|

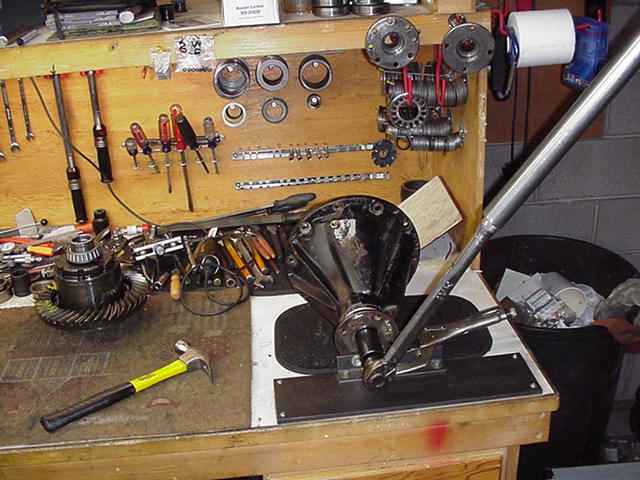

Chris has a 1995 FZJ80 with 176,000 miles. It has had a screaming whine from the rear 3rd since he bought it....it

was very loud on both acceleration and de-acceleration. Upon dis-assembly, I noticed the pinion bearings were

badly pitted. The 488 ring and pinion looks to be re-usable. The master kit, shown above, will bring peace and

quiet to Chris's future road trips.

|

|

|

This 3rd also has an old style RD33 ARB. It seemed like a good idea to replace the o-rings and the clamping plate. A call to the

ARB techline and 4 days later had this manilla envelope at my doorstep.

|

|

|

New pinion races are tapped in.

edit---Best to stay away from all punches/chisels...

use an old race to evenly "pat down" the new race.

Using a punch could result in "oscillating" pinion

preload measurements with the torque wrench.

1-8-2011 ZUK

|

|

|

Old carrier bearings come off with ease with the right puller.

|

|

|

These are the "adapter bearings" being pressed on. This ARB case has the larger 50mm journals...

which is no issue with Timken 32010X bearings. That's a 9.5" ring gear :)

|

|

|

The worn inner pinion bearing is pressed off.

|

|

|

The factory .053" shim will set the correct pinion depth.

|

|

|

...

|

|

|

The crush sleeve will be installed immediately since pinion depth is not a question.

|

|

|

Lots of gear oil on both pinion bearings.

|

|

|

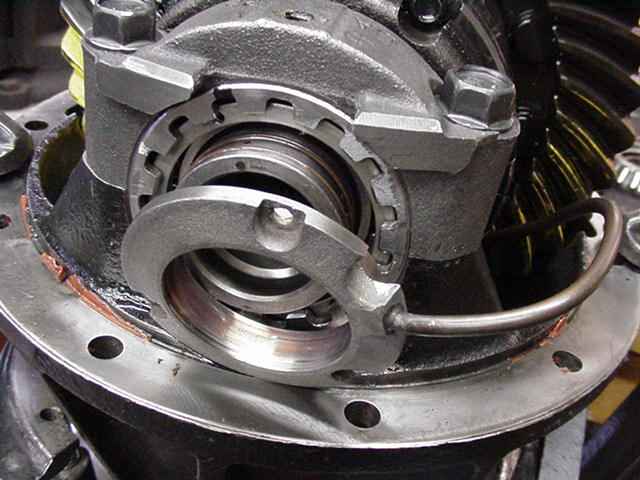

A thick grease is packed on the inside of the seal to prevent the spring from popping off during install.

|

|

|

A jam nut was supplied with this master install kit. The nut had 3 dents on the top threads to cause thread interference

which will prevent the nut from working its way loose. I used lots of silver anti-seize on the threads which

helped greatly in crushing the sleeve.

|

|

|

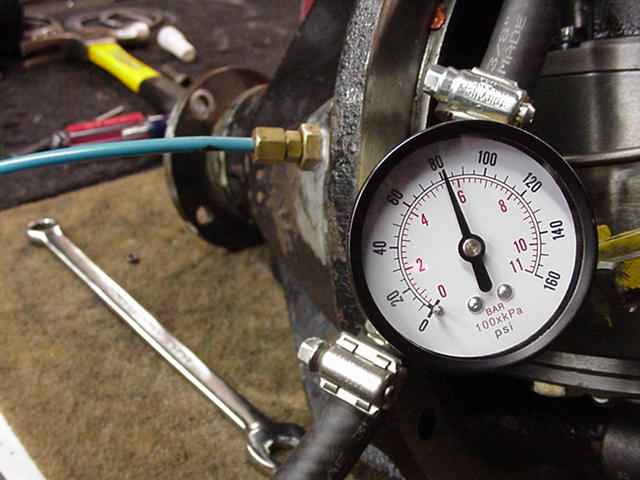

I choose to run the PPL (pinion pre-load) up to the upper spec of 17 in/lb.

|

|

|

Lots of gear oil and the new o-rings are installed.

|

|

|

This is the old clamping plate which is why I ordered a new straight one. This happens when the 3 tiny allen

screws are tightened up with too much zest.

|

|

|

The new clamping plate with 3 tapped holes is loosely captured behind the carrier bearing adjuster wheel.

|

|

|

This painted pattern looks very similar to the preliminary pattern before it was dis-assembled.

|

|

|

Good.

|

|

|

Backlash was set to .0075".

|

|

|

Carrier bearing adjusters are evenly tightened while monitoring the backlash. Many hammer hits later, everything is

looking good.

|

|

|

The seal housing is carefully aligned and pushed on.

|

|

|

With no tension coming from the hard copper line, the 3 allen screws are carefully cross-tightened to a mere 3.5 ft/lb

per ARB's tech notes. There will be no potential leaks if the o-rings are actually self-centering the seal housing...

and the Loctited screws are snugged evenly to lock the housing in place.

|

|

|

With my air hose assembly pumped up to 80 psi, no loss of pressure was observed even after a 30 minute period.

|

|

|

Bullseye has a nice cushy blanket on the top shelf he uses to watch me from. :)

|

|

|

10 ft/lbs and loctite on the tab bolts. The 4 bearings cap bolts see 81 ft/lb per the FSM.

|

|

|

One last look at the routing of the copper line.

|

|

|

The symbol on the left means its Motive...and it's a 488 ratio for a Landcruiser.

|

|

|

Manufacturered in 10/98....this 488 Motive was likely installed in about mid 1999 along with the ARB RD33.

|

|

|

Some notes that I like to inscribe on the ring...

|

|

|

...and specs used. Done.

|

|