|

Getting ready to put in a used 3rd that you just bought from a BBS?

.......or maybe just took yours out to put a lunchbox locker in? Well then, before putting

it back in now is a good time to crank those carrier bearing adjuster rings as tight

as you can. That would be about as hard as you can with a 12" long wrench. A differential

with 100,000 miles will have somewhat loose carrier bearings just through simple wear and tear.

By "re-energizing" the Carrier Bearing Pre-Load (CBPL), the effective strength of the

ring and pinion can be doubled. No actual need to actually measure backlash....just mark the

present position of both rings and tighten each an equal number of notches. Many times, it

is possible to get 6 notches from each side. That's a bunch. Now go pull your buds out

of that mud pit with your gears and don't worry very much about busting teeth. Start worrying

about those 30 spline axles ;)

In the above pic, I can get the ring to rattle back and forth with just my pinky.

This means basically there is no CBPL to speak of. No special tools needed to fix this....just

tighten both adjusters the exact same amount. Tighten them 'til you can't physically

tighten them anymore.

|

|

|

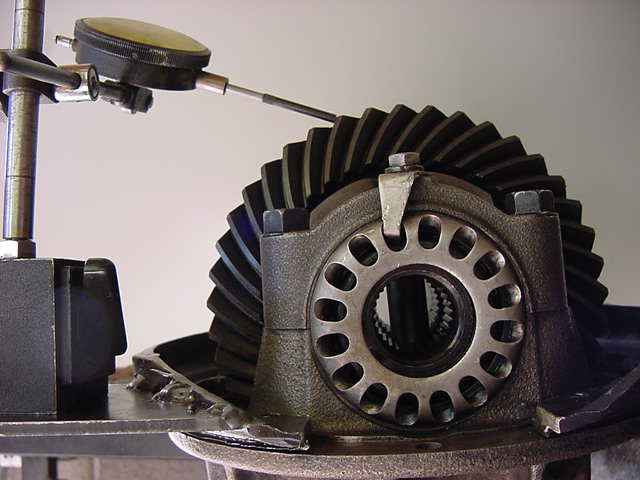

Using a dial indicator is not mandatory for this procedure but what the heck.

Consider this a lesson in how to properly measure backlash. Here, I've lined

up the dial indicator to be at a right angle to the axle centerline. This is

the wrong way.

|

|

|

This is the correct way...set the dial indicator at a right angle to the

curvature of the tooth surface. This is referred to as NORMAL BACKLASH and

is the way ring and pinion data sheets are specified.

|

|

|

Back to business...Mark the adjuster ring on both sides as shown above.

Remove the lock-tab bolt.

|

|

|

Turn the adjusters one or two notches at a time (to both sides). Use

light hammer taps on the right spot while turning the

pinion like I'm doing. This will "equalize" the bearings on both sides.

Tighten then equalize again and again.

|

|

|

Both adjusters have been rotated exactly 6 notches before I felt a pain

in my groin. I would imagine that most other diffs would take less than

6 notches as this one I am adjusting was looser than loose to start with.

|

|

|

I used my torque wrench as a check and it took over 80 ft/lbs of force before

the adjusters started to move.

|

|

|

This is the sweet spot where I was tapping it with the hammer. Not directly

over the threads for obvious reasons.

|

|

|

Torque the cap bolts to 70 ft/lbs and tighten the lock-tab bolt to 10 ft/lb.

Use Loctite if unsure. This diff will now have very little

ring gear deflection which will allow greater torque strains without loosing

teeth.

|

|