|

|

|

|

|

|

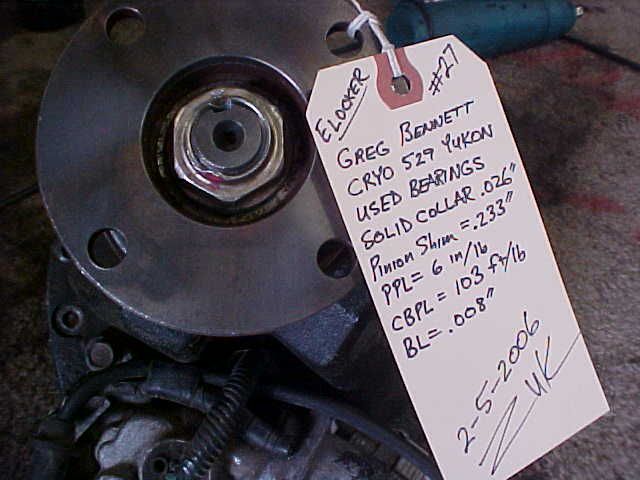

Greg Bennett from Cumming,GA found a good deal on an E-Locker and sent it my way here in Arizona. |

|

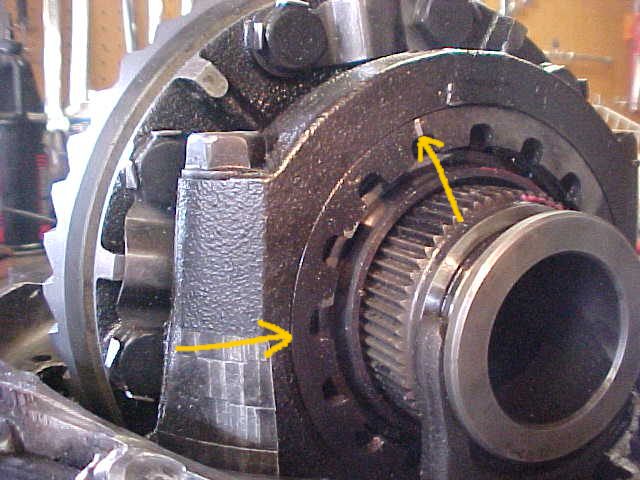

Upon receiving it, I thought I would do a test. Even though this 3rd has only 12,000 miles on it, I wanted to see if the carrier bearings could use a little "freshening up". I was able to easily tighten BOTH adjusters 3 notches as shown above. This is a simple way to increase the over-all strength of the 3rd by simply cranking carrier bearings TIGHT TIGHT TIGHT (an equal number of notches on both sides). Tight carrier bearings minimize ring deflections and the subsequent load bearing pattern from moving to the heel. |

|

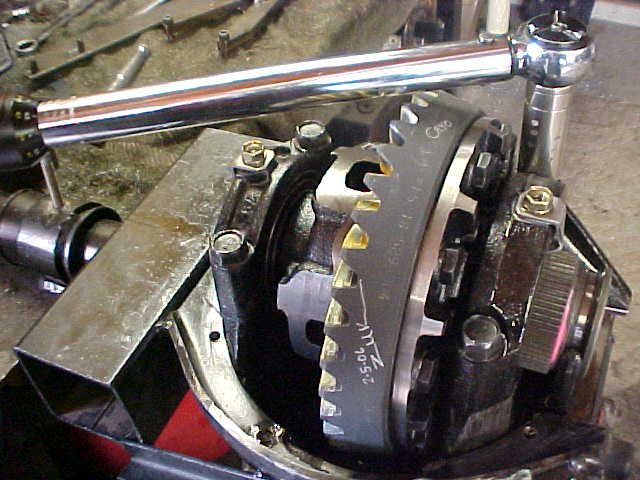

The tool I made to allow me to tighten the large spanner on the E-Lockers.... |

|

...and the simple tool I made to adjust the other side which also fits the V6 and 4 cylinder 3rds. |

|

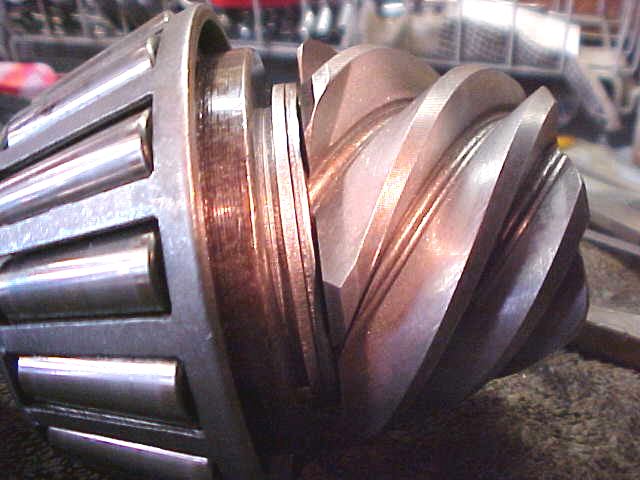

Back to business, the plan is to install 529 yukon gears that have been cryogenically treated but without the heat-treatment softening step. Cryo-genics on ring and pinions still increases strength but also improves the wear durability by 200~300%. This process would be a great idea for carrier and pinion bearings but that's another link/another day. |

|

Solid collar is the pro way. |

|

I like to re-use the factory pinion shim but getting a stubborn bearing off can be a prob....not with the right tool though and I have it here. |

|

The 2 pinion shims on the left are compliments of Ace Hardware :) |

|

shims pressed in place....short pinion head using long shims. |

|

I wonder how many installers have been bitten by this...and ended up with a false pinion pre-load reading.....many of the E-Lockers and the High Pinion 3rds have an oil retainer just below the outer pinion bearing. As it turns out, the short necked collars (left one) rub and interfere as the pinion nut is tightened. The long necked one on the right clears. Either one is ok to use as long as there is no oil retainer. FYI |

|

The ring gear bolts will never be a problem if Locktite is applied to clean threads and 70 ft/lbs is applied. |

|

close...but a little deep here. |

|

Coast side seems to back that up. |

|

Take the case back out...take the flange off. This one was a tight fit. Very rare. Hi Bullseye! |

|

I guess I could beat the pinion out with a hammer but that would chinger the threads up and leave chatter marks in the small pinion race. A small press is the way to go. |

|

It's only a 10 tonner and it has never let me down. |

|

The brand new big pinion bearing comes off with relative ease with the 360 degree capture of my custom tool. |

|

I use my calipers sometimes and micrometers at other times... |

|

This is with 4 thou less pinion shim....much better. |

|

Coast side says right on. |

|

My simple test for CBPL...place 2 fingers on the ring and if I can't get it to rock back and forth then the bearings are at least tight. I use a 100 ft/lb torque wrench on the carrier bearings and that gets my pre-load where it needs to be. |

|

70~75 ft on the bearing cap bolts and some red Locktite on the tang retainers. |

|

|

|

Good thing the socket didn't slip off....this is not the way I normally do it but it makes the point ;) My nuts rarely loosen up. |

|

Ready to box up for Fedex back to Georgia. |

|