|

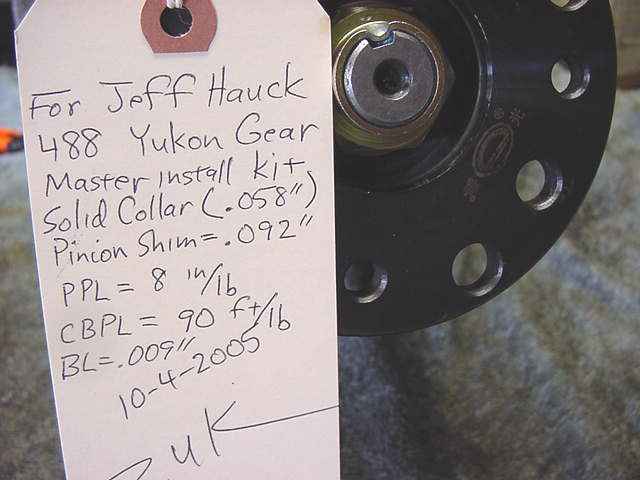

Initially, I wasn't going to do this install as Jeff had purchased a Genuine Gear. After

we discovered that they had slipped in a higher quality brand into the box then I was

ok with it. Jeff wanted it done right so he supplied the master kit, solid collar and

a new flange.

|

|

|

The ring gear had the "304" on it (Yukon). Nice to have a camera with a decent macro. ;)

|

|

|

Tapping in the new races....(with a soft steel punch).

edit---Best to stay away from all punches...

use an old race to evenly "pat down" the new race.

Using a punch could result in "oscillating" pinion

preload measurements with the torque wrench.

1-8-2011 ZUK

|

|

|

With the help of my machinist dad, I transformed a cheap Harbor freight bearing

separator into a special purpose bearing puller.

|

|

|

This allows me to remove even the most stubborn bearing and no damage...to the tool

or the bearing.

|

|

|

Micrometers can be had for as cheap as 20 bucks.....a must have for its precision.

|

|

|

The solid collar is especially important in rear end use. I used .060" worth of

shims here.

|

|

|

This resulted in a nice 10 in/lb of pinion drag.

|

|

|

New Timken carrier bearings.....

|

|

|

Best carrier bearing puller I've ever used. The pointy shape of the fingers

and the strap in the middle that pulls the legs together is a nice design.

|

|

|

Almost ready to do a pattern check....just need to preload the carrier bearings some...

|

|

|

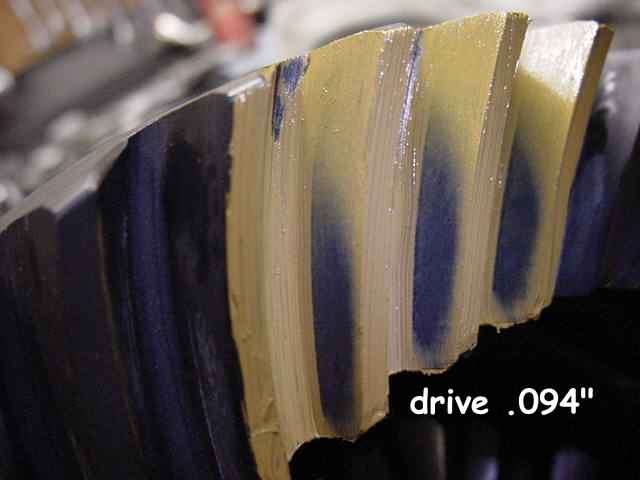

too deep...

|

|

|

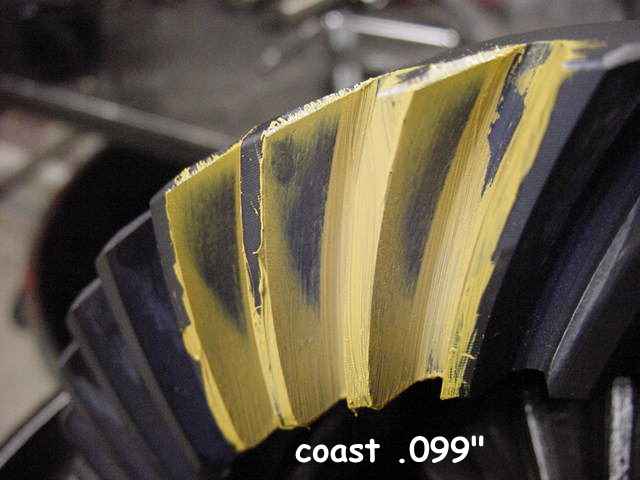

the coast agrees with that...

|

|

|

still a touch deep...

|

|

|

|

|

|

Everytime I changed the pinion shim, I made use of the press. I could have

used a hammer to beat the pinion shaft out but it might have dented the outer

pinion cup.

|

|

|

I got a little carried away and now the pattern went shallow.

|

|

|

|

|

|

Good pattern with .091" pinion shim

|

|

|

coast looks nice.

|

|

|

I might spend 20 minutes or more getting the backlash dialed in and some strong

carrier bearing pre-load.

|

|

|

Done! :)

|

|