|

|

|

|

updated 8-4-2011 7-12-12 3-4-14 8-25-19 7-21-21 |

|

If I was attempting to do my own Toyota install then these are the tools I would want. I show the tool, I show

it used in a typical application, and I show a bargain place to get it from. The above carrier bearing puller

is a must-have tool on my list. The best price I've seen in the past was $49 or $59

but googling it I came up with this...

|

|

OTC-4520 shown in operation. |

|

Another must-have tool is the monster bearing splitter. There are smaller bearing splitters out there for as cheap

as $20 but they do not get into some of the tight places that this one does. Here's the best price I've found...

|

|

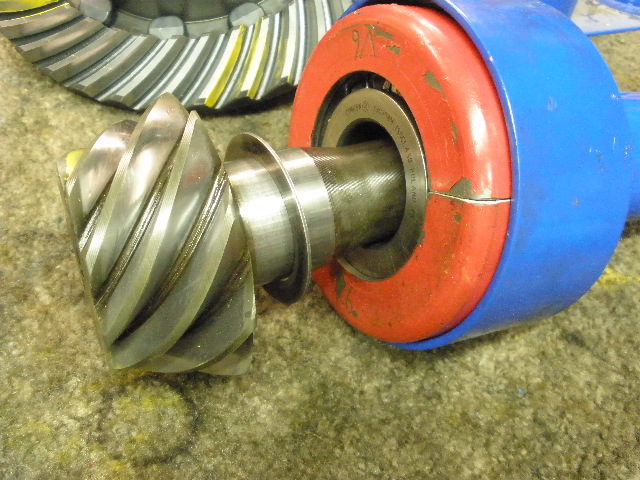

OTC-1130 shown removing a V6 pinion bearing. |

|

If the above bearing splitter and side bearing puller are purchased then it's unlikely that this carrier/pinion bearing

puller will be needed. I have never needed to used it on carrier bearings...and only perhaps a dozen times on certain

pinion bearings. This tool is a low priority on the list of "needed tools" for the average Toyota gear install. It's

kind of 'pricey' also.

|

|

....................... |

|

... |

|

... |

|

... |

|

This is a high priority tool also...it takes 95% of the work out of pressing bearings on and off. A 12 ton is

more than enough press for any Toyota gear install. For me, it's kinda nice to have 2 of them...each set up

for a different operation. :) Harbor freight sometimes has them on sale for as cheap as $99 plus about $12 shipping. This

is what they have going now...

|

|

Another must-have measuring tool are 6" calipers...also, micrometers are an equally good investment. One must be able

to accurately measure pinion and solid collar shims to know where it's at

and where it needs to go. Harbor Freight has some great deals...

|

|

A must-have tool...needed to measure the critical backlash. Doing it by feel just does not work in real life.

|

|

Dial indicator with magnetic base shown measuring backlash. |

|

Another must-have tool...a sensitive 60 in/lb beam type torque wrench used for critical pinion pre-load measurements.

|

|

A TW-1 is shown measuring pre-load on the bearings. There are 2 ways to measure pre-load....rolling and start. I measure start torque now because the Toyota FSM only specs START. Start is easy to measure also. From a no movement point, slowly increase the push on the torque arm and note the maximum reading before the rollers started to roll. Start-up is always higher than rolling torque....and can vary quite a bit. |

|

These 2 are almost must-have tools...it's needed for torqing ring gear/bear cap/lock-tab bolts to their proper specs.

Husky brand(Home Depot) has a lifetime warranty much like Craftsman at Sears and these cannot be purchased on-line.

They go for about $50 each, I believe. They work well for me. |

|

Not exactly a must-have but an electric impact really is a time saver. This is the model I use and I am 100%

pleased with it's performance. I found a great deal on them here...

|

|

There's many other common tools that are used for the casual gear install but looking at the top of my workbench, these come to mind. The Dremel tool on the left is nice for marking and with the tiny cutting wheel it can be used for cutting old bearings off. The hammer is almost always in my hands during the gear install. Red Loctite and anti-seize are very important. The soft harborfreight chisel is really handy for seal removal and for starting the pinion races into the carrier pinion bores. And, of course, how would one check the pattern without a good yellow paste? The yellow paste always comes in the master install kits. It can also be found in a large tube at the Chevy dealership...just go to the parts counter and ask for the gear marking compound. |

|

I made my own spanner wrench for properly tightening the adjuster wheels that press against the carrier bearing (CBPL). I bought the flat-stock steel (1.5"x18"x.188") at Home Depot and drilled/tapped 2 holes near the end. The left end shown is used for the 4cyl/V6 wheels and the right side has a slightly wider spacing and is used for the ARB wheels that they supply. |

|

For the usual 4cyl/V6 applications, the center/center dimension should be as close to 2.5" as possible. Grade 8 5/16" fine-threaded bolts are preferred....3/4" bolt length is good. |

|

I chose to tap and thread the steel flat-stock but it could have also been welded in place. |

|

If it doesn't fit just right then a flat file can rub some of the offending threads off until it does.

A commercial "spanner socket" for this 4cyl/V6 application can be had from here

|

|

The other side of my spanner wrench has the extra hard allen heads welded in place. It's nice to have a MIG welder for this :) |

|

These are spaced a little farther apart for the ARB wheel hole spacing(2 5/8" center/center). I also fine tuned the fit by filing the threads 'til they were squarish. |

|

...and a perfect fit in those ARB machined wheels. |

|

The extra-large wheel adjuster used on the 8" Electric lockers require a custom spanner wrench. This one took more time to fab up. |

|

/////// |

|

Center/center dimension is a very wide 3 3/8". |

|

Not a must-have but a good platform to work on the 3rd is certainly nice...like this simple H pattern fixture. Very sturdy and rigid. It fits numerous different models of Toyota 3rds. |

|

How to securely locate the pinion flange in order to crush the crush-sleeves. |

|

Shown in operation. |

|

In the upper left corner of the pic is my pinion seal installer tool made from an old useless flange and an inner pinion race. The rest are various races and bearing parts that are extremely handy at the hydraulic press. |

|

Gear installs go alot easier with a good selection of shims and washers. |

|

................... |

|