|

1993 SAS'd pick-up gets a front Spartan and a much needed check-up

|

|

(~107 BIG pics loading)

|

|

OCT 18 2014

|

|

|

|

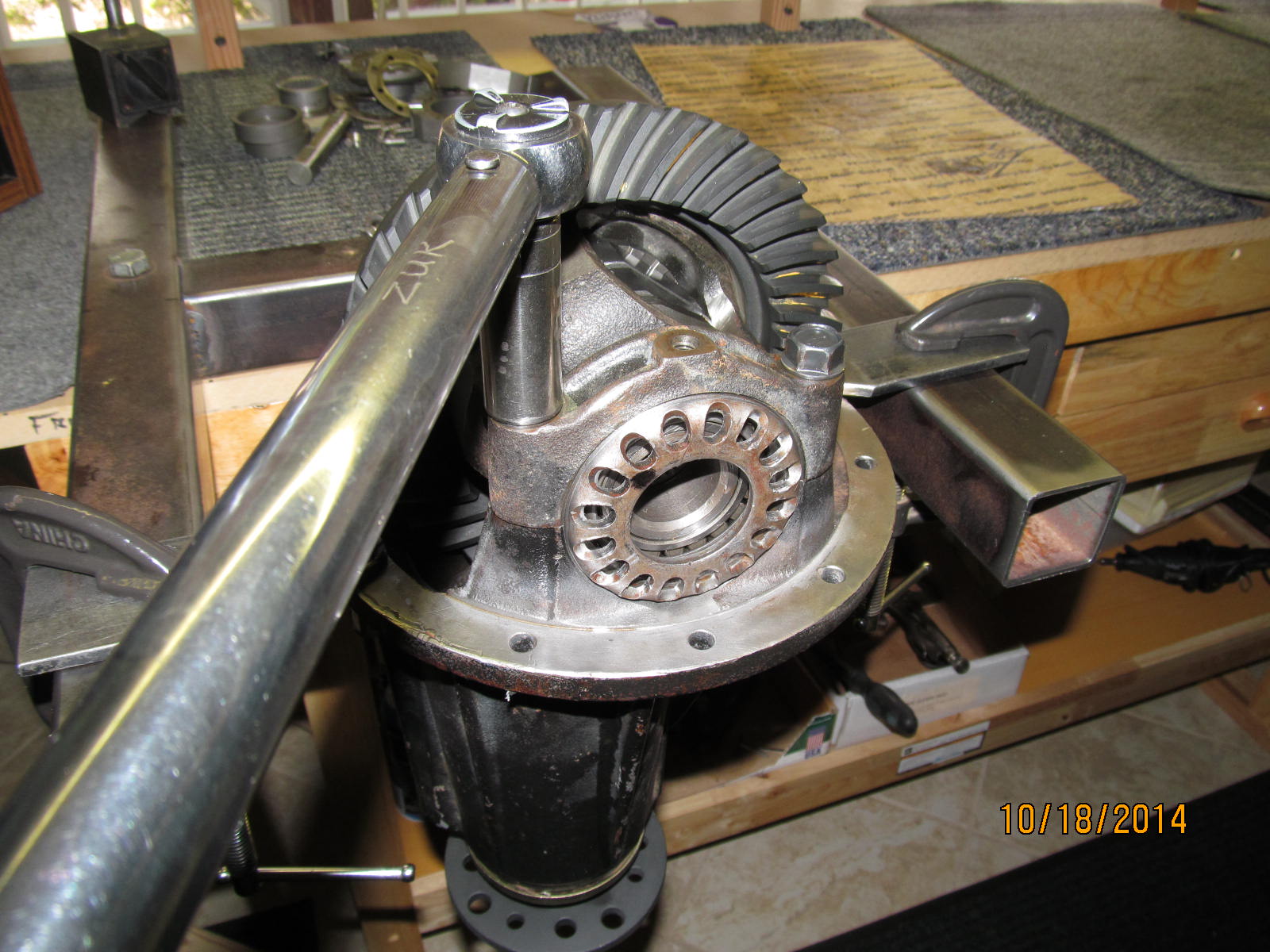

Here's what Mark's 1993 SAS pick-up looks like as I work on his front 3rd at this moment. Nice weather :)

|

|

|

|

|

...................

|

|

|

|

|

...................

|

|

|

|

|

As received from Mark...good plastic tote with zip ties.

|

|

|

|

|

Lots of packing paper...Cola is very interested for some reason.

|

|

|

|

|

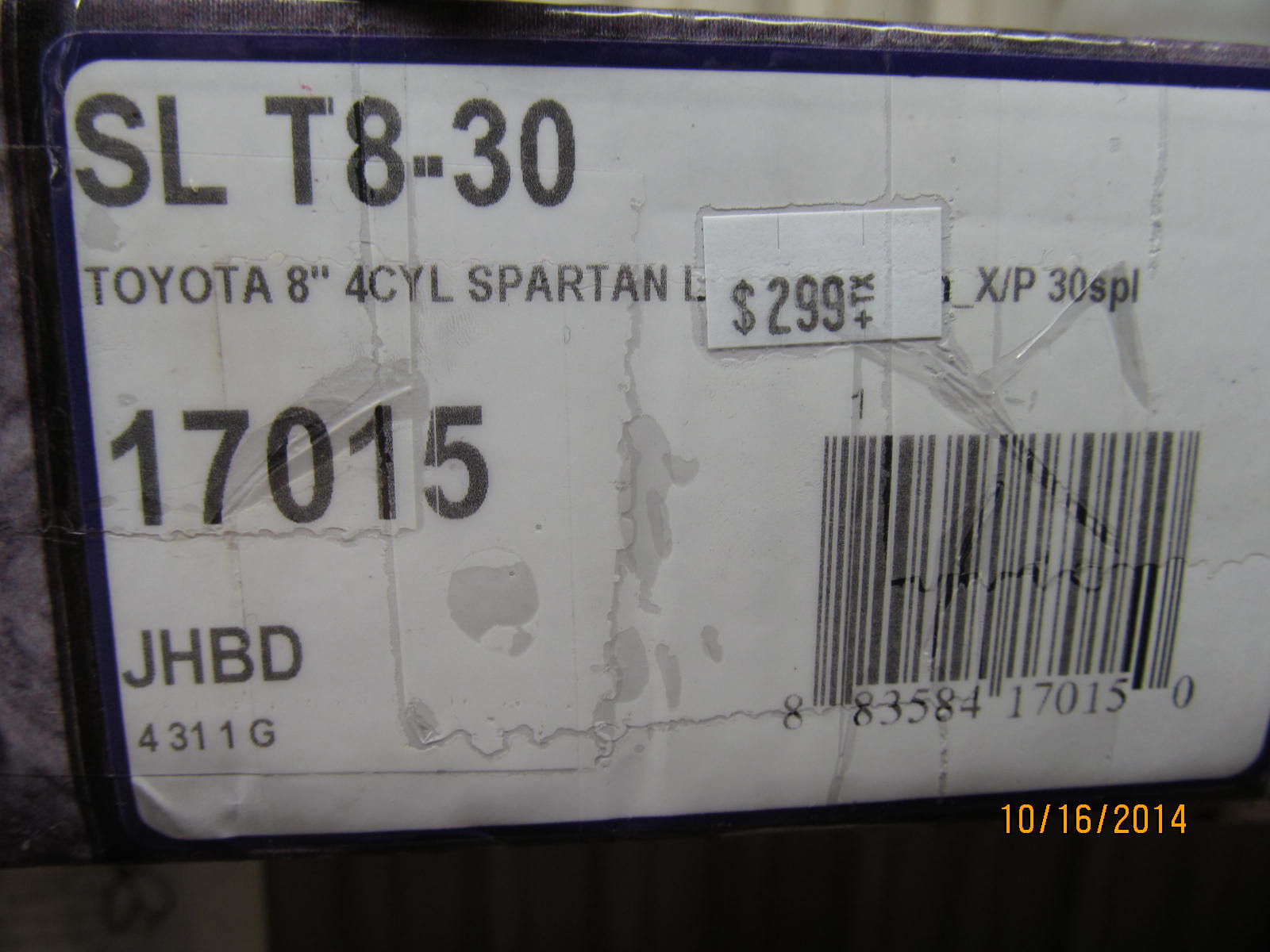

Looks like the Spartan Locker is in that package.

|

|

|

|

|

Front 3rd is there.

|

|

|

|

Bottom of tote has minor damage due to the 3rd's lip punching at the floor. It takes a lot more padding to

protect the tote floor ;)

|

|

|

|

|

...................

|

|

|

|

|

......................

|

|

|

|

|

4 cylinder Spartan and diff on the bench.

|

|

|

|

|

.............

|

|

|

|

|

.................

|

|

|

|

|

.................

|

|

|

|

|

Those 4 pins are so much more stout than the other lunch lockers.

|

|

|

|

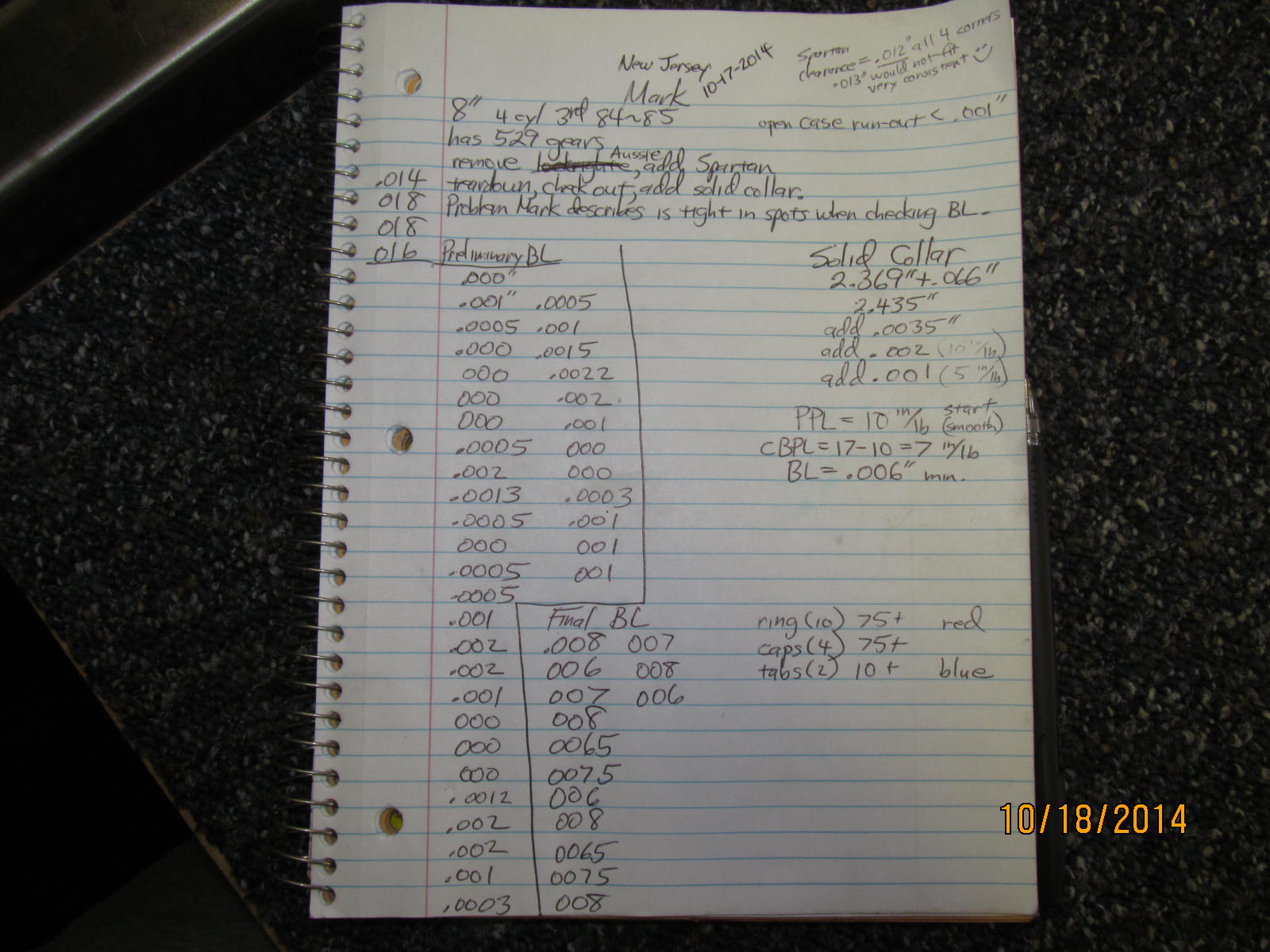

The first order of business is the pre-check. Backlash is checked on every tooth and was basically zero. See

the notes at the end of this link to see the recorded values.

|

|

|

|

|

.........

|

|

|

|

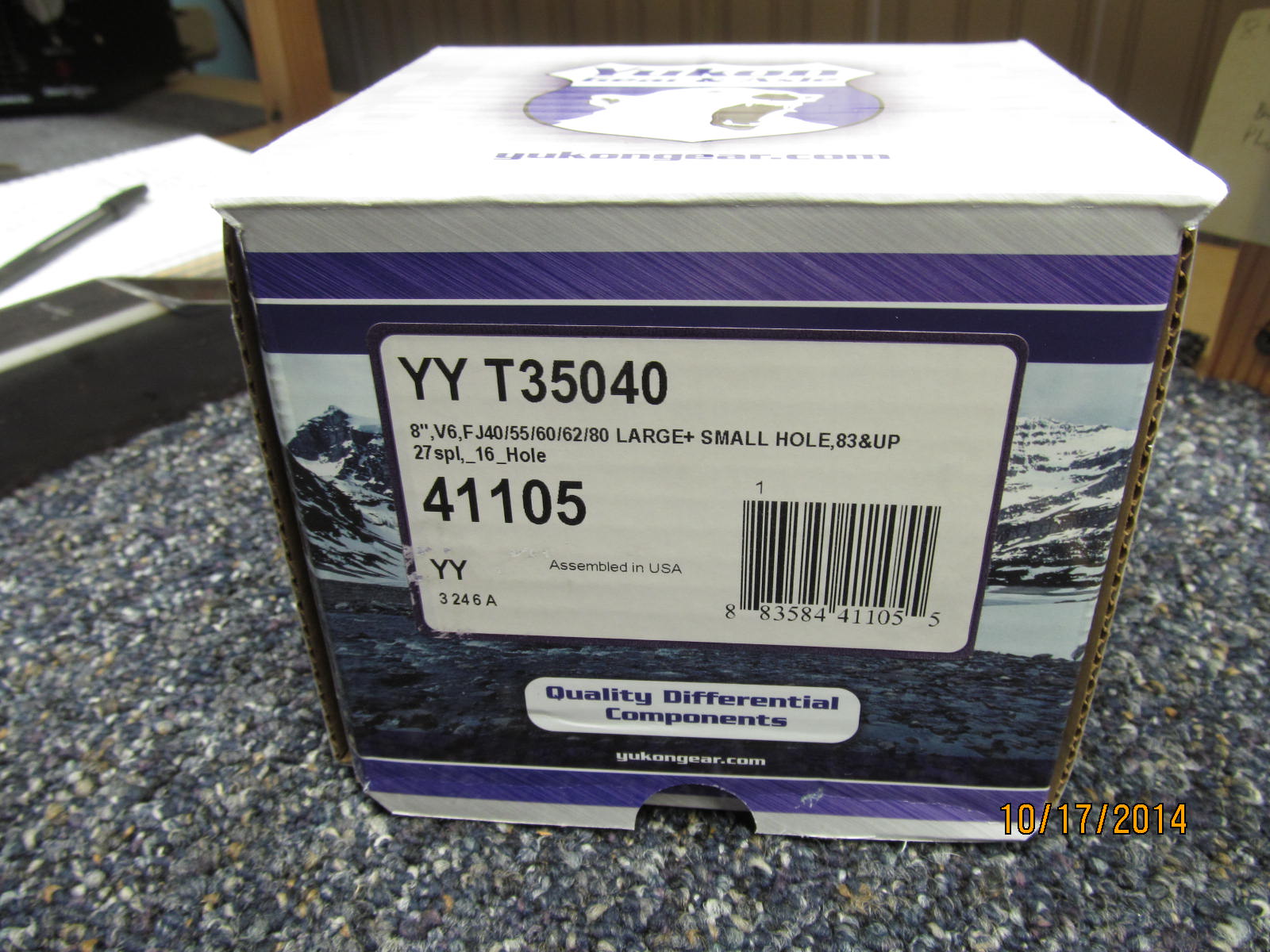

The 304 means this is from a Yukon box. This "brand" of gear is ok but I do have my favorites and those are

Nitro and G2.

|

|

|

|

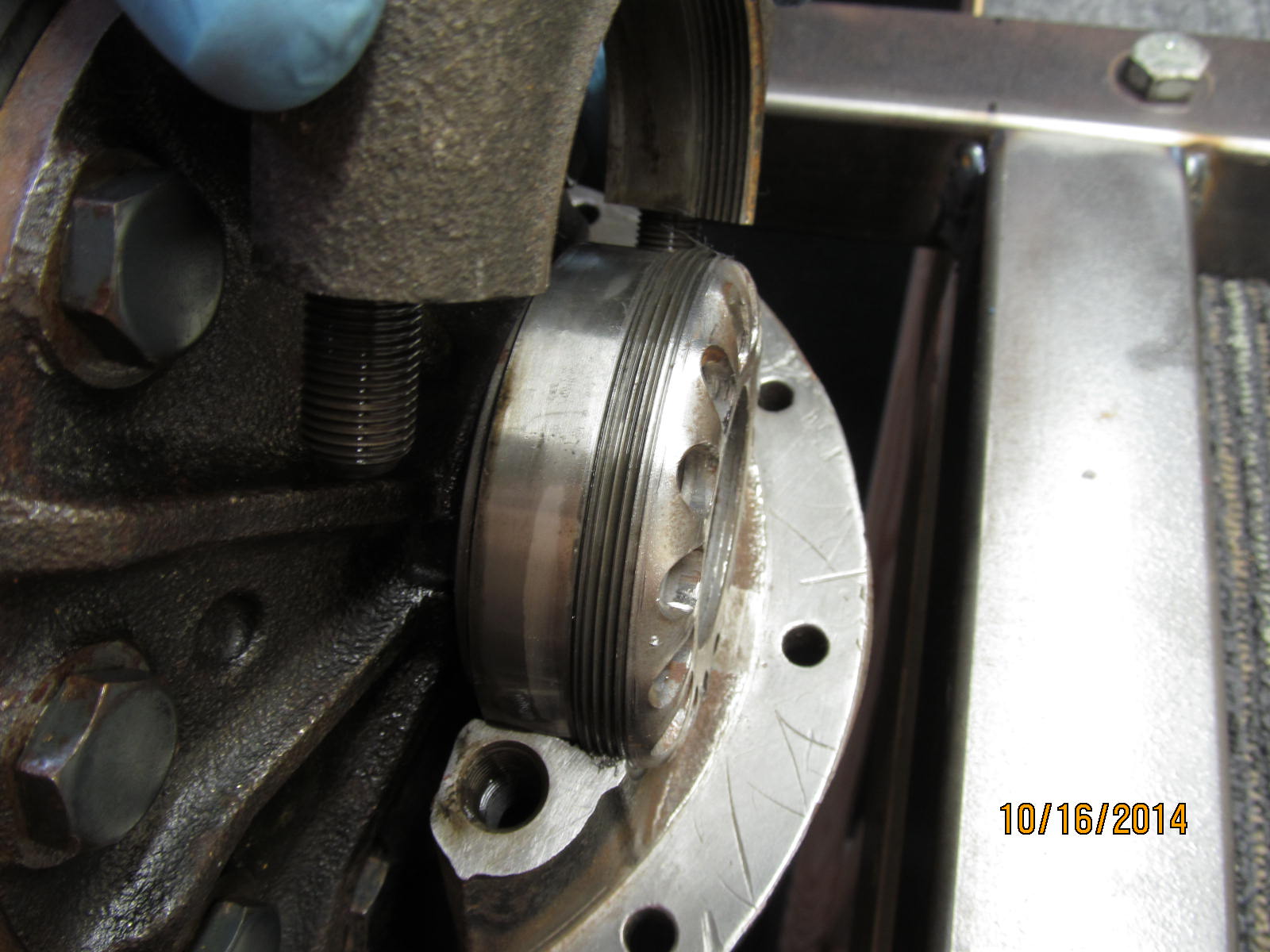

This wheel adjuster was not as tight as it needed to be.....If I tighten this side then I can increase the

backlash and the carrier bearing pre-load will also firm up much more.

|

|

|

|

|

This side would not even turn indicating the threads were likely out of alignment.

|

|

|

|

It's more obvious to me but the camera does not show it too well that the adjuster is "cock-eyed"....

pushed in more at the top than the bottom.

|

|

|

|

|

These 2 cap bolts were not as tight as they should have been...

|

|

|

|

...so I carefully removed the cap without disturbing the adjuster wheel. It was quite obvious that the

threads were off one.

|

|

|

|

|

Wheel threads were just fine....no damage.

|

|

|

|

A quick look at the carrier bearings shows that they are in perfect shape...looks like maybe the hubs

were never locked in yet.

|

|

|

|

|

Placing the wheel into the threads correctly shows that it still turns easily in the groove and no real damage.

|

|

|

|

|

Start the threads on the 2 long bolts... line up the bearing cap into the threads...

|

|

|

|

|

...it drops down just like it should...

|

|

|

|

....and a smack with the rubber end of the hammer makes a nice, solid seating sound indicating the threads

are now in harmony with the universe.

|

|

|

|

Now the bearing caps can be tightened and the wheels will now turn with relative ease.

|

|

|

|

|

Backlash is set to about .007"

|

|

|

|

|

This adjuster is rotated about 4 notches tighter than before....

|

|

|

|

|

...and this adjuster is a "don't know" because everything changed when the threads were re-aligned.

|

|

|

|

|

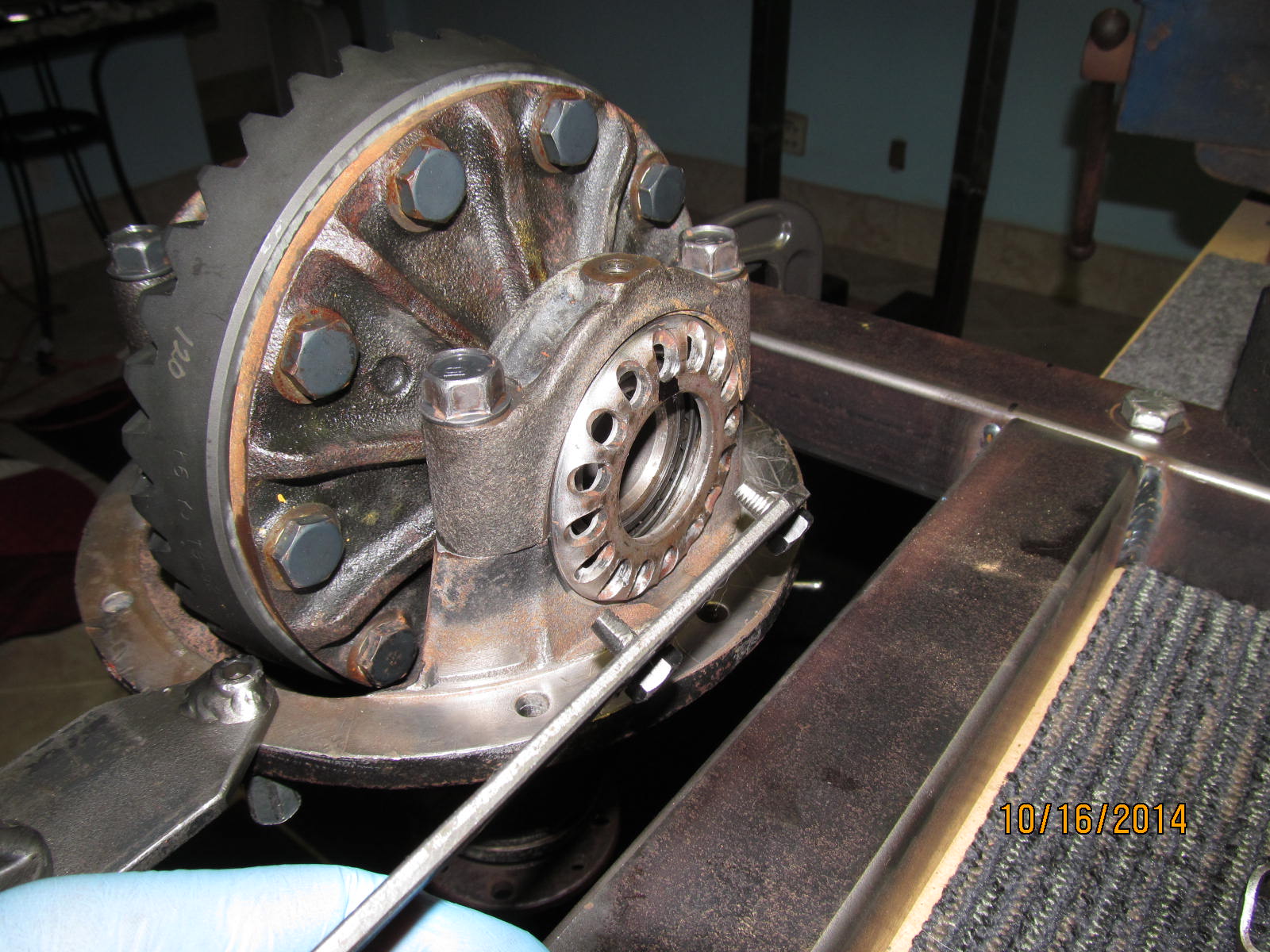

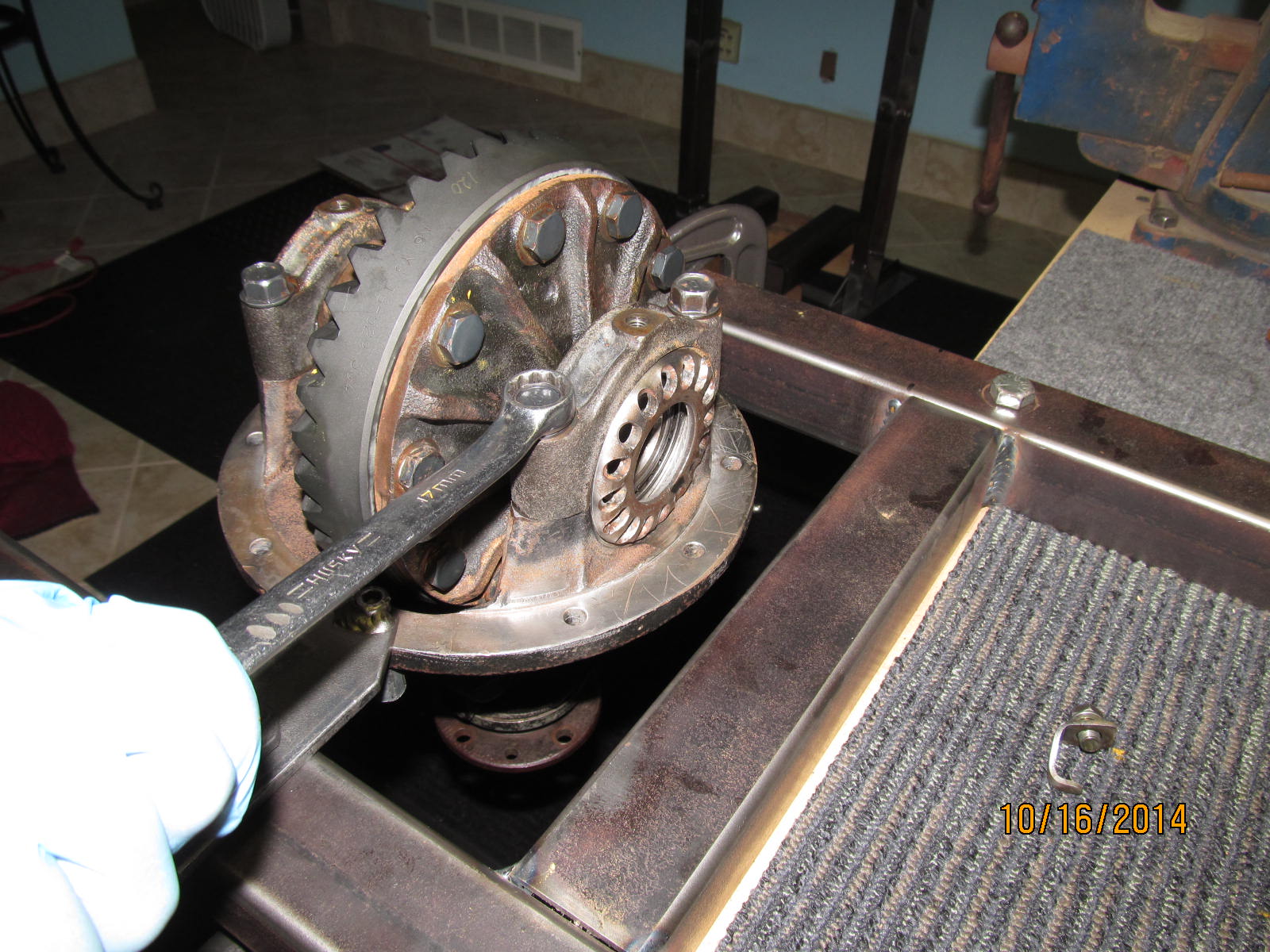

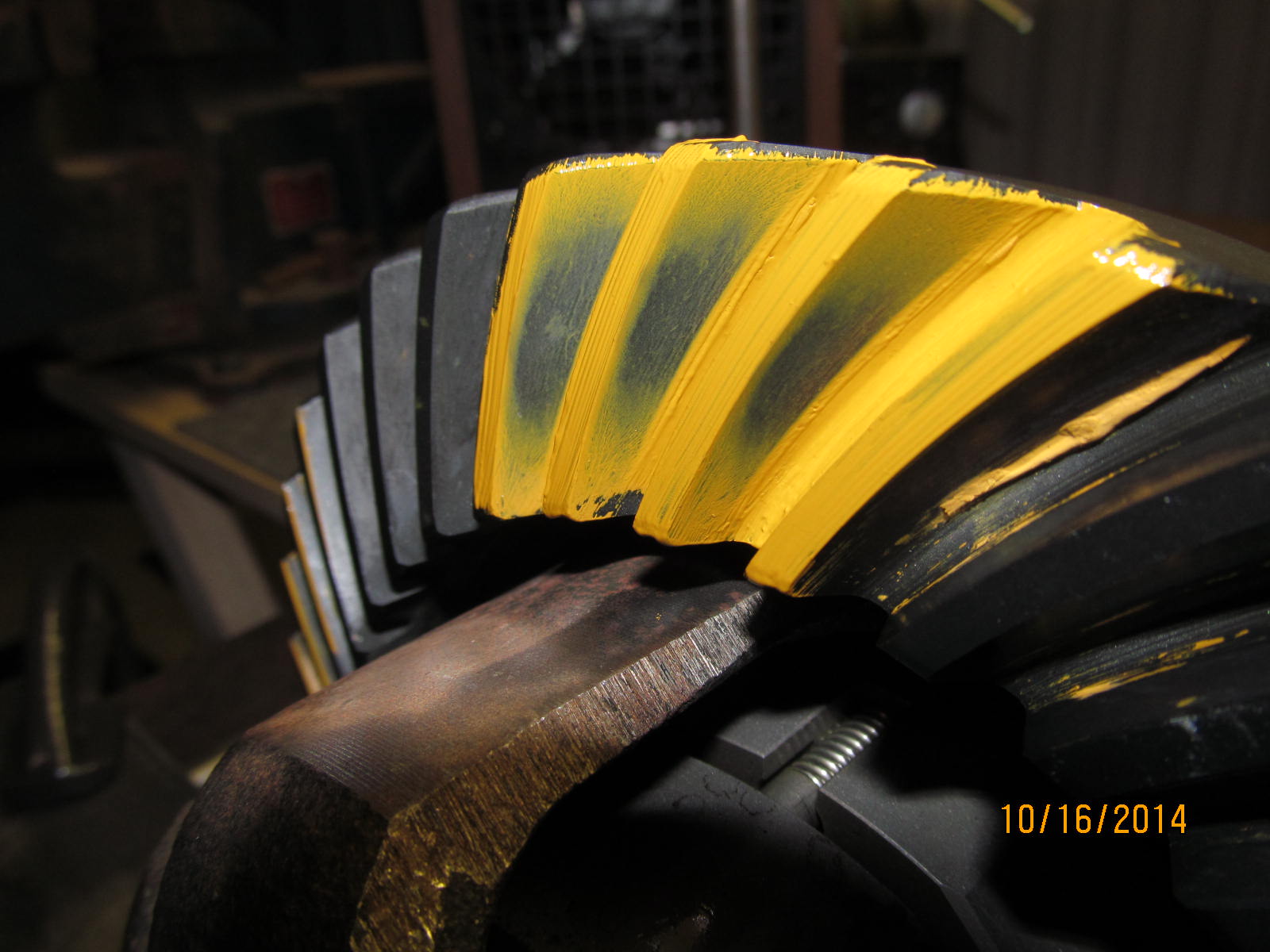

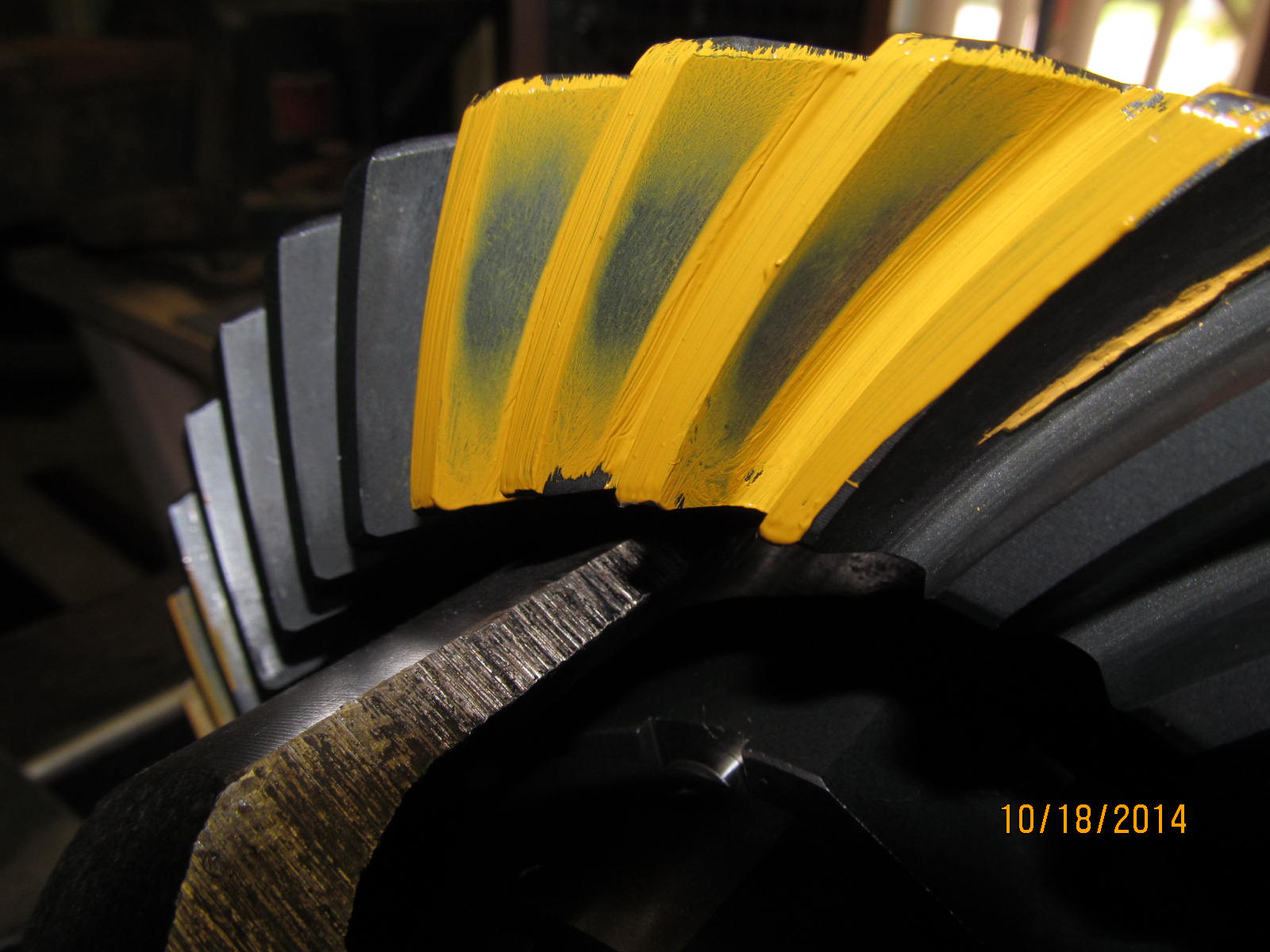

Paint is applied to 3 teeth and I'm using packing paper here to offer some resistance...

|

|

|

|

|

...while the ring gear is turned back and forth with a 17mm wrench.

|

|

|

|

|

Drive----nice...centered and slightly deep. My preferred condition.

|

|

|

|

|

Coast---surprisingly good.

|

|

|

|

|

Look at the tail of the comet....centered. Very good. (The right side is the tail)

|

|

|

|

|

This fuzzy pic of the 2nd tooth says the same.

|

|

|

|

|

And the 3rd tooth shows the comet about in the center from the face to flank direction.

|

|

|

|

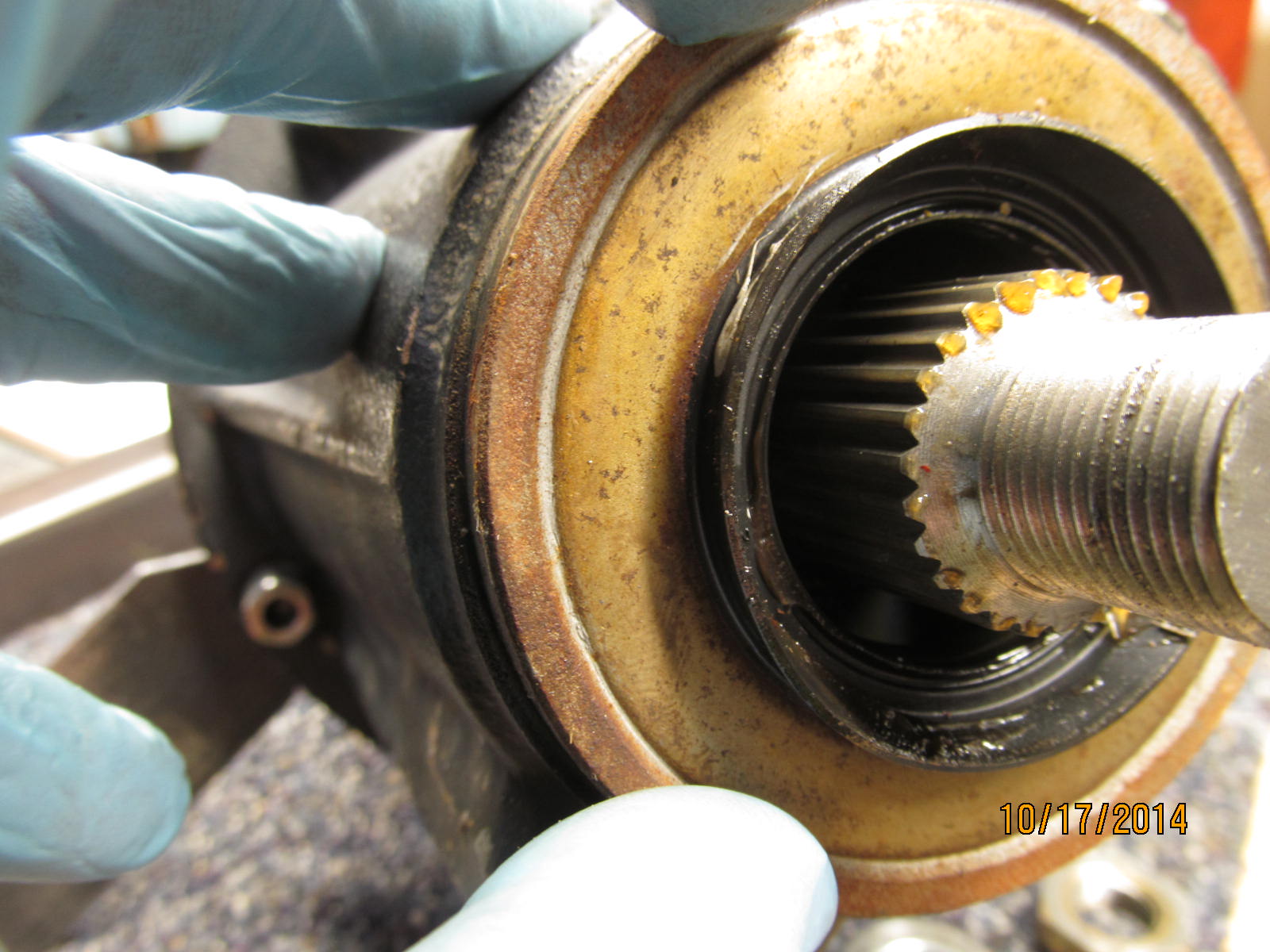

Now to look at the pinion end ... For some unknown reason, the last installer decided to grind/flapper off about

a full 1/8" of pinion and some nut also.

|

|

|

|

|

..................

|

|

|

|

|

.................

|

|

|

|

|

This triple drilled flange will replace the old one.

|

|

|

|

|

The nut was not exactly "tight". No Loctite either.

|

|

|

|

|

...............

|

|

|

|

|

....................

|

|

|

|

|

Grey RTV was used on the outside of the seal and it appears to be in good shape. No big dents in it.

|

|

|

|

|

Push the pinion out...

|

|

|

|

|

It already had a good solid collar on it....a Marlin collar as indicated by the tall neck at the top.

|

|

|

|

|

The 10 ring bolts were tight and appeared to have a high strength Loctite on them.

|

|

|

|

|

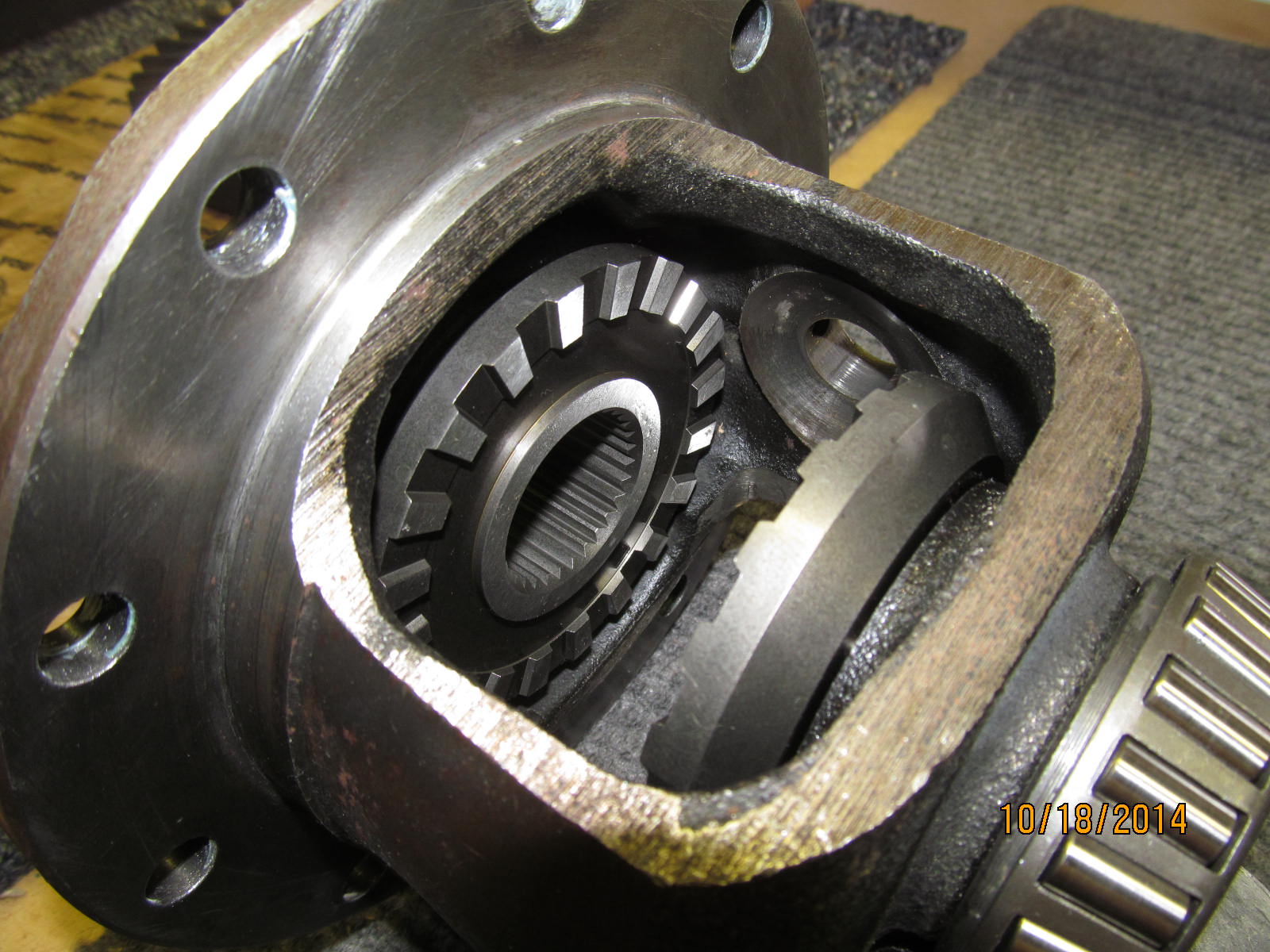

The Aussie Locker is to be removed ....and a Spartan will be put in its place.

|

|

|

|

|

But first, to finish up on the pinion end. Remove the seal.

|

|

|

|

The solid collar had some chatter wear so I used a flat surface and 120 grit to sand it smooth.

I only remove .001" or less.

|

|

|

|

|

I checked all the way around the collar with this extra large set of 12" calipers and it was within .001" variance.

|

|

|

|

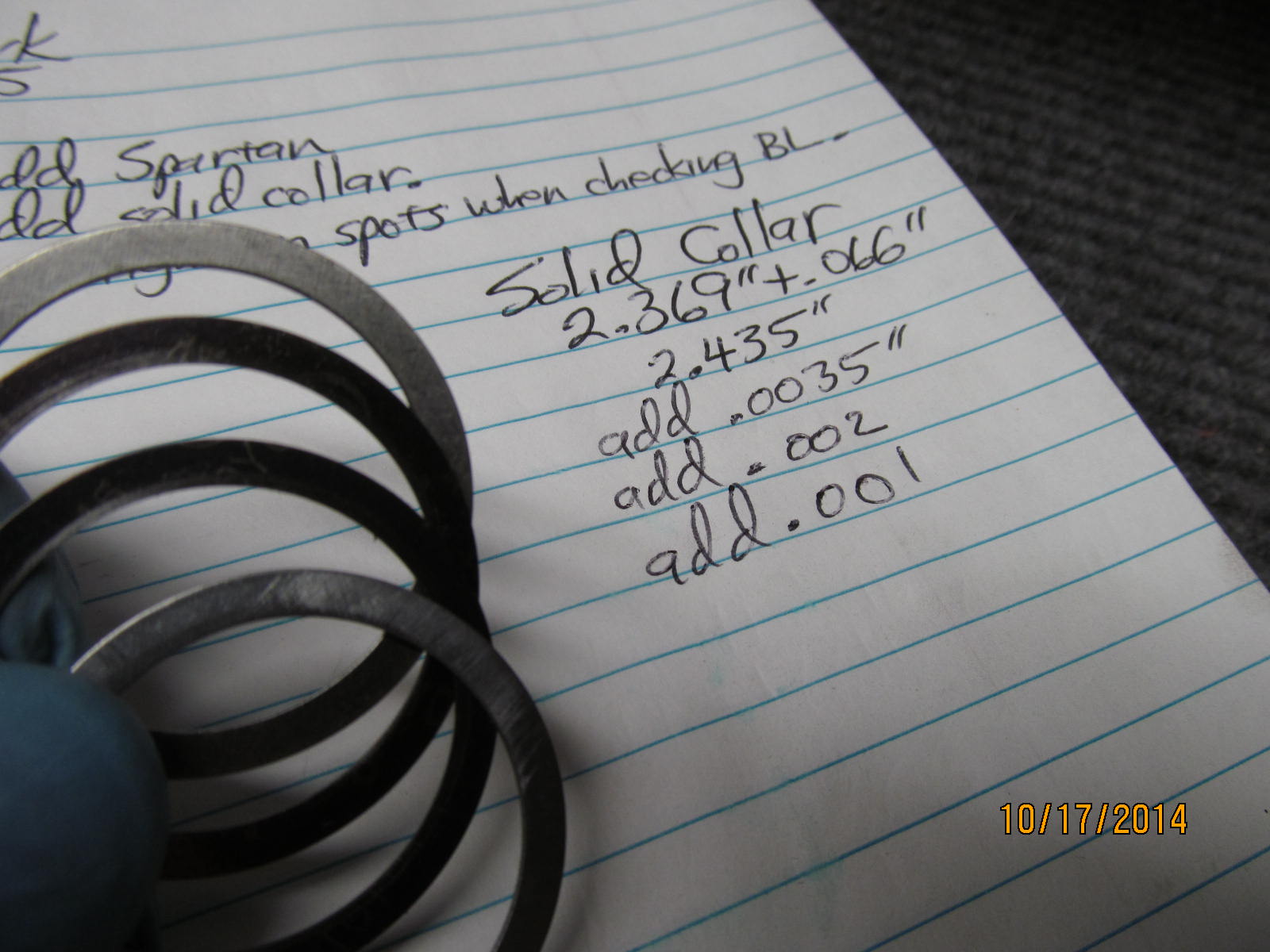

I tried the original 2.435" (collar plus shims) and the pinion pre-load was way too tight.....then added in

another .0035" and still too tight,...added another .002 and still kind tight....added .001" and perfect

at 5 in/lb pre-load. I can tweak the 5 into 10 just by tightening the nut a little tighter. That was

.0065" that was added to the collar.....that means the collar was not installed properly....means it

was effectively rattling around inside there.

|

|

|

|

|

Last chance to smother the bearings in gear oil.

|

|

|

|

|

The old flange was pretty rough over-all.

|

|

|

|

|

The seal surface did have a groove.

|

|

|

|

|

Glad that Mark wanted this new triple drilled flange.

|

|

|

|

|

Grease on the garter spring and grey rtv inside the bore.

|

|

|

|

|

This homemade seal installer works great. Made from an old race and an old flange.

|

|

|

|

|

A quick inspection inside to make sure the garter spring did not pop loose. All is good.

|

|

|

|

|

No anti-seize on this one...red loctite on those extra clean threads.

|

|

|

|

|

Ran it down hard with the electric impact and have about 7 or 8 in/lb preload.

|

|

|

|

|

I can get a little more rotation with the 150 ft/lb torq wrench and the double that it is attached to.

|

|

|

|

|

10 inch/pounds. Good.

|

|

|

|

Gonna be tough to ding that nut because of the limited surface left. The red loctite is more than sufficient

but the ding will still happen.

|

|

|

|

|

Ding!! Jeez....I needed a more tempered punch it looks like.

|

|

|

|

|

Surfaces checked with a big file and checked aok. Hmmm, too much flash in this pic.

|

|

|

|

|

A quick check of ring gear run-out shows less than .001 deviation. Very good. Definitely too much flash.

|

|

|

|

Now onto the Spartan install.

|

|

|

|

|

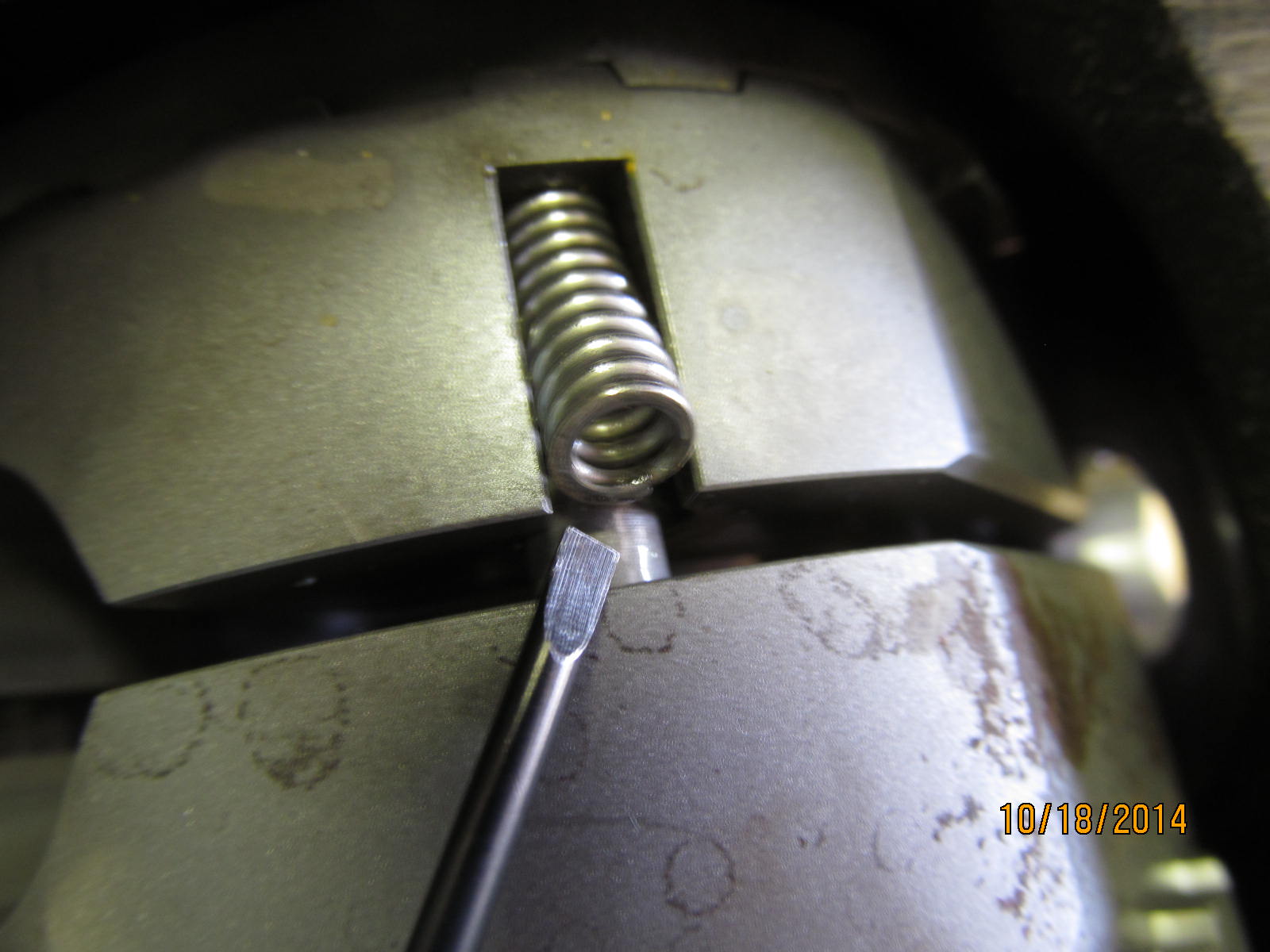

These Aussie springs come out fairly easy with the right slotted screwdriver.

|

|

|

|

|

.....................

|

|

|

|

|

But first, it's a good idea to drive out the steel dowel that holds the cross-pin in place.

|

|

|

|

The cross-pin came out and was a snug fit. Sometimes, these holes get wallowed out and egg shaped but

this one was as good as new.

|

|

|

|

|

Remove the remaining 3 springs.

|

|

|

|

|

Remove the drive couplers.

|

|

|

|

|

The Aussie is going back to Mark...less the steel dowel that does not belong in this pile.

|

|

|

|

|

Here is the Spartan ready to go in.

|

|

|

|

|

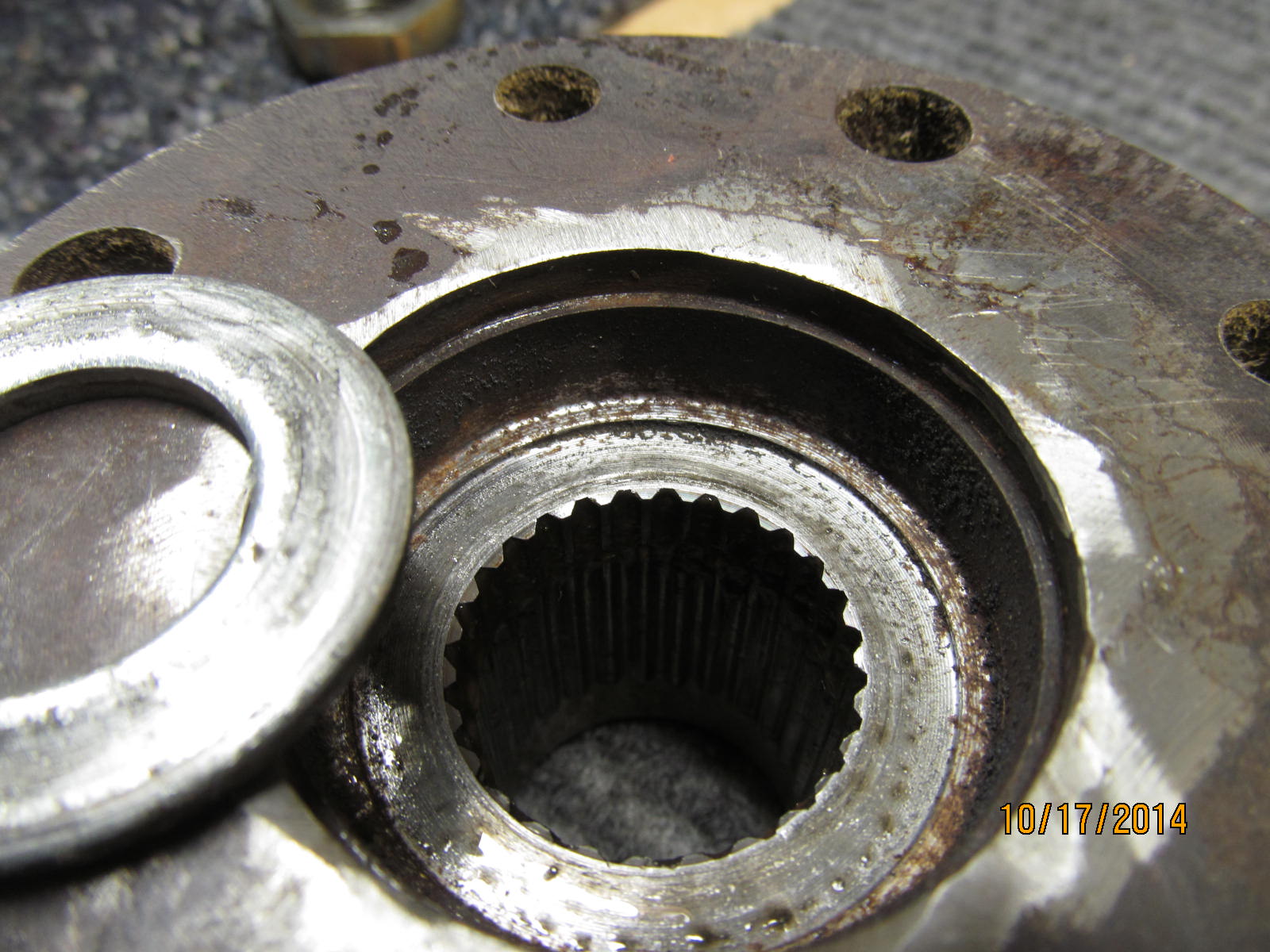

Sidegear couplers go in first....with NO thrust washer plates.

|

|

|

|

|

Loading the pins in place.

|

|

|

|

|

Push the pin down and insert the steel wire.

|

|

|

|

|

...............

|

|

|

|

This is a pre-check that should be done and that is to measure the clearance between the crosspin and spacers.

Needs to fall in the range of .006" to .020".

|

|

|

|

|

.013" would not fit and .012 fit snug in all 4 places.....unusually consistent.

|

|

|

|

|

Drop the one coupler in place....

|

|

|

|

|

...and then the other. But, don't do as I just did and have the washer on the right side in backwards :)

|

|

|

|

|

It was easy to hold both couplers in place while pulling the wires out with the pliers.

|

|

|

|

|

Then slide the couplers til the pins snap into place.

|

|

|

|

|

....almost in place....

|

|

|

|

|

Bam!!! In place now. :)

|

|

|

|

|

The new Spartan cross-pin goes in place.

|

|

|

|

|

Tap the dowel in place.

|

|

|

|

|

Use a center punch to distort the round hole so the dowel never gets a chance to wiggle out.

|

|

|

|

|

.........

|

|

|

|

|

Red loctite...

|

|

|

|

|

...and 75 ft/lb on all 10 ring gear bolts.

|

|

|

|

Put the carrier/case in place making SURE the adjuster wheels are in the threads correctly and tighten

the 4 long bolts also to 75 ft/lb

|

|

|

|

|

Set backlash while making sure there is good carrier bearing pre-load.

|

|

|

|

|

Medium strength blue loctite....

|

|

|

|

|

.....10 ft/lb on both lock tabs.

|

|

|

|

I measured 17 in/lb for the total preload. 17 is the start torq required to turn the pinion AND the ring gear.

Earlier, I measured the pinion bearing pre-load at 10 in/lb....so that means the carrier bearing pre-load

must be the difference between 17 and 10.....that be 7 in/lb for CBPL.

|

|

|

|

|

Drive pattern check--- Centered and slight deep.

|

|

|

|

|

Coast pattern--- Again, it's centered and slight deep.

|

|

|

|

|

......

|

|

|

|

Back to NJ Back to NJ

|

|

|

|

Back to NJ

Back to NJ