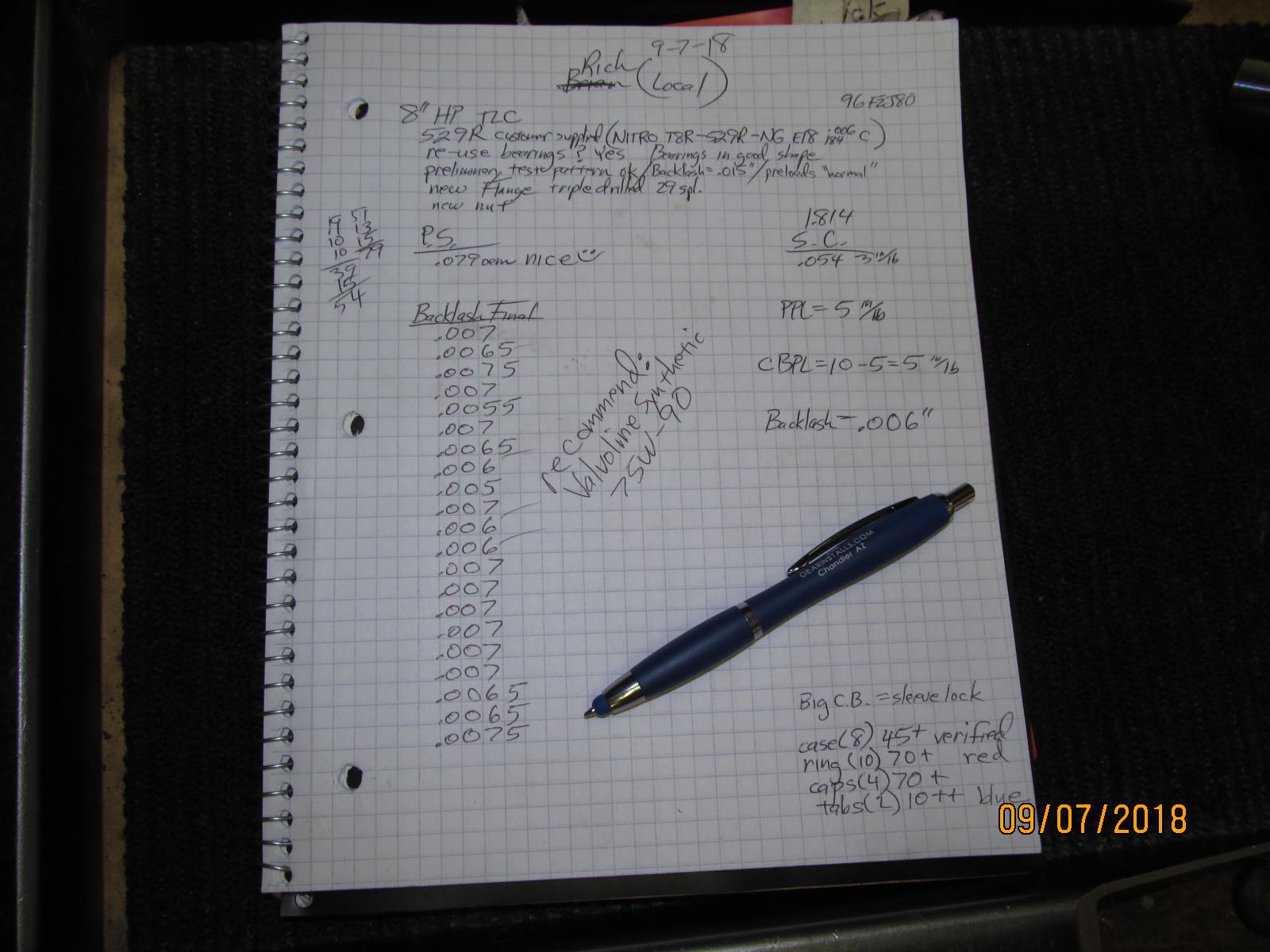

| Loose ring gear bolts on front 8" elocker (Rich's 96 FZJ80) |

|---|

| (41 BIG pics loading) |

|---|

| SEPT 8 2018 |

|---|

|

| Rich in Moab on the Pickle trail. |

|---|

|

|

| Lion Spring trail near Payson AZ |

|---|

|

|

Rich is local and contacted me about 2 chipped teeth he happened to notice while the 3rd was out during some front axle mods.

It was regeared to Nitro 529's back in 2013 somewheres in CA and it has never made a noise since then. No whines or ticking noises. |

|---|

|

|

I had Rich hang around while I did a few pre-checks because my curiousity was up on how could 2 teeth get 'nuked' like that.

Not looking for a scapegoat but these things sometimes just happen...... |

|---|

|

|

| The backlash was kind of excessive measuring in at .016"....normally about half that. |

|---|

|

|

| A quick paint pattern test shows that the pinion depth was "OK" but the driveside pattern is showing unusual wear. |

|---|

|

|

| Coast side indicates something strange going on. Definitely not too shallow. |

|---|

|

|

| Then I noticed that 1 ring gear bolt had broken off. |

|---|

|

|

| ......................................... |

|---|

|

|

Then I showed this new discovery to Rich....all 9 of the remaining bolts were loose enough so that my 2 fingers could move them.

So, the ring gear was just loose enough to move around some and make the load bearing pattern wonder off the edge of the tooth

......and then it chips away. |

|---|

|

|

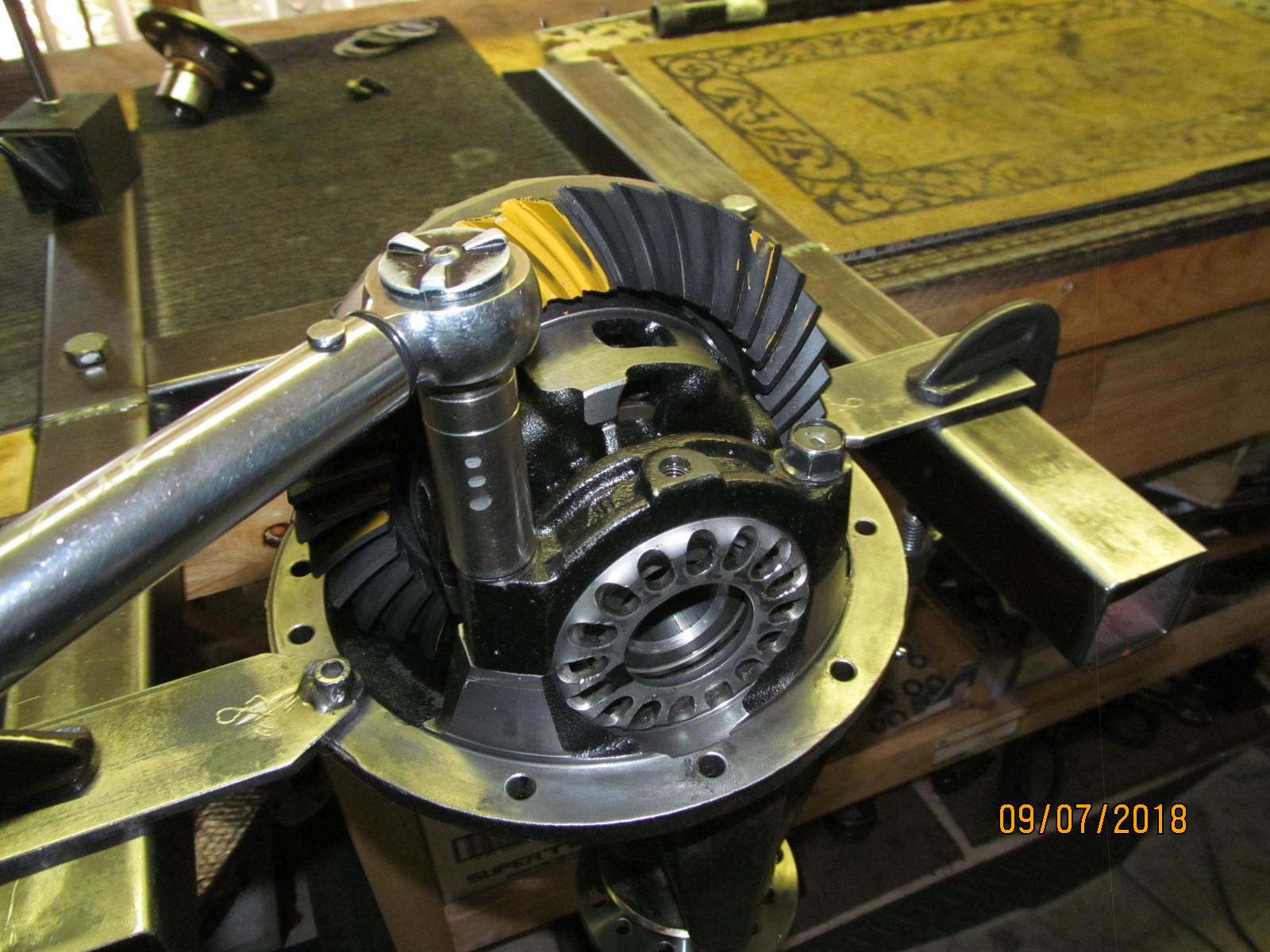

| A new reverse cut 529 Nitro Gear will be installed. |

|---|

|

|

| Nitro Gear is a top shelf gear. Sierra Gear is another decent one.....and so is G2 Gear. |

|---|

|

|

| Old ring gear bolts are stressed out so they go in the garbage. New ones to replace them. |

|---|

|

|

| Rich wanted the old 529 ring/pinion back for his "yard art". |

|---|

|

|

| I don't recommend everybody do this and re-use the old ones....but it can be done once in a while....if the bearings are in good shape and these are. |

|---|

|

|

| I did note that the large carrier bearing did pull off "easy" which means surfaces will be cleaned and a sleeve retainer will be used. |

|---|

|

|

| I had to remove the big bearing in order to verify these 8 case bolts and all were at the 45 ft/lb mark(good). |

|---|

|

|

| Loctite 638 is the solution to loose fitting bearings onto journals. |

|---|

|

|

| Both surfaces are checked with a large file and all was good. No unusual burrs or high spots. |

|---|

|

|

| Clean threads and Permatex High strength red threadlock and 70+ ft/lb of torque. |

|---|

|

|

| Now onto the pinion end of things.....turns smoothly and not wobbly at all...probably means the pinion bearings are ok. |

|---|

|

|

| Nut was staked somewhat. |

|---|

|

|

| It is also missing the metal "dust shield". |

|---|

|

|

| Here in the Arizona climate it really isn't mandatory to have it. Might upgrade Rich to a new triple drilled one with a shield. |

|---|

|

|

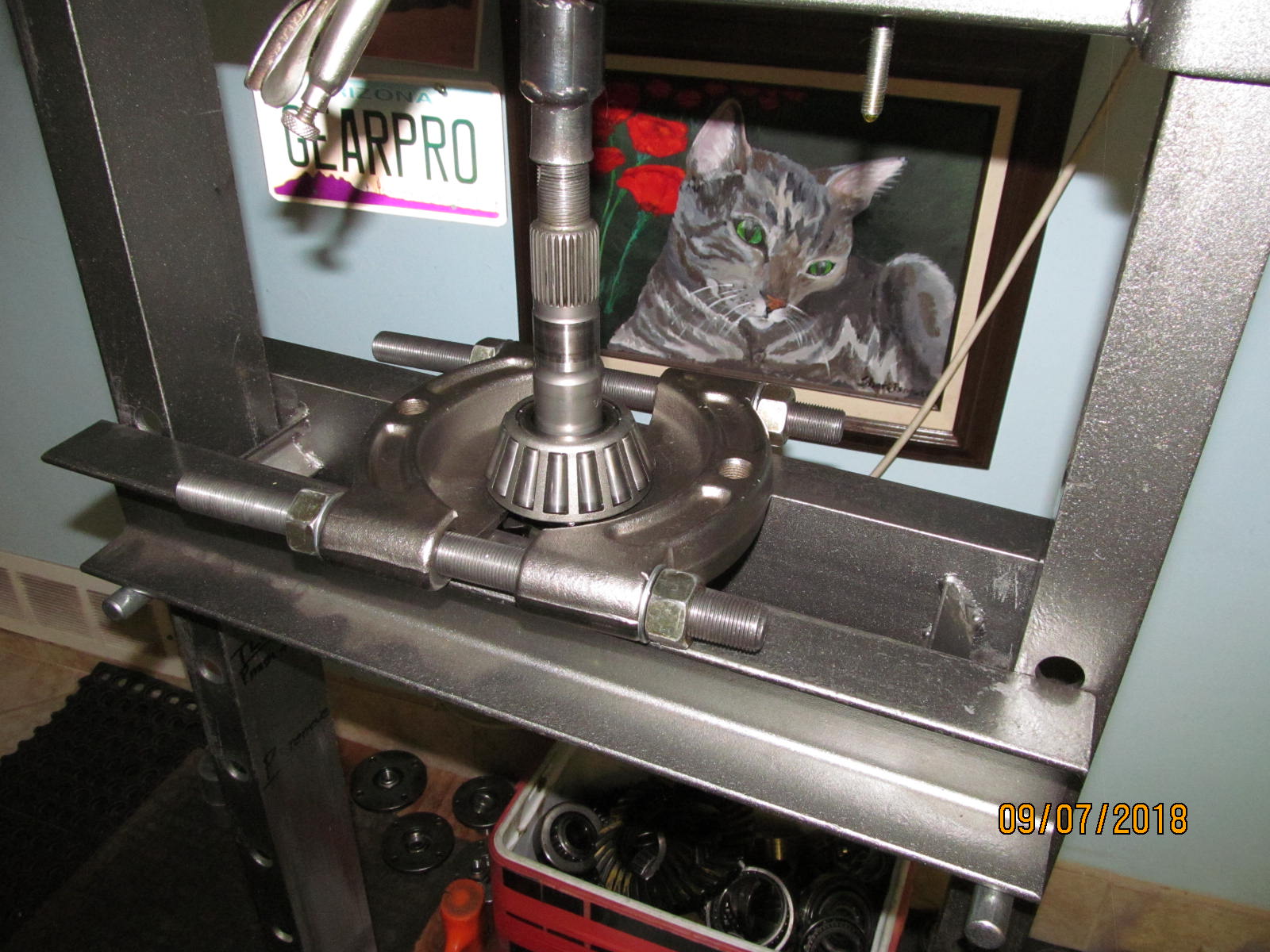

| Press the pinion out....sometimes they fall out but not this one...took a good amount of harborfreight press to convince it. |

|---|

|

|

| Solid collar was used. |

|---|

|

|

| Some ding marks in the collar....but the bearings show absolutely no damage. Go figure. |

|---|

|

|

| This pinion goes to Rich's yard art collection and re-use this V6 bearing. |

|---|

|

|

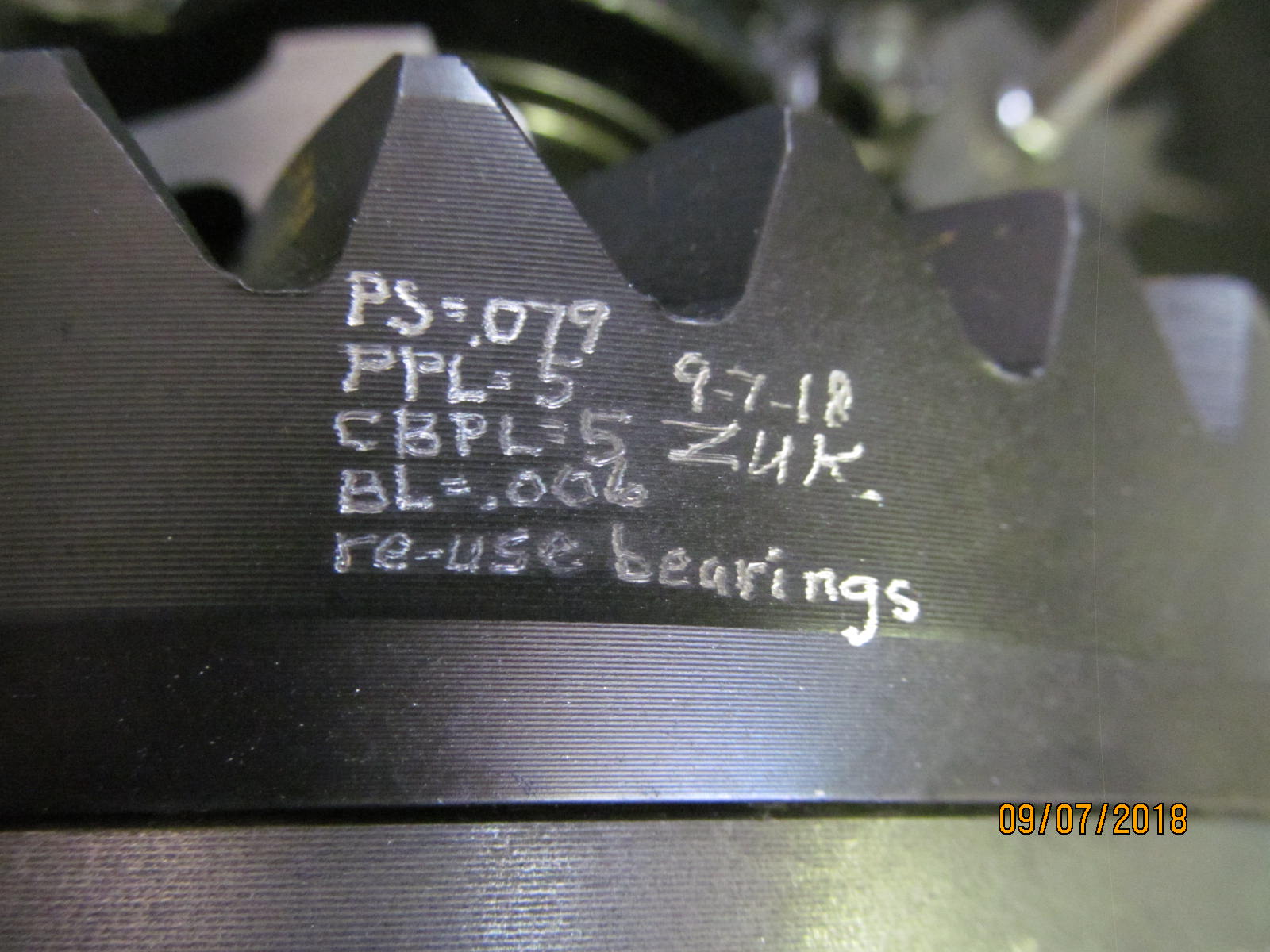

| Gonna use the same shim value the last installer used...... |

|---|

|

|

| Put it back together and this drive side pattern shows it to be about perfect. A slight deep condition. |

|---|

|

|

| Coast side.....right on. |

|---|

|

|

| Even the comet tail shown here with the tail swinging to the center says to leave it alone. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

Skipped a few steps but the solid collar was installed with no pictures......

Trail Gear has a very nice 29 spline seal that I am happy to use in this application. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

With used bearings, pinion preload should stay very light. Must keep it under 6 in/lb if the small outer bearing is expected to live.

The seal is offering about 1 in/lb of resistance so that means the real preload is a safe 3 or 4. |

|---|

|

|

| 70+ ft/lb on the 4 bearing cap bolts. |

|---|

|

|

| Backlash values were recorded on every other tooth. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| The final notes..... |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| Ready for Rich to pick up. :) |

|---|

|

|

|