|

Mike is local to me so he tore into his truck, removed the rear diff, and showed up at my shop....

|

|

|

....the plan is to use a 529 Yukon and an Aussie Locker, all new bearings, and a solid collar.

|

|

|

Step one is to remove the bearing caps...

|

|

|

I'll work on the case last and get the pinion end ready to go.

|

|

|

Even though the nut was well-staked, the electric impact took it off in about 1 second.

This tool has paid for itself many times over.

|

|

|

I have a soft chisel and this does not damage the race while it's being tapped in.

edit---Best to stay away from all punches/chisels...

use an old race to evenly "pat down" the new race.

Using a punch could result in "oscillating" pinion

preload measurements with the torque wrench.

1-8-2011 ZUK

|

|

|

The larger inner race is is a little trickier to get it tapped in straight but doable.

edit---Best to stay away from all punches/chisels...

use an old race to evenly "pat down" the new race.

Using a punch could result in "oscillating" pinion

preload measurements with the torque wrench.

1-8-2011 ZUK

|

|

|

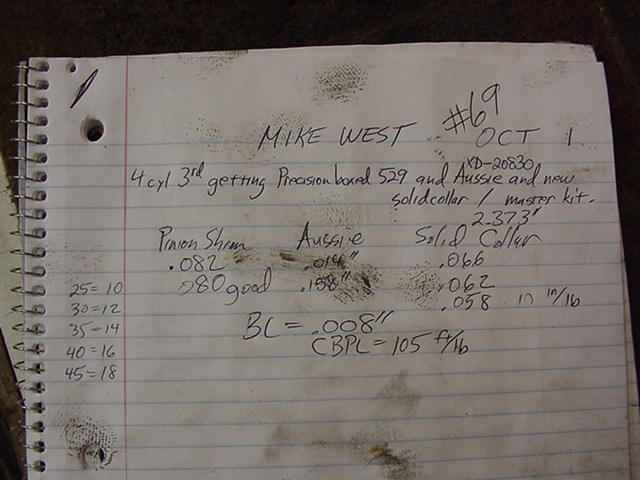

I'm skipping a few steps here but I loaded up the pinion with a .082" pinion depth shim. I pressed

the inner pinion bearing on then slipped the solid collar on with .066" worth of shims. I then

mounted the pinion in the case only to find out that it was loose on pinion pre-load so, in the pic

above, I am now pressing the pinion out to reduce the shims on the collar and try again.

|

|

|

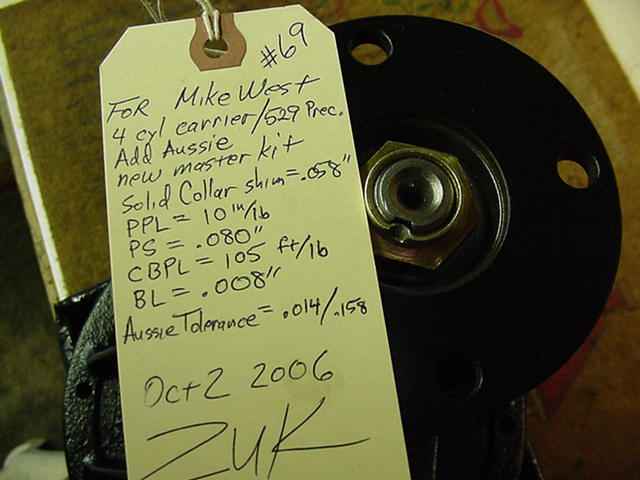

On the 3rd try, using .058" for the collar shim, I was right at the

desired 10 in/lb of pinion drag.

|

|

|

Back to the case...with the bearing puller in place, I quickly realized that the bearings required

very little coaxing to get them off. They just about fell off. I will use the Loctite Sleeve

Retainer compound with the new bearings.

|

|

|

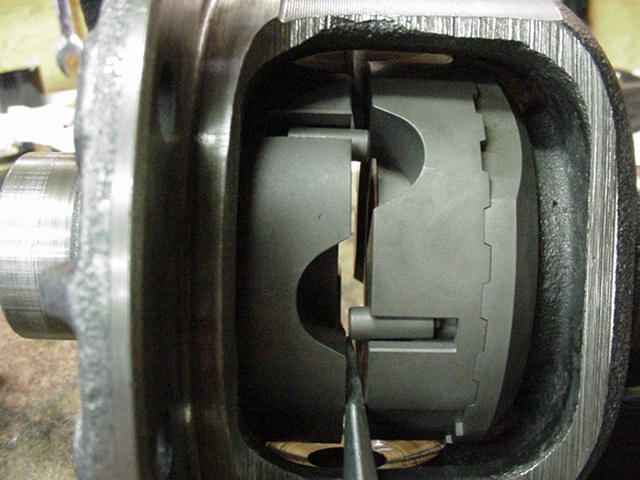

Bearings are off...ring gear is off...Time to install the Aussie so I have removed

the center pin here.

|

|

|

The spider gears in my hand are no longer needed...

|

|

|

The factory sidegears also are not used. The thrust washers both measured .067" thick

and they do get re-used. Some people unknowingly leave them out and then the locker does

not operate properly.

|

|

|

The first step is to check a tolerance listed in the Aussie assembly manual.

|

|

|

Using feeler gauges, all 4 spots are checked and found in spec. I was able to slip a

.014" feeler in there and the spec wants to see between .006" and .016".

|

|

|

The couplers would not go in...

|

|

|

I used a large rat-tail file to remove some material...

|

|

|

...and then it slipped right in.

|

|

|

Line the drive couplers up and insert the 4 pins.

|

|

|

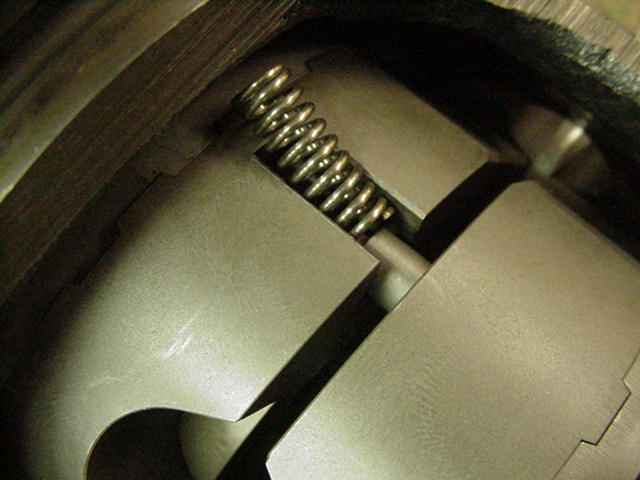

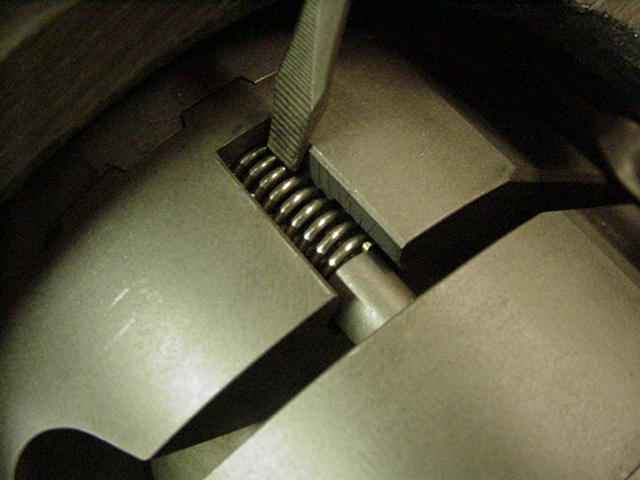

With the pins in place, now it's just a matter of installing the springs.

|

|

|

I find it easiest to line this end up first...

|

|

|

...then tap the other end in with a small screw-driver.

|

|

|

I checked the second tolerance and all was good.

|

|

|

Slip the power pin in place and tap the roll pin and the Aussie is done.

|

|

|

I applied Red Loctite on the new ring gear bolts and 75 ft/lbs of torque.

|

|

|

I used starting fluid to clean the surfaces and applied the sleeve retainer compound. For loose

fit bearings, this will "lock" them in place and prevent spun bearings.

|

|

|

With the case in place, I ran a pattern...drive side...looks a little on the deep side.

|

|

|

coast

|

|

|

I tore the diff down and removed .002" off the pinion depth shim...this is much better.

|

|

|

coast.

|

|

|

While I turn the pinion, I rap on both bearing caps numerous times to shake the carrier bearings

into an equal tension state. This helps with accurate backlash measurements.

|

|

|

Markings on the ring gear to help identify these particular ring and pinions...

|

|

|

|

|

|

My notes during the install...

|

|

|

Done :)

|

|