|

Rear and front Sierra boxed 529 gear install for Ben's 1994 FZJ80

|

|

(101 BIG pics loading)

|

|

AUG 22 2014

|

|

|

|

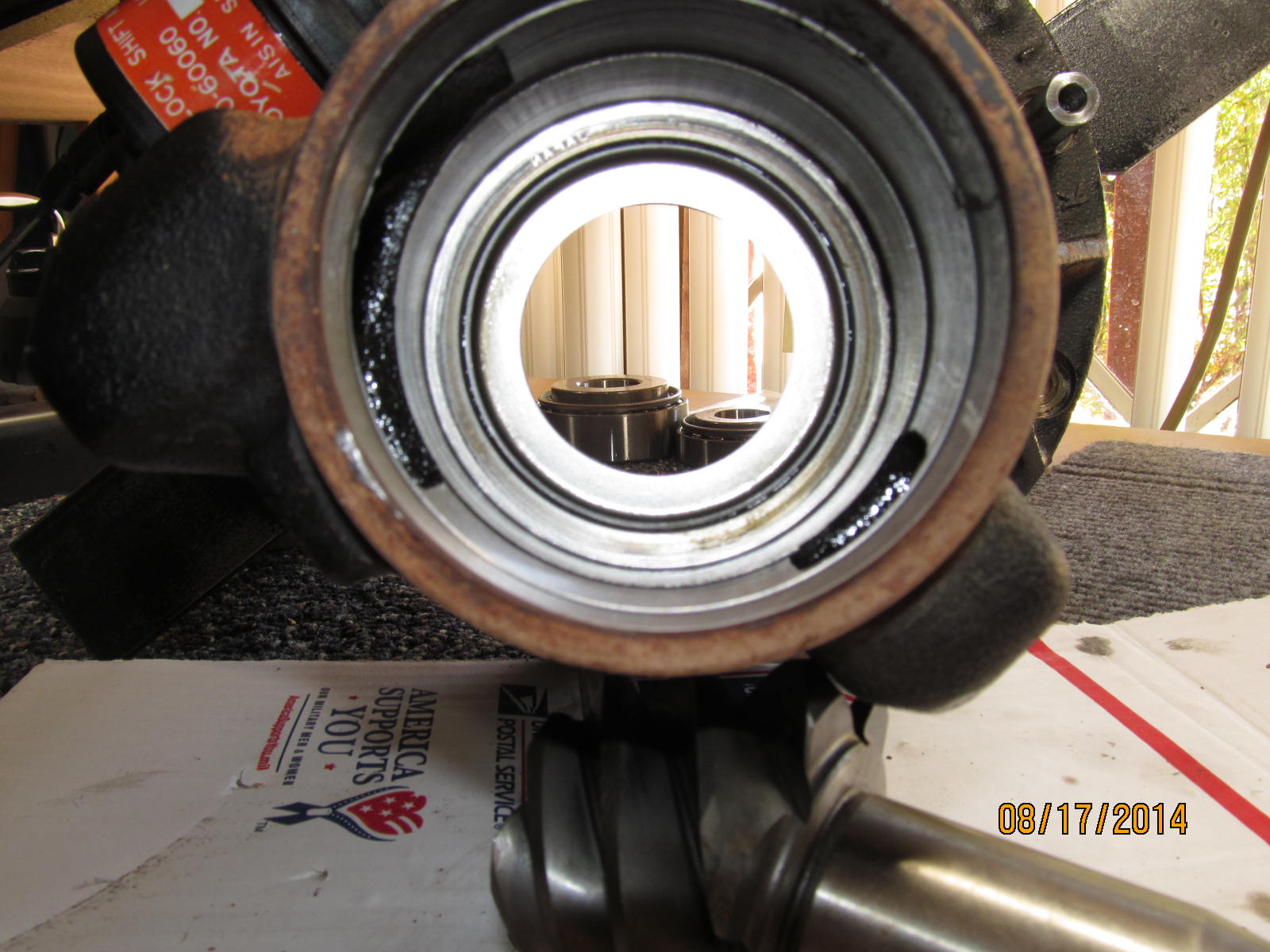

Ben is local to me and dropped off both 3rds and the ring/pinions/master kits. The heavy rear 9.5" 3rd will be first.

|

|

|

|

|

The parts came from CruiserOutfitters.com

|

|

|

|

These are the important parts I will install. Because the rear 3rd tilts up pretty steep due to the

6" slee lift

I will be using an oil slinger normally reserved for the 8" high pinions. Not 100% sure

how much it will help the oiling of the outer pinion bearing but it can't hurt to get

the best oiling retention possible when dealing with a steeply pointed pinion.

|

|

|

|

|

The actual branding on the ring gear just happens to be an AM Gear. Excellent gears from Italy.

|

|

|

|

|

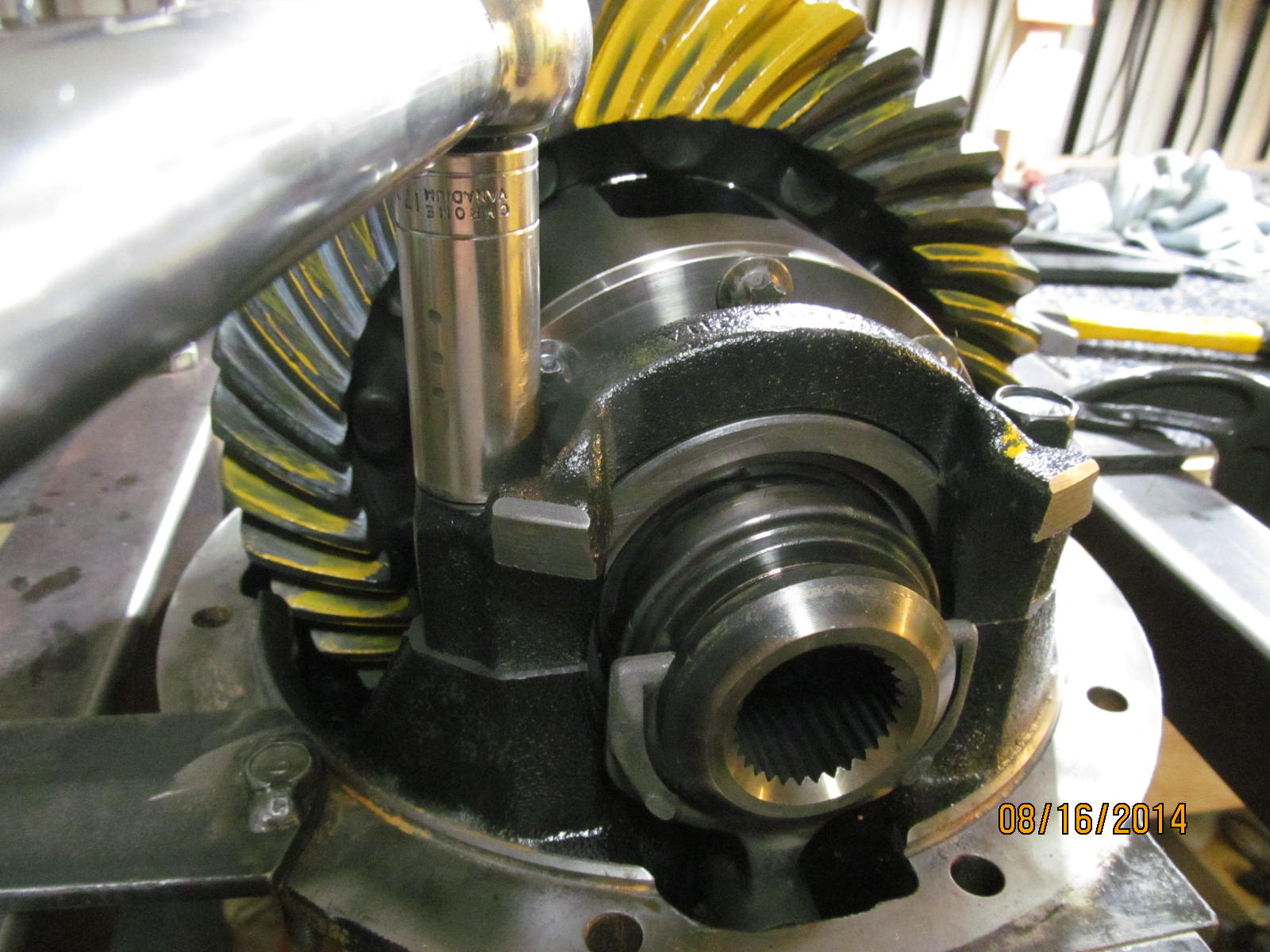

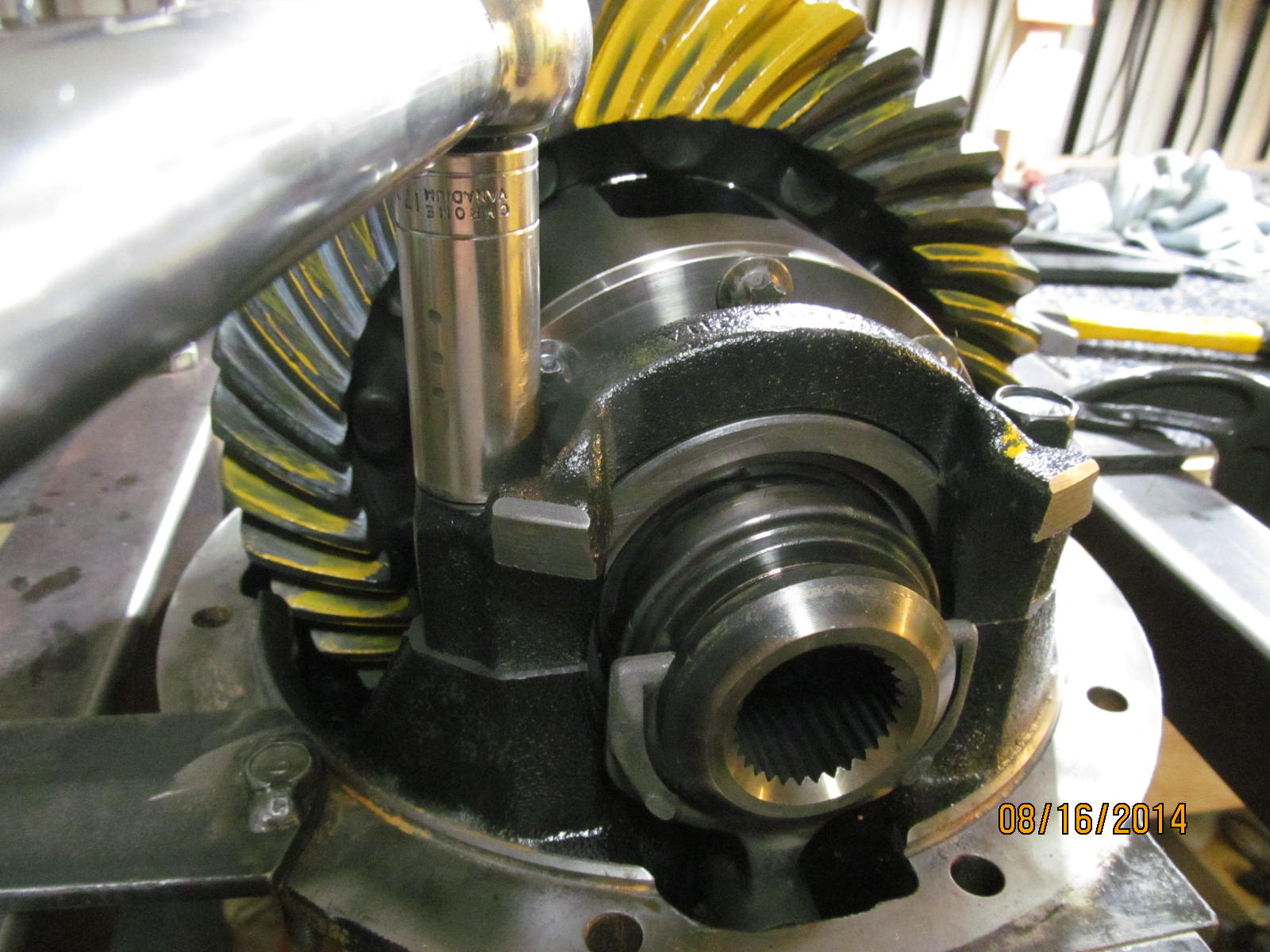

The expensive e-motor has been left on for this install.

|

|

|

|

|

.....................

|

|

|

|

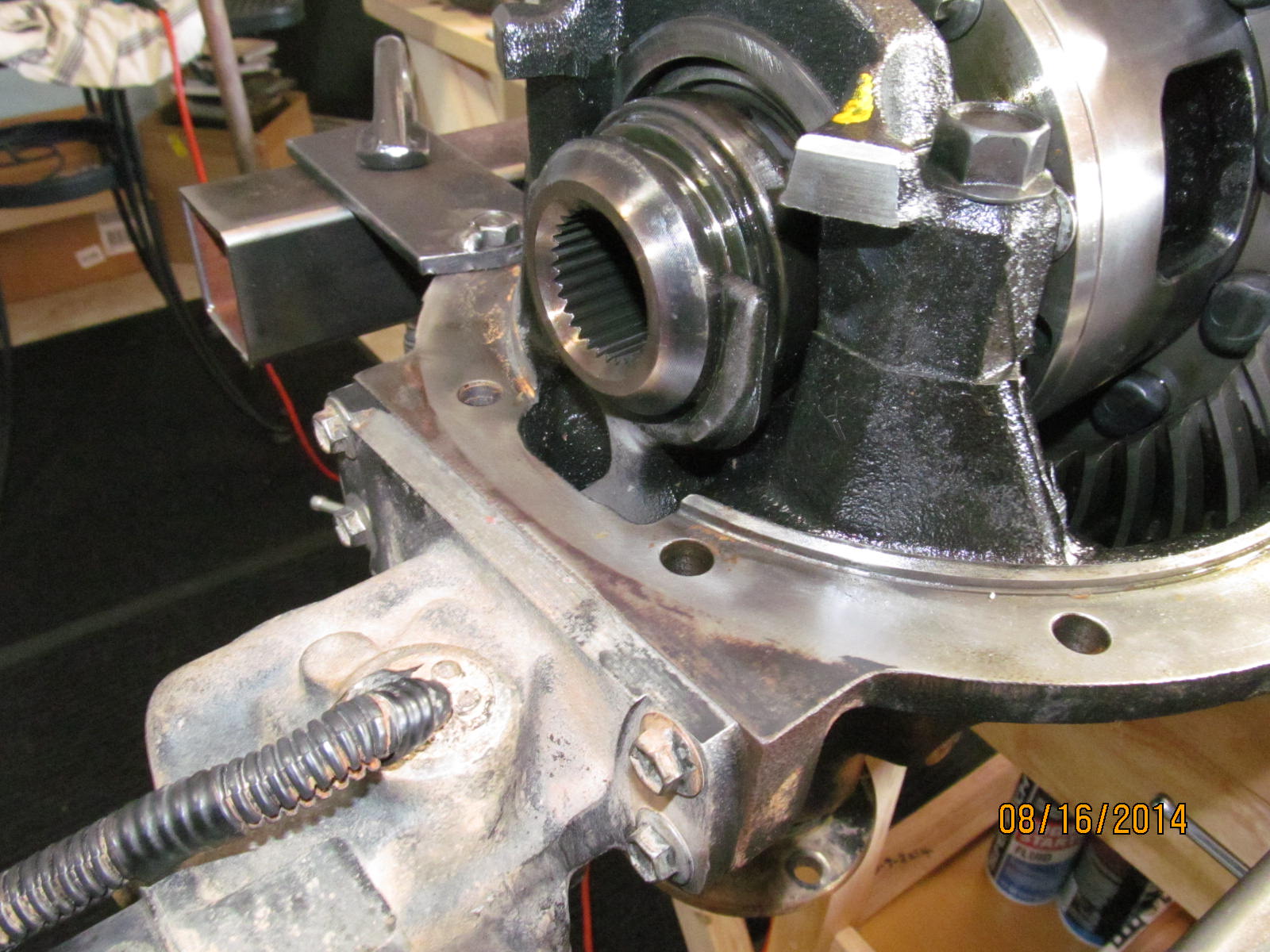

The fork is all the way in....locked position. I noted that these forks really push in HARD. That splined

coupler/driver is really pre-loaded or bias inwards. When locked there is no play in the shifting fork for sure.

|

|

|

|

|

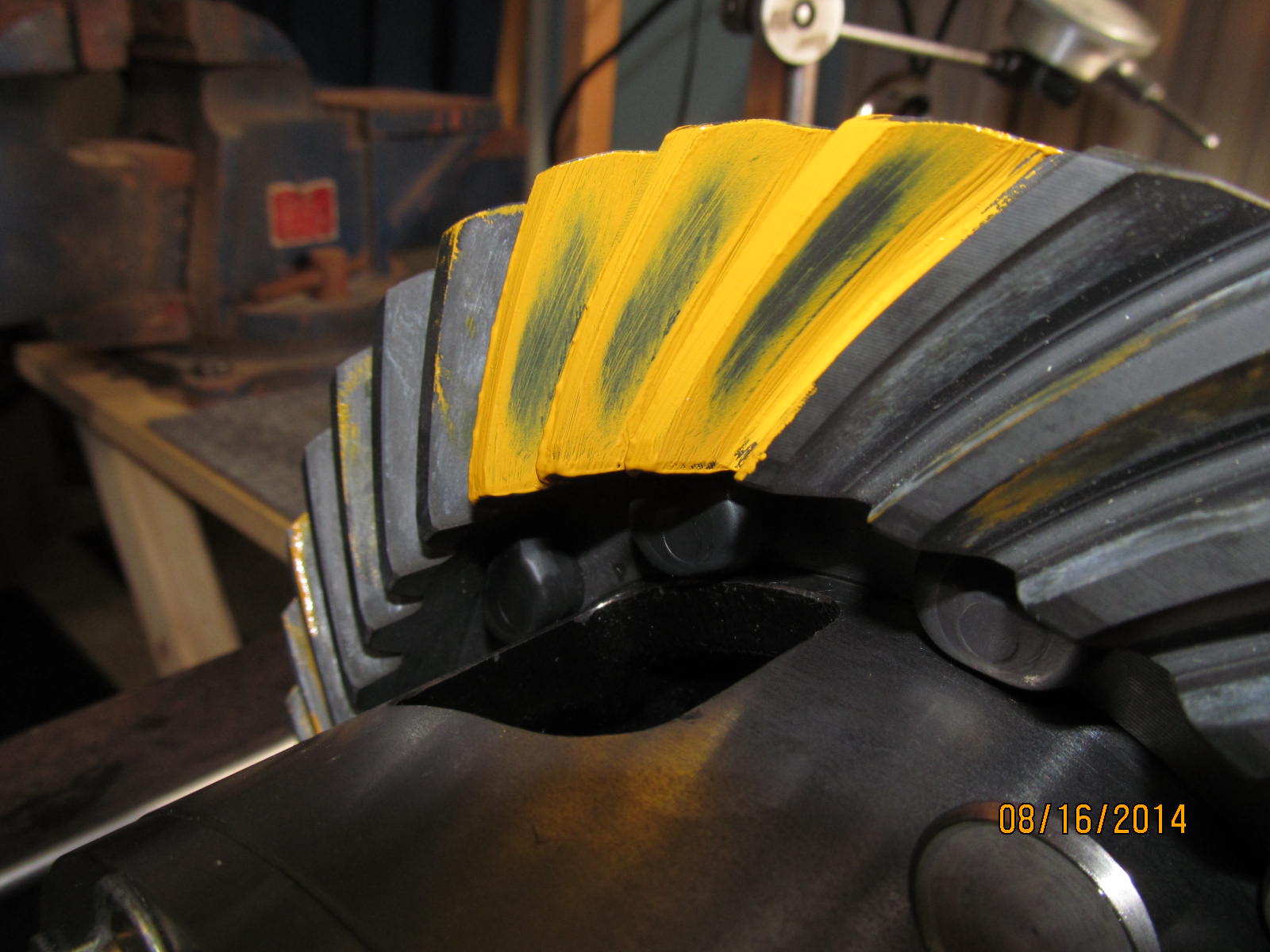

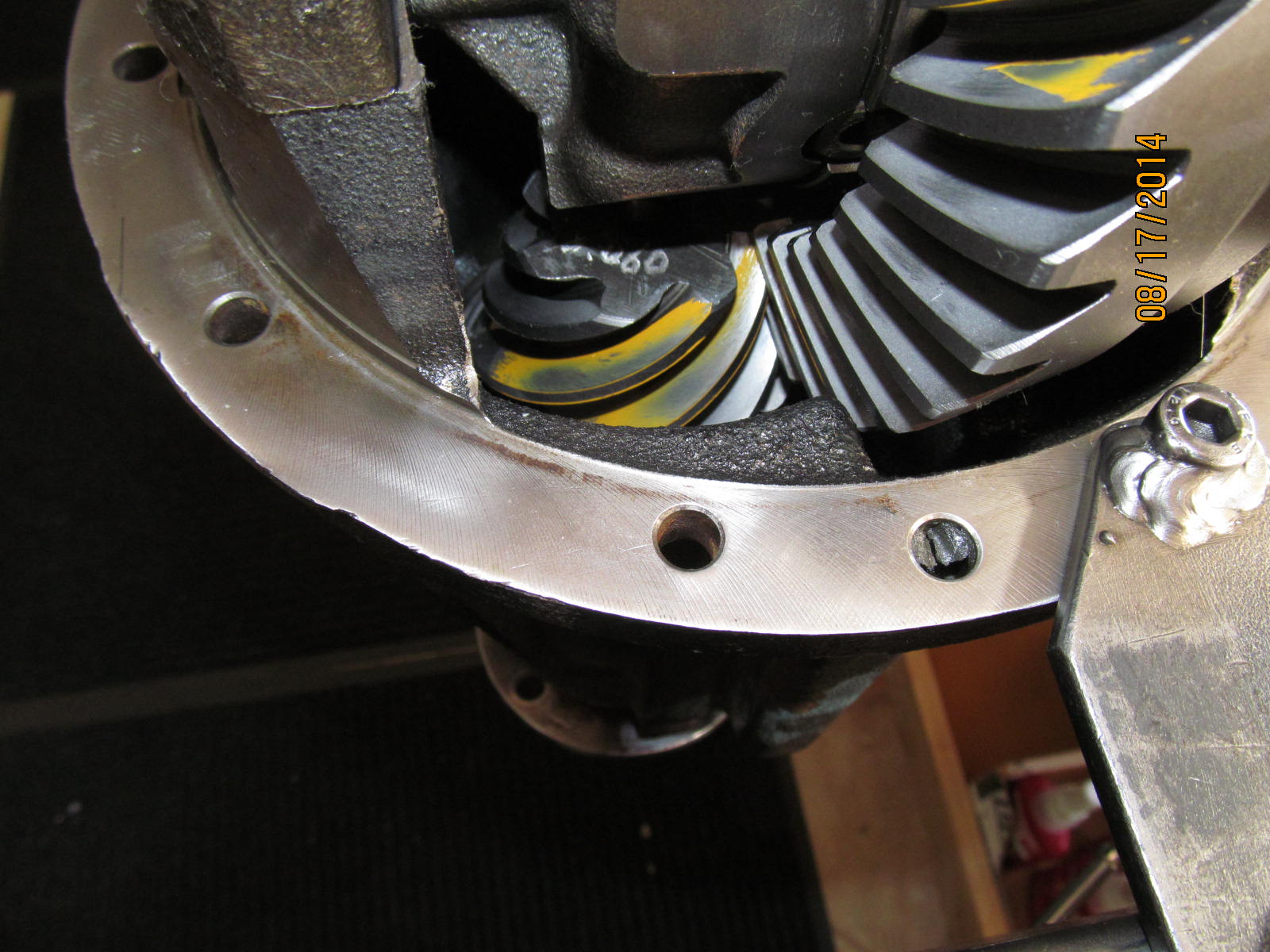

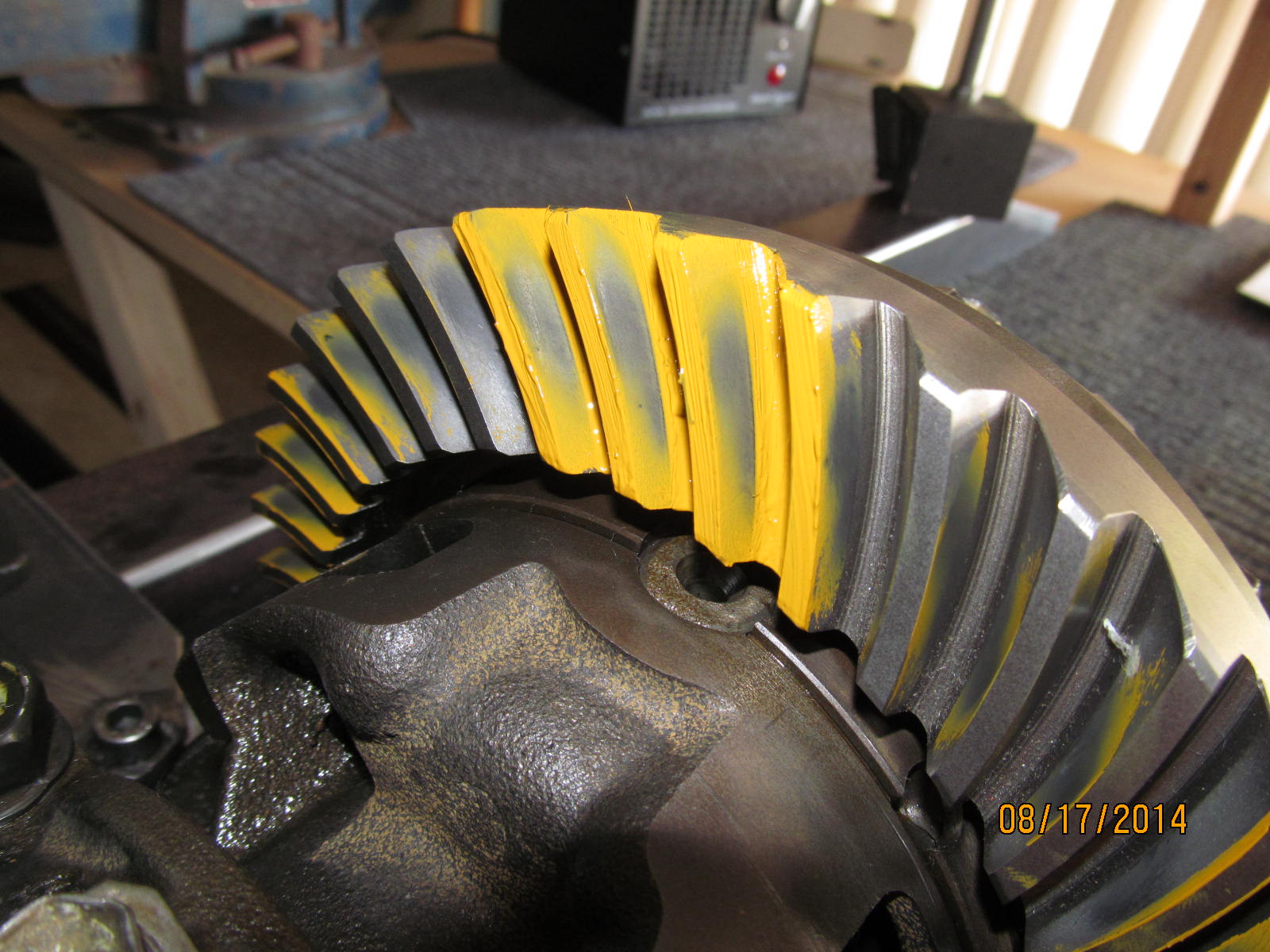

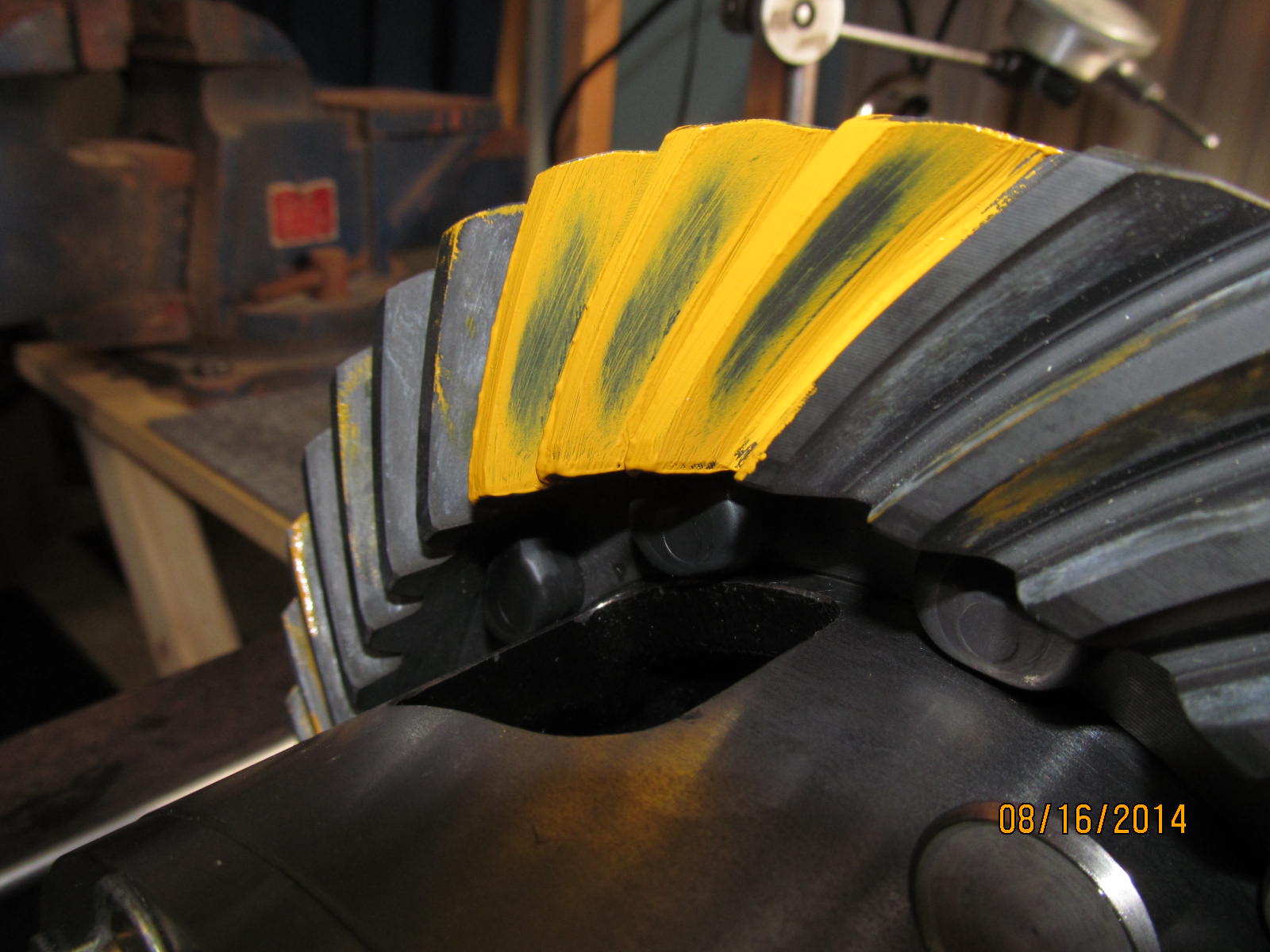

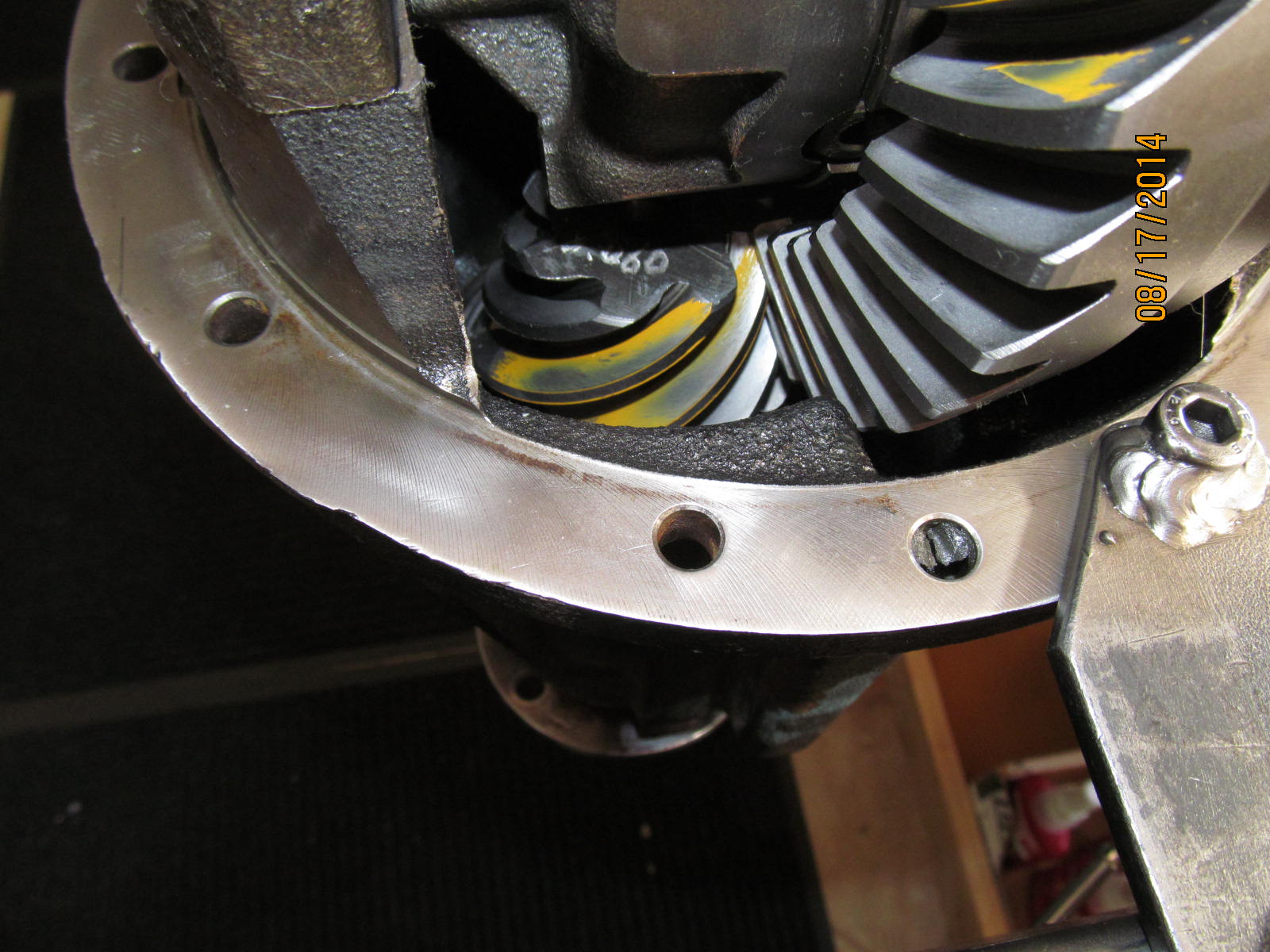

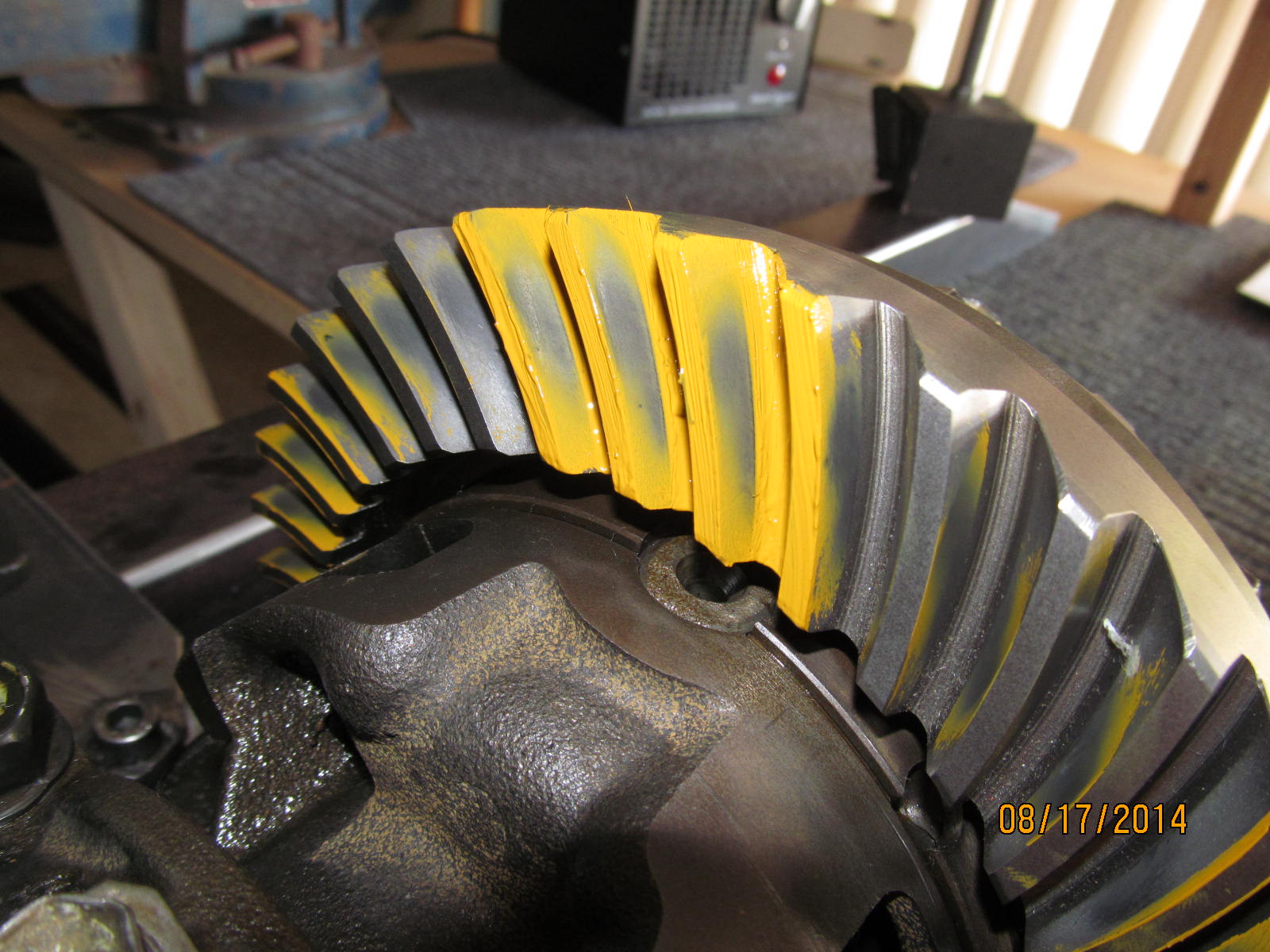

Not needed but I took a paint check on the old ring gear and it looks rather good for over 200K miles.

|

|

|

|

|

Coast is nice as well.

|

|

|

|

|

Mental note to self.....remember to re-install this and not leave it out.....

|

|

|

|

|

used carrier bearing races look pretty good....

|

|

|

|

|

This bearing can be removed easily with the OTC-4520 side bearing puller.

|

|

|

|

The other side has no room for the fingers to grab to so the dremel tool actually makes quick work of it.

Split the cage and remove all the rollers....

|

|

|

|

|

Use the mini-grinder to cut 90% thru...

|

|

|

|

|

...and let the screwdriver finish the last 10%. A light tap with a small hammer does it all.

|

|

|

|

|

It will lift right of the journal with the screwdriver attached.

|

|

|

|

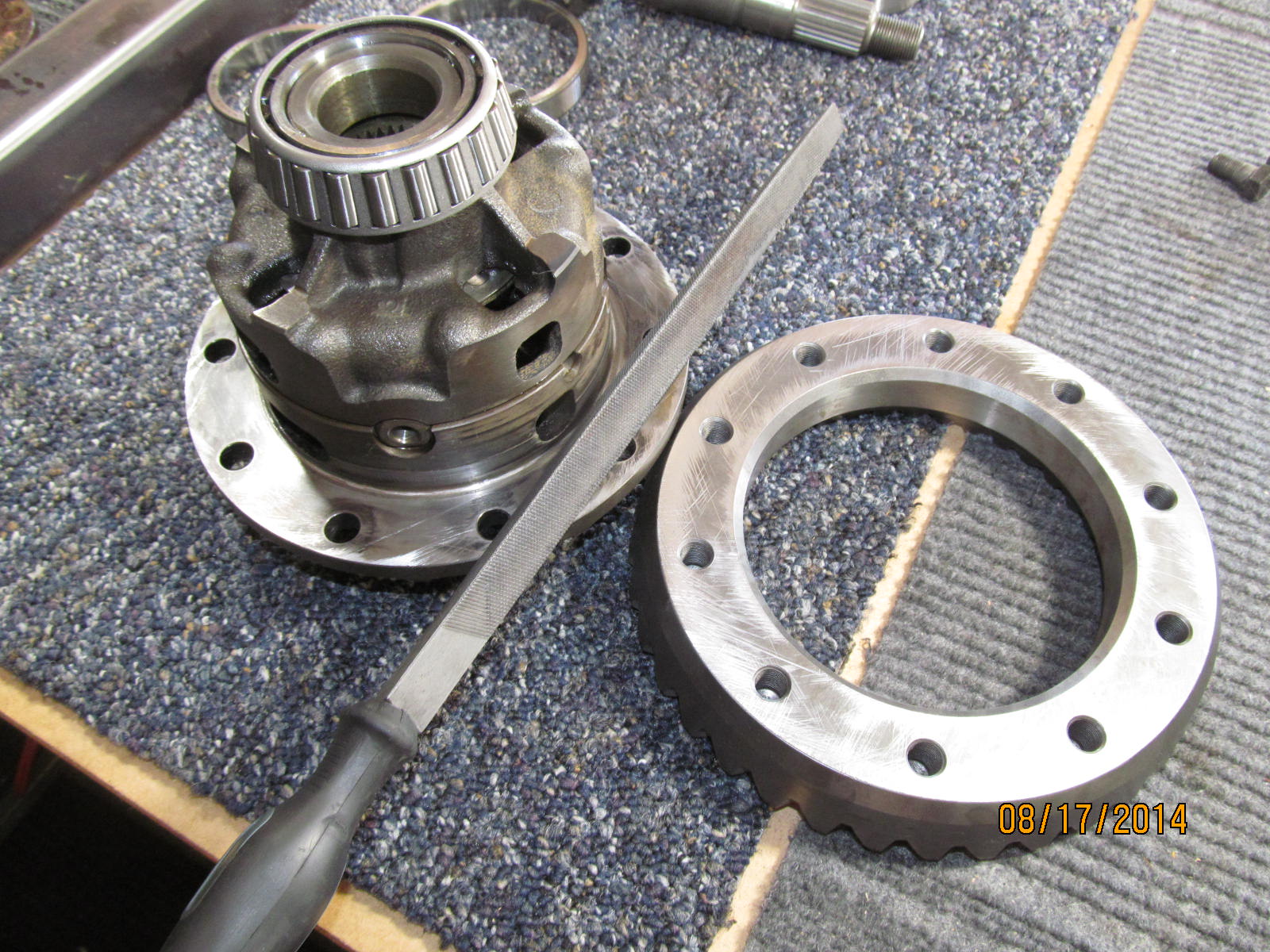

The electric impact can take all 12 nuts off in short order. These are hardened high quality nuts and bolts. They

can be re-used on the new ring gear with no issues.

|

|

|

|

|

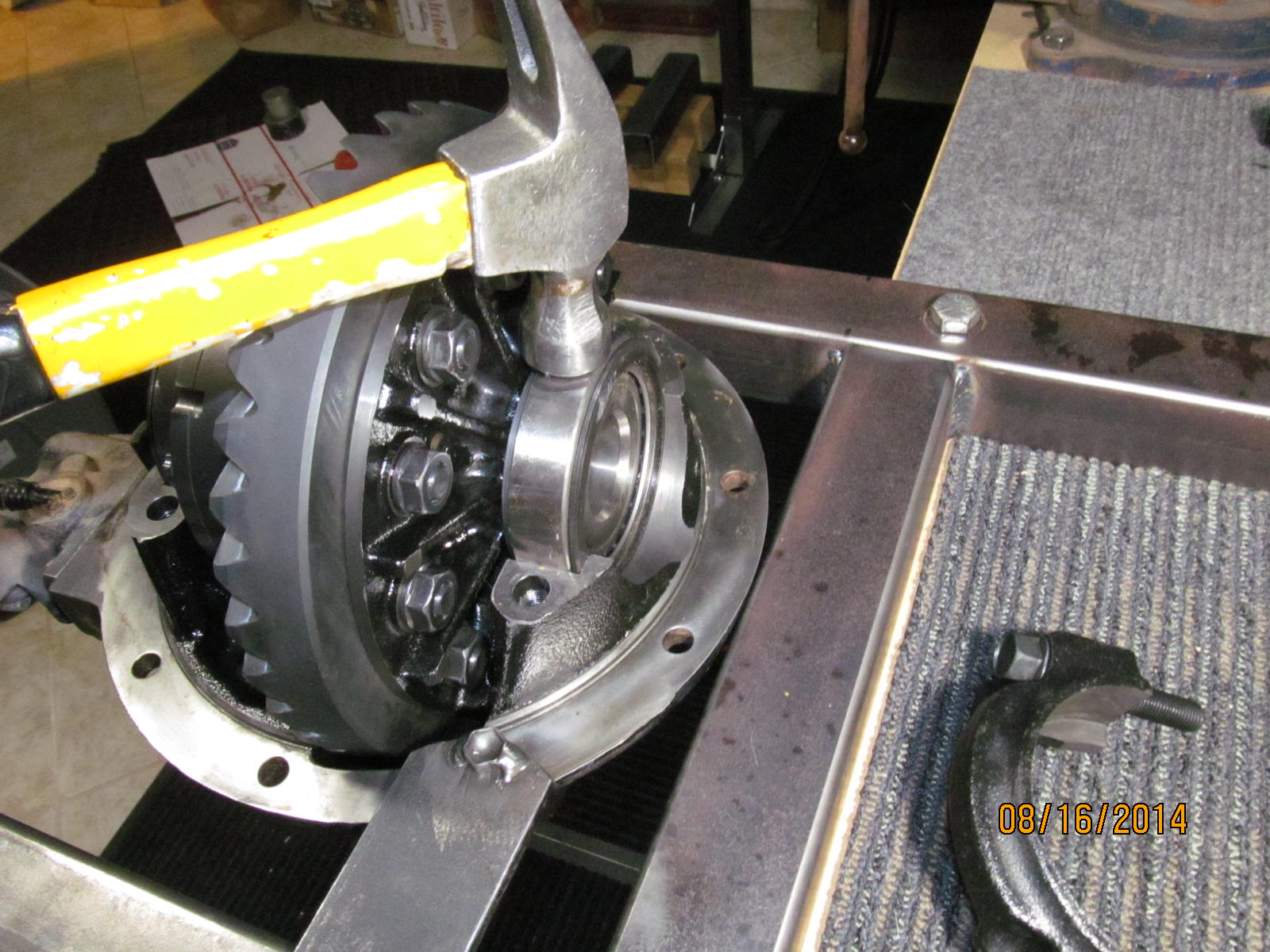

It was a tight fit but with alternating taps back and forth...the ring finally did drop free.

|

|

|

|

|

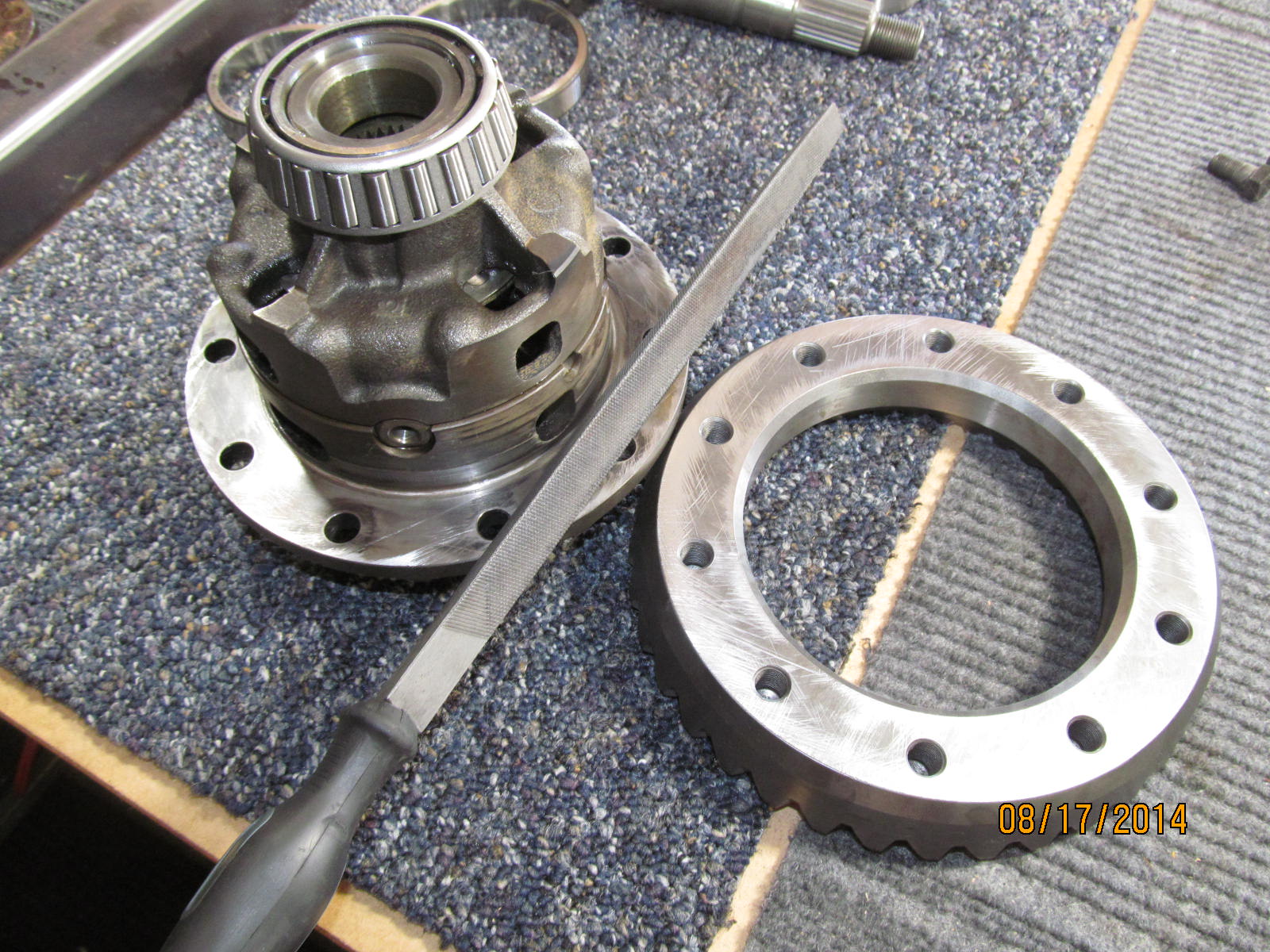

Surfaces checked for burrs and ridges with a large file. Ring gear bolts/nuts cleaned with ether...

|

|

|

|

A snug fit for sure. The ring teeth dug into the wood a little but it eventually seated. I dropped a few bolts in

the holes to make sure it was in close alignment.

|

|

|

|

|

Loctite #271 on all 12.

|

|

|

|

|

The FSM says 81 ft/lb and that's what they got.

|

|

|

|

The first pinion shim I wanted to try would be .058" and I considered putting some of the shim behind the

large inner race but decided that would be more trouble than it was worth.

|

|

|

|

Both races are seated down 100%. The small outer is ok to tap in place with the usual 360 degree support....

and the large inner race is pressed in place(not shown).

|

|

|

|

|

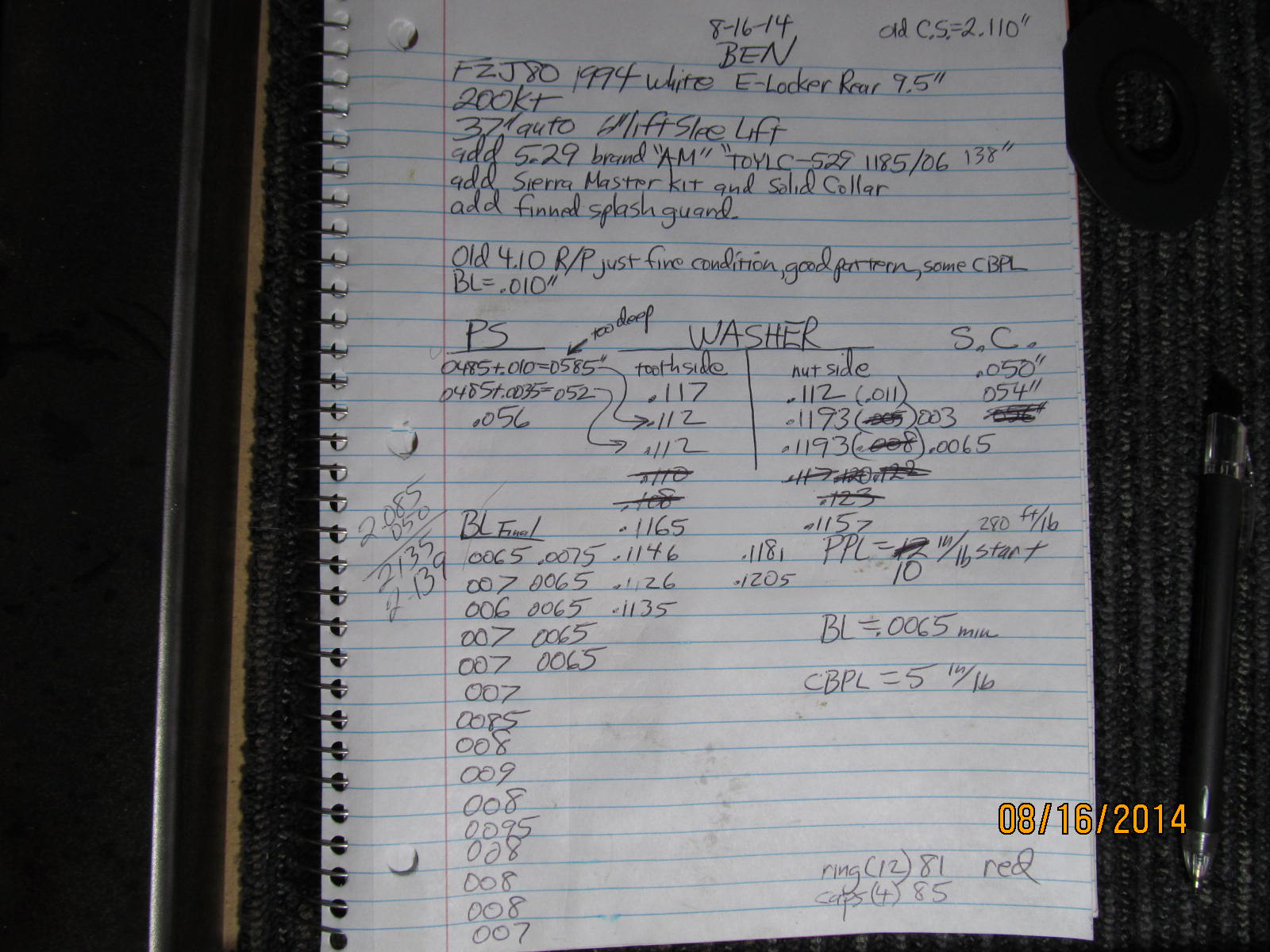

1st pinion depth shim will be .0485 plus .010"

|

|

|

|

|

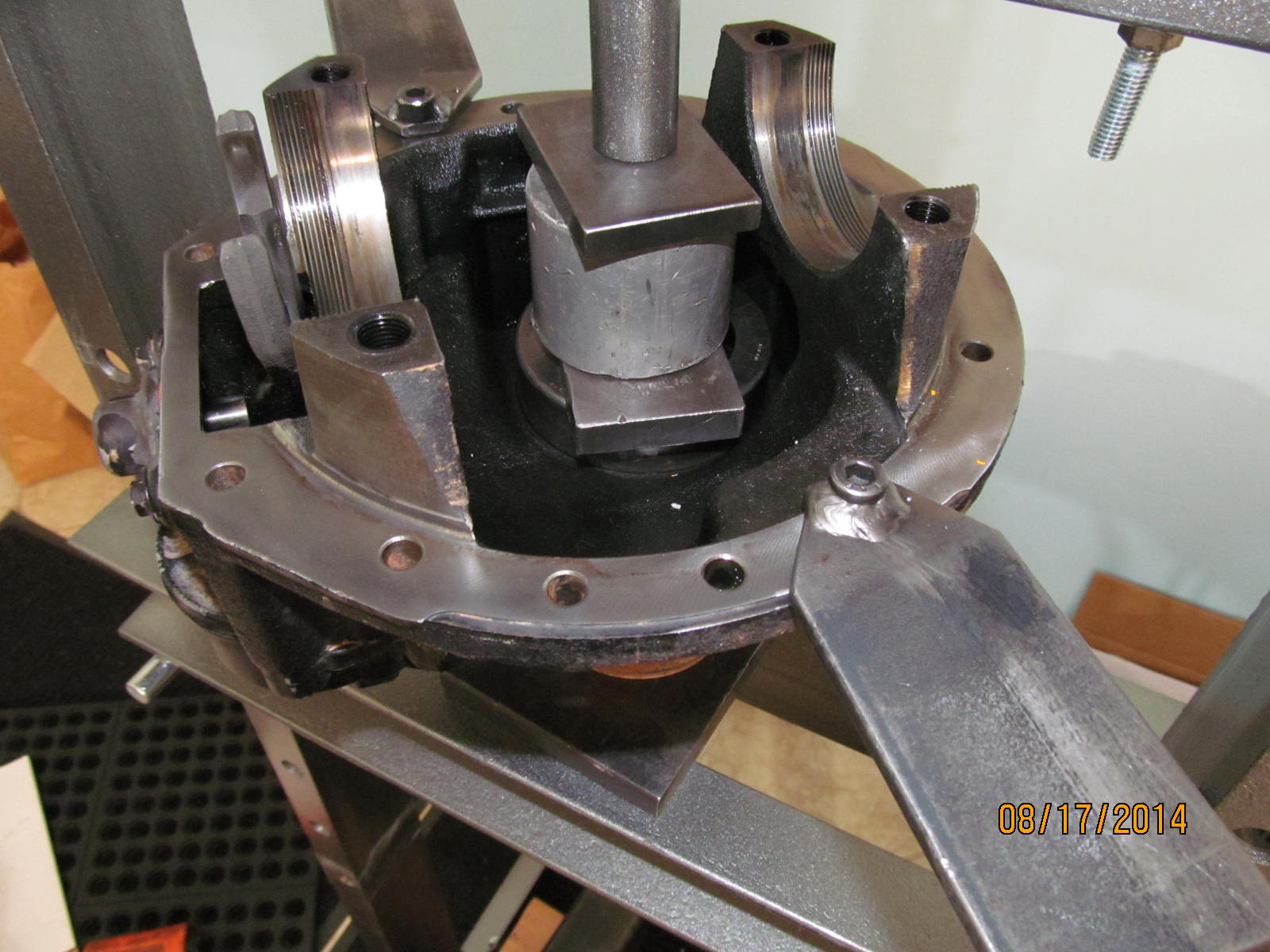

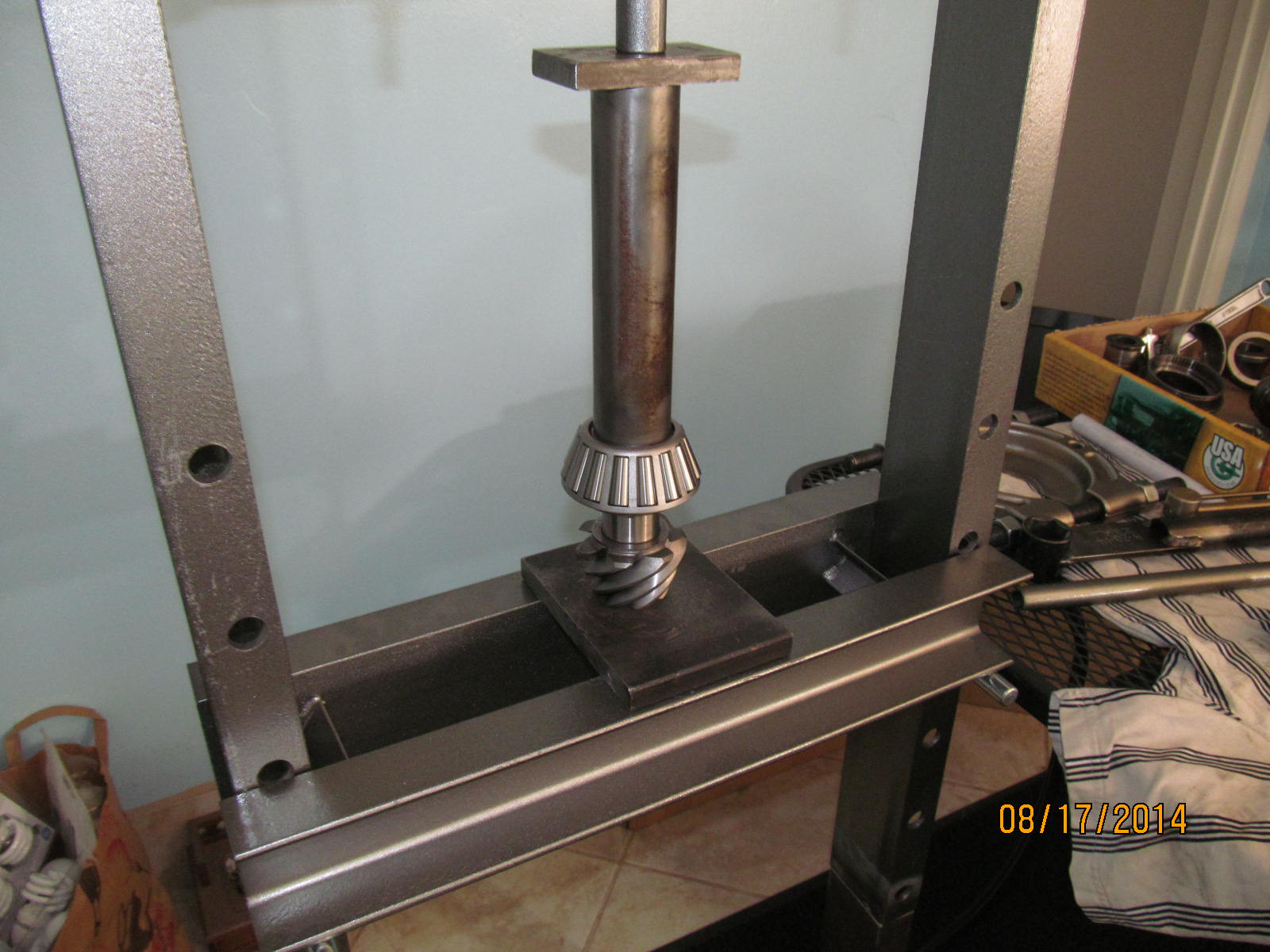

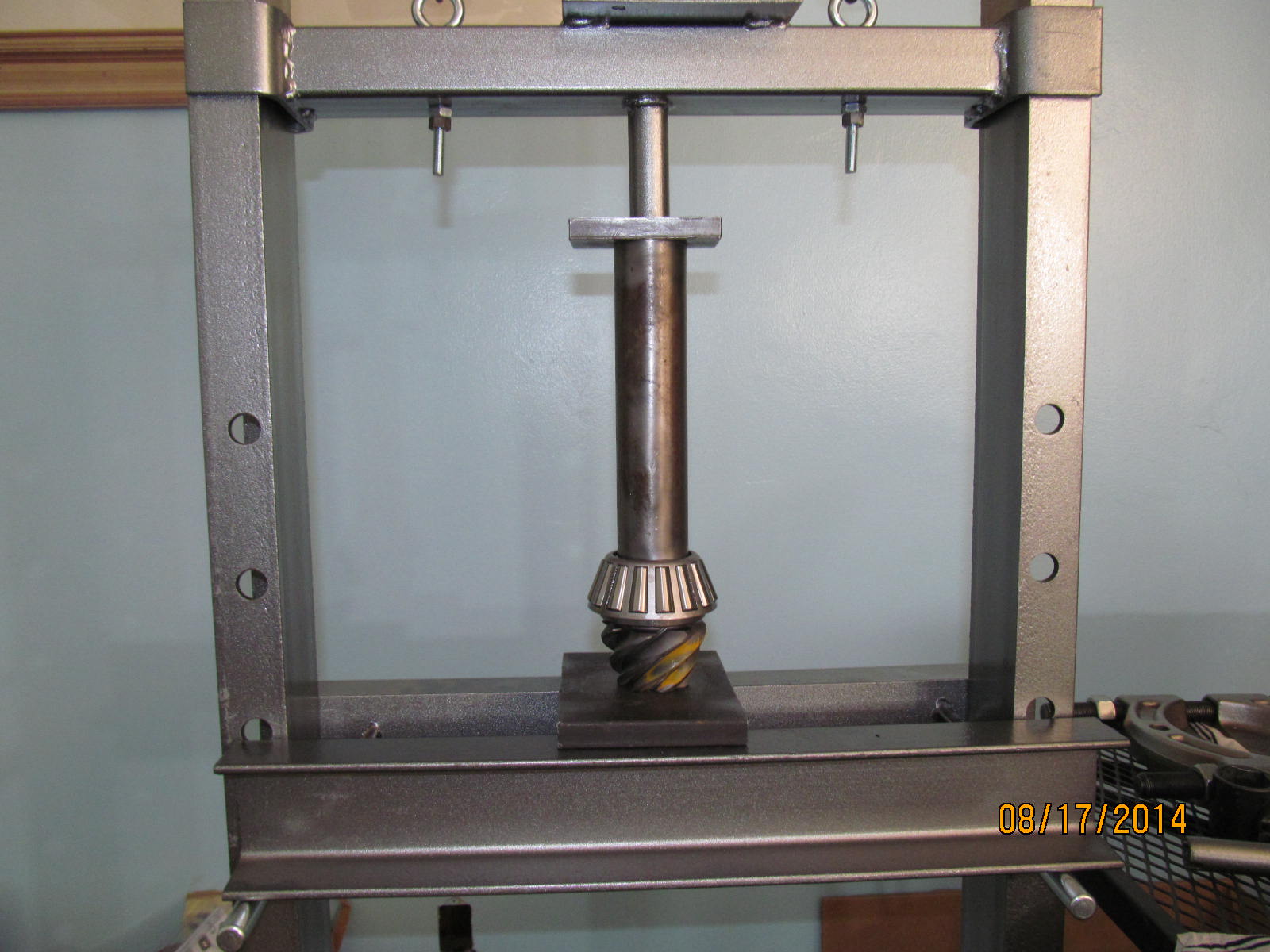

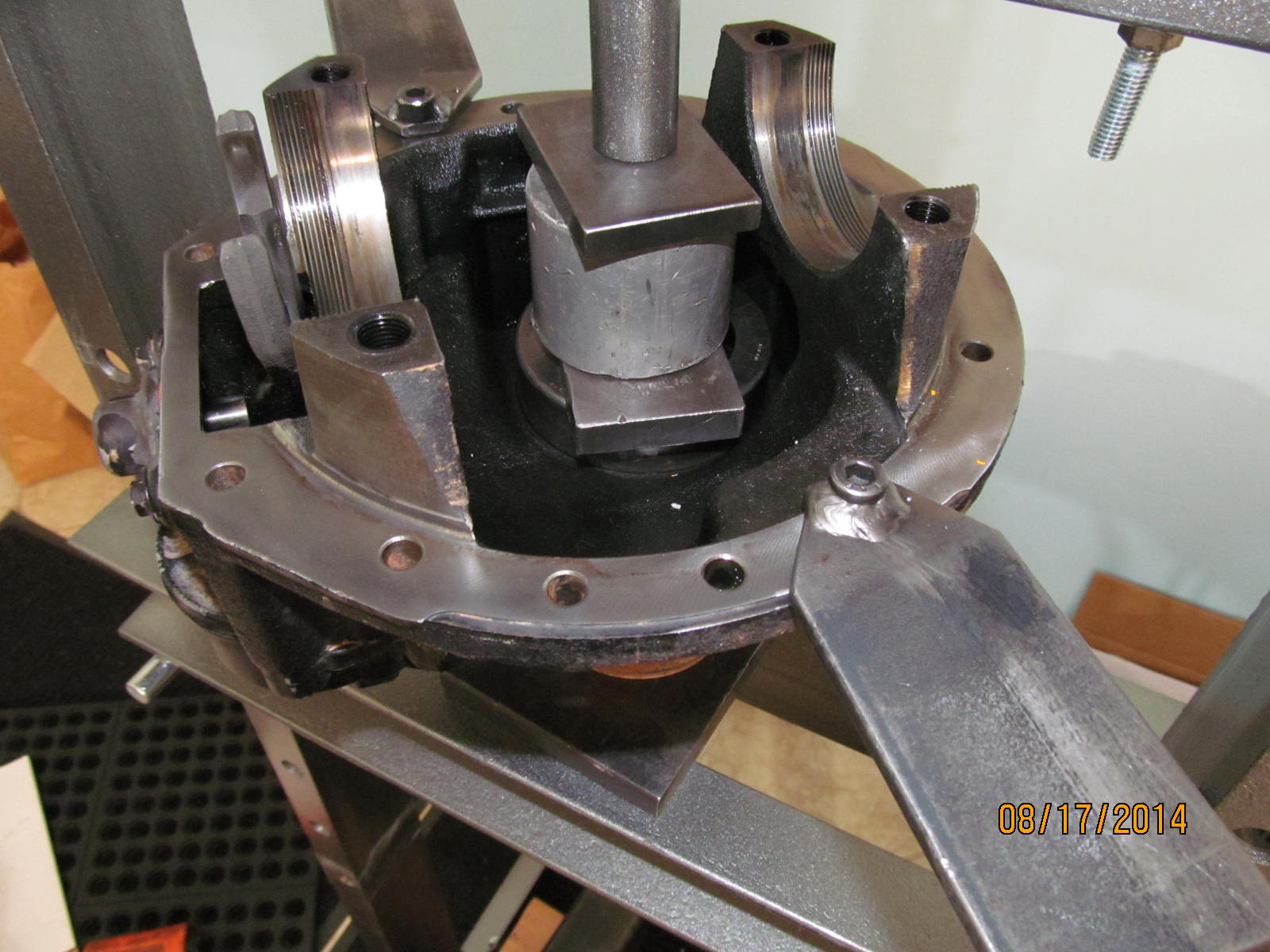

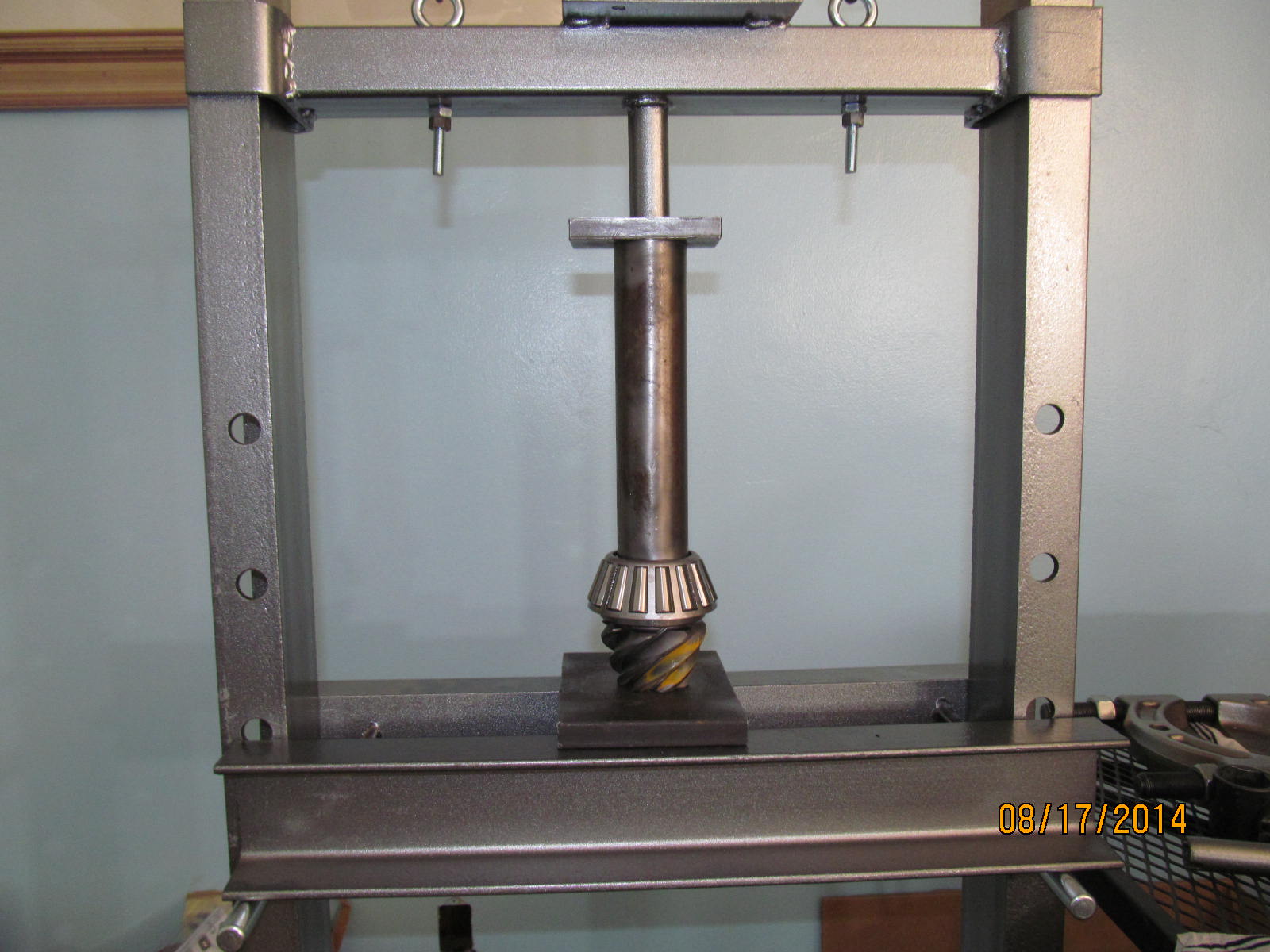

Press the shim and new bearing in place...and I've said it before....it's great to have a welder :)

|

|

|

|

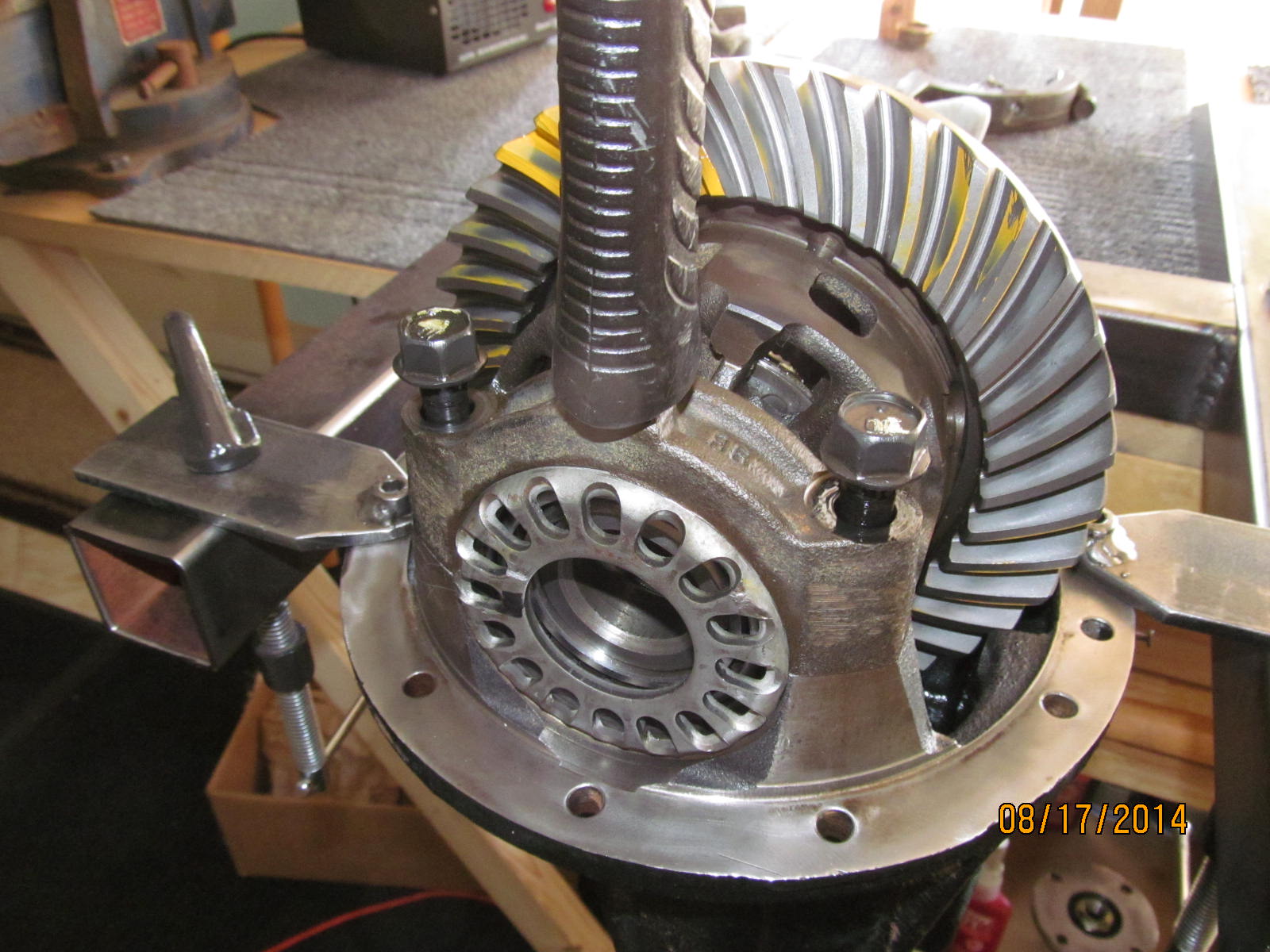

Load the pinion end up...drop the heavy 3rd on it...flange....tap it on with the plastic hammer...zing the nut

tight til one measures about 20 in/lb of pre-load.

|

|

|

|

|

The race is not actually being hit but the washer plate to the right of it was hit until it seated 100% down.

|

|

|

|

|

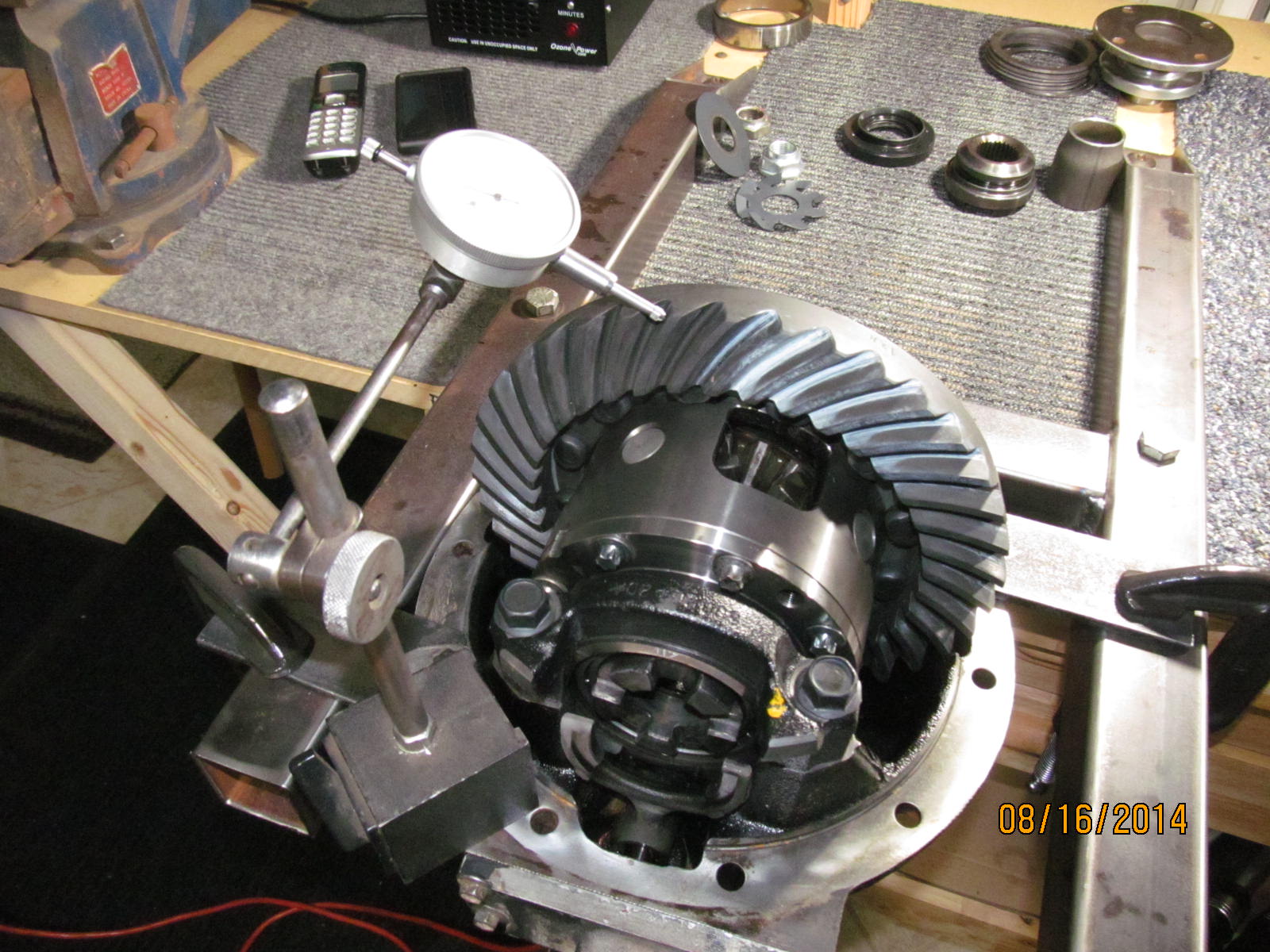

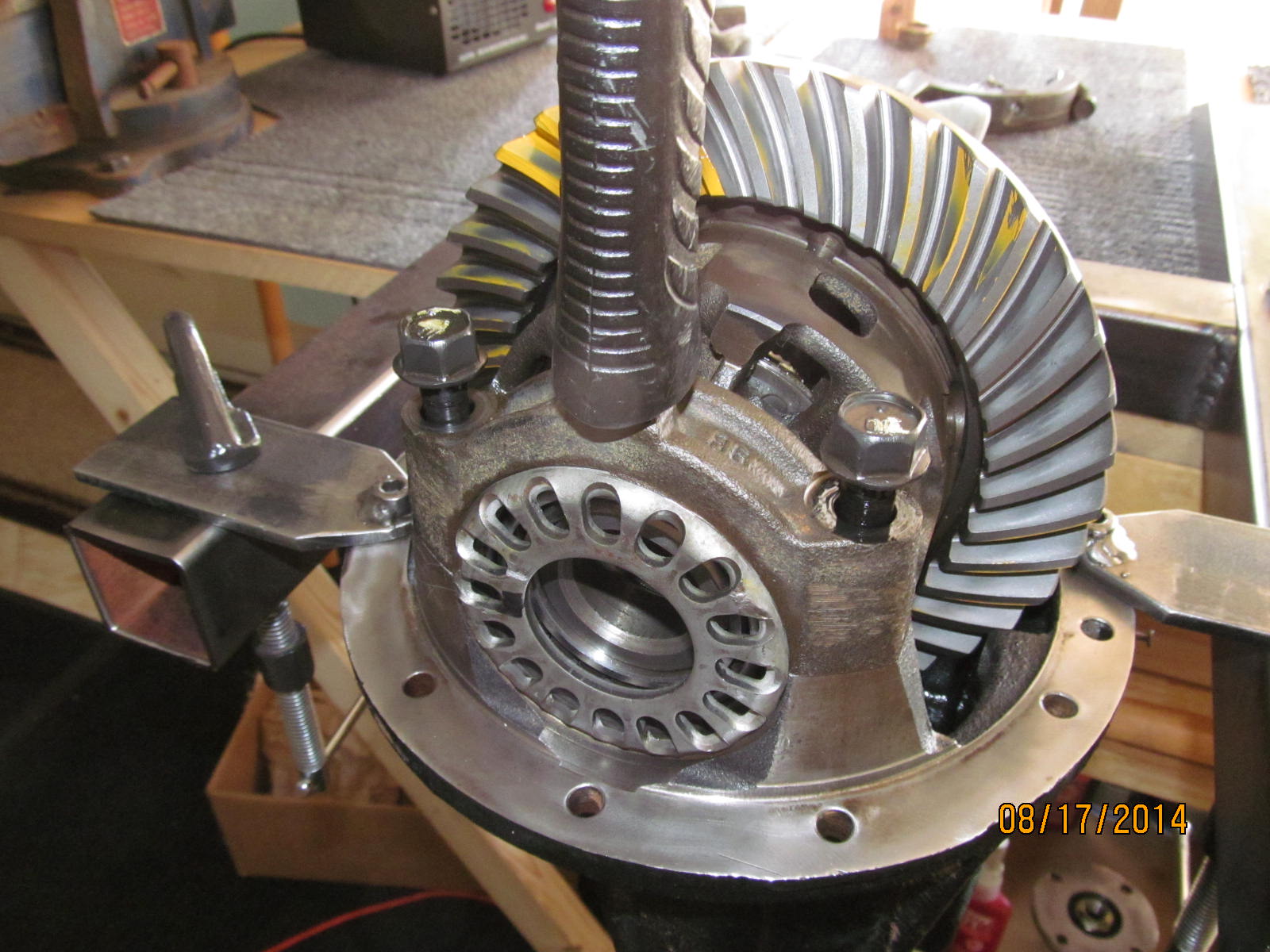

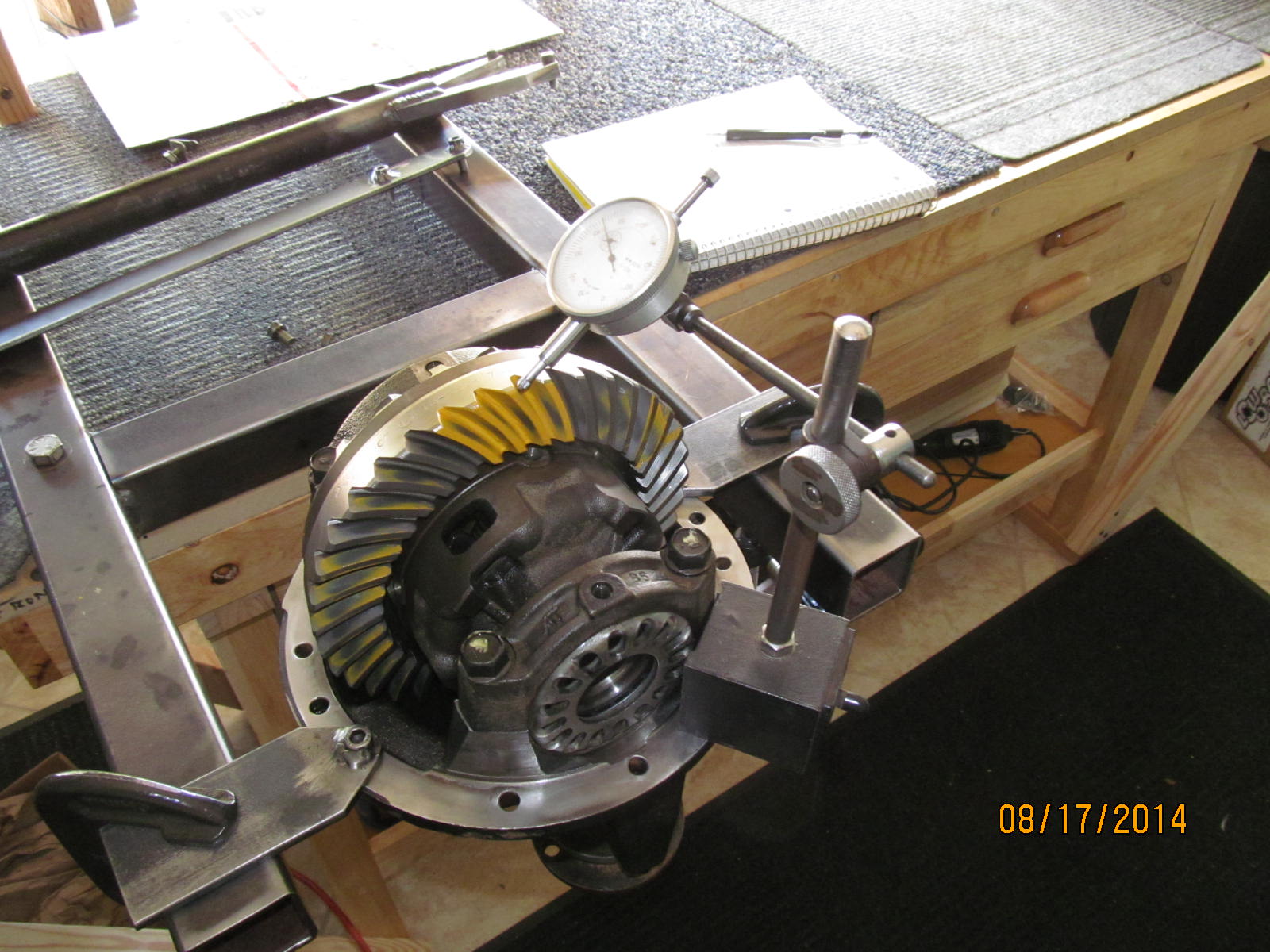

Now check the backlash to see if it's in the ballpark.

|

|

|

|

|

Paint the drive side and it says it's favoring the toe end...might be deep.

|

|

|

|

|

Coast is saying it's too deep.

|

|

|

|

|

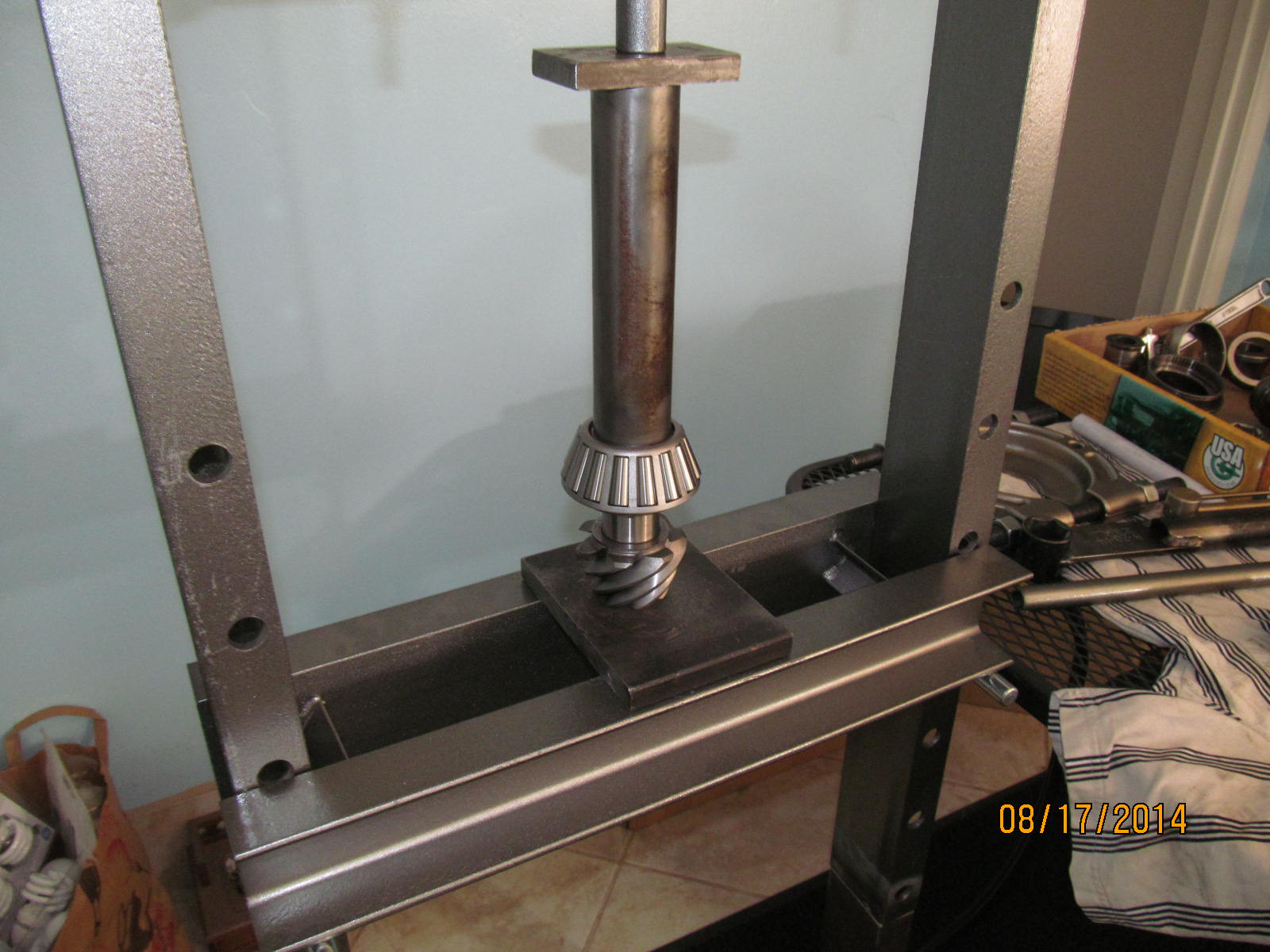

It comes all apart again. Pressing the bearing off...

|

|

|

|

|

....and press it back on with a thinner .052" shim.

|

|

|

|

|

Too shallow now.

|

|

|

|

|

slightly shallow.

|

|

|

|

This means .056" is going to be the final pinion depth based on the window seen. So 056 has been placed on the

pinion and the solid collar has been installed with no pictures of that part. After 3 shim reset of the solid

collar, I now have a minimal 2 or 3 inch/pounds with the decent torq pounds of the electric impact....

roughly 150 ft/lbs.

|

|

|

|

|

The oil slinger is next...

|

|

|

|

|

...followed by the greased up seal.

|

|

|

|

|

Flange next.

|

|

|

|

|

Aluminum based anti-seize is the best.

|

|

|

|

This X2 torque multiplier turns a 150 pounds torque wrench into a 300 pound capable one. I recorded a maximum

of 280 ft/lb before all was said and done.

|

|

|

|

|

Such a good shop cat...

|

|

|

|

The solid collars can be compressed enough to take a 3 in/lb reading up to an 10 in/lb reading.....

and more if I want it.

|

|

|

|

|

DING and this end is complete.

|

|

|

|

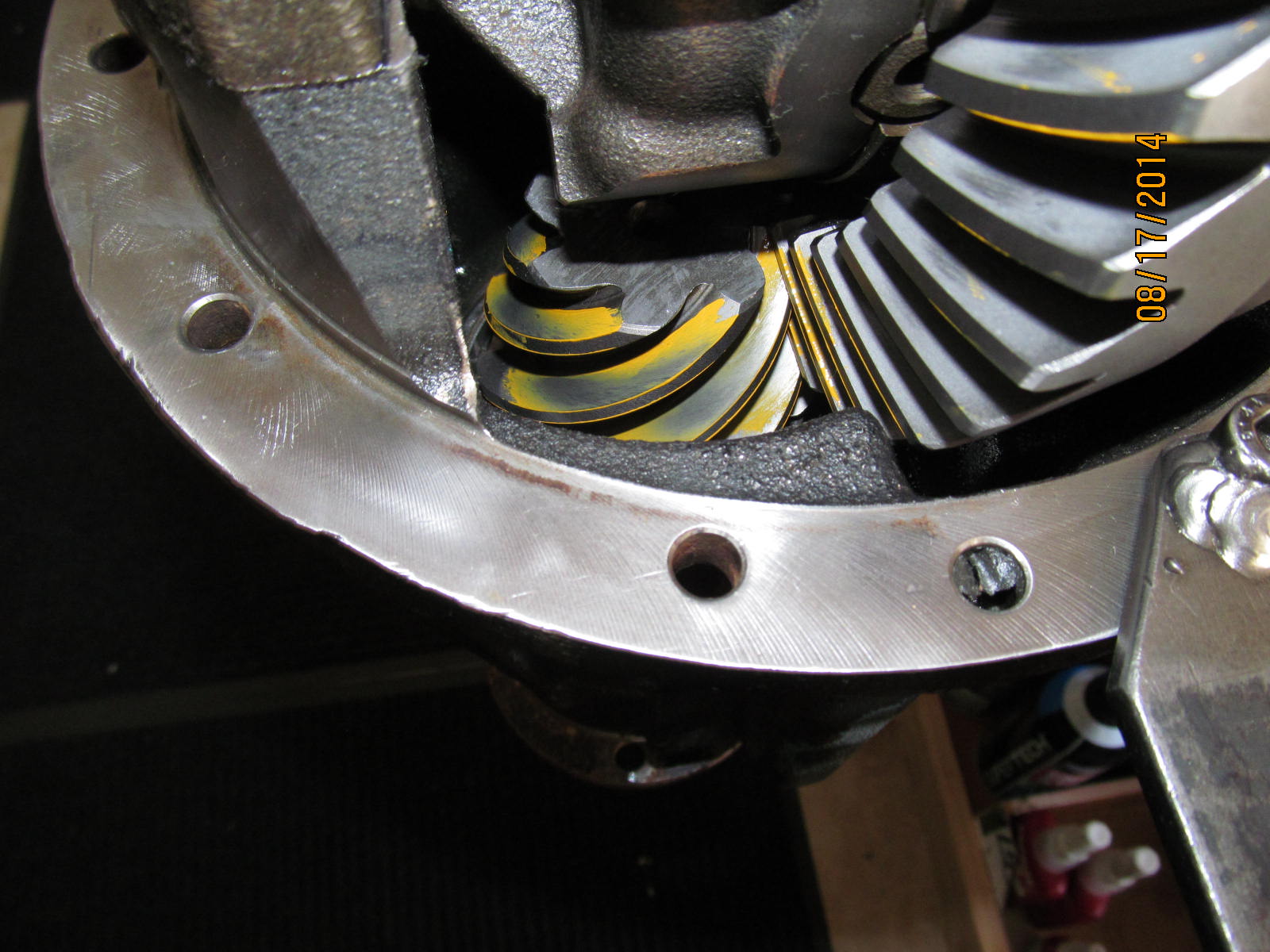

Final drive pattern with a minimum recorded backlash of .0065" and a maximum of .0095.....favors toe for

sure and good depth.

|

|

|

|

|

Coast actually appears centered and depth is right on.

|

|

|

|

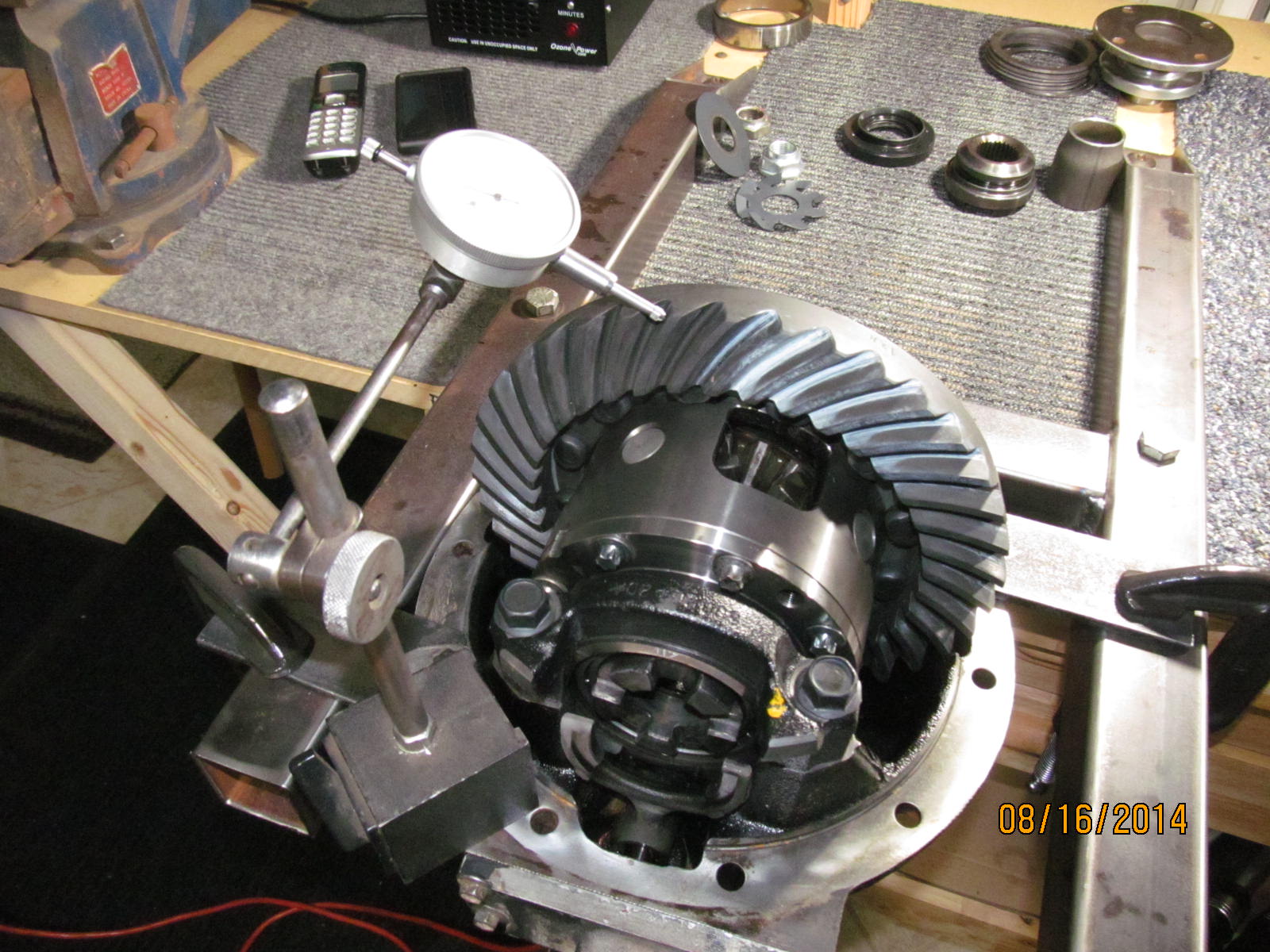

Verifying that these bearing caps are torqued to 85ft/lb per the FSM. Not shown are all the repetitive steps to

get the backlash and carrier bearing preload with the correct washer plates. See my notes a few pics down.

|

|

|

|

|

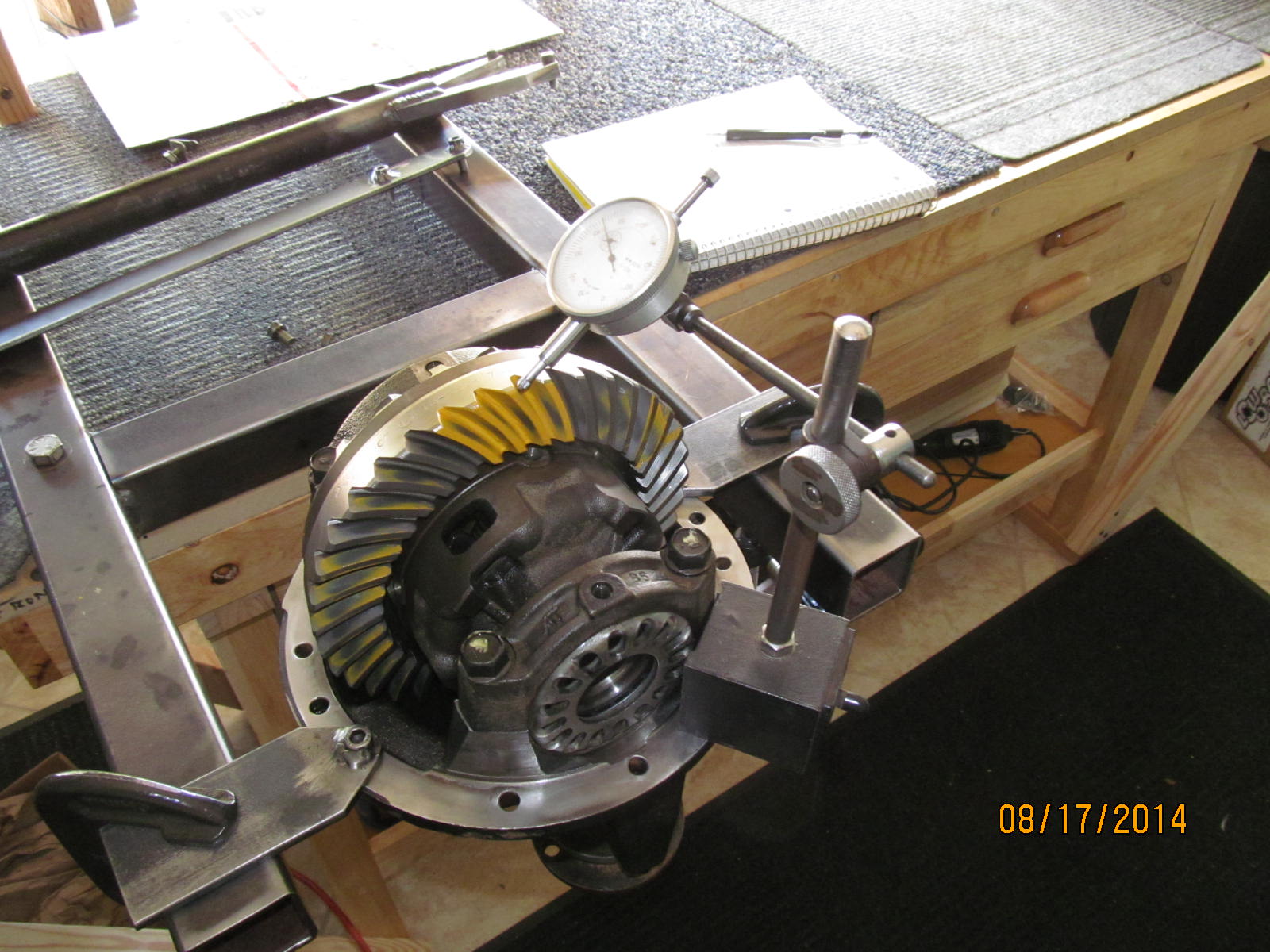

Backlash is checked on every other tooth.

|

|

|

|

Total pinion preload is 15 start torque.....the torque requied to turn both the pinion and carrier bearings.

15 - 10 = 5 which is the CBPL (Carrier Bearing Pre-Load).

|

|

|

|

|

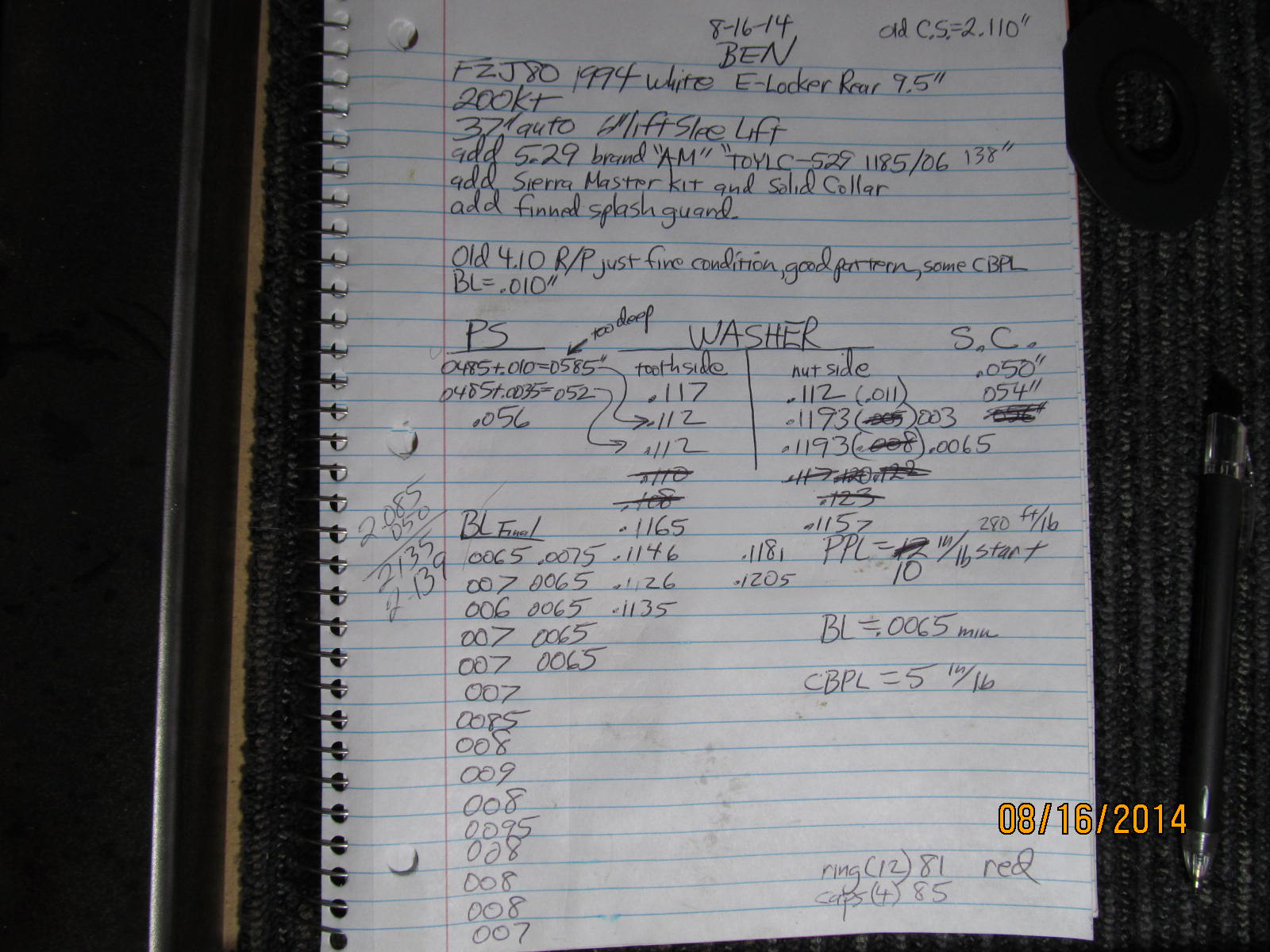

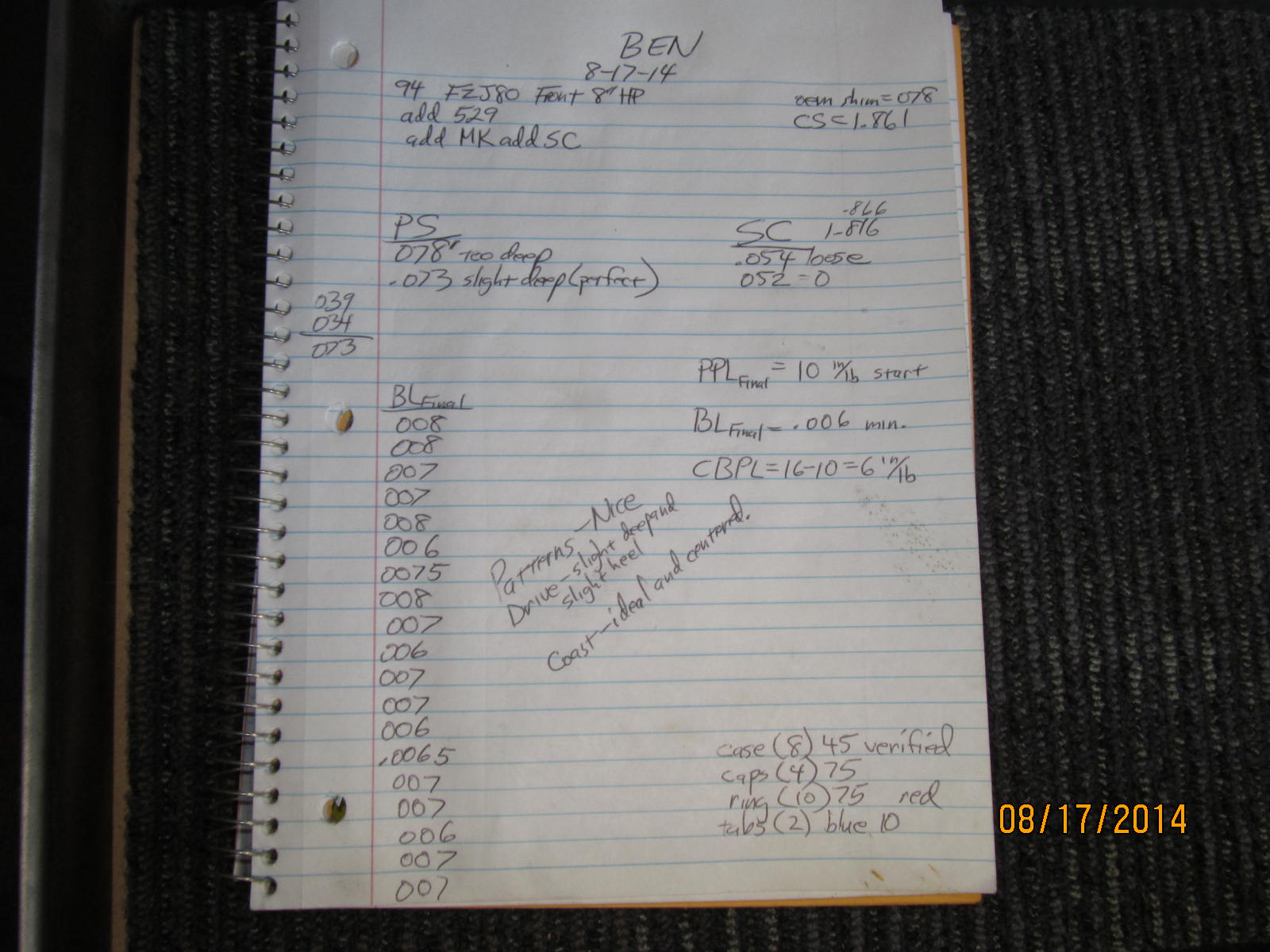

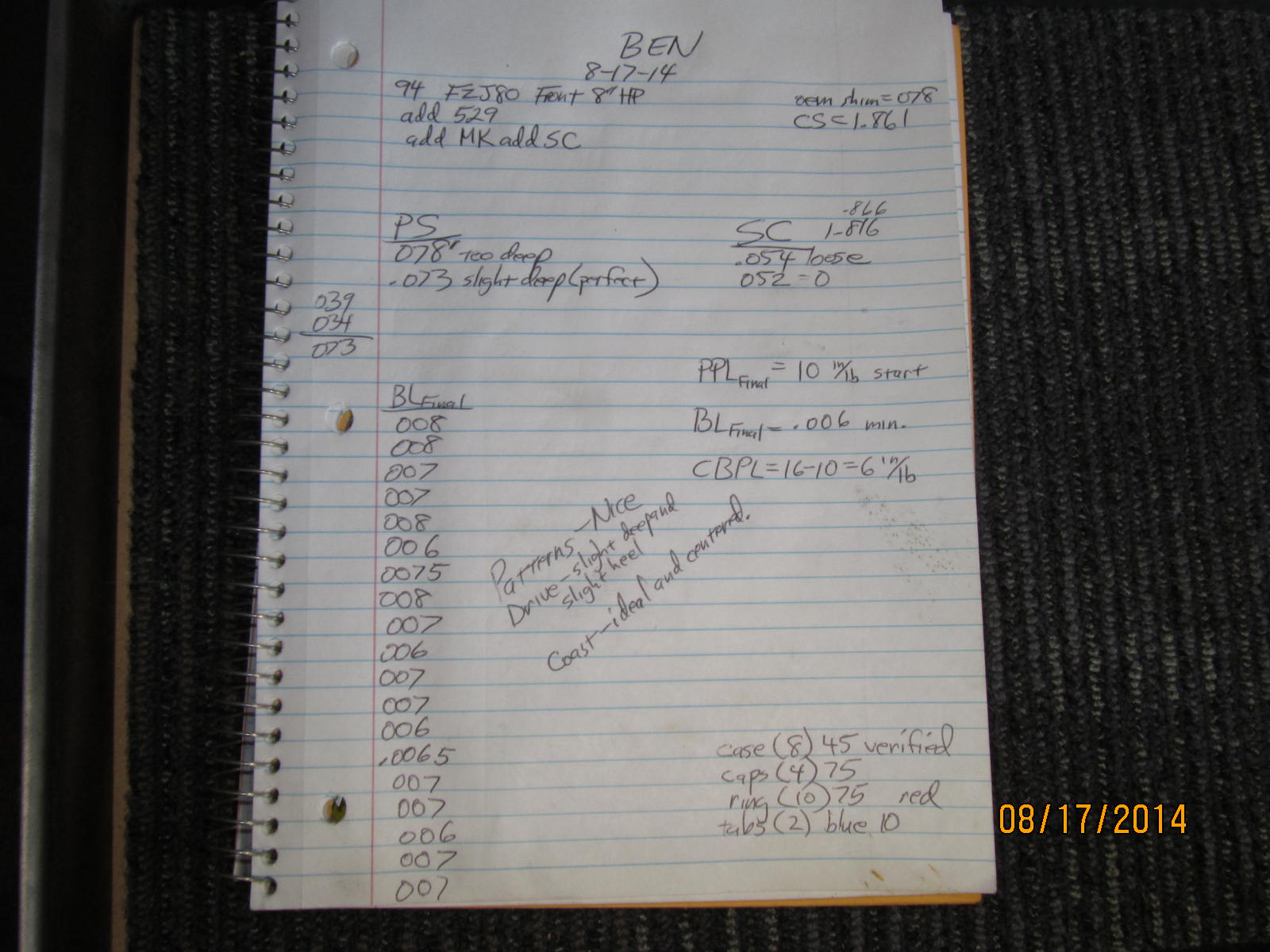

Measured specs are recorded and dated.

|

|

|

|

And that completes the rear 3rd. :)

Please scroll all the way down to the bottom to see rpm verses speed info that Ben has supplied.

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

Ben's front high pinion 8" 3rd below

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

|

|

|

|

Ben's front high pinion is getting a similar treatment...new 529 ring/pinion, master install kit and a solid collar.

|

|

|

|

|

The product is from CruiserOutfitters.com

|

|

|

|

The box for this gear was printed Sierra Gear....but inside is a top notch Circle K gear. I particularly like

these gears because of the apparent quality and the way they set up so nicely. These gears I have heard are out

of Korea.....one brother is in Korea sending them.....and the other is on the West Coast receiving them. That's

the story and not sure if it's true or not.

|

|

|

|

Not needed but I painted the oem 410 gears....not too bad. The bearing wear has caused the pattern to shift

towards the heel...

|

|

|

|

|

...and on the coast it has shifted exact opposite towards the toe end. But otherwise good patterns.

|

|

|

|

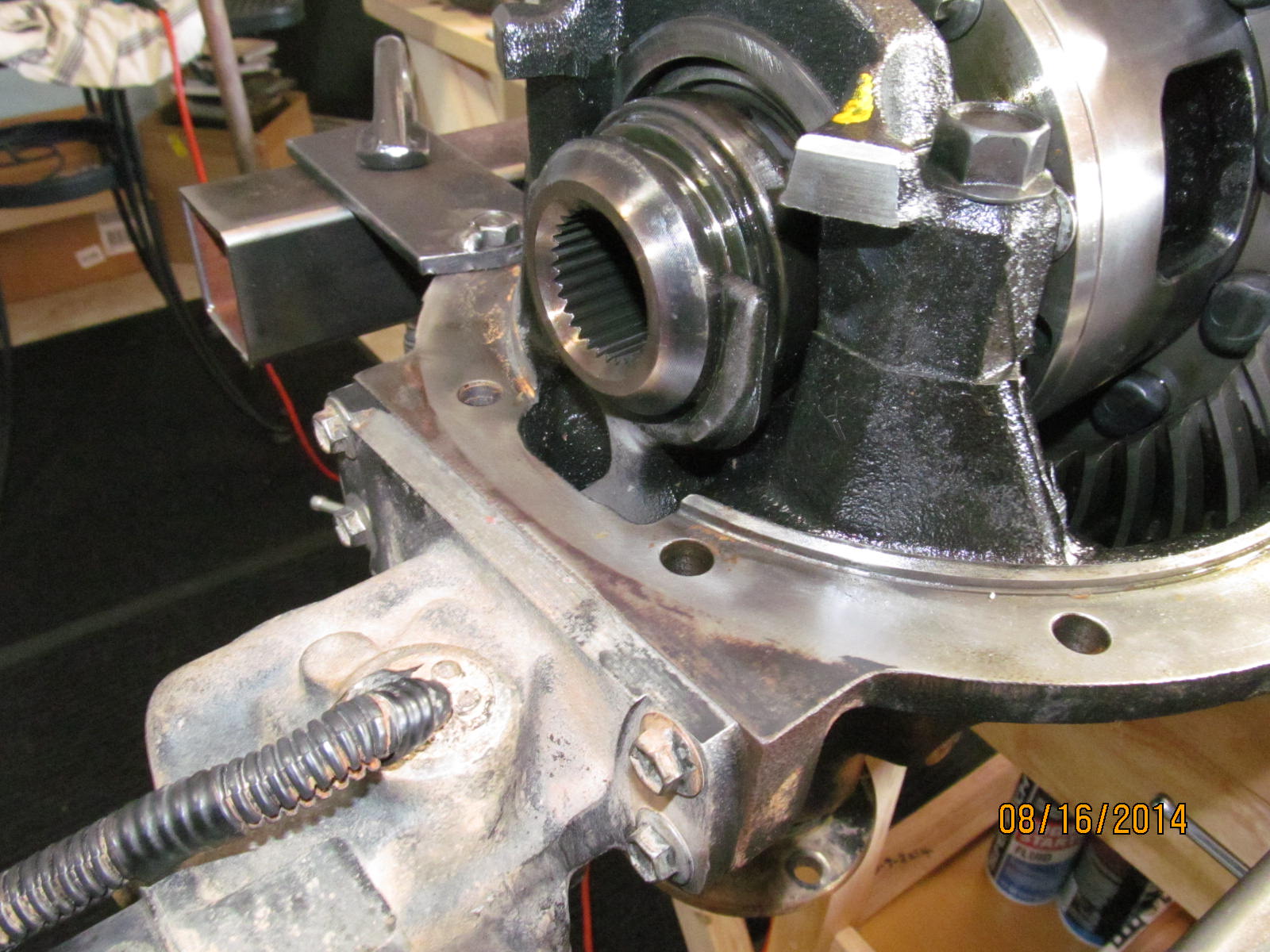

I have already dived into it...pulled the case out, removed the ring gear and

started to remove the carrier bearings here.

|

|

|

|

|

The 8 case bolts are verified tight......40 ft/lbs in this case.

|

|

|

|

The carrier bearings pressed off easier than I thought they should so "retaining compound" will guarantee they

stay tight.

|

|

|

|

|

The usual checking the surfaces for burrs and high spots and all was good.

|

|

|

|

|

Red Loctite on all 10 ring gear bolts is my protocol.

|

|

|

|

|

75 ft/lbs torque.

|

|

|

|

|

This end is complete and now to address the main 3rd...

|

|

|

|

|

I cleaned up the oem flange and it actually looks aok.

|

|

|

|

|

1000 grit sandpaper smoothed it out nicely.

|

|

|

|

|

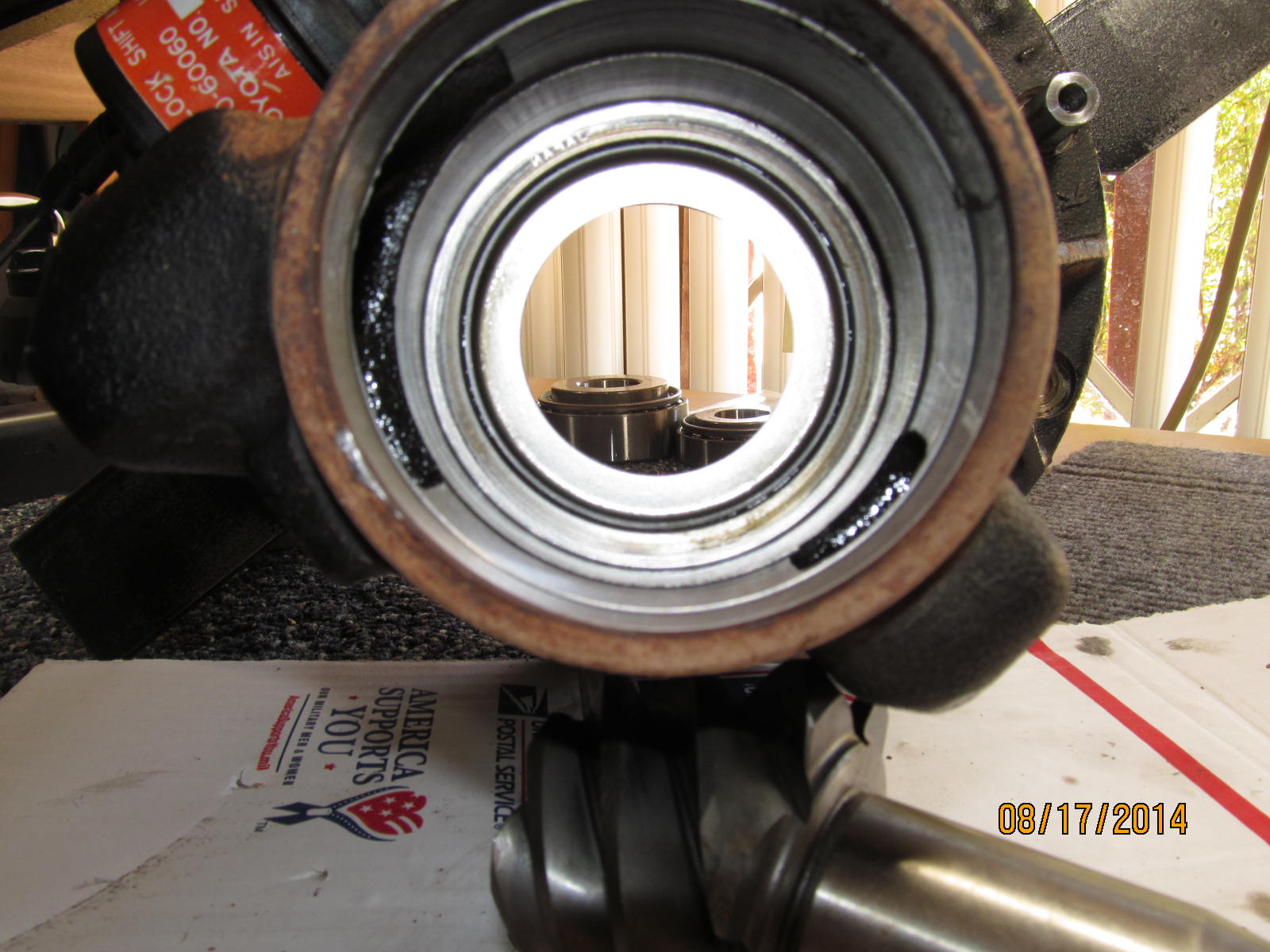

Teardown of the pinion end. Patented seal tool easily removed it.

|

|

|

|

The races are out and the oil retainer has no damage to it whatsoever. Ace Hardware had the right big washer

to make it possible.

|

|

|

|

|

New KOYO race is tapped in....

|

|

|

|

|

....and the large inner race is pressed in. If it is started straight and level then it will push down easy.

|

|

|

|

|

Looks good.

|

|

|

|

|

Ready for the pinion so let's start with 078"

|

|

|

|

|

...............

|

|

|

|

|

It is centered but definitely too deep.

|

|

|

|

|

See what happens when the flash does not fire.....coast side....too deep also.

|

|

|

|

|

The drive side of the pinion says it all....too shallow on the pinion means too deep on the ring gear.

|

|

|

|

|

Teardown and pressing in the thinner .073" pinion shim here.

|

|

|

|

|

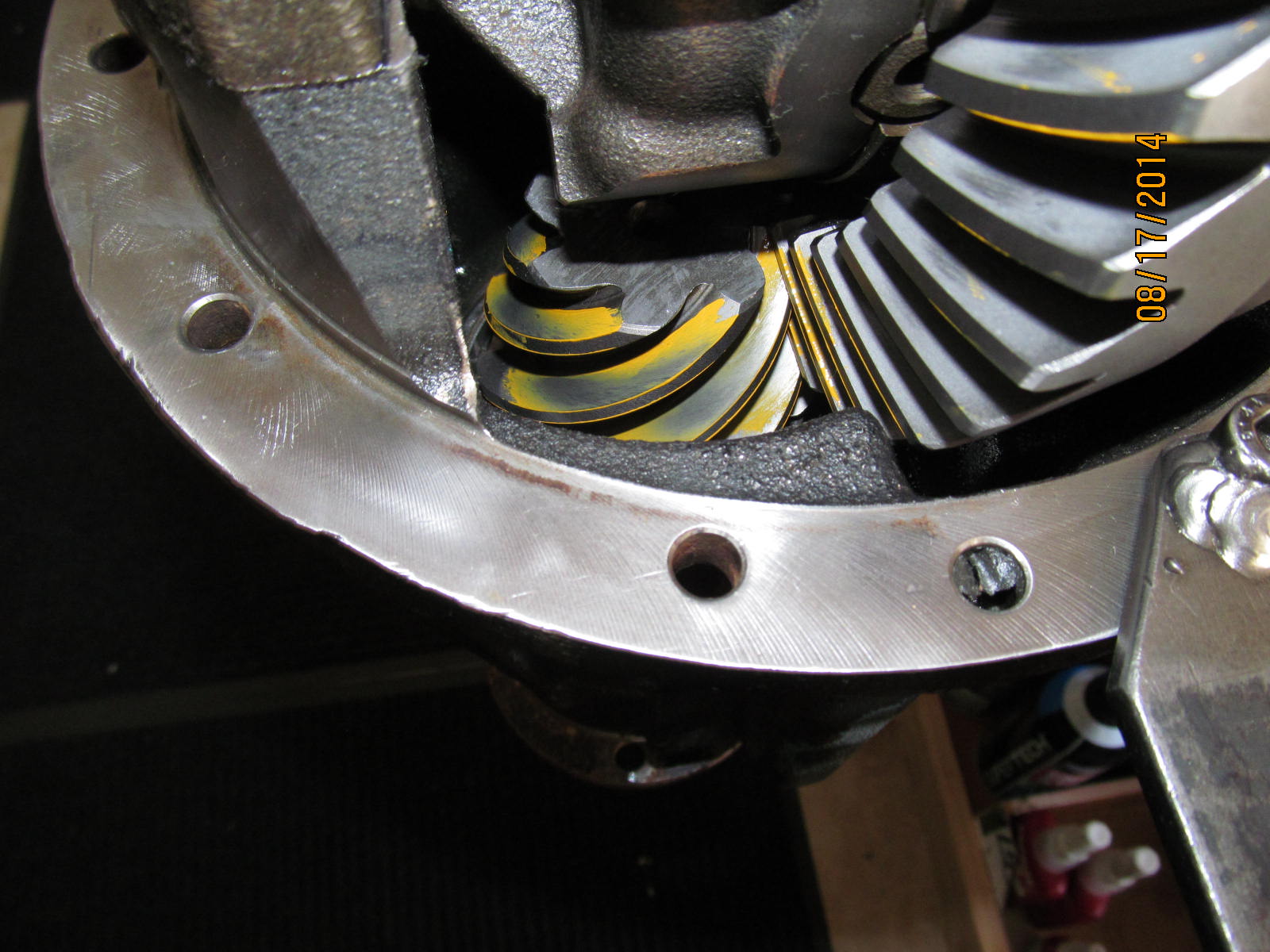

Much better...there's that Ferrari car look I like to see. Do you see it or am I the only one that sees a Ferrari?

|

|

|

|

|

Coast is great....notice it is centered and maybe slight toe which is my favorite.

|

|

|

|

|

Notice on the left side of this pinion tooth how the pattern has spread to the root nicely.

|

|

|

|

|

..........................

|

|

|

|

Same thing on this 3rd....no pics of the solid collar selection process ...see notes a few pics down. On the 2nd

try the solid collar was set.

|

|

|

|

|

......................

|

|

|

|

|

.......................

|

|

|

|

|

I started with 0 in/lb.....and dialed in a solid 10 in/lb with my X2 torque wrench.

|

|

|

|

|

It's a flange style nut....and I used a thick oem washer on it so that's why a few threads are showing.

|

|

|

|

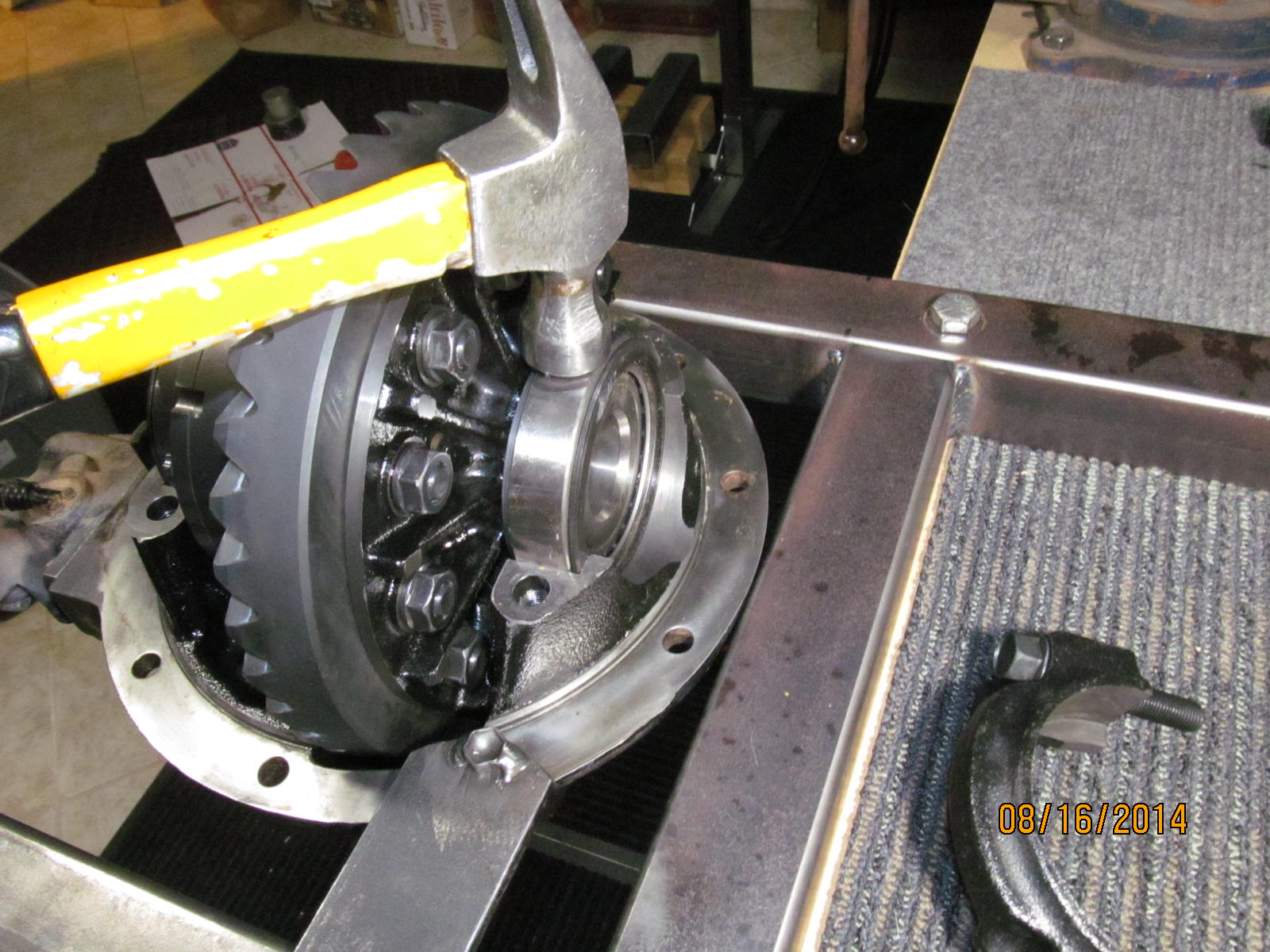

If the bearing cap threads are lined up then a smack from the rubber end of the hammer will make a

solid SNAP! sound as it seats down.

|

|

|

|

|

75 ft/lb on all 4 bolts.

|

|

|

|

|

Backlash is dialed in..... .006" minimum and .008" was most I saw. see documentation.

|

|

|

|

|

Total CBPL is measured at 16 in/lb..... 16 - 10 = 6 in/lb for the actual CBPL.

|

|

|

|

|

10 ft/lb and blue loctite.

|

|

|

|

|

Look at all those Ferrari's.

|

|

|

|

|

Coast- Nice.

|

|

|

|

|

Drive....nice.

|

|

|

|

|

....................

|

|

|

|

|

|

|

|

|

So passing on some useful info as to the actual rpm and actual speeds involved with a FZJ80 automatic

with 37" tires and 529 gears...... Ben used his GPS unit to get accurate speed info......

70 real mph at 2700 rpm

90 real mph at 3400 rpm

|

|

|

|