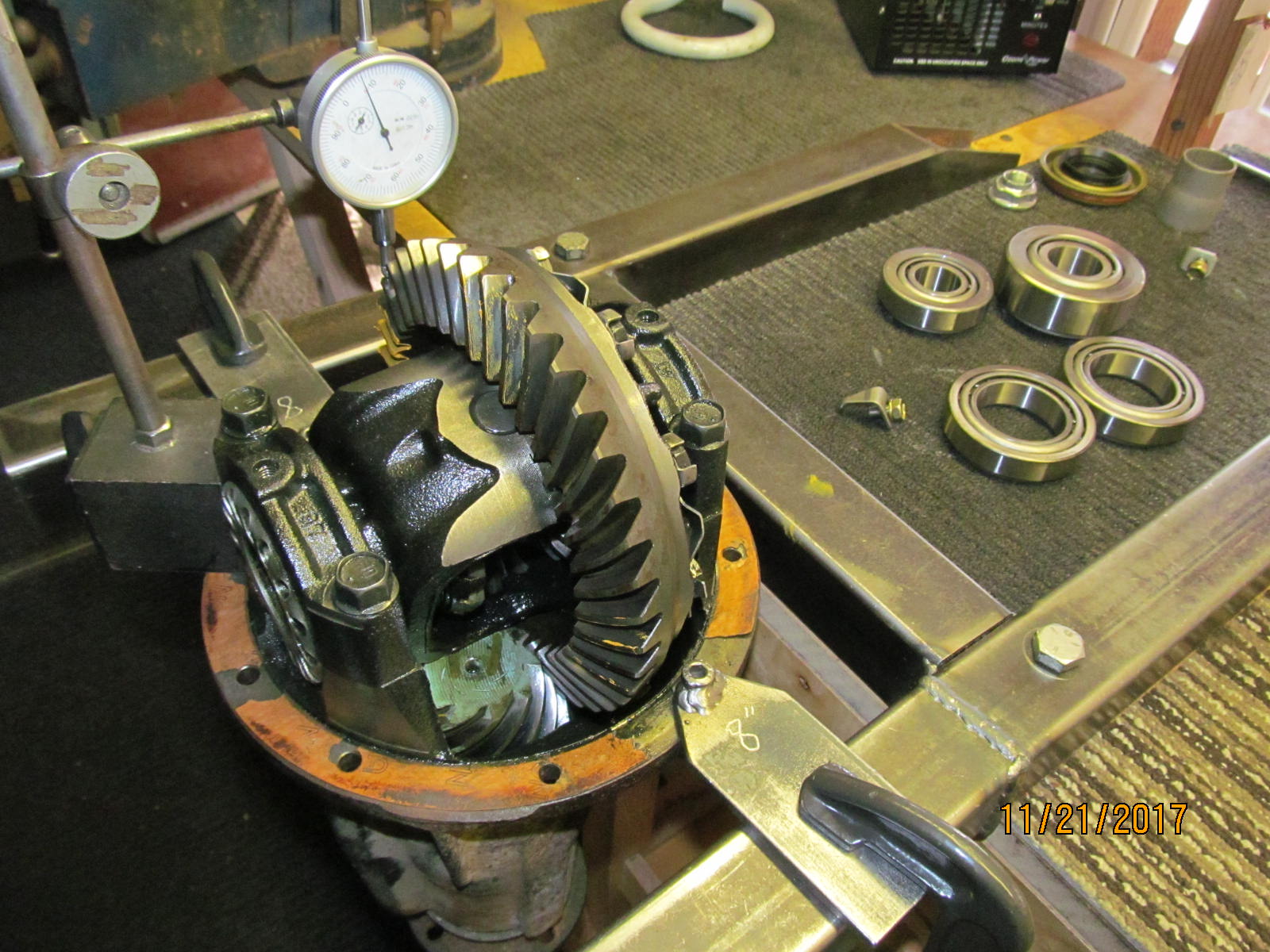

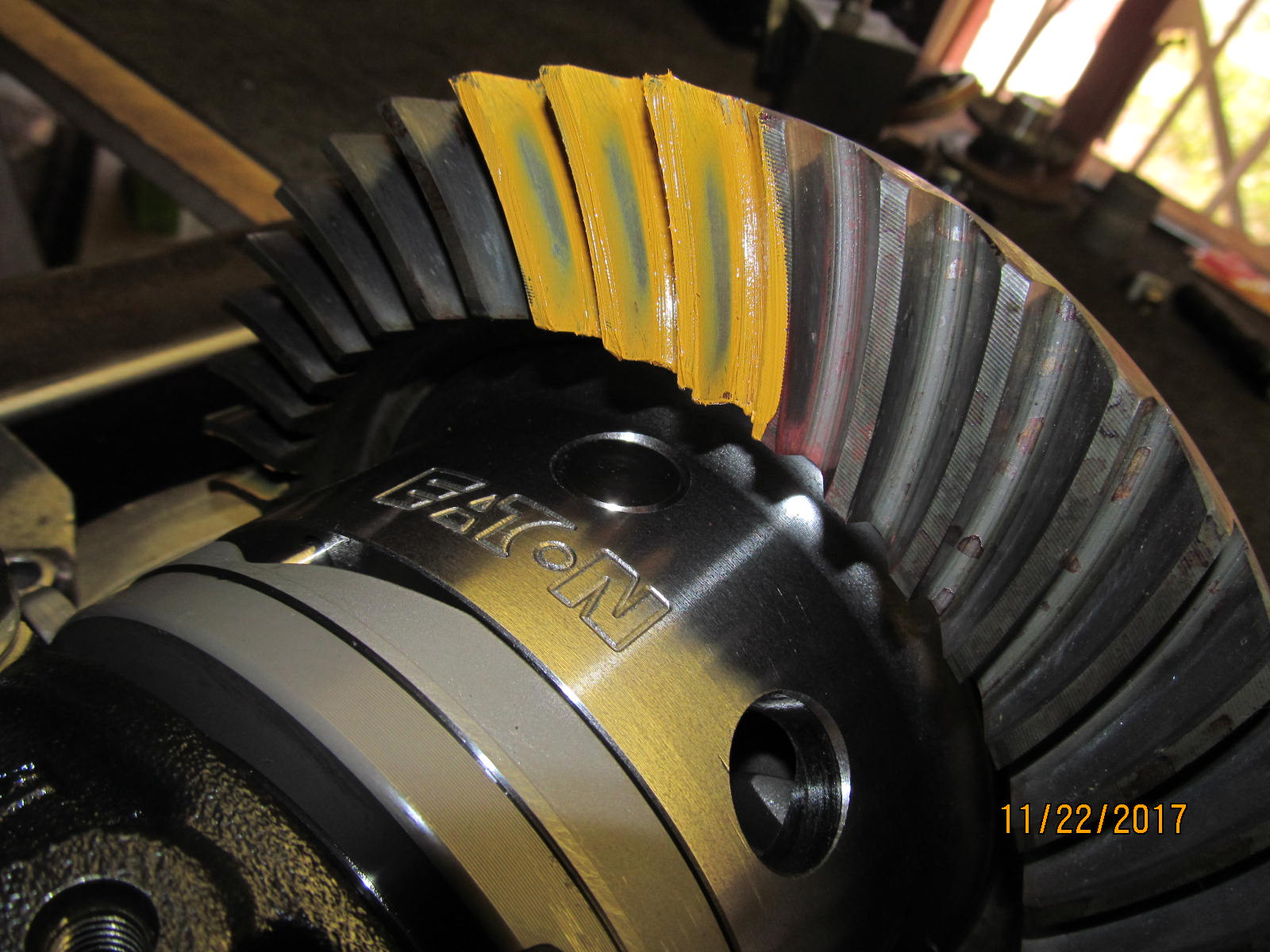

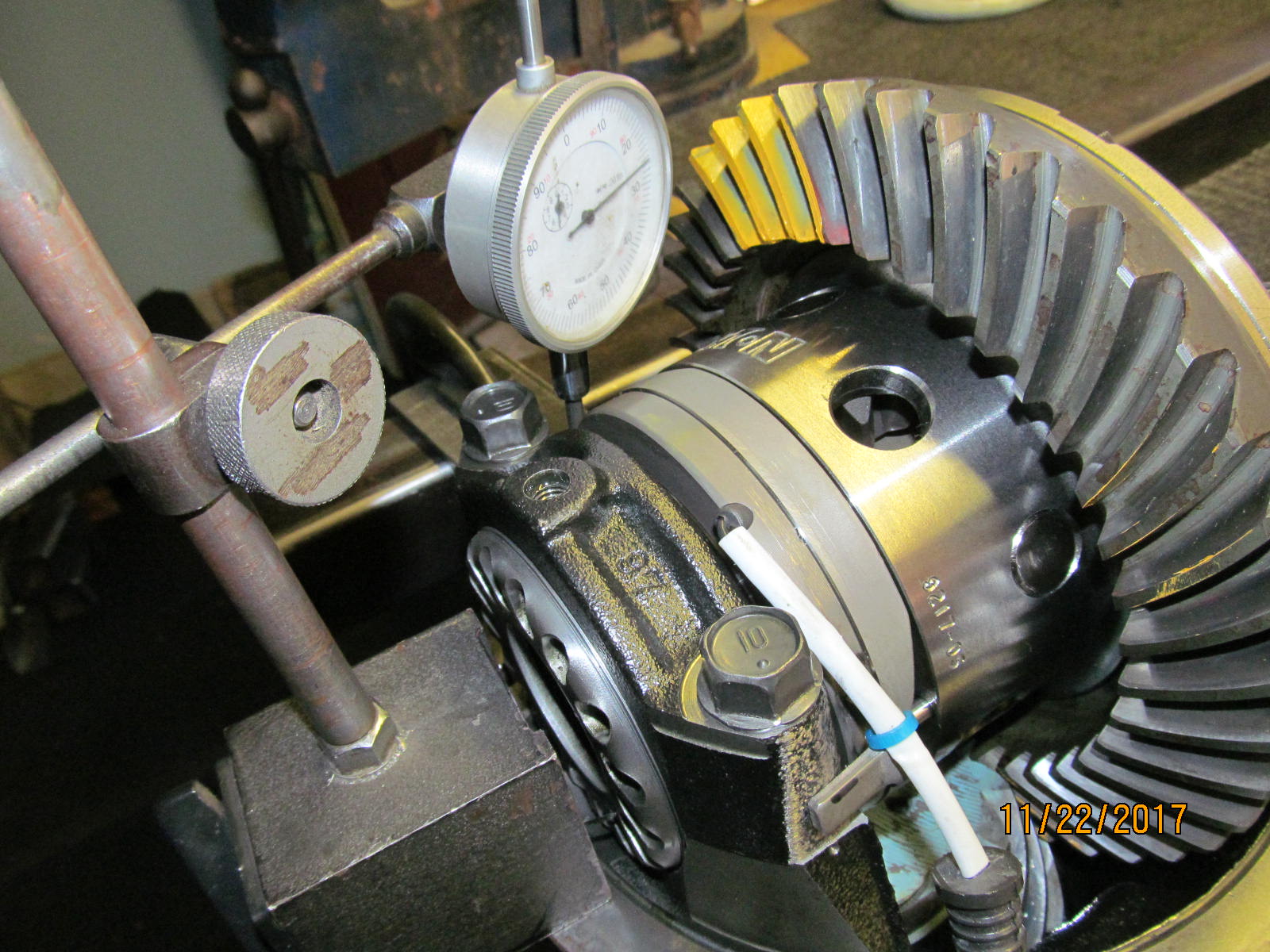

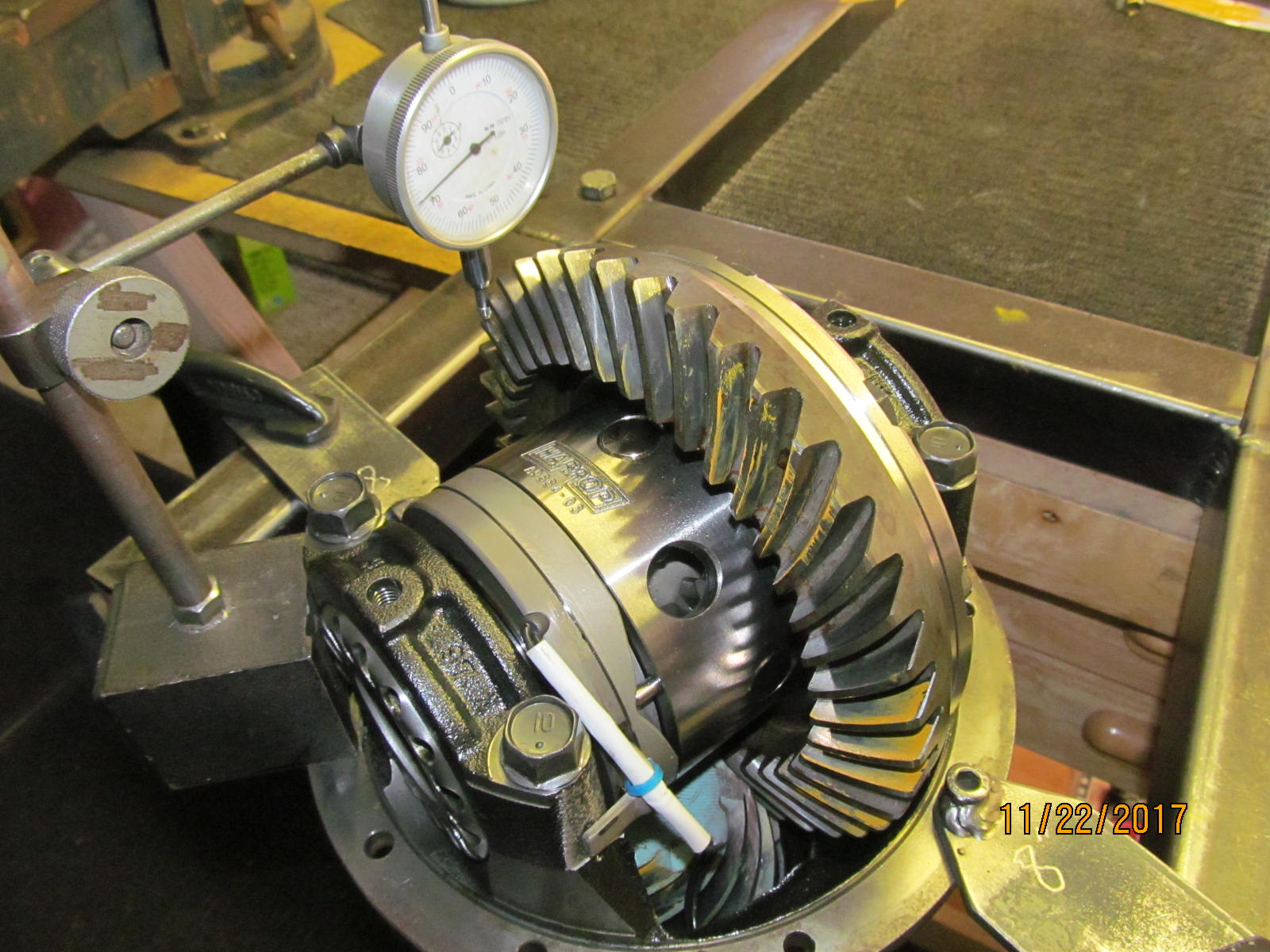

The 410 gears visually appeared aok.....but the pre-paint check tells us if the gears were wearing "out of place" which would means noisy gears.

This is the drive side and I'm very pleased with this pattern. |

|---|

|

|

Coast and looks wonderful. These gears can go another 500,000 miles if the 85W-140 gear oil is kept clean ;)

Mike-If you're reading this... switch the inner axle seals to the MarlinCrawler "eco" version....

It will keep the gear oil on this side and the grease on the other side. |

|---|

|

|

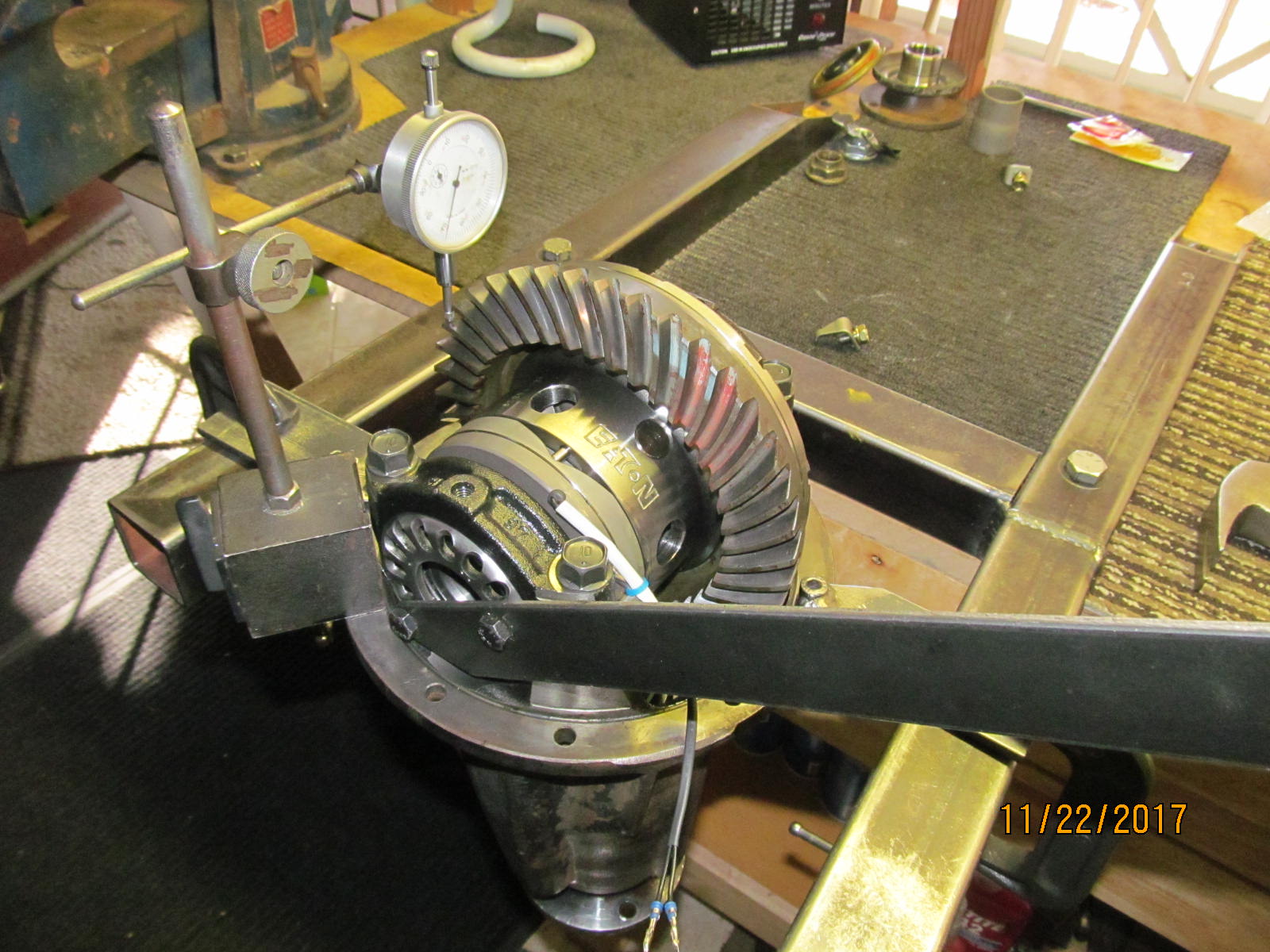

| Backlash check.....measuring in spec. |

|---|

|

|

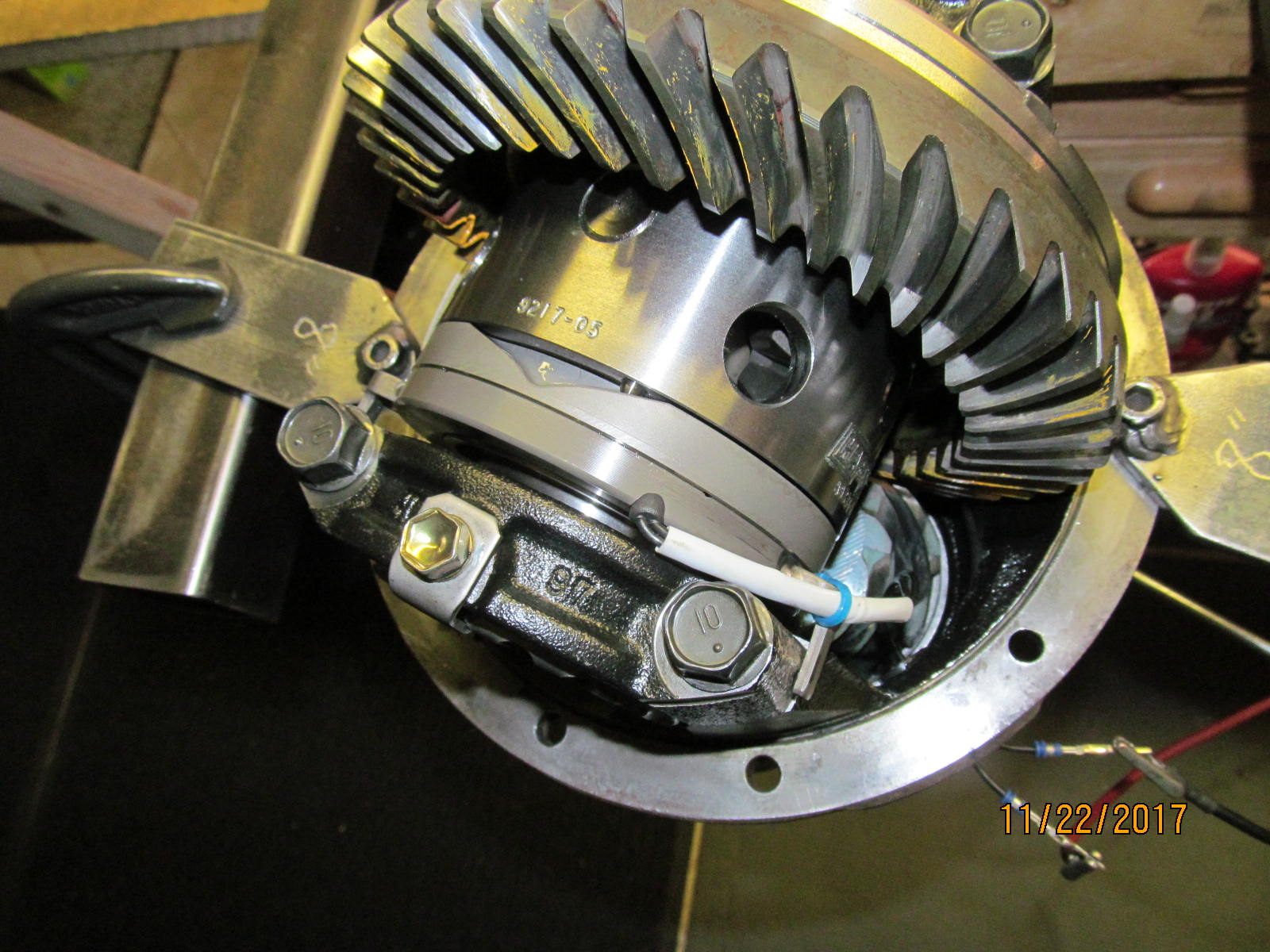

| So the original open carrier was discarded and the 410 ring/elocker are now checked for any burrs or ridges. All was great. |

|---|

|

|

| Ring gear is tapped down with the help of the lead filled plastic hammer. Sometimes, patience really is the key. |

|---|

|

|

| The last 50ml bottle of blue Loctite lasted 6 months on the bench.....upgrading now to the Bigboy 250ml and see if it will last 2.5 years. |

|---|

|

|

| 70+ ft/lb per the fsm. |

|---|

|

|

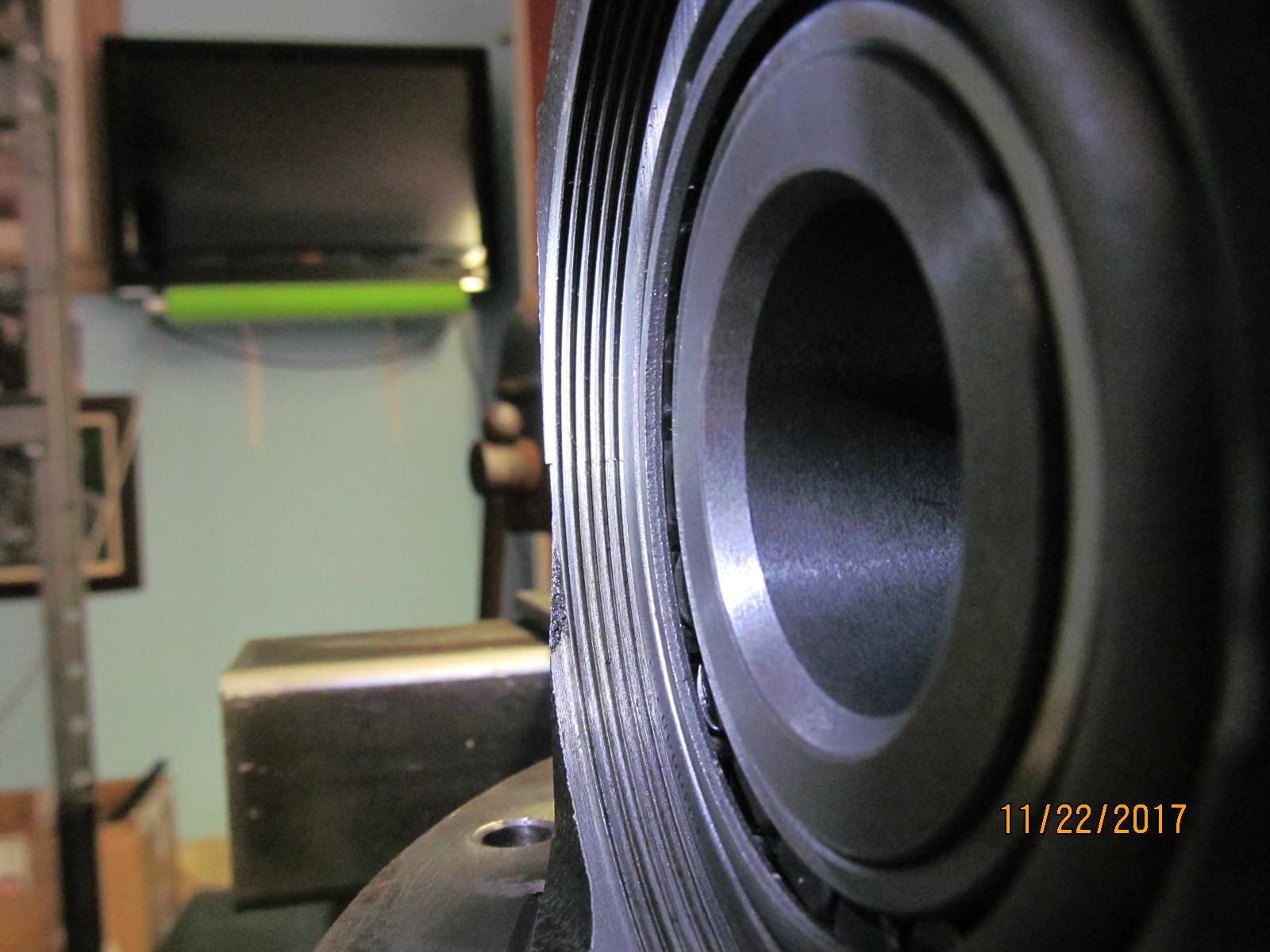

| The new carrier bearings are tapped on. Anybody guess at what Jet Li movie that is? One hint.....collar. |

|---|

|

|

| This portion is complete. |

|---|

|

|

| Now on to the pinion end of things. |

|---|

|

|

| New koyo inner bearing will be used with the original .047" pinion shim. |

|---|

|

|

The 12ton Harborfreight press is perfect for gear installs. Never in 16 years have I needed anything else.

On sale at Harborfreight for $99 right at this moment. |

|---|

|

|

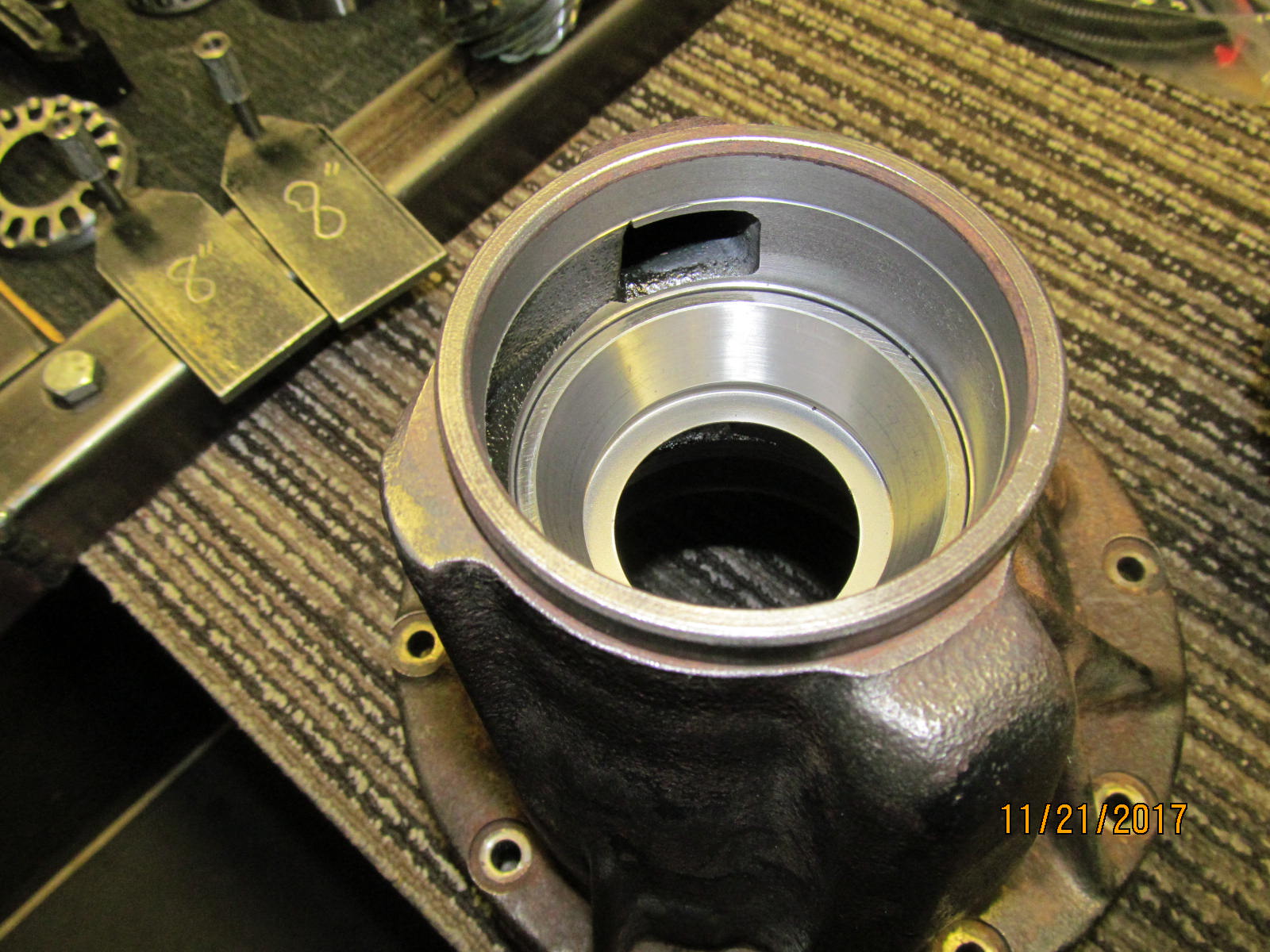

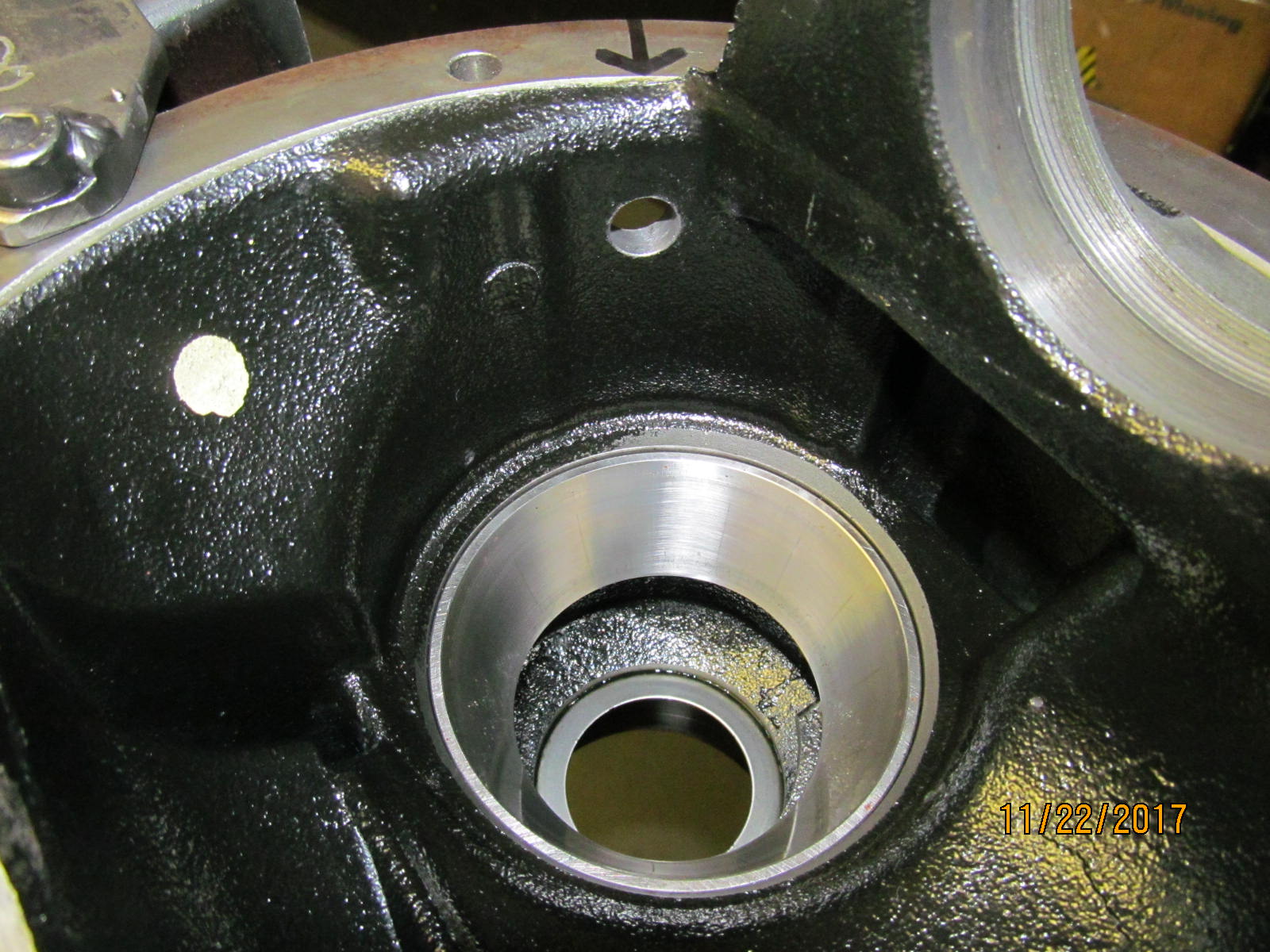

| The empty 3rd is cleaned up and now the outer race can go in. |

|---|

|

|

| '''''''''''''''''''''' |

|---|

|

|

| It was a good tight fit in the bore. |

|---|

|

|

| The larger inner race takes more patience. |

|---|

|

|

| But once it is started evenly then it will go smoothly after that. |

|---|

|

|

| 100% seated....no stress points from using a soft chisel either. |

|---|

|

|

| All 3 items are ready. Put the pinion in and tighten the nut just enough to offer some resistance. |

|---|

|

|

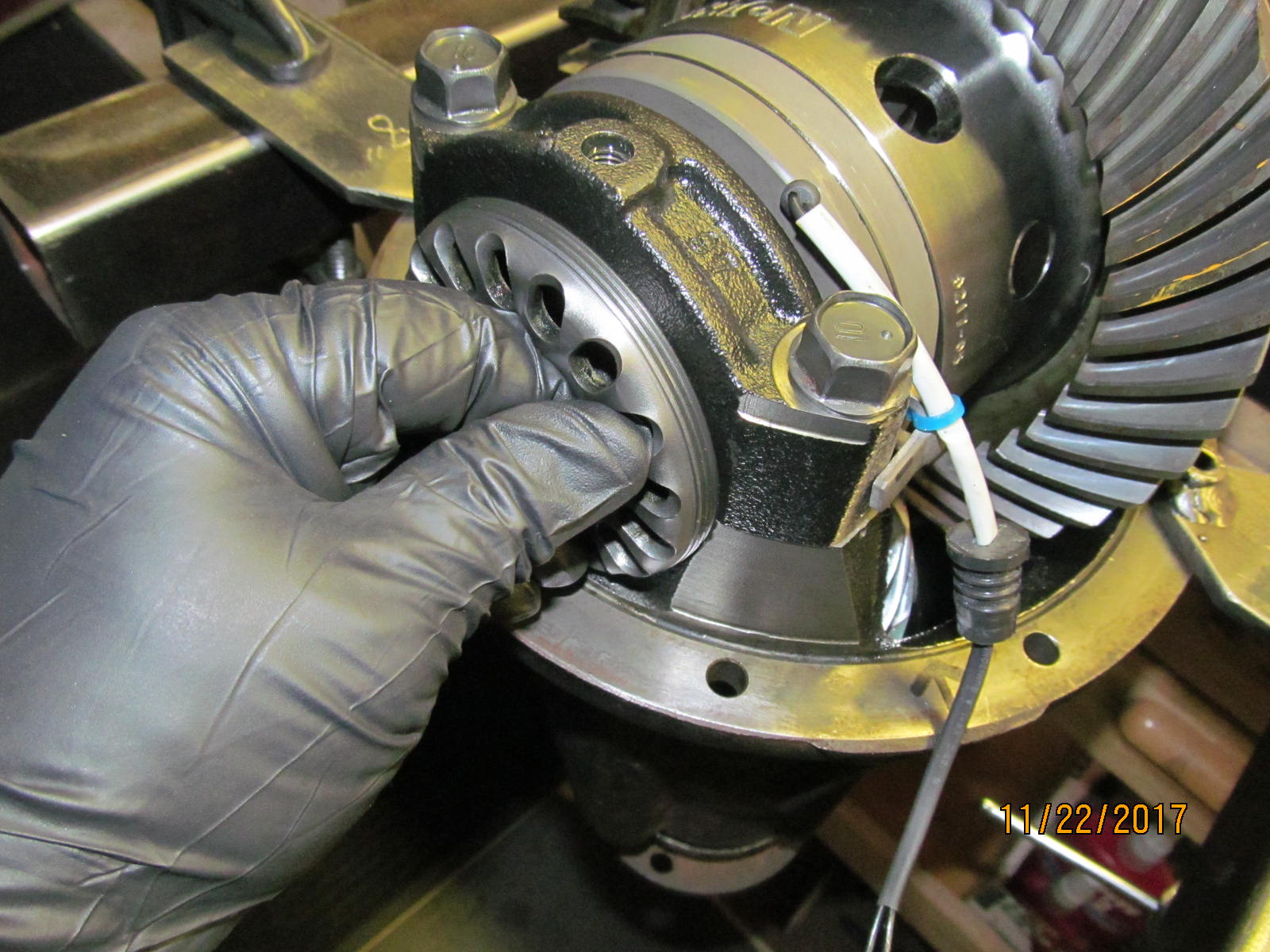

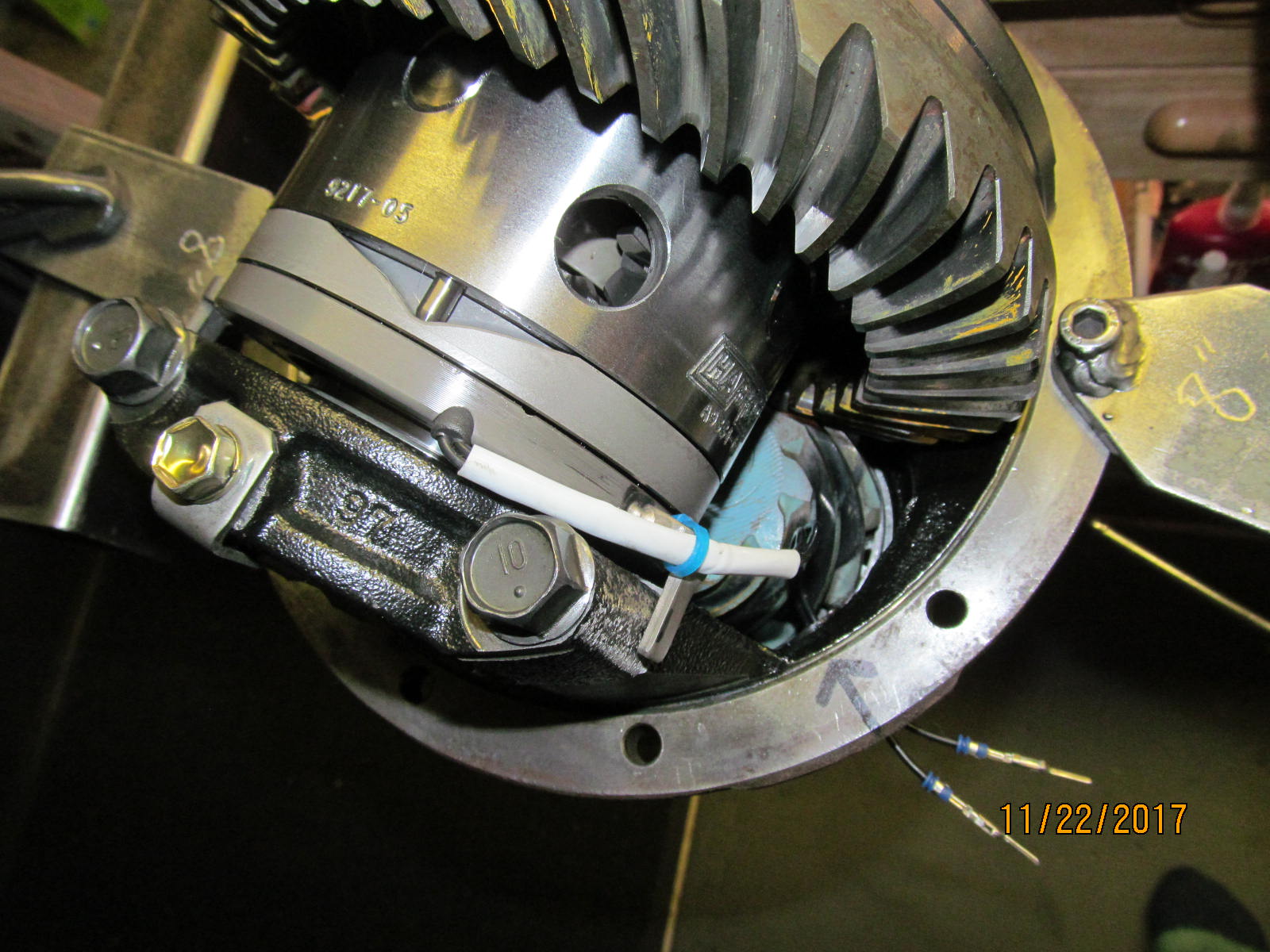

| Mount the Harrop elocker....I have a little bit of interference with the stop tab. |

|---|

|

|

| Adjust the stop-tabs a little. |

|---|

|

|

| It's not the full 2mm of freeplay but good enough for the paint check. |

|---|

|

|

| A little bit of bearing pre-load and a backlash adjustment..... |

|---|

|

|

| And it's no surprise that the drive side looks about the same as it did with the old bearings. |

|---|

|

|

| Coast......Nice. |

|---|

|

|

| To increase the freeplay, I will smooth the edges and probably hit the sides of the bearing cap with a file. |

|---|

|

|

| Same with the other side. |

|---|

|

|

| Might as well drill the .453" hole |

|---|

|

|

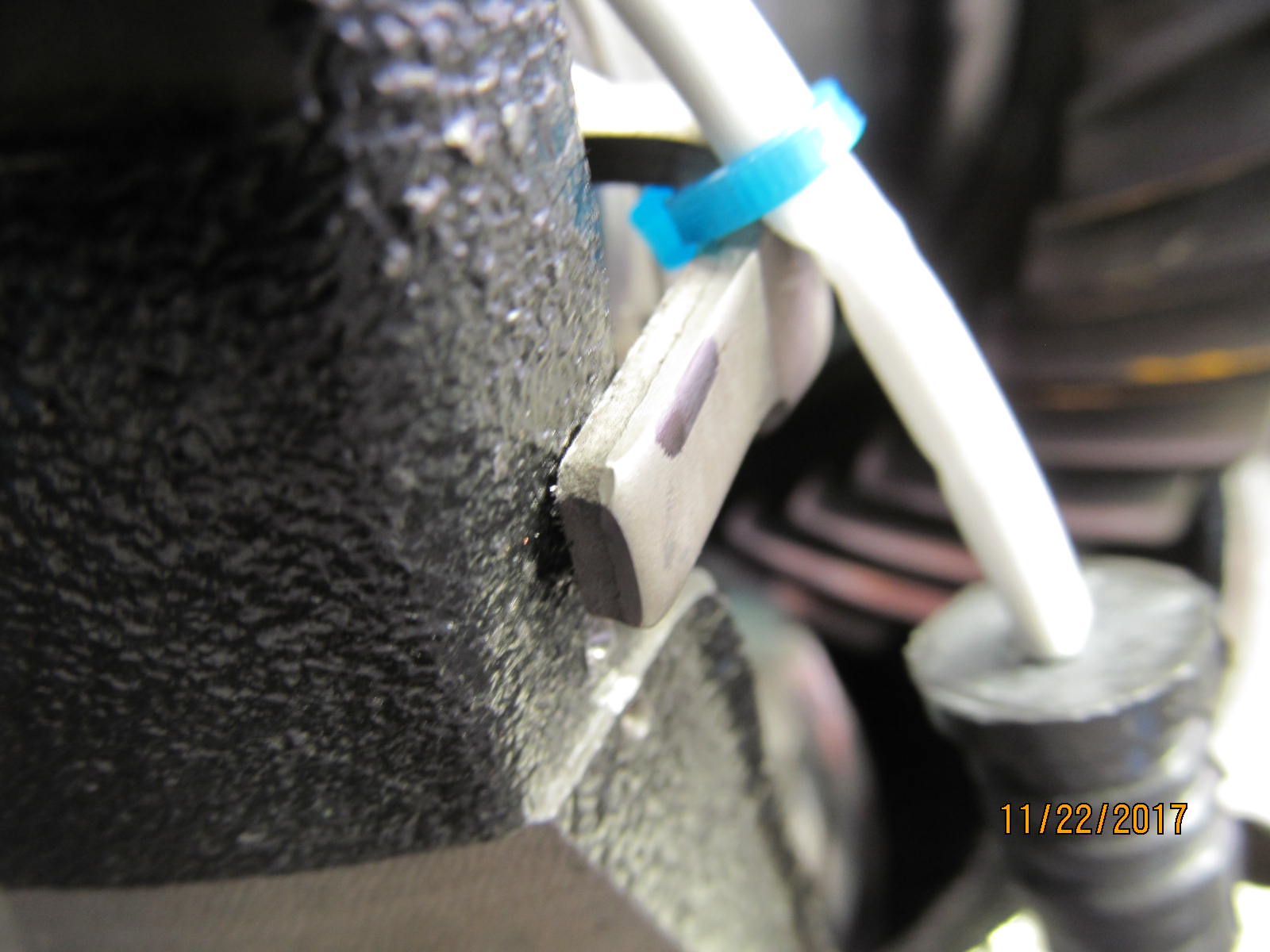

| Mark the approximate spot with a big sharpie.... |

|---|

|

|

| The hole is drilled. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| Crush sleeve time now. |

|---|

|

|

| Marlin seal is one of the best guarantees against leaks. |

|---|

|

|

| The original flange has been wire brushed, cleaned, and sanded with #1500 extra-fine paper. A light coating of gear oil has also been applied. |

|---|

|

|

| A nice, smooth 11 of pinion preload has been accurately measured. |

|---|

|

|

| DING!! |

|---|

|

|

| Slide the bearing cap in horizontally....then thread the 2 bolts. |

|---|

|

|

| Threads for the adjusting wheel are perfectly lined up so now the cap bolts can be tightened properly. |

|---|

|

|

| Bingo....the adjuster wheel threads very nicely into the bearing cap. |

|---|

|

|

| I have my 2mm of freeplay now I note. |

|---|

|

|

| Verifying the 4 bolts are all torqued to 70 ft/lb. |

|---|

|

|

| Plenty of preload on the carrier bearings(8 in/lb) and the backlash is "spot on"(.0055" minimum). |

|---|

|

|

| Ring gear is inscribed. |

|---|

|

|

| Now to check the elocker operation. |

|---|

|

|

| Ohms measured at 3.8. |

|---|

|

|

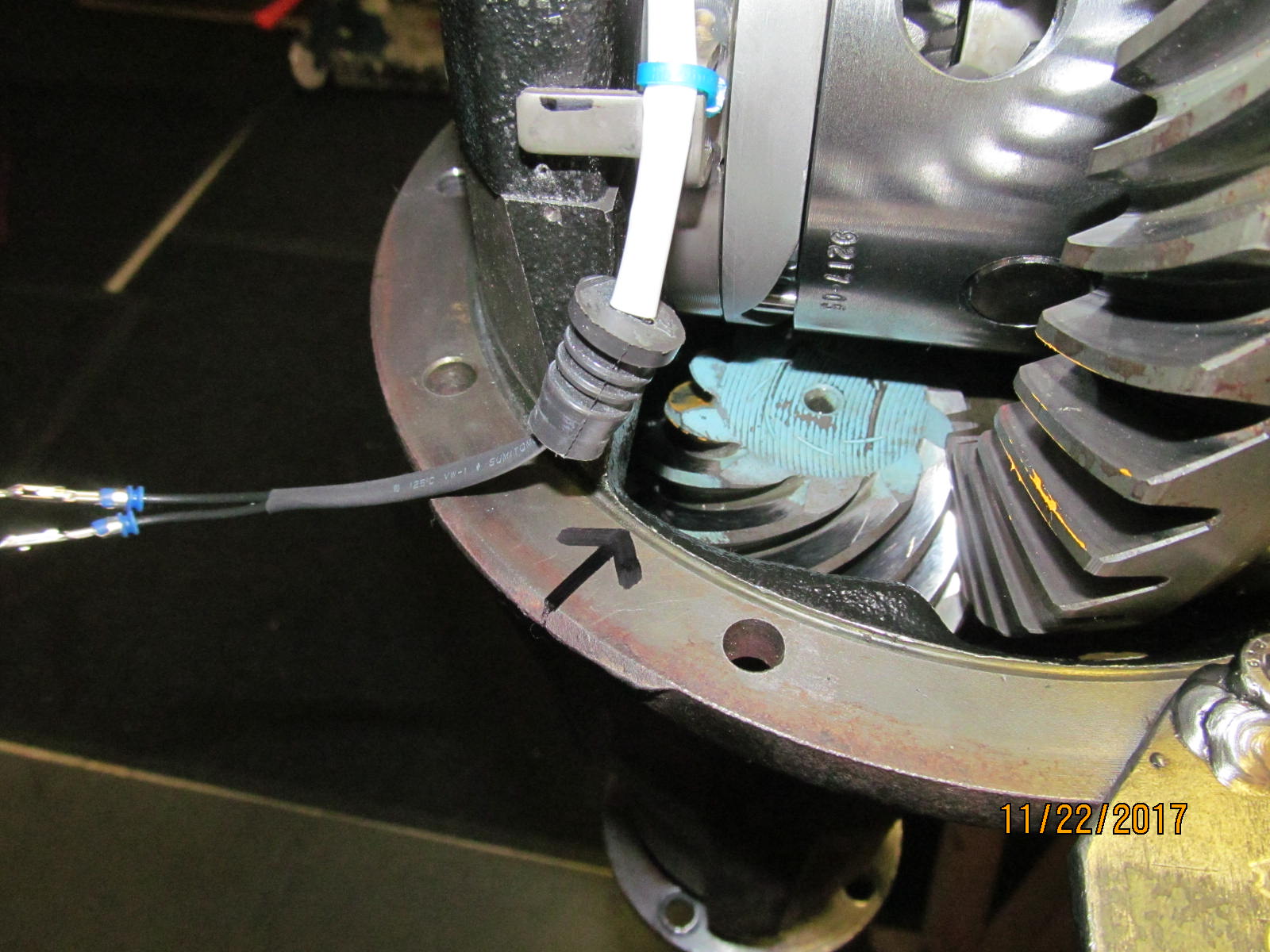

| Then 12 volts is applied..... |

|---|

|

|

....to the 2 wires in the lower right and the order does not make any difference....they have no polarity.

Ring gear is then turned and the 3 steel pins get pushed into the case. |

|---|

|

|

| Then release the 12 volts and the steel pins pop out instantly. |

|---|

|

|

| The hi-pinion elocker really takes nicely to a coat of black. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

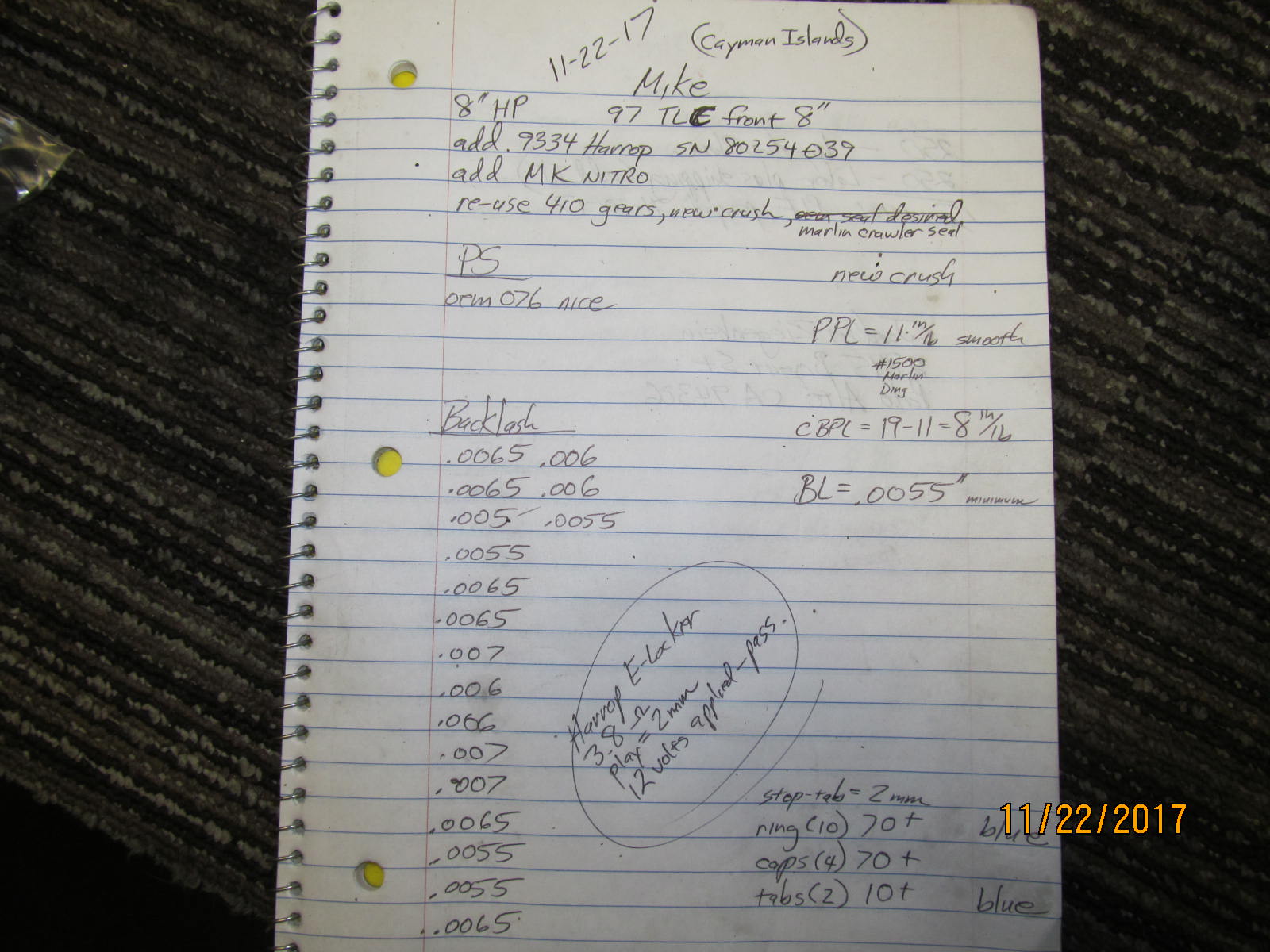

| A snapshot of the notes. |

|---|

|

|

| Packing the 3rd with the harness. |

|---|

|

|

| .................... |

|---|

|

|

| Here it comes, Mike. |

|---|

|

|

|