|

|

|

|

|

|

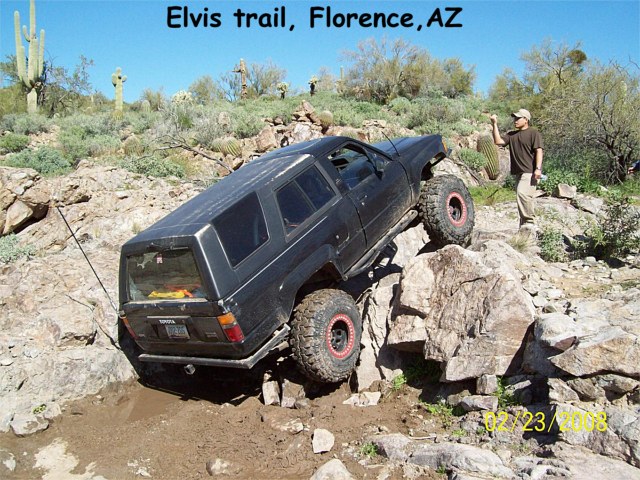

Brian's 88 4Runner has a good combo of lift, gearing, and protection. The 22RE/5 speed combo has no problem turning 36" Super Swamper SX tires with the 2.28/5.0 dual cases and 571 gear sets. |

|

Recently, Brian busted the rear 571 gearset while up in Moab. Not much history on this 3rd....bought from an on-line forum from someone that said it was originally set up in a Denver 4x4 shop. |

|

These are Genuine brand gears....that's a small part of the issue here. The actual gear install is the main cause of this failure mode. |

|

... |

|

... |

|

... |

|

Marks to help ID Genuine gears. |

|

... |

|

... |

|

The bearing that seems to always take the worst beating is the small outer pinion bearing. This one seemed ok. |

|

Some minor chinger marks on the cage and one small chip on the race. |

|

Some small dents in a non-critical spot. |

|

2 small shims totaling .020" were found hidden behind the large inner race...typically the shims go behind the pinion head....not the race. |

|

With all the chunks of metal floating around, it's a good idea to inspect the inside of the Detroit SoftLocker. |

|

The spring is fairly strong and it won't knock your face off if it's secured with one hand while the small allen screws are removed. |

|

... |

|

The driver and side couplers look great. |

|

The 15 little inside square teeth are all there. I have seen all 15 of those teeth on 2 of my Detroits sheared off in the distant past. |

|

This one is good as well. |

|

... |

|

The axle coupler splines both look great. |

|

When compressing the 2 halves together, getting the last 1/2" to mesh is a minor hassle but is doable. |

|

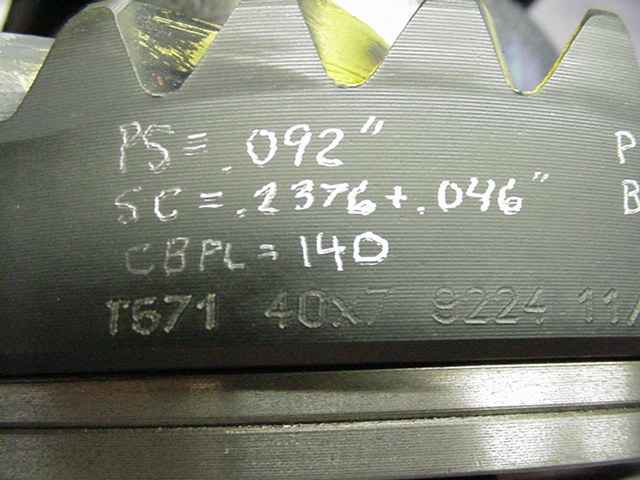

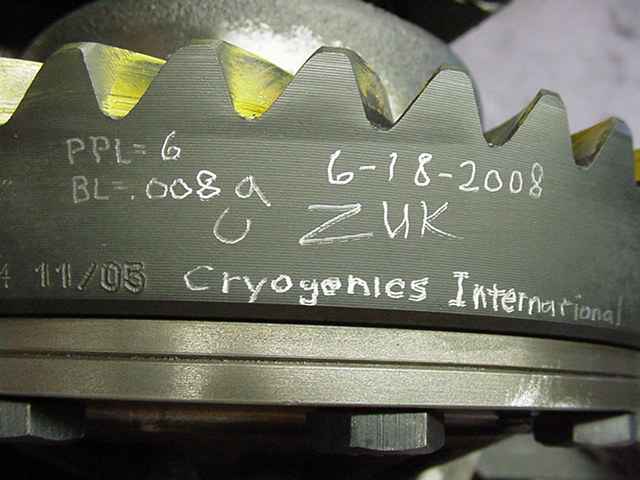

Now to file the surfaces and check for high spots. None found. These are quality 571 Motive gears and they have been professionally cryo treated by Cryogenics International. |

|

Red Loctite and 75 ft/lbs. |

|

Races are pressed in....no shims behind the races. |

|

A few steps skipped here....basically installed the pinion with no crush sleeve...set it for about 10 inch/pounds of rolling drag and loaded up the case with about .008" for backlash. This pattern is much too shallow. |

|

... |

|

Even the pinion tooth says the ring tooth is running very shallow. |

|

Teardown and .016" was added to the shim stack. |

|

The pinion seemed to be turning 'rough' and, upon dis-assembly, noticed a new chip in the outer pinion bearing. I wasn't going to take chances with this discovery and substituted in a good used pinion bearing/race I had laying around. |

|

Now it's a little deep. |

|

I will remove .004" now from the pack. |

|

Pinion tooth agrees that the ring is deep as indicated here with a 'shallow' pinion tooth. |

|

Now is a good time to install the solid collar. |

|

The pinion bearings are used so I shoot for 6 inch/pounds. |

|

Aluminum based anti-seize on the threads... |

|

Nice drive pattern....centered and the proper depth. |

|

... |

|

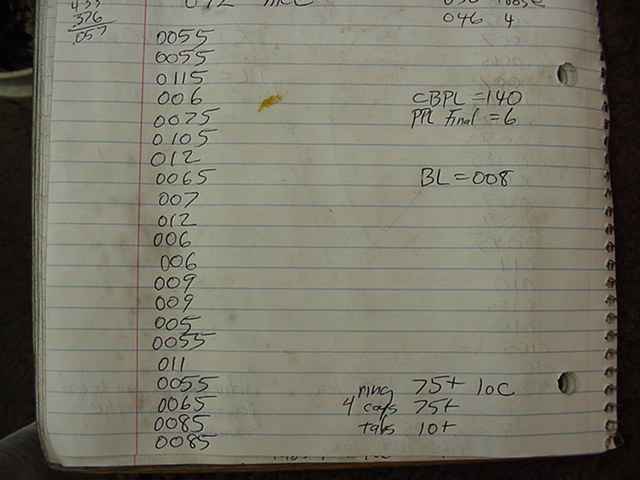

Carrier Bearing Pre-Load(CBPL) and BL are tweaked in. |

|

I normally complete the top pinion end before installing the case(Detroit) but it can be done out of order with a solid collar involved. |

|

Loctite and tighten the nut. |

|

Backlash is verified all the way around the ring on every other tooth for a total of 20 measurements. All was good as shown 2 pictures below. |

|

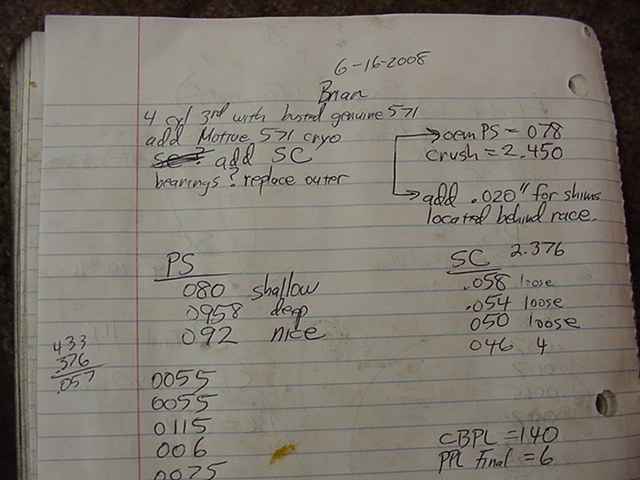

Notes taken on Brian's install. |

|

... |

|

... |

|

|

|

ZUK

ZUK