|

Randy double boxed the front 8" 3rd also...did a nice job.

|

|

|

The second box was full of rolled up cardboard strips. There was so much packing tape holding it

together that there was no chance of the boxes self destructing.

|

|

|

The 3rd was pretty gooey.

|

|

|

The plan is to install 571 PRECISION gears and an Aussie Locker. A solid collar will be used.

If the bearings are ok then they will be re-used which is considered ok by me in this front application.

|

|

|

|

|

|

There was no carrier bearing pre-load at all as determined by the ring gear rattling

back and forth thru the backlash region. I marked everything before I tore it apart.

|

|

|

Putting the Aussie in is the first task. Remove the ring gear and use a

long punch to knock out the roll pin.

|

|

|

Slide the power pin out and throw away the sidegears and spiders.

|

|

|

Both of the sidegear thrust washers measured .067" with the micrometers so it was not important to

keep track of what side they went on.

|

|

|

A partial assembly is done to measure the gap between the power pin and the 2 spacers showhn in my hand.

This is one of two measurements that should be done during an Aussie install...but I suspect few folks actually

measure anything.

|

|

|

The first measurement...

|

|

|

The last 3 Aussies that I installed required mild filing to get the last coupler to slip into

the case. This one squeaked its way thru.

|

|

|

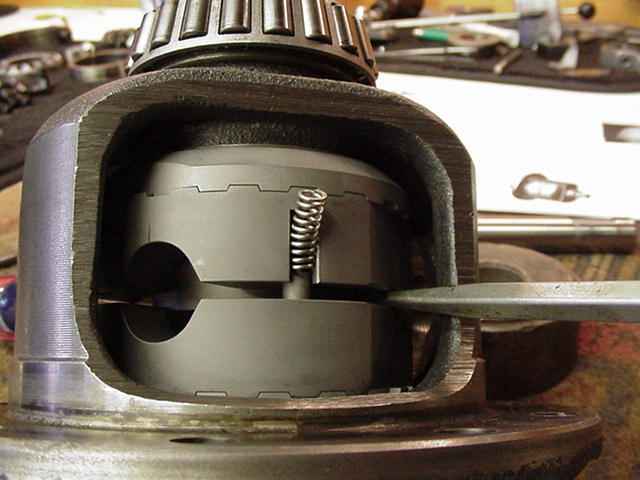

By rotating one coupler at a time, I was able to get the pins in properly...I think I figured the easiest way

to get the springs in also...

|

|

|

I employed 2 screwdrivers to spread the couplers from each other...that gave me maximum room to get the

springs in. I start by pushing the spring in at the bottom side first...

|

|

|

...Then I push the top side in with a small screwdriver...

|

|

|

...then I tap it in evenly with a small screwdriver and hammer.

|

|

|

Aussie then recommends a second measurement be made. The gap between the 2

couplers measured .150" all the way around so this one is well within spec

and should be trouble free for years to come.

|

|

|

The power pin now goes in and the roll pin gets tapped back in.

|

|

|

A couple of raps with a dull chisel will partially cave in the hole so the

roll pin won't wiggle its way out.

|

|

|

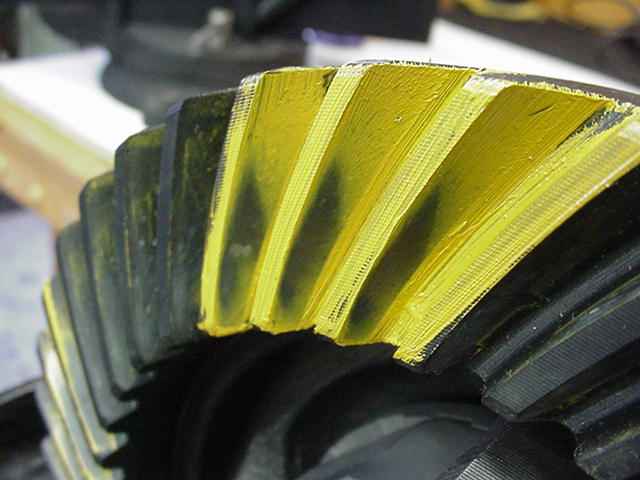

DRIVE. The new 571 Precision ring gear goes on now. The surfaces were filed first and red loctite

with 75 ft/lbs of torque will keep things tight. Shown here is the drive side. The pattern

are classic picture perfect. All PG gears get this pattern check from the factory. That's

a gear company that cares! :)

EDIT 1-8-2011....Too bad Tom (President) retired from that company because the gear source changed and things are no longer the same.

|

|

|

COAST. The coast side is perfectly placed also. If the Toyota carrier is within spec, I should

be able to duplicate these painted patterns.

|

|

|

The ring gear went on very tight...no sloppy fit here for sure. I bet they

hold that tolerance to "two tenths of a thou". ;)

|

|

|

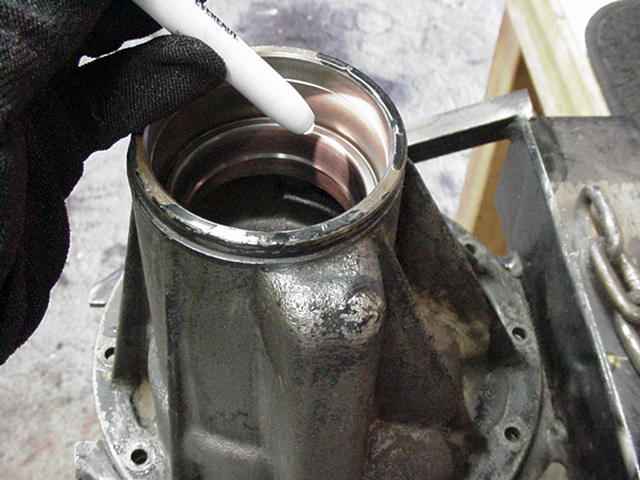

The front 3rd does not see the 100% duty use that the rear does....actual usage is probably

closer to 1% for most wheelers so as long as the bearings are in decent shape, I will often re-use them

in a front end application to help keep costs down. Close inspection reveals these are ok....not pitted and no score marks.

|

|

|

My first choice is .071" for the pinion shim. Harbor freight has some great deals on

these micrometers...usually right at $20.

|

|

|

Backlash is set near the .008" recommended spec while the carrier bearing pre-load is set to medium high levels...

turning the pinion while rapping the bearing cap will allow both carrier bearings to equalize with each other.

|

|

|

The gear marking compound that comes in the Yukon master install kits is my favorite. The bright yellow is of the right

consistency and easy to read.

|

|

|

This has got to be the best and easiest way to run a pattern on the Toyota 3rd...mild drag applied to the pinion

while turning the ring back and forth with a 17mm wrench. This takes 3 seconds to do.

|

|

|

DRIVE. Too shallow (high and to the heel)

|

|

|

COAST. shallow agrees.

|

|

|

No ZUK....check your math again. We want to try 5 thou deeper for a value of .076".

|

|

|

DRIVE. Probably would work just fine with this but it's still a touch shallow...

|

|

|

COAST. Just a little shallow.

|

|

|

Add .002" for a final pinion value of .078".

|

|

|

DRIVE. Nice.

|

|

|

COAST. Nice again. :)

|

|

|

Sometimes I get "gabby" so I add my two cents ;)

|

|

|

If the 3rd is sent to me clean on the outside, I will do a 2 step paint process that seems to

be unbelievably durable...I spray a special "adhesion promoter" followed almost immediately by a shot of Krylon

glossy black.

|

|

|

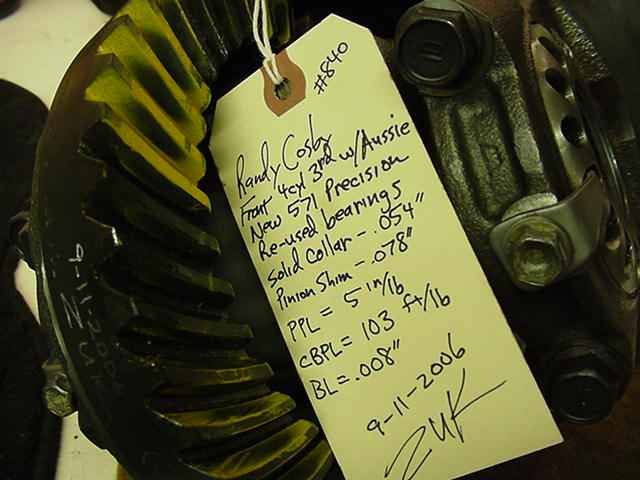

I served time back in '76 at R.I.T. and documentation was drilled in my head...so I include

a tag with the important data. Done. :)

|

|