|

Here's a shot of Brian on trail #42 in the Phoenix, AZ area.

Specs -

'86 Toyota LWB

'89 22RE

W56 Transmission

Dual Marlin Crawler T-cases

37x13.5 Pitbull Rockers on Allied Beadocks

Front axle - '85 Toyota w/ ARB locker, Longfields...

Rear Axle -ARB locker

Warn winch, Flatbed, full exo cage, custom f/r bumpers..

|

|

|

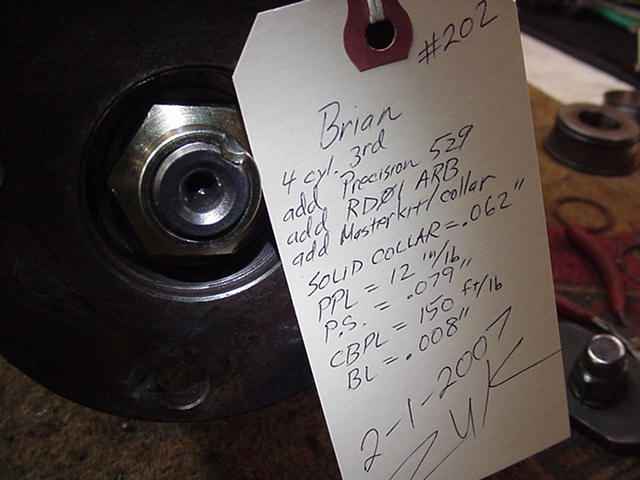

Brian is local to me and brings over the RD01 ARB Locker. A new master kit/solid collar and quality 529 8"

gears are going in the 4 cylinder carrier.

|

|

|

This model has been dis-continued and is being replaced by the RD23 model. The RD01 uses 4 cylinder bearings

and a "captured" o-ring seal housing(ours had the RD23 style seal housing). The newer RD23 is a semi-floating

design and also uses V6 dimensioned bearings.

|

|

|

I had to take a peek inside....

|

|

|

well made...

|

|

|

...

|

|

|

excellent machine work.

|

|

|

I started by tapping in the pinion races. These "harbor freight chisels" are just mild steel

so they're safe to use for this application.

|

|

|

Red loctite and 75 ft/lbs all the way around.

|

|

|

Press the carrier bearings on and line up the "adjuster nut"

|

|

|

tighten up the cap bolts finger tight...

|

|

|

Apply some pressure with the rag and turn the ring gear back and forth 3 times...

|

|

|

082 is a little too deep.

|

|

|

coast agrees

|

|

|

This means the carrier has to be broken down all the way. Press the pinion out to prevent

damage to the outer pinion race.

|

|

|

Press the inner pinion bearing off to access the shims...

|

|

|

Remove 3 thou and assemble the .079" shim pack...

|

|

|

Very acceptable.

|

|

|

Good.

|

|

|

Using a hammer to equalize the bearing tension...

|

|

|

Key to long gear life and maximum strength is maximum carrier bearing pre-loading.

|

|

|

Click goes the 150 ft/lb torque wrench. Actual pre-load as measured in earlier tests was 15 in/lb on the bearings

themselves.

|

|

|

The meat of the gear install is done. Time to drill (7/16" drill bit) and tap with a 1/4 NPT tap.

|

|

|

Liquid PTFE thread sealant was used on the pipe thread to keep the gear oil in.

|

|

|

The seal housing with the 2 o-rings must be carefully wiggled on with lots of gear oil.

|

|

|

Having a service loop is probably a good thing. The copper tubing forms very easy.

|

|

|

...

|

|

|

I was able to check clearances using the dummy cover I have. Lots of room for the copper line.

|

|

|

The retainer clip easily goes in place.

|

|

|

Loctite the Toyota tab in place.

|

|

|

A quick double-check to verify 80 ft/lb on the cap bolts.

|

|

|

The fat o-rings get plenty of gear oil.

|

|

|

Make sure to screw on the correct side.

|

|

|

45~50 inch/pounds feels about right for a good seal.

|

|

|

With a new seal installed and clean threads, the original Toyota flange is installed.

|

|

|

Ready to install. :)

|

|