|

|

|

|

|

|

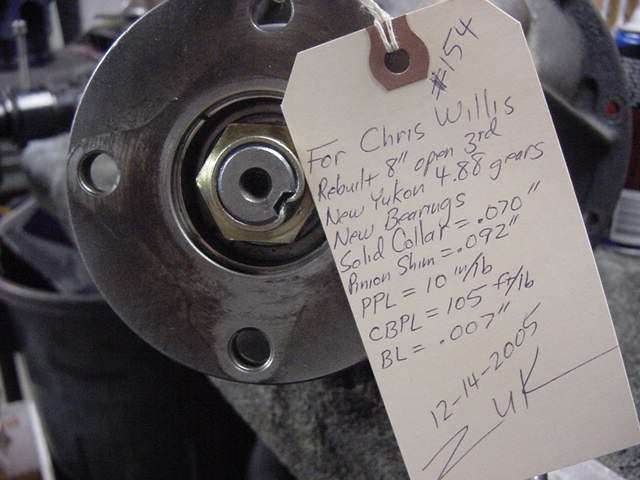

Chris Willis from the state of Washington couldn't have any downtime with his situation so I happened to have an extra 4 cylinder 3rd (core) laying around and I offered to set it up and ship it out. The plan was to do a pro install with Yukon 488 gears with new bearings and a solid collar, of course. |

|

I ordered these Yukon gears from PORC. Some things are not shown here....but all the right stuff is going in this 3rd :) |

|

I like working on clean surfaces. It took 1 full can of starting fluid to get there...I think I need a real parts cleaner vat :) |

|

The old bearings came off basically with just hand pressure. After using #800 sandpaper and more cleaning, I applied this special bearing sleeve lock compound. God help the person that ever has to remove these bearings in the distant future. |

|

Notice the cosmetic damage on this case. This happened because a crush sleeve was used and it loosened with time allowing the pinion teeth to eventually touch the case. The solid collar shown will prevent this from occurring again. |

|

For my starter pinion shim, I will re-use the factory .082 shim and add .010 in for good measure... |

|

I don't have to but I will also install the collar at this point. I started with .066" for this shim. |

|

In the end, .070" got me a nice 10 in/lb. |

|

Anti-seize on the threads allows me to truly get some torque on the carrier bearings. |

|

With the carrier bearings set tight and the backlash in the .007" area, this is the drive side pattern. Depth is very good. |

|

coast. |

|

These particular Yukon gears seem to have the quality and set up well. These have the "304" on the ring. I believe these gears come out of Ambrose, Italy but not 100% sure. |

|

I usually put a solid 75 ft/lbs on the 4 bearing cap bolts. The 2 smaller 12mm bolts that hold the tab in place usually see blue loctite. |

|

The pinion nut gets splashed with blue Loctite and tightened to the max with the electric impact.... then I secure the flange and do the final tightening with the 4 foot bar. I get about an 1/8 of a turn more with the bar. And Yes, that does have an effect on PPL and I take that into consideration when I am setting final PPL. |

|

I find that just right box and stuff more cardboard inside and add a little foam to prepare this diff

for the trip back. I shipped it Fedex (my fav) and actual weight was just under 53 pounds. I emailed CW and recommended he

use synthetic for the break-in period. It will run cooler and the bearings will love you for it.

An extra little hint here from the voice of experience.....replace the 2 inner axle seals at the same

time. The synthetic will find its way past old seals and leak onto your tires. The left side seal is

most likely to leak. :) New seals are only 5 bucks each. All Done!!!

|

|