|

|

|

|

|

|

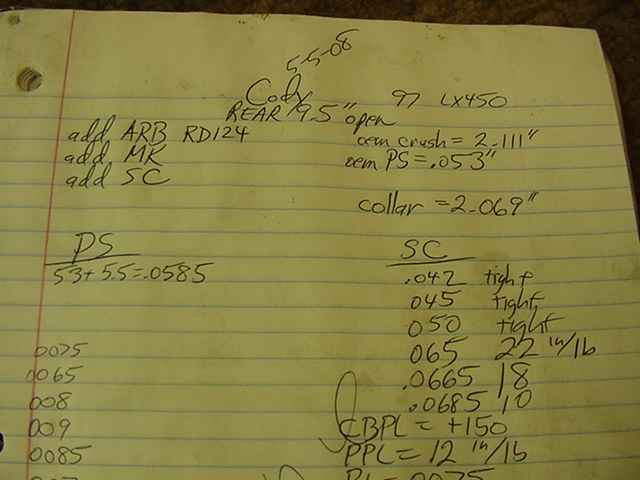

Cody lives in Prescott Valley, AZ and has been running 410 gears with 38.7" Michelin XML tires. Time for a re-gear and 529 was the only choice with that tire. An ARB would be added with a solid collar. |

|

Nitro Gear....I happen to know that Carl from JustDifferentials.com was personally involved in the R&D of these gears and it's their premium line. |

|

Markings on the ring... |

|

NG = Nitro Gear |

|

... |

|

ARB RD124 |

|

... |

|

The master kit as supplied from Nitro Gear and Axle. |

|

Adapter carrier bearings with the 50mm inside diameter. |

|

The 3rd is torn down.... |

|

In the process of removing the old races with a soft chisel, I left some little dents. This is leveled flat using my thumb file. |

|

The pinion is installed without a solid collar or crush sleeve. The nut is tightened carefully until about 10 inch/pounds is measured. |

|

Surfaces are lightly filed to check for high spots. |

|

The ring was a tight fit onto the ARB case but the press made easy work of it. |

|

Red Loctite and about 100 ft/lbs makes it right. |

|

While trying to dial in the backlash, I found that the ring tooth was making contact with the carrier. This doesn't happen with all 529 gears but it did happen with this one. |

|

The contact is "strong" and the fix is an easy one. |

|

Using the handgrinder, remove a minimal amount of material....maybe .080" deep or so is more than enough. |

|

2 spots on the carrier need to be clearanced like this. |

|

Lots of clearance on this side... |

|

180 degrees away it clears fine also. |

|

Now that the ring gear will turn smoothly, now the backlash can be set to about .007 for a pattern check. |

|

Beautiful pattern. Depth is exact. |

|

The metal to metal "scuffing" that shows the same drive pattern. |

|

Coast looks good also. |

|

... |

|

Drive side on the pinion tooth looks nice. |

|

Coast is good. There's nothing wrong with these Nitro Gears...the quality is there. |

|

The fitting for the ARB hose is drilled and tapped at this point. |

|

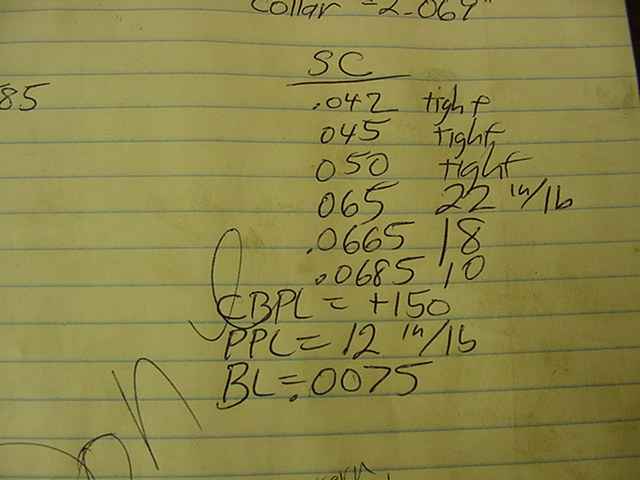

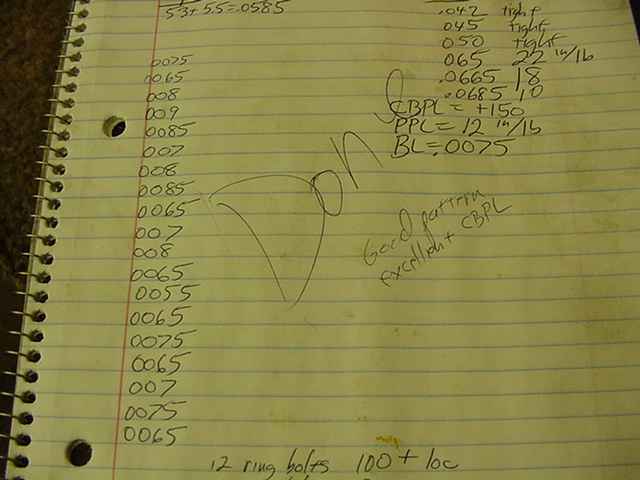

With the pinion depth established, now the solid collar can be installed. It took me about 6 times to get the shim right for the collar. |

|

Finally, the seal is prepped with RTV and thick red grease. |

|

12 inch/pounds is measured for PPL. |

|

The adjusters are carefully tightened until the CBPL reaches 150 ft/lb or even a bit more. |

|

The seal assembly is pushed in place. The clip is snapped in place. |

|

Verify that the tab does not contact or push down on the seal assembly. Air leaks could possibly happen if it does. |

|

Carefully route the soft copper line with a service loop. |

|

The fat little o-ring is lubed up and carefully pushed in. |

|

Leak tested and all is good. |

|

Specs are dremel drilled on the ring... |

|

These are the notes I took....here, it took me 6 times to get the PPL right. |

|

The backlash was checked on every other tooth (about 19 places). |

|

Done....Check out the link below for the front gear install. ZUK |

|

|

|