|

8" E-locker from 2005 Tacoma Chunked the Ring Gear.

|

|

(44 BIG pics loading)

|

|

MAY 31 2016

|

|

|

|

Aaron has a 2005 Tacoma with rear 8" e-locker and enjoys the hot Arizona "trails"......

|

|

|

|

|

....and doesn't mind a little cold mud during the winter.

|

|

|

|

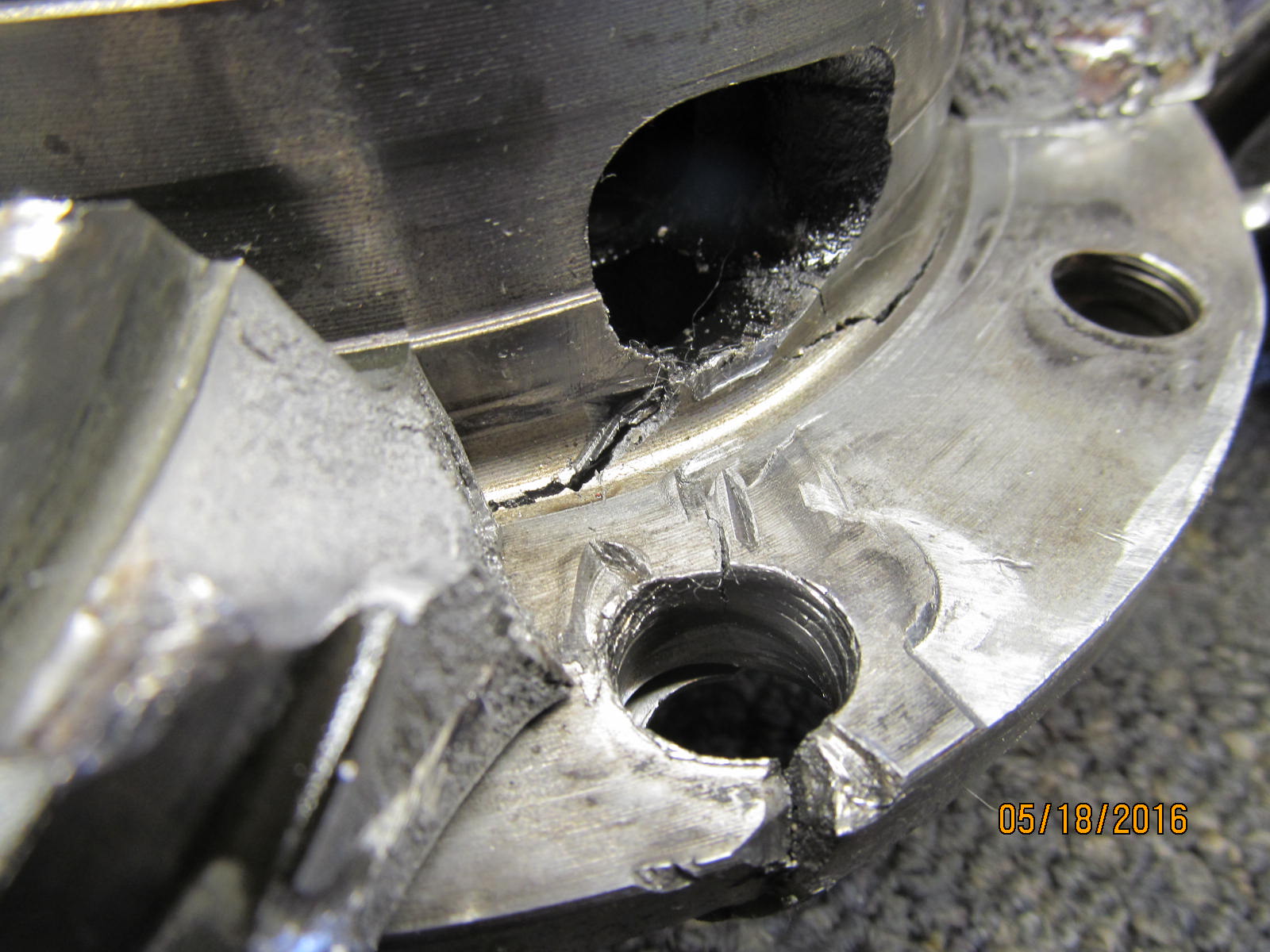

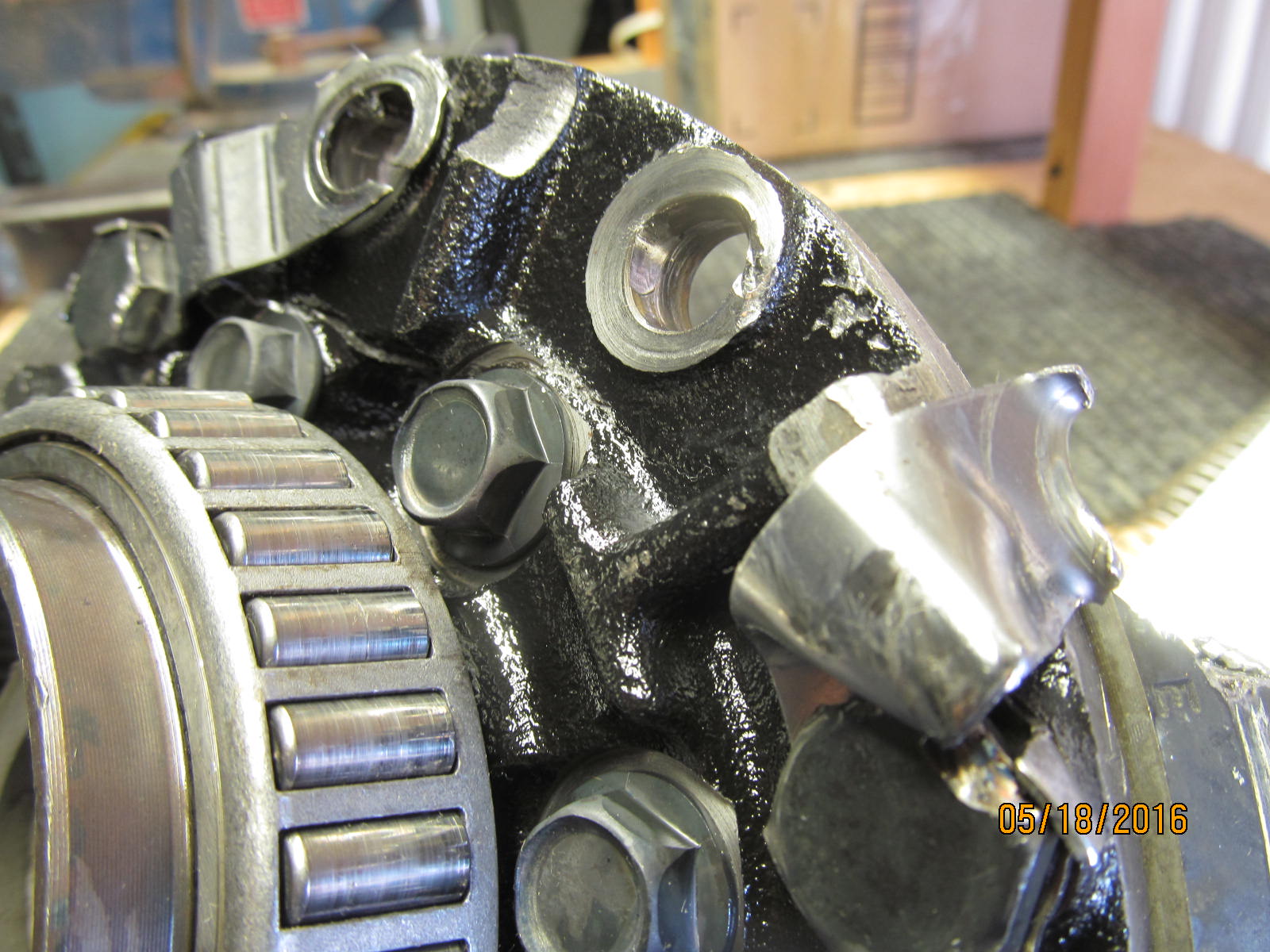

This is what he did recently.....this one gets the "most damaged ring-gear" award.

|

|

|

|

|

He was out wheelin' at Butcher Jones near the Sahuaro Lake East of Phoenix.

|

|

|

|

|

Locker case half is trashed.

|

|

|

|

|

'''''''''''''''''''''

|

|

|

|

|

..................

|

|

|

|

|

.......................

|

|

|

|

|

'''''''''''''''''

|

|

|

|

|

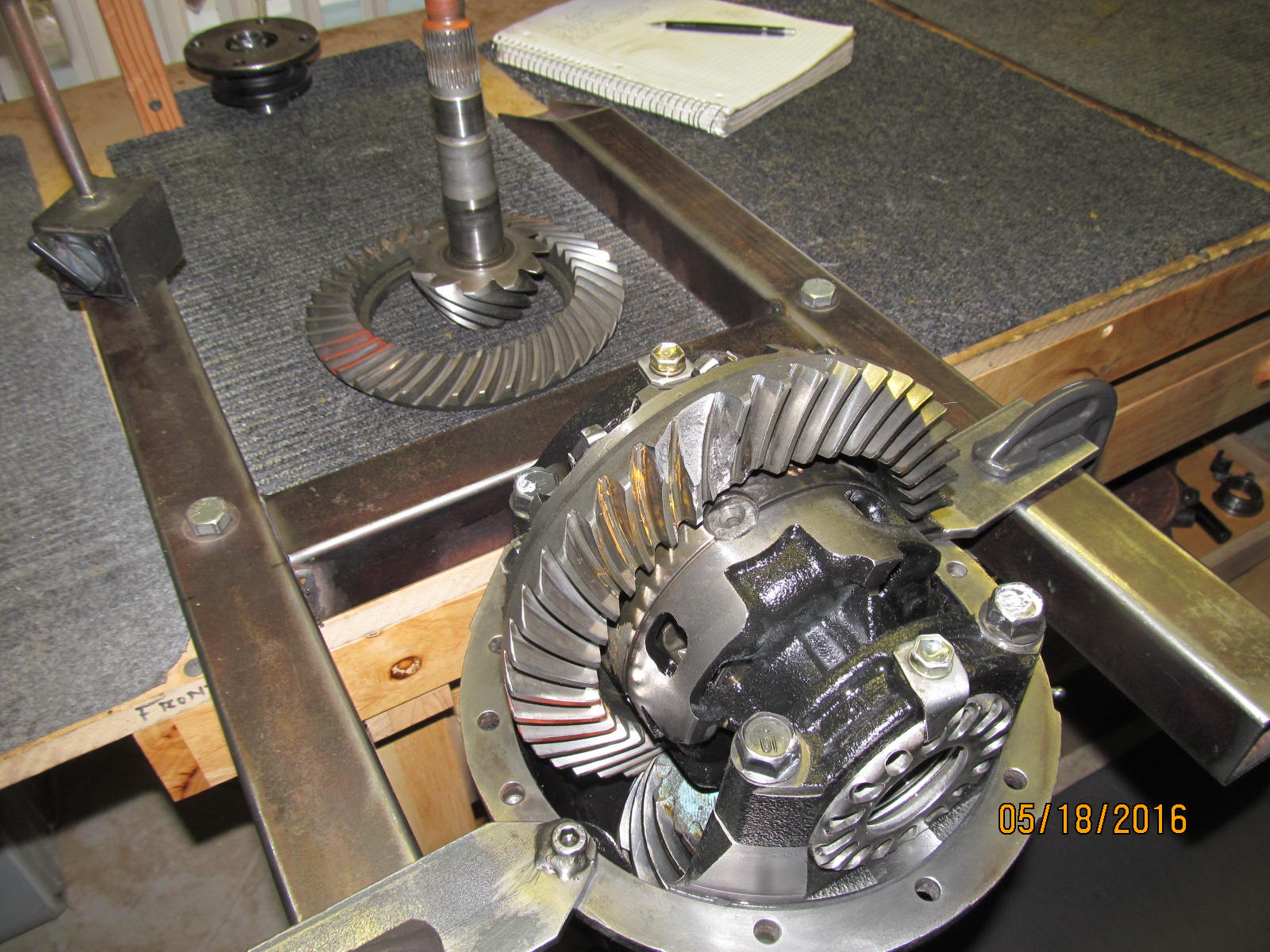

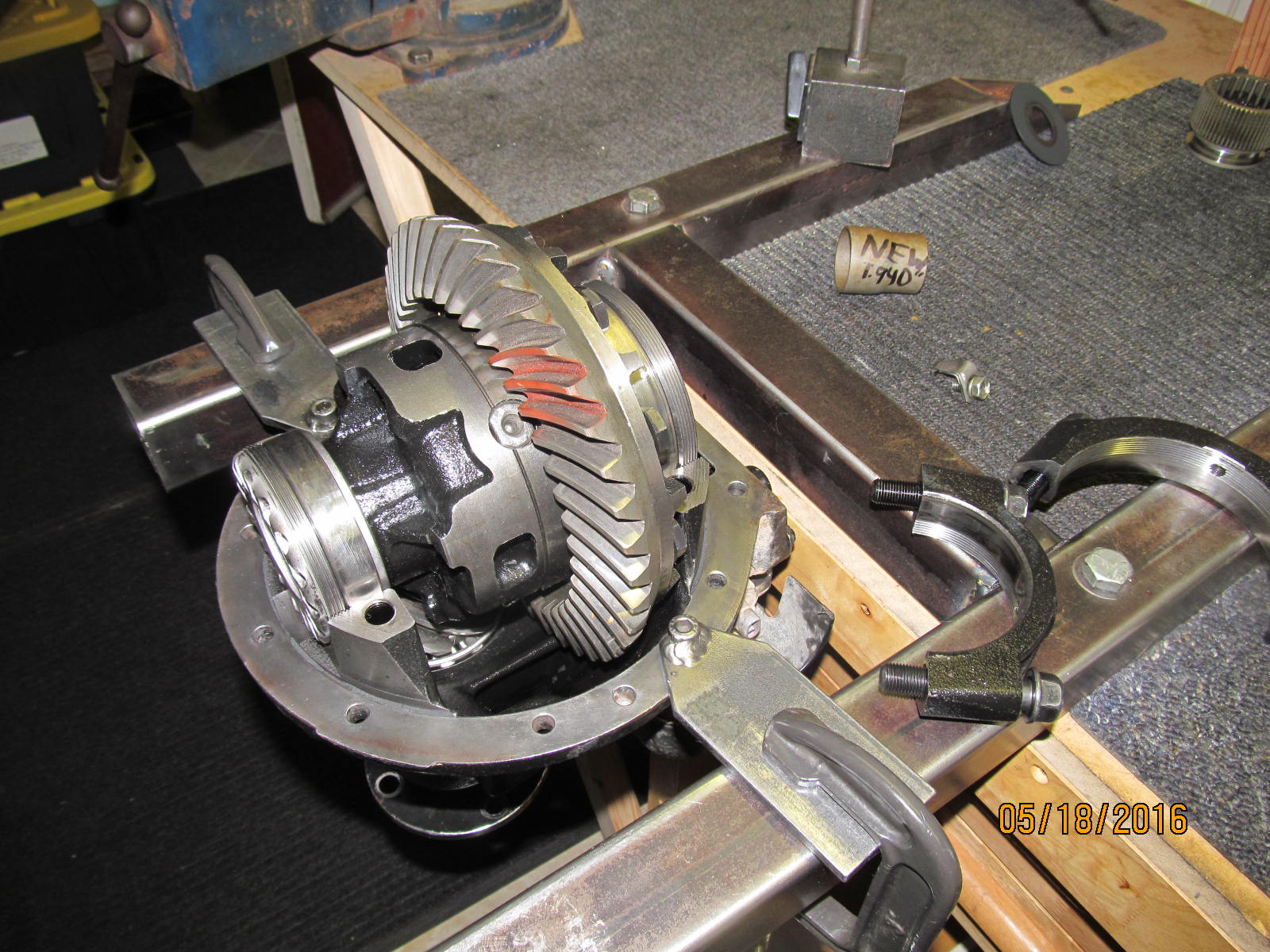

Aaron also brought over a donor e-locker to use.

|

|

|

|

The plan is to use a known good used set of 3.73 gears(shown in the background) and examine

the bearings to see if they are re-usable.

|

|

|

|

|

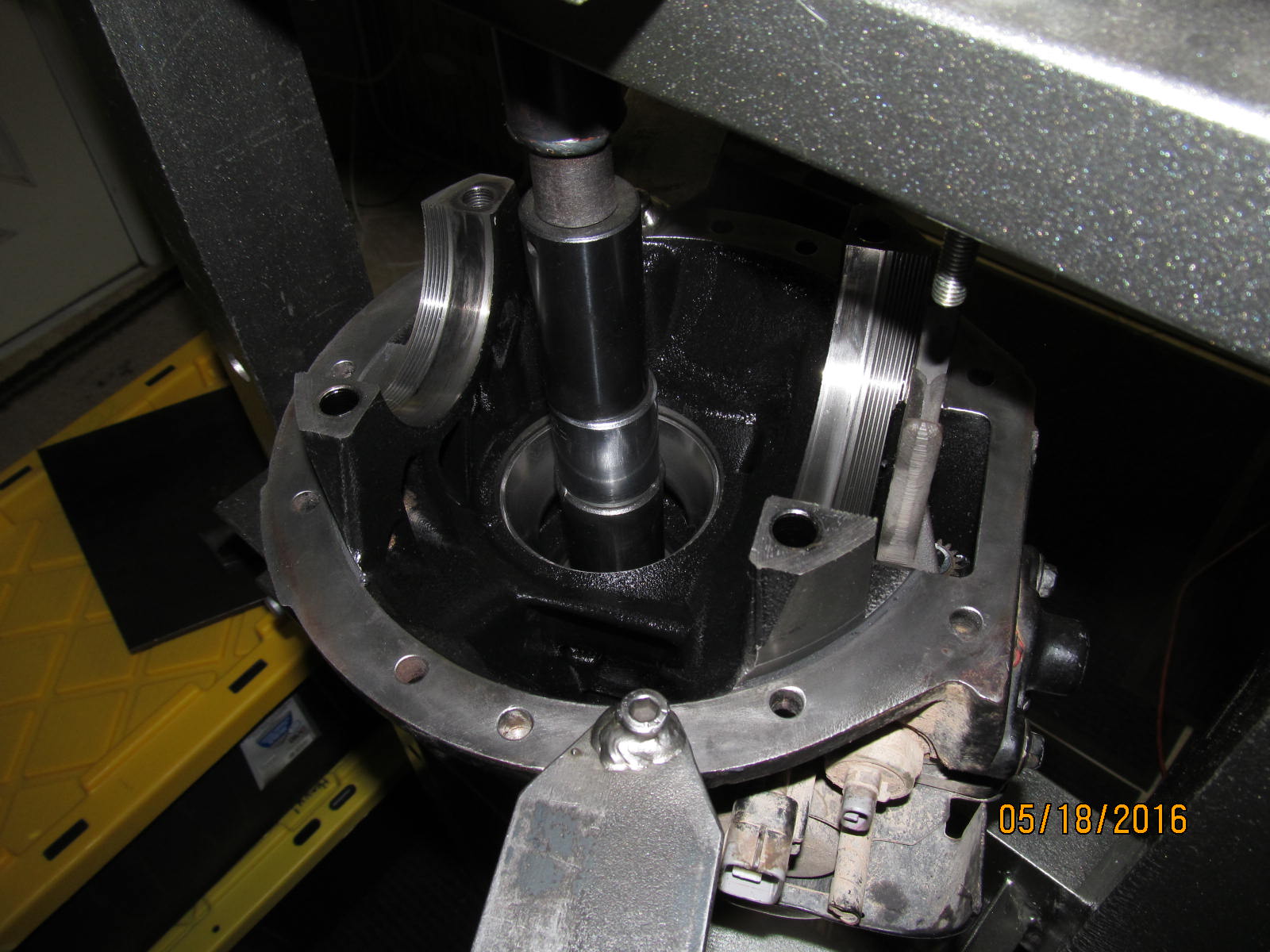

Diff teardown has begun. Pressing the pinion out.

|

|

|

|

|

The outer pinion bearing and race are pitted. A new one will replace it.

|

|

|

|

Easy way to get the race out without even a scratch in the oil retainer is to use a washer

cut in half and a plastic cap.

|

|

|

|

|

Press it out....

|

|

|

|

|

This time the oil seal fell out with the race.

|

|

|

|

|

A new KOYO oem bearing will be used. Oil retainer shown in the background.

|

|

|

|

|

Close up of the outer pinion race.....mucho pitting.

|

|

|

|

|

Old race on left and new on right.

|

|

|

|

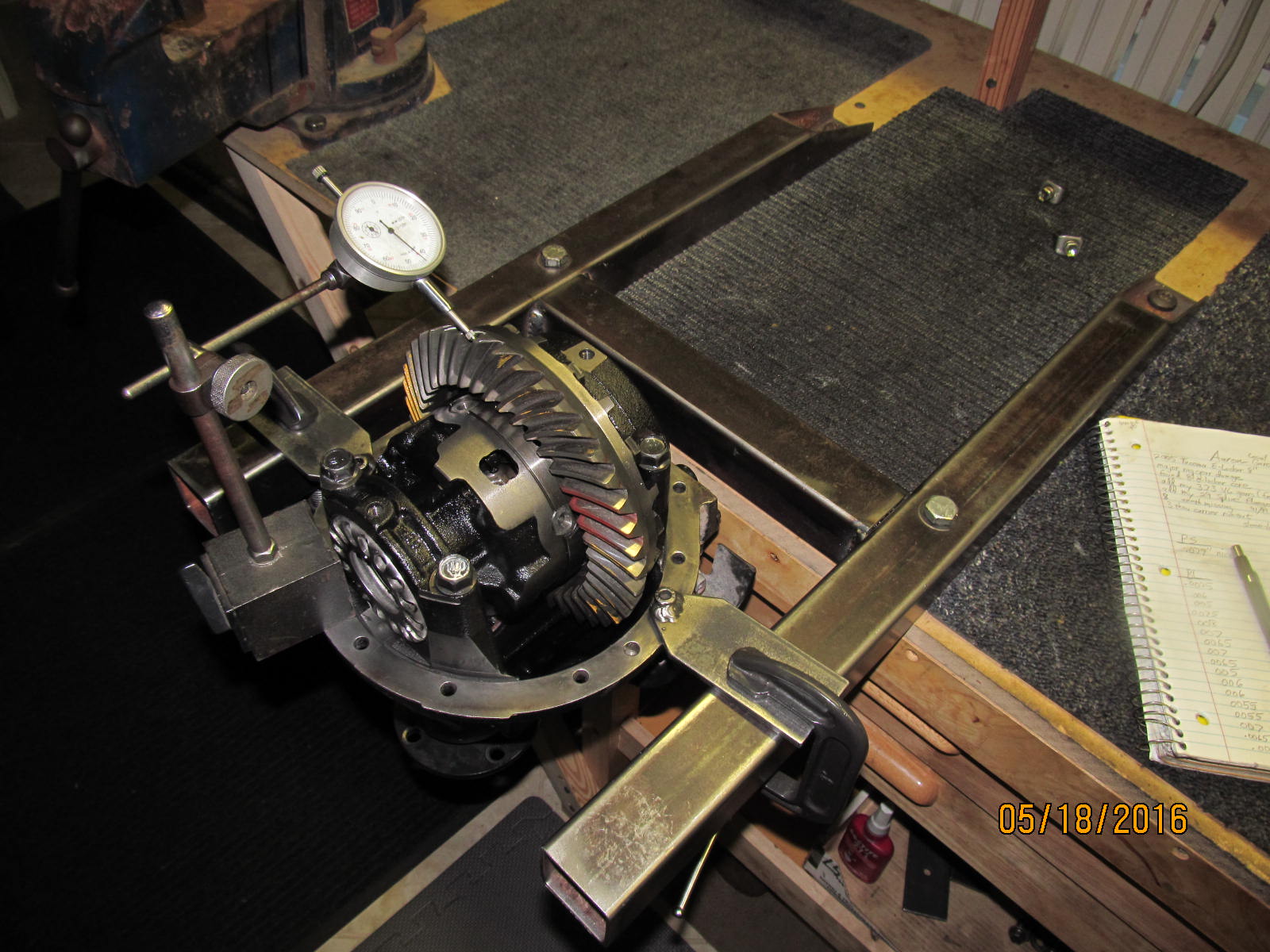

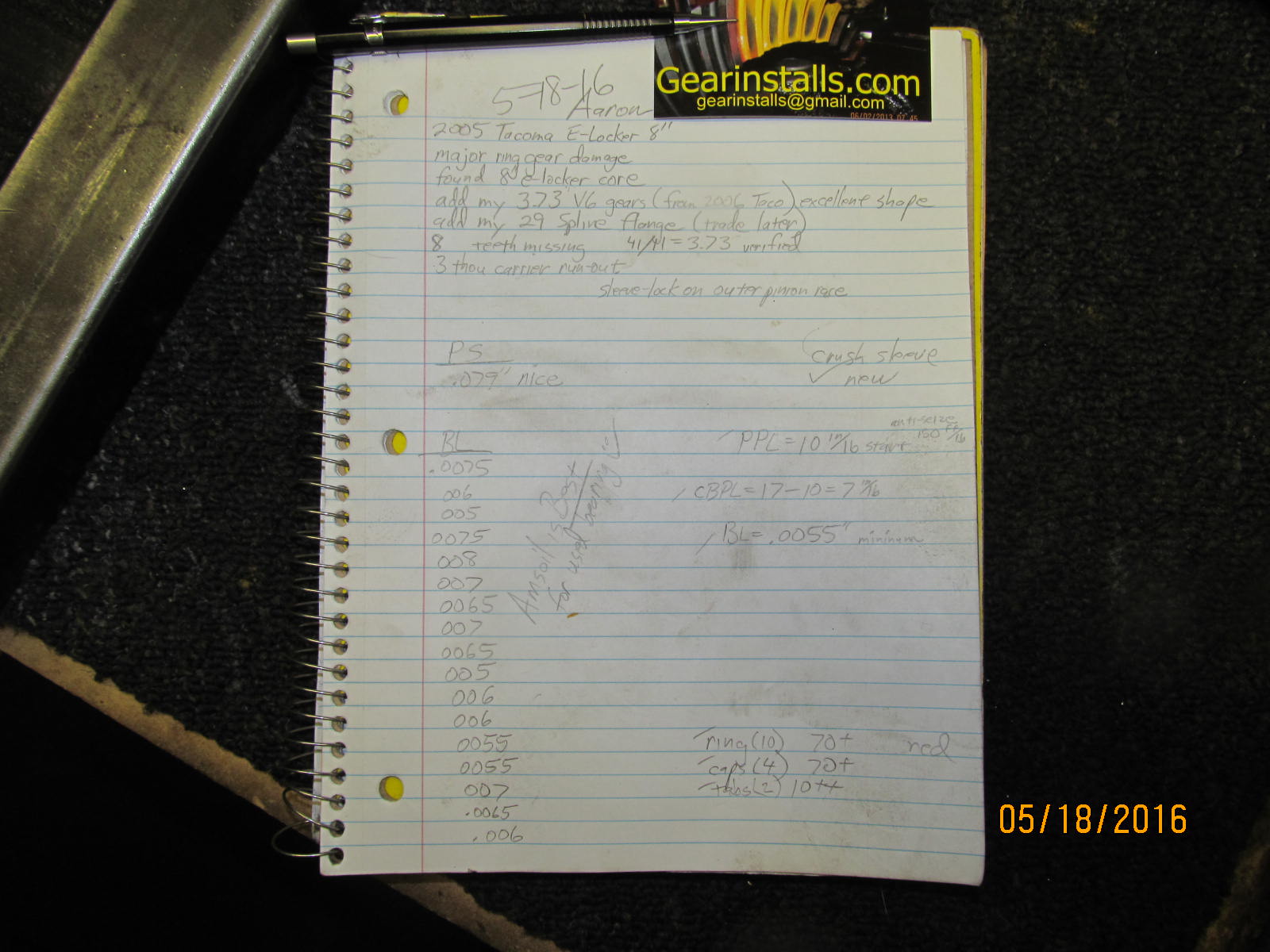

Run-out was checked with a dial indicator and was ok at .003". This is something that should

always be done when broken teeth were involved beforehand.

|

|

|

|

|

A good, snug fit but the plasic hammer made it all happen. Boiling water not needed.

|

|

|

|

|

Red loctite and 70 ft/lbs.

|

|

|

|

|

The oem .079" shim is re-used along with the used bearing.

|

|

|

|

|

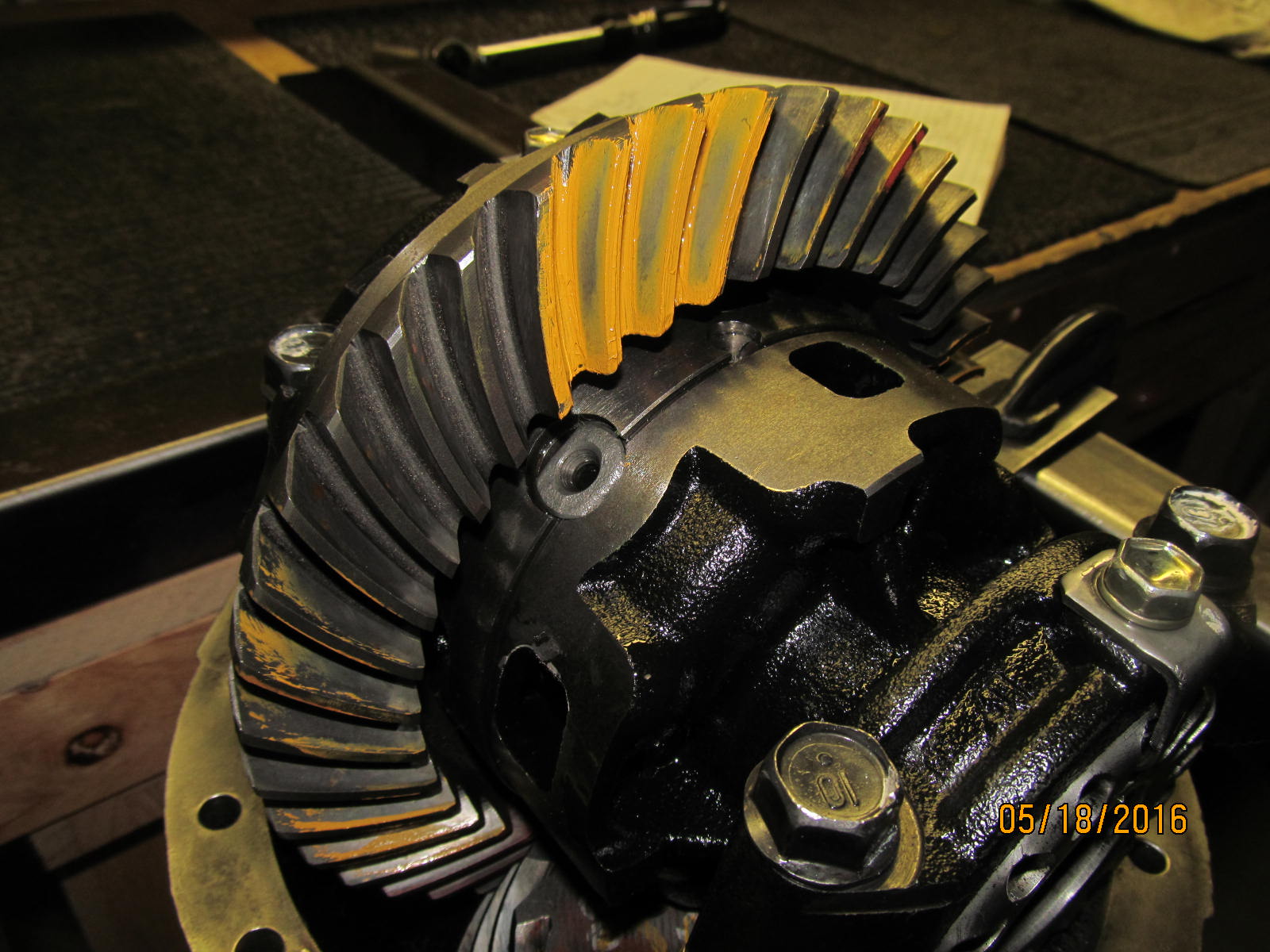

Pattern check so the new crush sleeve is left out for now.

|

|

|

|

|

Caps are then bolted down....backlash set....bearing preload somewhat....

|

|

|

|

|

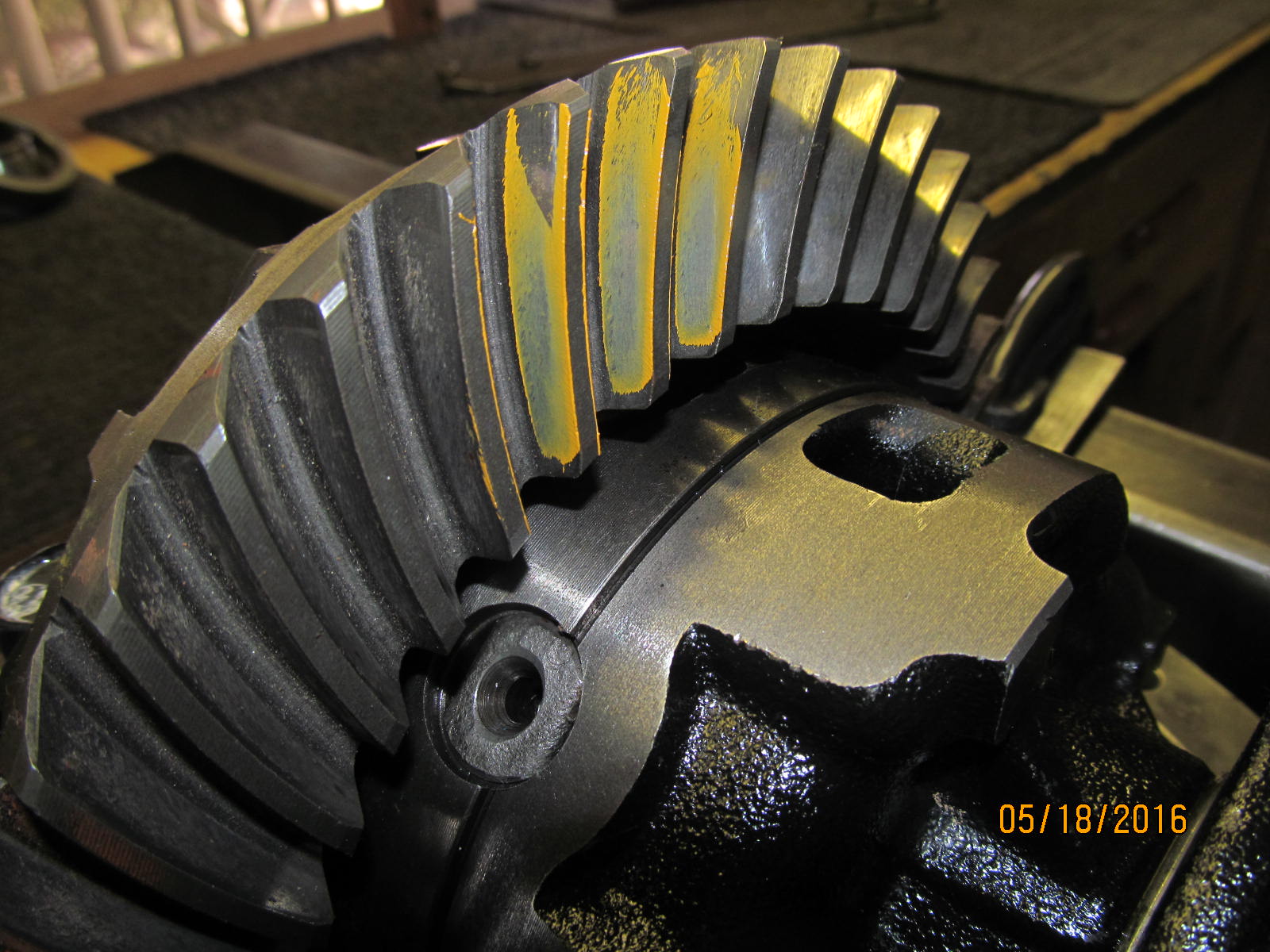

Driveside.

|

|

|

|

|

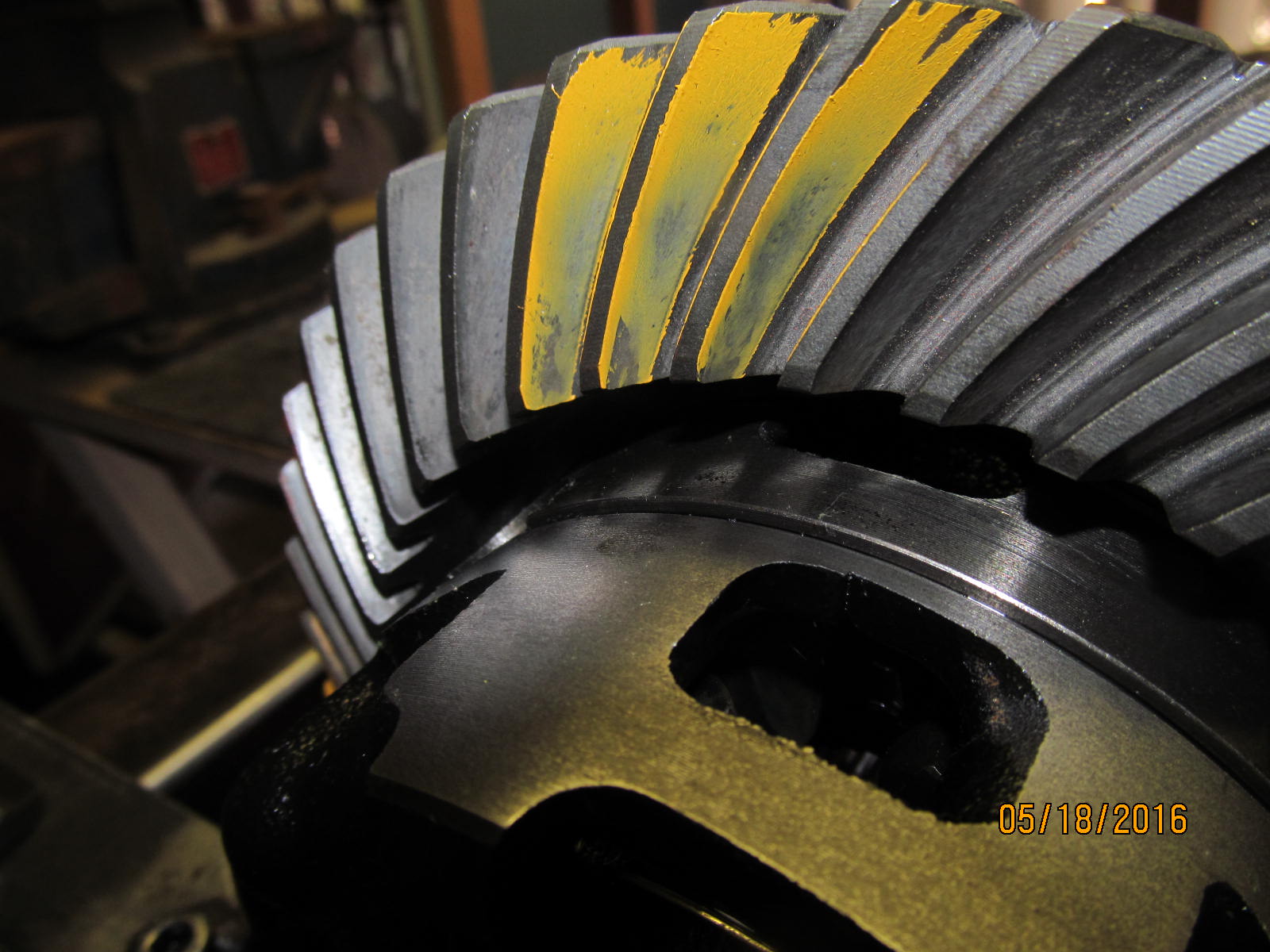

Coast. Favors toe end.

|

|

|

|

|

Driveside on the reverse painted teeth. Looks better.

|

|

|

|

|

Coast on the reverse painted teeth.

|

|

|

|

|

Driveside on the pinion teeth.

|

|

|

|

With the pinion depth now verified, The new crush sleeve can now be installed.

This is a trick I learned from JT's.... Some aftermarket crush sleeves take

a tremendous amount of torque even with aluminum anti-seize. Even a new

nut can receive alot of thread damage. The trick is to use the 12 or 20 ton

press to crush until 95% of the slop disappears. Then remove it from the

press and tighten the nut the last 1/4~1/2 turn until the target preload

is reached. Much less damage to the threads this way.

|

|

|

|

The crush sleeve has just been crushed 98% of the way and now is the last chance to add

some gear oil to both pinion bearings.

|

|

|

|

|

Oil sling and new rubberized 29 spline seal are in place. Anti-seize shown on the threads.

|

|

|

|

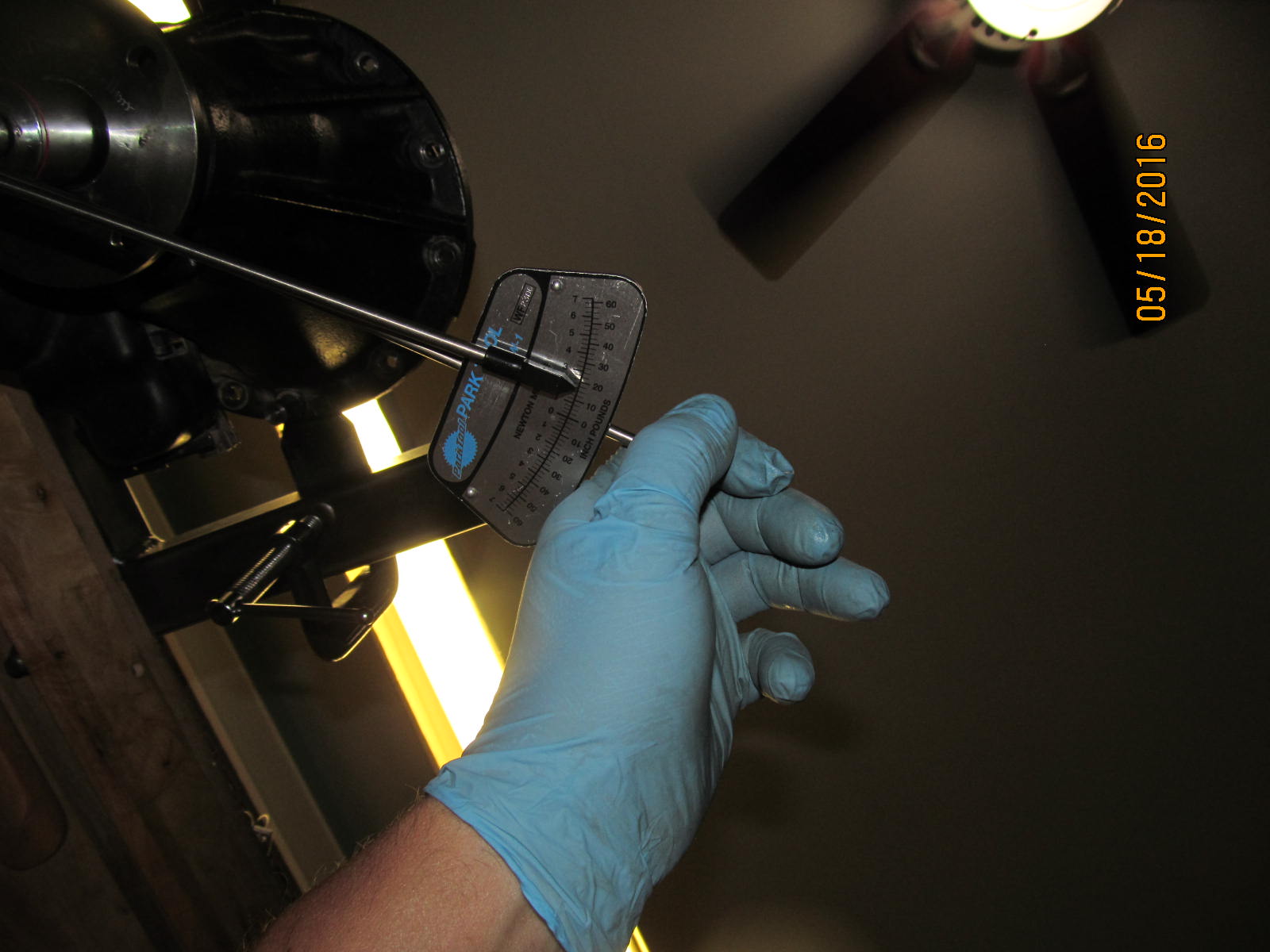

10 inch/pounds noted with the large used inner bearing and small new outer bearing.

DING! the pinion nut and done with this side.

|

|

|

|

|

The 4 bearing cap bolts are now final tightened to 70 ft/lb.

|

|

|

|

|

Backlash is dialed in as well as the carrier bearing pre-load.

|

|

|

|

|

Satisfied with the readings now the lock-tabs go in....10 ft/lb.

|

|

|

|

|

Total pre-load is 17....pinion preload is 10 so that means the Carrier Bearing Pre-Load is 7 in/lb.

|

|

|

|

|

Drive side.

|

|

|

|

|

Coast side.

|

|

|

|

|

Notes taken.

|

|

|

|

|

Ring gear data.

|

|

|

|

|