|

|

|

|

|

|

Chris is local to me living in the same Chandler area. Here's a before-pic of his Runner. |

|

Here's an after-pic. This was taken in the Butcher Jones area. |

|

Chris ordered everything from Marlin crawler. This is for his front hi-pinion V6 3rd. |

|

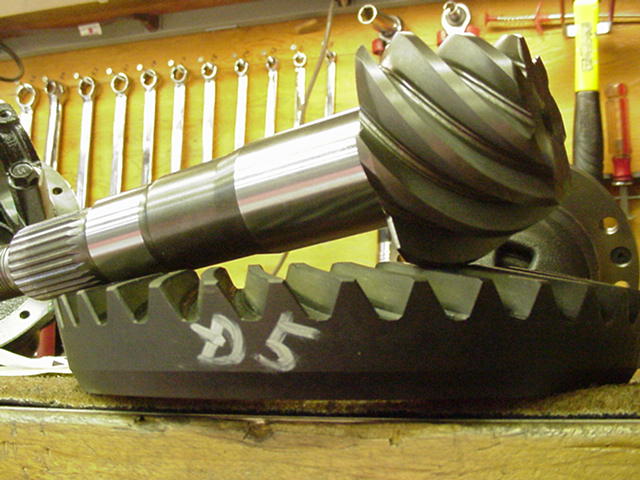

The reverse cut gears had no markings other than "D5" in white paint. |

|

I was very pleased with the quality machine work. |

|

Both races are pressed into the carrier. |

|

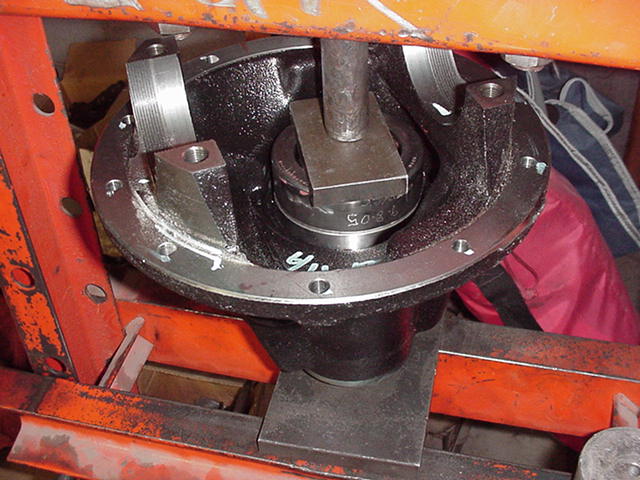

This is a V6 pinion as the measurement is in the 1.666" area. If it was a "4 cyl" version then the measurement would be closer to 1.535" or so. |

|

I chose a .078" shim. The bearing is then pressed on. |

|

It's best to assemble without the solid collar the first go around. The pinion nut can be cautiously tightened until about 10~15 in/lb of PPL has been achieved. |

|

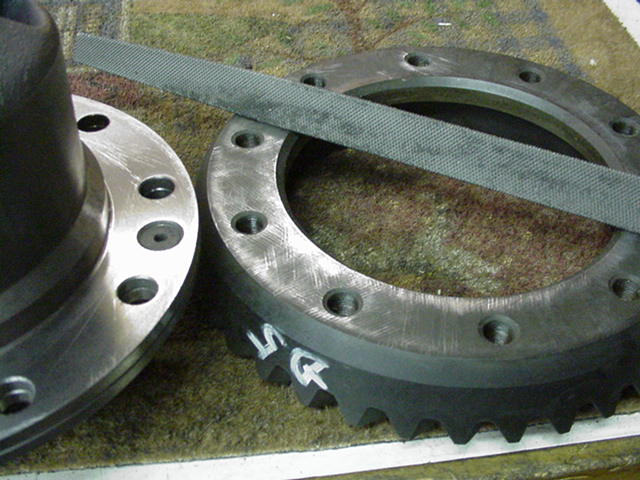

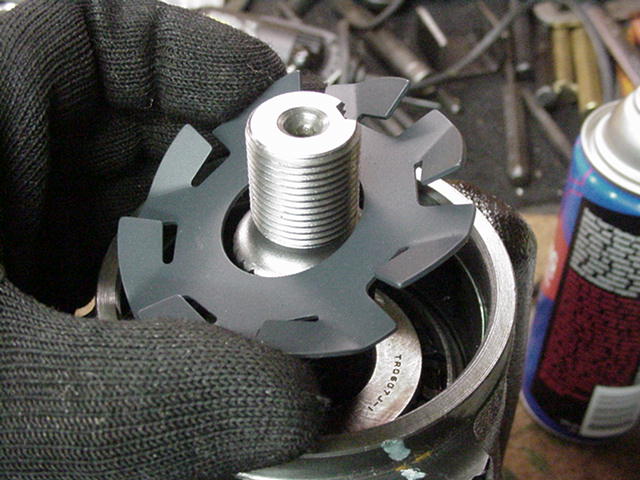

With that done, it's onto the Detroit and ring gear...a file checks for high spots. All was good here. |

|

Red Loctite and 75 ft/lbs... |

|

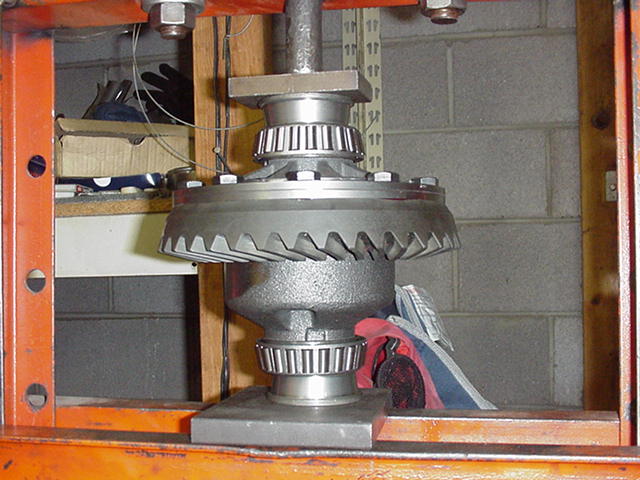

New carrier bearings are pressed on. |

|

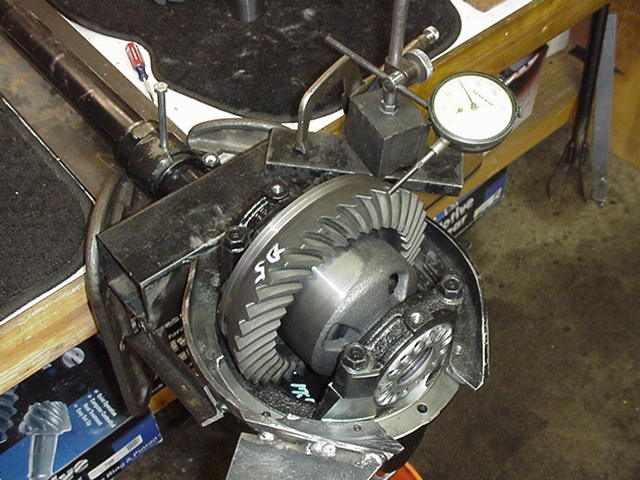

Backlash is set to about 7 or 8 thou and the CBPL just needs to be minimal for a pattern check. |

|

I am using a rag on the pinion flange to apply some resistance while turning the ring gear with a 17mm wrench. Back and forth 3 times is all it takes. This is how I get such nice, easy to read paint patterns. |

|

Excellent. Depth is right on and the pattern favors the toe end which is great. |

|

Nice. |

|

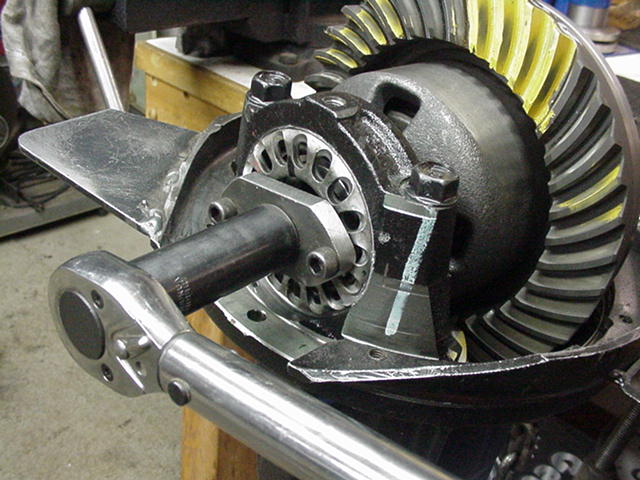

Skipped a few steps...carrier was torn down and the solid collar was installed. Then the oil slinger and seal were installed followed by the pinion flange. |

|

The Detroit was then re-installed and the adjusters were tightened to get the right BL and CBPL. |

|

The torque on the adjusters was finalized using a torque wrench. 150 ft/lbs is what I shoot for. Backlash was held at .008". Not shown is all the hammering on the tops of the bearing caps to equalize the tension on both bearings. Failure to do this might mean a shift in backlash on its first road trip. |

|

Specs and date coded. Ready for Chris to pick up! :) |

|