|

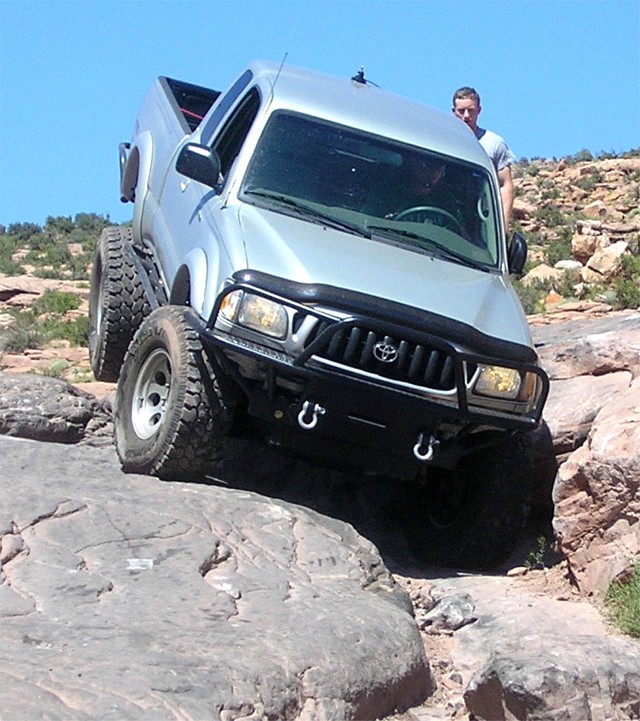

Josh, out of Colorado, is having too much fun with his 2004 Tacoma 4x4. He's running

35" tires and has already had someone install the 488/ARB combo in the front IFS. I will

be setting up the supplied rear E-Locker with a Cryo treated high quality MOTIVE 488.

|

|

|

10.9 ring gear bolts, seal, collar, nut, cryo bearings, and cryo Motive 488's.

|

|

|

The E-Locker supplied had a busted ring gear. I noted ZERO CBPL so, most likely, the ring

deflected under high load and KABOOM.

|

|

|

Off with the carrier bearings and the ring gear...

|

|

|

The new cryo bearings are pressed on at the same time.

|

|

|

Loctite on the 10.9 bolts...I seem to be using alot of the Loctite lately so

I bought the BIG 250 ml size. Just barely over a cup here and costing over $100.....that

would be $1600 per gallon!

|

|

|

.216 for the first pinion shim selection. Cryo inner and outer bearings, of course.

I am so glad that I am now cryo'ing the bearings in all of my master kits. It just

makes so much sense. They become much more 'durable' and surface roughness decreases resulting

in about 200% greater life and less generated heat.

|

|

|

I chose to load the pinion up with no solid collar the first go around. By carefully

tightening the pinion nut, the 15 inch/pounds of pre-load can be easily generated.

|

|

|

Nice pattern but perhaps 3 more thou in pinion depth and it will be spot on.

|

|

|

...

|

|

|

...

|

|

|

If I was to use a hammer to beat the pinion out I might chinger the top threads

and leave some dent marks in the outer race. A small press like mine is a must have.

|

|

|

Heavy grease on the compression spring keeps it from popping off when I tap the

seal on with a hammer.

|

|

|

A little rtv on the outer metal circumference and gear oil on the inner rubber lip....

|

|

|

I can 'control' the pinion pre-load sometimes by how tight I crank the pinion nut on. With the nut

tight, I measured about 10 in/lb....but by using a 3 foot cheater bar, I managed to rotate the

pinion nut an additional 45 degrees...pinion pre-load increased another 7 in/lb. Perfect...17 in/lb less about 2 in/lb

of seal drag equals a net 15 in/lb of PPL.

|

|

|

Camera went a little fuzzy but the load bearing looks nice.

|

|

|

...

|

|

|

It can take 20 minutes sometimes getting the backlash/CBPL just right. The last adjustment

I make is to the ring gear side bearing adjuster(the side shown in the pic)

...this is the side that sees the real torque so I make

sure it is 'tensioned' from that side and surely not the other side.

|

|

|

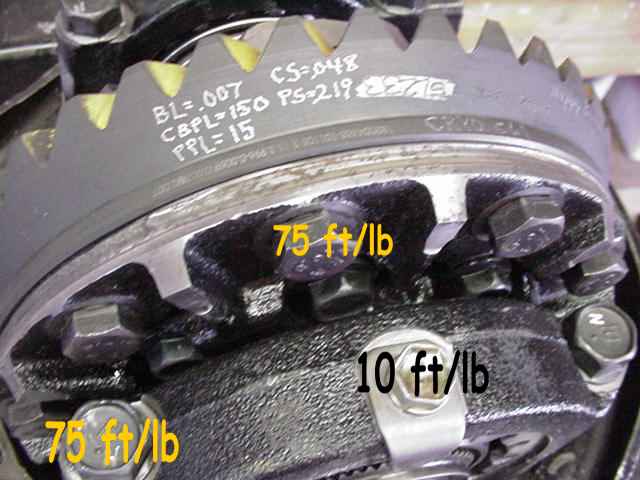

75 ft/lbs on the ring gear and bearing cap bolts...a soft 10 ft/lbs on the lock tabs...actually

10 ft/lbs with a little extra nudge ;)

|

|

|

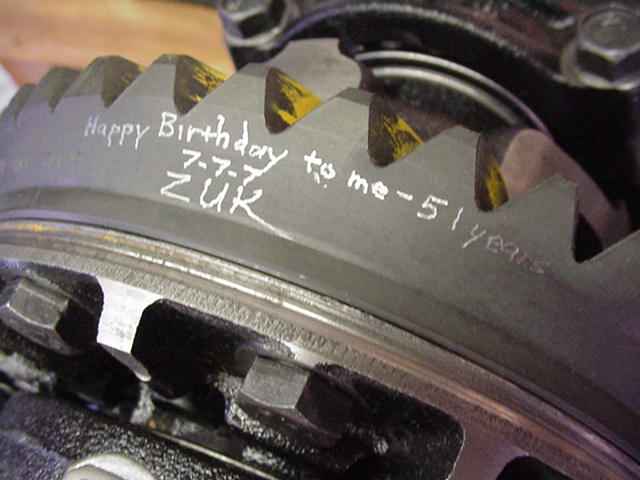

Date coded.

|

|

|

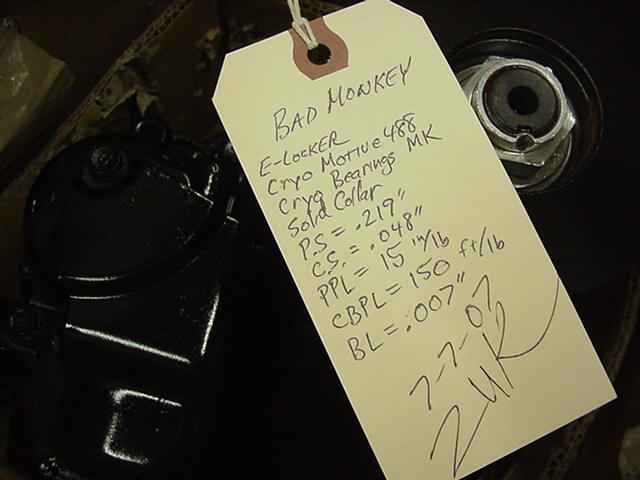

The E-Locker dropped right into the genuine Toyota box. Just a matter of stuffing some

packing materials all around to lock the nose cone in place.

|

|

|

...

|

|

|

Ready for the trip to Fedex...72.6 pounds :)

|

|