(rear install link at bottom of this page) |

|

|

|

|

|

Ben is the proud owner of this 1997 FJ80 40th anniversary edition. He has the OME 2.5" lift and 33" tires. 1997 is the last

year Toyota offered the 4.5 liter in line straight 6 engine (1FZE) which he has.

Here's a copy/paste from a portion of Ben's email to me to help explain why I was doing his diffs......

|

|

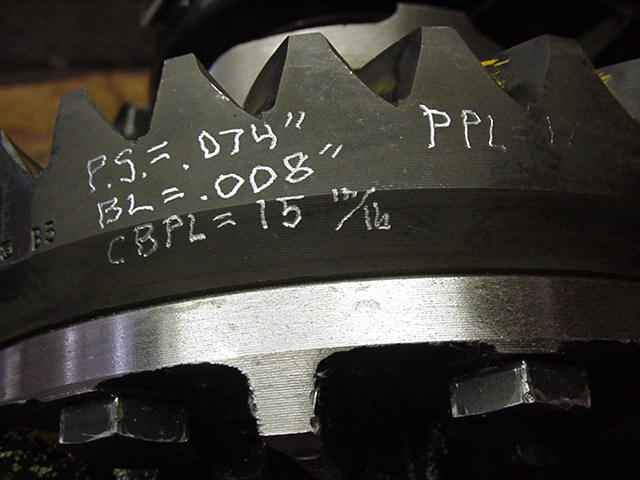

This is the front 8" E-Locker...it's a high pinion with reverse cut 488 gears. I received it this way and all the parts are here. I assembled the pinion with the factory .074" pinion shim. I assembled the pinion assembly without the crush sleeve. I will save that part of the install for last. Some pics are missing...so then I installed the case with the ring gear bolted in place and set the backlash to a reasonable .007". |

|

The depth was perfect. |

|

... |

|

perfect |

|

.......... |

|

This is US GEAR brand. |

|

With the depth right, now I could install the crush sleeve...press the pinion out... |

|

Install the crush... |

|

This oil slinger promotes better lubrication for the outer pinion bearing. |

|

The seal gets the thick grease on the micro spring(keeps it from popping off while the seal is being hammered on) and an anaerobic rtv to make sure no gear oil leaks out. |

|

I still use a penlight to make sure the spring is not laying on the oil slinger. |

|

Red Loctite is applied to the nut and the crush sleeve will yield to my 3 foot bar. |

|

Ding. |

|

Now to set the BL and CBPL....anti-seize on the threads allows for minimum thread damage and maximum pre-load. |

|

This is my ZUK-fabbed spanner wrench...very simple...just a piece of flat stock with 2 bolts thru it. It offers good leverage. |

|

Wrapping with a hammer while the pinion is turned helps equalize the bearing tension. It helps me get the bearing pre-load tighter and, by equalizing the tension, will prevent a sudden backlash change during the first few miles on the road. |

|

Backlash was set to .008" and the CBPL reached 150 ft/lbs. 150ft/lb on the spanner rings translates

into 15 inch/pounds of actual carrier bearing drag as verified by some tests earlier in the year.

|

|

Ready to go back to Texas :) |

|

... |

|

... |

|

|

|