|

|

|

|

|

|

Steve has a very modded 2002 Taco with dual cases and 37" tires. Here's a link to his build thread. Automatic trannys cushion the torque spikes on all driveline components but, in spite of that, a loud BOOM! came from the rear e-locker while going up a mild dirt hill. |

|

The e-locker case on the right is a donation from Tbob on the TTORA bulletin board. |

|

To the far inside of this sidegear is a 'tear'... |

|

.... |

|

The donor EL case has a number of re-usable parts....and it's a good thing, too. |

|

The donor's sidegear is in good shape here. |

|

Before removing the case, the adjuster wheels are both marked. |

|

YG TV6 529 304...This is a Yukon Gear...large V6 pinion head...529 ratio...classic 304 series unknown build location(J6 perhaps?). So far, I've only seen 1 QC issue in the past with Yukon. |

|

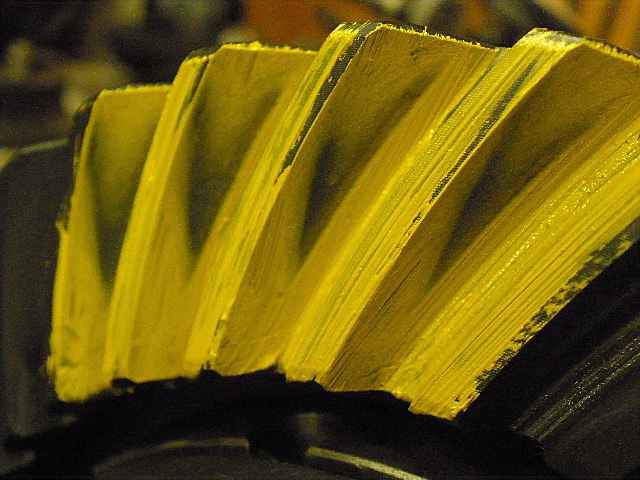

Paint was applied and a pattern check appears to show a deep pattern. This will be left as is. |

|

Coast looks deep also. |

|

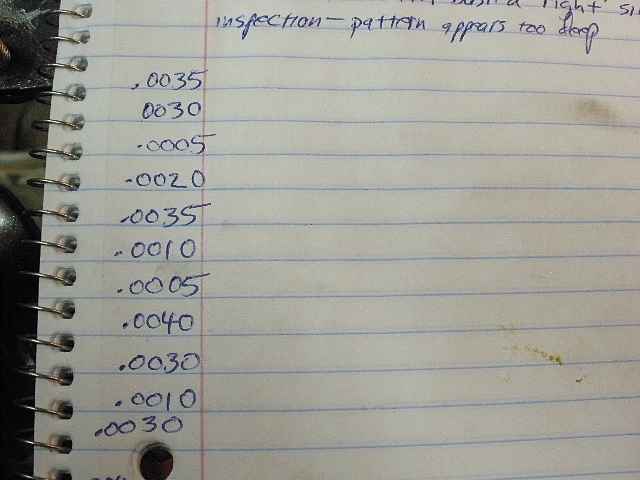

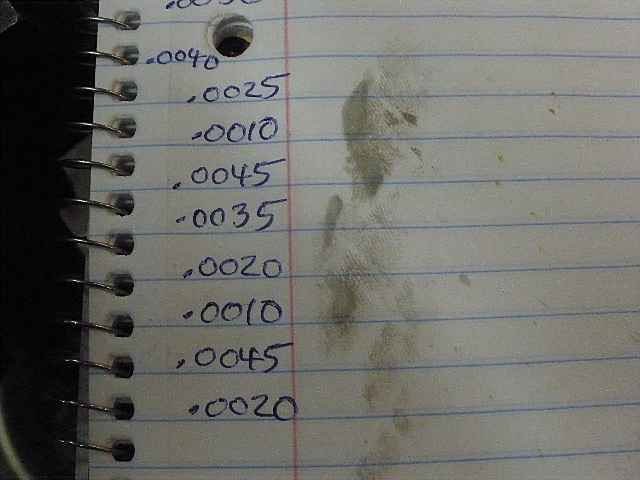

Measurements on every other tooth reveals readings very close to zero lash...see the next 2 pics for measurements. |

|

... |

|

... |

|

Now to remove the bearing caps. |

|

This wheel was never properly meshed...there's an air gap on this corner. This causes a small mis-alignment between race and bearing....and damages threads. |

|

Notice the thread position on this side... |

|

...and how it differs on the other side. |

|

Hard to tell from the photo here but the threads in the carrier are mildly damaged...still appears functional though. |

|

The wheel on the other side had the usual cosmetic damage from being chiseled...it was also 'warped' or bowed so a new one will replace it. |

|

Both of the carrier bearings came off with just my fingers. Luckily, there was no obvious spin damage on the case. |

|

With the case out now I could run a quick pinion pre-load check and there still was a couple of inch/pounds. The pinion end will be left undisturbed. |

|

Back to the EL case, I noted that the ring bolts were only torqued to about 55 ft/lb...and no loctite. |

|

The ring is removed and the surfaces are checked with a file. No unusual high spots. I will Loctite and torque them to 75 after I repair the innards of the EL case. |

|

On the left is the good donor sidegear. The 8 bolts are removed from Steve's case on the right. |

|

Here's the damage...the sidegear sheared in two. I'd hate to think that this is the weak point in the e-lockers. Perhaps it was just a coincidence but the same exact day that Steve did this to his EL, another buddy of his did the same exact thing to his EL on the Woodpecker trail in Florence, AZ. |

|

This is the sleeve part of the sidegear that the axle splines slide into. The spun damage here indicates that the case might also have damage... |

|

Yes, the case has damage...fortunately, the case half on the donor is like new and it can be substituted in. |

|

The other sidegear on the driver side had some chinger damage and again, the donor sidegear on the right is in perfect condition and will be used. We think that this damage might be the result of the locking fork being offset 1 tooth and perhaps was not allowing the 2 sets of splines to separate a good distance. Steve is aware of this and will investigate it. |

|

So far, these are the 3 things that are being replaced....good thing nothing else is damaged because the donor case has run out of good parts :) |

|

The case is re-assembled and the 8 bolts are set to 50 ft/lbs. |

|

Sleeve retainer would be used on the both of the old carrier bearings. |

|

The case is loaded into the carrier with the wheel adjusters set snug while the retainer compound is drying. Now's a good time to check run-out which was ok at .002". |

|

I started to think about it and consulted with Steve with the recommendation that we use new carrier bearings. I was more concerned about the old ones self-destructing due to pitting and the heat marks on the races. The old bearings were removed before the sleeve retainer had a chance to set up. |

|

New ones were tapped on with the addition of a Permatex version of sleeve retainer. |

|

Red Loctite and 75 ft/lbs on the 10 ring gear bolts. |

|

75 ft/lbs also on the bearing cap bolts. |

|

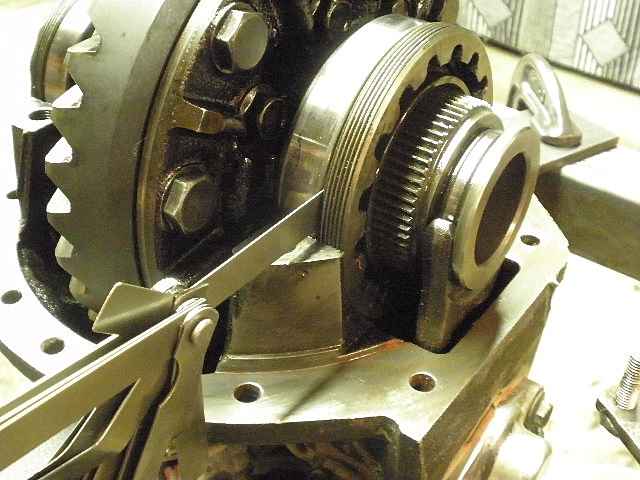

The adjuster wheels are tightened on both sides while monitoring the backlash. |

|

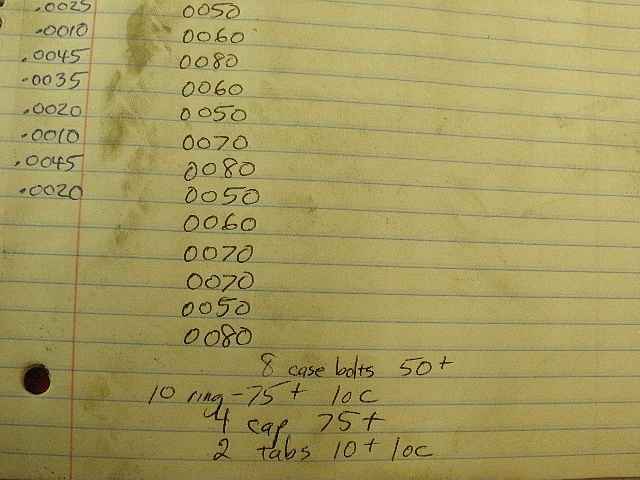

Backlash is measured on every other tooth. It varied from .0050 all the way up to .0085 which is more common than not. |

|

When I was satisfied with the CBPL and BL, then the tab bolts could be loctited and torqued to 10 ft/lbs. |

|

No significant change with the drive side even with the increased BL. |

|

Coast- almost the same as before. |

|

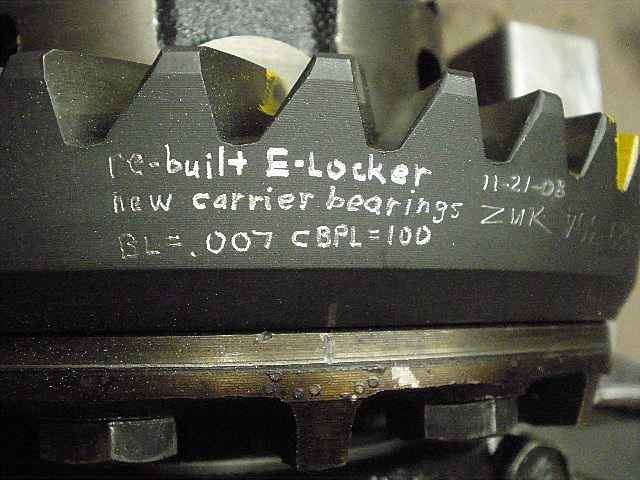

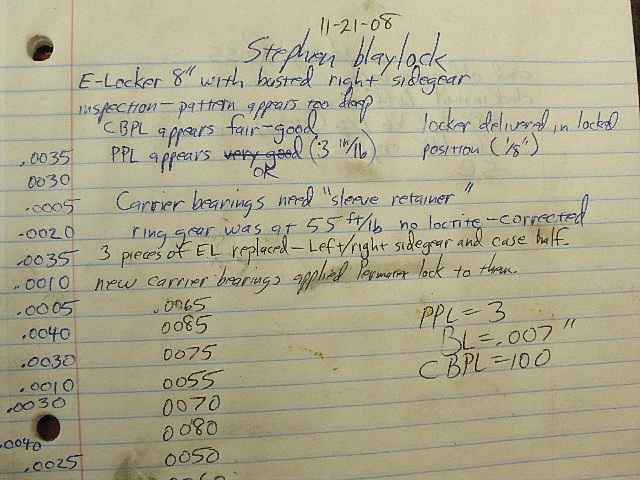

Some documentation... |

|

These are all the parts that were replaced. |

|

Notes during the install... |

|

Done. ZUK |

|