|

Bill's 1989 2wd Pickup Gets a Spartan from ECGS and New Bearings

|

|

(78 BIG pics loading)

|

|

JUNE 23 2016

|

|

|

Bill has a pretty much stock 1989 Toyota 2WD pickup that will soon see

a Spartan lunchbox locker in the rear 7.5" diff.

White Rim 2016ep1 - Hell-n-Back

|

|

|

|

340,000 miles and it still purrs like a kitten. His friend, Scott, has a 4wd Landcruiser

that he will be following on the White Rim Trail in Moab, Utah. A small tug-strap

will be available for those tricky spots but the Spartan should help tremendously.

|

|

|

|

|

As received via Fedex Ground in a heavy duty yellow lidded tote. Properly secured and padded.

|

|

|

|

Seems like 1 out of 4 has this type of damage. Nothing to do with Bill's packing and most likely has everything

to do with Fedex stacking other packages on top of this tote in transport.

|

|

|

|

That's why I am now recommending a double or triple strong box in a box.....something like this. Just beat

the corners in with a hammer and the inner box should slip into the outer. Shown here are 2 double

corrugated boxes. Plenty strong enough for a 90 pound diff.

|

|

|

|

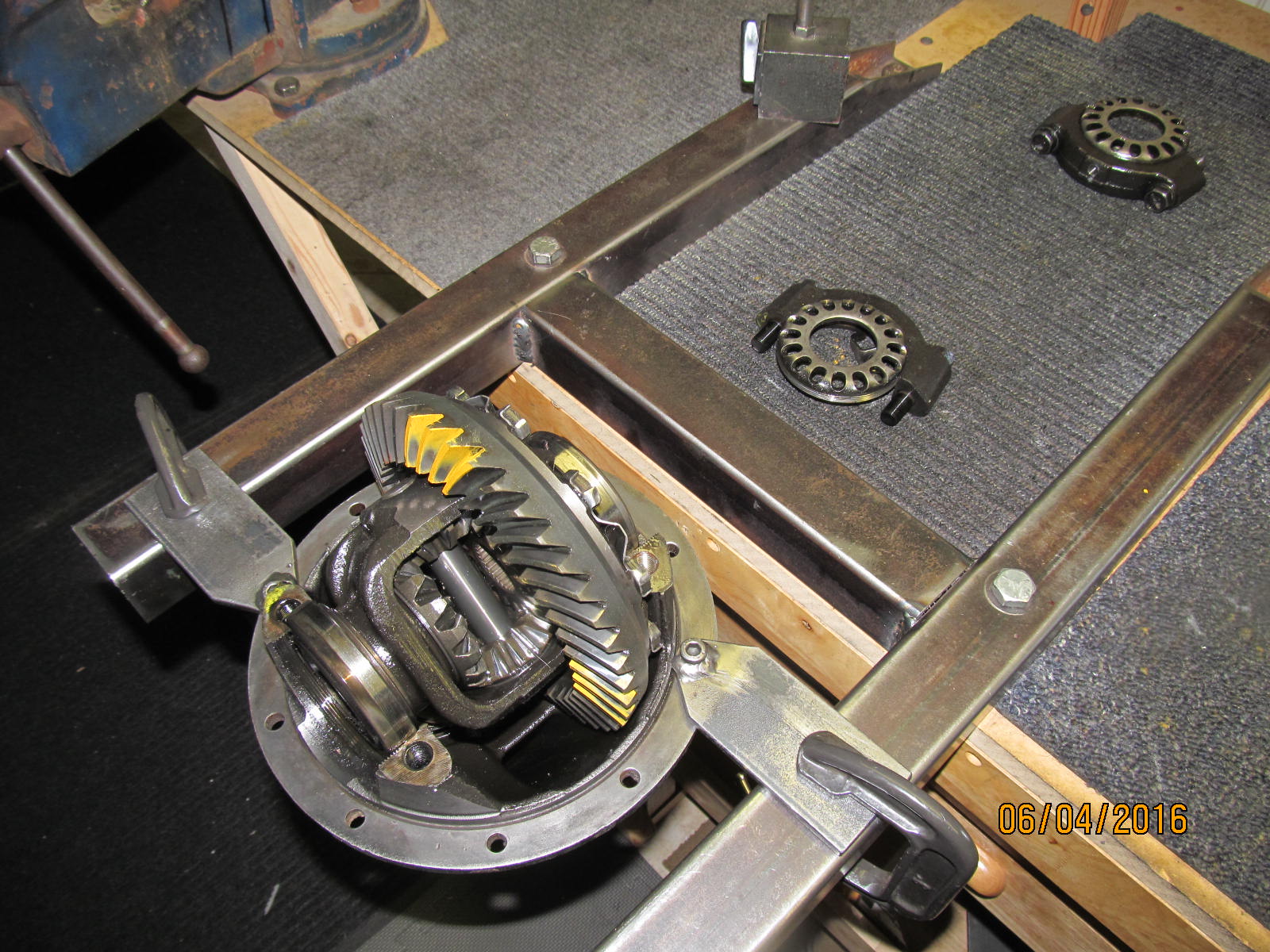

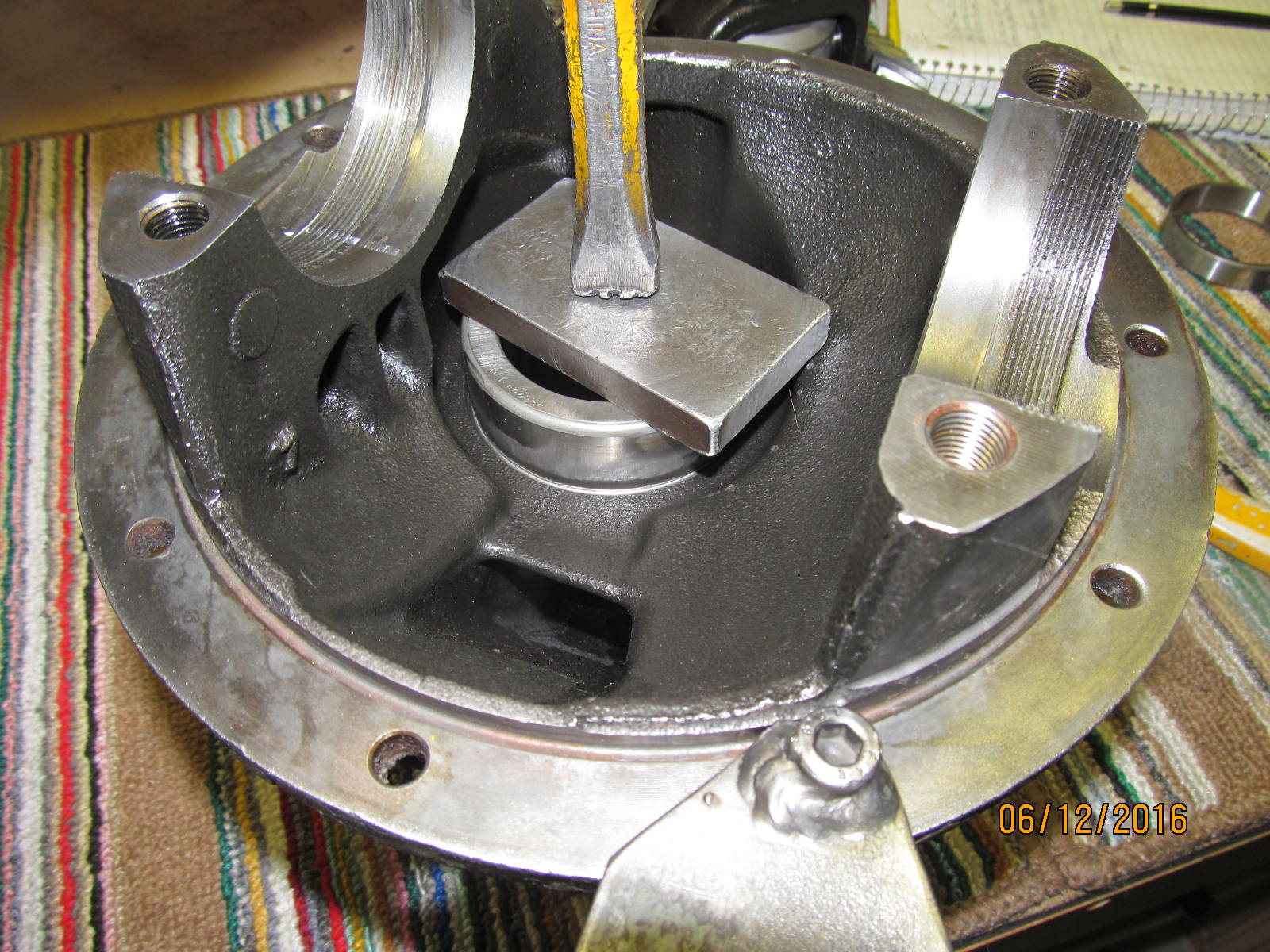

Bill purchased the Lockright 1611 and had it sent separately to me....The new Nitro master kit MKT7.5-REAR

from JustDifferentials works perfect with 2wd pickups with the 7.5" diff that have the

45mm carrier bearing journals. In the picture above, initial backlash is recorded.

|

|

|

|

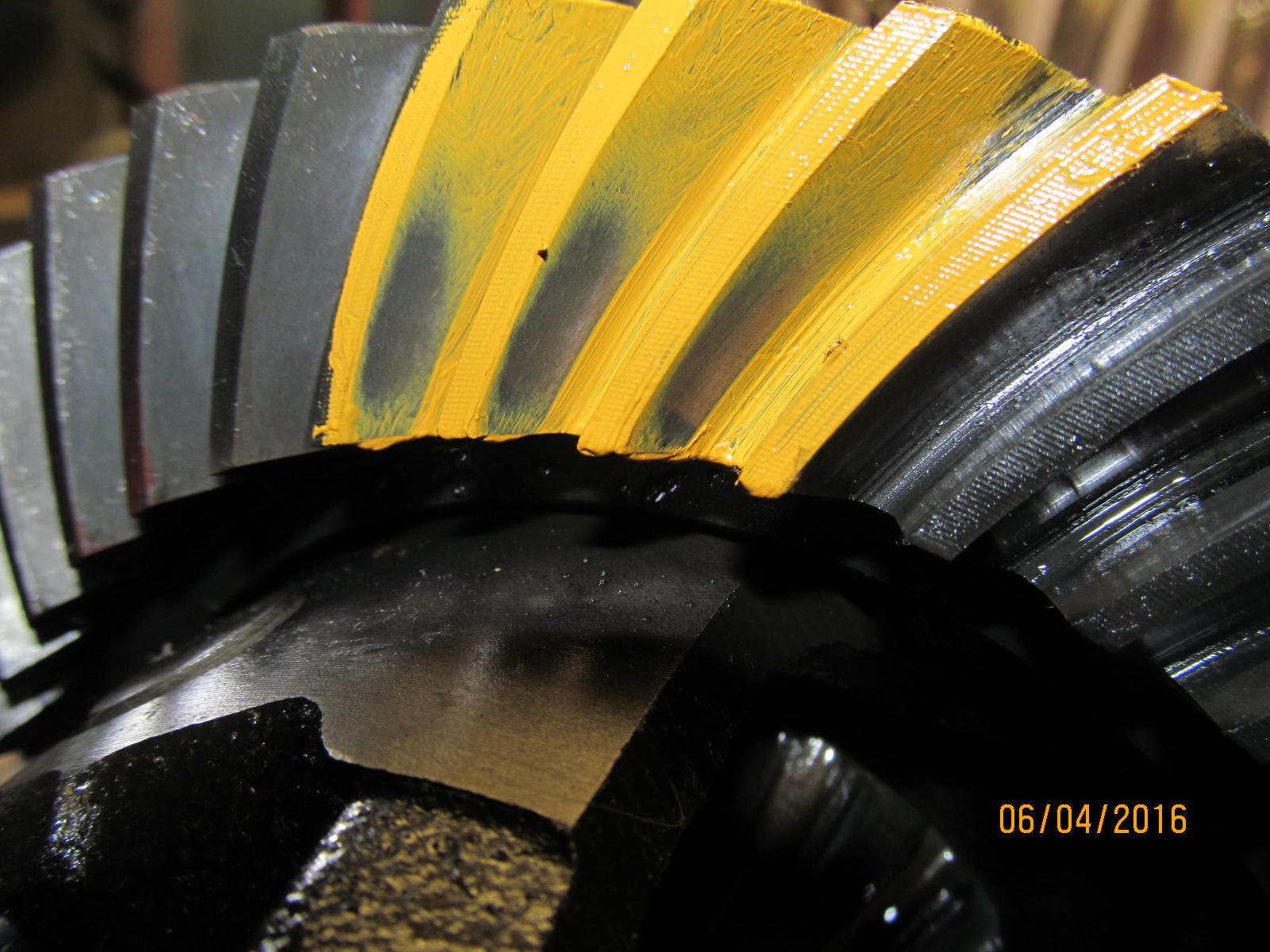

This pickup had an axle code of F372 which means 7.5" 3.58 ratio with 2 pinion open. These gears will

be reused and a pattern check shows the drive pattern is very nice. Appears slightly shallow but

that is expected with 340,000 miles on original oem bearings. New pinion bearings will

improve the pattern appearance.

|

|

|

|

|

Coast side.

|

|

|

|

|

Teardown begins. Bearing caps are marked and removed.

|

|

|

|

|

Ring gear bolts are removed.

|

|

|

|

|

Ring gear tapped off.

|

|

|

|

The steel dowel is tapped out. This one was very stubborn and this is where the dremel tool is very

effective at clearing the obstruction.

|

|

|

|

|

The cross-pin comes out....

|

|

|

|

|

...then the spiders.

|

|

|

|

|

Lockright parts are layed out.

|

|

|

|

|

Sidegear thrust washers are re-used.

|

|

|

|

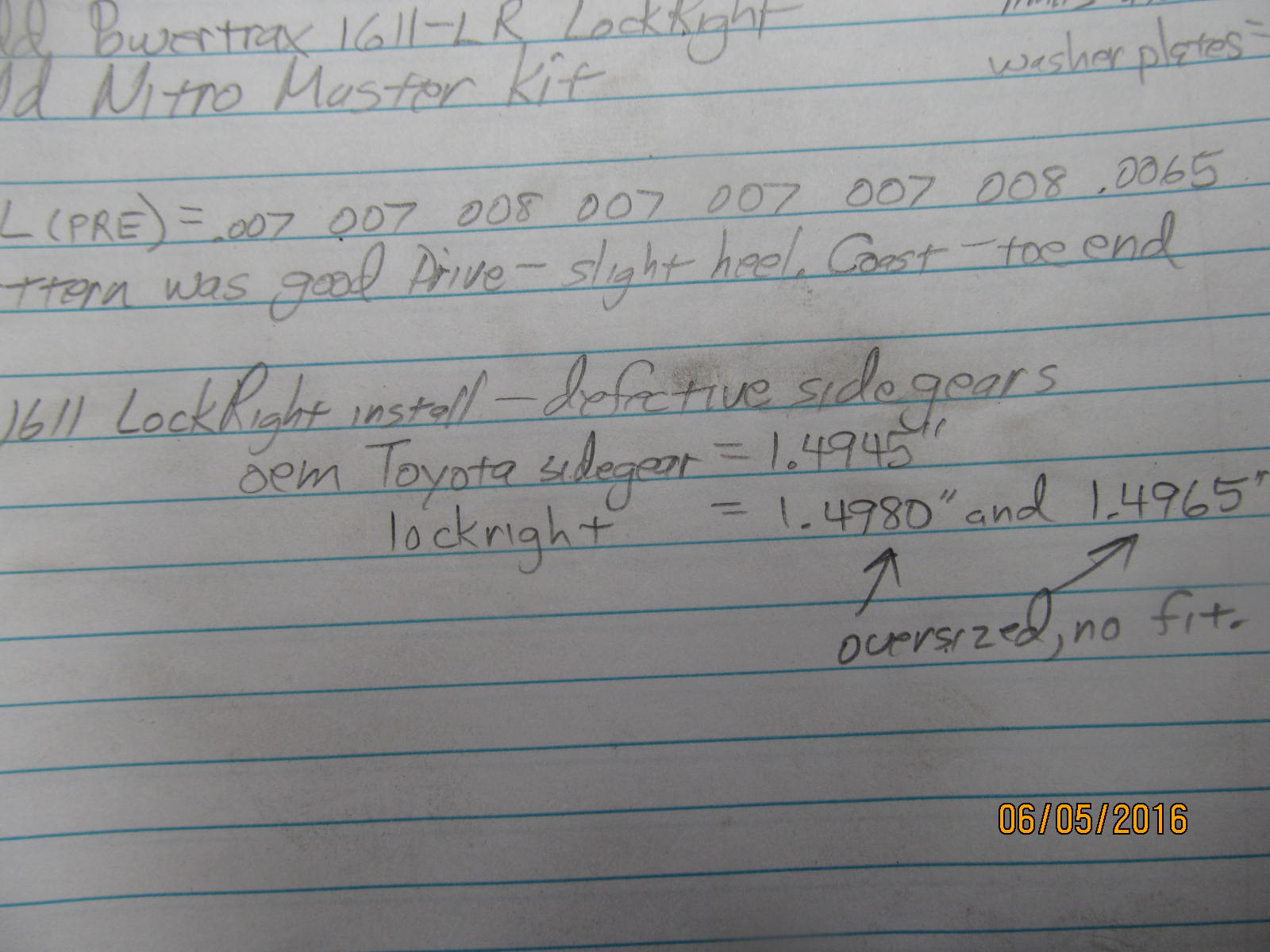

Then a problem occurred. The journals on the lockright sidegears seemed to be too large by a couple

thou and would not physically fit in the bore holes inside the carrier case. I then compared

the factory journal with the LR.

|

|

|

|

|

The factory Toyota sidegear was around 1.494"......

|

|

|

|

|

One of the sLR sidegears measured almost 1.947"....

|

|

|

|

|

The other LR measured over 1.498"

|

|

|

|

|

Not only are these LR sidegears improperly machined but they're not even machined the same.

|

|

|

|

|

Here's the OEM sidegear surface......

|

|

|

|

|

Here's the LR surface....

|

|

|

|

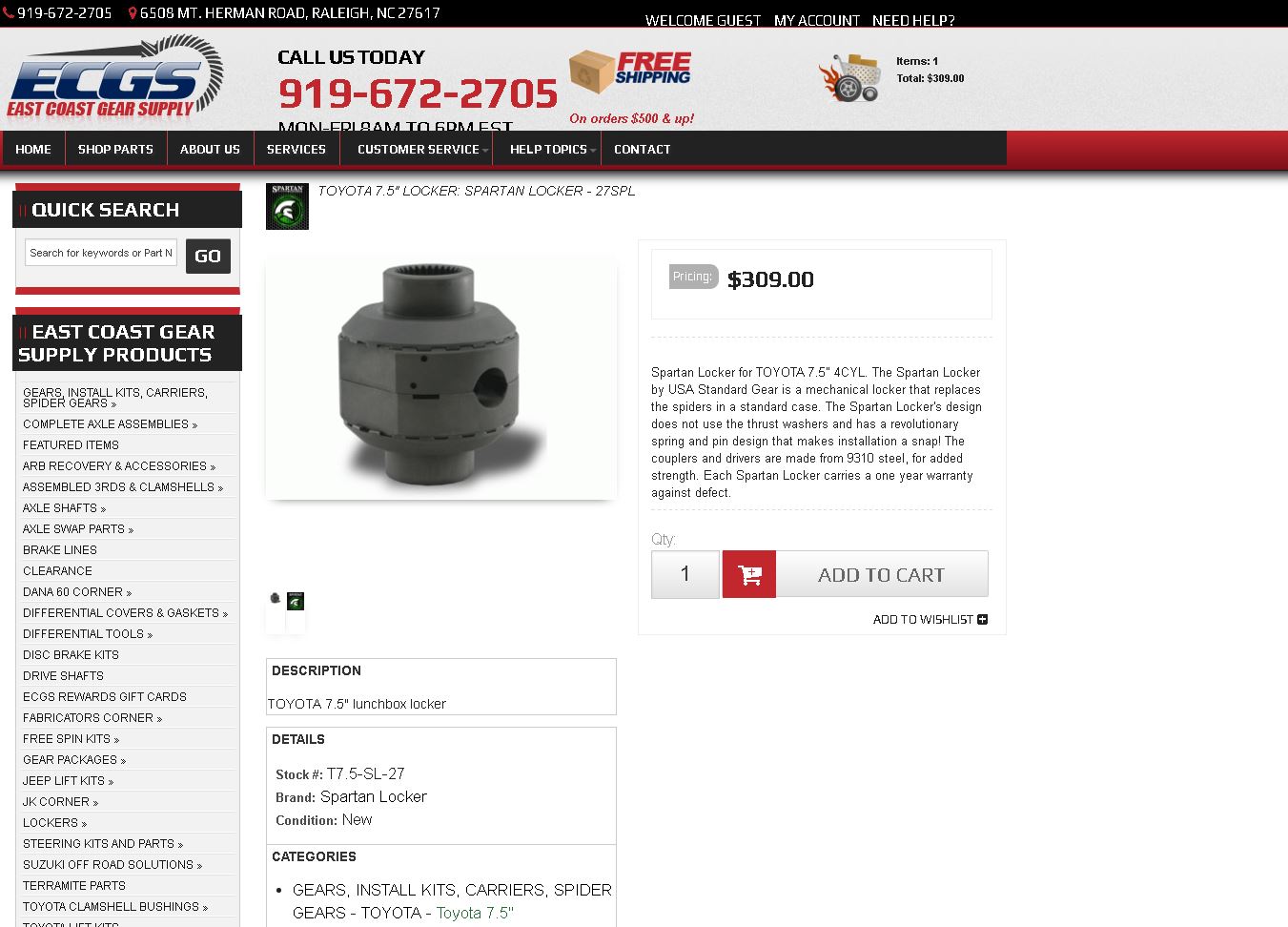

The build is on hold for a few days while a high quality Spartan autolocker is ordered.

The Lockright will be returned to the factory.

|

|

|

|

|

3 days later this arrived in fast order.

|

|

|

|

|

This is a snippet from ECGS. This is the price at the time of this copy/paste.

|

|

|

|

|

................

|

|

|

|

|

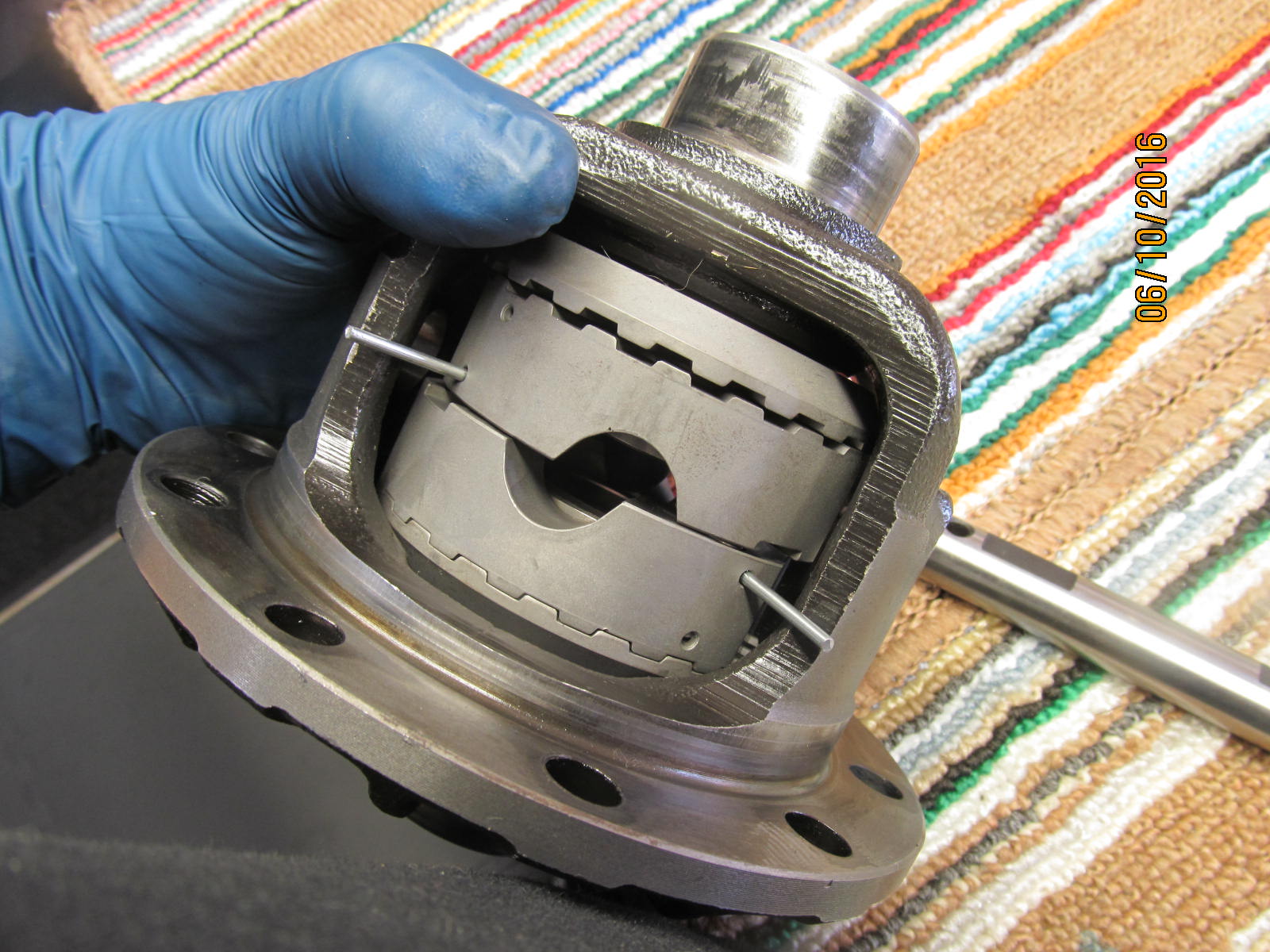

Sidegear couplers and the supplied crosspin....

|

|

|

|

|

....and drivers with the massive .375" diameter pins.

|

|

|

|

|

Everything is re-organized on the bench again...

|

|

|

|

|

Old carrier bearings are removed with the right tool....OTC-4520

|

|

|

|

New cross-pin fits in smoothly and is not wobbly in any way indicating the pin was machined right

and the carrier bore hole is not excessively worn.

|

|

|

|

|

This is a quick pre-check to make sure clearances are in spec. The spec is between .006~.020" and all was good.

|

|

|

|

|

Love the way the springs and pins are loaded on the drivers.

|

|

|

|

|

......................

|

|

|

|

|

Slide the assemblies in and make sure the inside spacers are facing the right direction.

|

|

|

|

|

Then, with pliers, just pull the 4 dowels out.

|

|

|

|

|

....................

|

|

|

|

Line up and push in the Spartan cross-pin and tap the steel dowel back in. Then dimple the case

so it never works its way out.

|

|

|

|

|

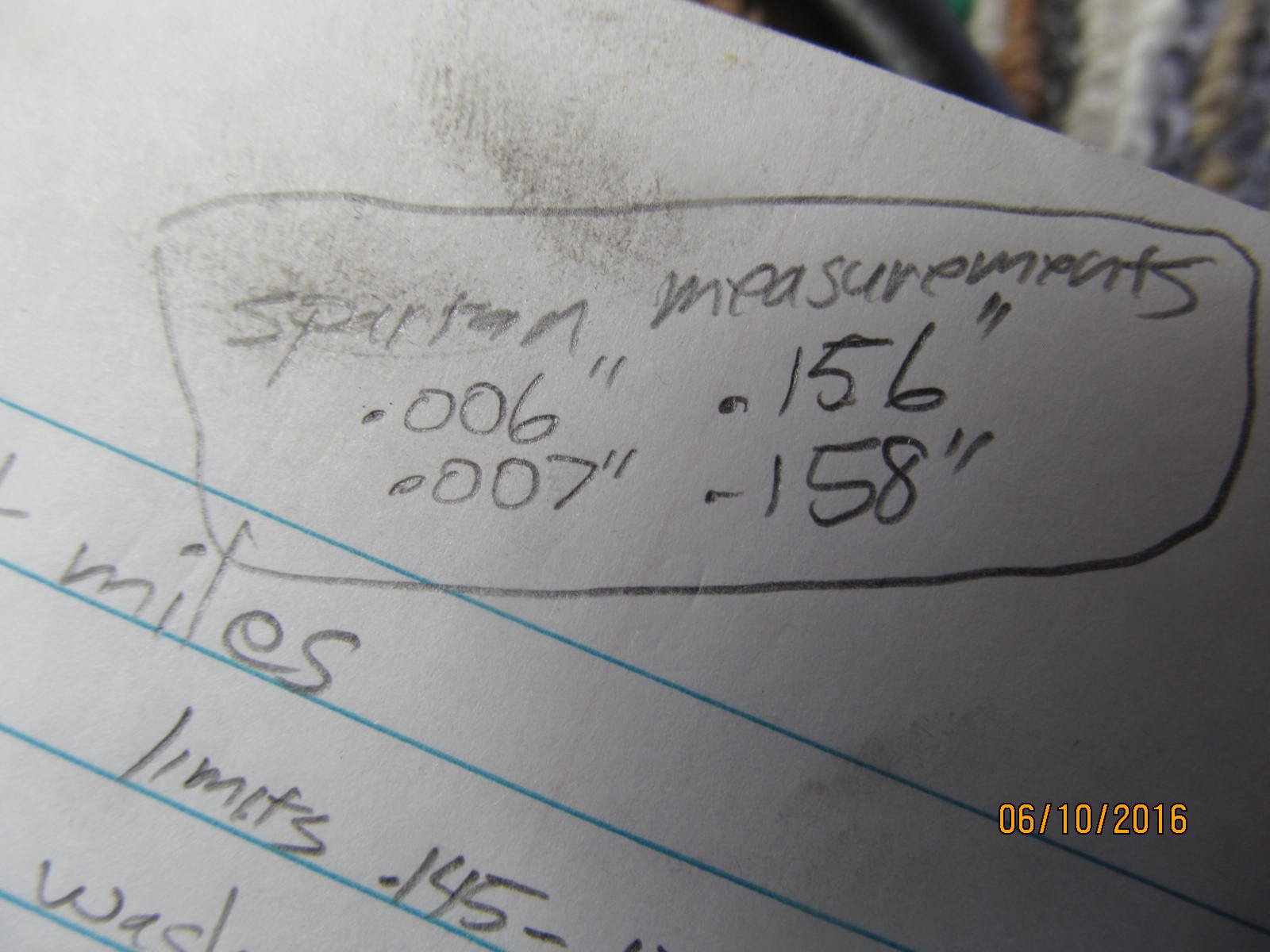

Measured the opening on both sides.....0.156" and 0.158" and the spec is no larger than 0.170" so it's good.

|

|

|

|

|

Spartan measured values.

|

|

|

|

|

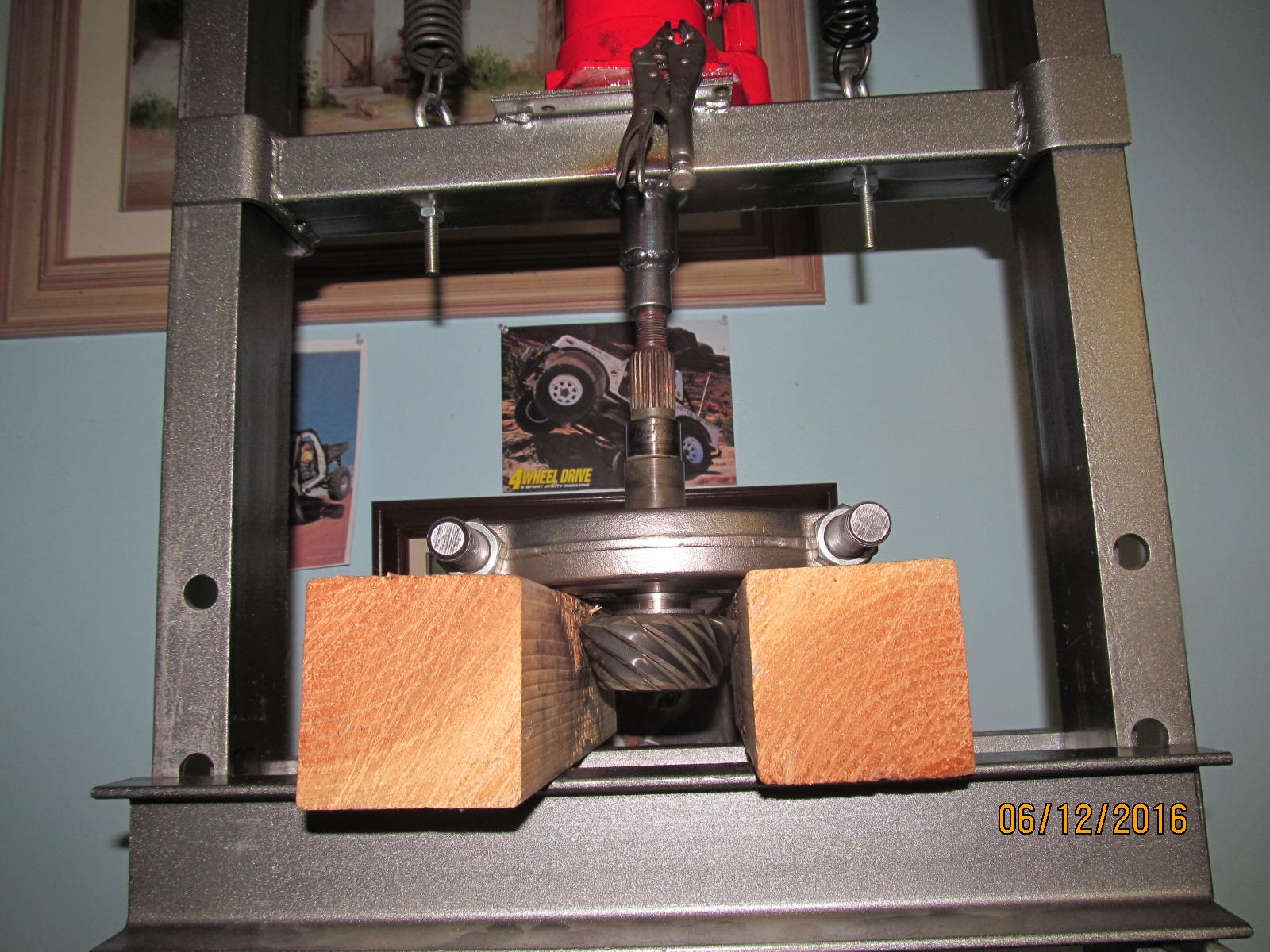

Now, with that done, the ring gear and new Koyo carrier bearings can be pressed on.

|

|

|

|

|

Blue threadlocker and 70 ft/lb.

|

|

|

|

|

Carrier bearings were a tight fit but still managed to tap them down with no damage with the right widgets.

|

|

|

|

|

The carrier case is complete and put to the side.....now to prep the pinion end.

|

|

|

|

The Makita electric impact is a real time save. No problem getting the 30mm pinion nuts off in about 1 second.

Had this Makita 6905h about 15 years and it's still impacting.

|

|

|

|

|

The pinion is easily pressed out.

|

|

|

|

|

Same with the old pinion bearing.

|

|

|

|

|

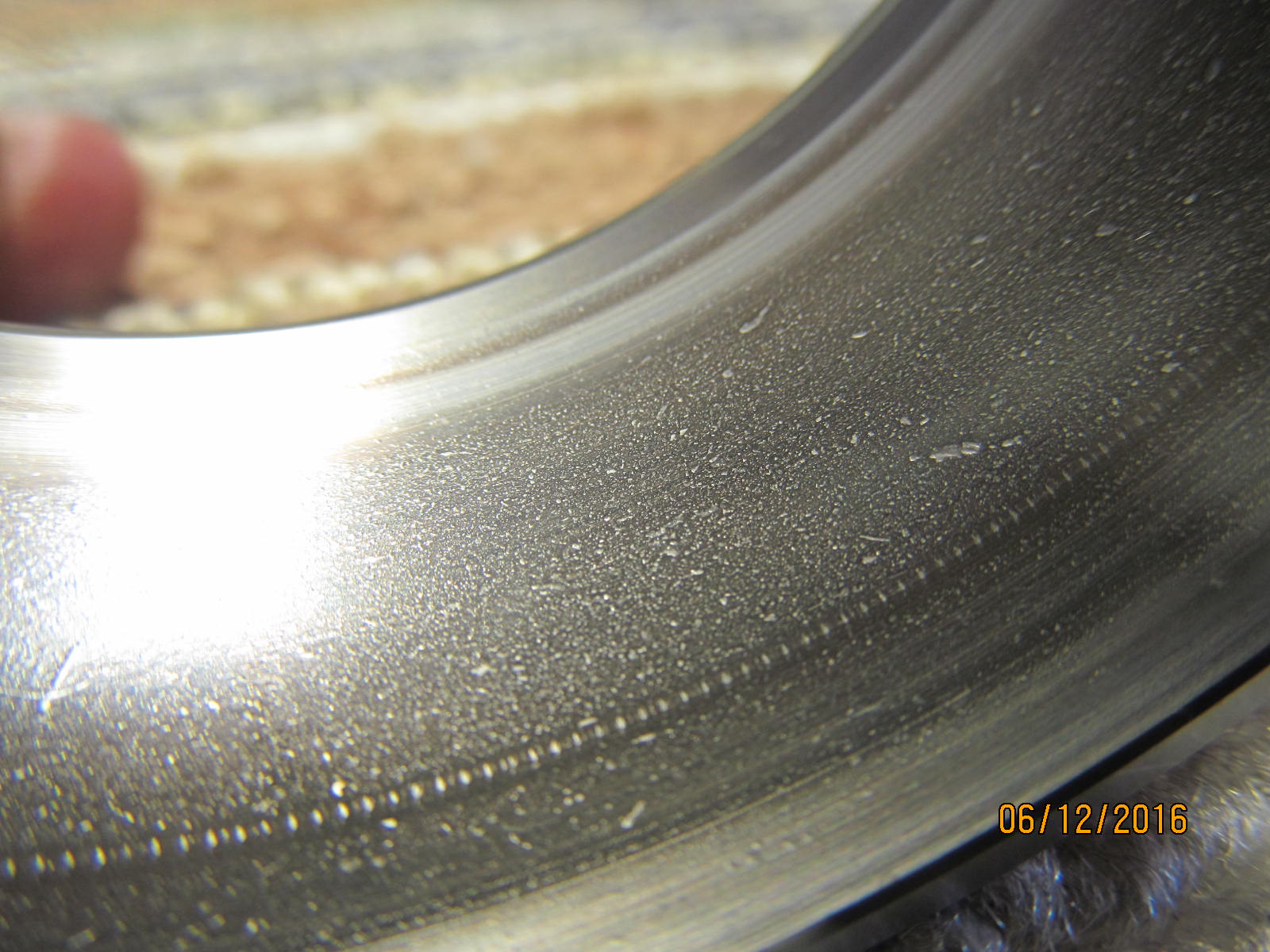

The little outer pinion bearing is rough...

|

|

|

|

|

...close up shows it's pitted.

|

|

|

|

|

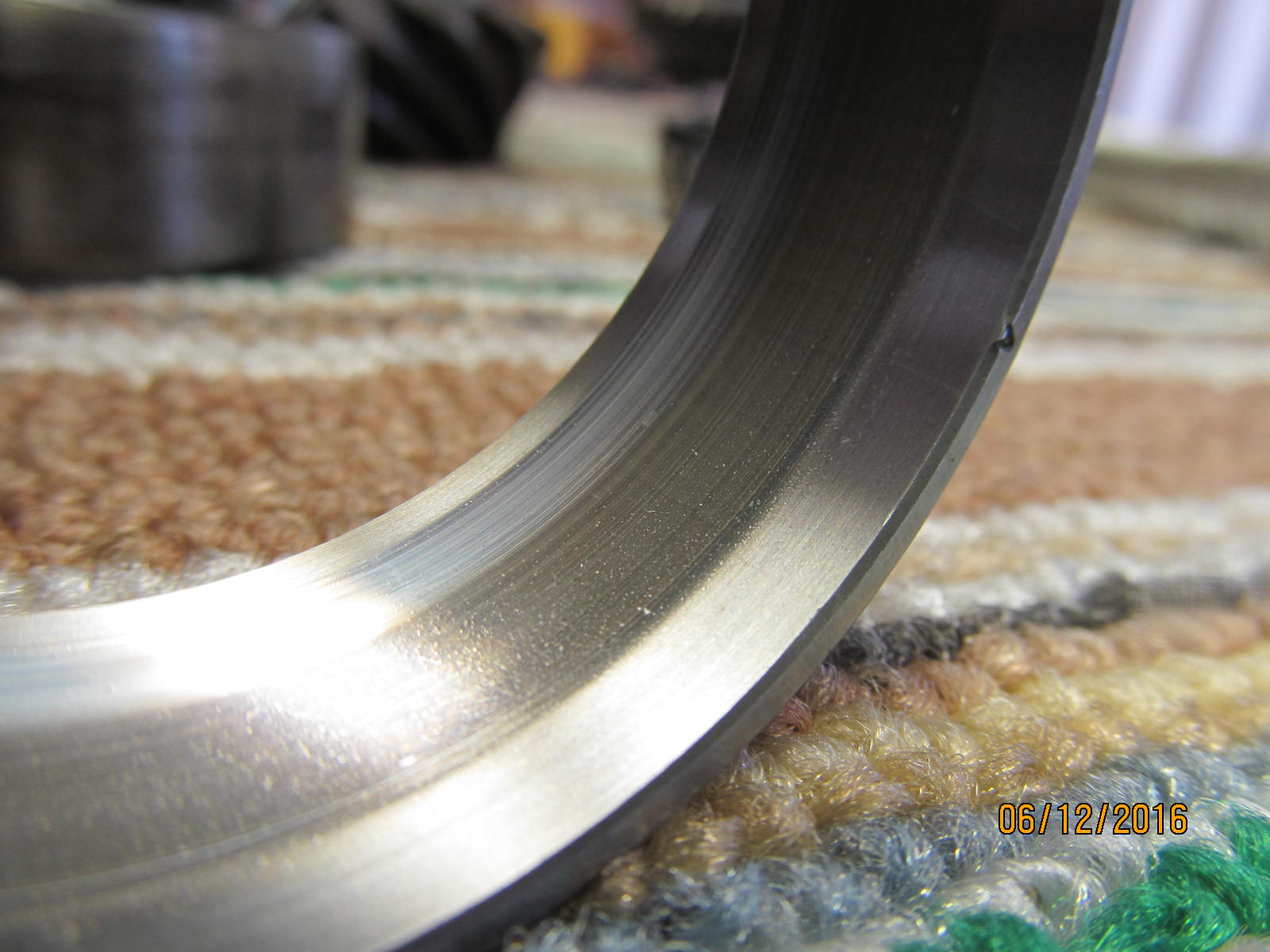

Some pitting on the race.

|

|

|

|

|

The large inner pinion bearing has pitting.

|

|

|

|

|

Its race has more noticable pitting.

|

|

|

|

|

New race(large inner).

|

|

|

|

|

The .0973" shim is pressed on with the new Koyo bearing.

|

|

|

|

|

Using a bubble leveler, the race can be tapped in 95% of the way with a chunk of steel.

|

|

|

|

|

Then I use an old race to fully knock it in 100%.

|

|

|

|

|

Problems happen when the race is thought to be fully seated and it's not....this one is for sure 100%.

|

|

|

|

|

Same with the other one.

|

|

|

|

A few pictures skipped here...pinion is prepped with a new crush sleeve and new seal is ready to be

pounded home.

|

|

|

|

|

Original flange surface was sanded with 1000 grit. Gear oil on all related surfaces.

|

|

|

|

No shortage of aluminum anti-seize. If the name of the game was to make it harder for the next gear guy to

remove the nut then I would have used some red loctite. Dimpling the nut will do the same job as loctite.

|

|

|

|

|

It took just about the full allowable 160 ft/lb on these 24mm nuts to develope the desired 10 in/lb of PPL.

|

|

|

|

|

A gentle DING will lock the nut in place...yet allow the next guy to remove it if need be.

|

|

|

|

|

70 ft/lb on all 4 bearing cap bolts.

|

|

|

|

Both adjuster rings are turned such that the backlash is in the target backlash of .007" and making

sure there are good bearing preloads.

|

|

|

|

|

Typically, it's good protocol to measure about 20 of the teeth for backlash as is the case here.

|

|

|

|

|

Measuring a combined total preload of 15 here......so if PPL is 10 then, doing the math, 15-10=5 is the CBPL.

|

|

|

|

|

Satisfied with the BL and CBPL, now both locking tabs can be tightened to 10 ft/lb with blue perma-lock.

|

|

|

|

|

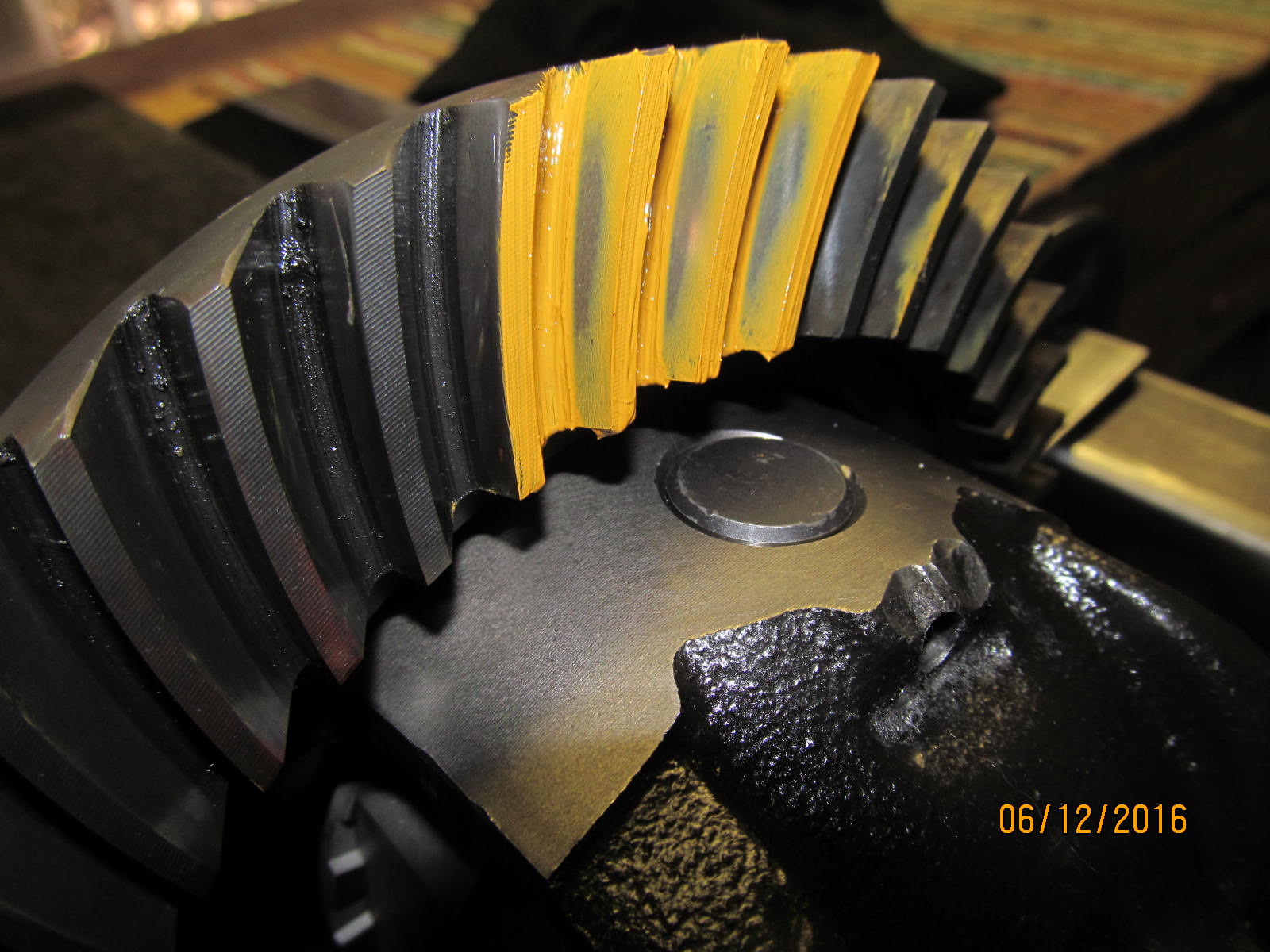

A final paint check reveals no surprises.....just a nice, solid pattern.

|

|

|

|

|

Coast looks great.

|

|

|

|

|

1 notch tighter than factory.....

|

|

|

|

|

1 notch looser than factory.

|

|

|

|

|

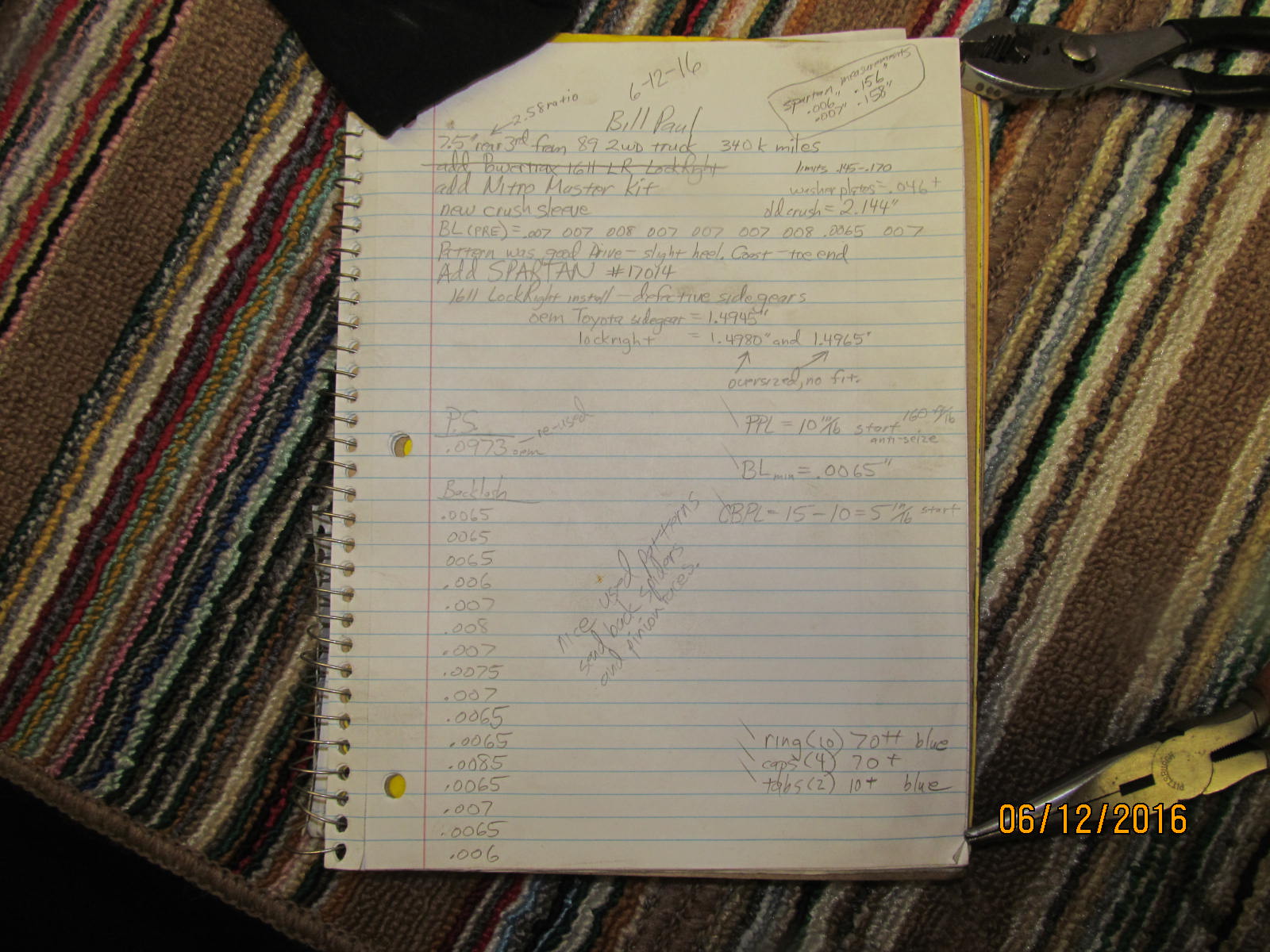

Some basic data and a time stamp...

|

|

|

|

|

A snapshot of my assembly notes.

|

|

|

|

|

Both the oem sidegears and spiders go back to Bill as well as the LockRight so he can return it for a credit.

|

|

|

|

|