|

|

|

|

|

|

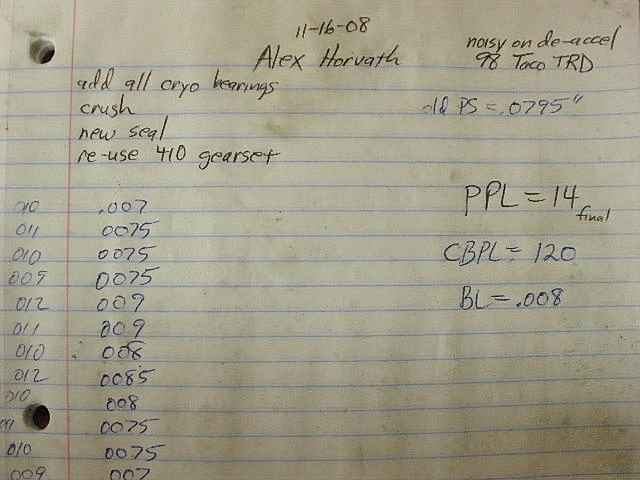

Alex sent his e-locker to me from San Jose, CA. The plan is to re-use the stock 4.10 gearset and install new cryogenically treated bearings. I can see, from the position of the locking fork, that Alex had wisely locked the diff before dis-assembly. |

|

The noted distance from the fork to the edge is 5/8"...for the locked position. |

|

Alex had removed the motor and switch sensor before shipping it to me. This is a good idea to prevent any kind of damage from the shipping process and from the installer accidentally breaking the plastic sensor, etc. |

|

The carrier bearings will be replaced and the wheel position will likely change but I still marked the wheel just from habit. |

|

Remove the 4 cap bolts. The electric impact speeds things up nicely. |

|

This is one of the old carrier bearing races. The camera has a hard time capturing the pitting and the heat marks. |

|

The other CB race has the same issues with pitting and heat patterns. The light caught the race differently here and is making it look green. |

|

All 4 bearings have been cryo treated from Cryogenics International. Cryo treating metal does not harden or soften it....it basically makes it more 'durable', fatigue resistant, stronger, smoother surface on a microscopic level, and removes stresses. These bearings will wear probably 2 to 4 times longer and keep their preloads longer. |

|

Both carrier bearings are removed with this puller. |

|

Those lock tabs get in the way when I try to attach the 17mm wrench that is used for pattern checks. |

|

The tabs have been discarded and the ring gear bolts are now re-installed with red Loctite. 75 ft/lb. |

|

Cryo carrier bearings are pressed on. |

|

Before removing this 30mm pinion nut, I did notice considerable play indicating loose bearings. A loose pinion will tend to cause a rumble during de-accel. Theoretically, one should be able to tighten the pinion nut until the play is gone and problem solved. But what if the small outer pinion bearing has already been destroyed from being run in this loose mode for too long a period of time? |

|

The flange's seal surface looks ok with only one tiny groove from the original seal lip. |

|

The pinion is pressed out. If I recall correctly, this one took considerable effort to push out. That would mean that the outer bearing was a little seized onto the pinion...perhaps due to excessive heat? |

|

A new crush sleeve will be used upon re-assembly. |

|

This inner pinion bearing was really stuck on there...I almost had to break out the Randys Ring And Pinion $400 puller. |

|

There must have been some heat involved to partially weld the bearing to the pinion and leave some tell-tale marks. |

|

The fresh cryo bearing is pressed on with the factory .0795" shim. |

|

The old seal is removed... |

|

The small outer pinion bearing is all but destroyed. Why would this happen? My guess would be oil starvation due to a very low oil level in the pumpkin....or perhaps old black gear oil that has lost its lubrication properties over time. |

|

The race looks terrible. |

|

The oil retainer received minor damage while the outer race was being pounded out with a sharp punch. |

|

... |

|

By smoothing out the damage with a flat punch and orienting the holes in the 3 and 9 o'clock positions, the oil retainer will still function 100% in its duty. |

|

By casting the light on the big inner race just right, some pitting can be seen. |

|

New cryo races are pressed in. |

|

The top end is assembled with a new crush sleeve and seal. |

|

The new pinion nut gets a healthy coating of loctite. |

|

Even with a 4 foot cheater bar, the crush sleeve did put up a good fight. I chose not to use anti-seize which would have reduced the effort by about 30%. |

|

I was very happy with 14 inch/pounds. |

|

Ding and this end is done. |

|

The case is now loaded in place and the bolts are tightened to 75 ft/lb. |

|

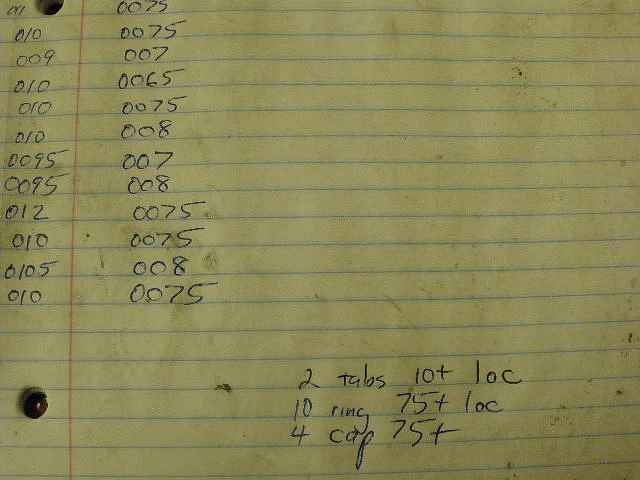

The wheel adjusters are tightened to 120 ft/lbs on the wheels which is equivalent to 12 inch/pounds of actual drag on the 2 bearings. This, I determined in previous tests. The final backlash was .008" as determined by averaging the 21 measurements around the ring. |

|

drive side |

|

coast |

|

A permanenet log of what was done... |

|

Actual notes taken. |

|

... |

|

... |

|

Done. Ready for San Jose. :) |

|