|

The main purpose of this link is to show how easy it can be to install

your own Aussie with minimal tools. Don't even need the dial indicator

for the backlash. A hammer...a chisel...a screwdriver.....a wrench or 2...

and maybe a torque wrench. That's about it.

|

|

|

No worries about backlash as long as the adjusters are pre-marked on both sides. This

way, upon re-assembly, the same backlash and carrier bearing pre-load can exactly

be maintained. But this particular 3rd had fairly low CBPL so we can tighten both

adjusters exactly the same amount past the marked settings and do a very nice

"re-fresh" of the CBPL. The benefits of doing this are greatly reduced ring

movements and renewed strength.

|

|

|

Just remove the cap bolts and keep track of what goes on each side. No reason to

even touch the pinion....unless it wobbles around for some reason. On this

one, the pinion was ok....not alot of pinion pre-load but enough for now.

|

|

|

No way the cross-pin will slip out without removing the ring gear....even on

this thin 410 ring.

|

|

|

After the 10 bolts are removed, the ring gear drops relatively easy with gentle

coaxing with a chisel and hammer.

|

|

|

The steel dowel comes out easy enough with a 3/16" round chisel...this is the dowel

itself in Petes' fingers.

|

|

|

The crosspin now slides out and the spiders/side gears fall out. They get thrown

away and only the 2 thrust shims are re-used on the Aussie. The thrust shims might

not be the same exact thickness so keep track of which side the live on.

|

|

|

|

|

|

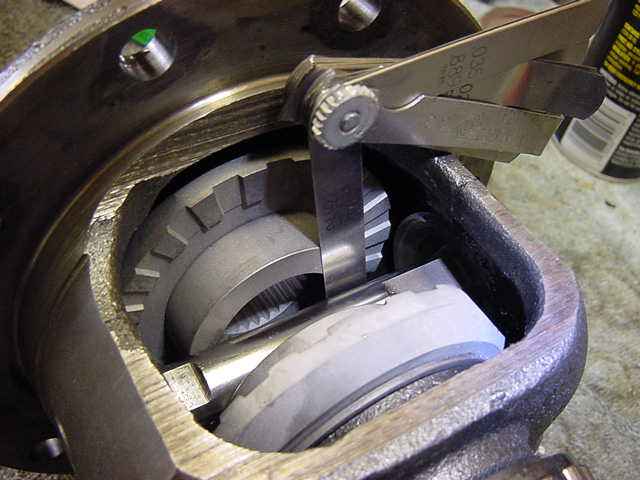

With the locker partially assembled, it is now time to check the cross-pin

clearances. Here, I can just squeeze a 12 thou gauge by the cross-pin. The window

allowed is 6 to 20 thousandths.

|

|

|

I tried using various levels of charm....but the coupler would not

quite slip in. :) just joking.

|

|

|

A few passes with a course rat-tail file took the rough edges off and allowed

the coupler to pass through.

|

|

|

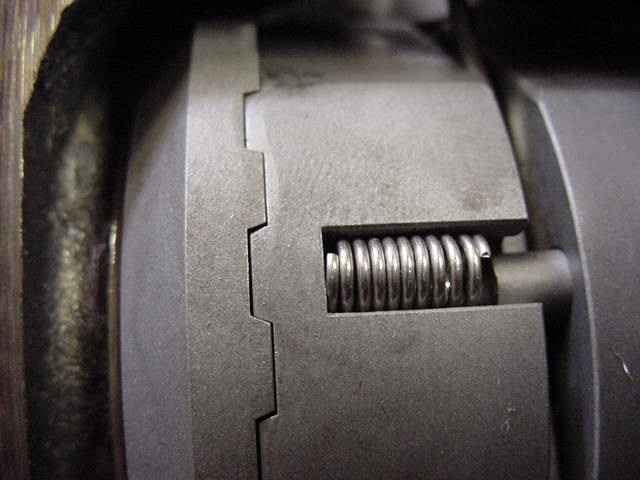

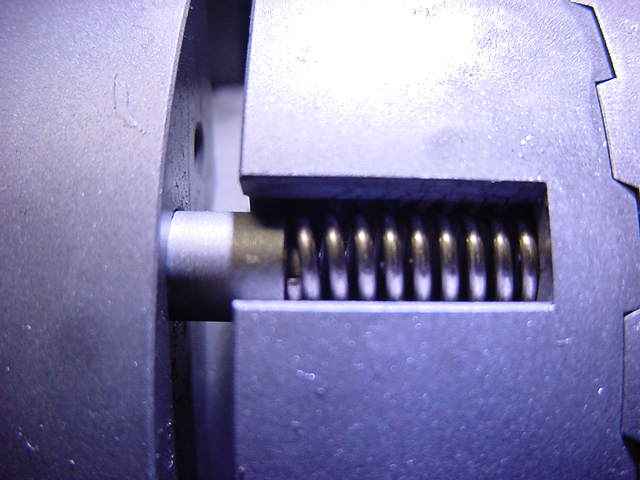

Putting the main guts of the locker in was easy....it's the pins and springs

that take a little more patience. Once you get the spring to this stage.....

|

|

|

....a nudge with a screwdriver will snap it down in place with little effort.

|

|

|

Align and push the crosspin in.....then tap the steel dowel in place.

|

|

|

Use a sharpened punch (prick punch) to dimple or distort the hole.

|

|

|

Align and tap the case down onto the ring gear with care. Let the ring bolts

pull the ring on the rest of the

way. I prefer to use blue Loctite and 70 ft/lbs.

|

|

|

I could have just aligned the marks and let it go like that.....but this 3rd has

seen over 130,000 miles so the bearings were getting a little loose. I was able to

tighten both sides an equal 6 1/2 notches or so resulting in excellent ring

'rigidity' and re-newed strength. Backlash is un-effected and the carrier bearings will

not suffer in the least.

|

|

|

I didn't have to but I took a pattern check and all is good for a used gearset.

Except for a few minor things this 3rd is done. It has an Aussie in it now

and freshened up bearings! ZUK

|

|