| 529 4-cylinder gears in a V6 elocker for Steve's 94 4Runner |

|---|

| (54 BIG pics loading) |

|---|

| MARCH 20 2019 |

|---|

|

| Steve's 94 4Runner is built to have fun. This is The V Notch at Wheeler Lake in Colorado. |

|---|

|

|

Steve had trouble trying to find a shop to install his almost new 529 4 cylinder gears in his front 8" elocker.

2 different differential shops said it can't be done....which kind of surprised me.

No magic involved. Just use a little bigger pinion shim ;) |

|---|

|

|

The 3rd and 529 gears are here in the box. I'm pretty sure that I can do a super job of setting up the

4 cyl gears in the V6 elocker diff. |

|---|

|

|

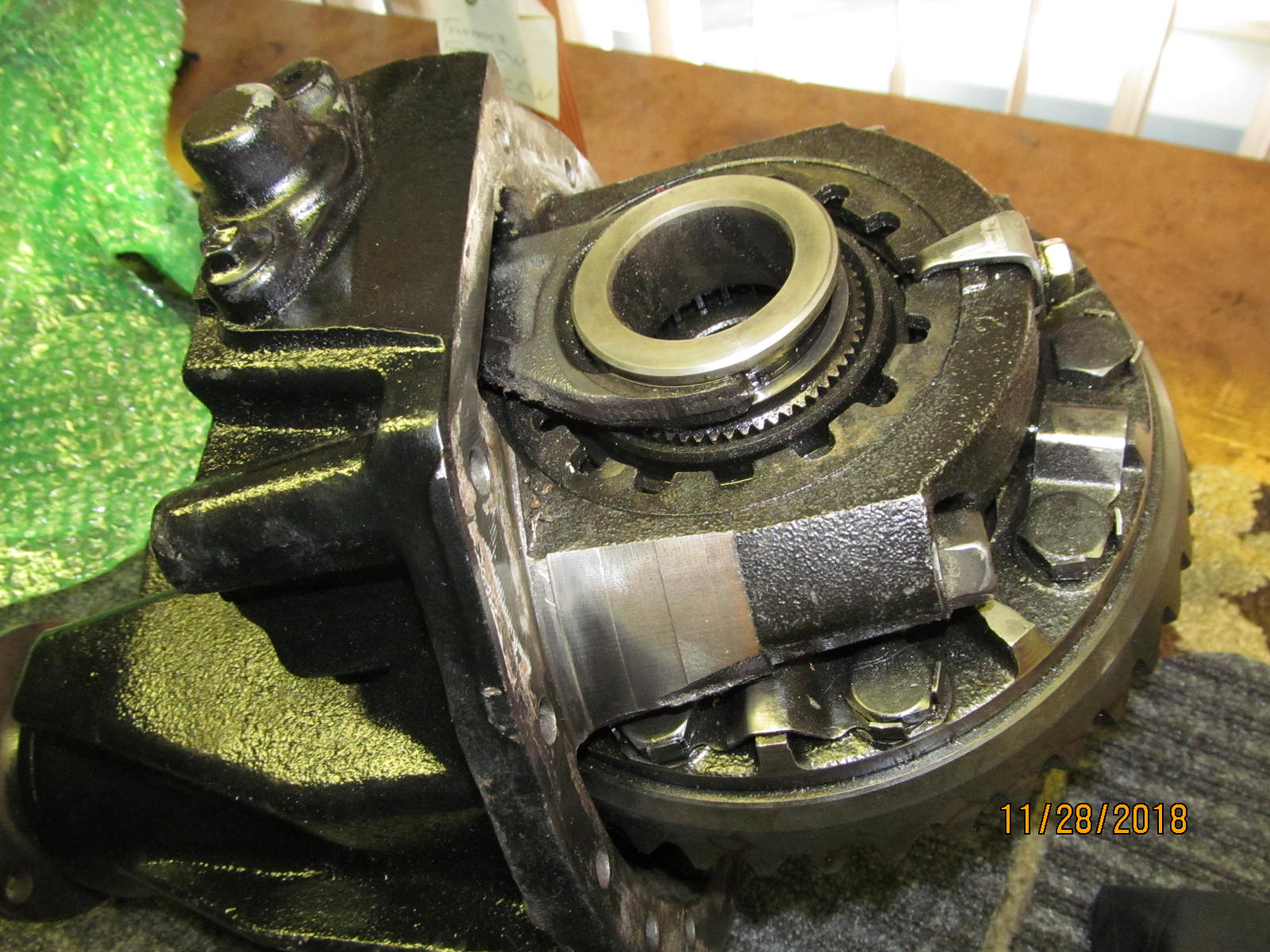

| The elocker arrived in good shape. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| Thank you Steve for sending such a freshly painted clean diff. The 27 spline "4 cyl" ring/pinion arrived undamaged, too. |

|---|

|

|

| 410 Elocker is mounted to the bench fixture. |

|---|

|

|

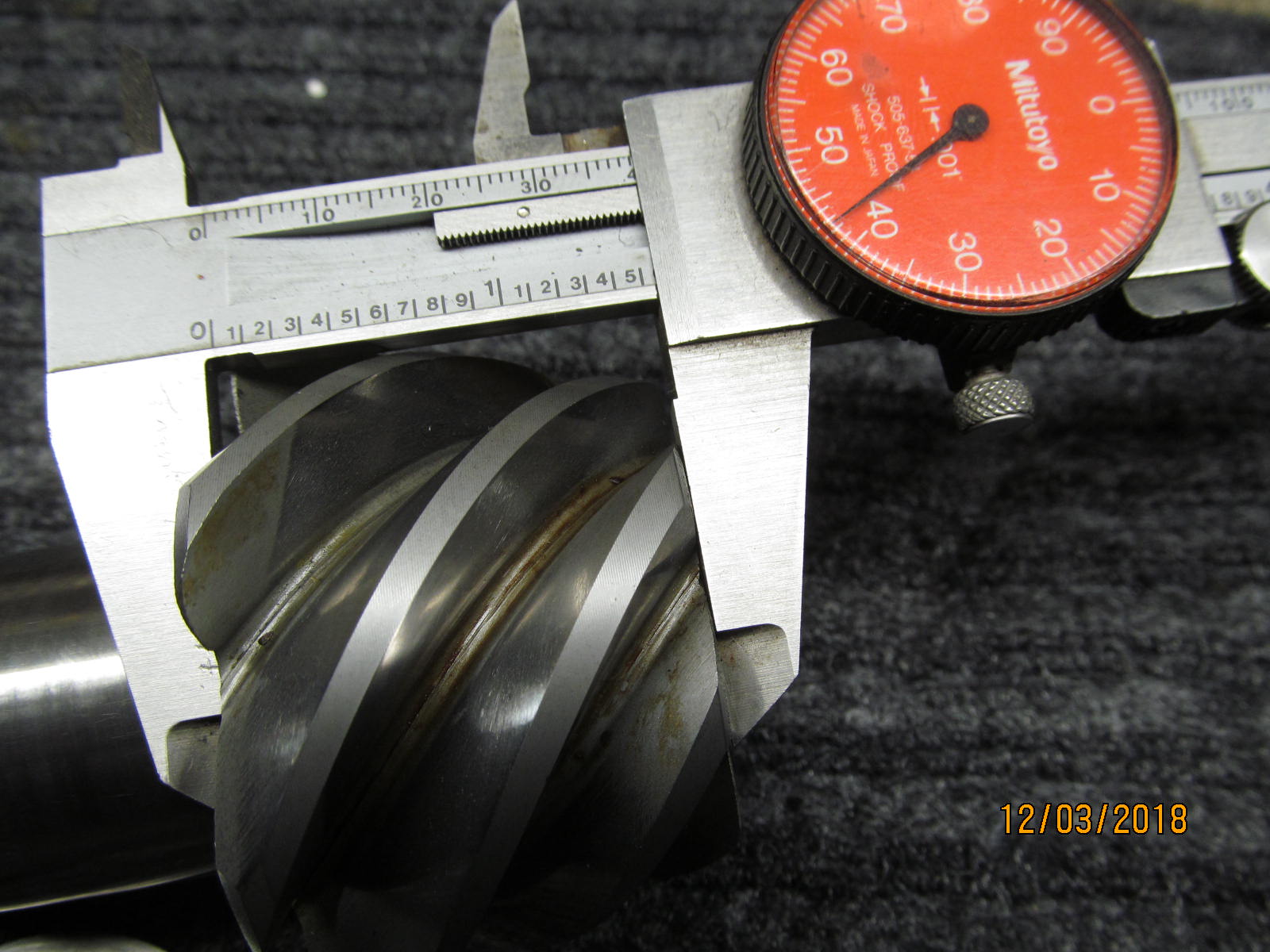

| The 529 pinion measures about 1.540 and that makes it a "short pinion head".....or 4 cyl gear set. |

|---|

|

|

| K T8-529.....that is a very good quality gear.....made in South Korea. Same place as the Nitro Gears. |

|---|

|

|

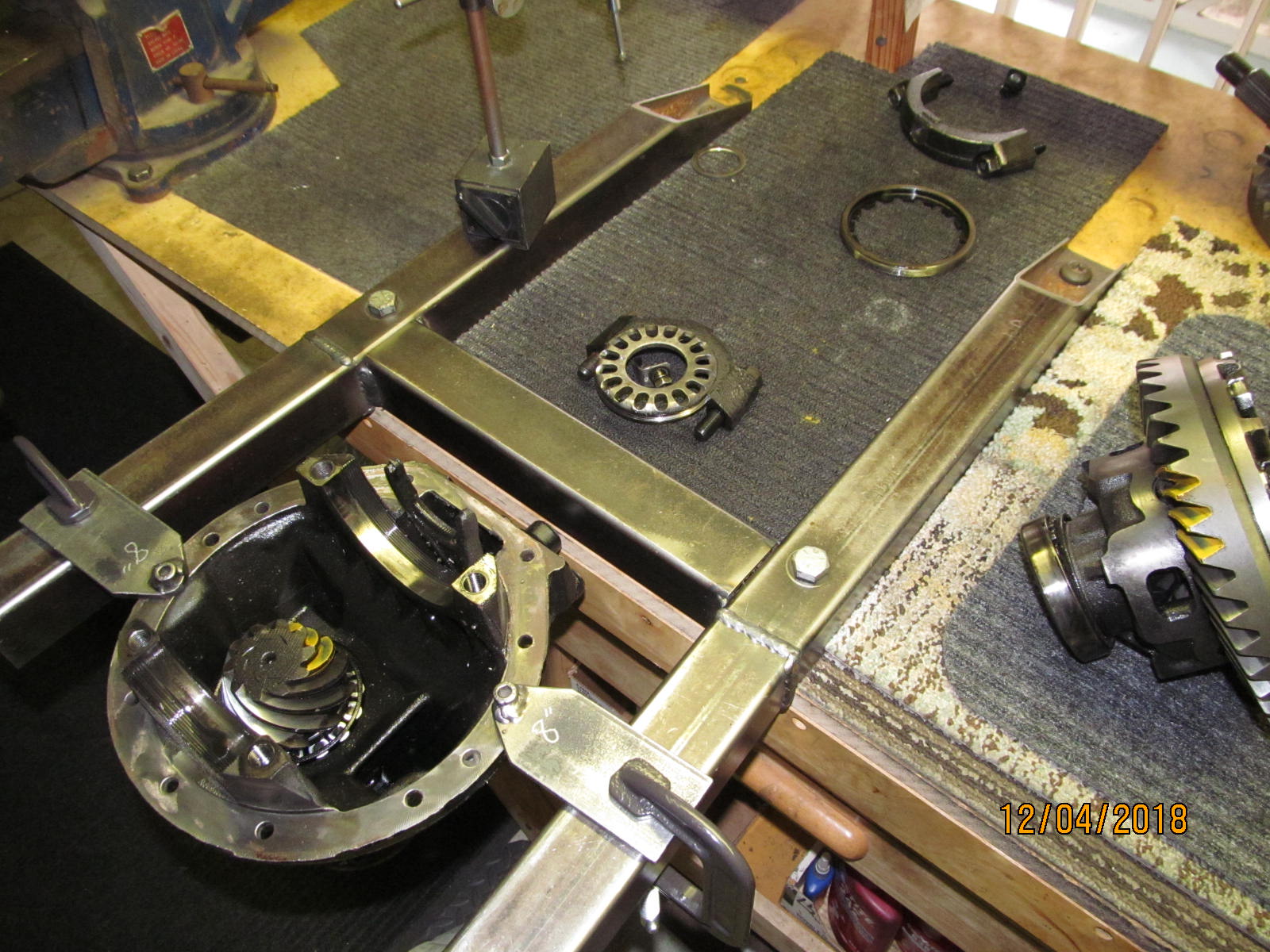

| Teardown of the 410 diff starts. Center carrier removed.... |

|---|

|

|

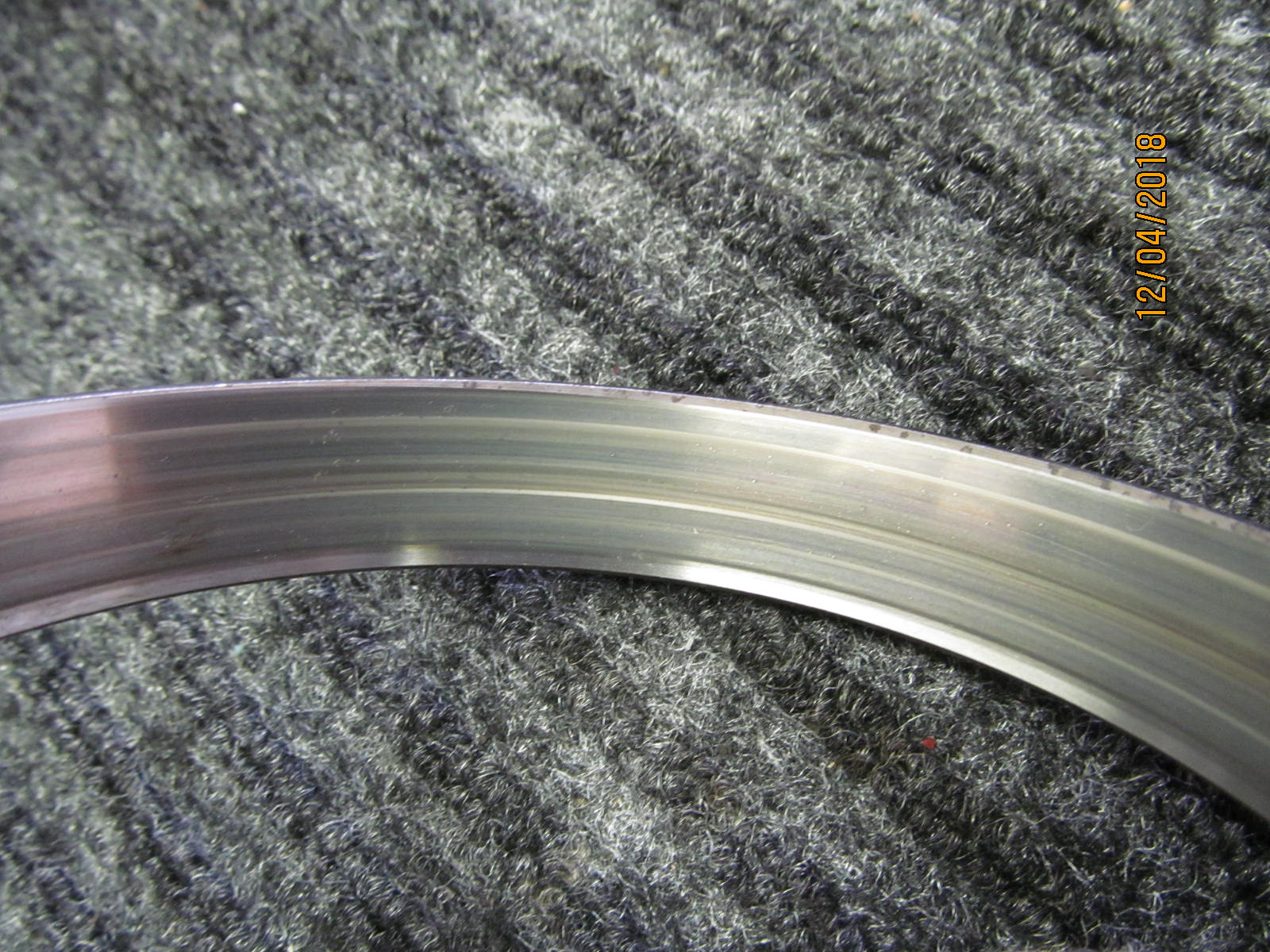

| The big carrier bearing race really has some unusual wear....good thing all the bearings are being replaced. |

|---|

|

|

| Looks like the rings of Saturn. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| 529 ring is checked with a file for unusual high spots and there were none. |

|---|

|

|

| Red Loctite and 70 ft/lb on all 10 ring gear bolts. |

|---|

|

|

| The Nitro bearing kit..... |

|---|

|

|

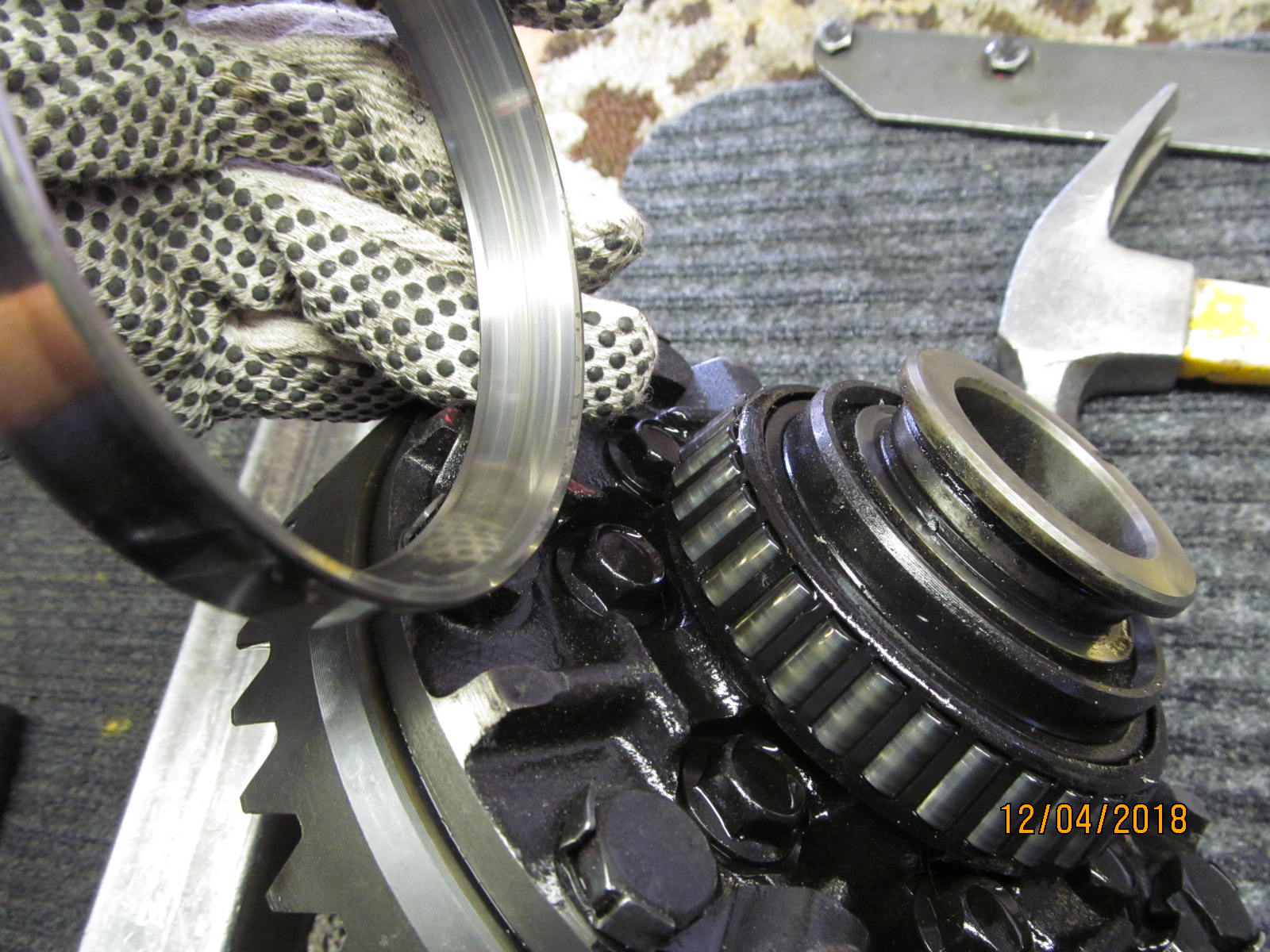

| New carrier bearings are tapped on and this end is complete. |

|---|

|

|

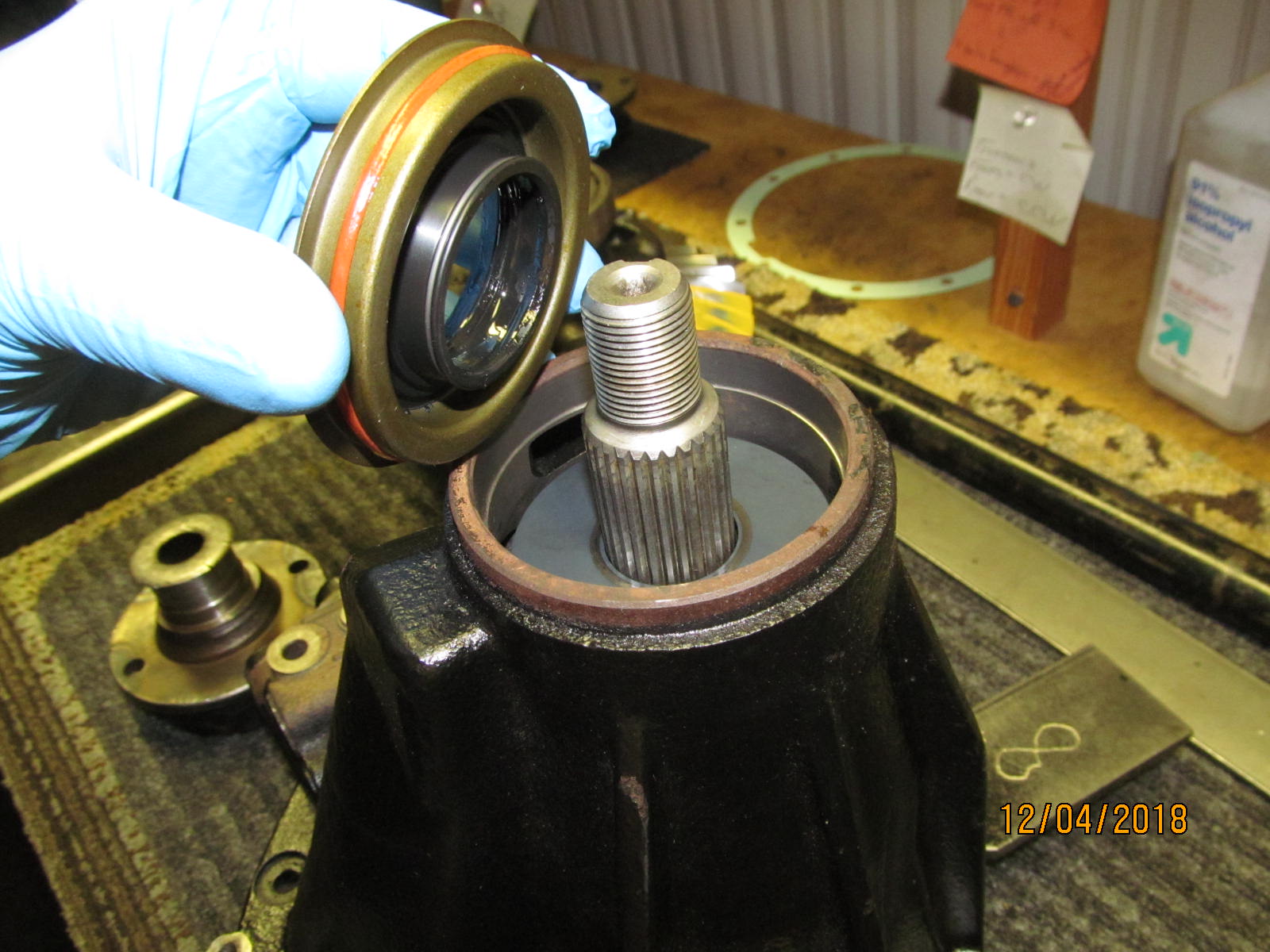

| The 27 spline pinion fits great in the 27 spline flange. Going first class and using a Marlin eco seal. |

|---|

|

|

| ================================================================= |

|---|

|

|

| Worn outer pinion bearing. |

|---|

|

|

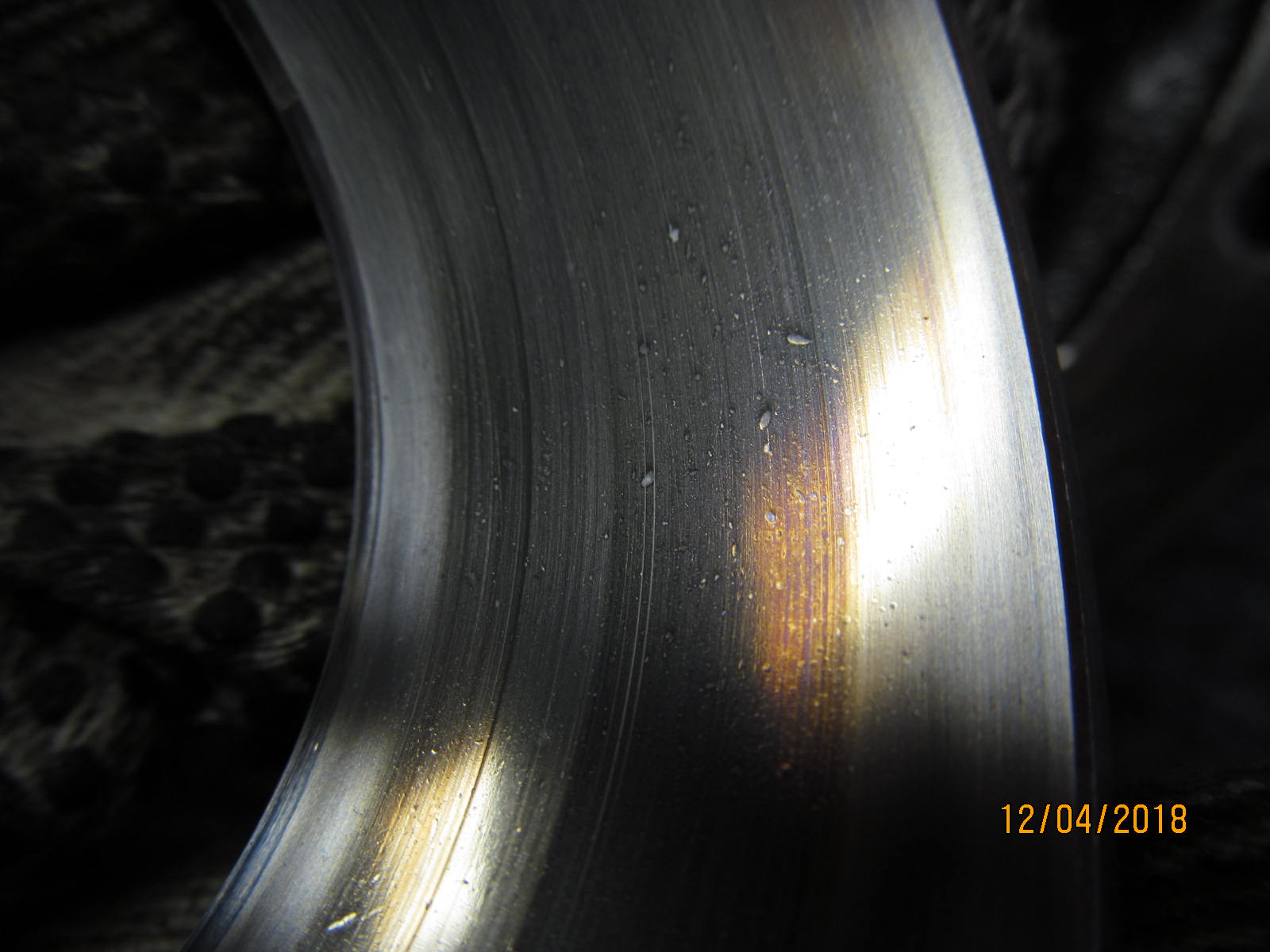

| The BIG inner race really looked the worst of the bunch. Not obvious in this picture.....but |

|---|

|

|

| .....it does become obvious in this one. Heat marks and moon cratering/pitting. |

|---|

|

|

My homemade tool for getting the small outer race out with no damage to the oil retainer....

a washer cut in half and a red bottle cap. |

|---|

|

|

| da dahhh.... |

|---|

|

|

| New races.... |

|---|

|

|

| The large inner race went in firmly. |

|---|

|

|

| Fully 100% seated too. |

|---|

|

|

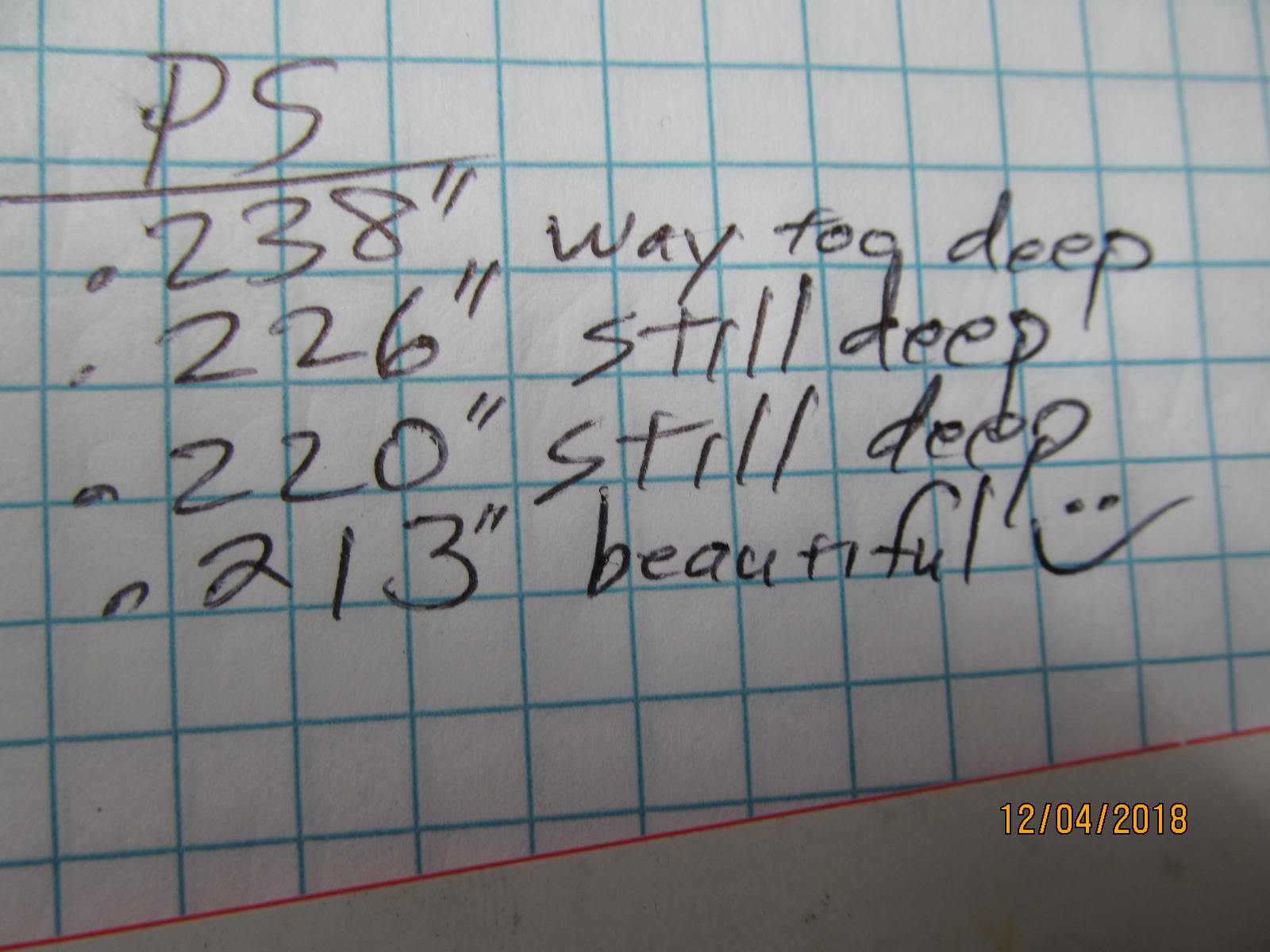

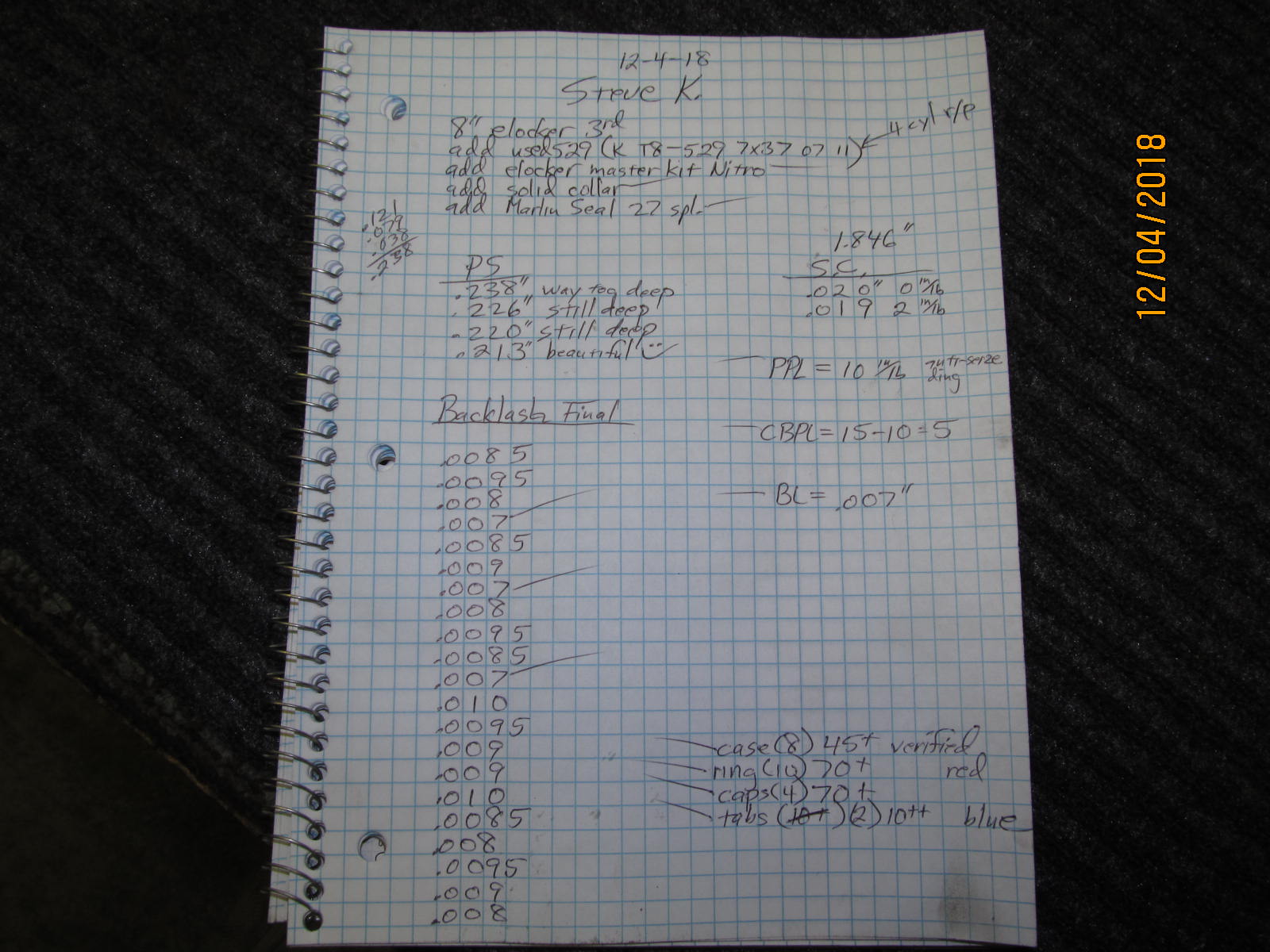

The only trick to get a 4 cyl gear set in a V6 diff is a little thicker pinion shim....

Instead of the usual .079" shim just step it up to roughly .238" and see what happens. |

|---|

|

|

| Press the new bearing on with the 12T Harborfreight press. |

|---|

|

|

| That's a lot of shim but does not affect strength in any way. |

|---|

|

|

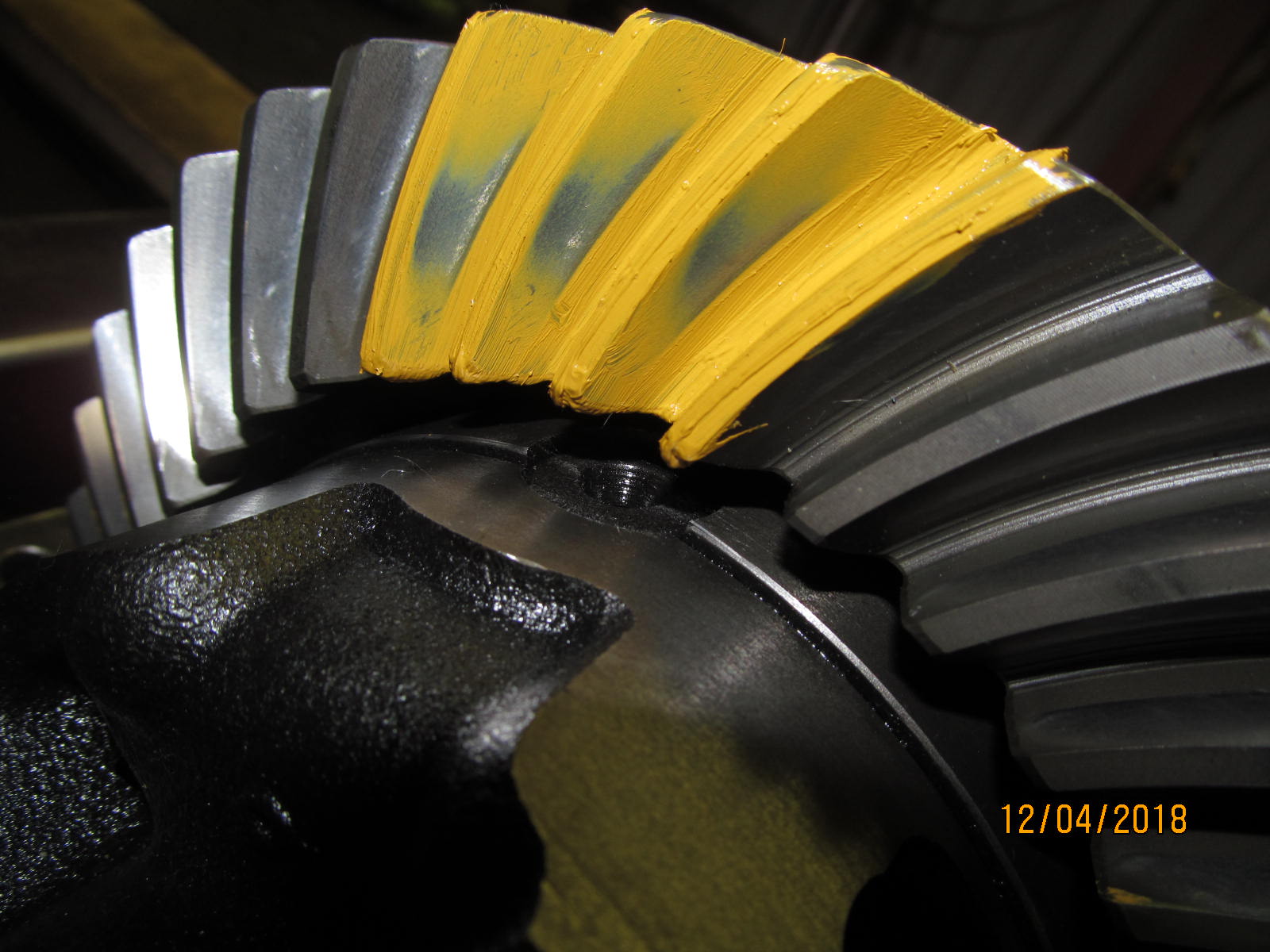

| Paint check.....DRIVE.....way too deep. |

|---|

|

|

| Coast agrees on the too deep. |

|---|

|

|

| Comet tail is saying the same thing(too shallow on the pinion tooth is too deep on the ring tooth). |

|---|

|

|

| Let's take .012" off for a total of .226" |

|---|

|

|

| DRIVE.....still too deep |

|---|

|

|

| COAST.....too deep |

|---|

|

|

| comet tail says too deep |

|---|

|

|

| Teardown ....take another 006 off (.220") and the drive side here says better but still too deep. |

|---|

|

|

| Coast really does say too deep still. |

|---|

|

|

| comet tail says too deep.....but getting real close. |

|---|

|

|

| Teardown and take another .007 off (.213") and this is really nice. |

|---|

|

|

| Coast is looking good. Face to flank is just about right. |

|---|

|

|

Comet tail gets the final word...and the word is to leave it alone. The tail is 10~20% out of the root of the tooth....

not close to the center(50%) and not hard into the root(0%)....like maybe 20 % out of the root. |

|---|

|

|

| Took 4 times to get that pattern. Sometimes I get lucky and nail it on the 1st or 2nd try....not today. |

|---|

|

|

With pinion depth established, now the solid collar can be shimmed up. Generally, on the V6 diffs, the collar plus shim

will equal about 1.865". The collar measured 1.846 and the final shim was .019" so it worked out perfectly this time. |

|---|

|

|

| Slinger is in place and now the Marlin seal. |

|---|

|

|

| A little bit of anti-seize.... |

|---|

|

|

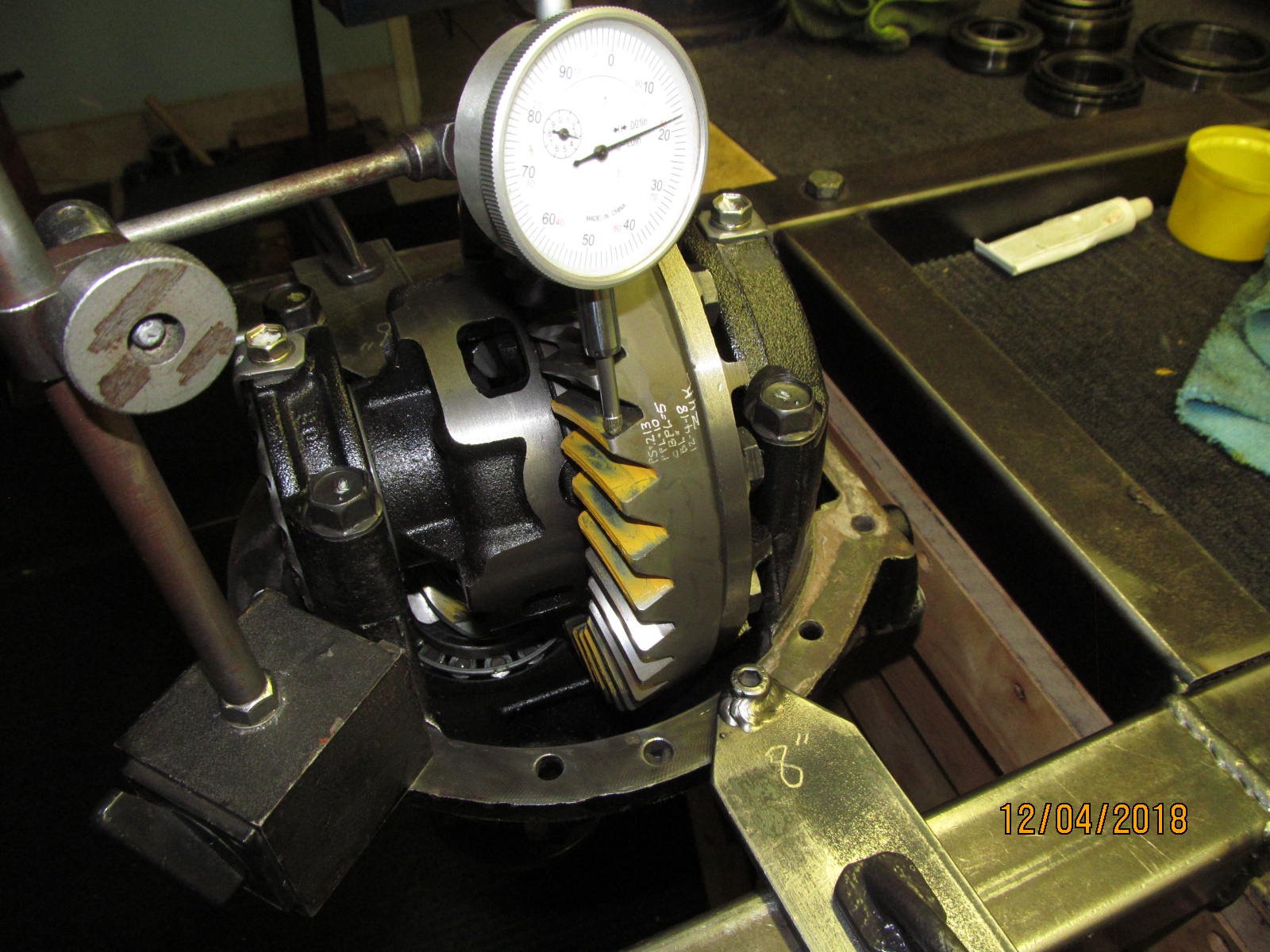

With about 100 ft/lb on the pinion nut, the actual pinion bearing preload was only about 2 inch/pounds.....

but tighten that pinion nut up to about 200 and watch the pinion bearing preload go up to a good number like shown

here......A nice smooth 10 inch/pounds final pinion preload. DING! and this end is done. |

|---|

|

|

| Tighten the 4 bearing cap bolts to 70 ft/lb and then crank in the carrier bearing preload with the adjuster wheels. |

|---|

|

|

| Backlash was measured and recorded on every other tooth. The minimum was noted to .007". |

|---|

|

|

| A snapshot of the install notes. |

|---|

|

|

| On this one, I chose to burrito wrap it in bubblewrap. |

|---|

|

|

| A combination of foam and heavy duty packing paper for the bottom. |

|---|

|

|

| More bubble wrap on top and close it up. Ready to go to Fedex now. |

|---|

|

|

| |

|---|

|

|

|