| Rip's rear 8" elocker gets cryo treated new bearings and a solid collar upgrade. |

|---|

| (25 BIG pics loading) |

|---|

| DECEMBER 23 2017 |

|---|

|

This write-up does not have as many pics as usual because the primary interest was the front 7.5" clam rebuild.

Clams are always more interesting if that's a good word to use.

But this 8" elocker is getting a bearing rebuild with bearings that have been cryo treated by

Cryogenics International as well as a solid collar upgrade. |

|---|

|

|

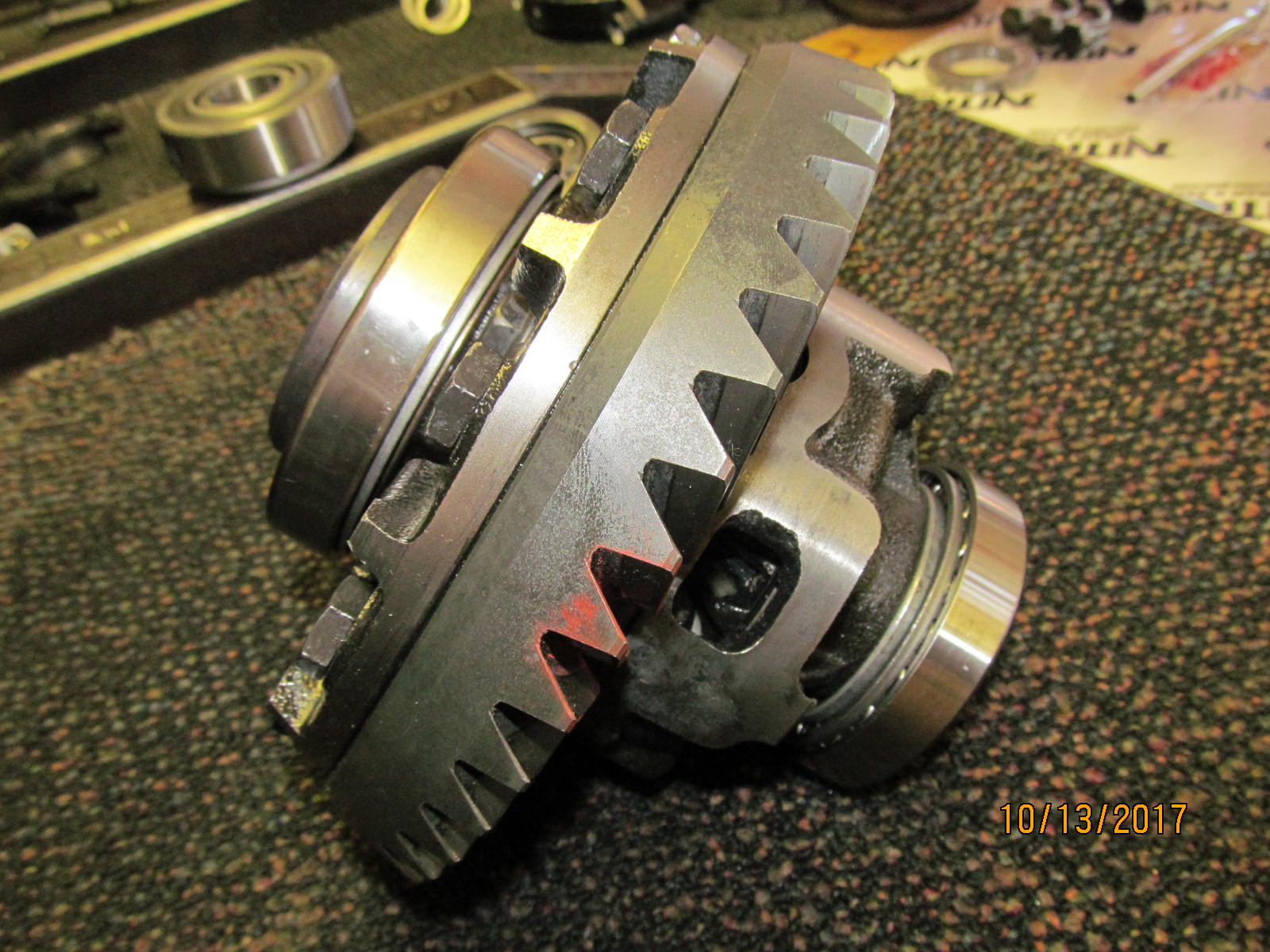

| The center carrier is removed from the 3rd and new cryo bearings are tapped on. |

|---|

|

|

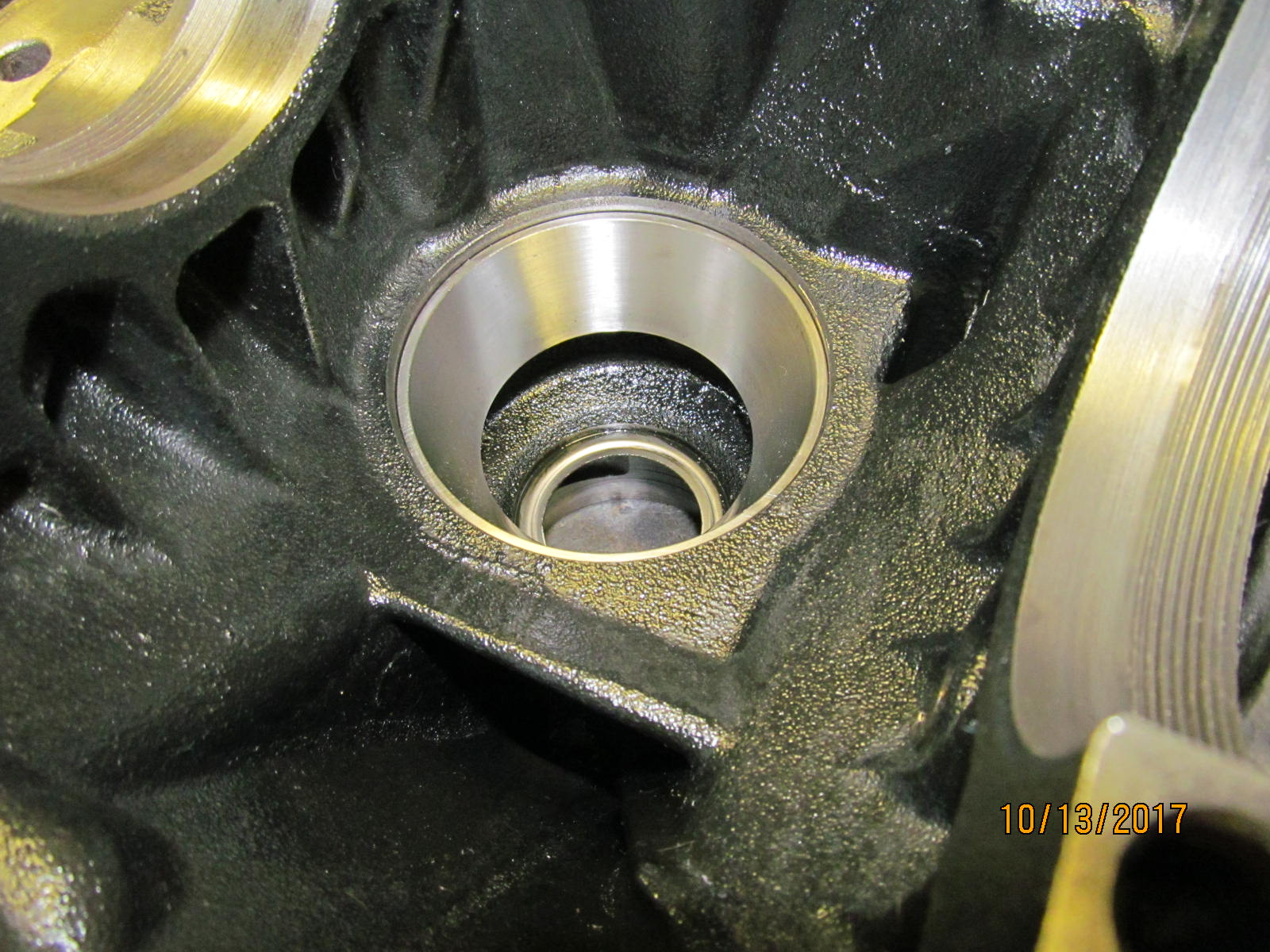

| The large carrier bearing is also tapped on. |

|---|

|

|

| This piece is done(we are re-using the factory 430 gears). |

|---|

|

|

The e-motor(actuator) seemed a bit rusted in place so I decided to leave it be and do the rebuild with the motor attached.

The flange has been removed and the pinion is now pressed out. |

|---|

|

|

| Re-use the oem .077" pinion shim with the new cryo bearing. |

|---|

|

|

| Press it on. |

|---|

|

|

| New inner cryo race is tapped in place (no chisels). |

|---|

|

|

| Same with the smaller outer race. |

|---|

|

|

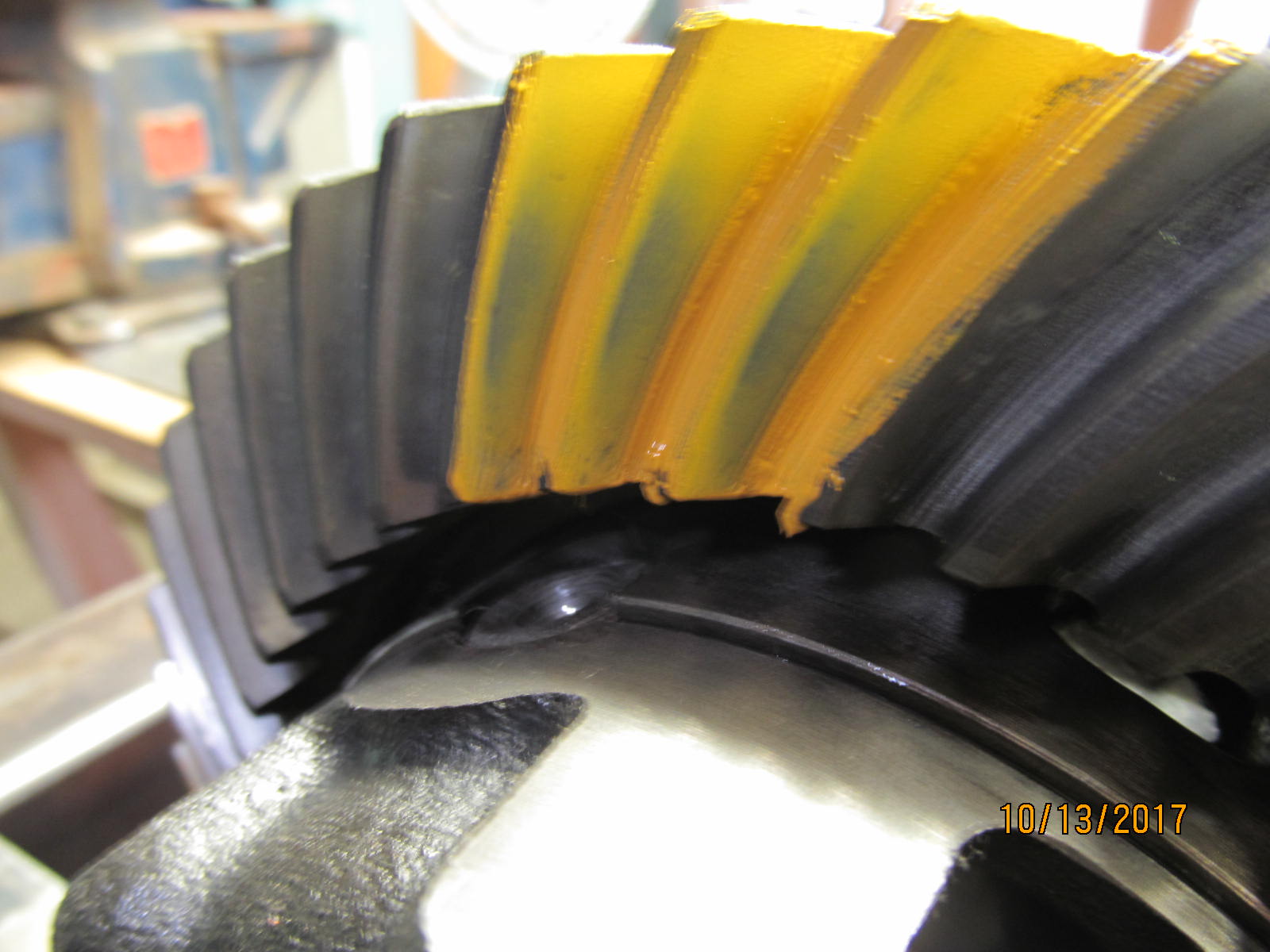

| Everything is assembled and a pattern check shows all is good as it should be. This is the drive side. |

|---|

|

|

| Coast side. |

|---|

|

|

| Now to load the solid collar in place. First try and real lucky....1.865" was the magic number for this one :) |

|---|

|

|

| This particular Nitro kit had the upgraded factory NOK seal already so I am happy to use that. |

|---|

|

|

| BH6832E is how you know. |

|---|

|

|

| Seal is in place. |

|---|

|

|

| Flange has already been sanded with #1500 super fine sandpaper and everything is oiled up. |

|---|

|

|

| A nice, smooth 10 in/lb of preload is noted and then DING the new pinion nut. |

|---|

|

|

Carrier is loaded in place....wheel adjusters are tighten to get the appropriate preload and backlash is being checked here on every other tooth.

Backlash minimum measured right at .006" which is a solid backlash. |

|---|

|

|

| Bearing caps were already tight but where still verified to be at 70 ft/lb. |

|---|

|

|

| The 2 tabs were at 10 ft/lb and blue loctite. |

|---|

|

|

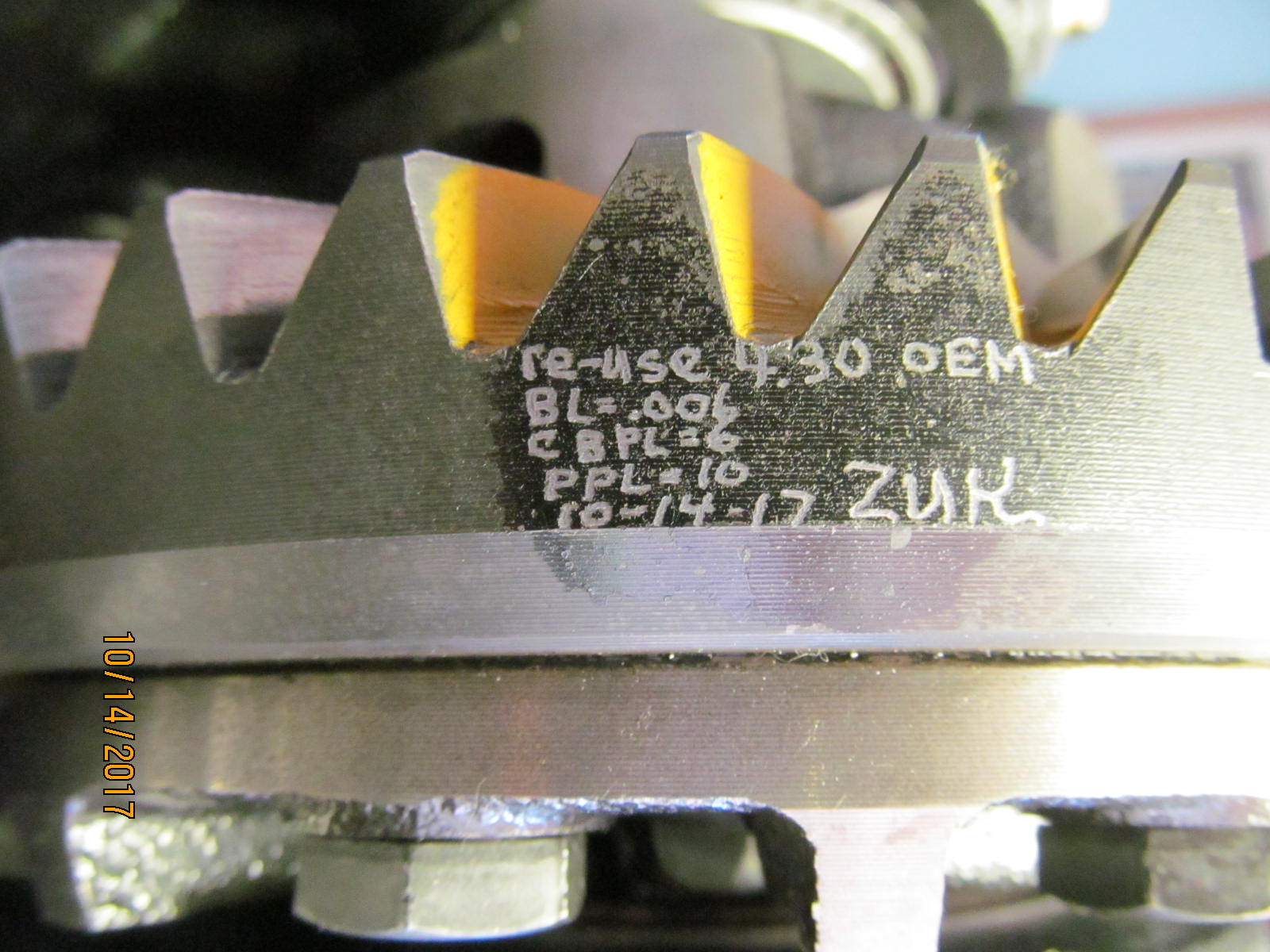

| A little documentation on the ring gear. |

|---|

|

|

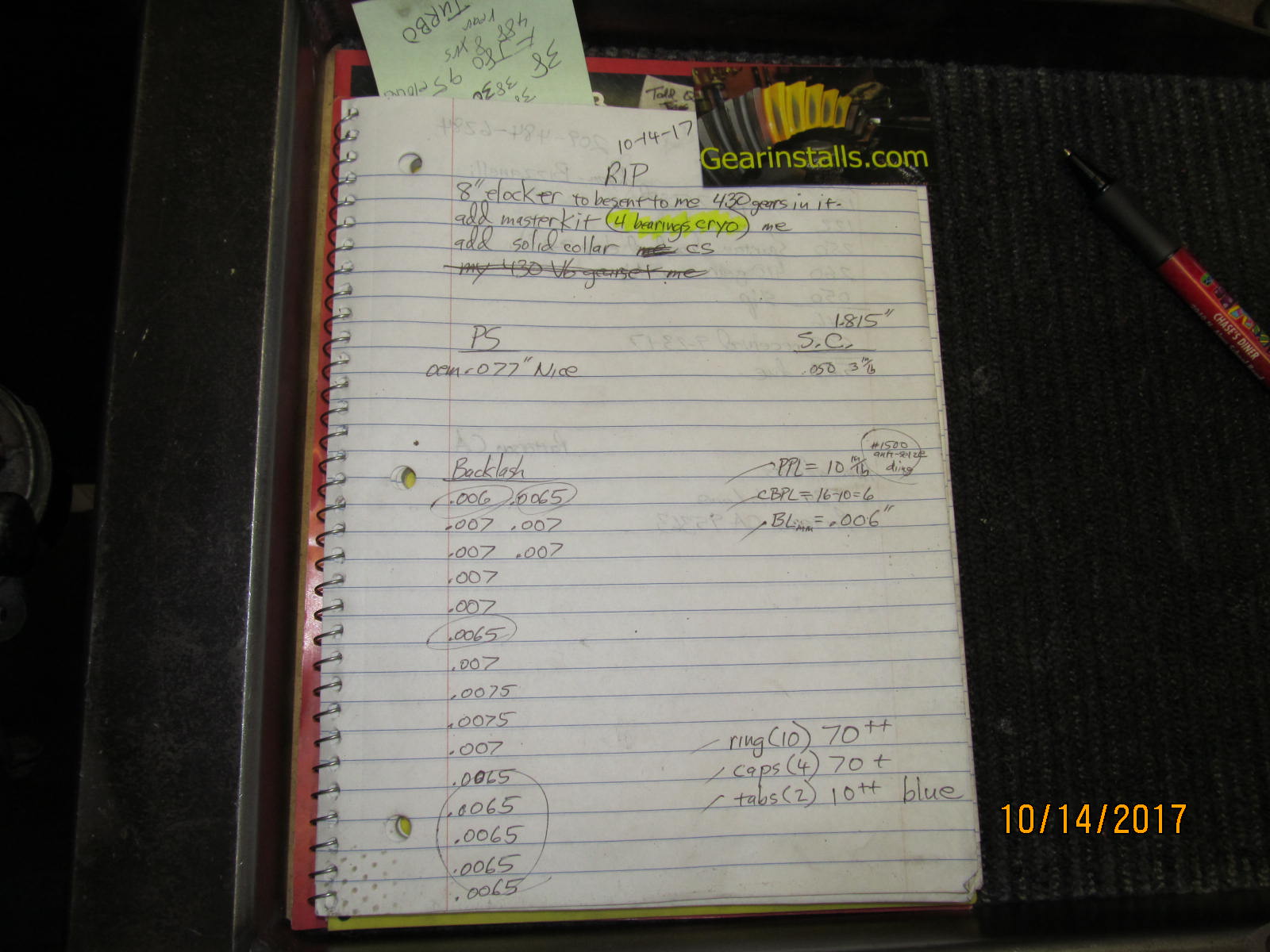

| My notes during the rebuild. :) |

|---|

|

|

|