|

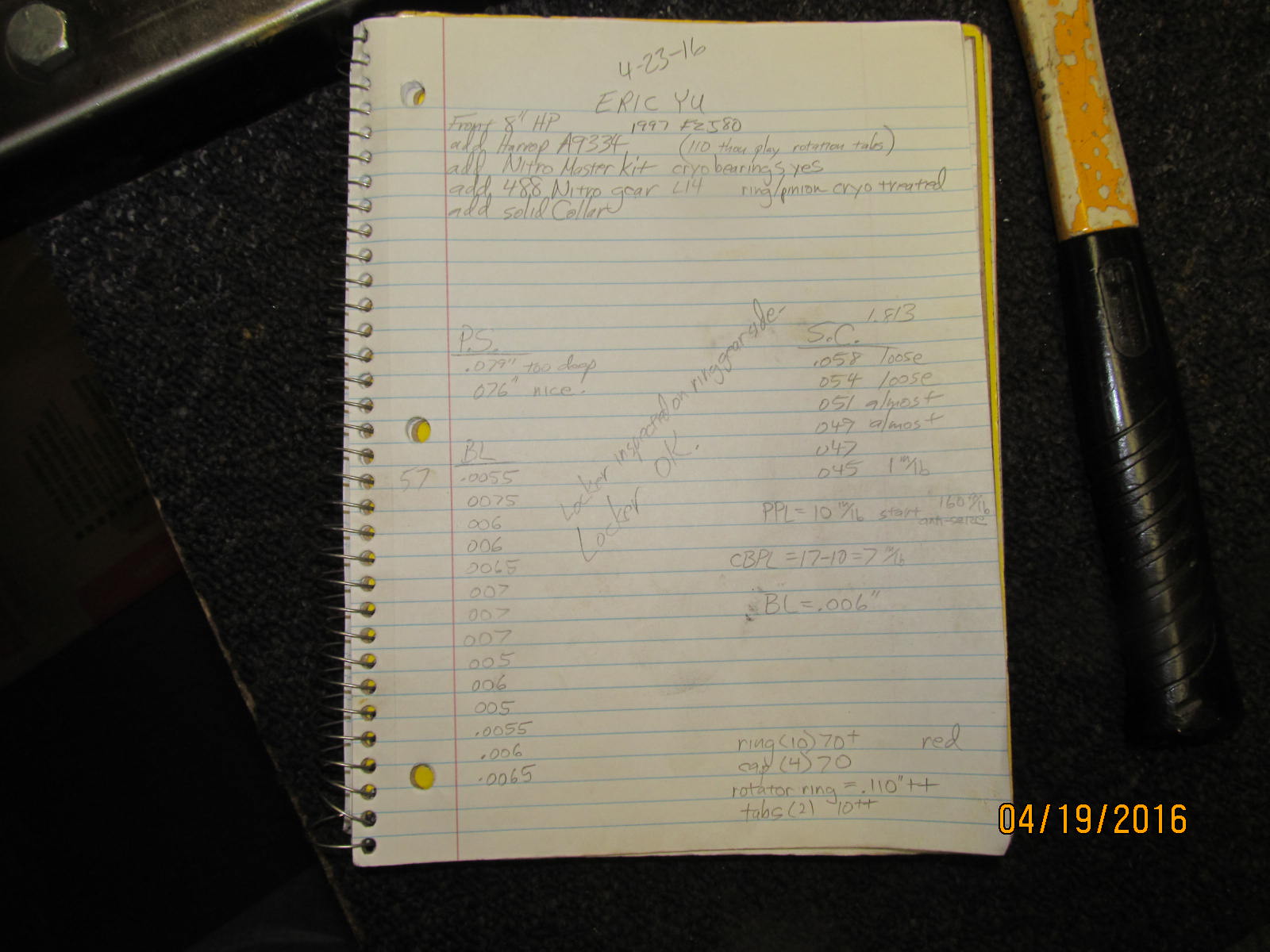

Harrop E-Locker for Eric Y's 1997 FJZ80 FRONT 8" Hi-Pinion Install

|

|

(48 BIG pics loading)

|

|

May 24 2016

|

|

|

Eric's front 8" 3rd is getting the same treatment as the rear....488 reverse cut Nitro gears cryo-treated

by Cryogenics International as well as the bearings also. Since the pinion is the larger

29 spline shaft means that a 29 spline flange is needed to mate with it.

|

|

|

|

Harrop e-locker 99-ELKR9334-00

Contact Ward Harris (National importer/authorized dealer for Harrop) at 1-800-224-7801

or email info@cruiserbrothers.com

|

|

|

|

|

The large inner race can be tapped out with a hammer and chisel.

|

|

|

|

The oil retainer, which is directly under the small outer race, is easily damaged if the chisel is used.

But a simple tool can be made with a big washer cut in half and that just right sized plastic cap.

Scott Szymanski, down near Tucson, emailed me this idea. He's accustomed to making his own tools for

the industrial differentials he works on. This is just a 2.25" diameter washer cut in 2 and is used

to remove the outer pinion race without any damage whatsoever to the oil retainer.

|

|

|

|

|

The plastic cap keeps the washers in place while the race is being pressed out.

|

|

|

|

|

Old races out and now to put the new ones in...

|

|

|

|

The large inner race must be started straight and true. It tends to want to get

cocked sideways if it's not pushed down evenly.

|

|

|

|

|

The smaller outer race is much easier....just tap it down with an old race and a hammer.

|

|

|

|

|

.079" will be the starter shim for the 1st pinion depth try.

|

|

|

|

|

The little 12 ton HarborFreight press takes all the work out of it.

|

|

|

|

|

Assemble pinion end. Just a paint check so no crush or solid collar is needed yet.

|

|

|

|

|

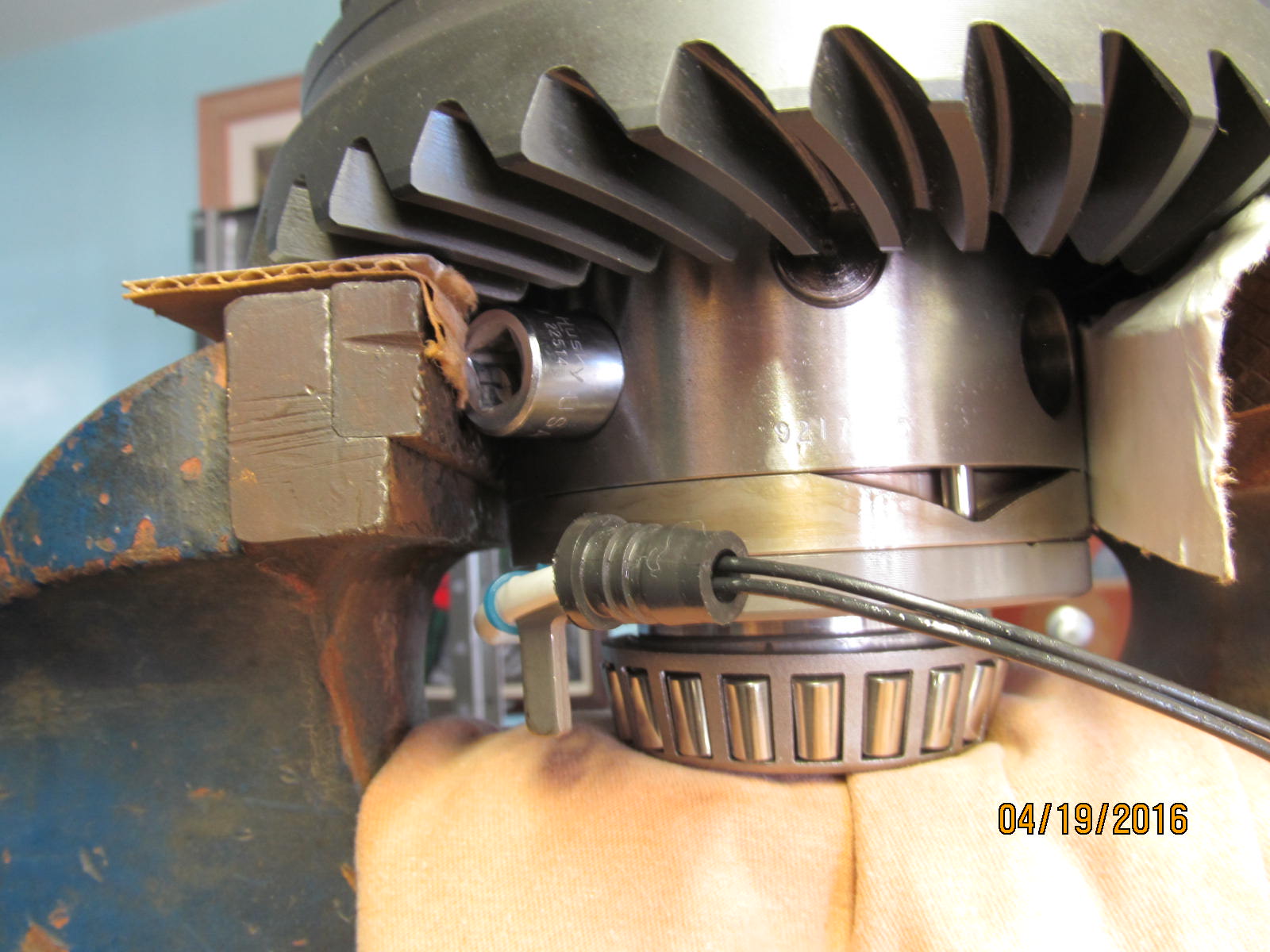

Impact the nut on just enough to get some solid roller bearing resistance.

|

|

|

|

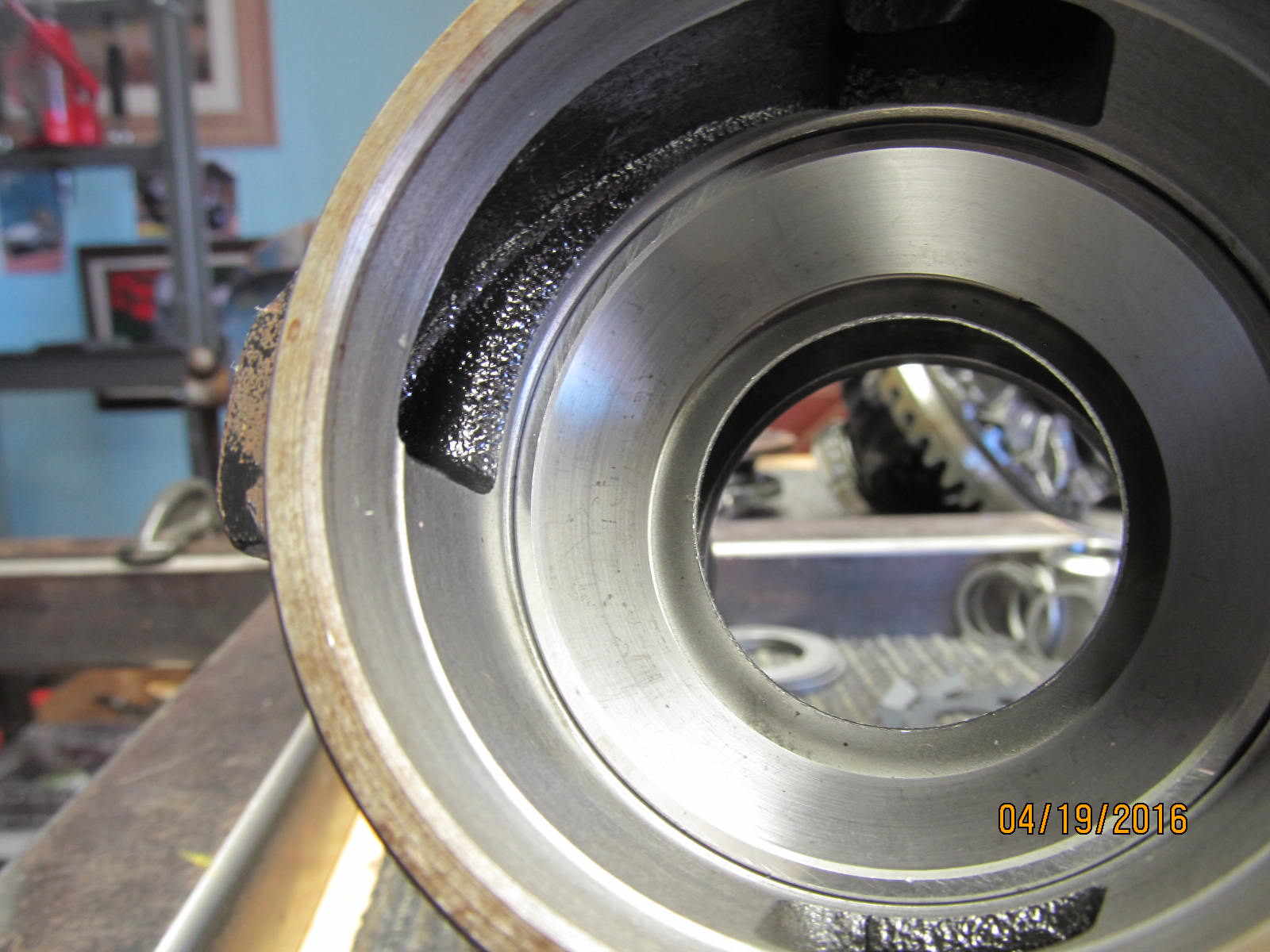

Now to prepare the other end....surfaces are always checked for burrs and bad spots.

As always, I never find any which is good. :)

|

|

|

|

|

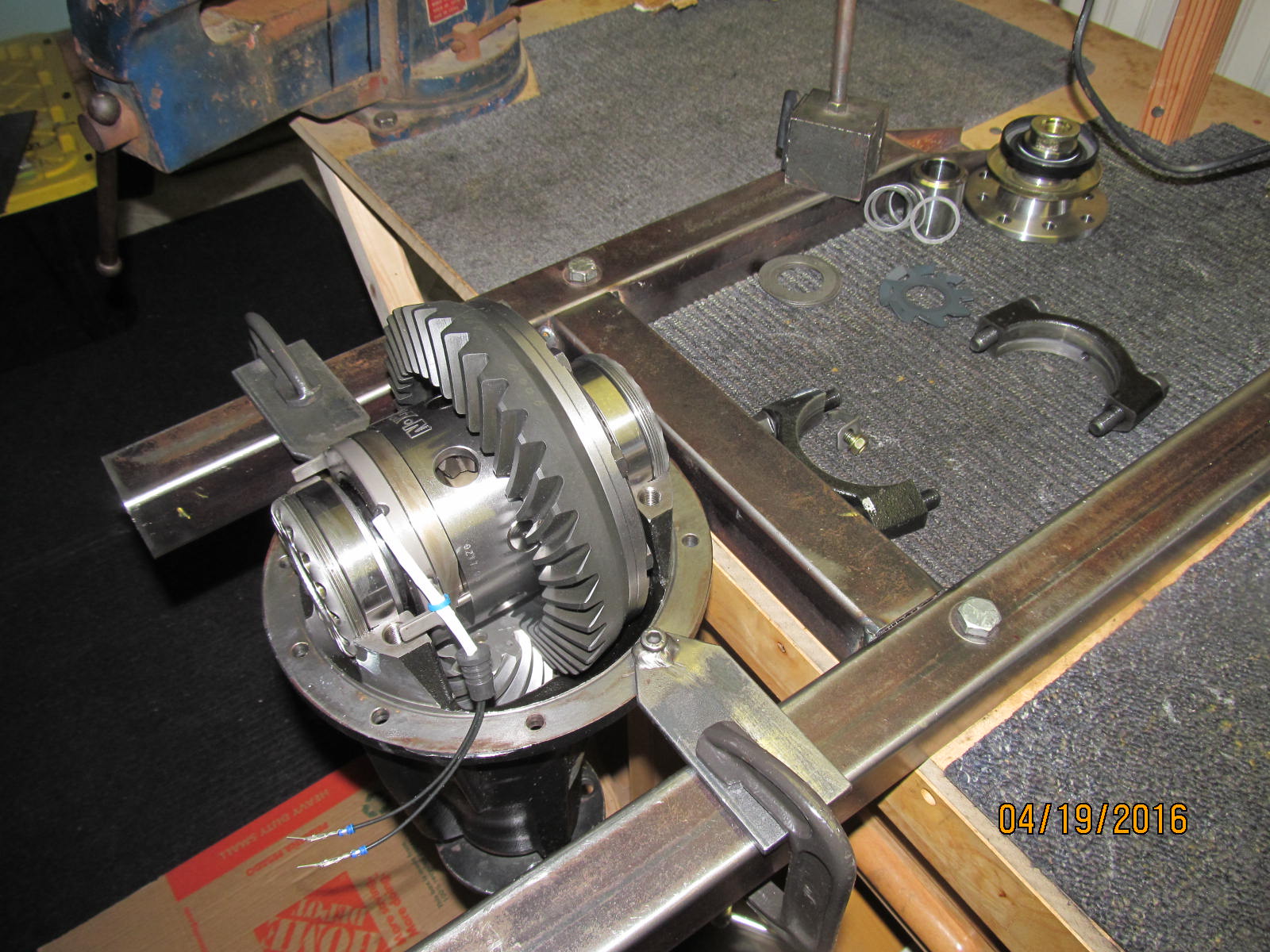

The order of assembly can be "varied like I did here.....I tapped the ring gear in place first.....

|

|

|

|

|

...then decided to tap both carrier bearings on....

|

|

|

|

|

...and then back to the ring and use red loctite and 70 ft/lb to secure all 10 of them.

|

|

|

|

|

An easy way to prevent the carrier from turning and scarring up the case....2 sockets shoved in opposite holes.

|

|

|

|

|

This end complete.

|

|

|

|

|

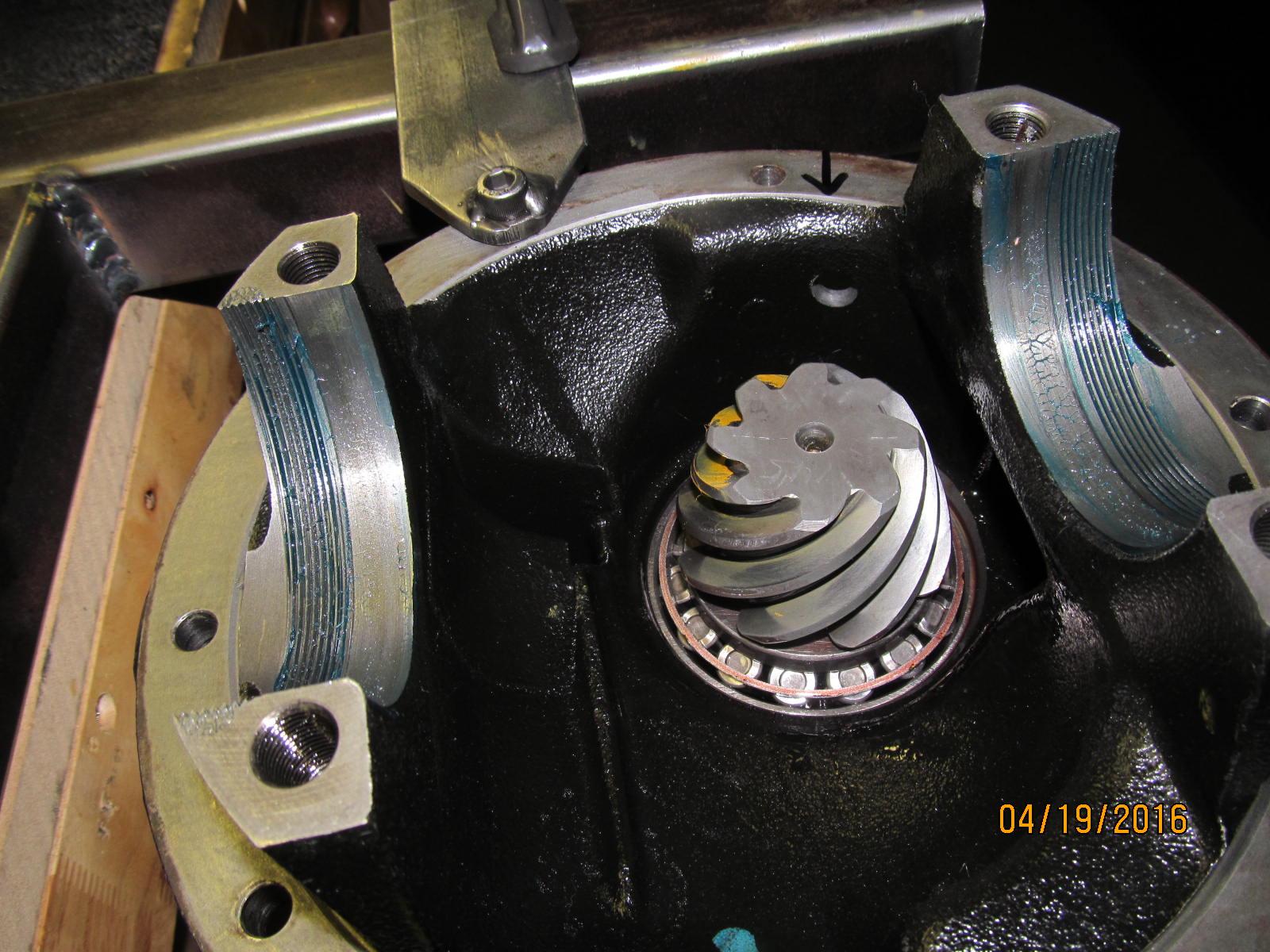

Now to install the Harrop with wheel adjuster in place.

|

|

|

|

It was discovered that the Harrop tabs needed to be bent out a few thousandths first to get the

desired 2 mm of up/down play....then the cap is secured down...then the wheel adjuster is screwed in last.

|

|

|

|

|

The tab bends out fairly easy.

|

|

|

|

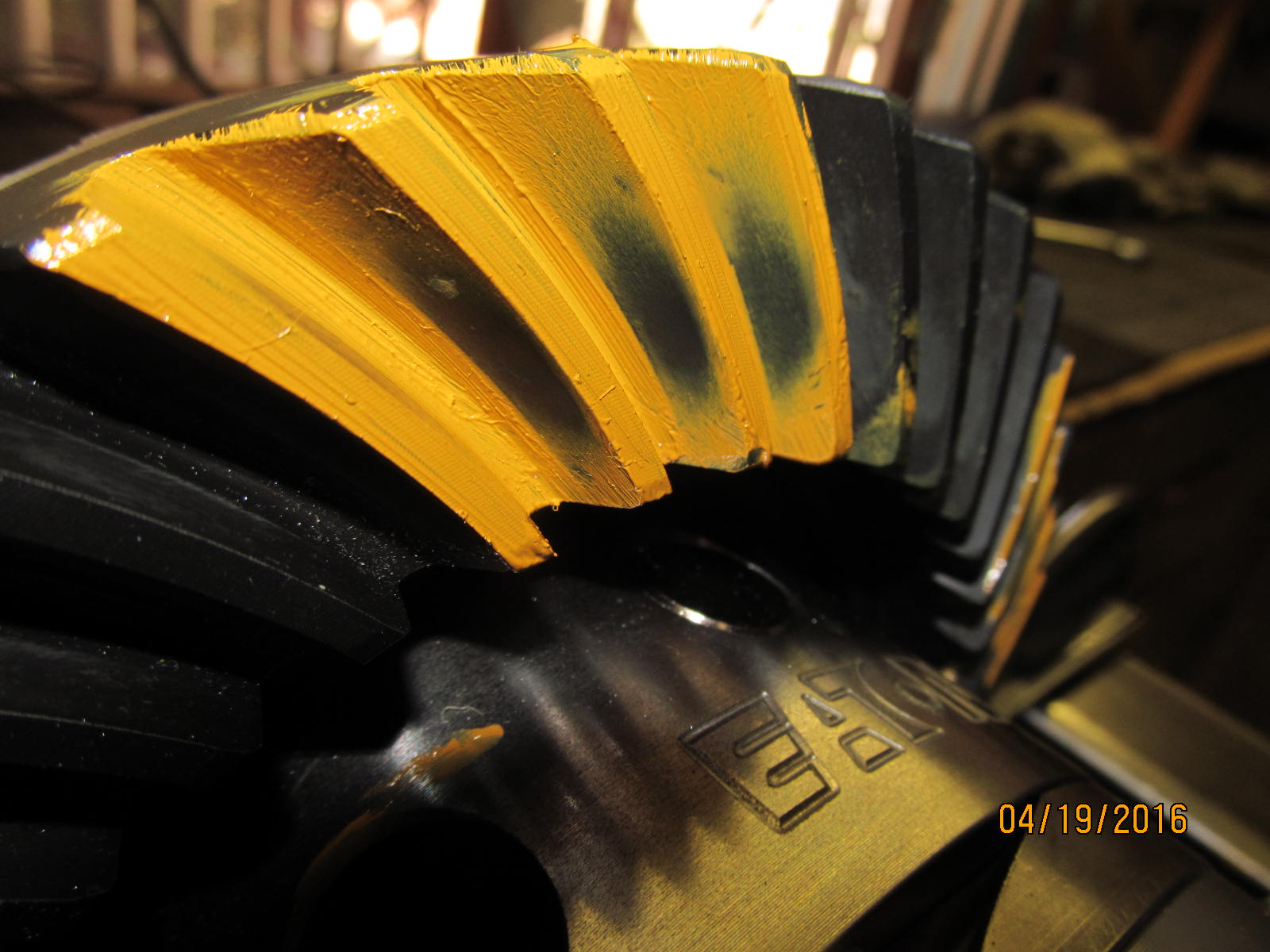

Skipped a few pics but once the bearing cap is back in place and there's about 2mm of up/down play....

and the backlash/carrier bearing preload is set THEN a paint check can happen.....

Looks like the drive side shown above is deeper than I like to see it.

|

|

|

|

|

The coast side appears deep also.

|

|

|

|

And the pinion paint definitely appears too deep as indicated by the comet tail

strongly favoring the outside of the tooth.

|

|

|

|

|

----------------

|

|

|

|

|

Teardown and replace the .079" shim with a thinner .076"

|

|

|

|

|

Re-assemble. Much better. Looks only slightly deep which is my preferred condition.

|

|

|

|

|

Coast looks beautiful. A slight favoring to the toe end and nice depth presentation.

|

|

|

|

|

Pinion has the paint right in the center.

|

|

|

|

|

Nice.

|

|

|

|

Now to dis-assemble and put the solid collar in. This can be a time consumming process.

It was for me because it took 6 teardowns to get this one right on the money.

|

|

|

|

Must use a 1/4" die grinder like I did to get this smaller 27 spline splashguard to fit over the

larger 29 spline pinion shaft.

|

|

|

|

|

The thick grease keeps the garter spring from popping off.

|

|

|

|

|

Last chance for a little gear oil on all related seal parts.

|

|

|

|

Pinion nut has anti-seize on the threads and is tightened until a nice 10 in/lb is measured.

Ding! the nut and this end is complete.

|

|

|

|

|

.453" hole is drilled with pinion on the high side so no shavings fall on the bearing.

|

|

|

|

|

-----------------

|

|

|

|

|

For me, it worked out best if I saved the wheel adjuster til last.

|

|

|

|

|

------------------

|

|

|

|

|

70 ft/lb

|

|

|

|

|

2 mm of up/down play is verified.

|

|

|

|

|

------------------

|

|

|

|

|

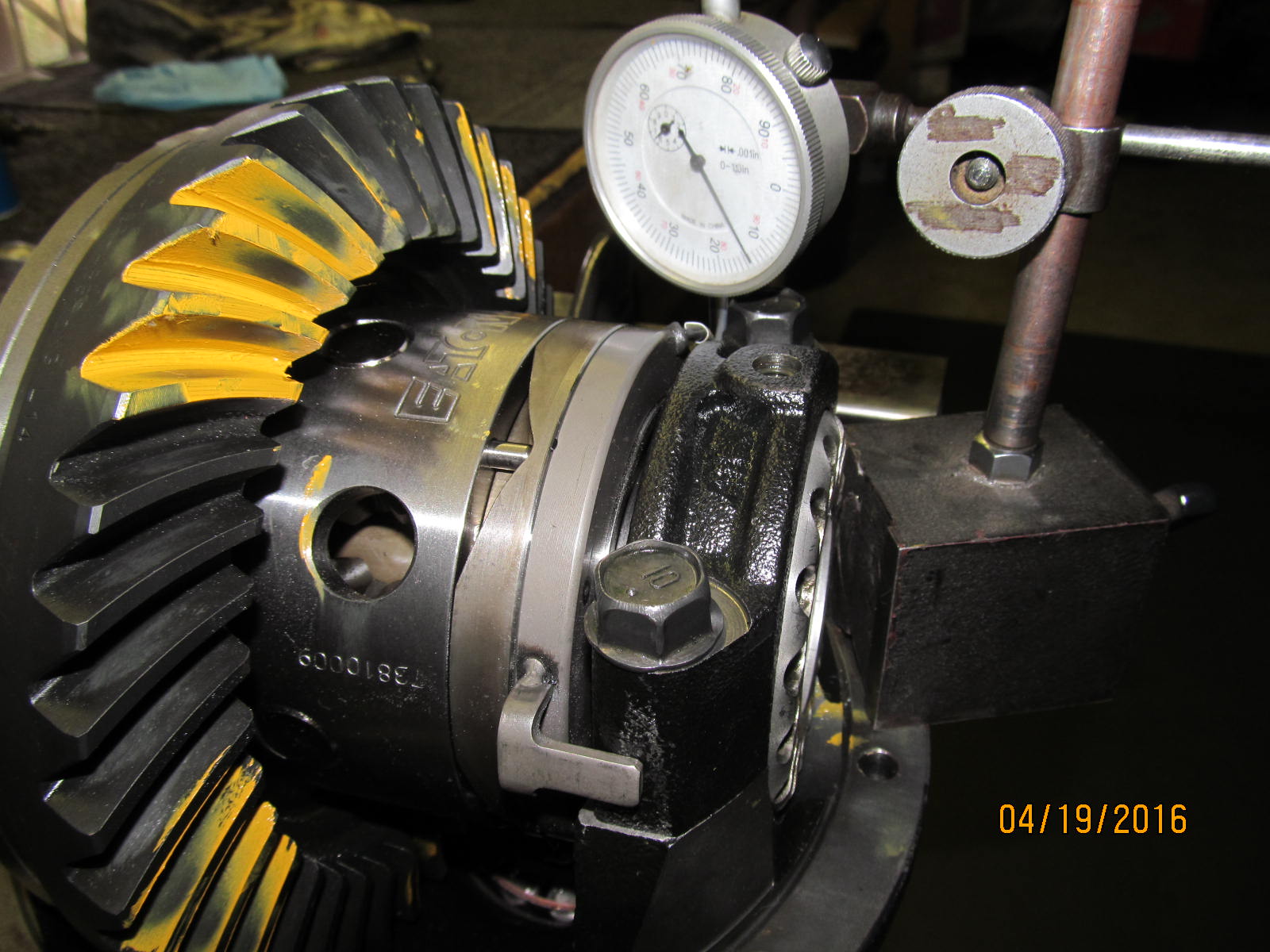

Backlash was recorded on about every 3rd tooth (14 places).

|

|

|

|

|

Combined total preload is measured....17 in/lb.

|

|

|

|

|

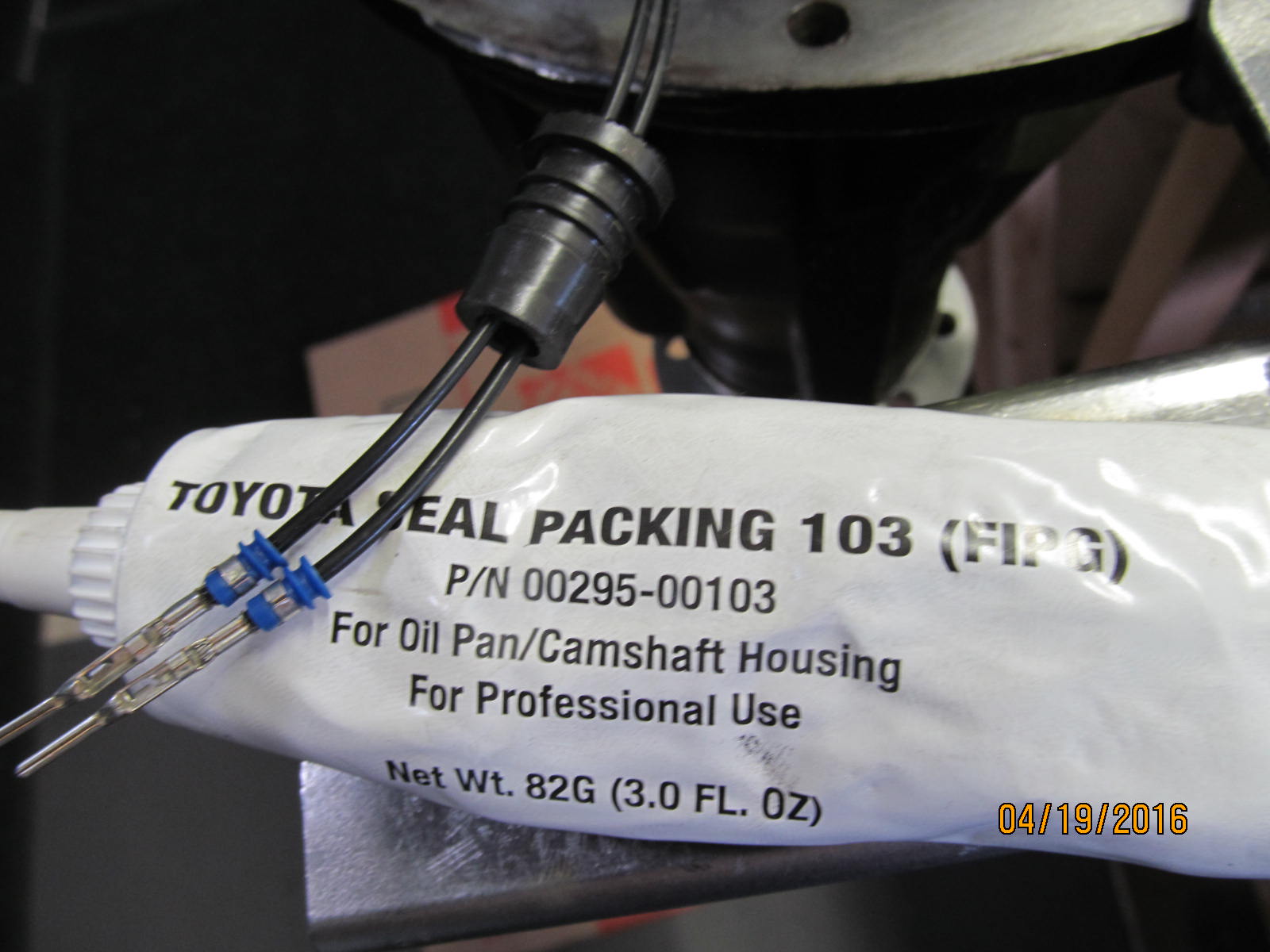

I used FIPG to help the rubber grommet pull thru easier and it really is a lifesaver.

|

|

|

|

|

One more paint check and it looks great.

|

|

|

|

|

nice

|

|

|

|

Final notes.

To order your Harrop e-locker....

Contact Ward at 1-800-224-7801 or email info@cruiserbrothers.com

|

|

|

|

|