|

Harrop Rear 9.5" Install For Ralph's 2009 Landcruiser 200 Series

|

|

(62 BIG pics loading)

|

|

MAR 29 2017

|

|

|

|

Ralph has a clean looking '09 TLC.

|

|

|

|

|

150,000 miles with factory 3.90 gears.

|

|

|

|

|

Received this particular Harrop model directly from Australia.

|

|

|

|

|

A box in a box.

|

|

|

|

|

Box in a box in a box.

|

|

|

|

|

Model 9574 elocker.

|

|

|

|

|

.................

|

|

|

|

|

A short time later this arrived from Ralph. The diff itself is amazingly heavy for a stocker....83.6 pounds just for the diff.

|

|

|

|

|

..................

|

|

|

|

|

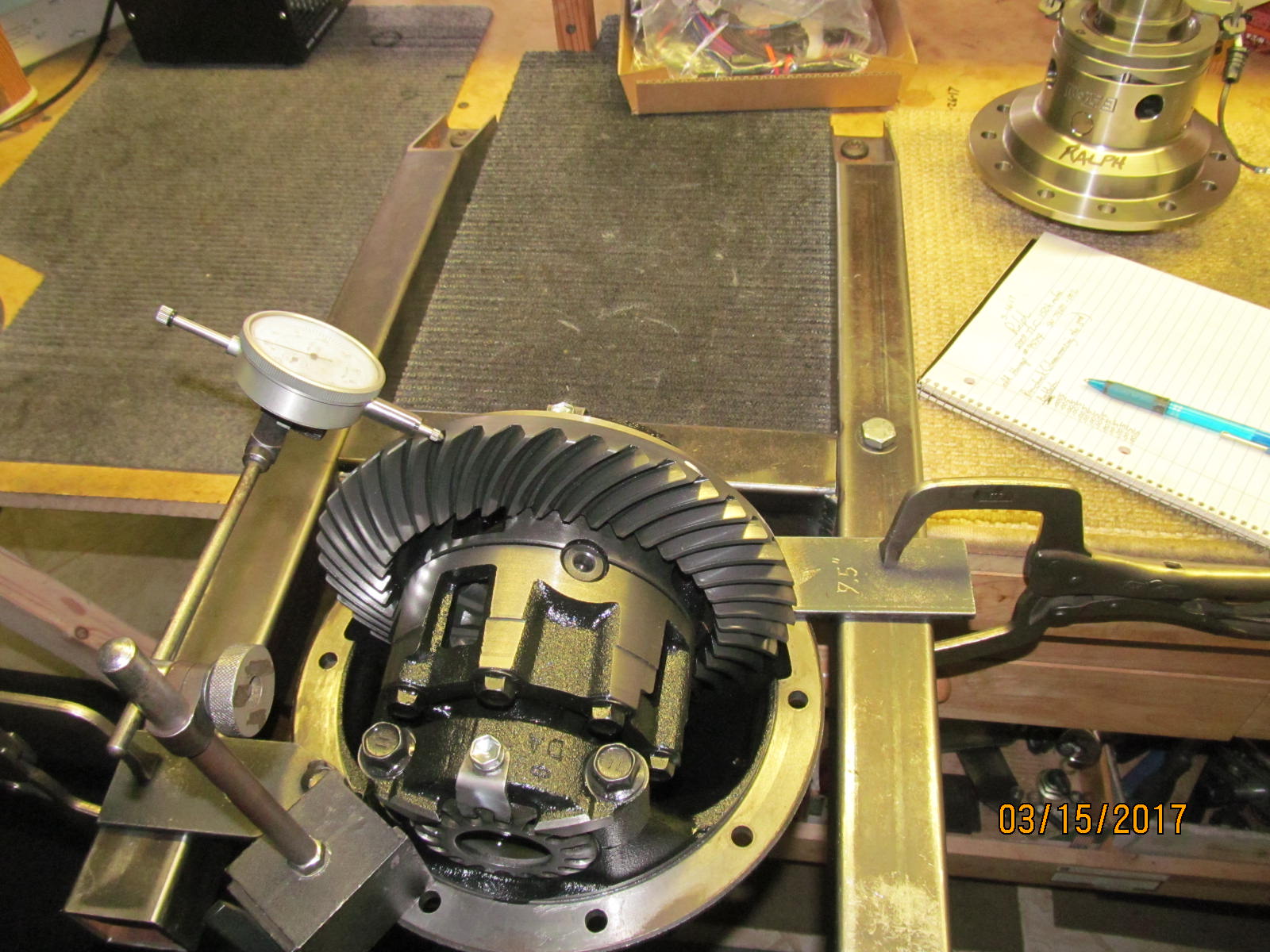

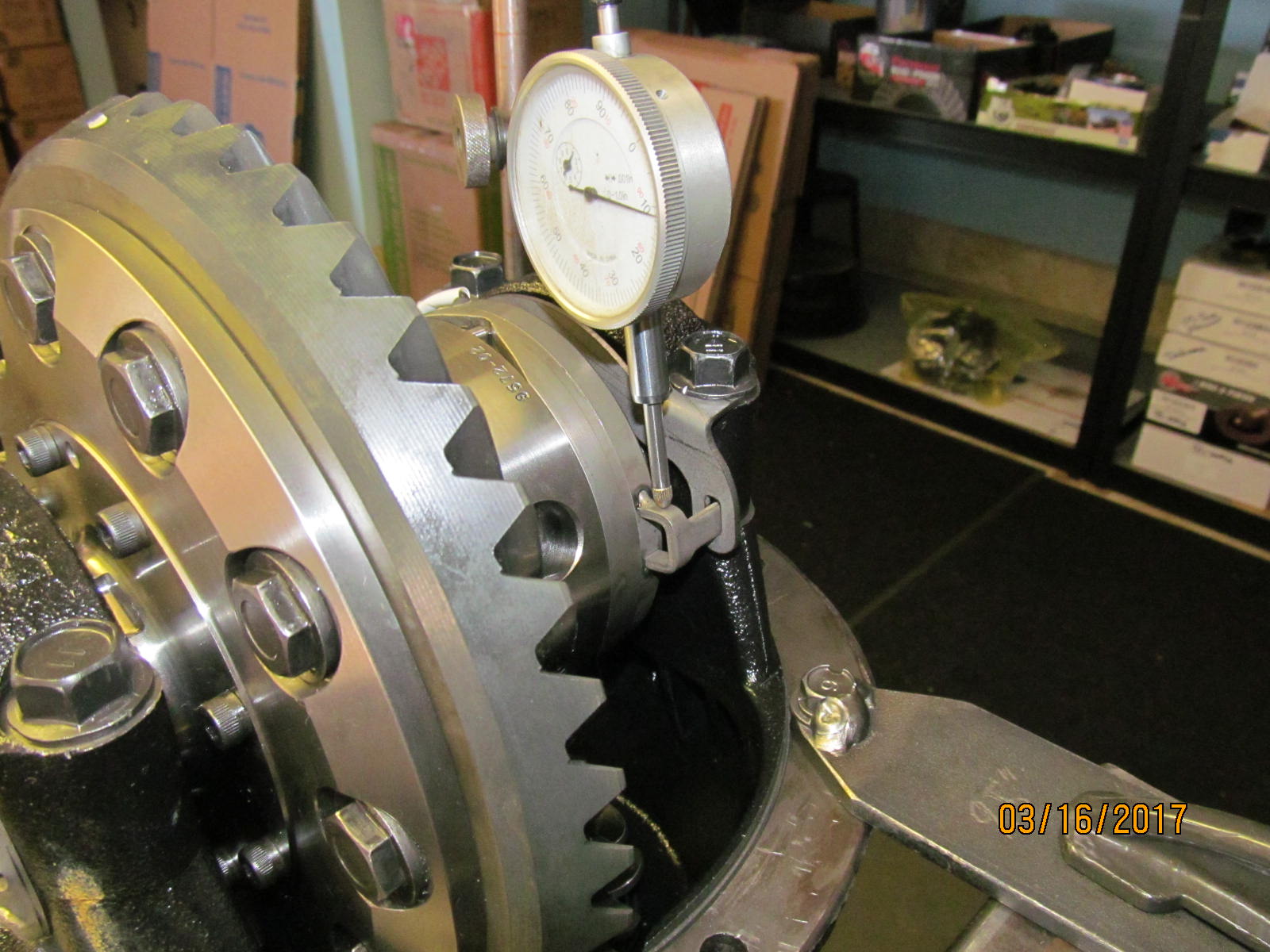

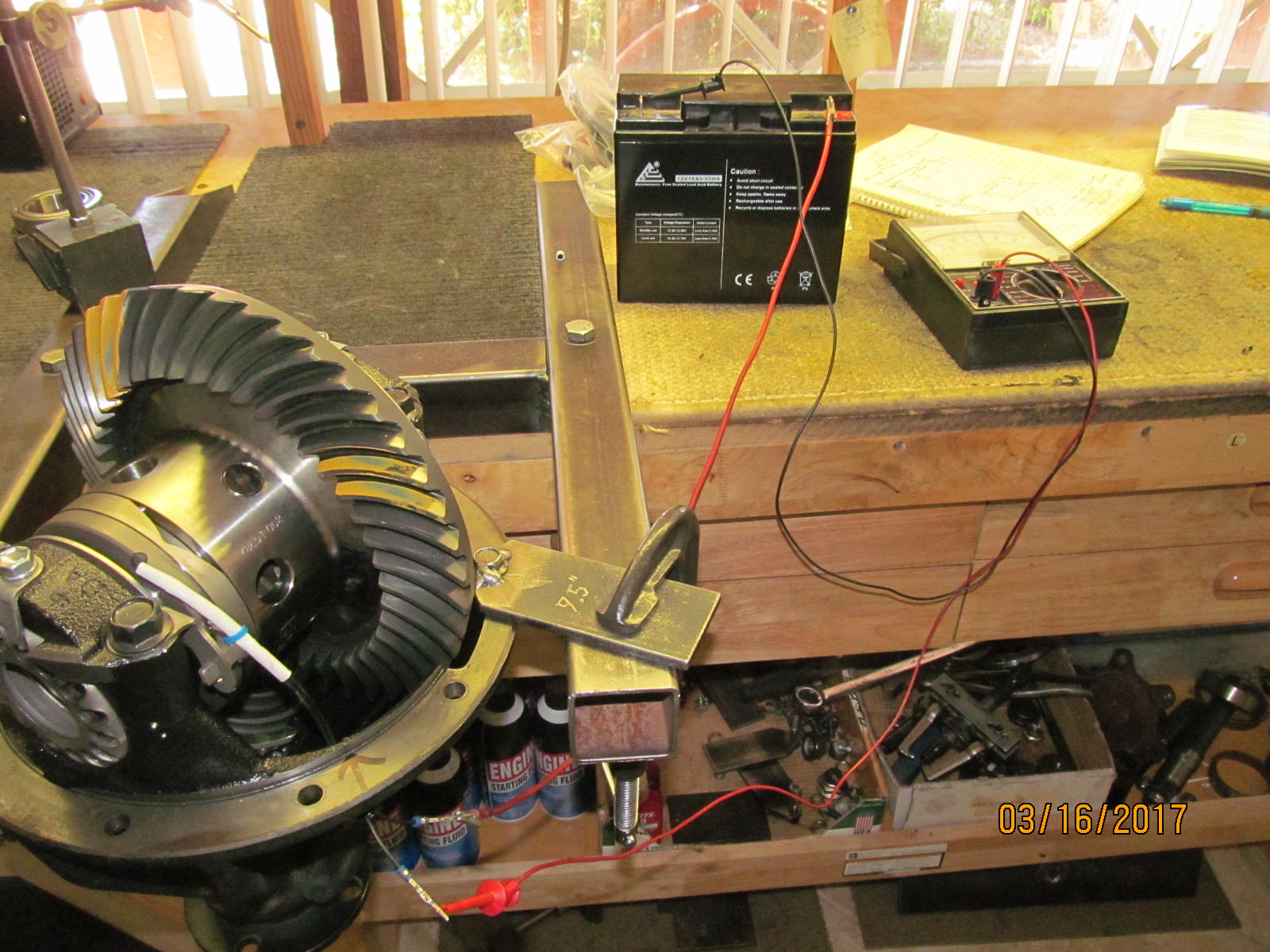

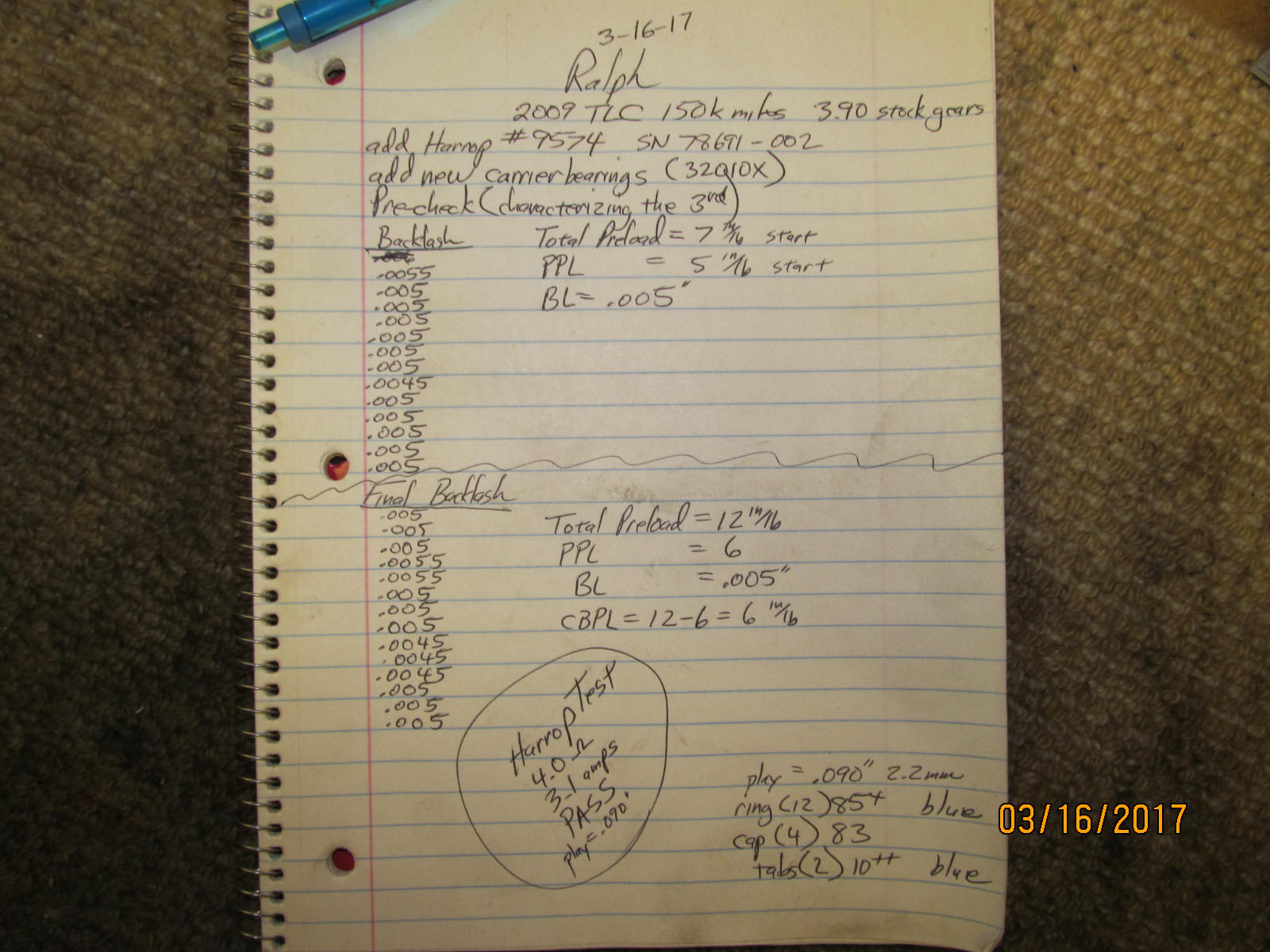

Before the partial teardown the backlash is recorded from every 3rd tooth.

|

|

|

|

|

Bearing preloads are noted.

|

|

|

|

|

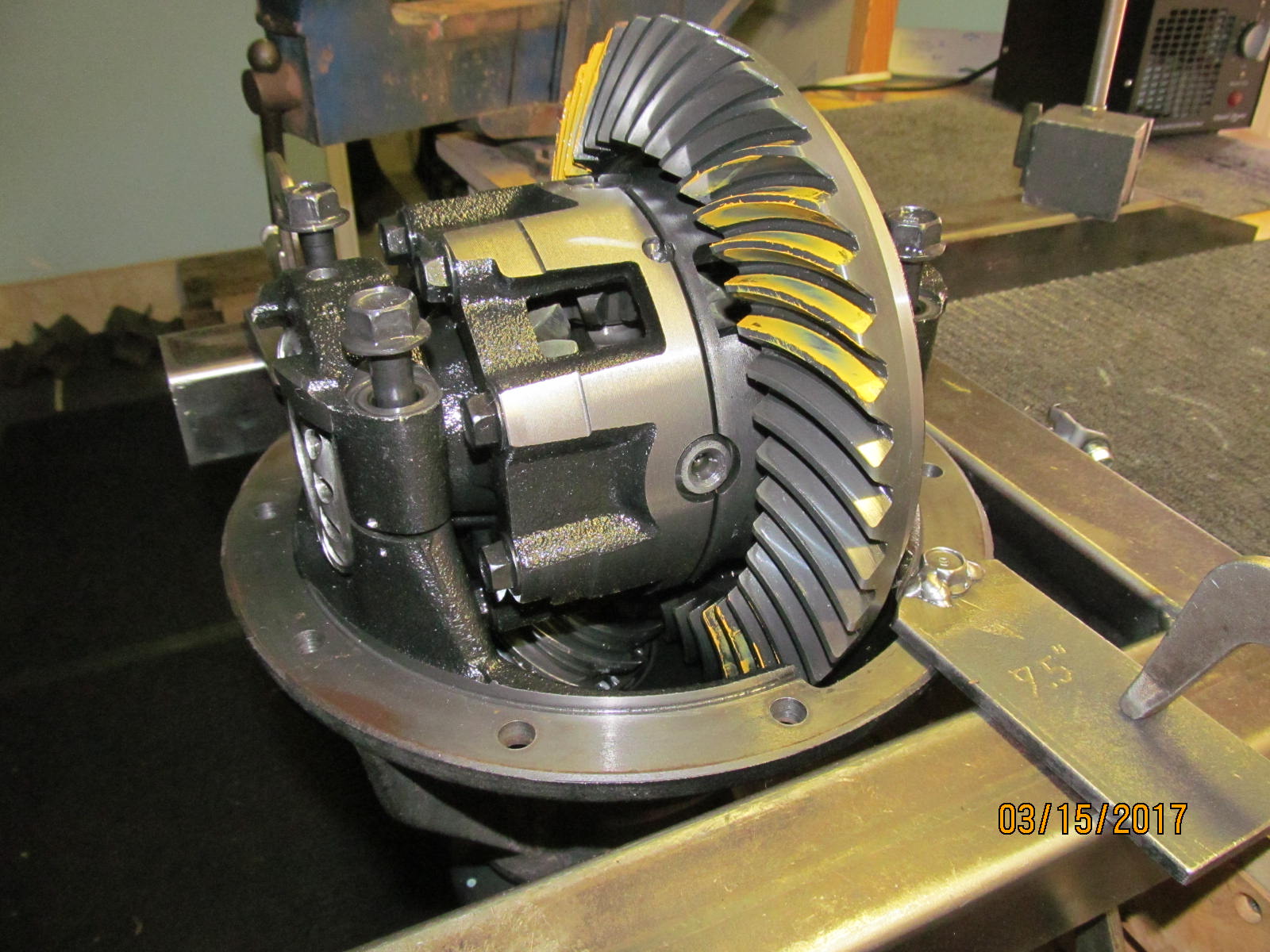

Not required but the teeth are painted. Drive side looks good.

|

|

|

|

|

Coast side looks very nice.

|

|

|

|

|

Drive side on the reverse painted teeth.

|

|

|

|

|

Coast on the reverse painted teeth.

|

|

|

|

|

Now down to business...mark 1 bearing cap and then remove both caps.

|

|

|

|

With the diff case out now I can get a clean measurement on just the pinion bearing preload....right at 5 in/lb which is

very good for 150,000 miles on it.

|

|

|

|

|

..................

|

|

|

|

|

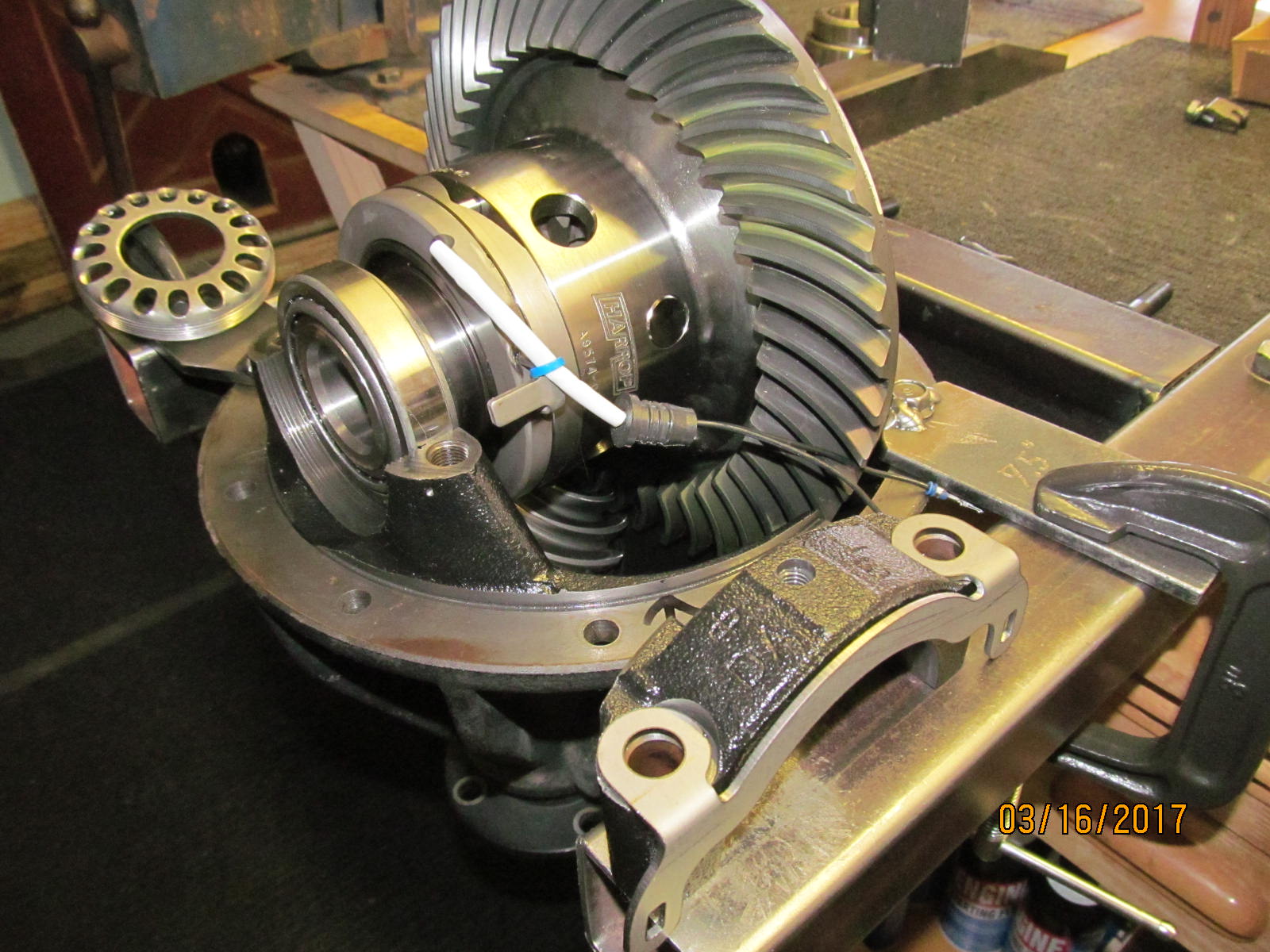

The original plan was to swap the ring gear over to the Harrop and possibly re-use the "old" carrier bearings.

|

|

|

|

|

The original bearings are removed. The wear and tear from 150,000 miles can even be seen in the above pic.

|

|

|

|

|

.........................

|

|

|

|

|

The Makita 6905H electric impact makes quick work of removing the 12 ring gear bolts.

|

|

|

|

|

Ring gear is tapped off.

|

|

|

|

|

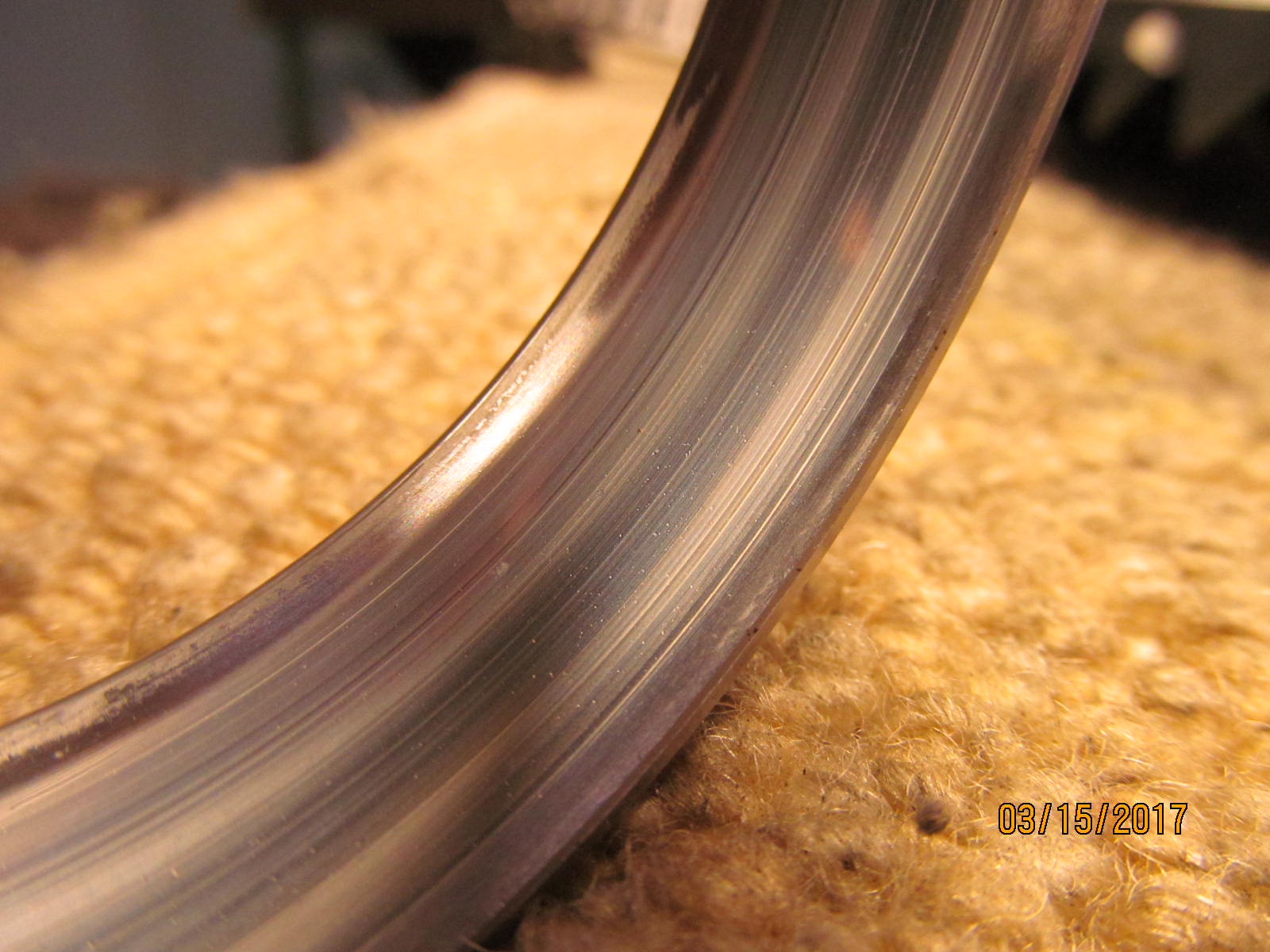

Some streaks in the rollers.

|

|

|

|

|

Race has seen better days.

|

|

|

|

|

......................

|

|

|

|

|

Ralph was in complete agreement about using new Koyo carrier beariings.

|

|

|

|

|

................

|

|

|

|

|

The ring was a tight fit....no problem for the 12 ton press....probably less than 1 ton of actual pressure.

|

|

|

|

|

Blue Loctite and 85 ft/lb on all 12 bolts.

|

|

|

|

|

Carrier bearings are tapped on.

|

|

|

|

Nothing needs to be done to the pinion end of things. It still has 5 in/lb of preload and it still turns very smoothly

as I'm doing in the photo.

|

|

|

|

|

Before the Harrop is mounted the .453" hole has to be drilled in this area.

|

|

|

|

|

Done.

|

|

|

|

|

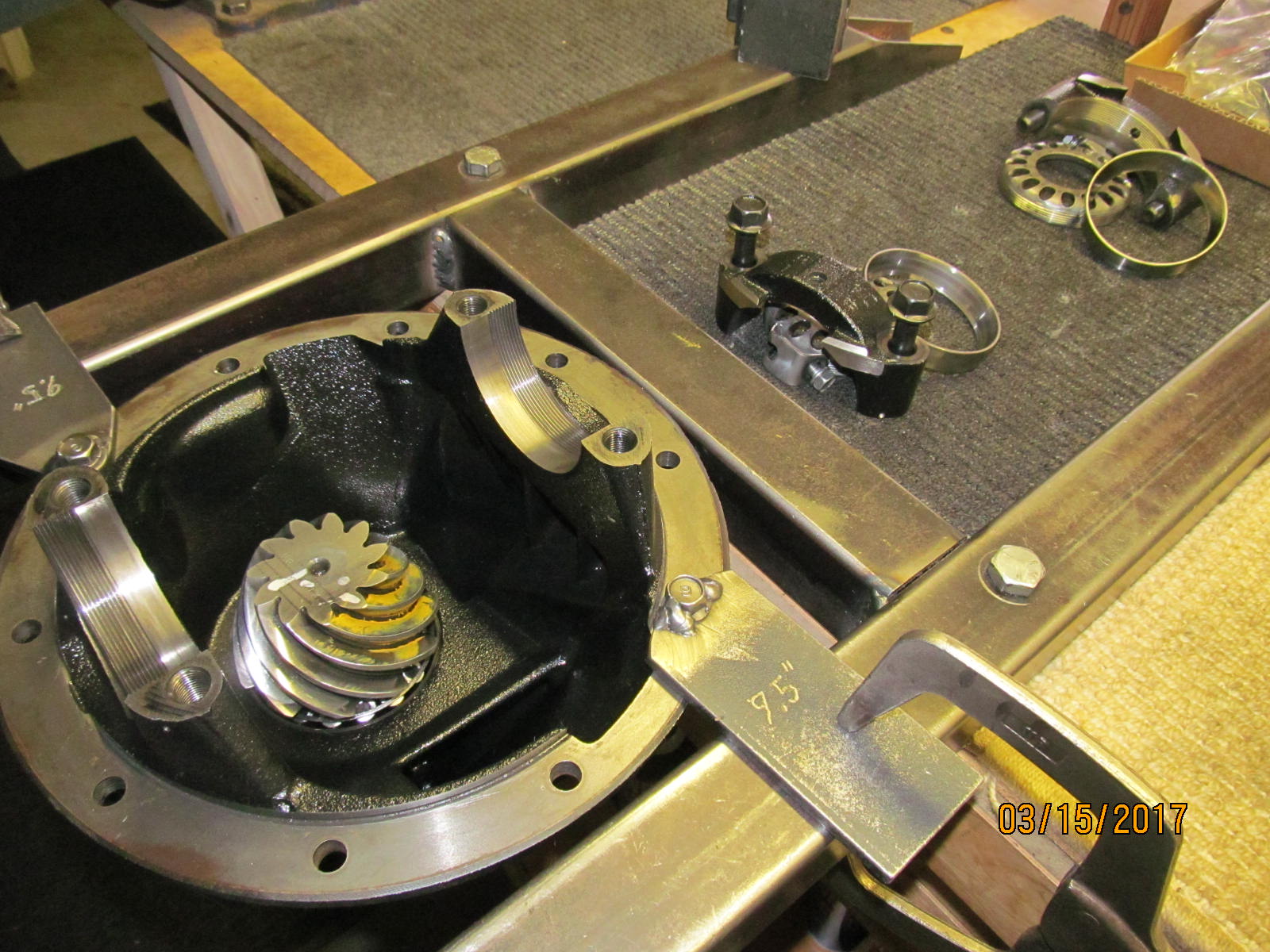

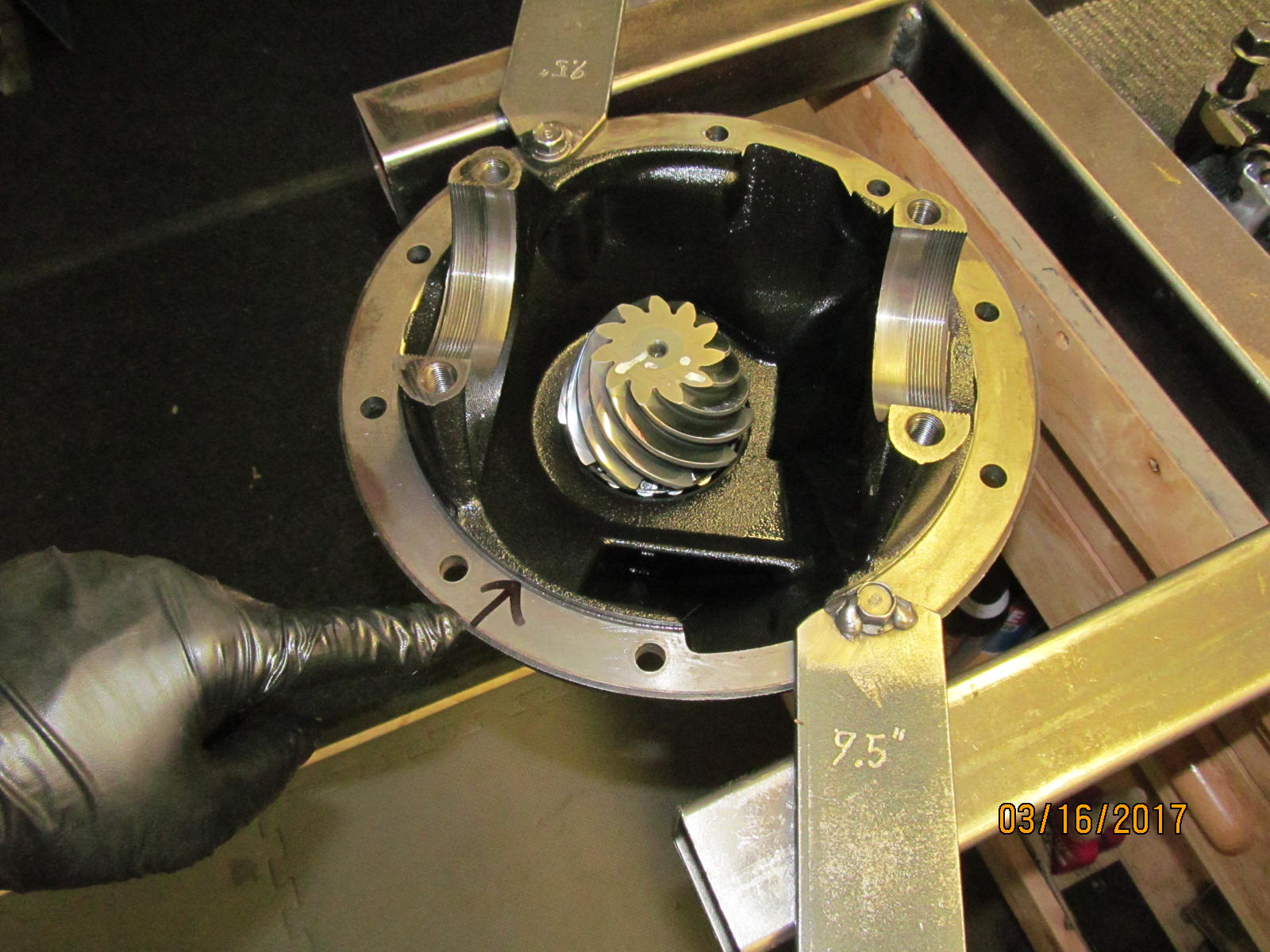

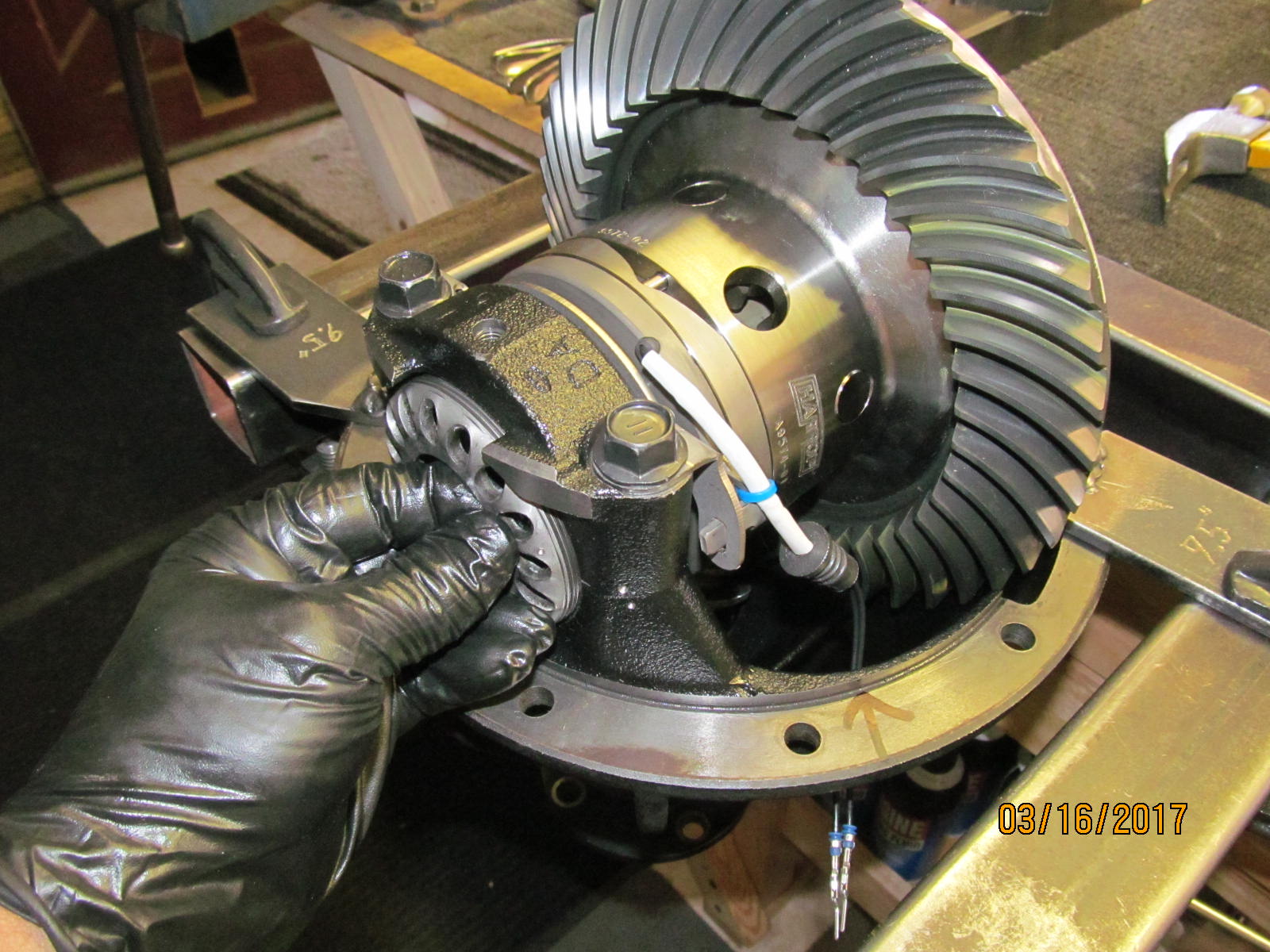

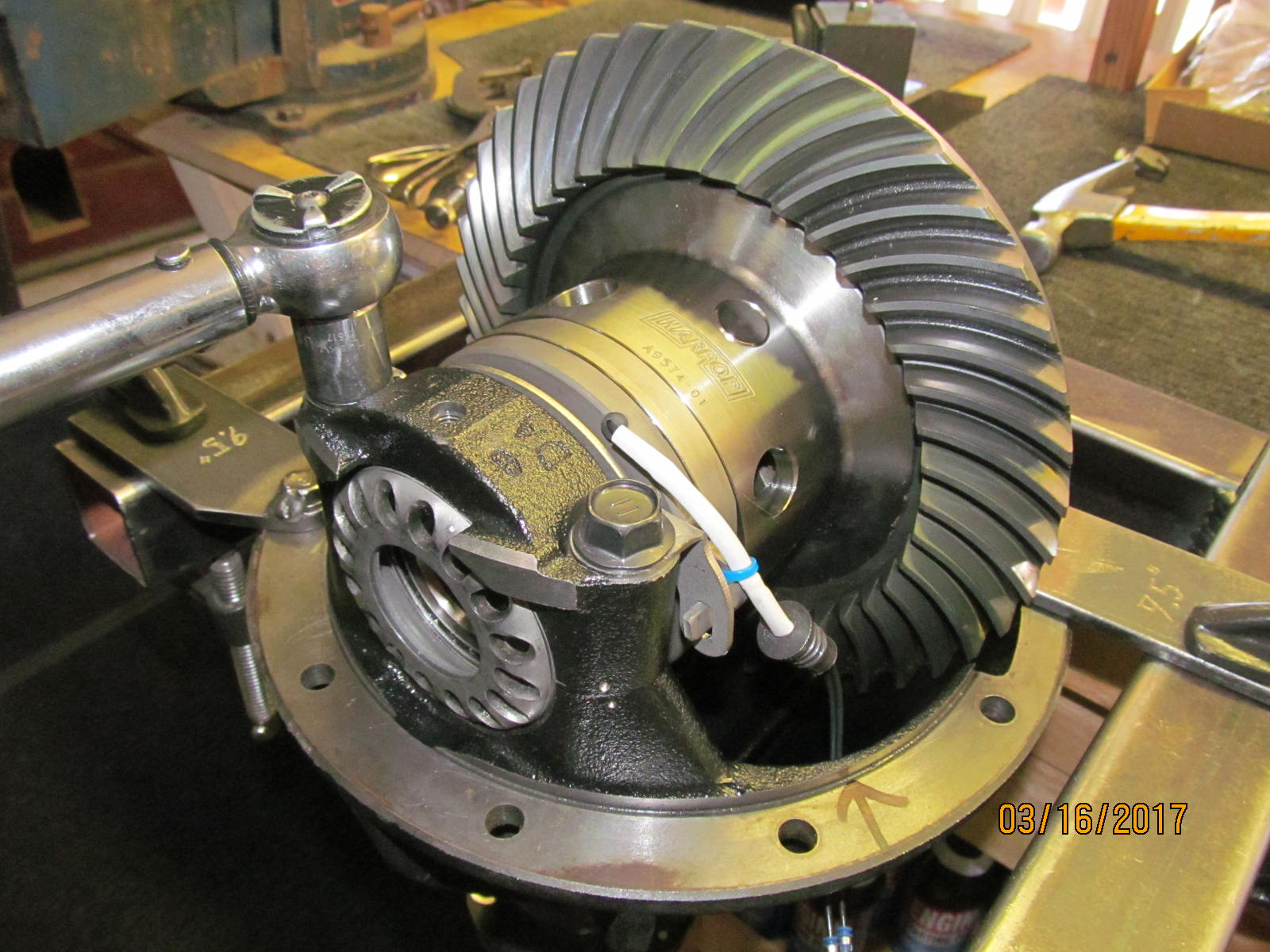

Harrop is placed in the diff carrier....

|

|

|

|

The anti-rotation bracket supplied with the Harrop has to be jiggled in place as shown. Ever so light taps to move

the bearing cap around.

|

|

|

|

|

Thread the wheel adjuster in place.

|

|

|

|

|

Check the freeplay of the tabs. I had to make some adjustments and the final freeplay checked in at .090" which is just over 2mm.

|

|

|

|

|

These bearing cap bolts were tightened to 83 ft/lb.

|

|

|

|

|

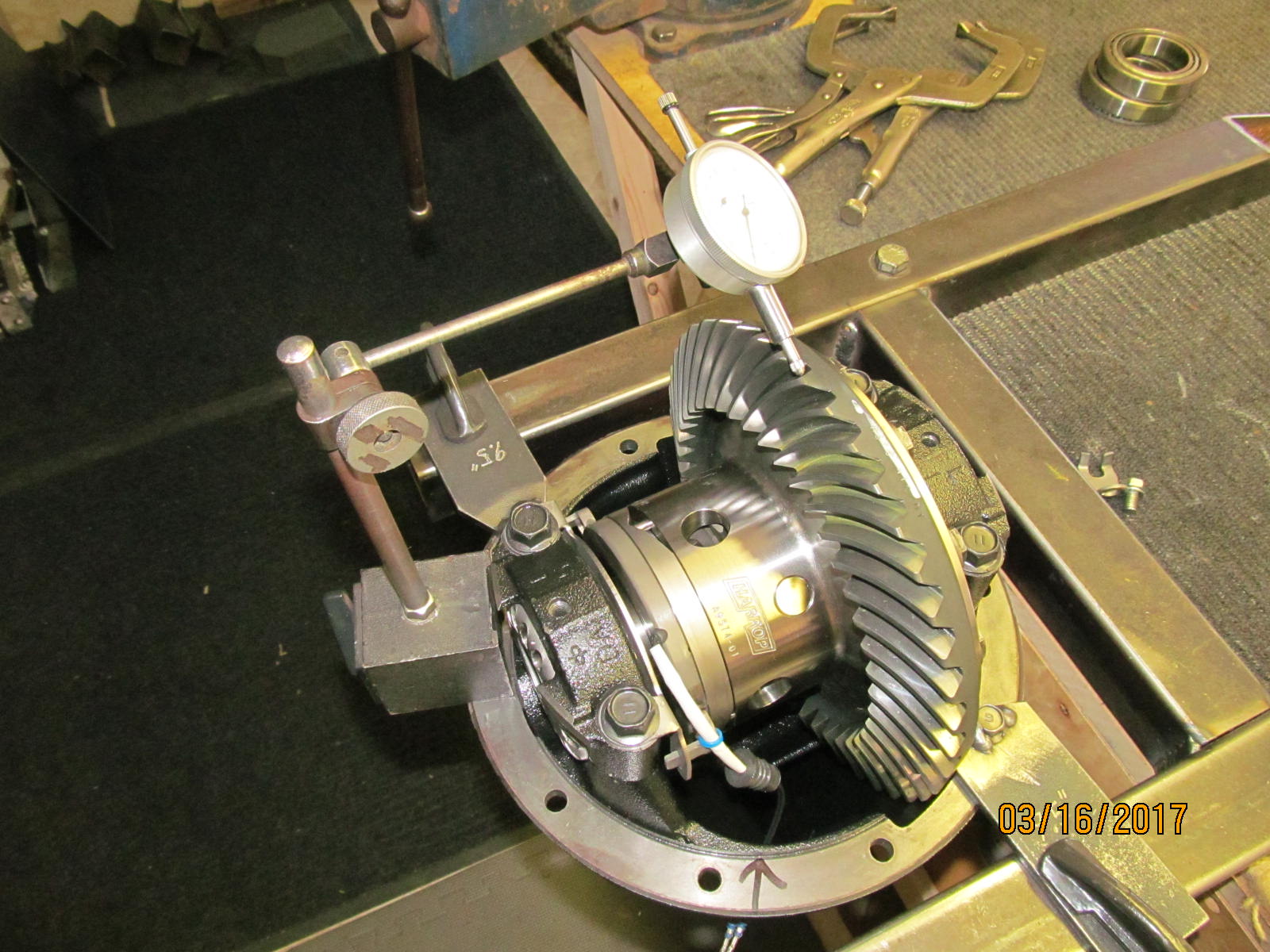

The adjustment wheels are carefully tightened to duplicate the tight backlash that was originally there.

|

|

|

|

|

Total preload(carrier plus pinion) measured 12 in/lb.

|

|

|

|

|

10 in/lb with blue loctite.

|

|

|

|

|

Re-checking the paint pattern.....drive side good.

|

|

|

|

|

Coast good.

|

|

|

|

|

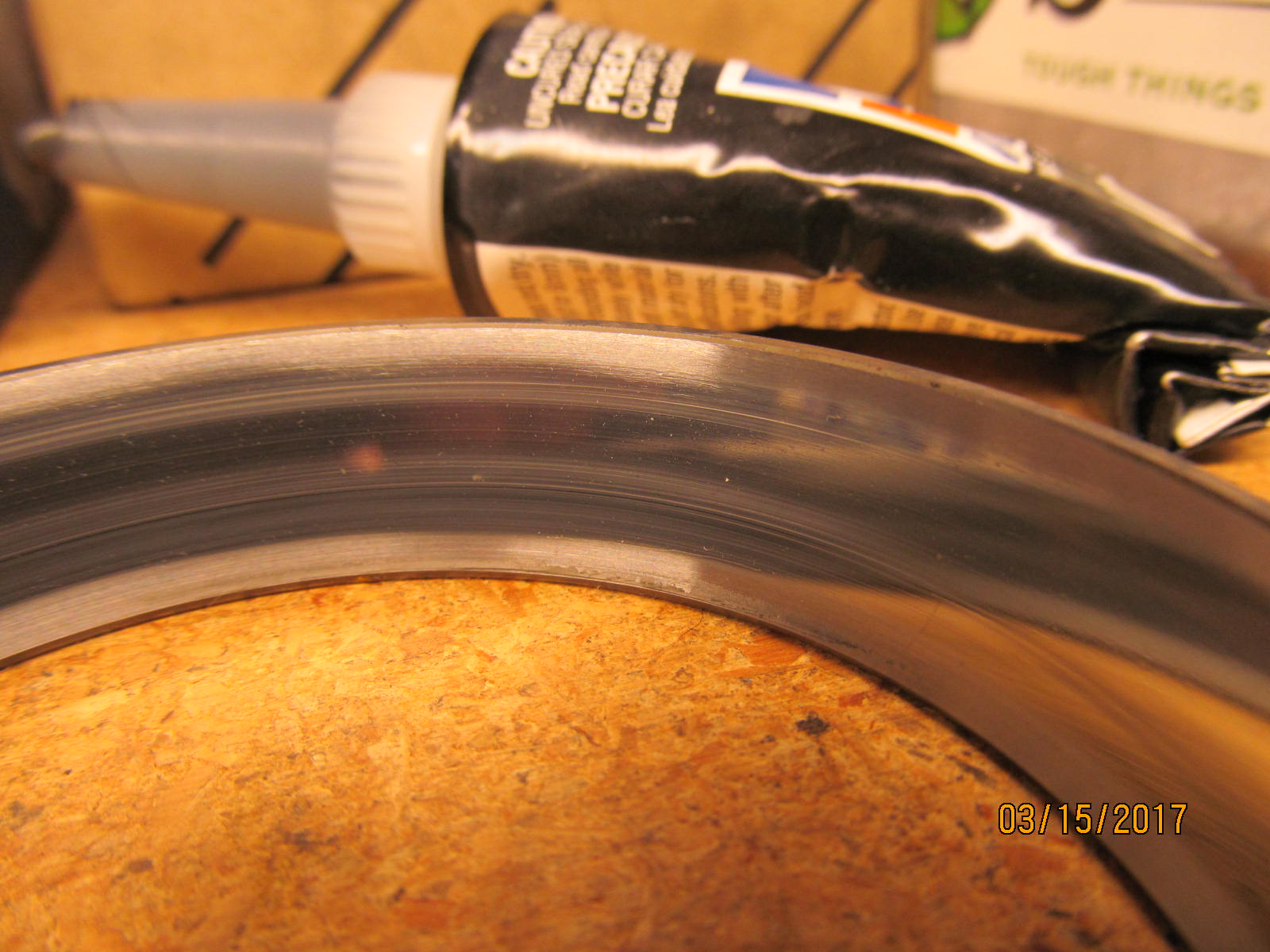

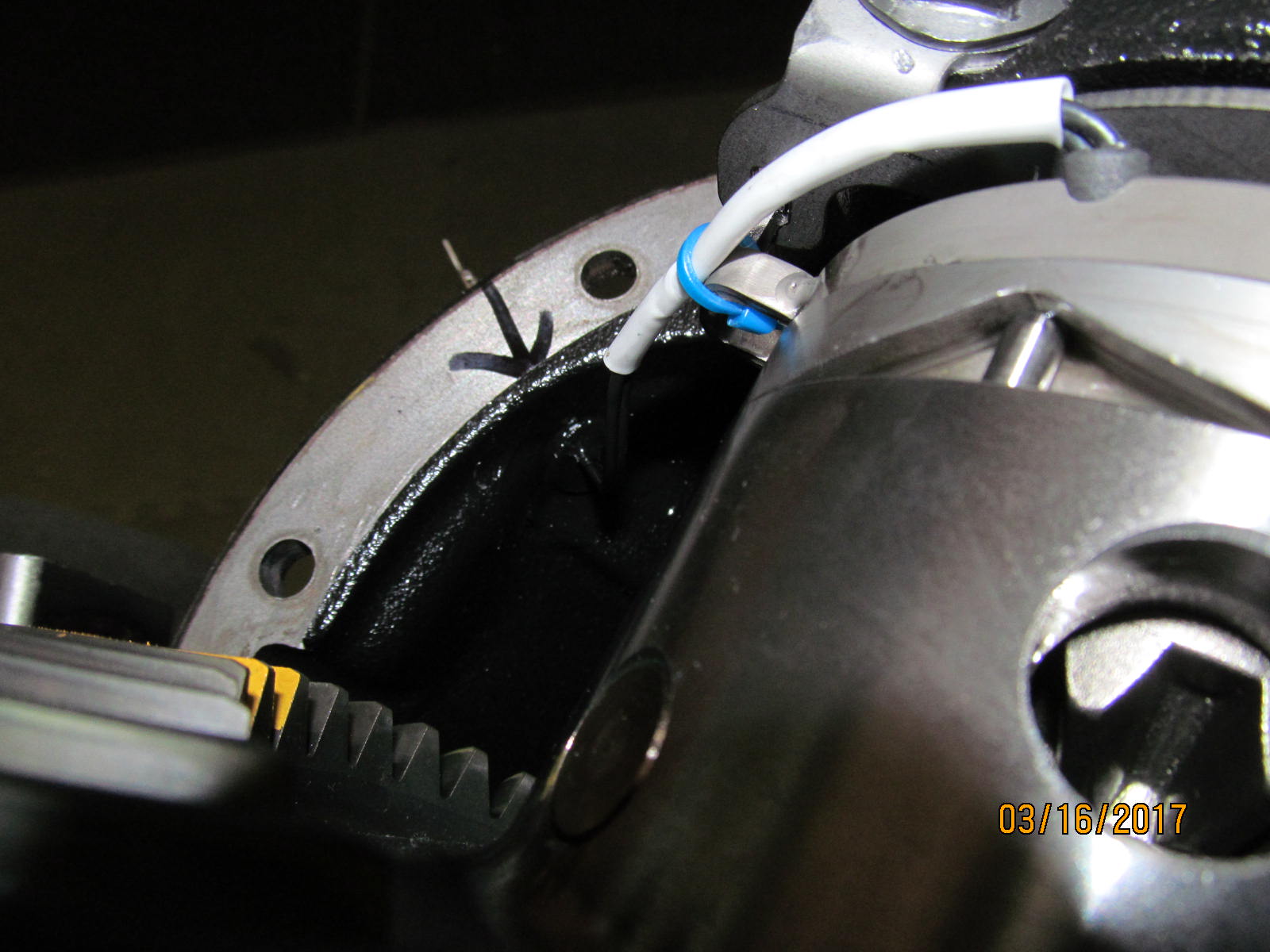

RTV was applied to the grommet....allows it to pass thru much easier and seal insurance.

|

|

|

|

|

.......................

|

|

|

|

|

................................

|

|

|

|

|

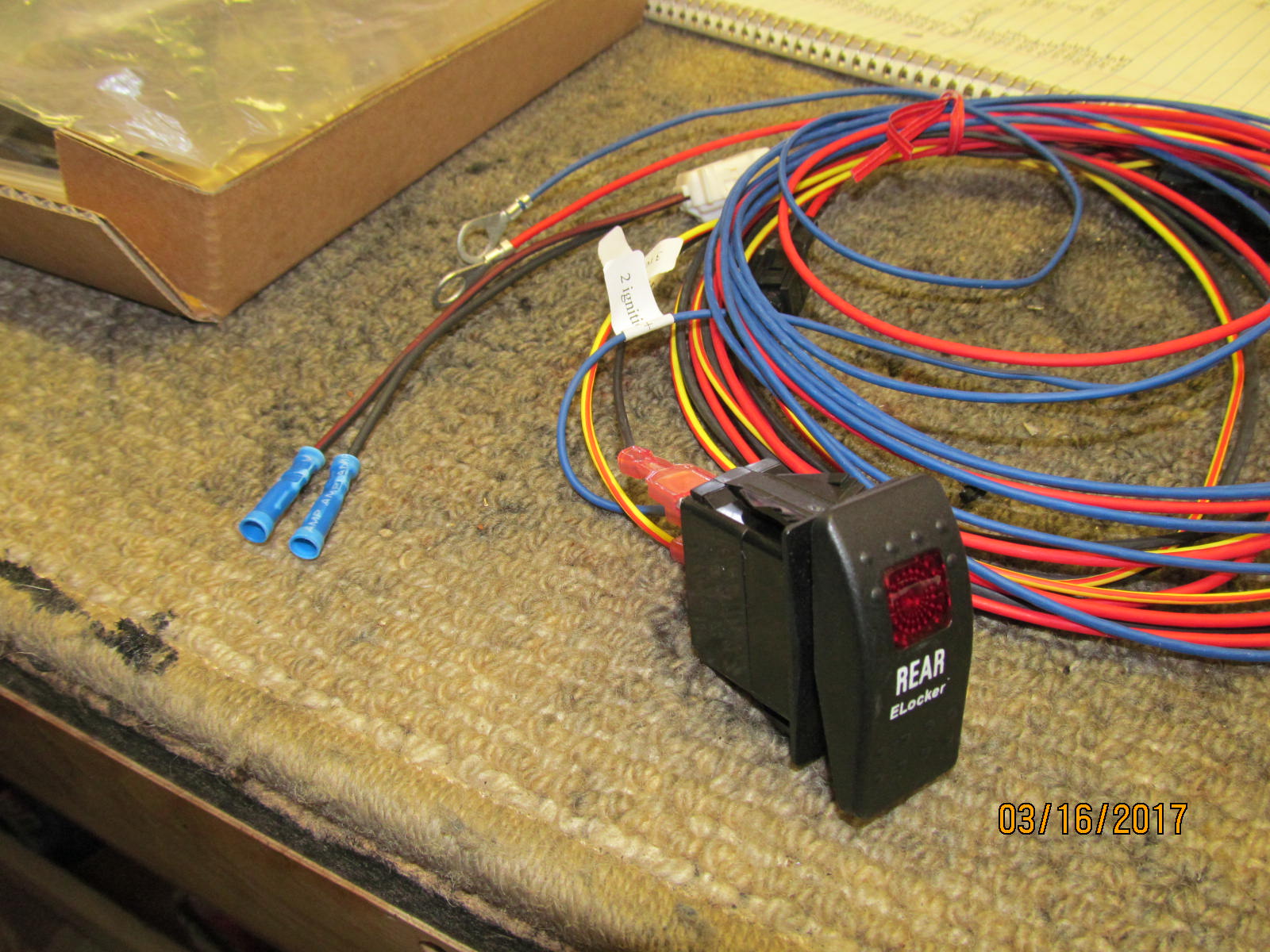

This is all the wiring harness materials.

|

|

|

|

|

The plug that goes to the rear Harrop to the 2 wires.

|

|

|

|

|

The dash mounted rocker switch that Harrop supplies....works ok but there is an upgraded switch option. See next small pic.

|

|

|

|

|

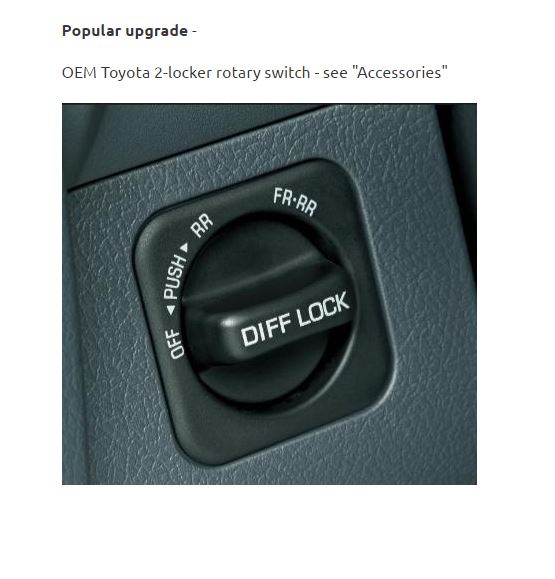

This is the optional upgraded switch offered by Yotalockers.com.

|

|

|

|

|

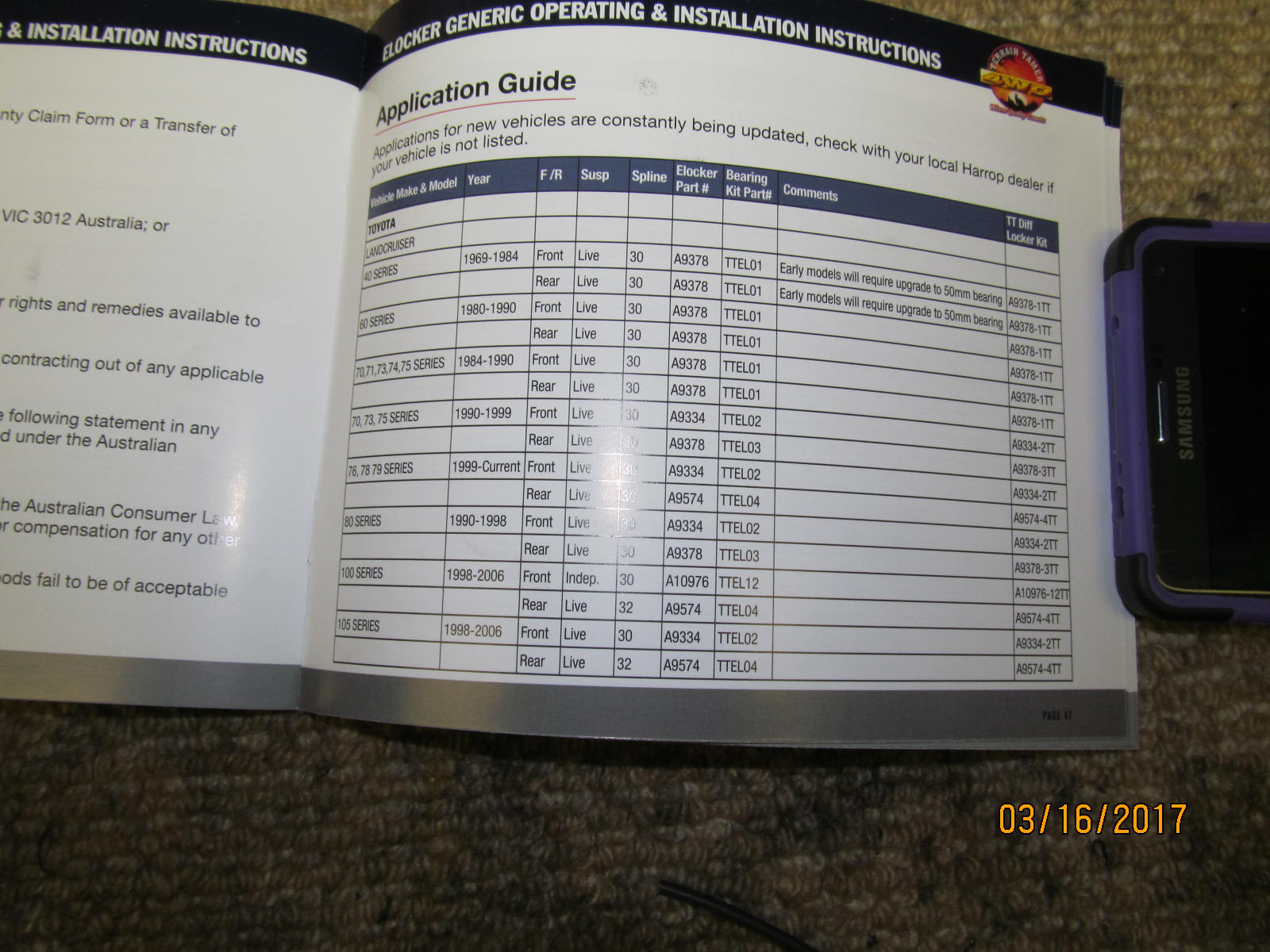

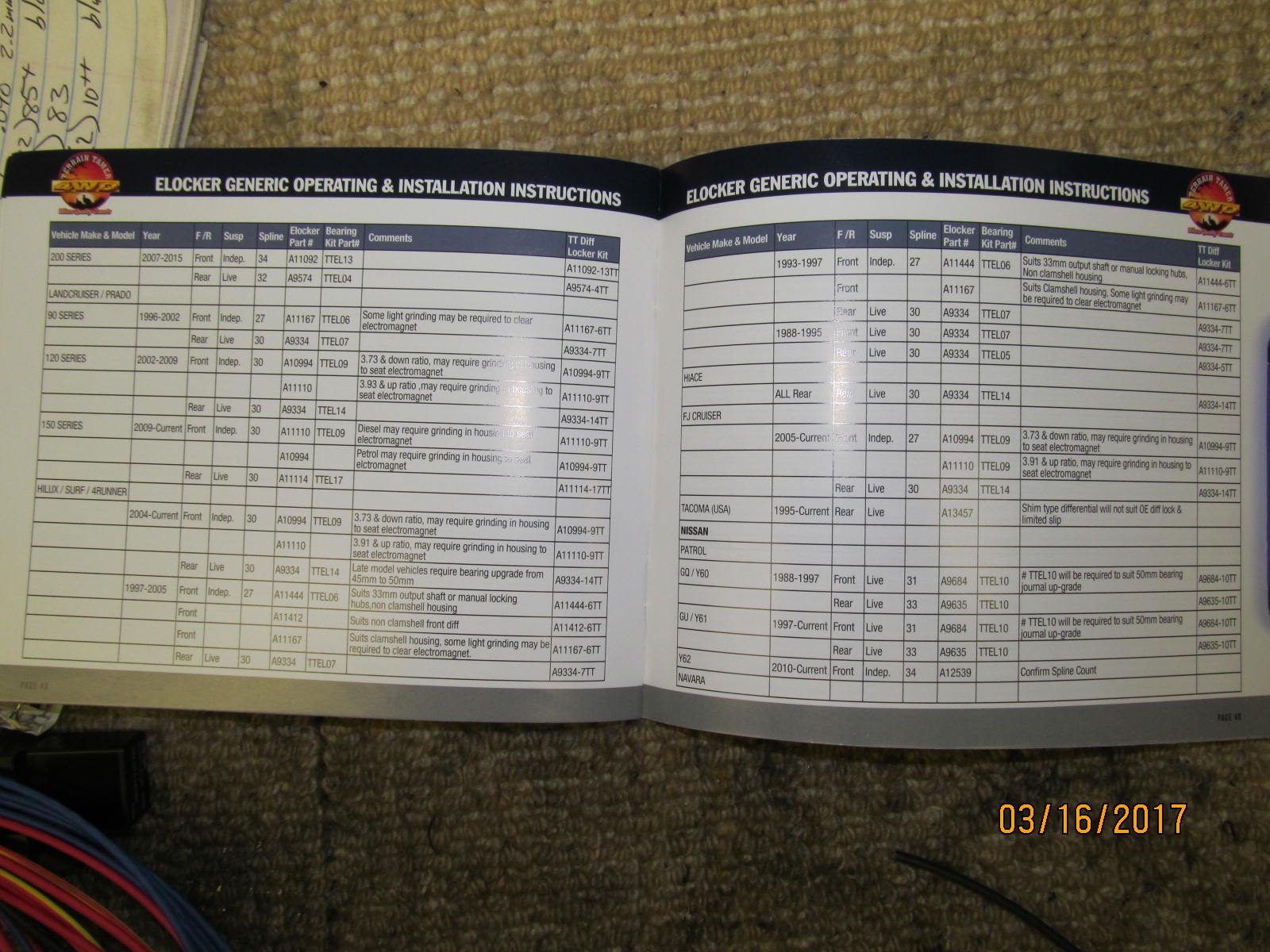

A snapshot of the Application Guide.... Page 1

|

|

|

|

|

Page 2 of the Toyota application page.

|

|

|

|

|

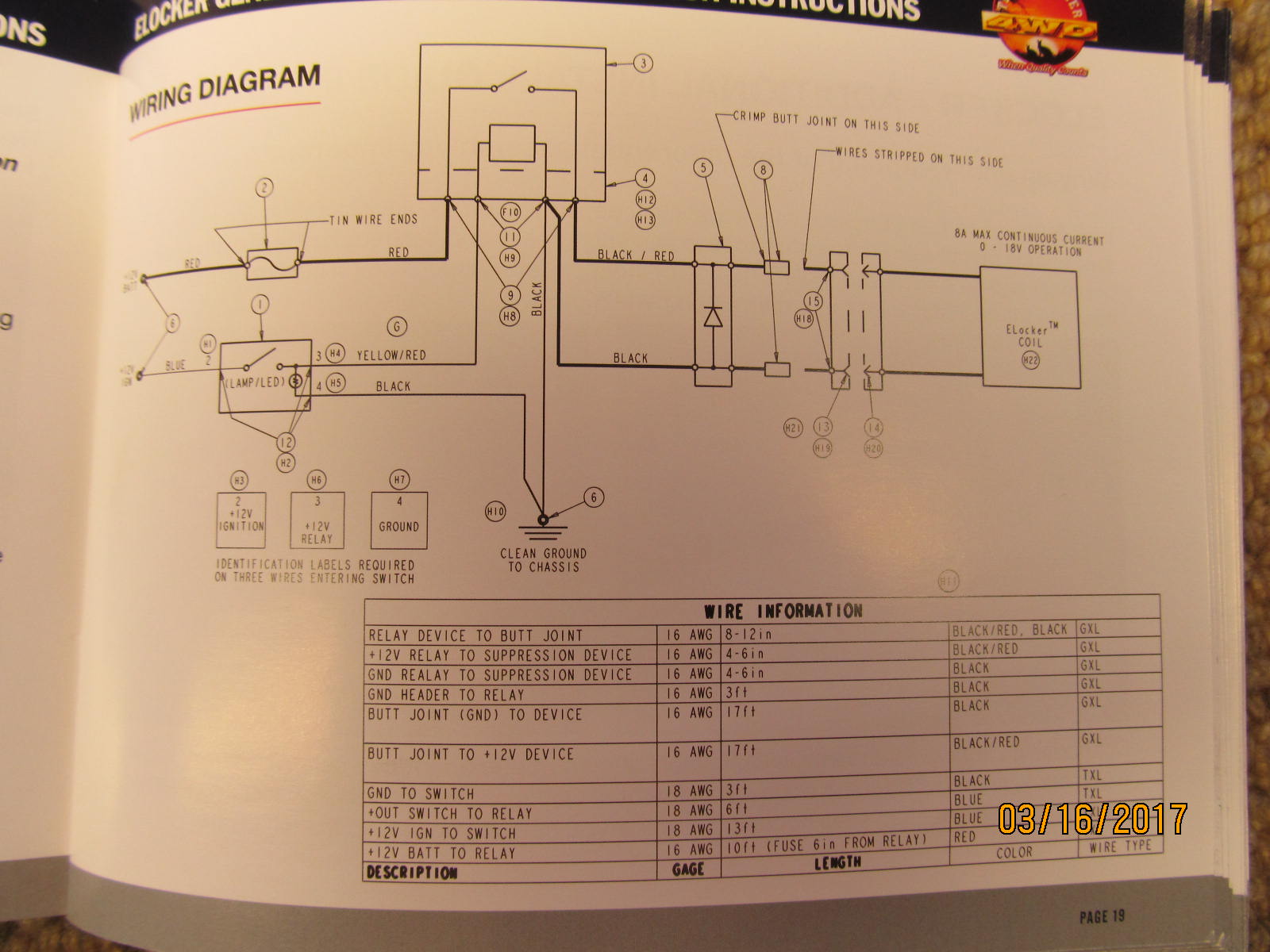

The wire harness lay-out.

|

|

|

|

|

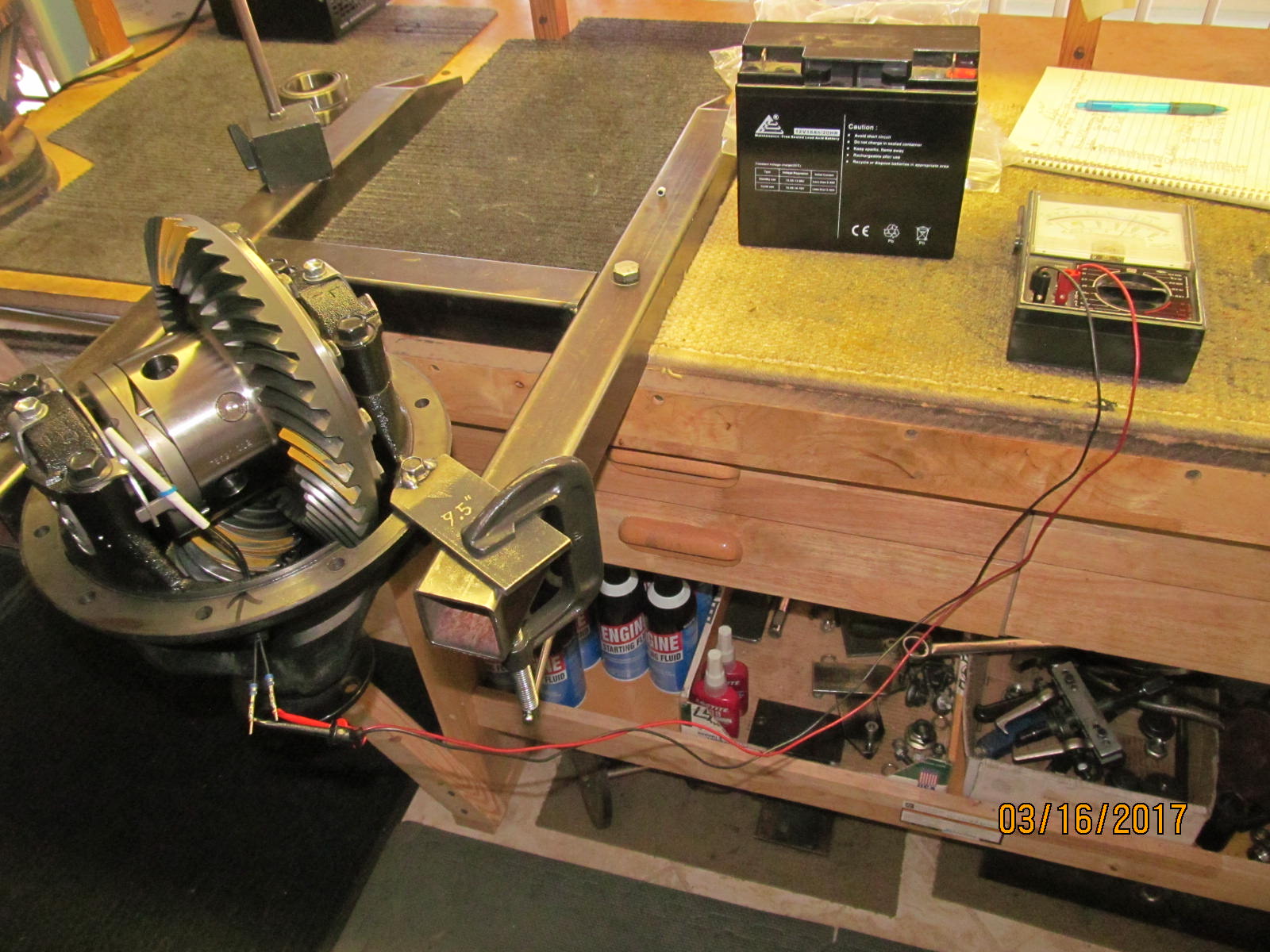

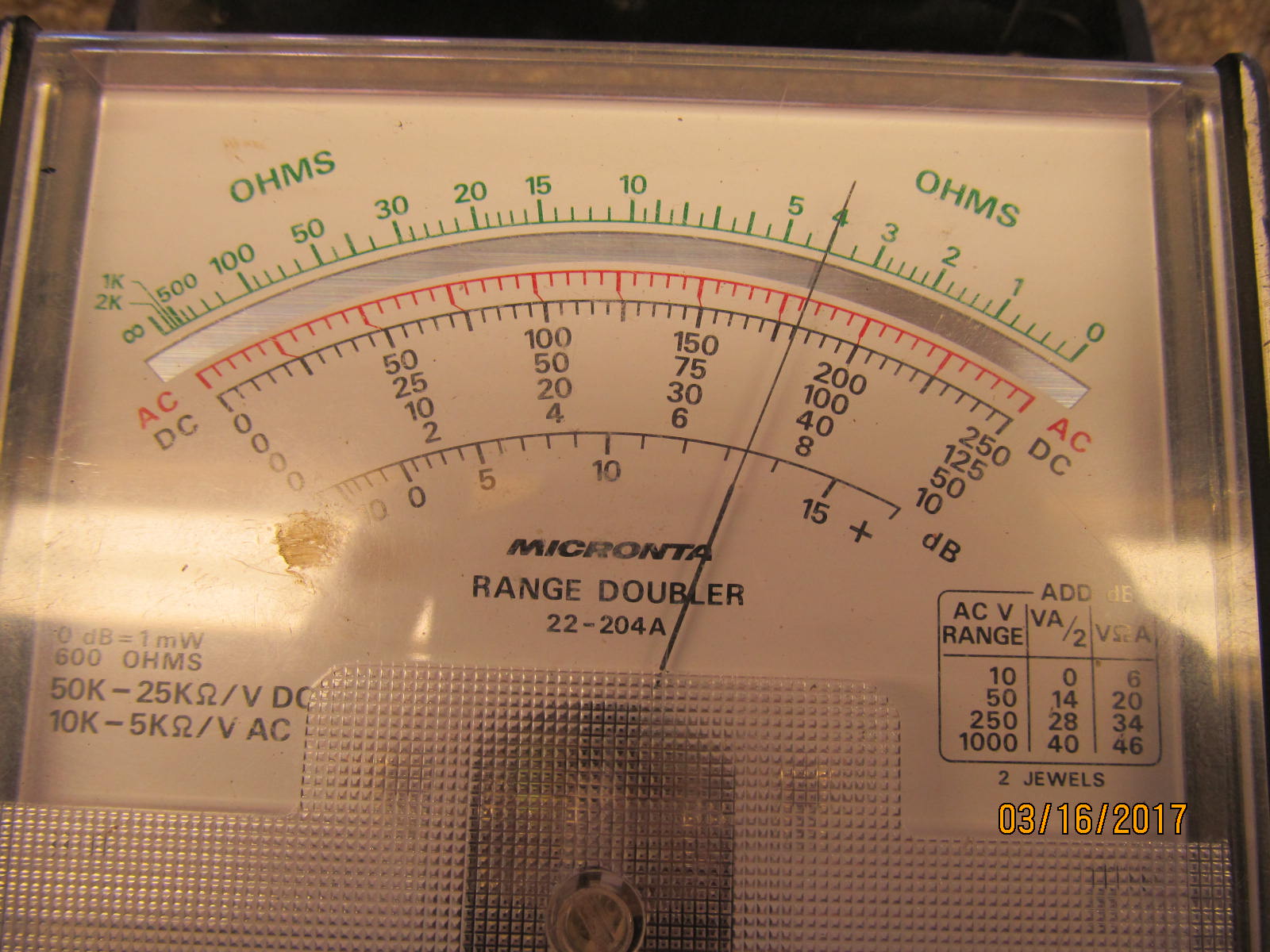

Final checks. Resistance check..... 4.0 ohms

|

|

|

|

|

It's called an analog meter....a collector's item.

|

|

|

|

|

And now checking the current draw (3.1 amps).

|

|

|

|

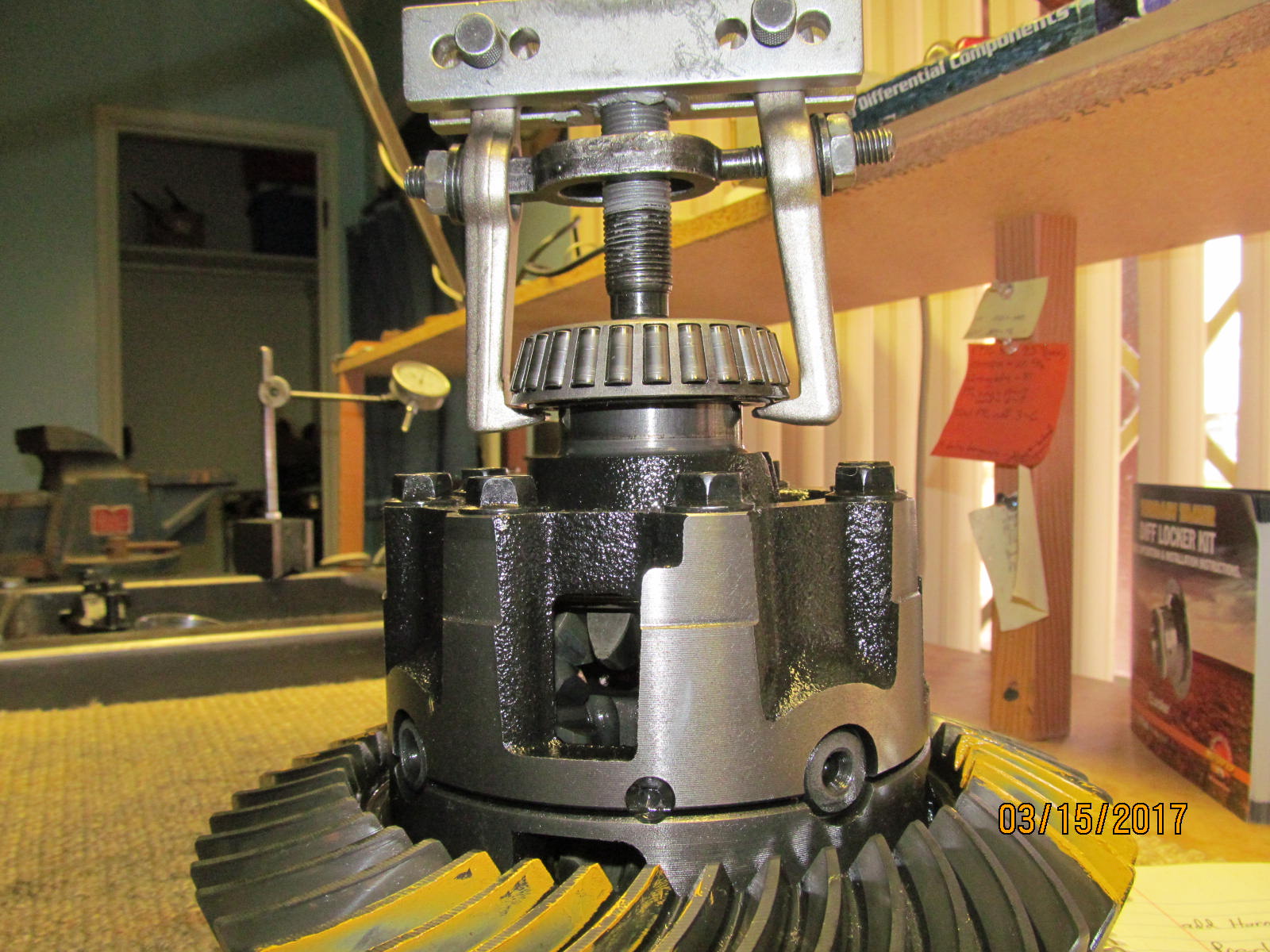

The 12volts is still applied....the electro-magnetic ring is locking down the ramp ring. I'm turning the pinion which means the

Harrop case is turning so the 3 pins(1 is seen) are now forced to retract into the holes. Unseen, inside the Harrop case the

3 pins are pushing a ring that locks the case to the sidegear.

|

|

|

|

|

Remove the 12 volts and the pins instant snap back by themselves to where you see here.

|

|

|

|

|

The dremel tool with diamond tip makes engraving info very easy and quick.

|

|

|

|

|

Sometimes, it's nice to know what your diff specs were and when.

|

|

|

|

|

The heavy diff still has adequate room in the small size 16x12x12 double corrugated

Home Depot boxes.

|

|

|

|

What you don't see is the steel lip in the center of the diff is not contacting the bottom of the box. A rolled up chunk of

cardboard is supporting it on the bottom. Prevents slice-thru of the lip.

|

|

|

|

|

Ready to go back to Colorado.

|

|

|

|