|

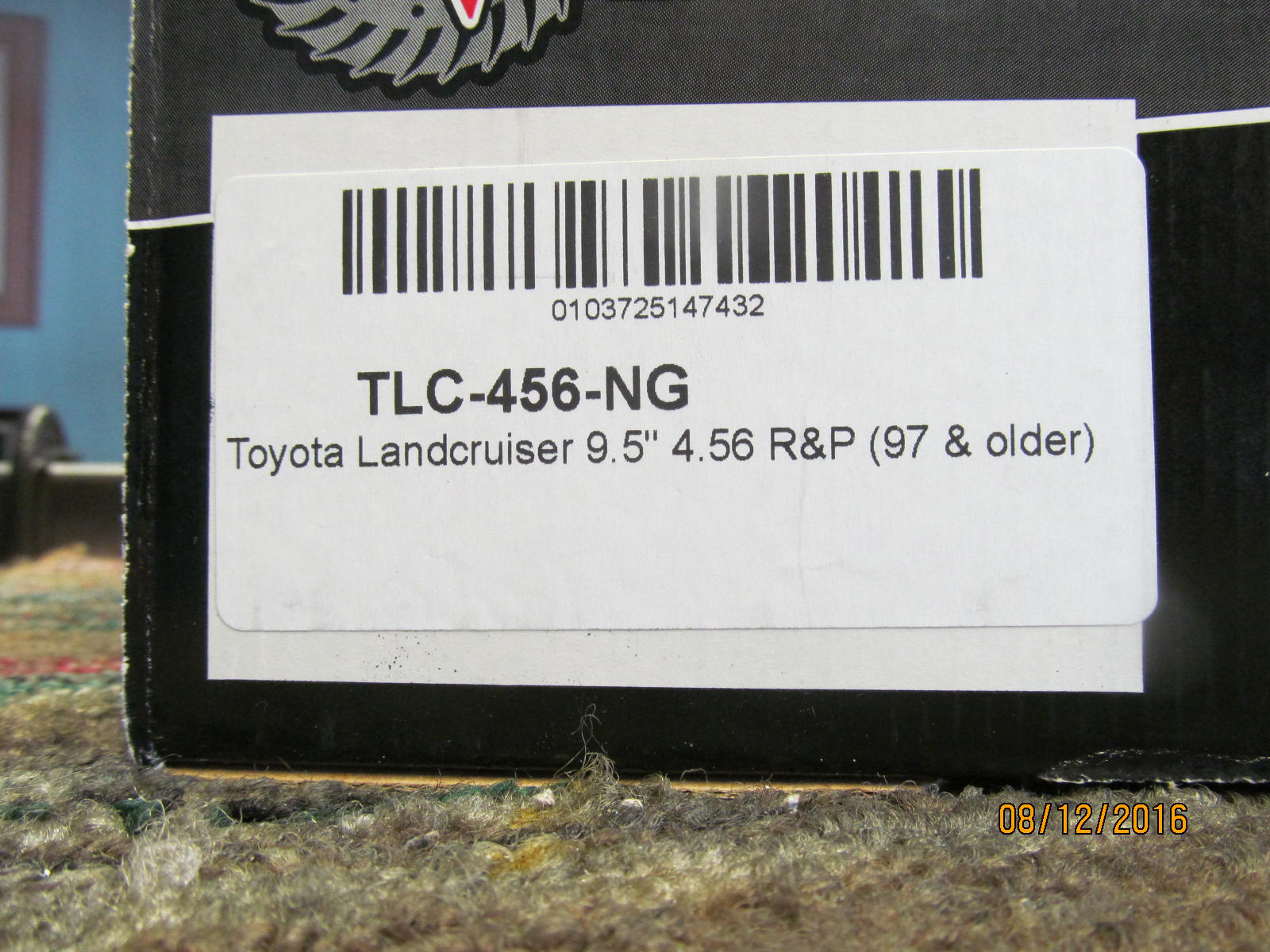

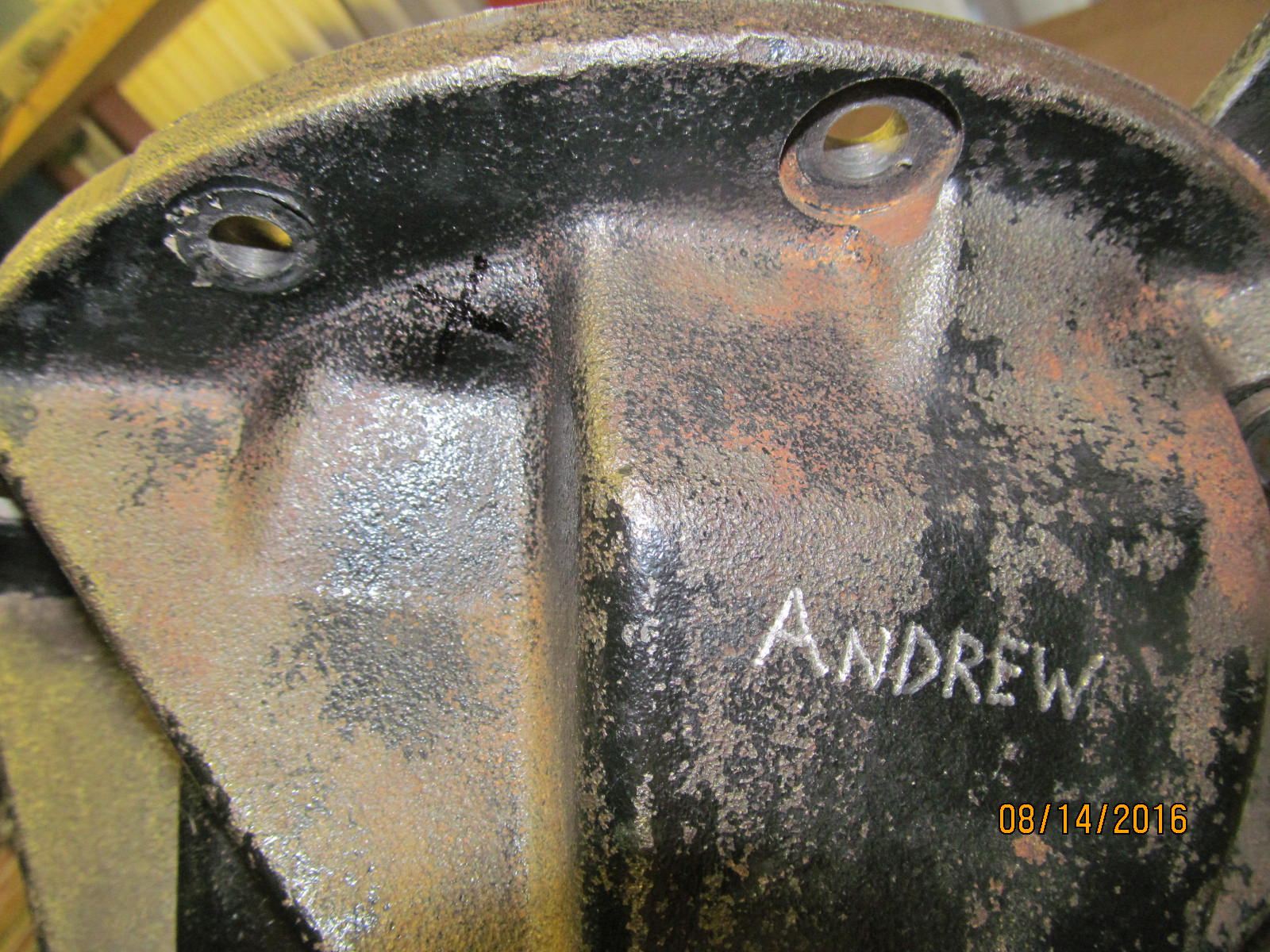

Harrop E-Locker with 456 Nitro Gear Install in Andrew's 1984 FJ60 Rear 9.5" 3rd

|

|

(89 BIG pics loading)

|

|

AUGUST 14 2016

|

|

|

Andrew's 1984 FJ60 that has been his for 12 years now.

The plan is a new Harrop rear elocker install with a gear change to 456 and new pinion bearings.

|

|

|

|

230,000 miles and still has the original 2F engine.

Has an H41 4-speed and a Marlin 4.8 Toybox....split transfercase.

|

|

|

|

|

Andrew sent a used set of 456 gears and hoped they would install with nice patterns....

|

|

|

|

|

...later it will be determined that a new Nitro set is best.

|

|

|

|

|

Cola has to check out every cardboard box I open. Not sure why cats do that.

|

|

|

|

|

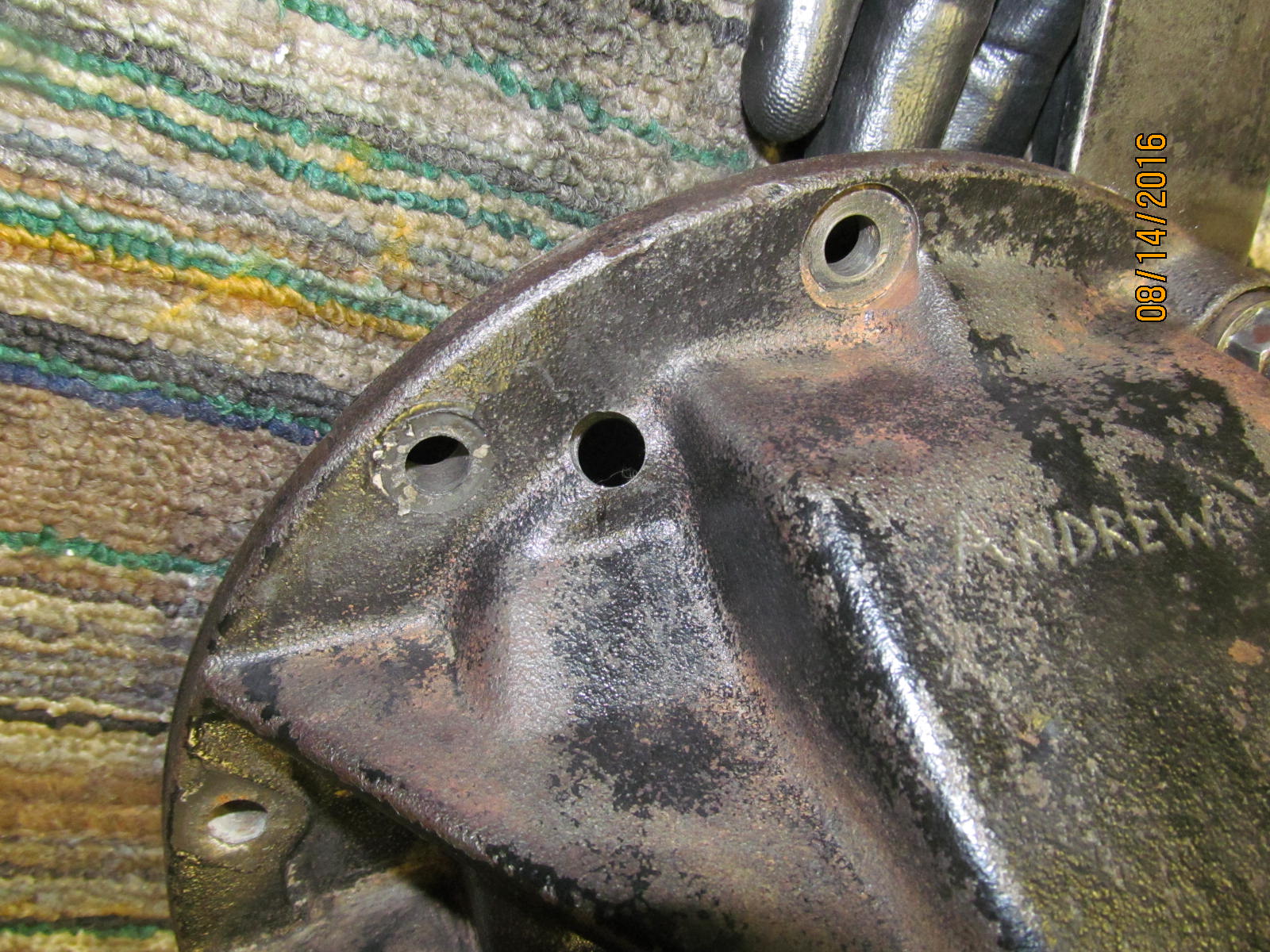

In the double box was a 1984 FJ60 rear 3rd. Relatively clean on the outside....thank you Andrew.

|

|

|

|

|

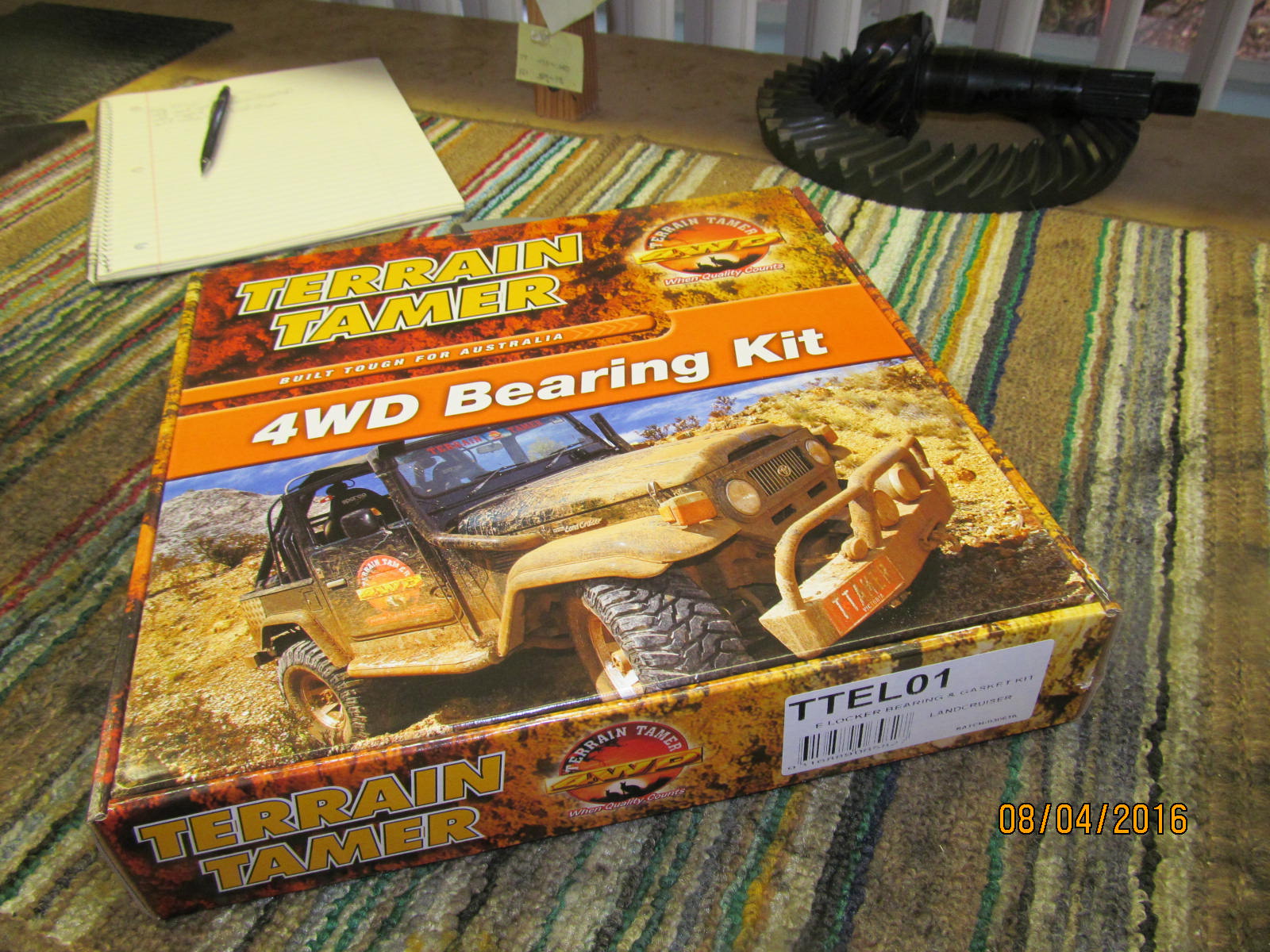

Another box arrives from the West coast.

|

|

|

|

|

Harrop e-locker

|

|

|

|

|

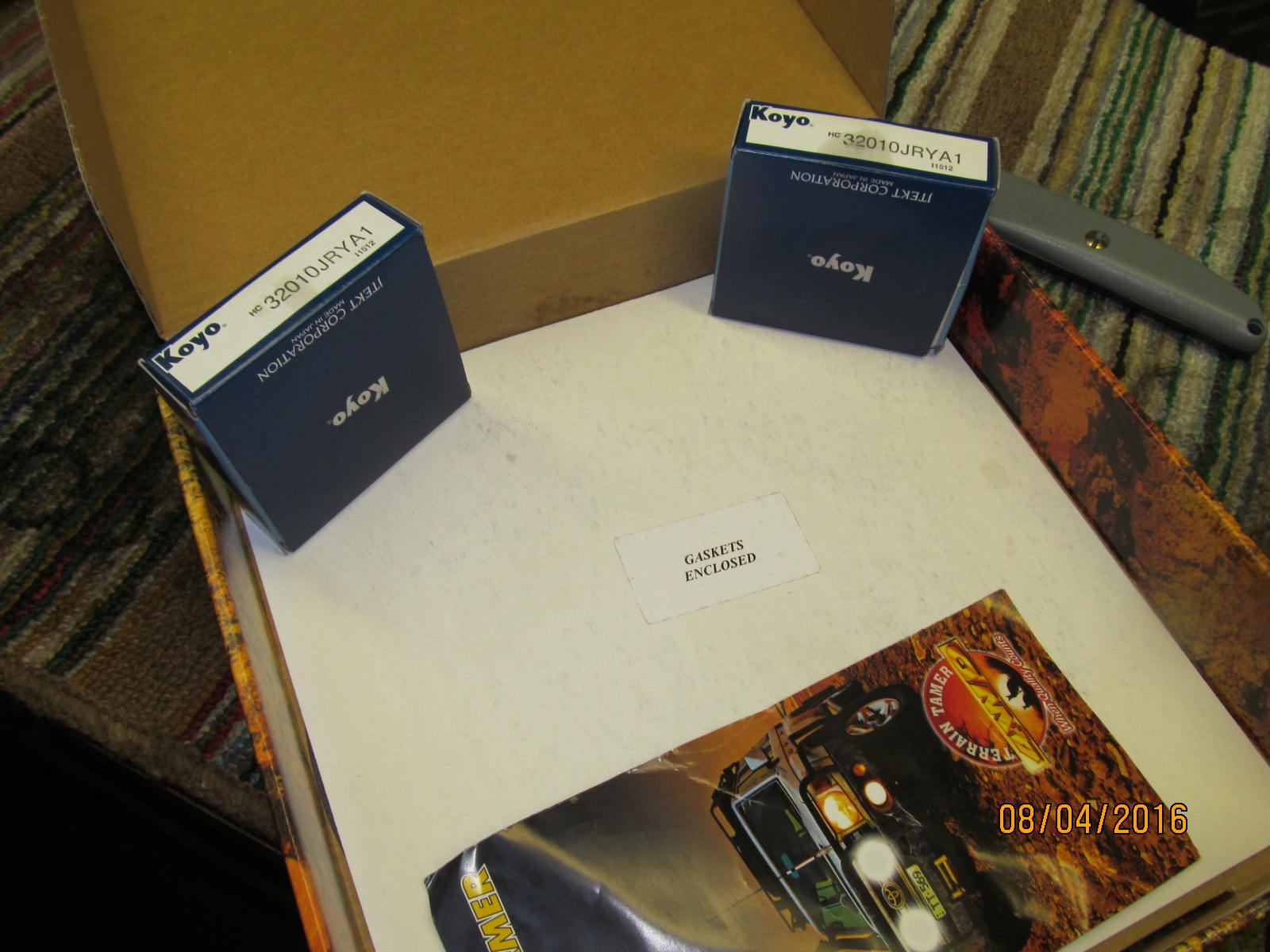

New carrier bearings in here....

|

|

|

|

32010 Koyo's.....has the larger 50mm inside diameter to press onto the 50mm journals of the Harrop

and the smaller 80mm outside diameter to fit onto the differential carrier.

|

|

|

|

|

Nice

|

|

|

|

|

Going deeper into the box....

|

|

|

|

|

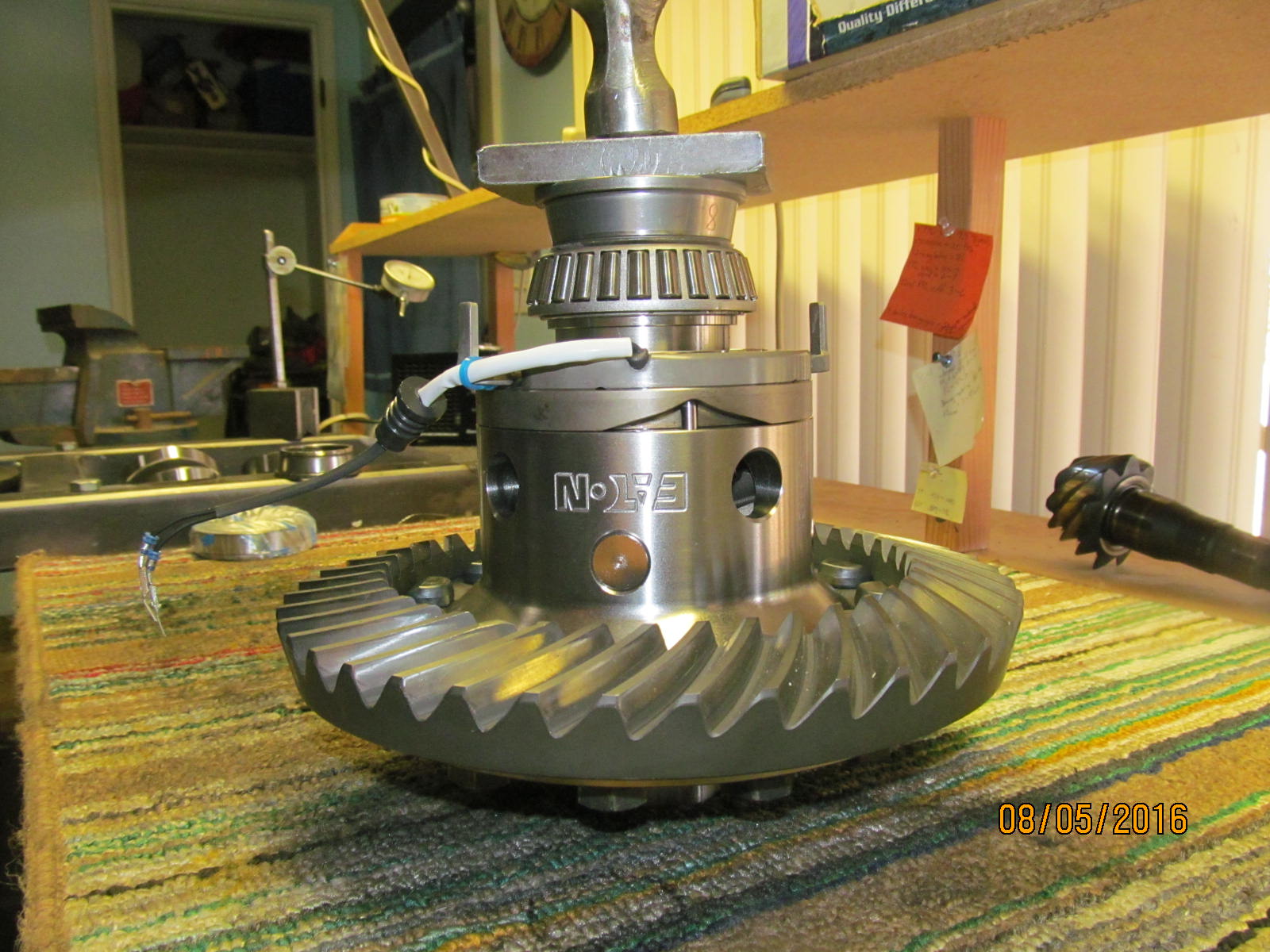

Yessiree.

|

|

|

|

A 9378 Harrop elocker...and as it says, Australian made, with Eaton technology, and a 3 year warranty to boot.

These are available for the TLC with full floater 9.5" rears and the high pinion 8" fronts of the TLC's.

The carrier bearings are included already in the box.

Contact Ward Harris (National importer/authorized dealer for Harrop) at 1-800-224-7801

or email info@cruiserbrothers.com

|

|

|

|

|

As shown on the left, this style of locker comes with an anti-rotation bracket.

|

|

|

|

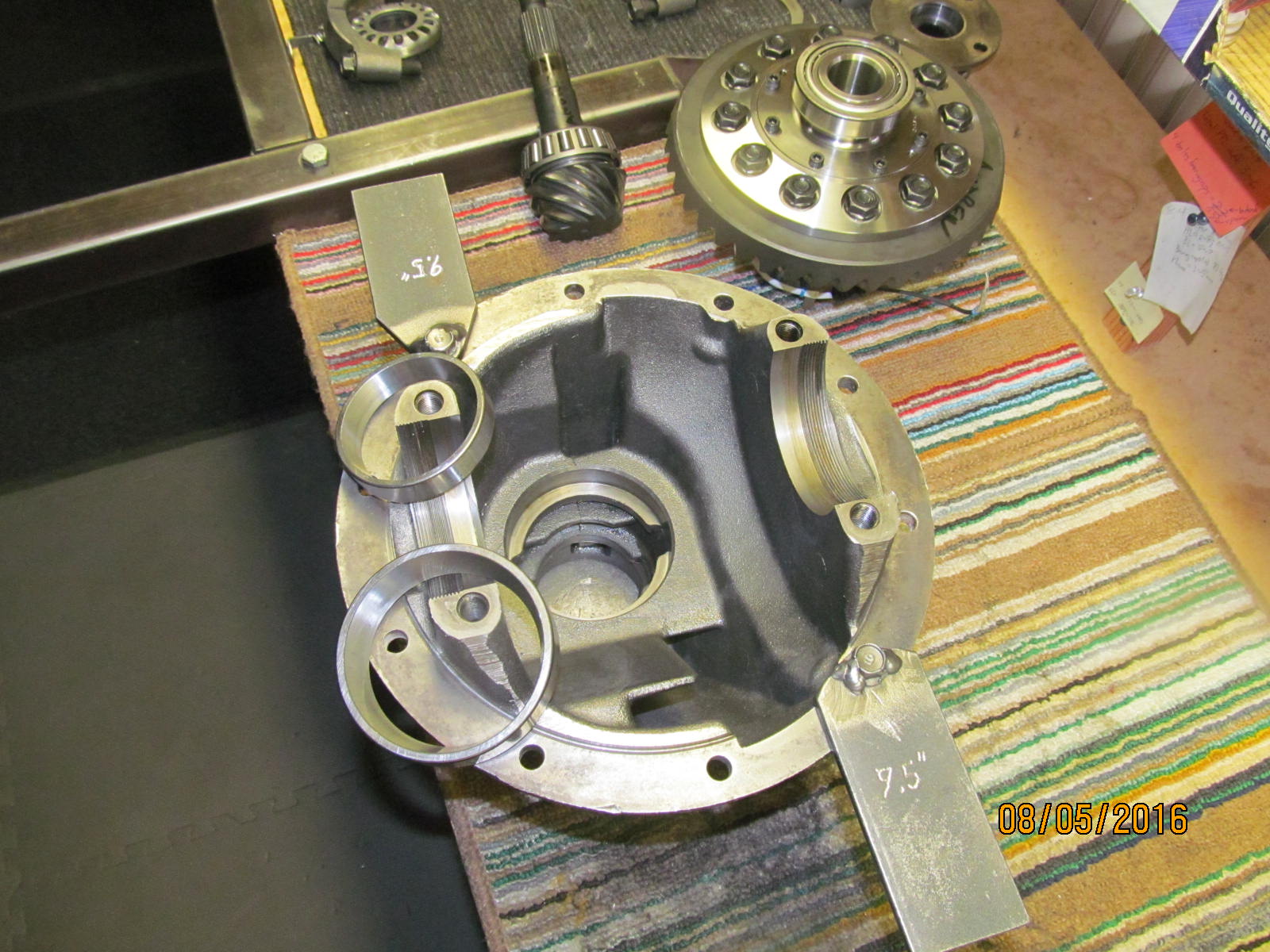

Since the carrier bearings were already in the Harrop box, Andrew had to only send me a pinion install kit.

As shown, he also included a new pinion flange and a solid collar. More on that solid collar later.

|

|

|

|

|

Here's everything laid out.

|

|

|

|

A quick pattern check of the old 370 gears shows that they are shallow at the moment but that would change

with a proper re-shimming. Basically, the pattern shows no damage so these

gears are still good and getting shipped back to Andrew at his request.

|

|

|

|

|

...................

|

|

|

|

|

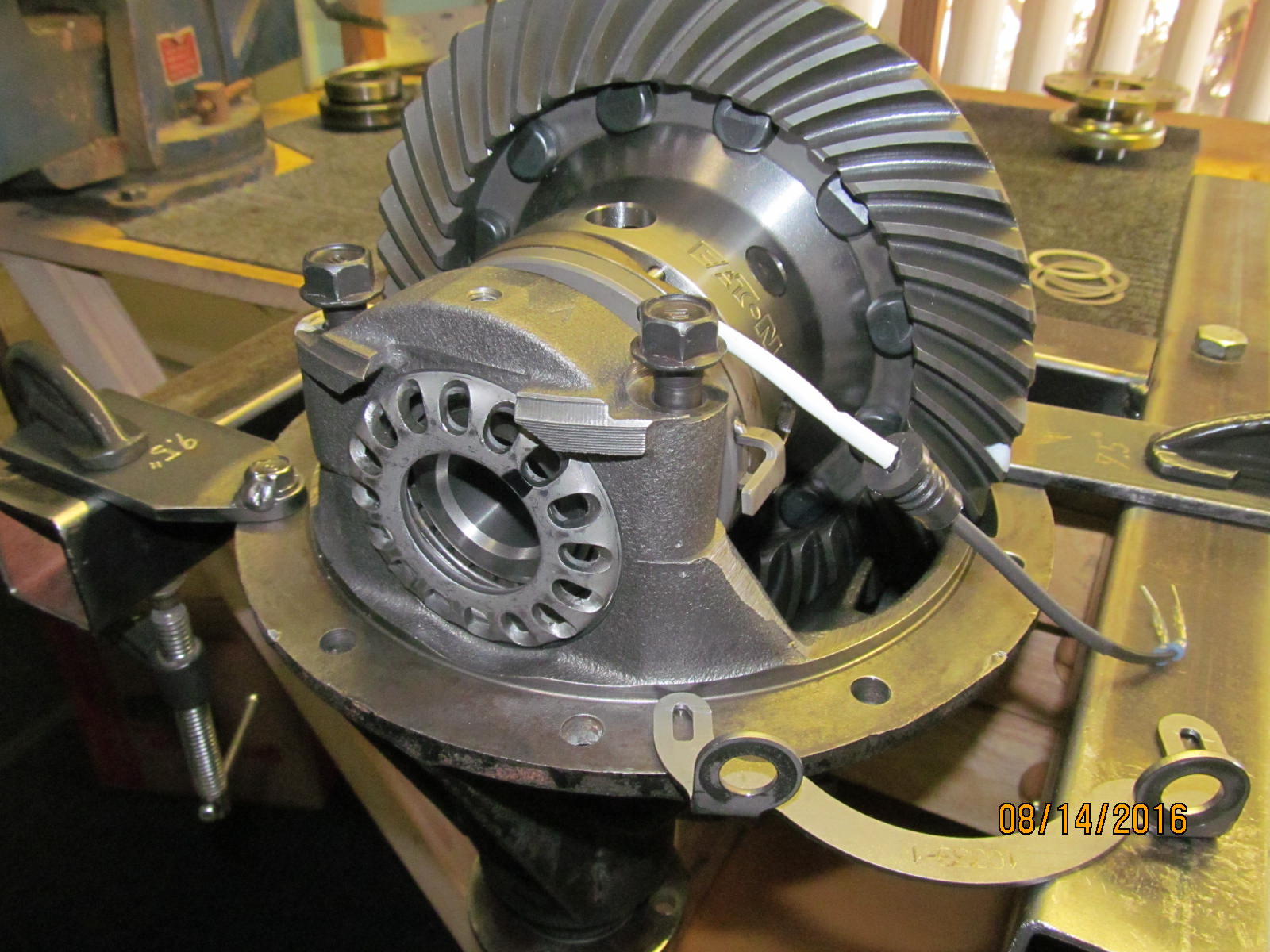

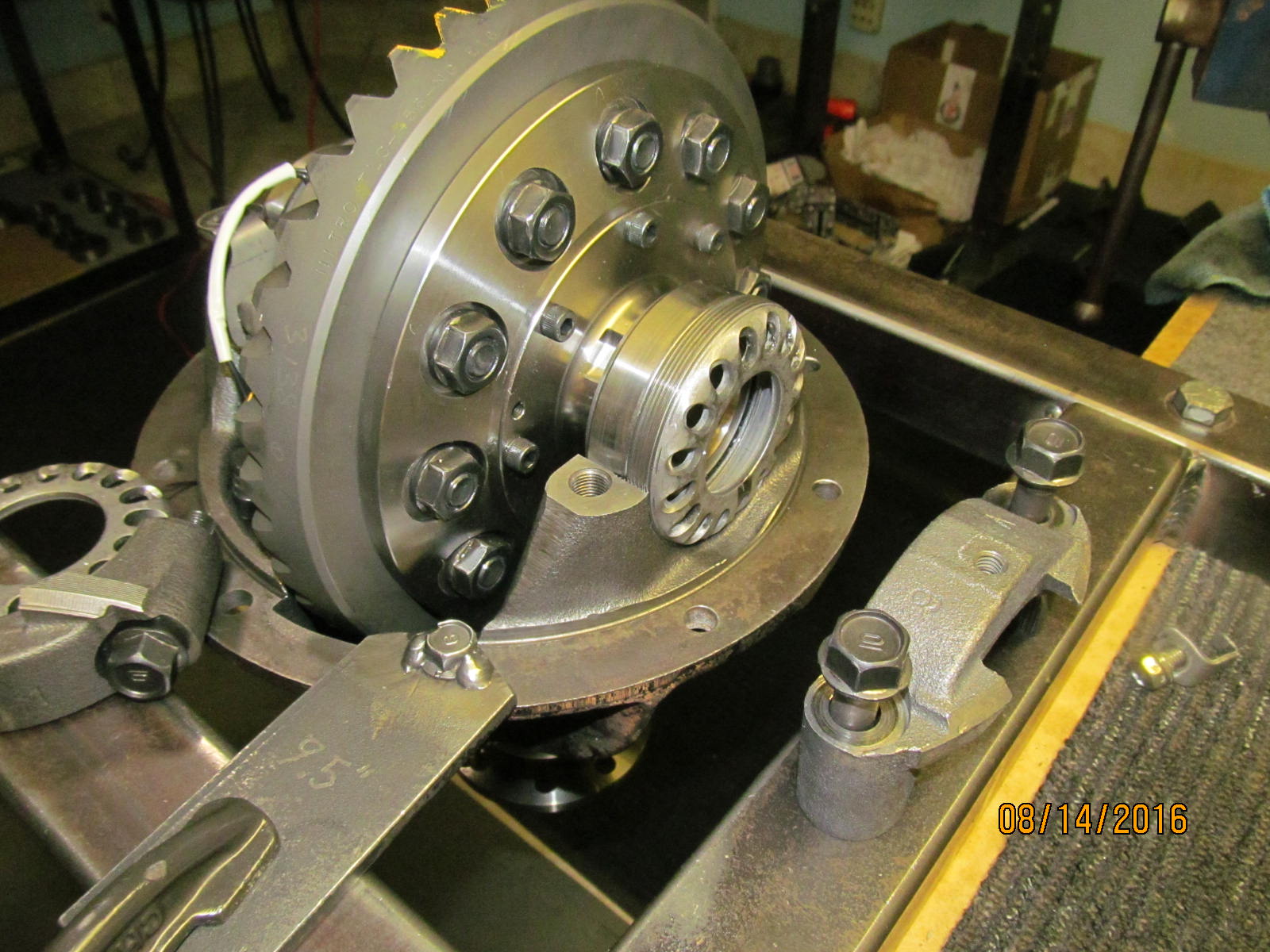

Might as well load the used 456 ring onto the Harrop case....

|

|

|

|

|

Surfaces are checked for irregularites and all was good.

|

|

|

|

|

It was a tight fit but the lead filled plastic hammer was up to the task.

|

|

|

|

|

.............................

|

|

|

|

|

A dab of blue Loctite and 81 ft/lb final torque spec.

|

|

|

|

|

The carrier bearings were also tight and now was a good time to load them on.

|

|

|

|

|

This piece is complete.

|

|

|

|

|

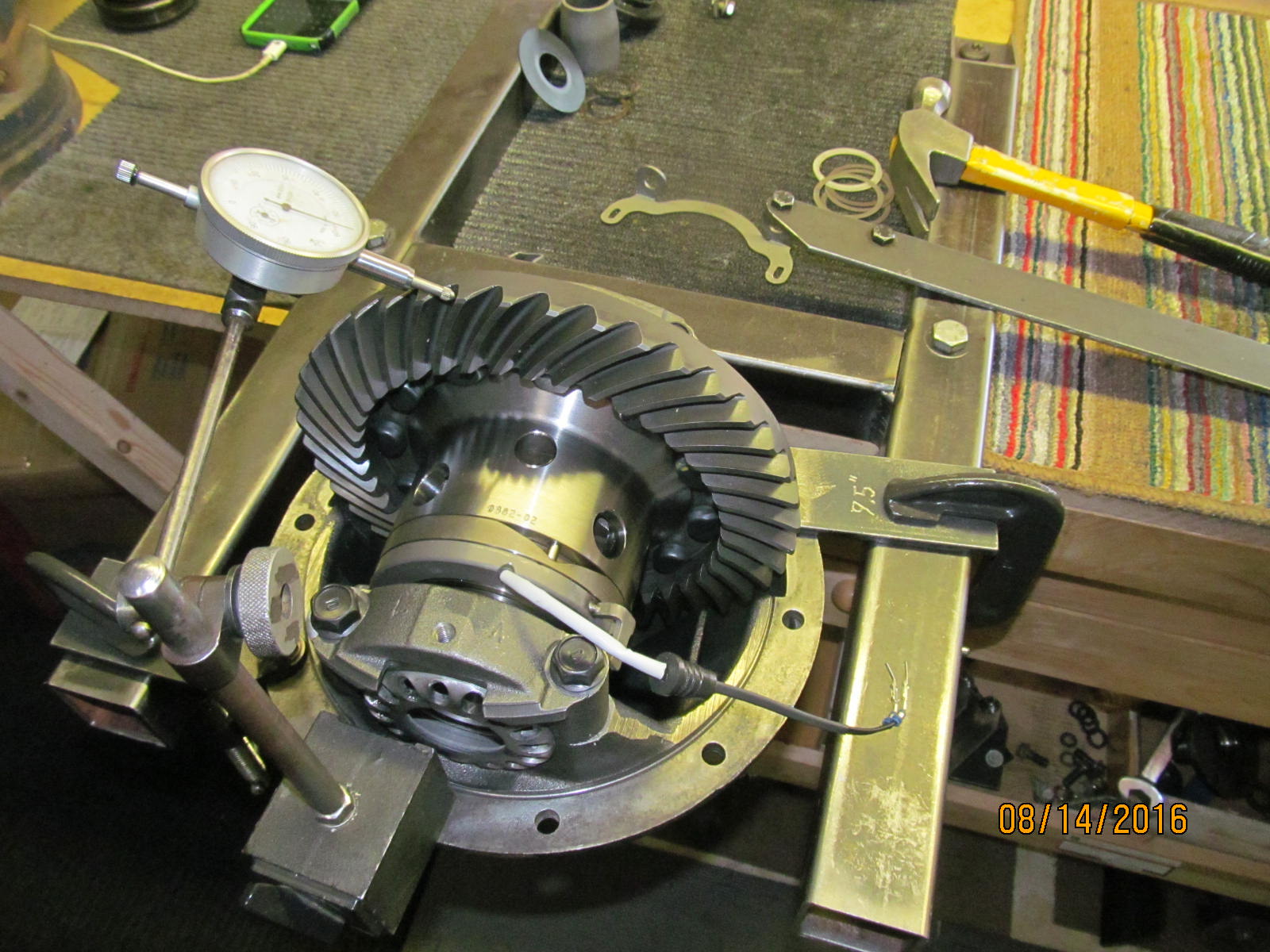

Used 456....new pinion bearings....Let's try 053" for the pinion depth check.

|

|

|

|

|

A Harborfreight 12 ton press makes the job so much easier.

|

|

|

|

|

New races going in. Amazing how a little starting fluid can make the 3rd appear spotless.

|

|

|

|

|

The large inner race has to go in evenly...almost down 100%...

|

|

|

|

|

Using the right sized backing race to seat the race 100%.

|

|

|

|

|

Fully seated.

|

|

|

|

|

Same with the upper race.

|

|

|

|

|

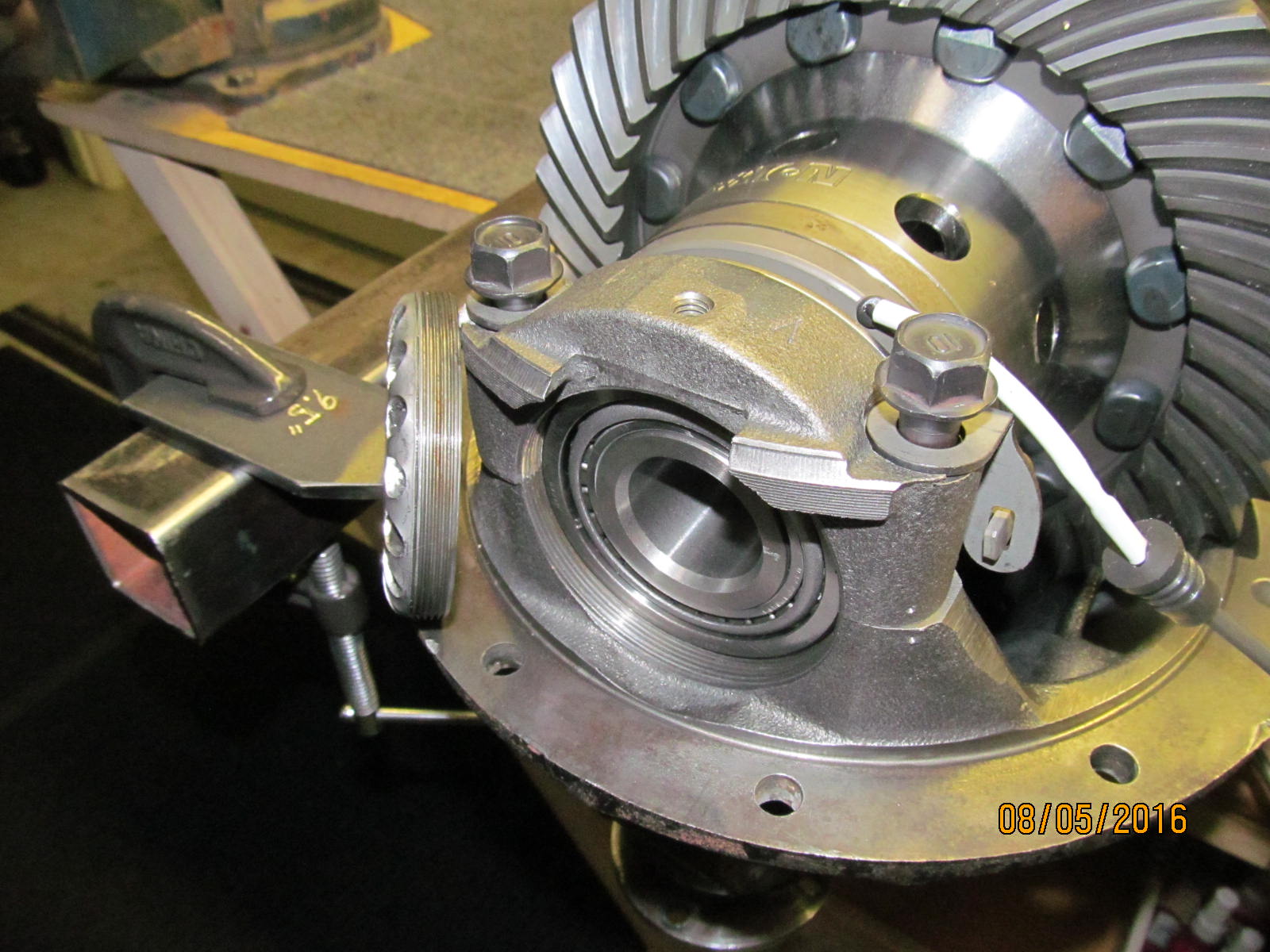

Just doing a pattern check.....so loading the pinion in place here.

|

|

|

|

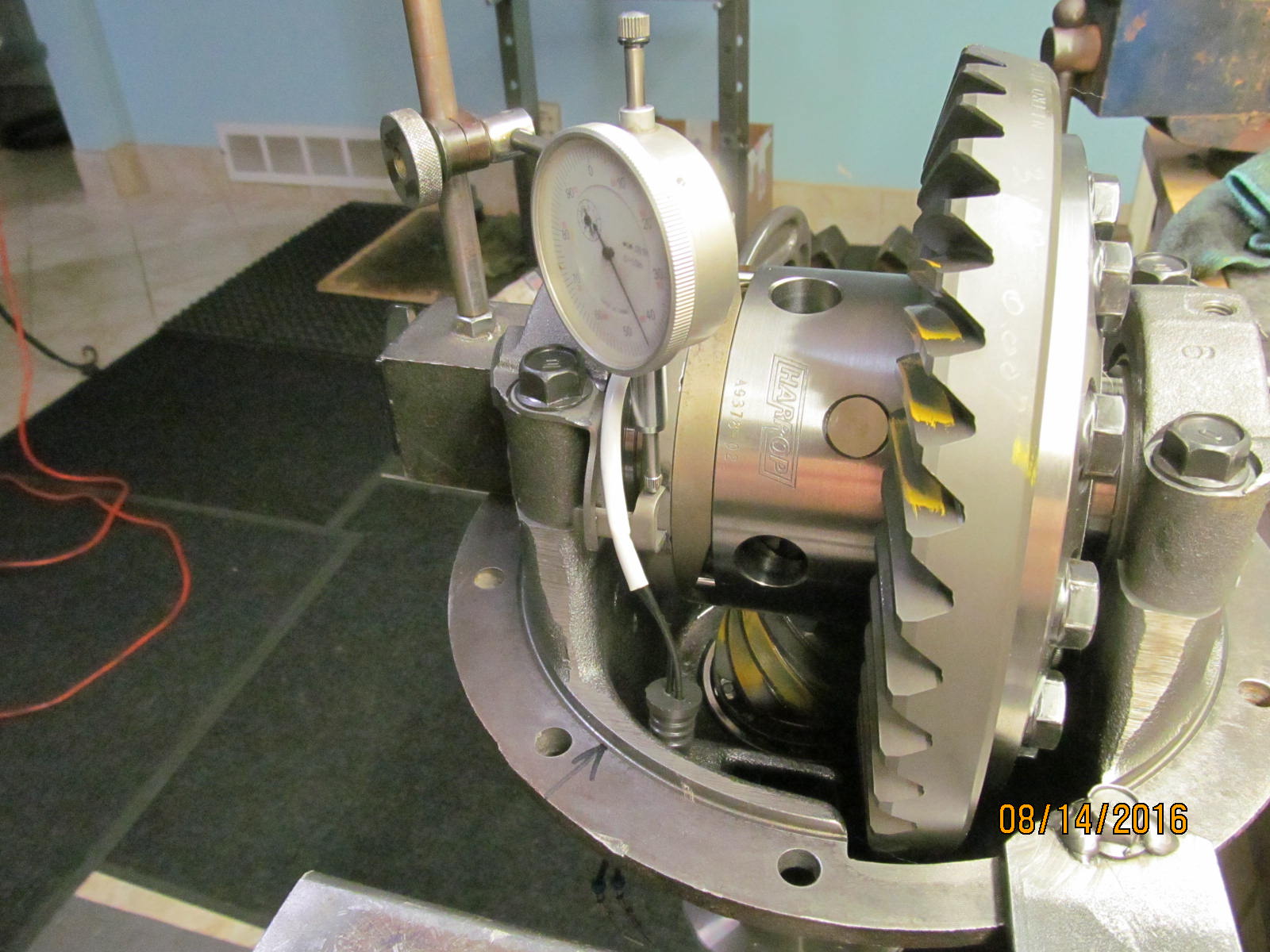

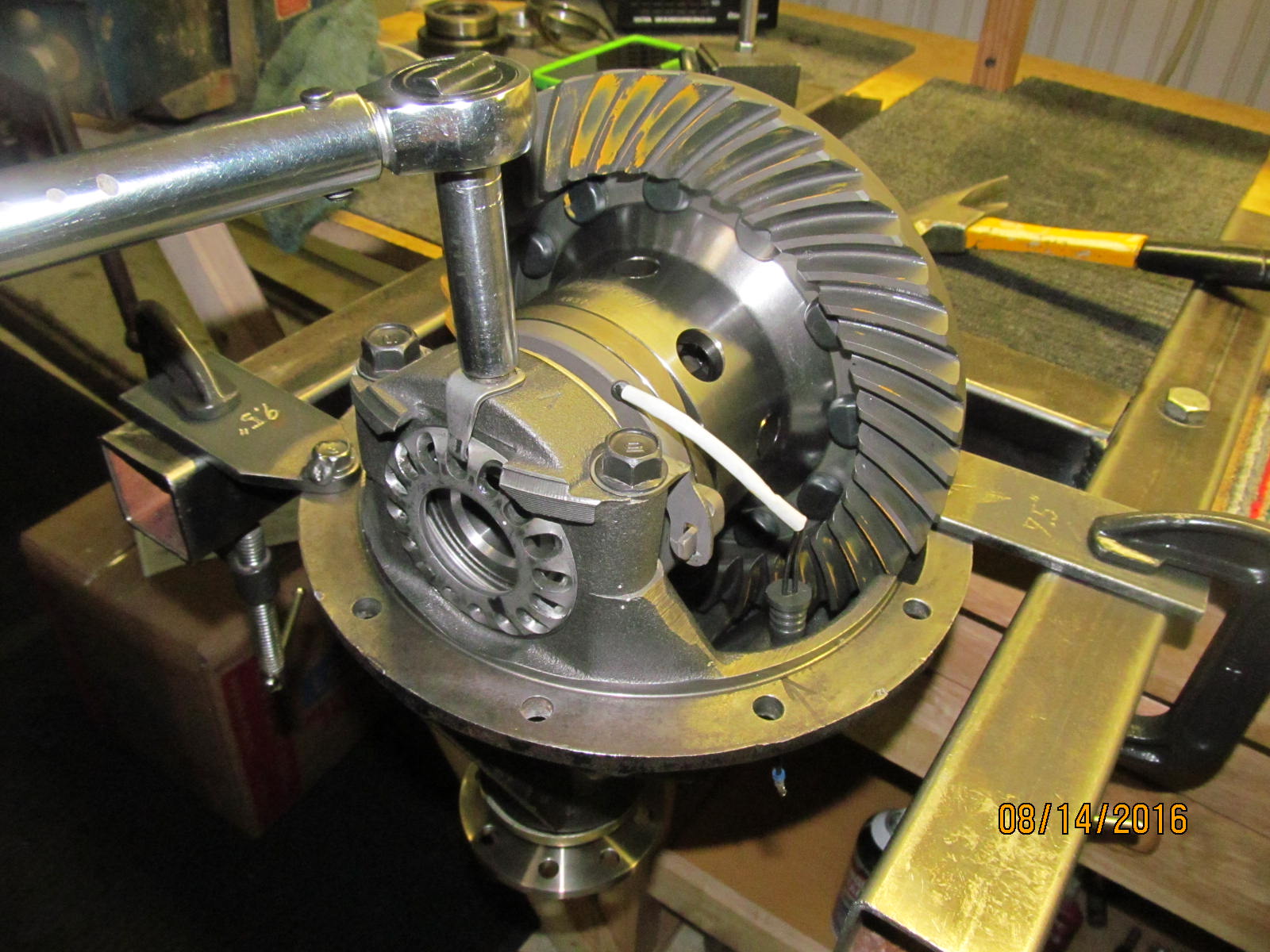

What the heck.....might as well check for the 2mm free-play in the anti-rotation tabs.

There's an order that works best for this configuration here...

Tab is loaded in place ...then bearing cap...then 2 bolts....lastly the wheels are threaded in.

|

|

|

|

|

After some tweaks, I have the 2mm of up/down play.

|

|

|

|

|

Sorry....pictures not shown but the preliminary paint was showing 053 was too deep so tearing it down....

|

|

|

|

|

And an .049" shim is on the pinion now so it is re-assembled without the anti-rotation tab.

|

|

|

|

|

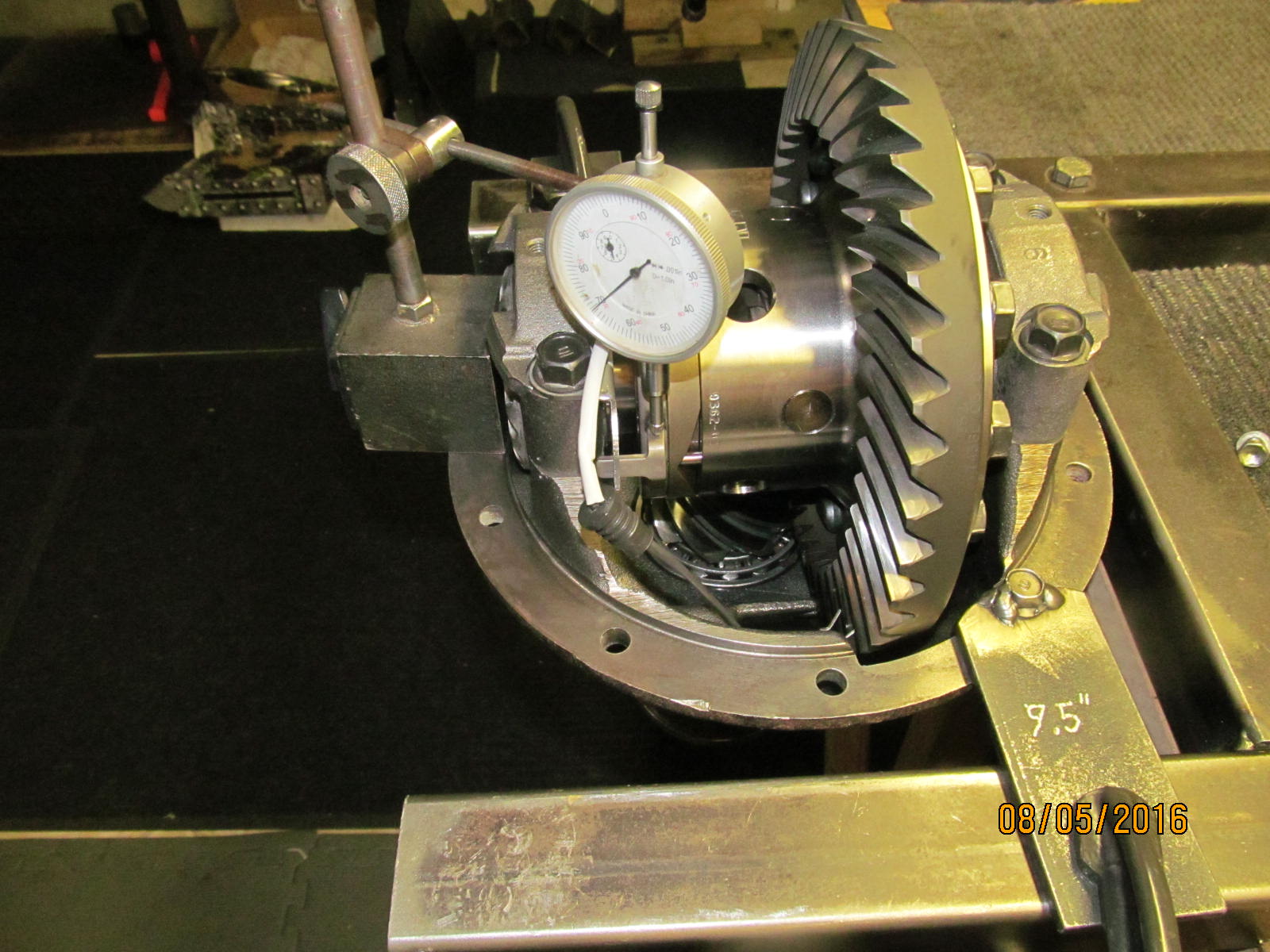

Backlash is adjusted in the ballpark. Tap tap tap on all 4 corners to equalize bearing tensions.

|

|

|

|

|

Drive---- has some out of place wear going on...

|

|

|

|

|

You can really see it on the coast side.

|

|

|

|

|

I don't really care for the look of the pinion drive side either.

|

|

|

|

|

A new Nitro Gear 456 soon arrives on my bench.

|

|

|

|

|

...................

|

|

|

|

|

Trying 056 for the first shim selection.

|

|

|

|

|

press it on again.

|

|

|

|

|

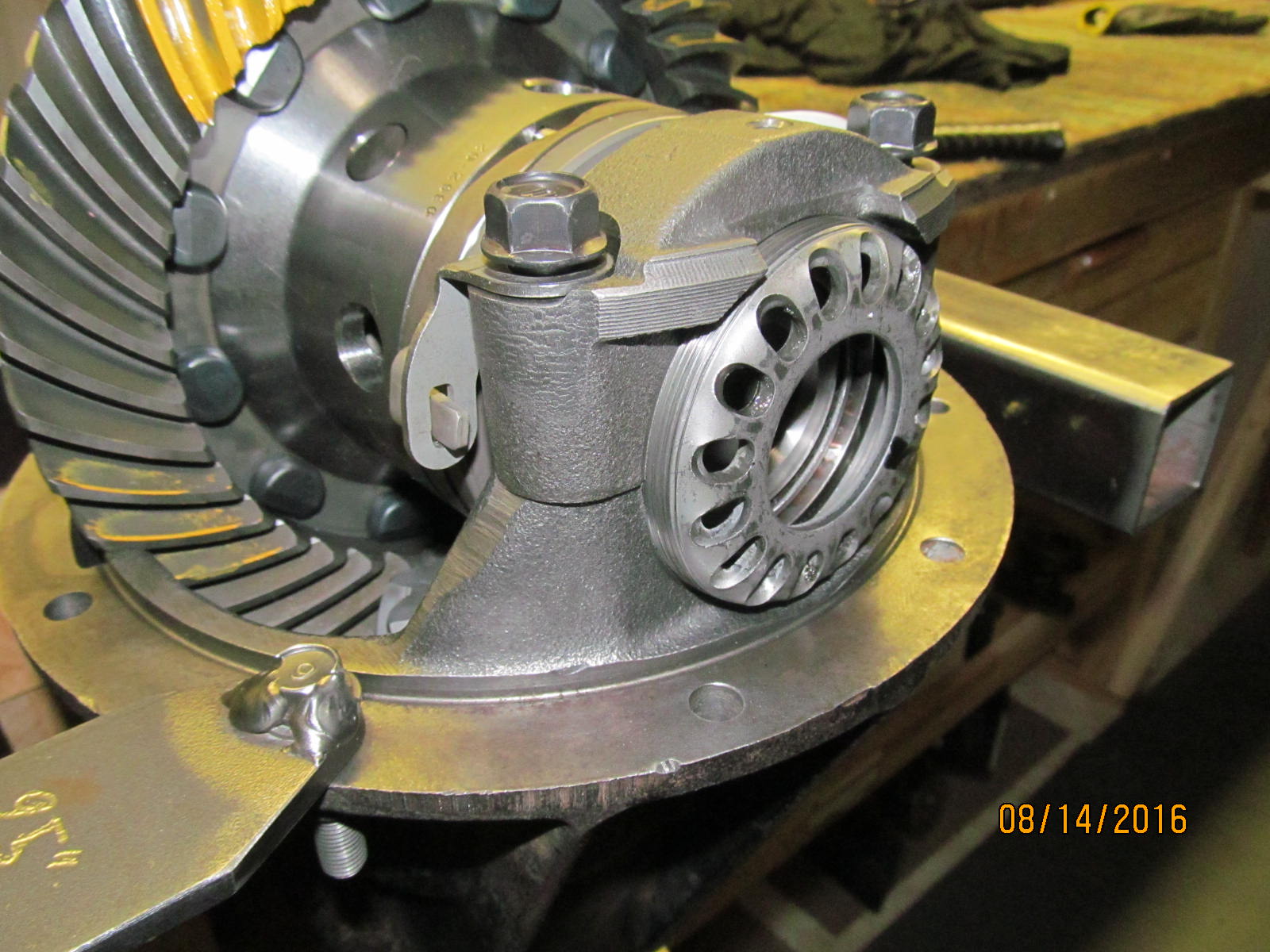

New ring mounted....

|

|

|

|

|

...and 81 ft/lb.

|

|

|

|

|

Mount the pinion in the 3rd...

|

|

|

|

|

This side goes in easy....

|

|

|

|

|

...and so does this side when the Harrop tab is not in the equation.

|

|

|

|

|

Some carrier bearing pre-load and set the backlash to .006"

|

|

|

|

|

Not bad for 056...

|

|

|

|

|

...slight shallow look....

|

|

|

|

|

Pinion comet tail is not shifting to the center as much as I like...

|

|

|

|

|

..................

|

|

|

|

|

Teardown...I can now combine several operations and tweak the pinion depth now.

|

|

|

|

|

Pressing the pinion bearing off.

|

|

|

|

|

Adding another .003" for a total of 059.

|

|

|

|

Seal is mounted.

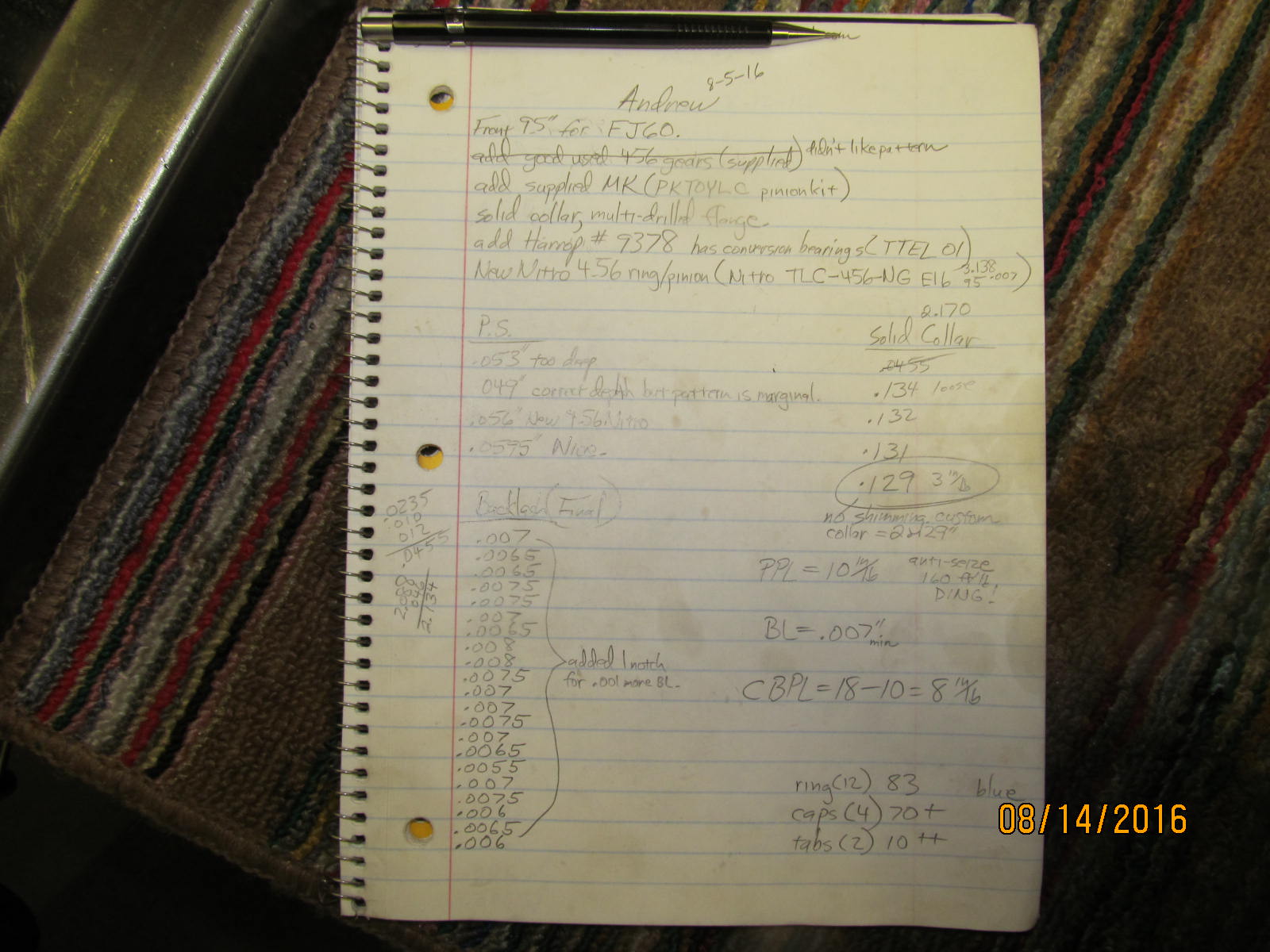

Not shown here but the solid collar required some rework. For an unknown reason, some FJ60's need the

shorter 2.090" collar and the one supplied to me was 2.170" which should have worked but not on this 84.

Resizing the collar is really no problem....using the side of a 14" chopsaw wheel to remove large

amounts of material and a sheet of 100 grit sandpaper on a flat surface made it all happen. I

started with 2.170 then went to 2.134...2.132...2.131...2.129. BINGO. Andrew now has an

exact size collar with no shims.

|

|

|

|

|

Generous with the anti-seize.

|

|

|

|

|

Tightened until I reached the target 10 in/lb.

|

|

|

|

With the pinion end now complete, now is the perfect time to drill the 29/64" hole. Marked with black

magic marker in the upper left.

|

|

|

|

|

The hole was being drilled with the pinion pointed up so no chance of shavings falling on the bearings.

|

|

|

|

|

Nice clean hole.

|

|

|

|

|

This side is easy...mount the adj wheel and install the bearing cap.

|

|

|

|

|

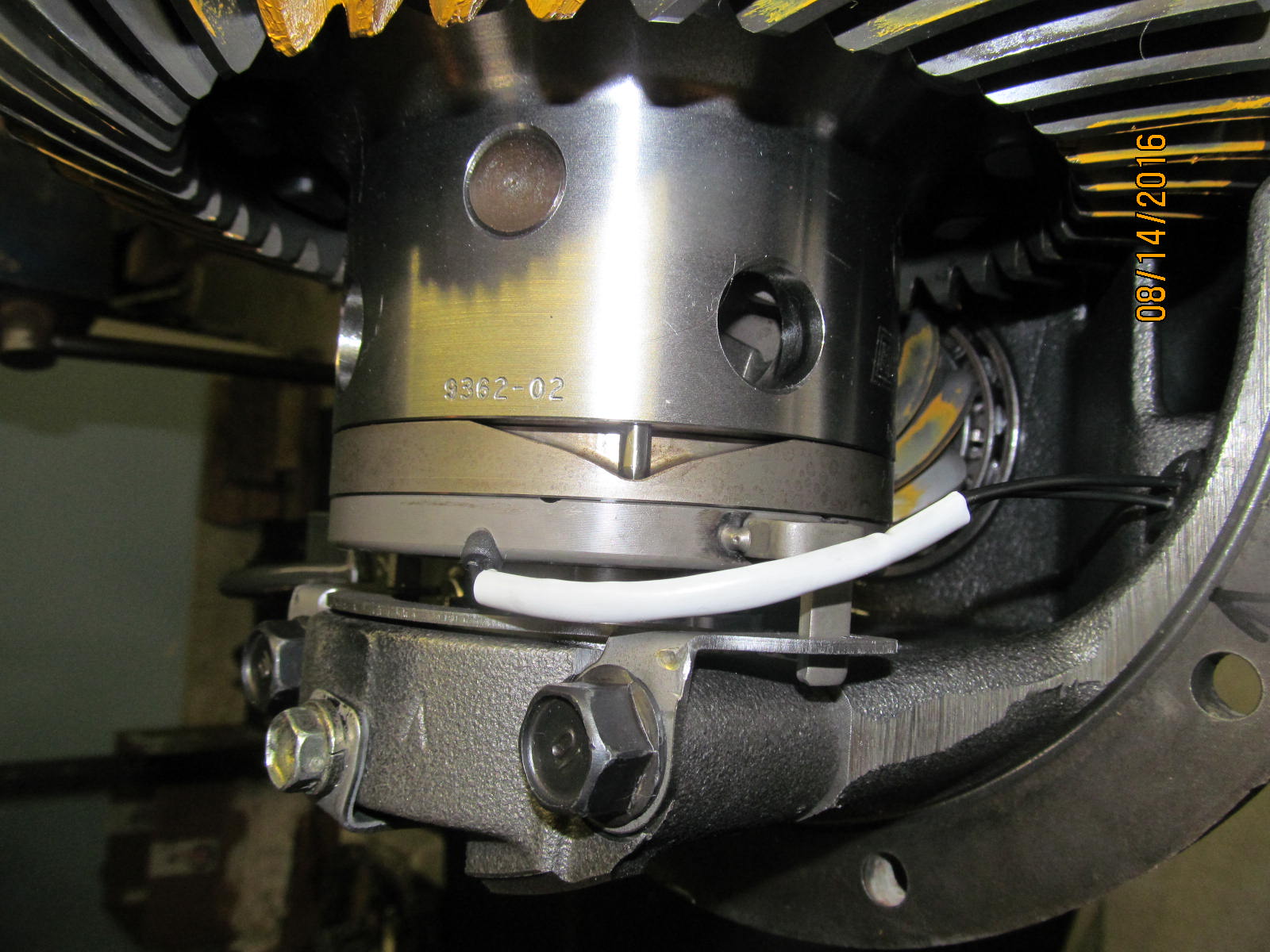

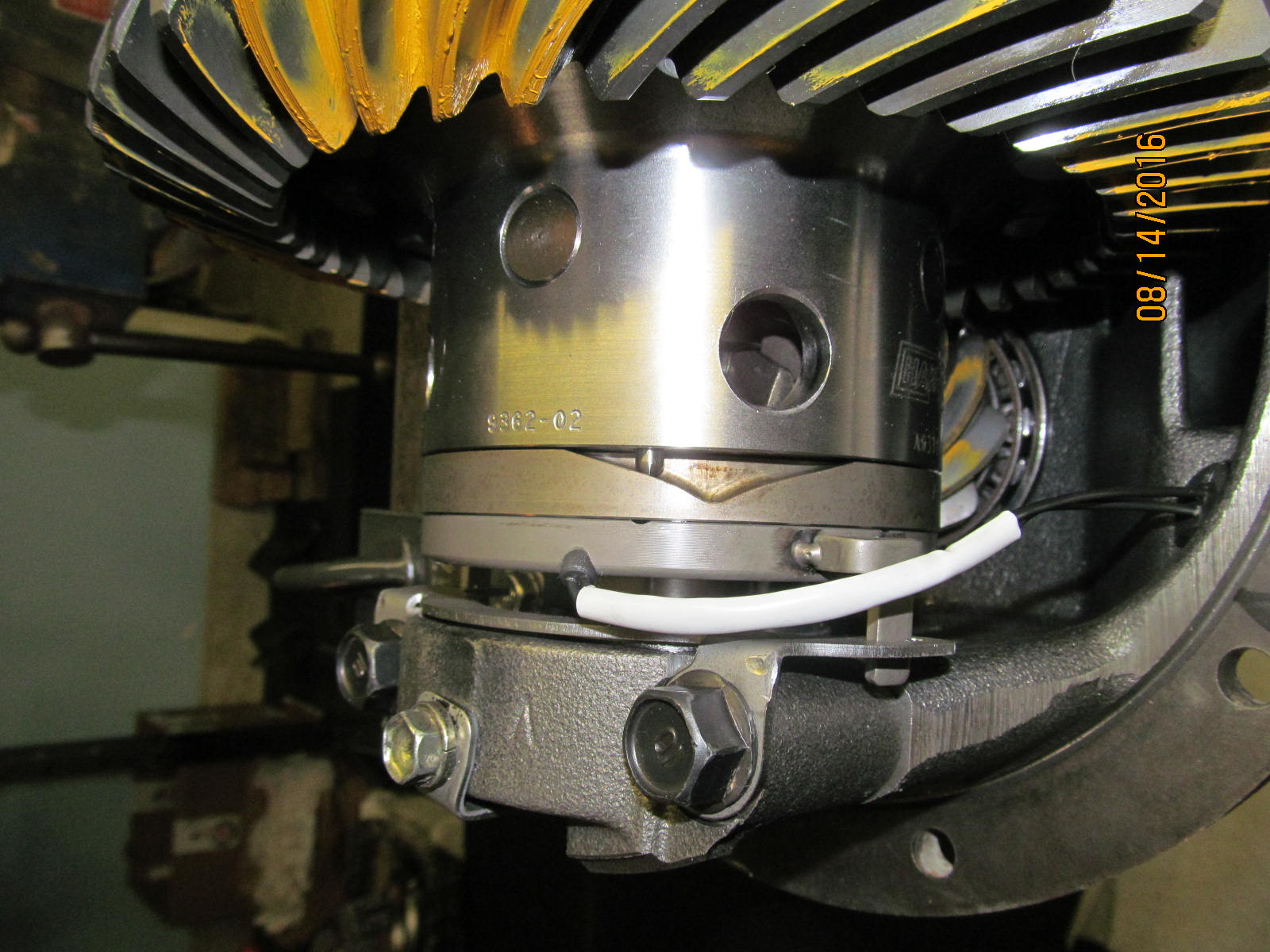

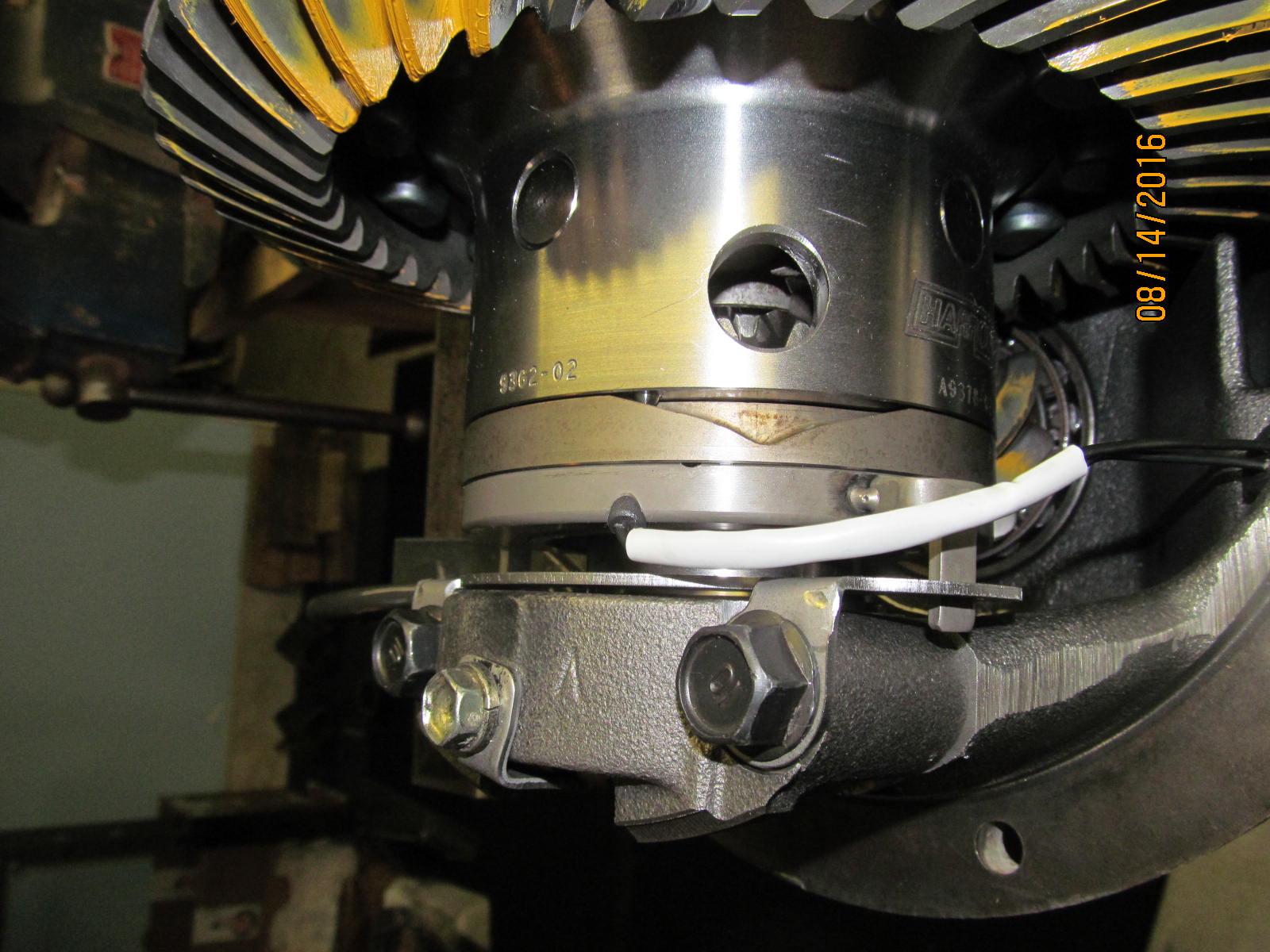

This side you have to mount the tab first...

|

|

|

|

|

...then slide the bearing cap in horizontally...

|

|

|

|

|

...and finally the 2 bolts and the adjusting wheel.

|

|

|

|

|

The 4 bolts are tightened close to the 70 spec and the free play is verified once again to be 2mm and it is.

|

|

|

|

|

Bearing caps are verified to be 70 ft/lb.

|

|

|

|

|

Final backlash is dialed in.

|

|

|

|

|

Carrier bearing preload is checked....18 is combined, 10 is pinion, so that means 8 is for the carrier bearings.

|

|

|

|

|

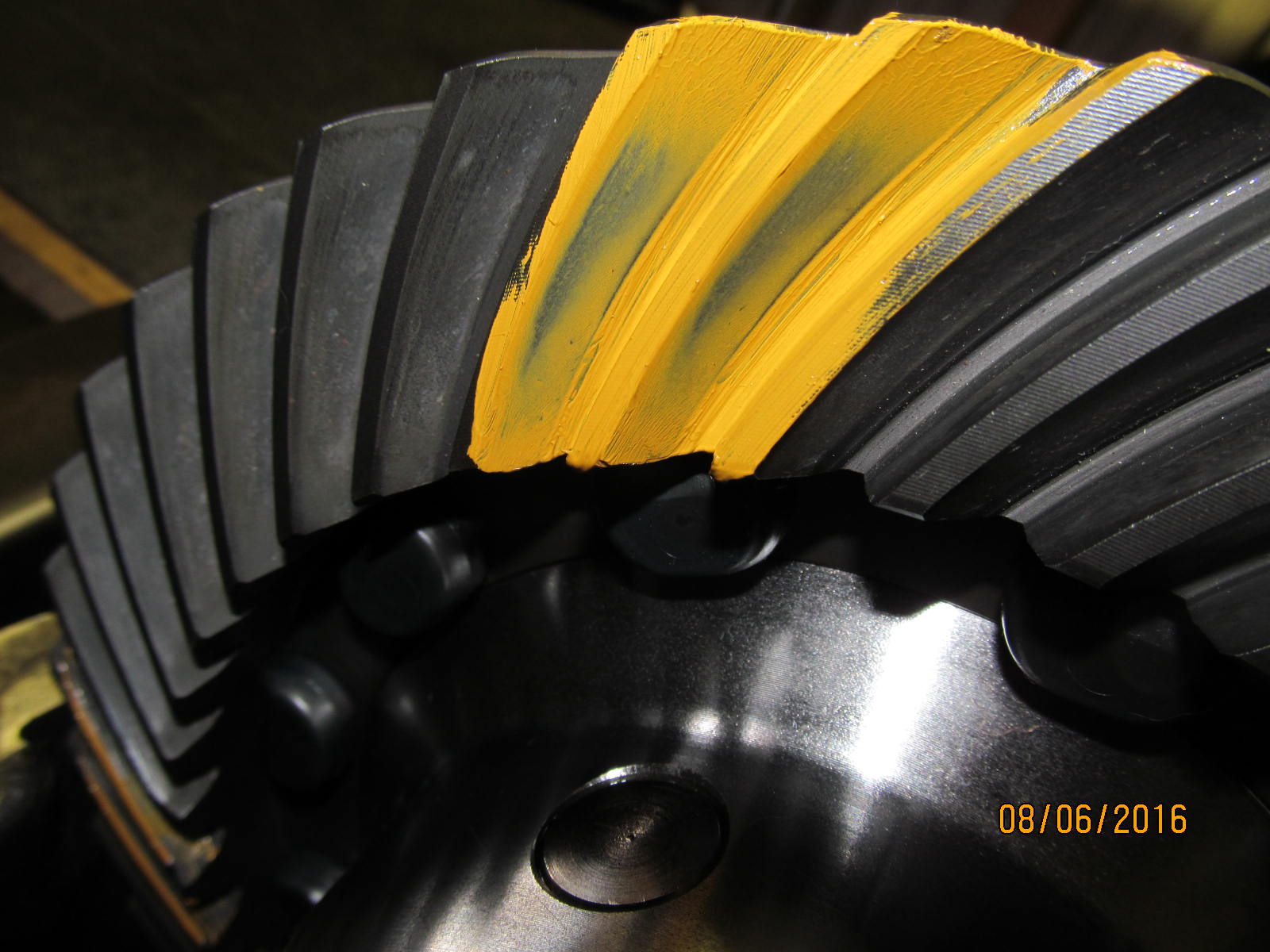

Another paint with the .0035" thicker pinion shim shows an excellent drive pattern.

|

|

|

|

|

Coast.

|

|

|

|

|

Pinion drive side....according to the comet tail it's as deep as it should ever be.

|

|

|

|

The reverse painted teeth are often easier to read than the directly painted teeth from earlier pics.

Slightly deep.

|

|

|

|

|

...................

|

|

|

|

|

Locktabs are torqued to 10+ ft/lb

|

|

|

|

|

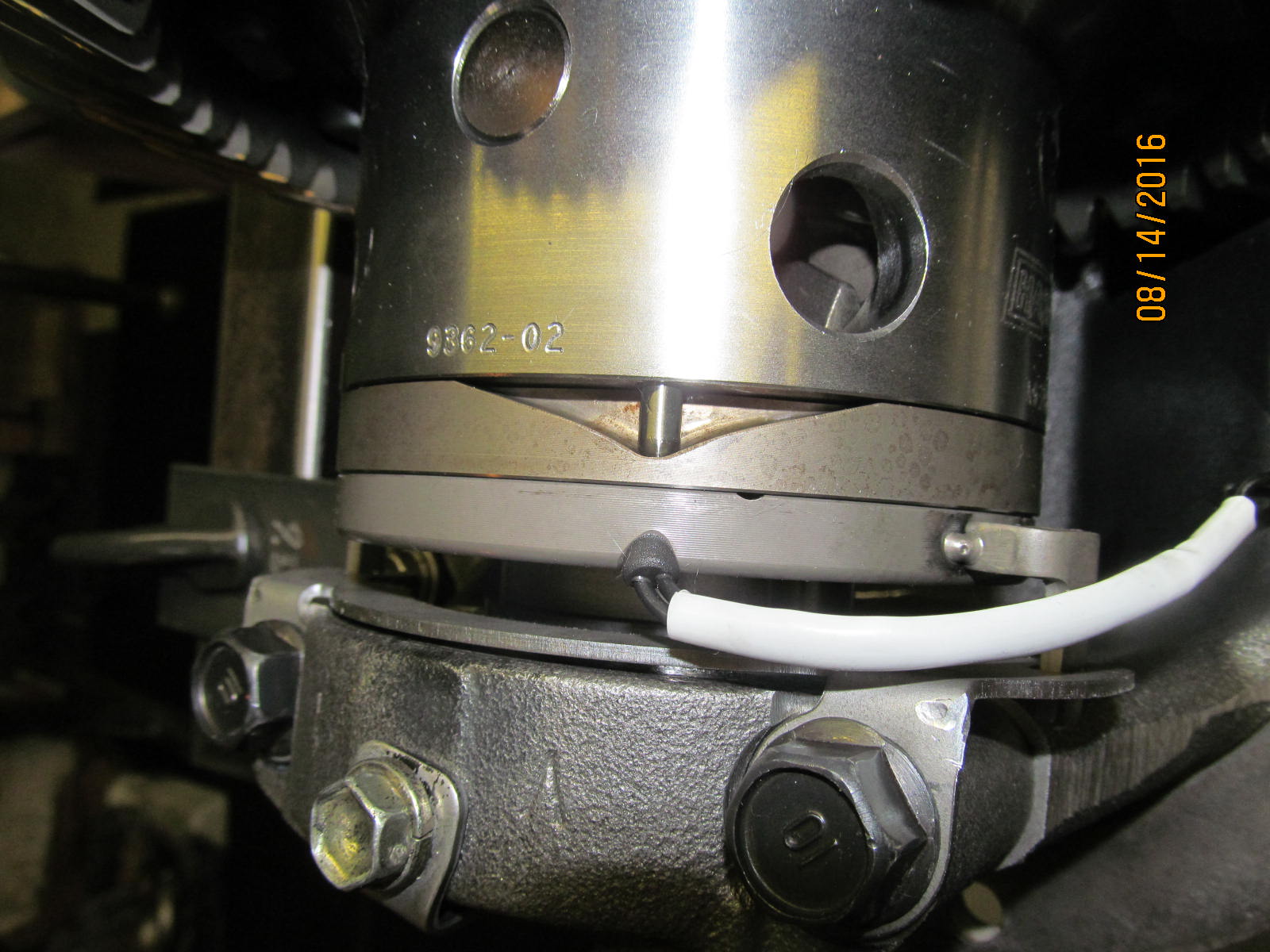

Specs measured are engraved on the Nitro ring gear.

|

|

|

|

|

The elocker current is measured under 3 amps.

|

|

|

|

|

3 pins are equally spaced around the case...

|

|

|

|

With the locker engaged, as the pinion and ring gear are turned, the spring loaded pins are forced into

the case by the ramping action.

|

|

|

|

|

Continuing the turning of the ring gear and it's fully ramped and will recess no further.

|

|

|

|

|

Remove the 12 volts and the pins instantly snap back to center.

|

|

|

|

|

A snapshot of the notes.

|

|

|

|

Securing the 3rd in a double corrugated double box with a smaller box inside that helps keep the 3rd

from rolling around.

|

|

|

|

|

Ready to go out.

|

|

|

|

|