|

Pre-assembled V6 3rd has pinion leak and set shallow.

|

|

(67 BIG pics loading)

|

|

March 22 2014

|

|

|

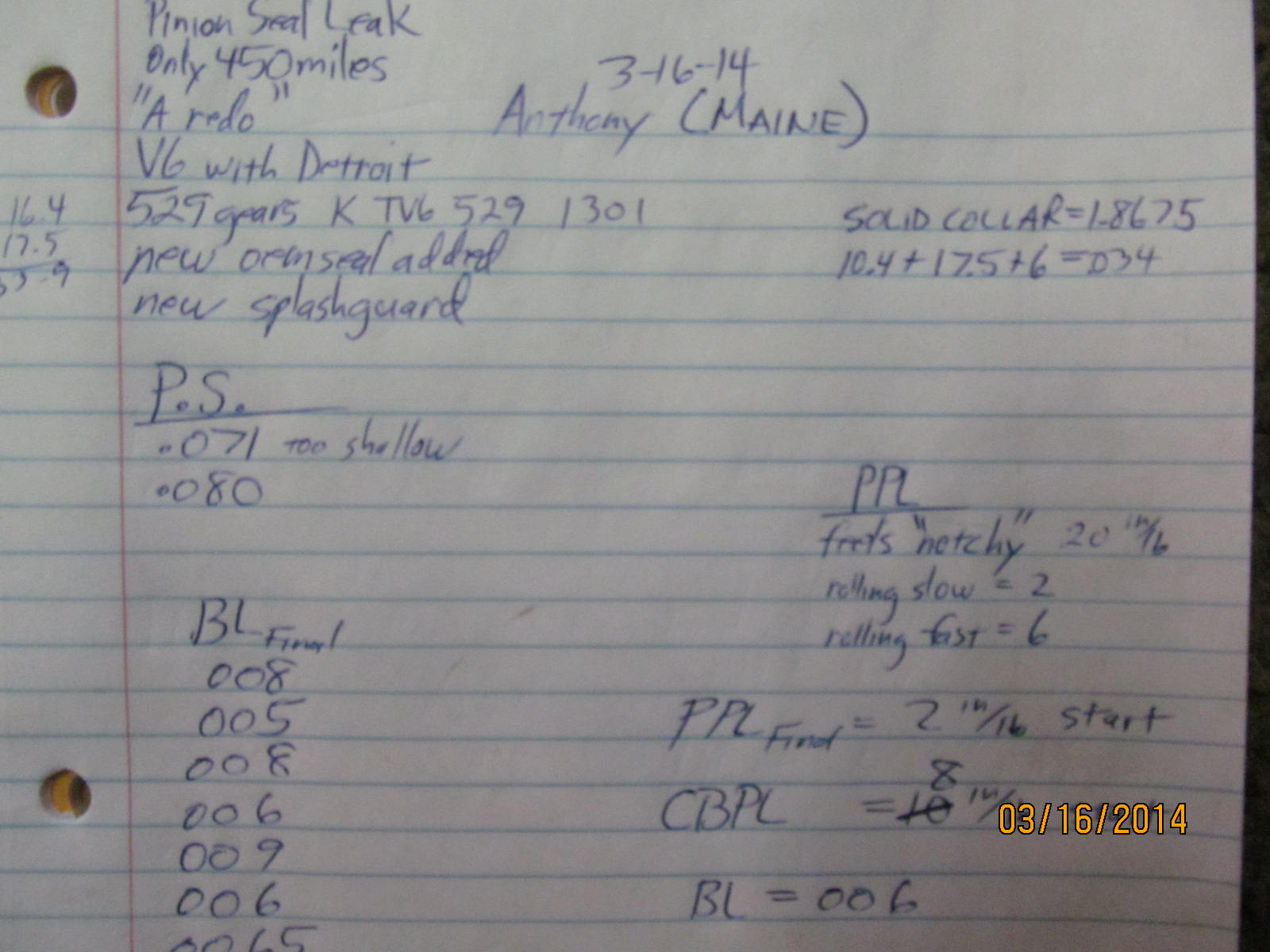

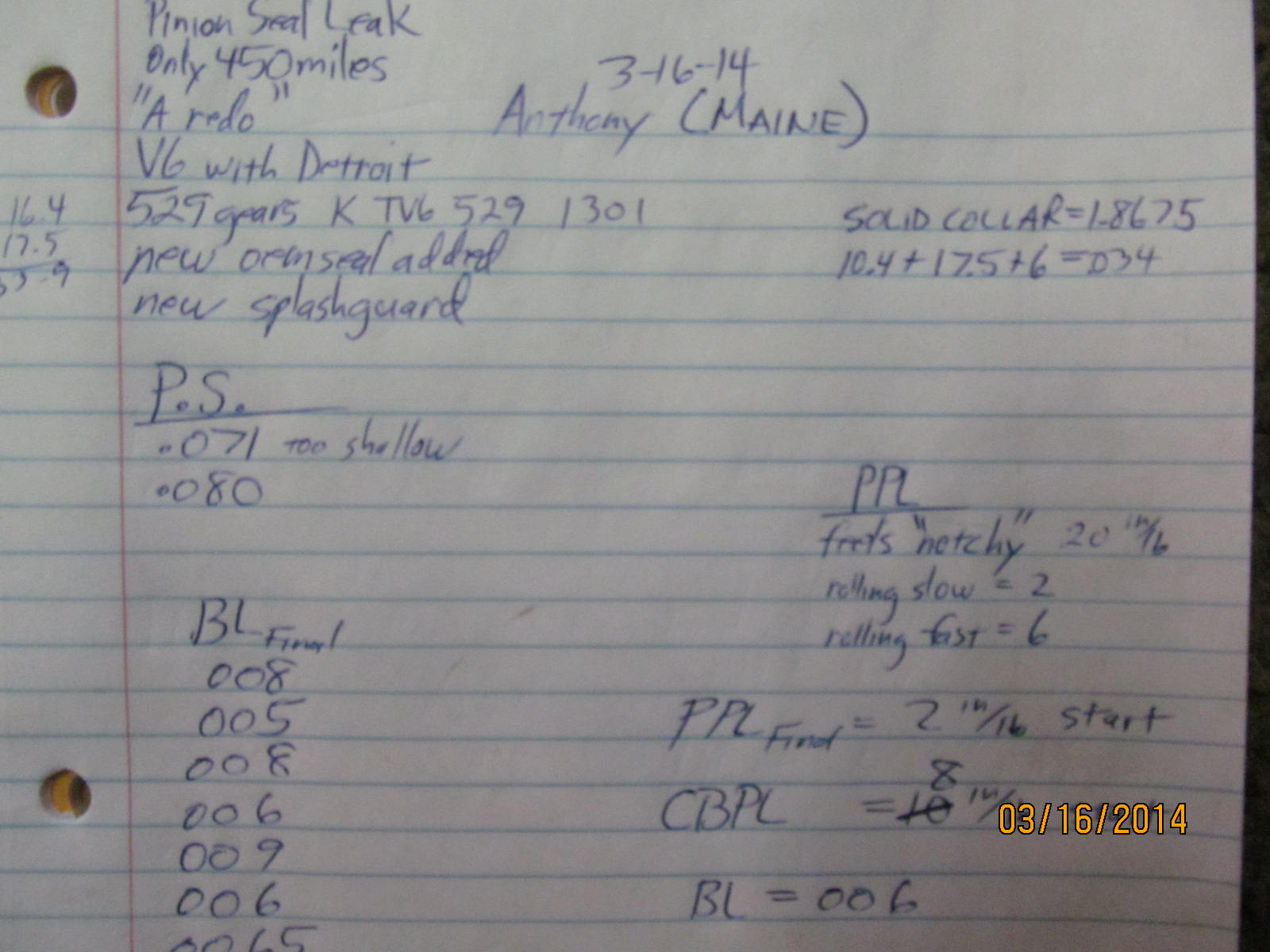

Anthony, located in Maine, has a 1992 3.0 with 5 speed....SAS...529 gears/lockright front/Detroit rear. 251,000 miles on the clock.

He recently experienced a pinion seal leak from a pre-built 3rd that came from a large internet company.

|

|

|

|

|

With less than 450 miles on the rear 3rd, Anthony boxed it up and sent it 2,709.2 miles to me.

|

|

|

|

|

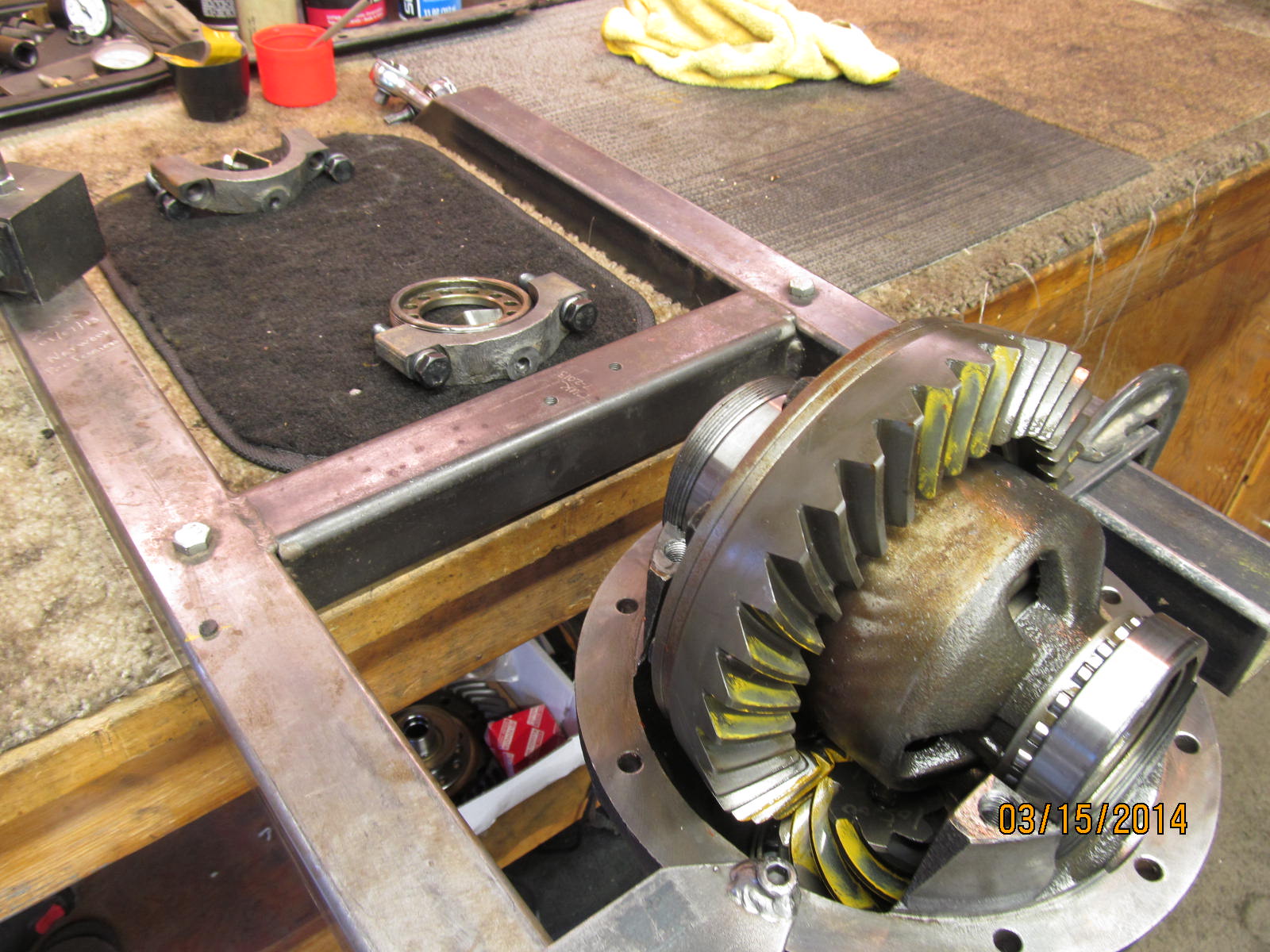

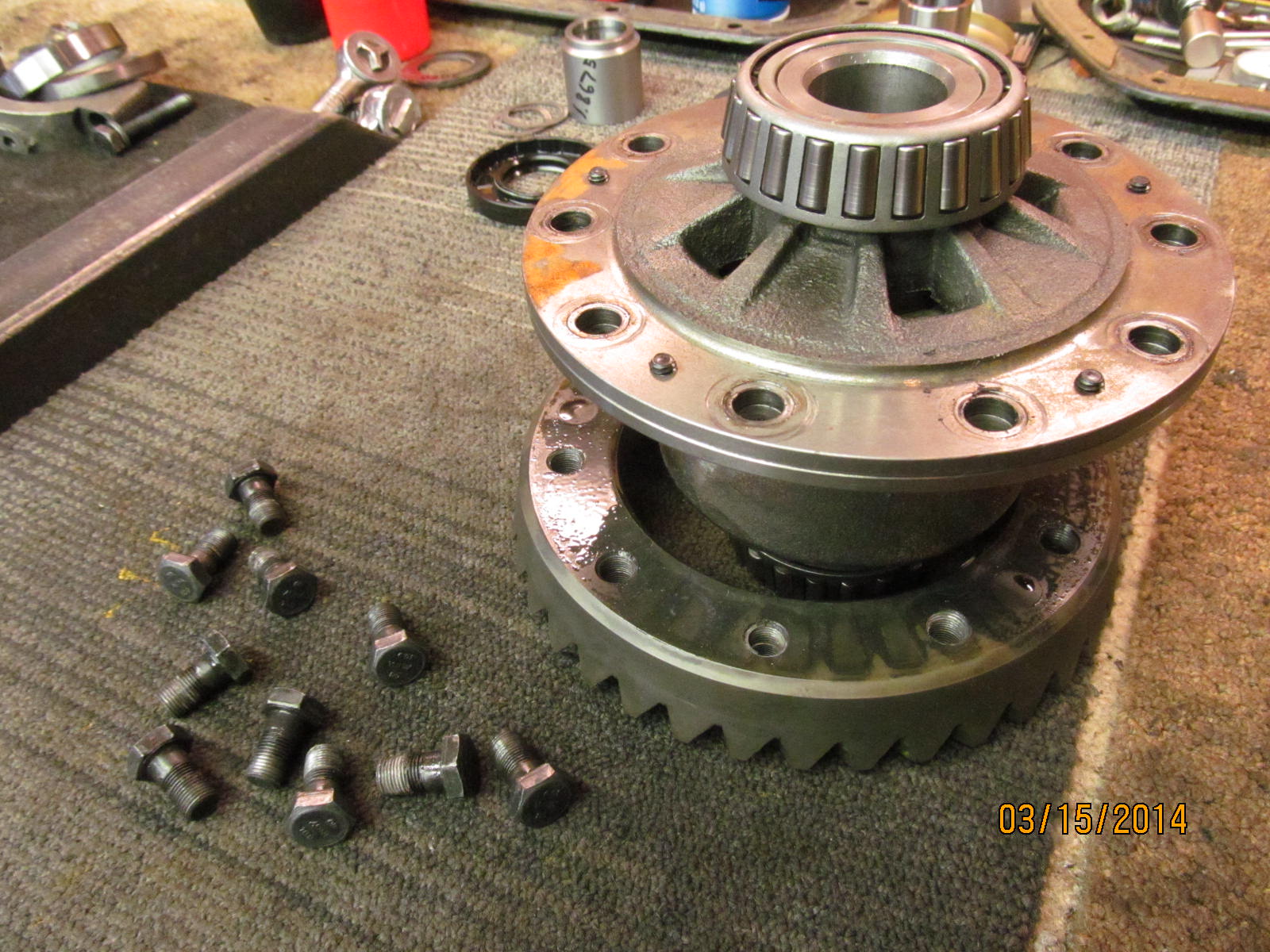

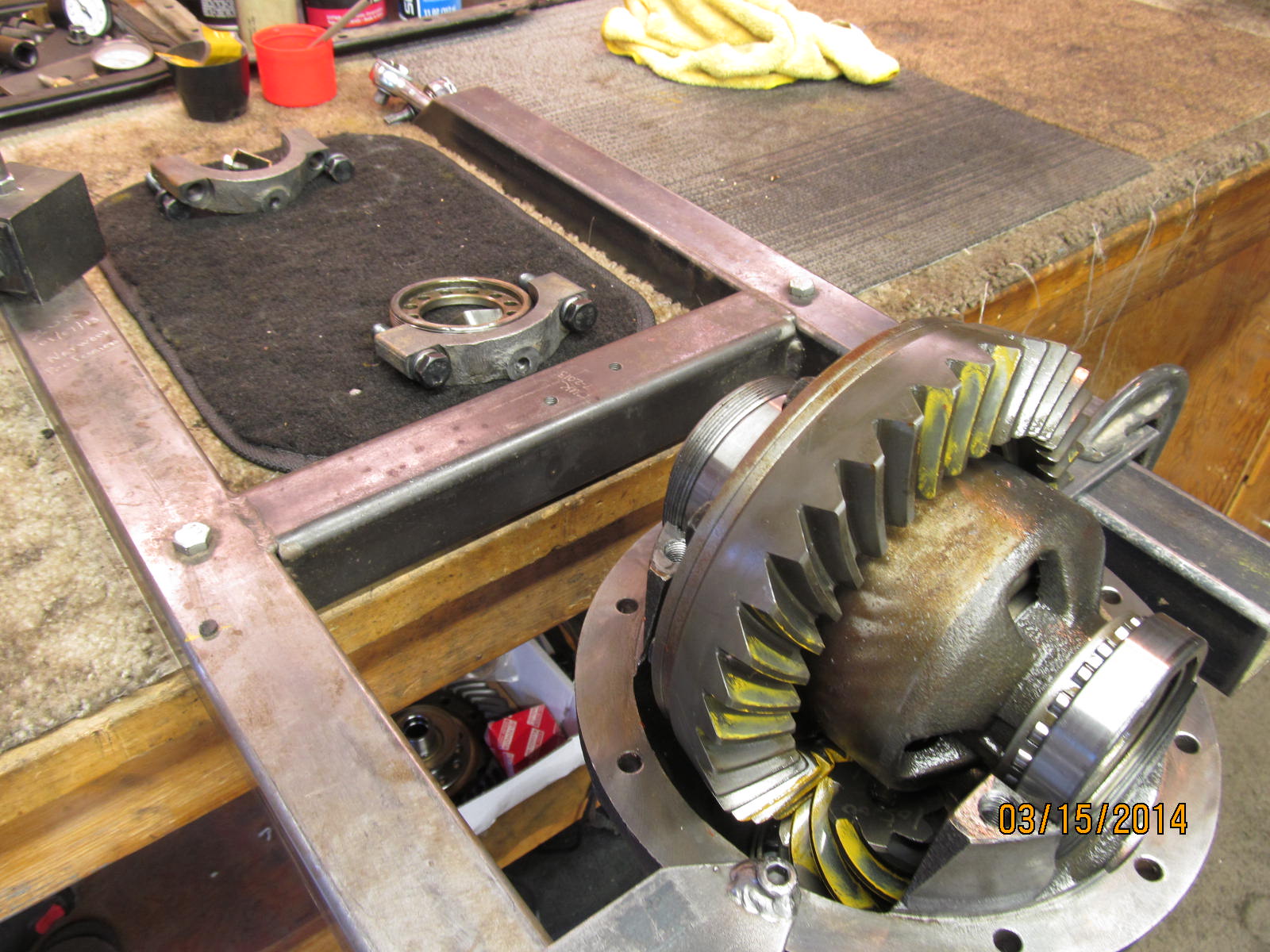

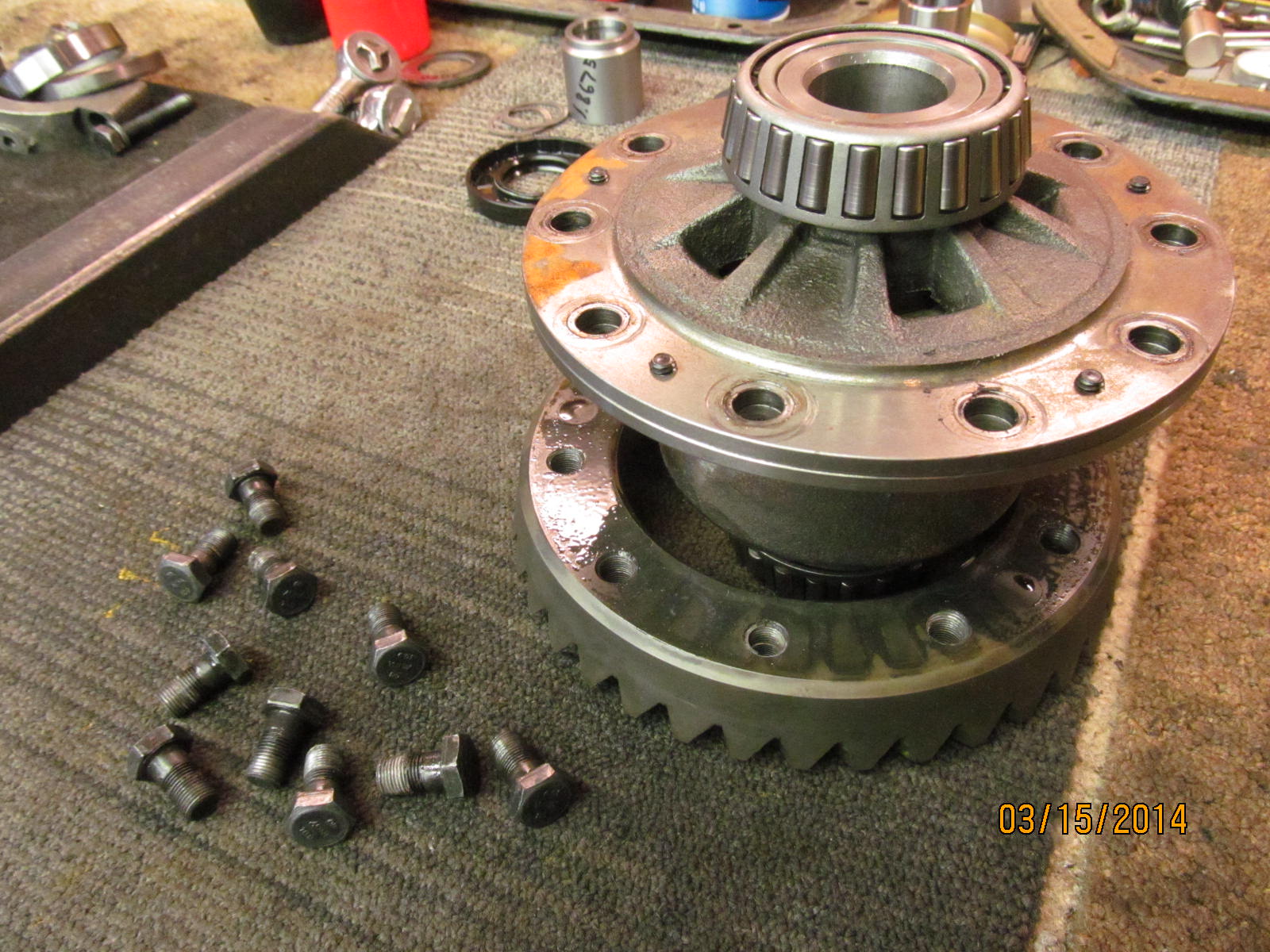

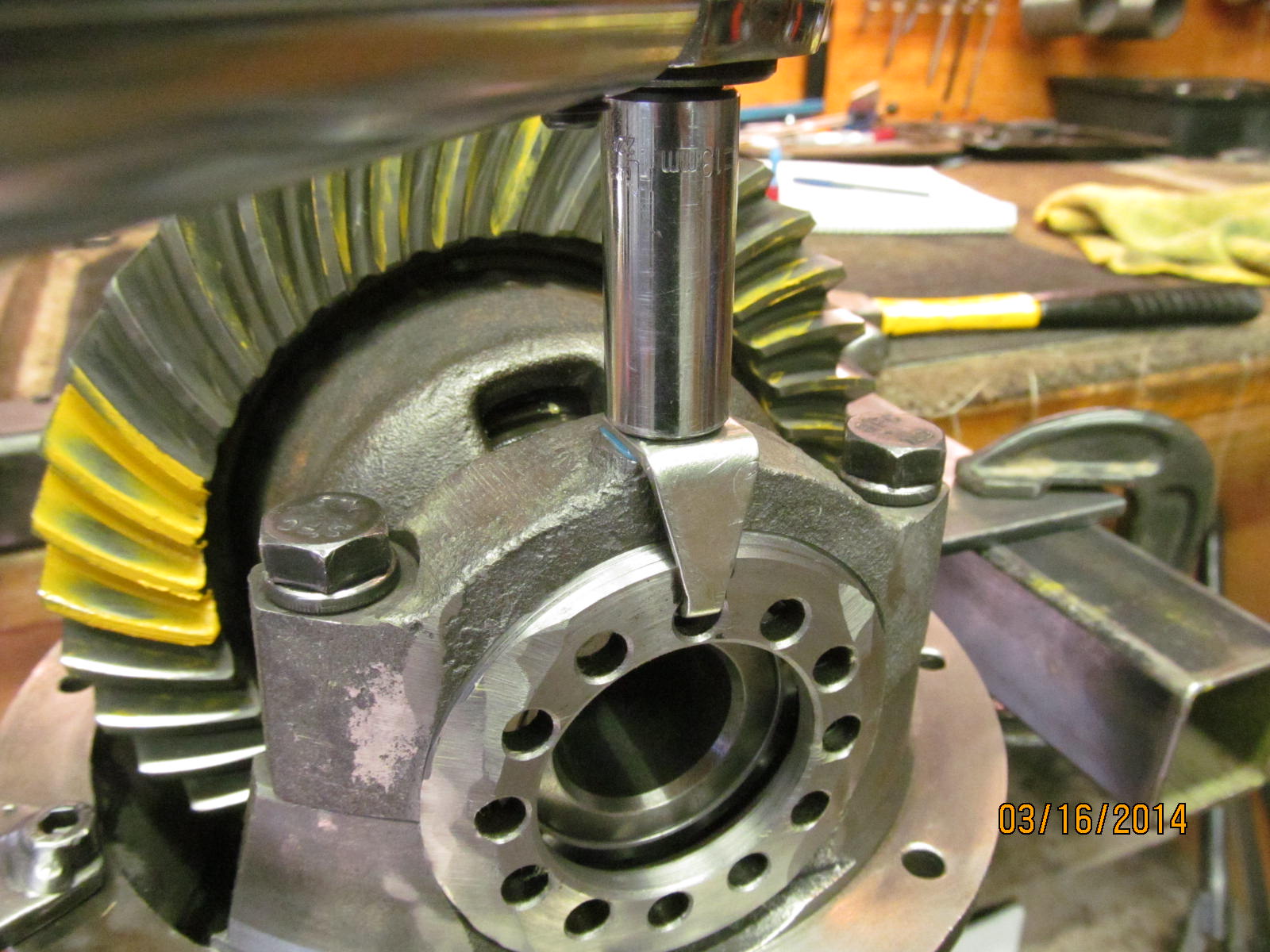

V6 3rd with 529 gears and a Detroit locker.

|

|

|

|

|

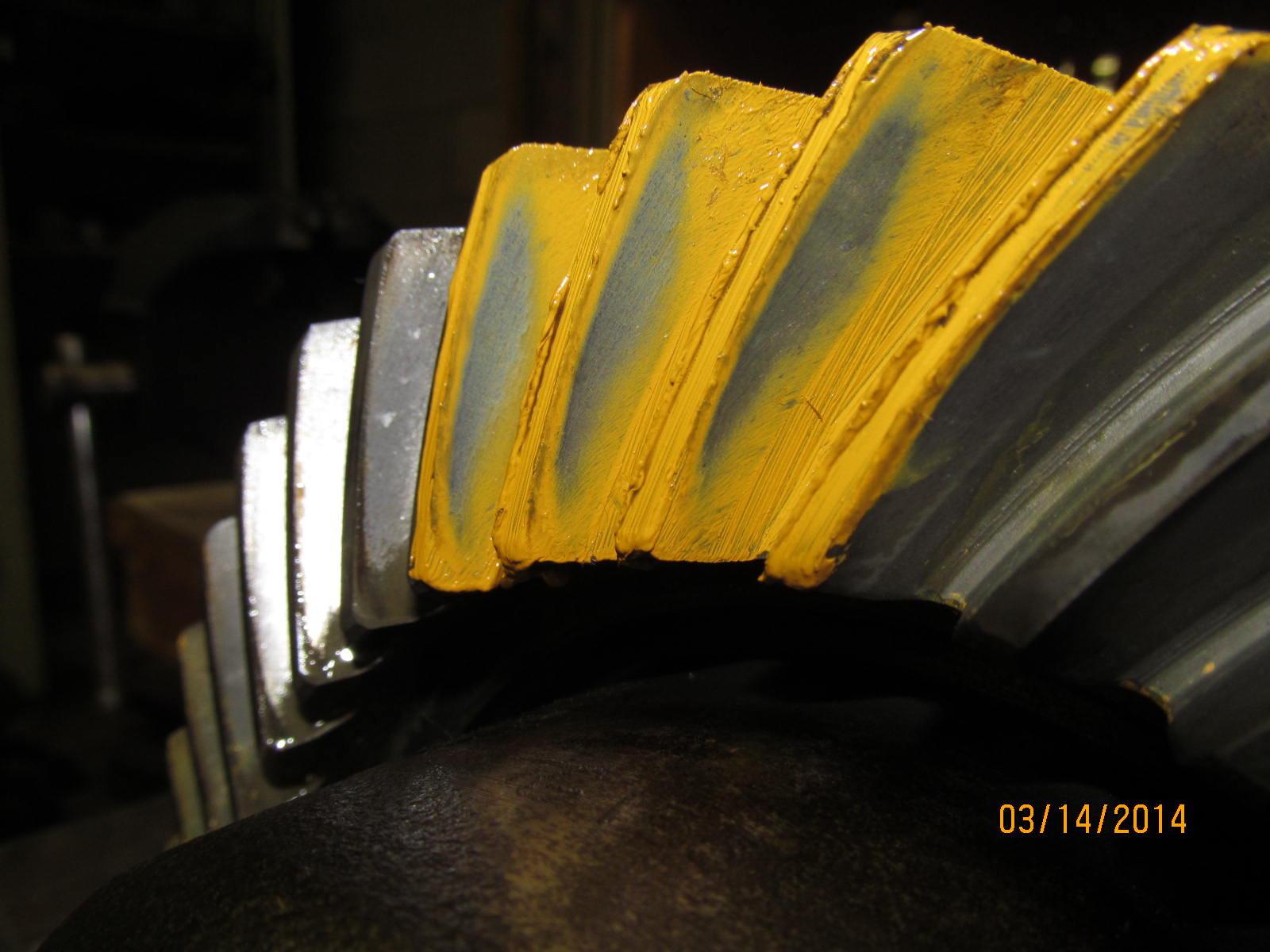

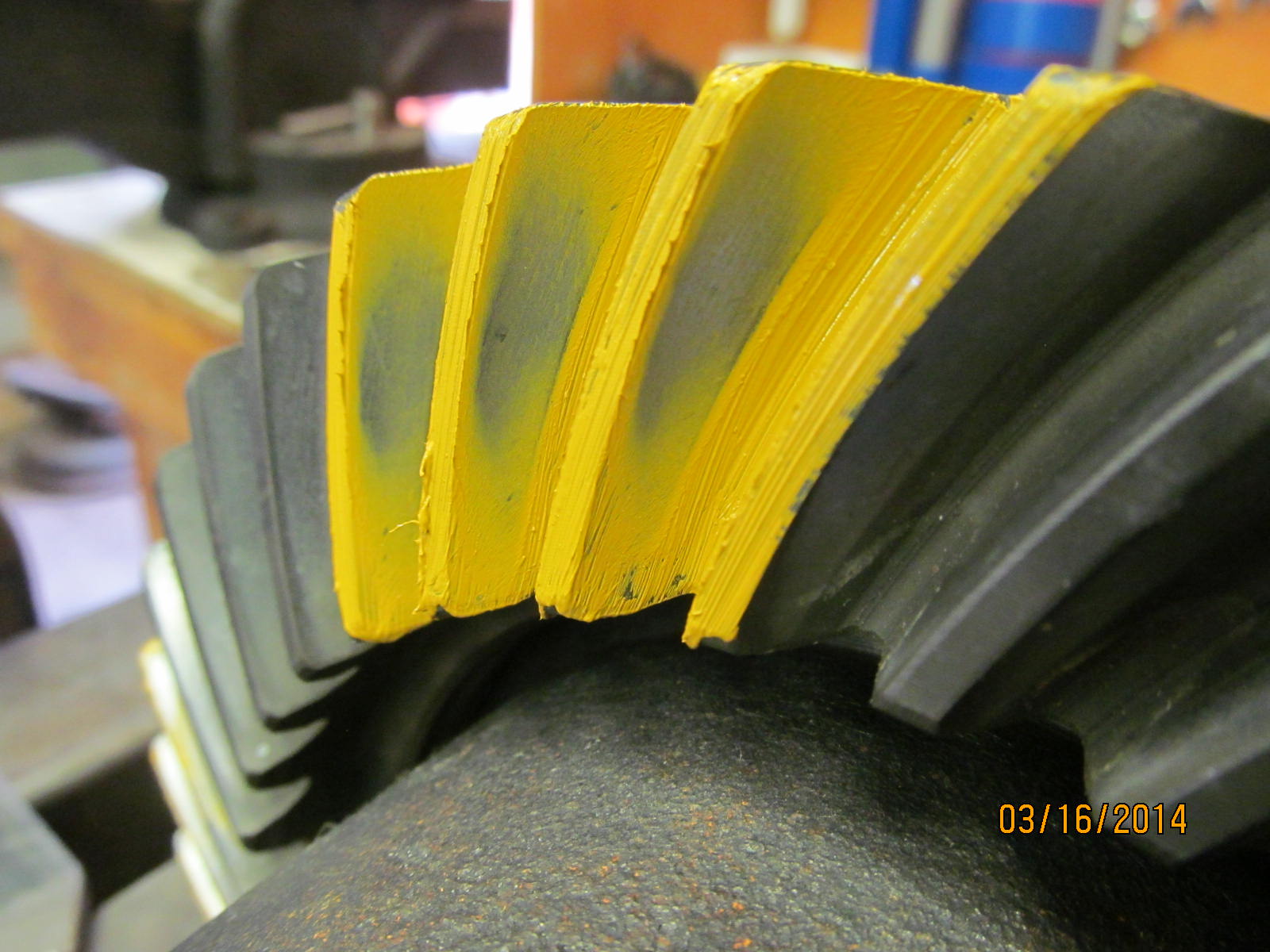

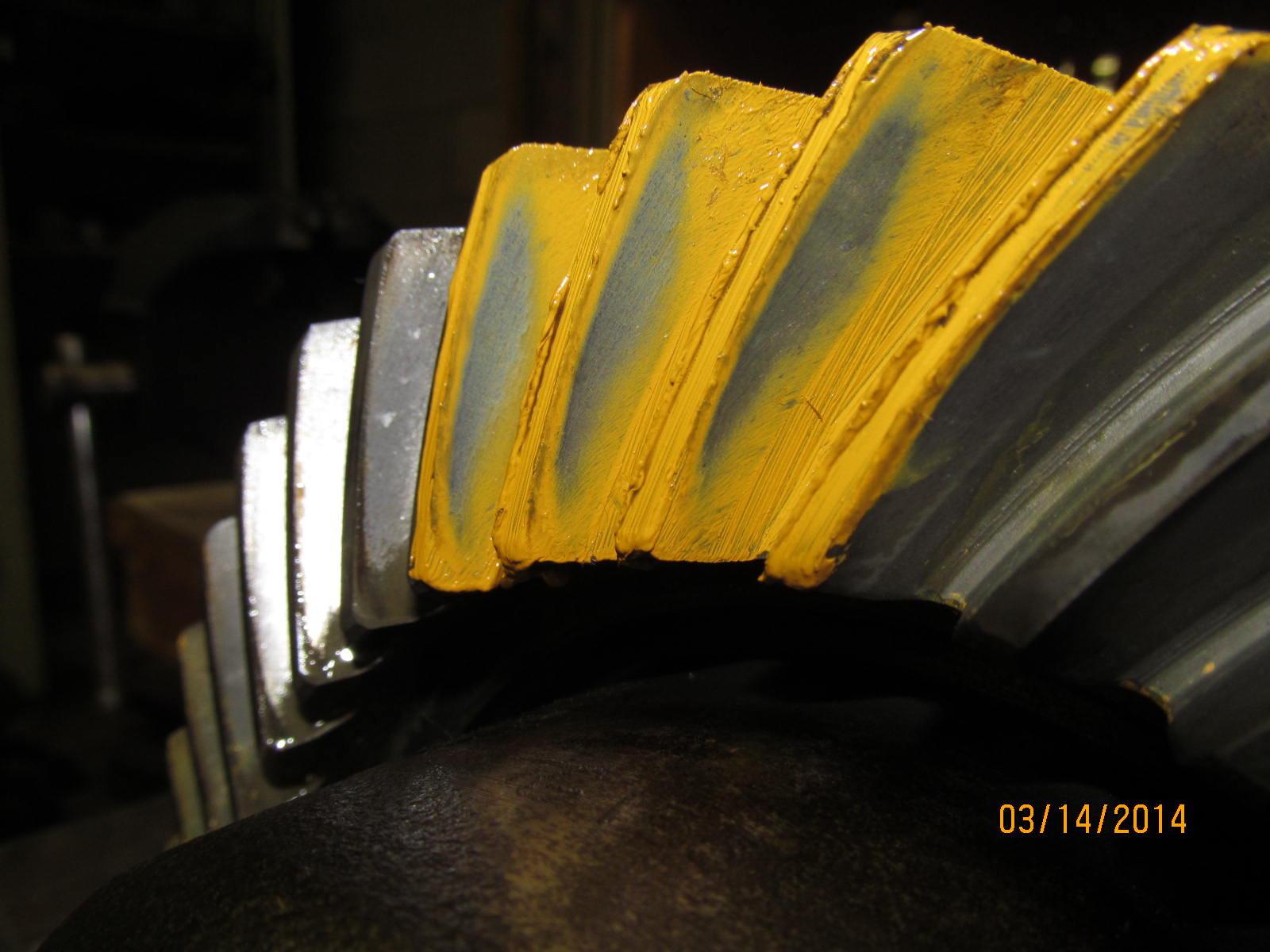

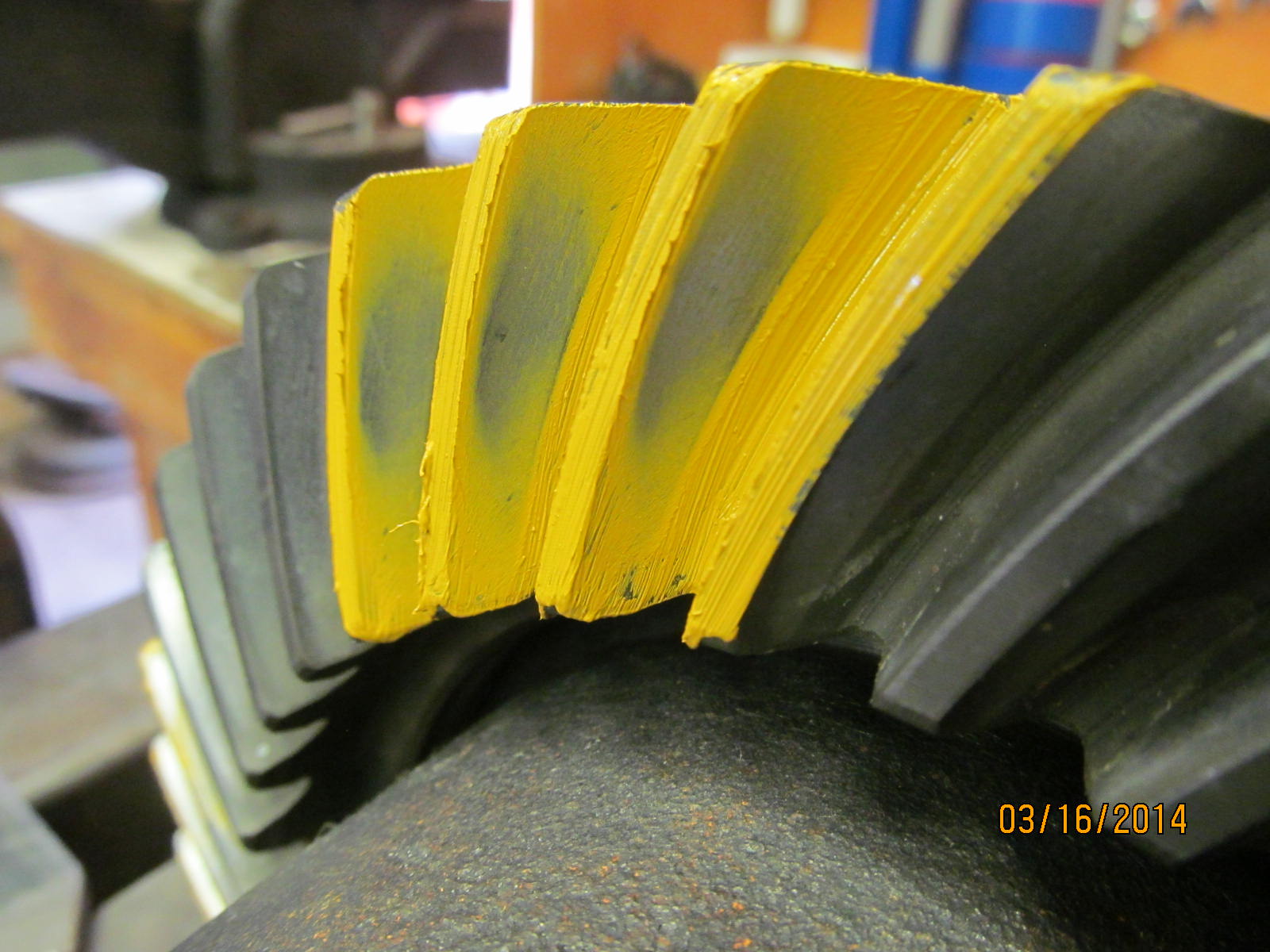

From the residual paint that was still there, he did not like the looks of the drive pattern.

|

|

|

|

|

I did a quick paint and all became obvious...drive side really does appear shallow and too close to the heel end.

|

|

|

|

|

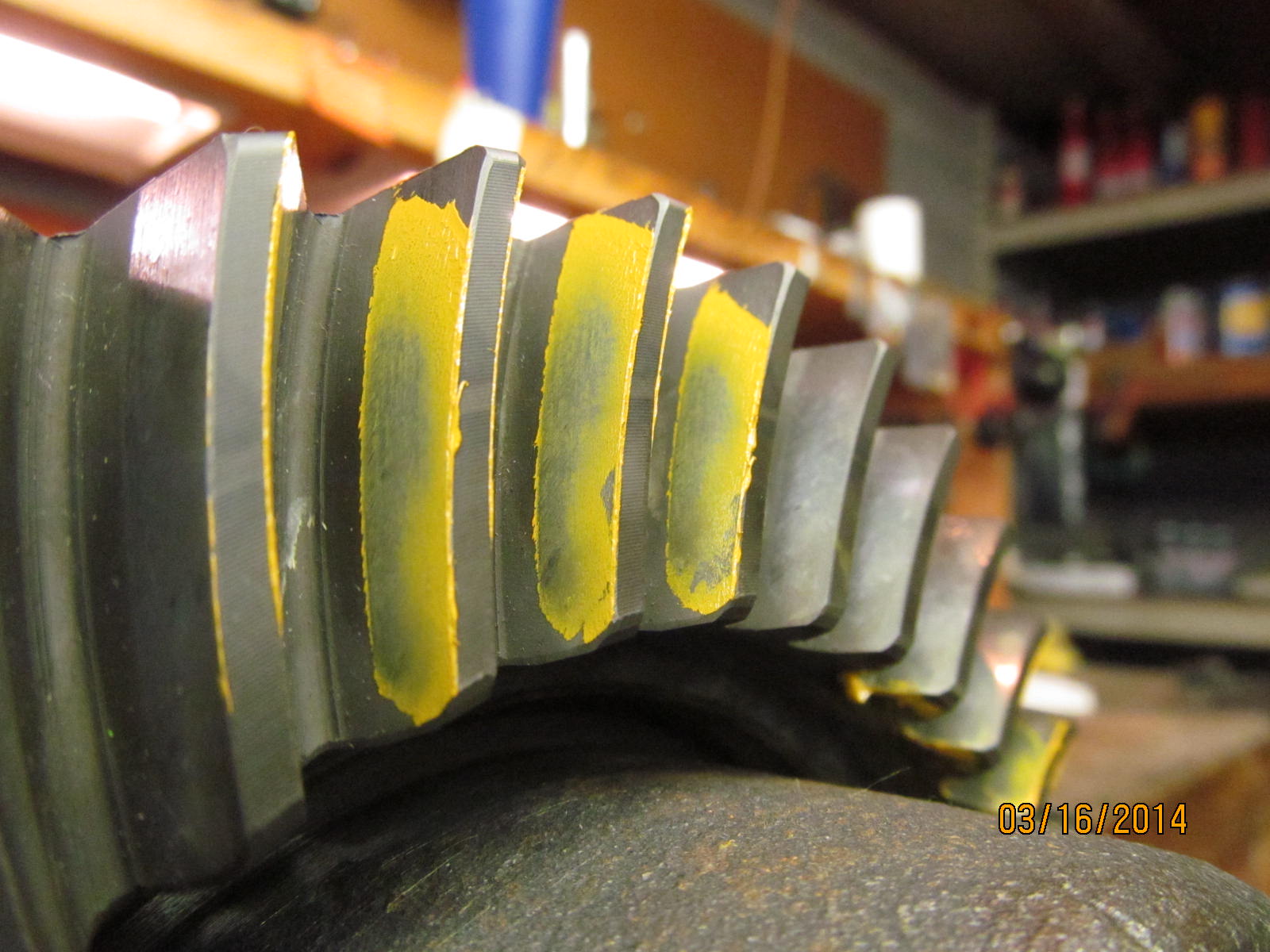

Coast side is favoring the top edges....shallow.

|

|

|

|

|

Comet tail is tucked into the deep root.

|

|

|

|

|

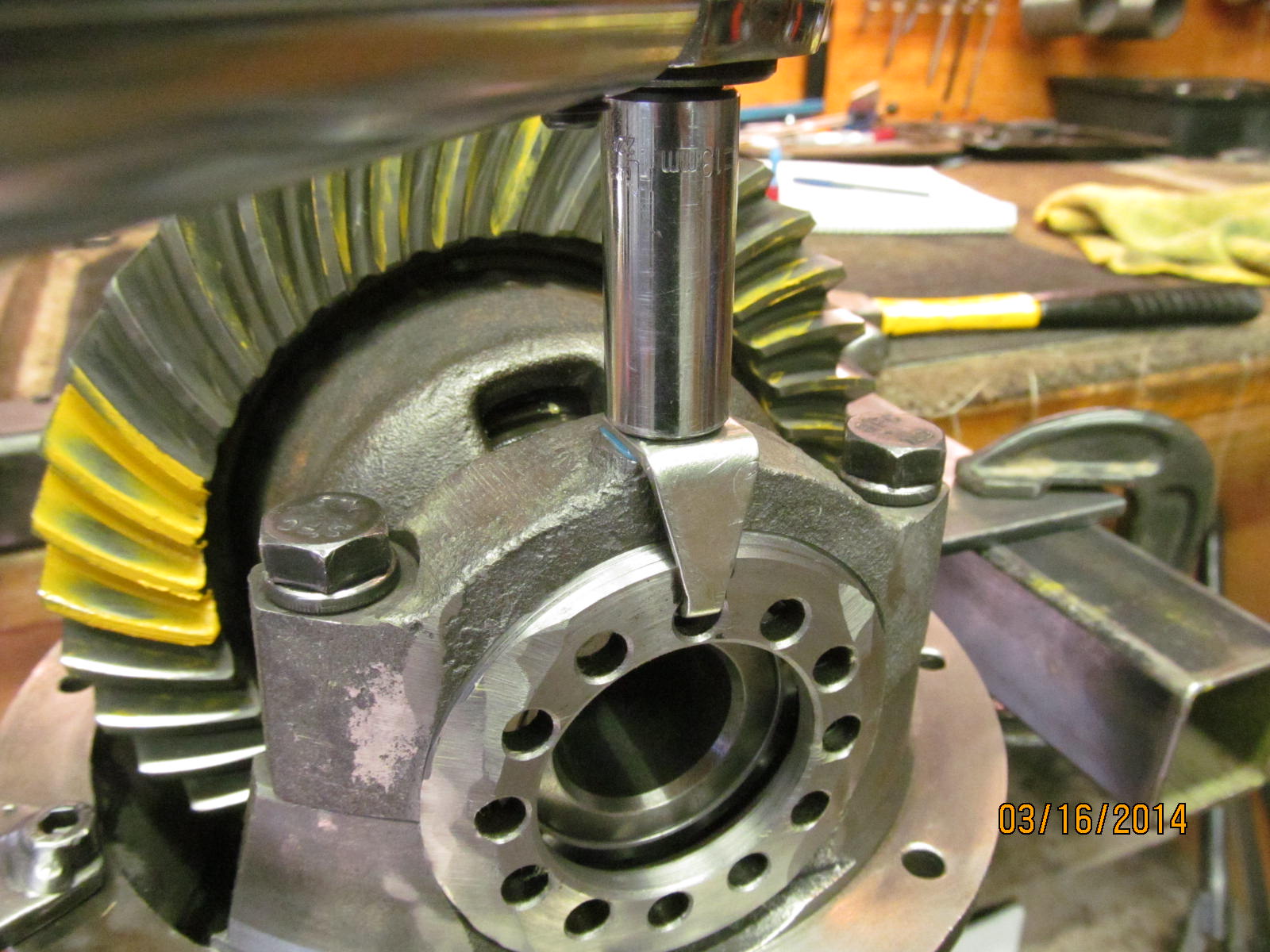

Dis-assembly begins. Of note is that the carrier bearing adjusters were set tight just like they should be...good grade there.

|

|

|

|

|

Carrier bearing races are ok. Nothing special going on here.

|

|

|

|

|

"K TV6-529 1301" is stamped on the ring gear. Not 100% sure what to think of these gears yet.

|

|

|

|

|

I use 1 or 2 cans of ether per gear install to efficiently remove the gear oils. No smoking please.

|

|

|

|

|

The pinion drag feels 'notchy'....stiff at first and then frees up as it is turned. Wobble is not a problem with this one.

|

|

|

|

|

I measured about 18 in/lb of PPL start torq(break loose).

|

|

|

|

|

Has a 2 in/lb of rolling torque turning it slowly.

|

|

|

|

|

Turning it a bit faster the rolling torque increases to 5.

|

|

|

|

|

The pinion nut was on very tight(good score there).

|

|

|

|

|

The aftermarket seal is revealed.

|

|

|

|

|

There is a 'crinkle' near the upper left side. That might have caused the seal to leak.

|

|

|

|

|

The pinion is pushed out.

|

|

|

|

|

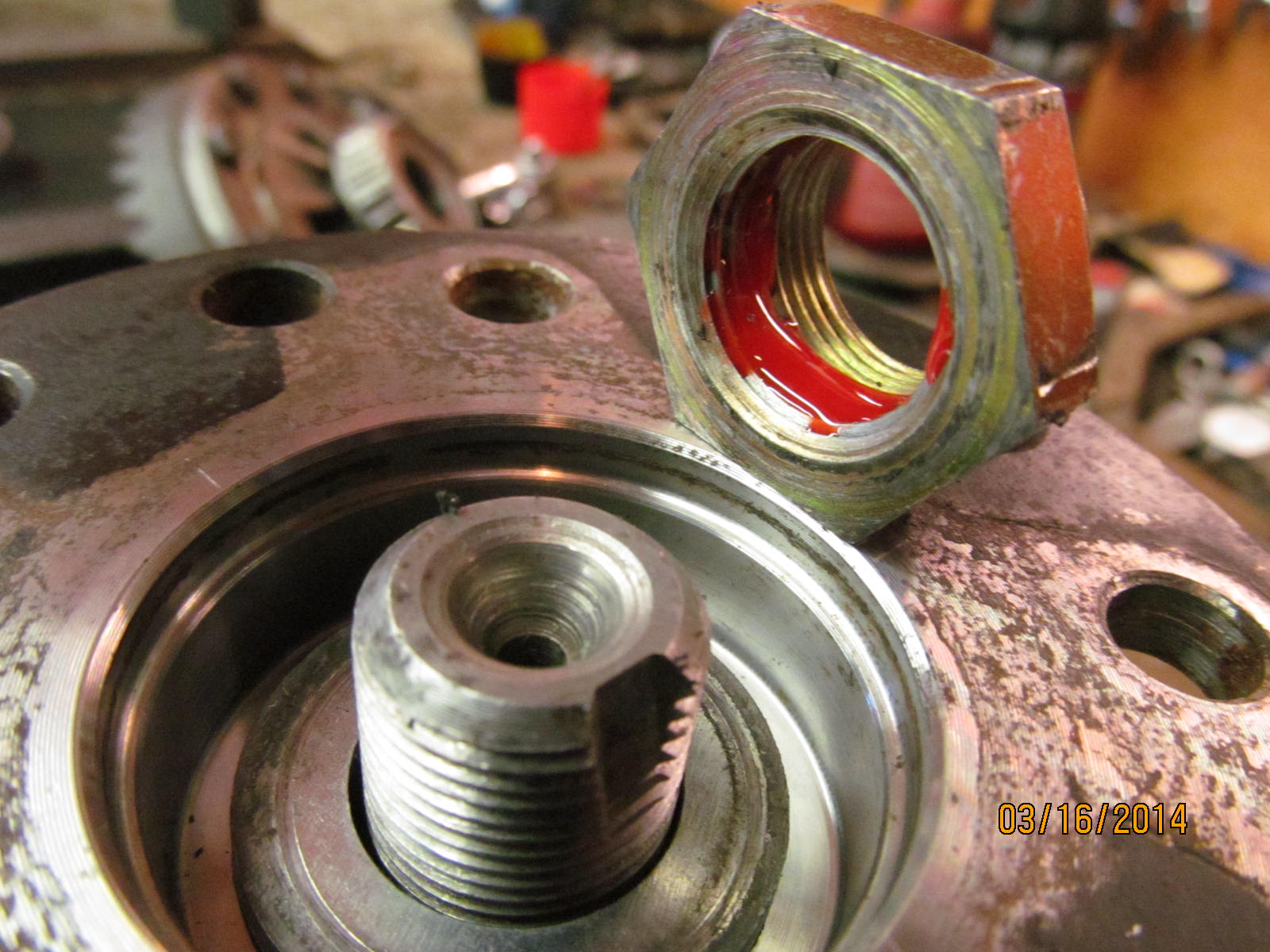

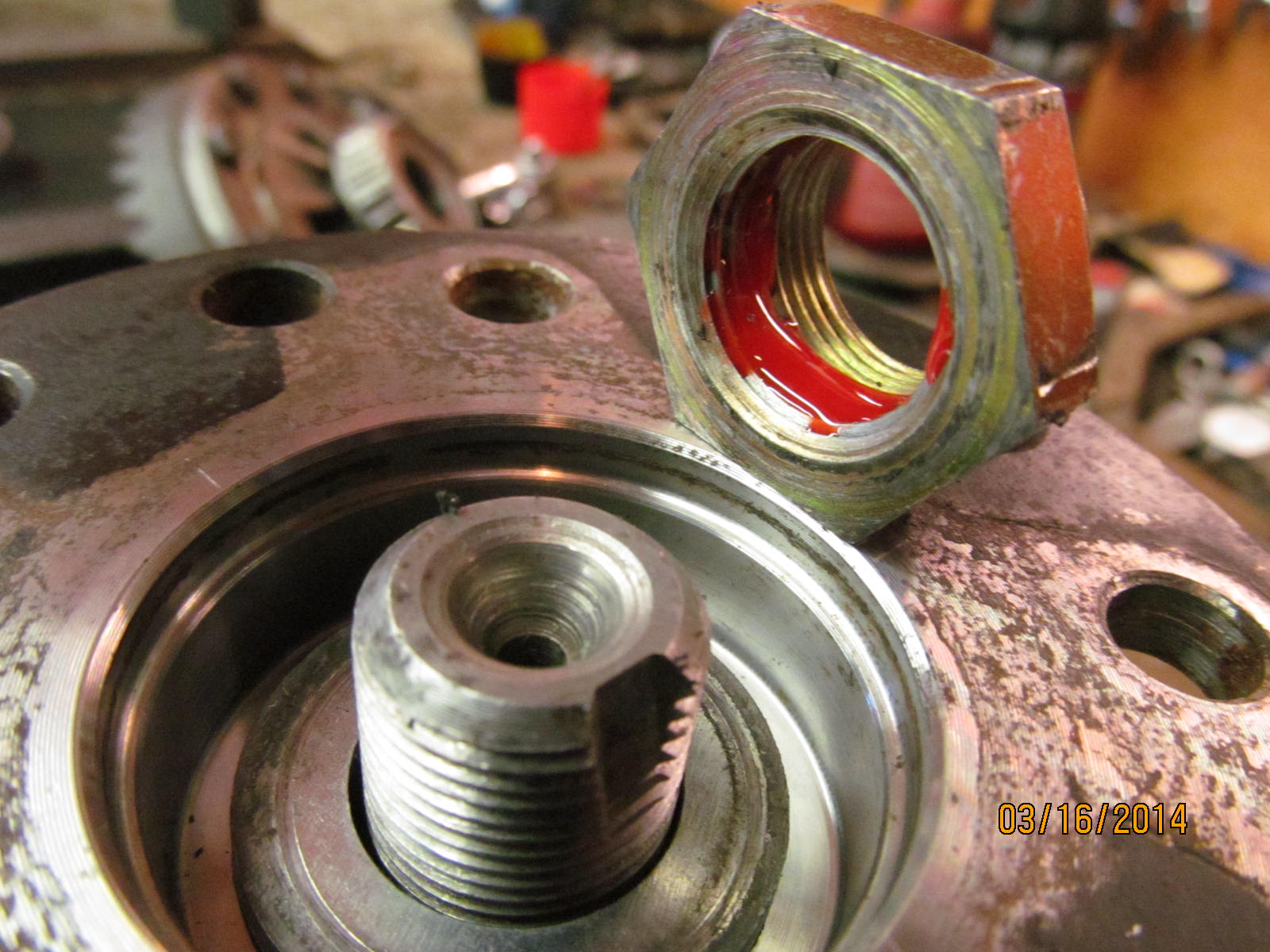

A solid collar was used.

|

|

|

|

A closer look at the wrinkle at the 10 o'clock position. The pinion bearing can be seen in the hole....what

happened to the splashguard?

|

|

|

|

|

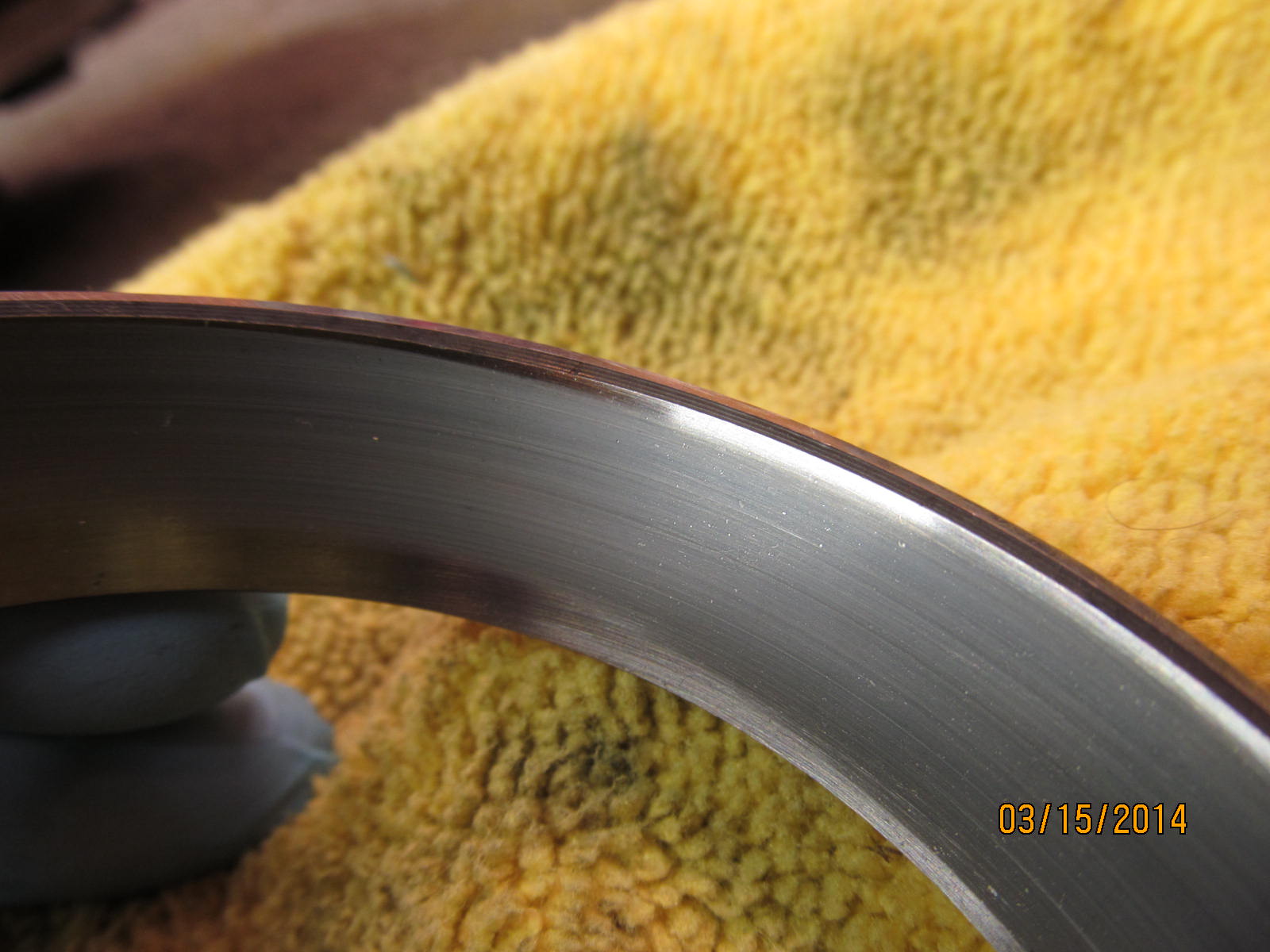

Just getting a feel how the old seal fits on the flange.....just a little looser than I am used to.

|

|

|

|

|

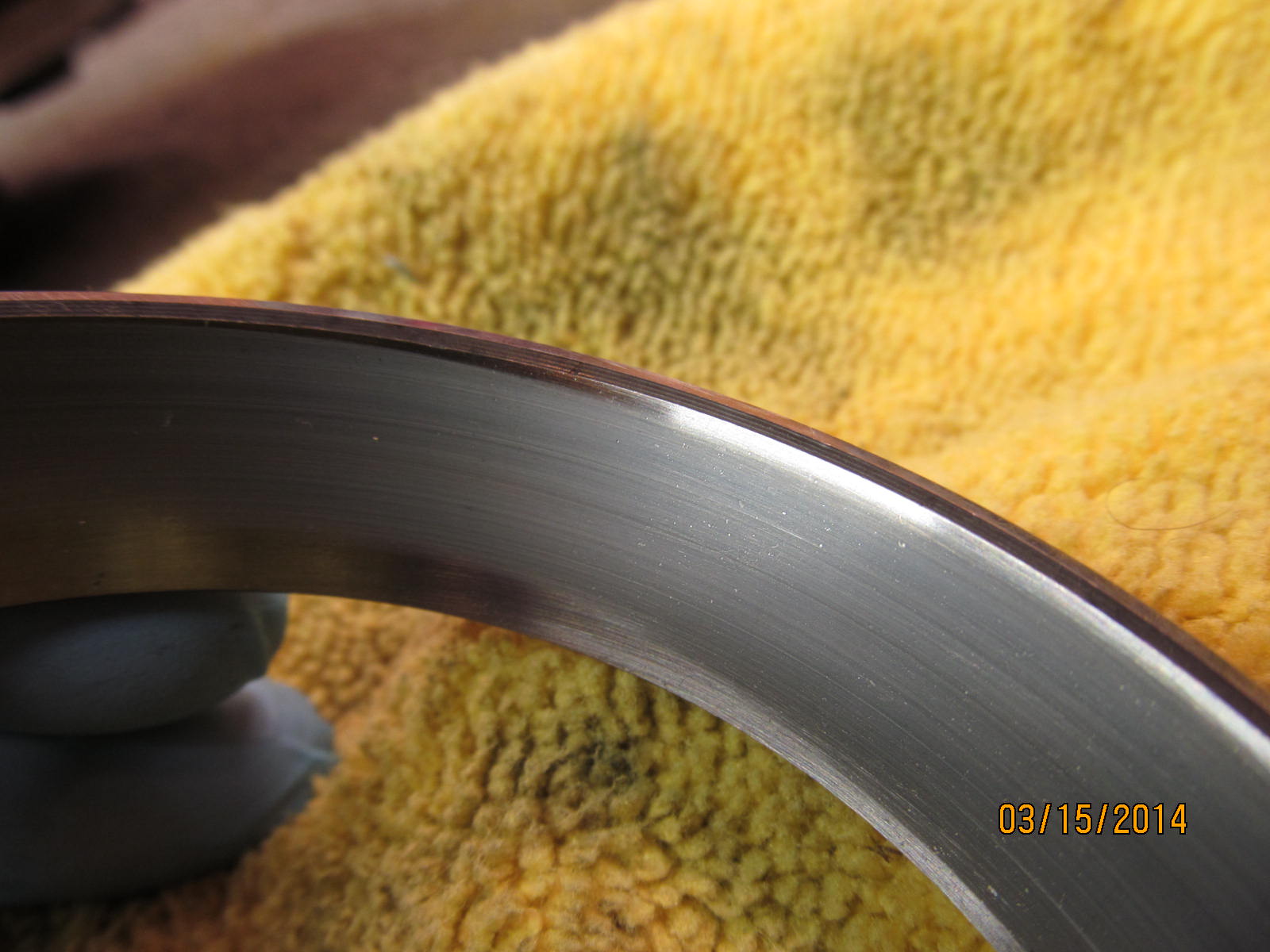

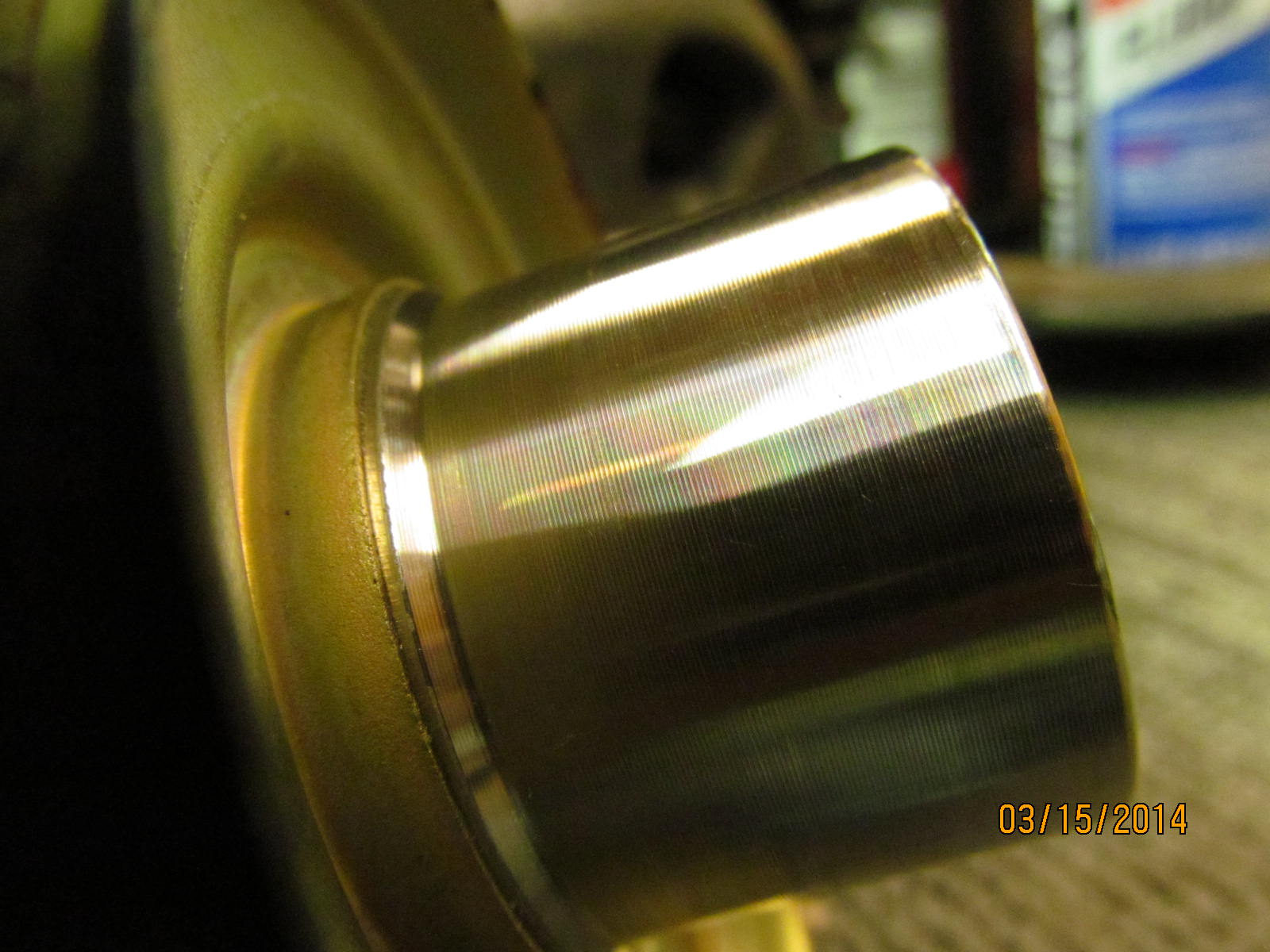

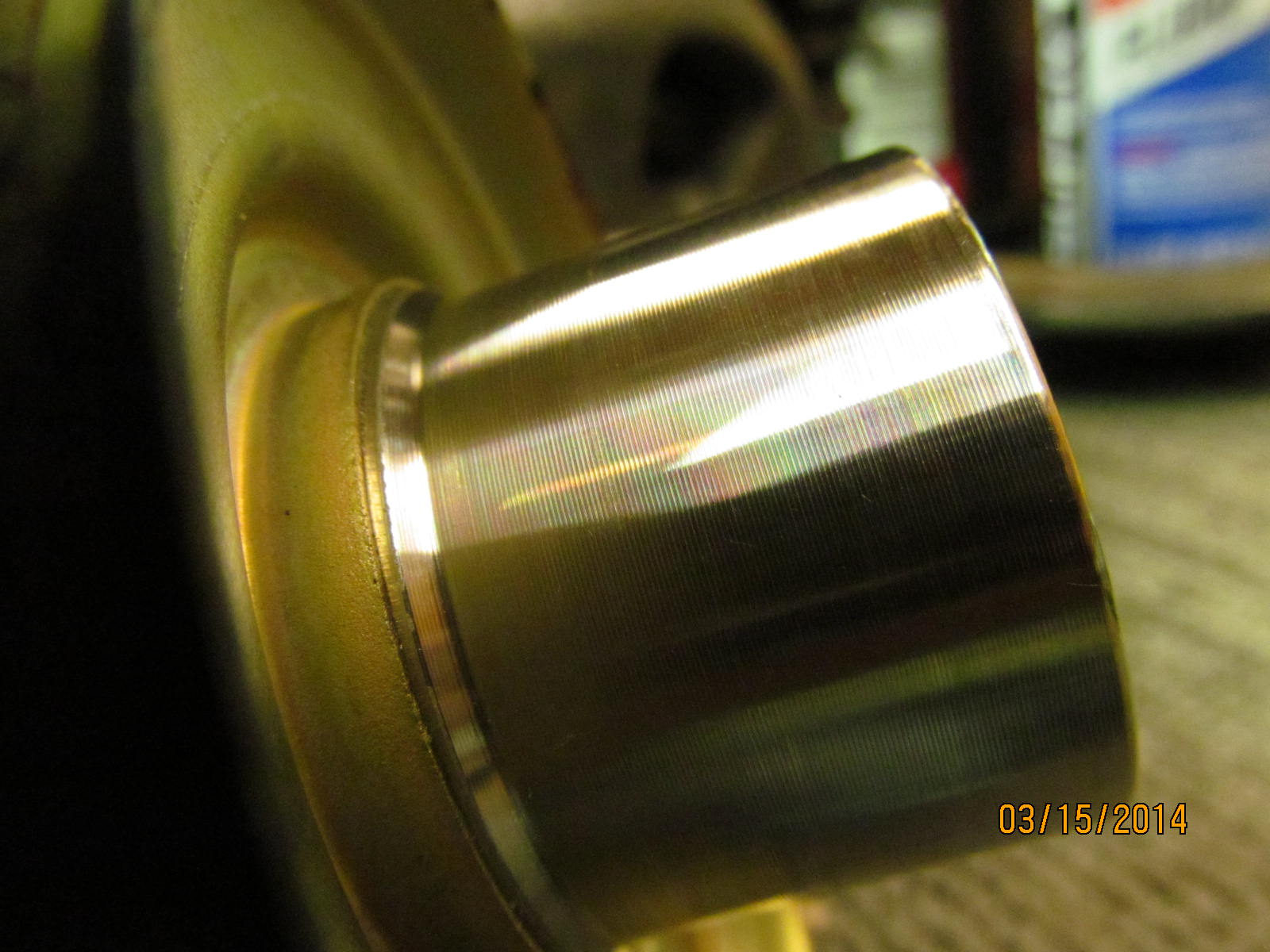

The flange is just like brand new.

|

|

|

|

|

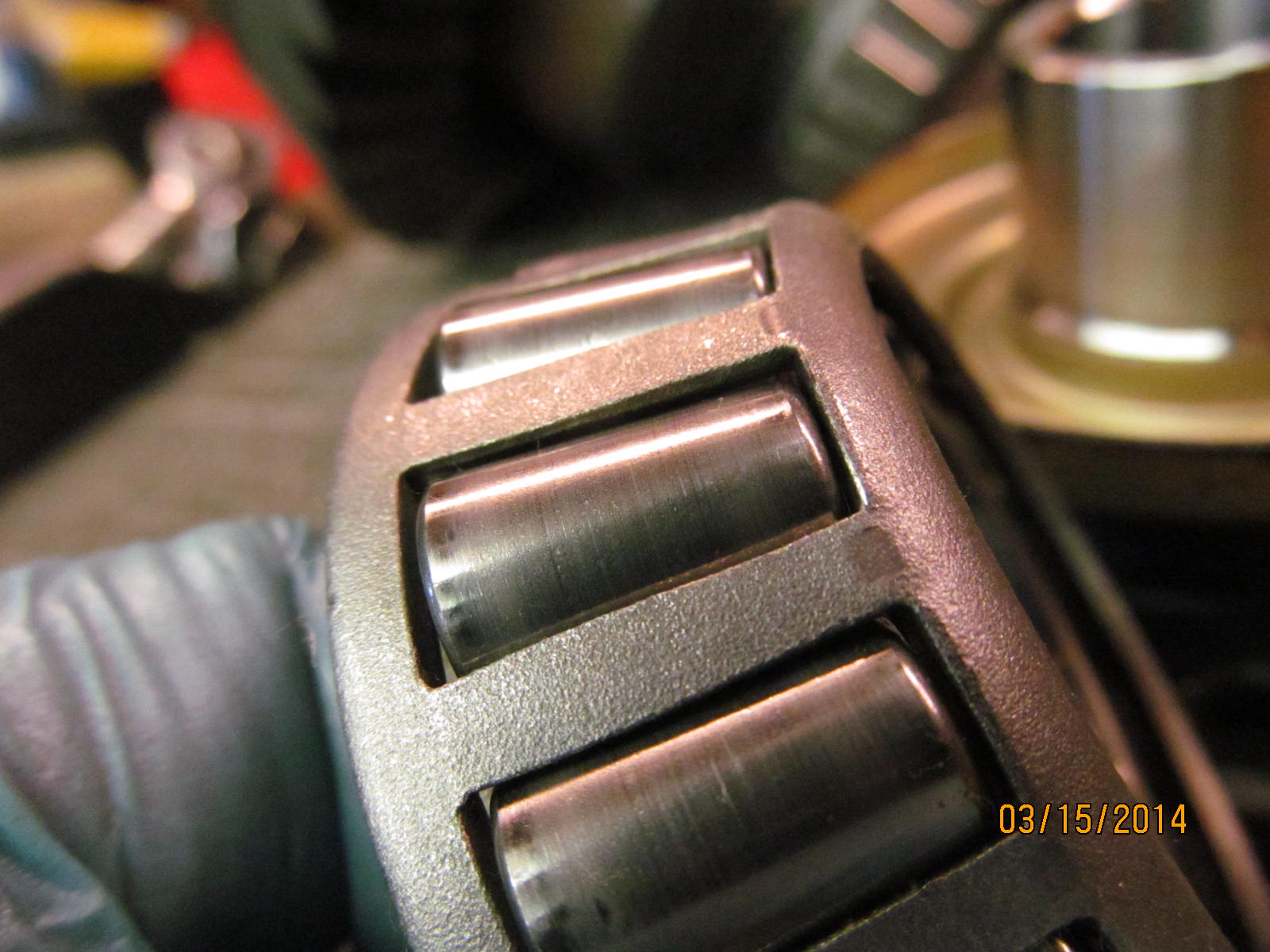

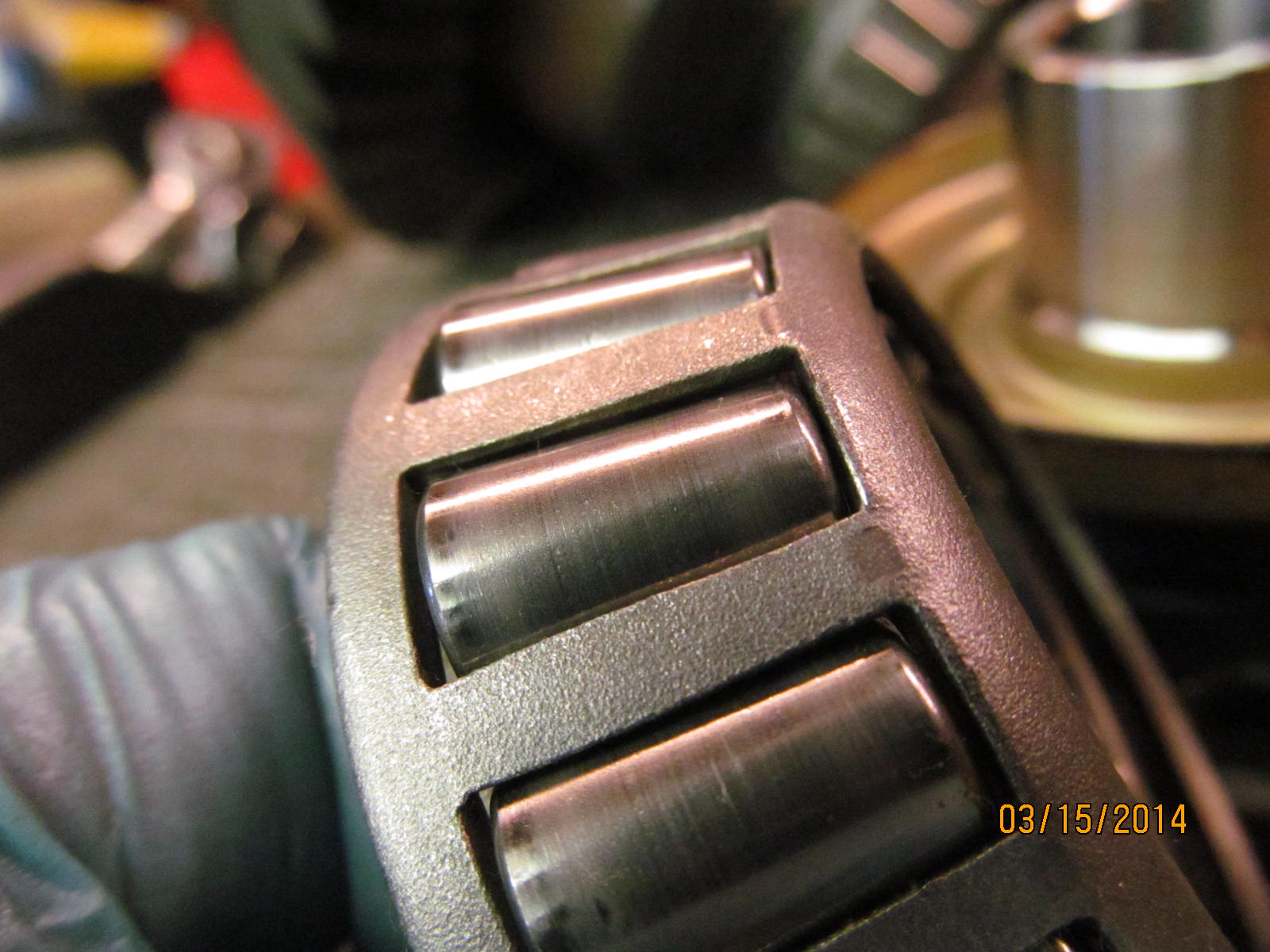

The small outer pinion bearing is ok....the notchiness did not hurt anything.

|

|

|

|

|

I'm real curious what pinion shim was used...press the big bearing off.

|

|

|

|

|

A total of .071" was used....this explains the shallow paint.

|

|

|

|

|

The 071 will be replaced with this 080 shim.

|

|

|

|

|

Pinion bearing is pressed on. That nice, new Harborfreight 12 ton in the background is soon to go in my living room.

|

|

|

|

|

Now to put the pinion in the diff carrier.

|

|

|

|

|

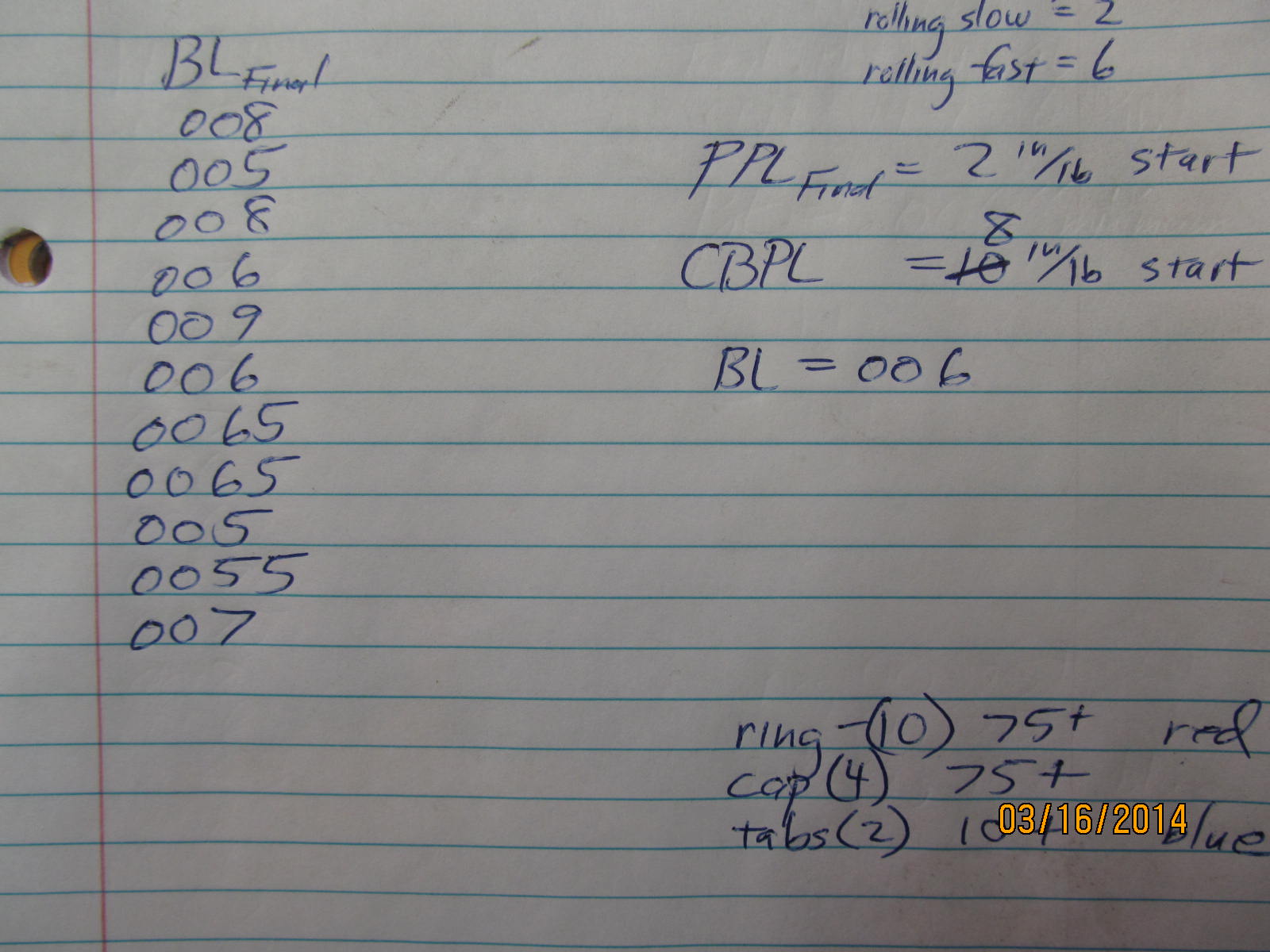

The pinion nut is tightened with the electric impact until a modest 3 inch/pounds is measured.

|

|

|

|

|

Before the ring gear assembly is placed in diff, some checks are made. All 10 of the bolts were tight and they used loctite.

|

|

|

|

|

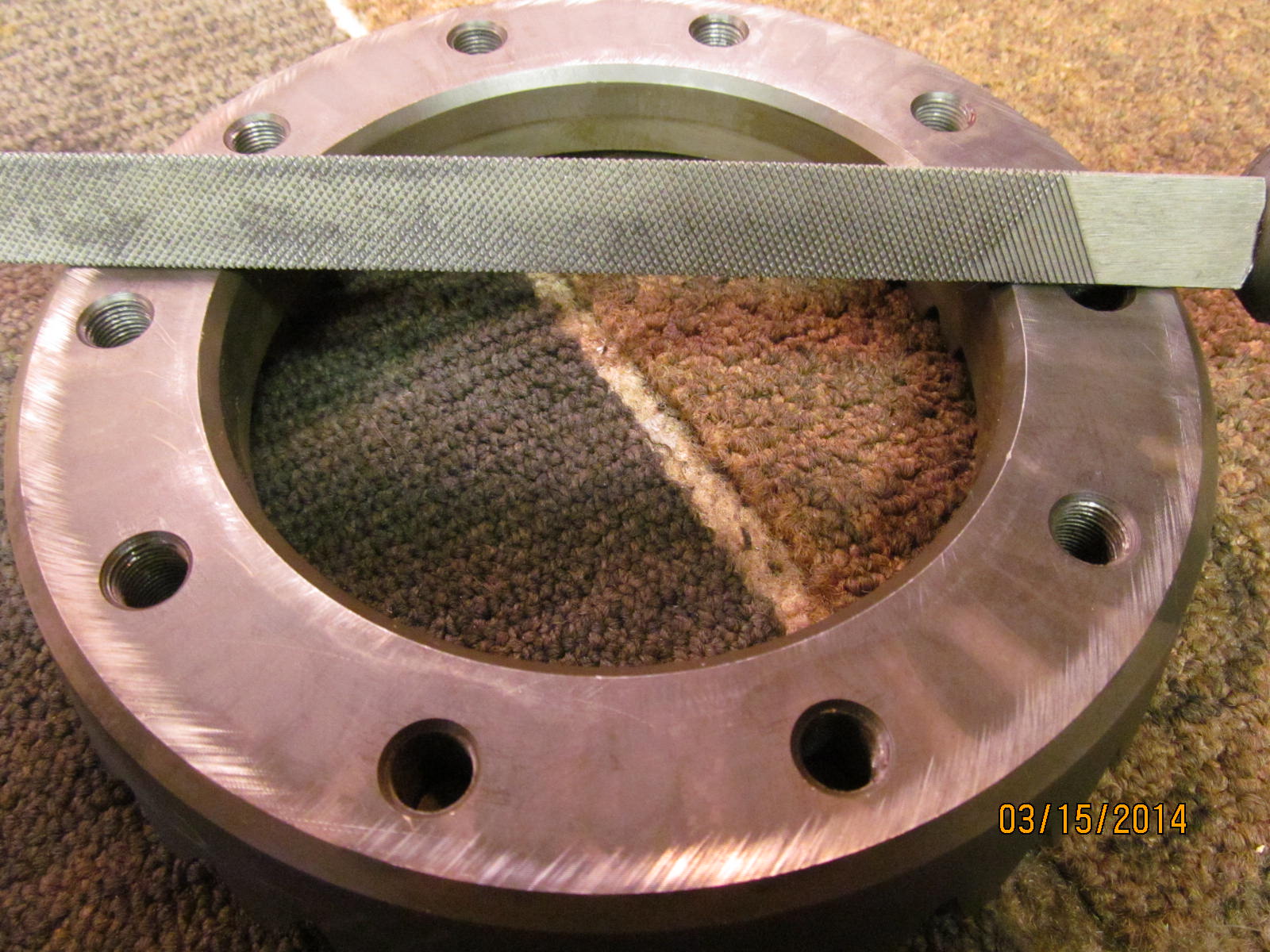

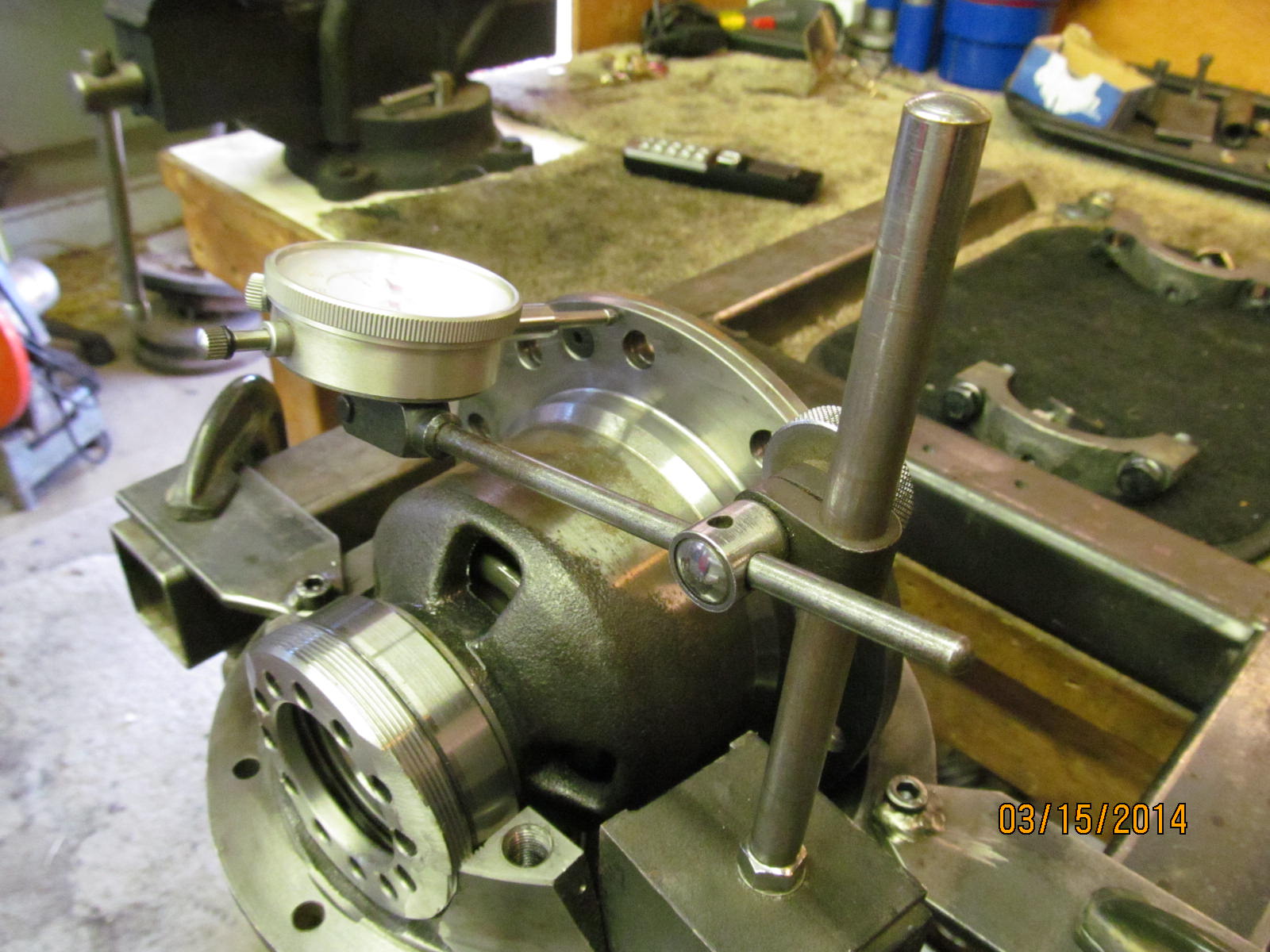

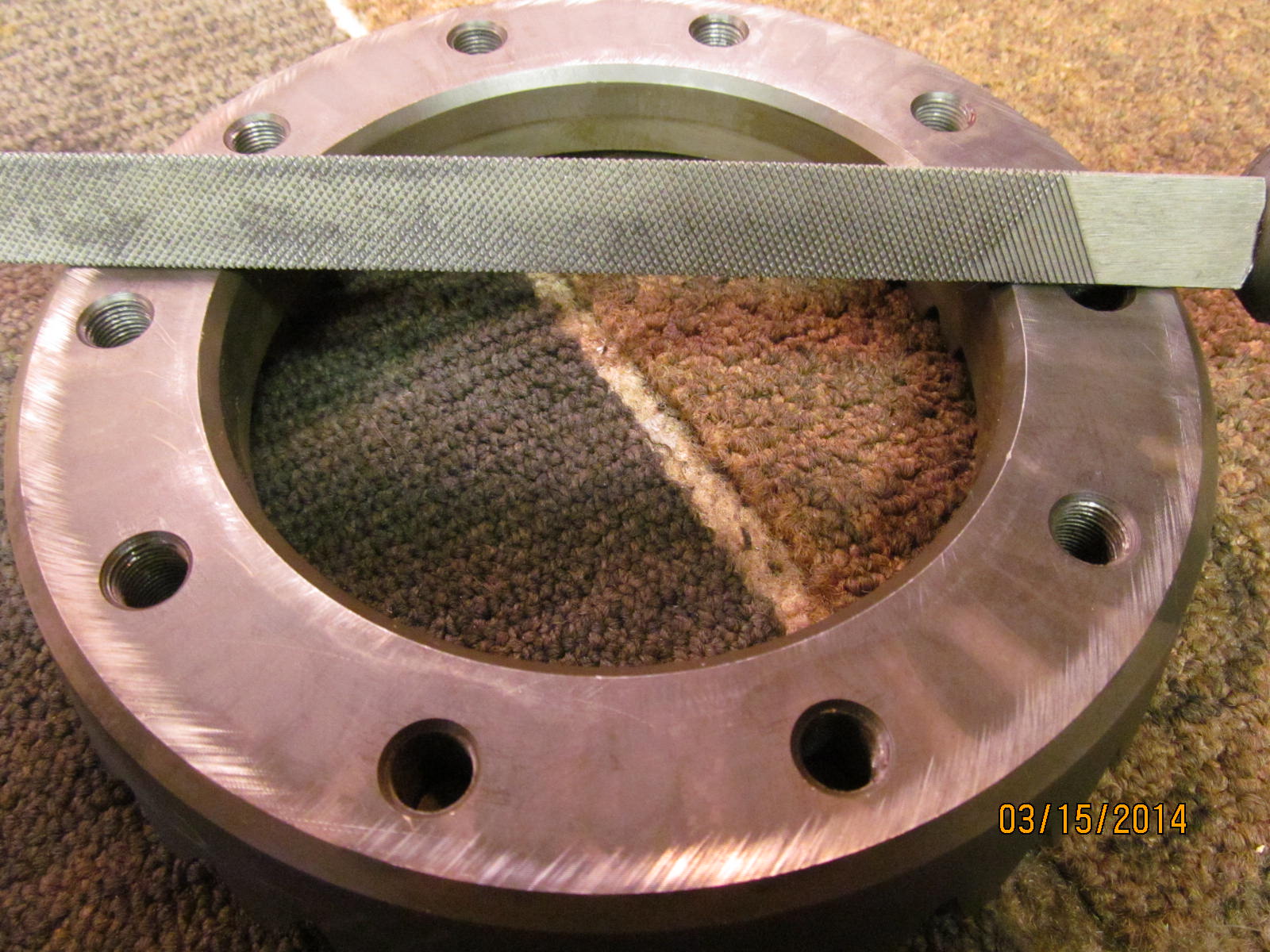

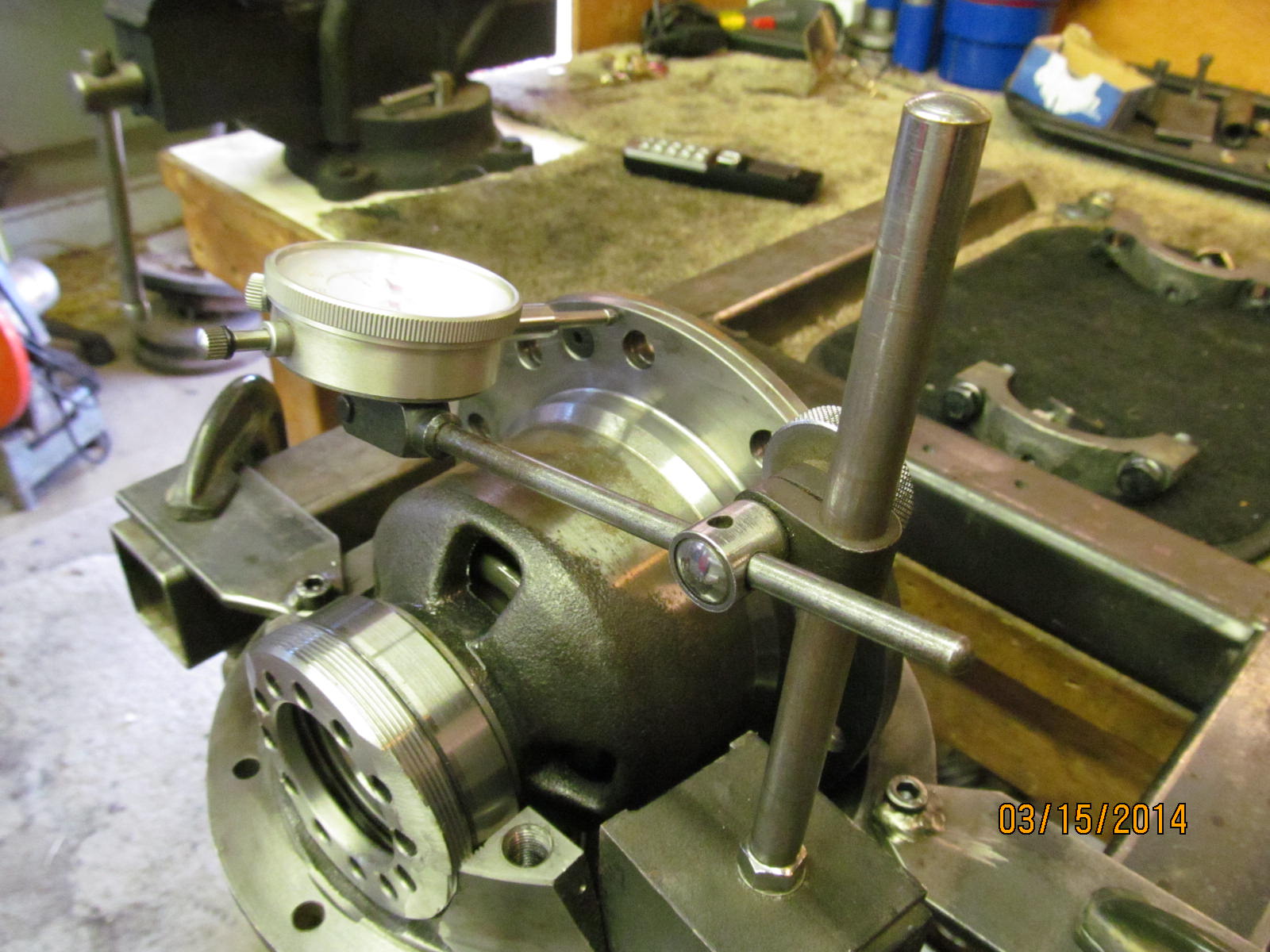

I didn't have to do this but I wanted to check the surfaces with a file and see how much run-out the Detroit has.

|

|

|

|

|

Surface filed and nothing unusual.

|

|

|

|

Pushing hard with the Chinese file I was able to actually make a few scratches in it.....usually I can't quite do that much

scratching...not sure if I can use that as a criteria of the hardness of the material...is it SAE 8620 alloy steel or 4027?

Who knows. But other than that, the surface was burr free and no unusual high spots.

|

|

|

|

|

Runout was just under .002"

|

|

|

|

The ring gear was a good, snug fit onto the Detroit. No press was needed or boiling water...just some love from the lead filled

plastic hammer.

|

|

|

|

|

Threads are cleaned with ether and red loctite applied.

|

|

|

|

|

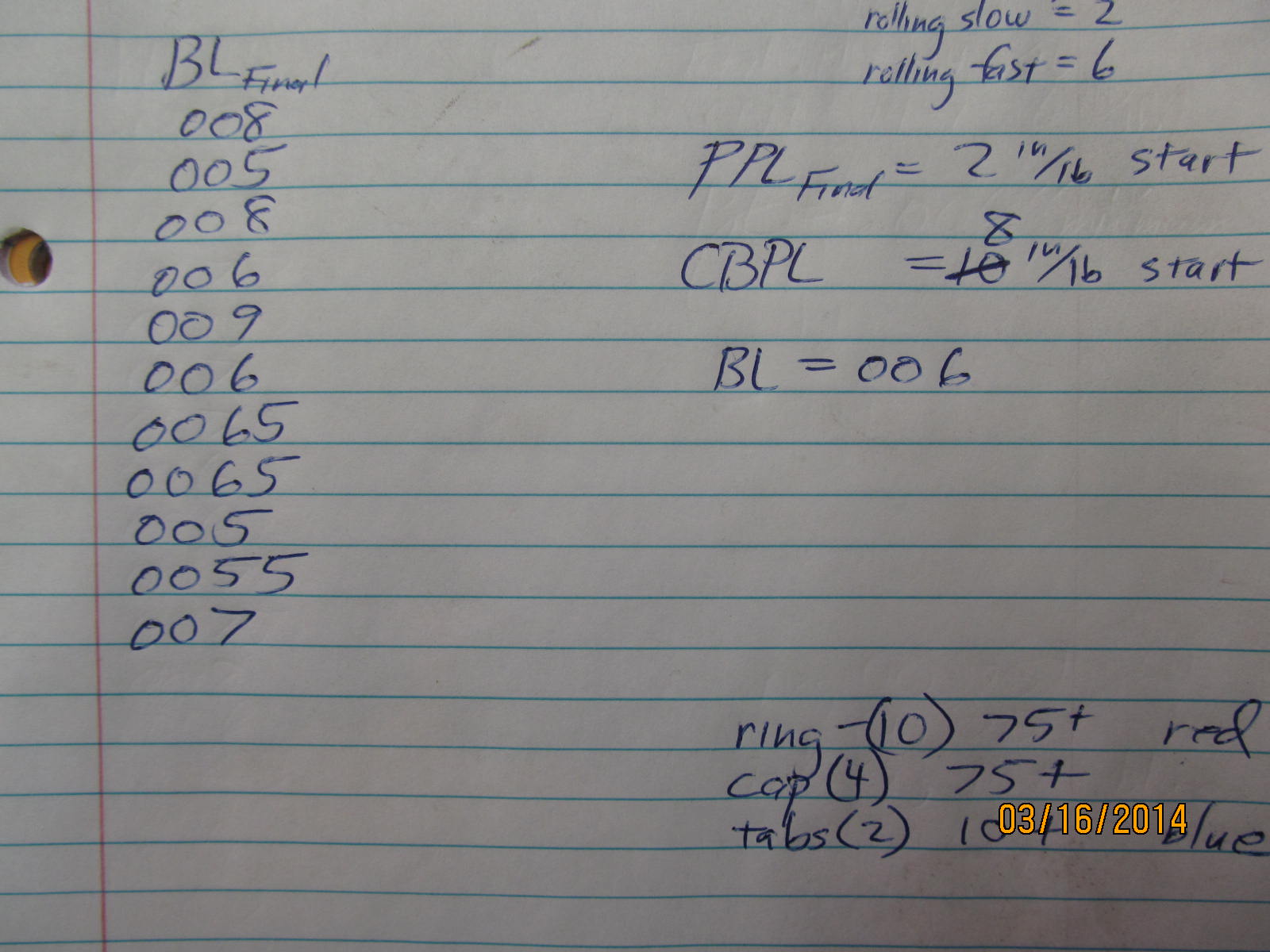

75 ft/lbs to all 10 fine threaded bolts.

|

|

|

|

|

Bearing cap bolts are snugged up fairly tight for this paint test.

|

|

|

|

|

The adjuster wheels are tightened to give some carrier bearing preload with a backlash of about .007".

|

|

|

|

|

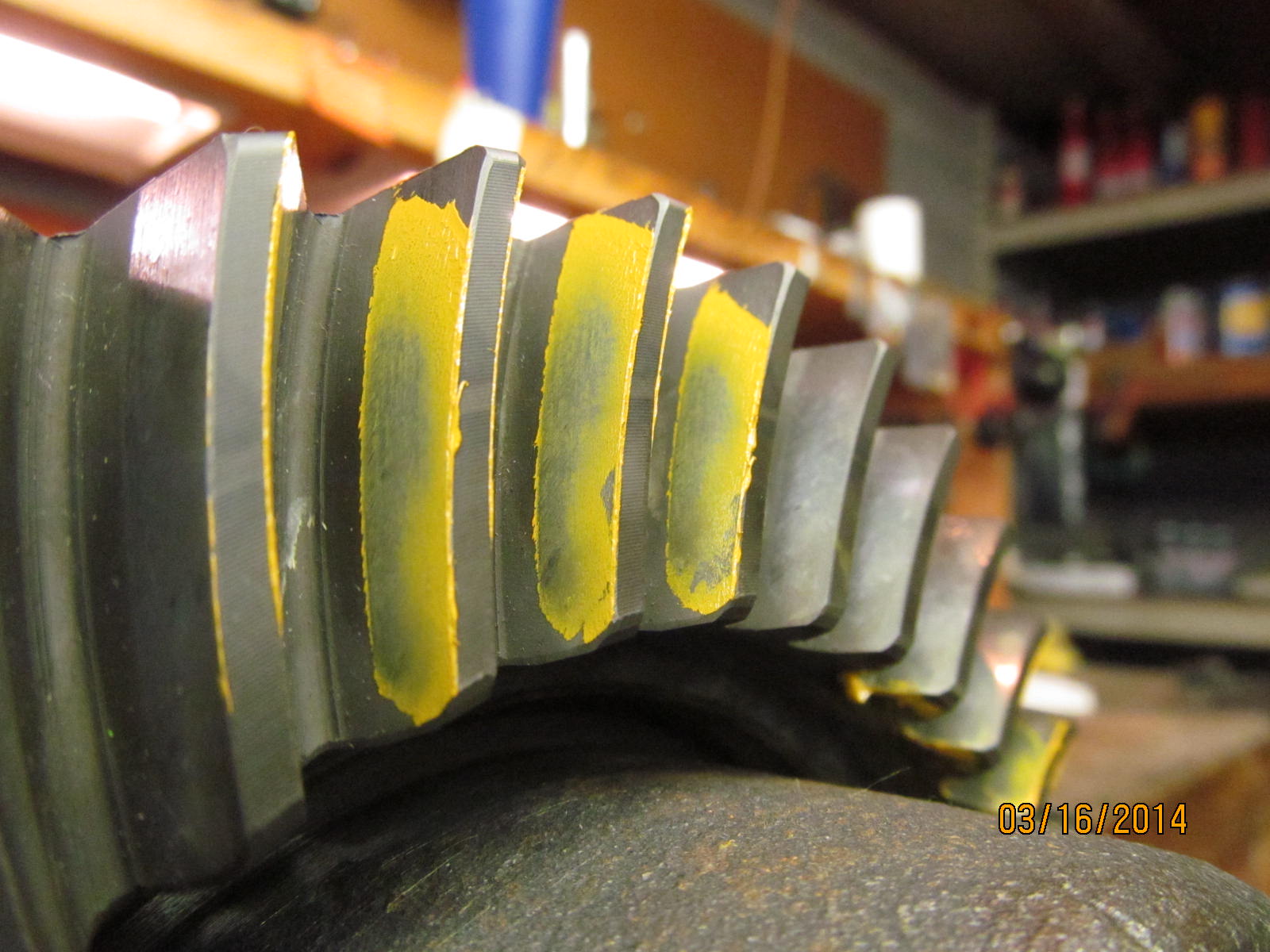

Nice drive side. To me, the pattern is in the shape of a sports car. Now it favors the toe and is deep like it should be.

|

|

|

|

|

Coast is much better than before. I'd like to see it closer to center but it is what it is.

|

|

|

|

|

The comet tail is now somewhere in the middle.

|

|

|

|

|

drive---this is the reverse painted teeth.

|

|

|

|

|

coast

|

|

|

|

|

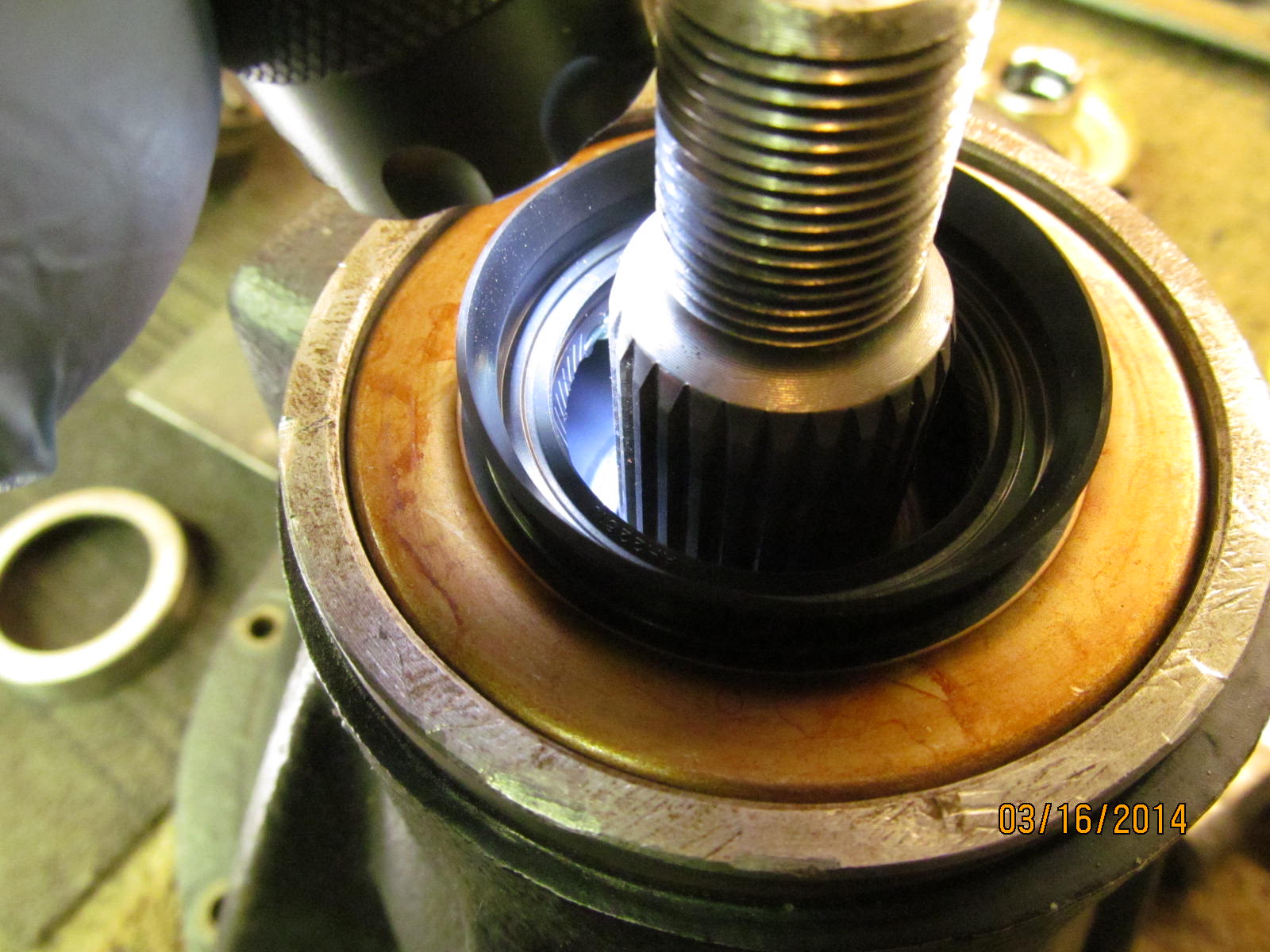

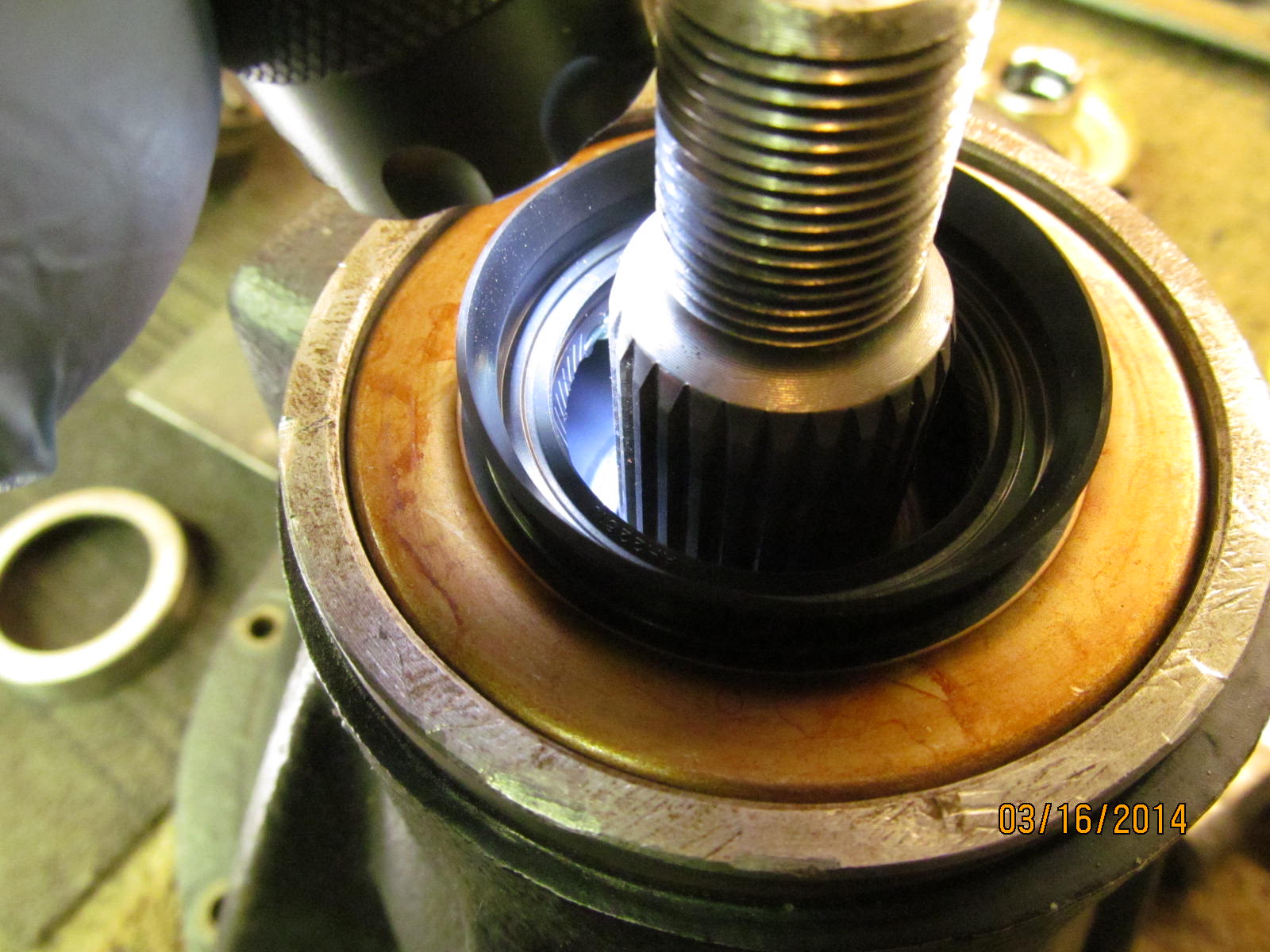

Now that the pinion depth is good, the solid collar and new OEM seal can be installed.

|

|

|

|

Skipped a few pictures but I had to re-shim the solid collar and had to tear it down several times to get it right. And now that

it is, a good, used splashguard can be installed.

|

|

|

|

|

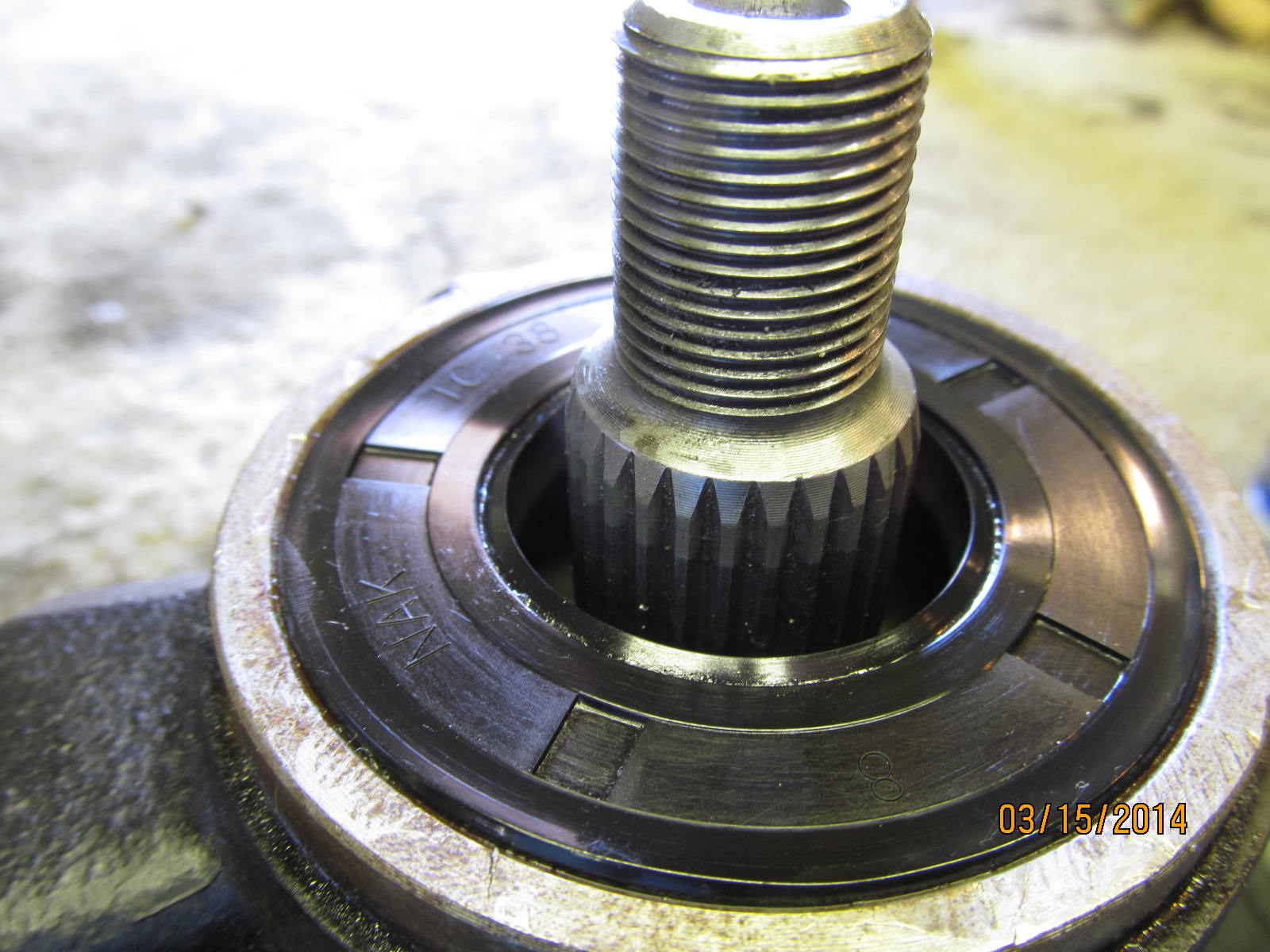

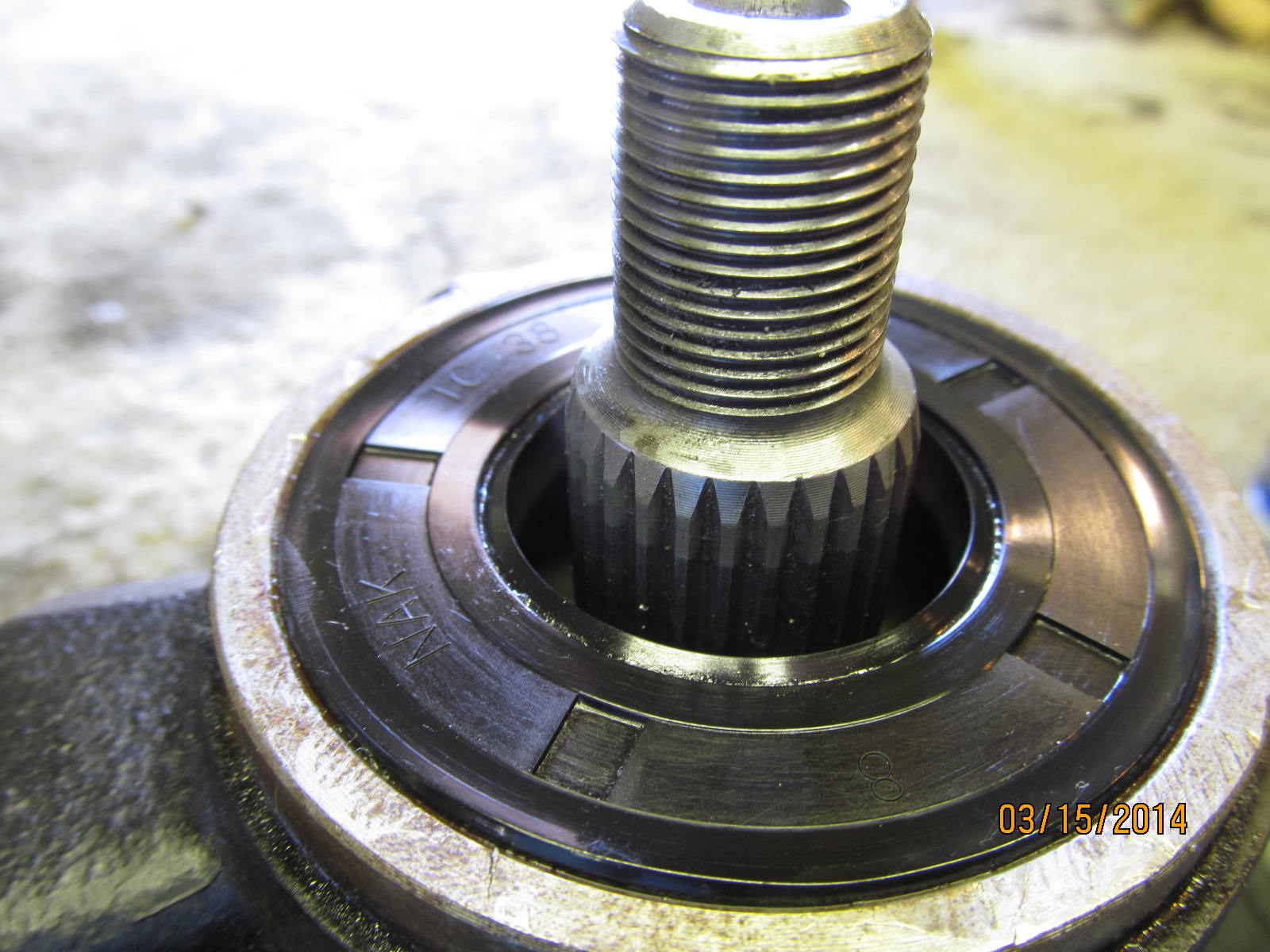

OEM 90311-38047 pinion seal.

|

|

|

|

|

A thick grease is applied to the inside to prevent the garter spring from popping loose.

|

|

|

|

|

The seal is evenly tapped in place.

|

|

|

|

|

I still shine a light inside to verify the spring did not pop loose.

|

|

|

|

|

Gear oil is applied to the effected seal surfaces to prevent a dry start up.

|

|

|

|

|

Threads are verified clean and red loctite on the pinion nut.

|

|

|

|

This nut is on very very tight. I only have a 2 in/lb start torque for pinion drag. We surely don't have to worry about these

bearings getting hot for sure.

|

|

|

|

The Detroit locker case is now installed. Bearing caps are in place. A solid smack from the rubber end of hammer should result

in a solid SMACK! sound of the upper tower cap seating down properly.

|

|

|

|

|

75 ft/lbs...

|

|

|

|

|

...and these wheel adjusters should turn easy if all is set down right and they did.

|

|

|

|

For my final adjustment, I smack all 4 corners while turning the pinion flange. This equalizes the carrier bearing

tensions with each other.

|

|

|

|

|

I measure a combined pinion bearing plus carrier bearing preload of 10....2 for the pinion and 8 for the carrier bearings.

|

|

|

|

|

Backlash was measured every 3rd tooth and was about .006"

|

|

|

|

|

Blue medium strength loctite and 10 ft/lb

|

|

|

|

|

Final repaint....sweet drive pattern. In no way shallow....slight deep. Favors toe end.

|

|

|

|

|

Coast....good. Slight favoring of the heel.

|

|

|

|

|

...

|

|

|

|

|

....

|

|

|

|

|

...

|

|

|

|

Going to Fedex to take a trip to Maine :)

|

|

|

|