|

Harrop E-Locker Install for Eric's 1997 LX450

|

|

(103 BIG pics loading....give it some time)

|

|

JAN 28 2016

|

|

|

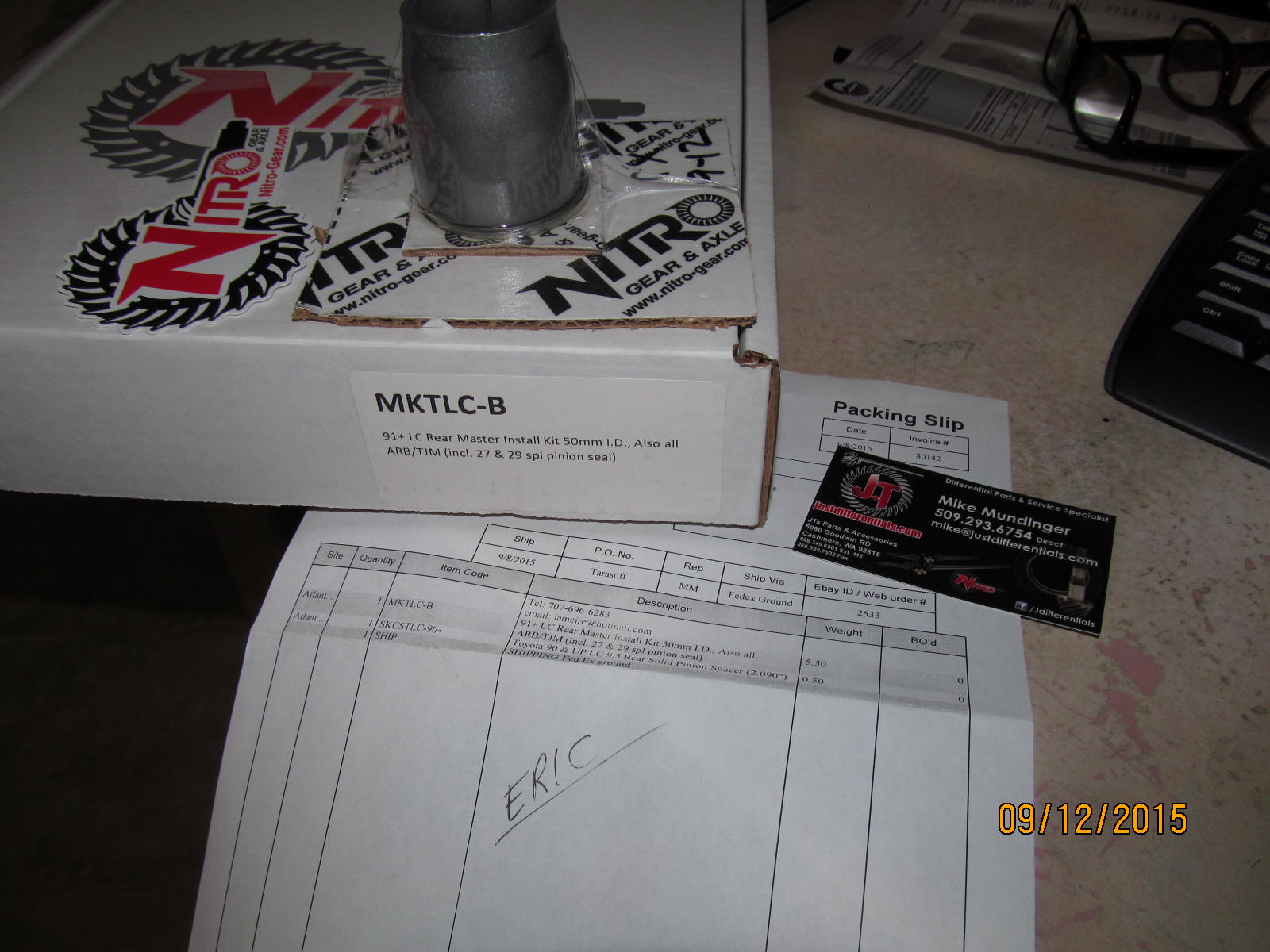

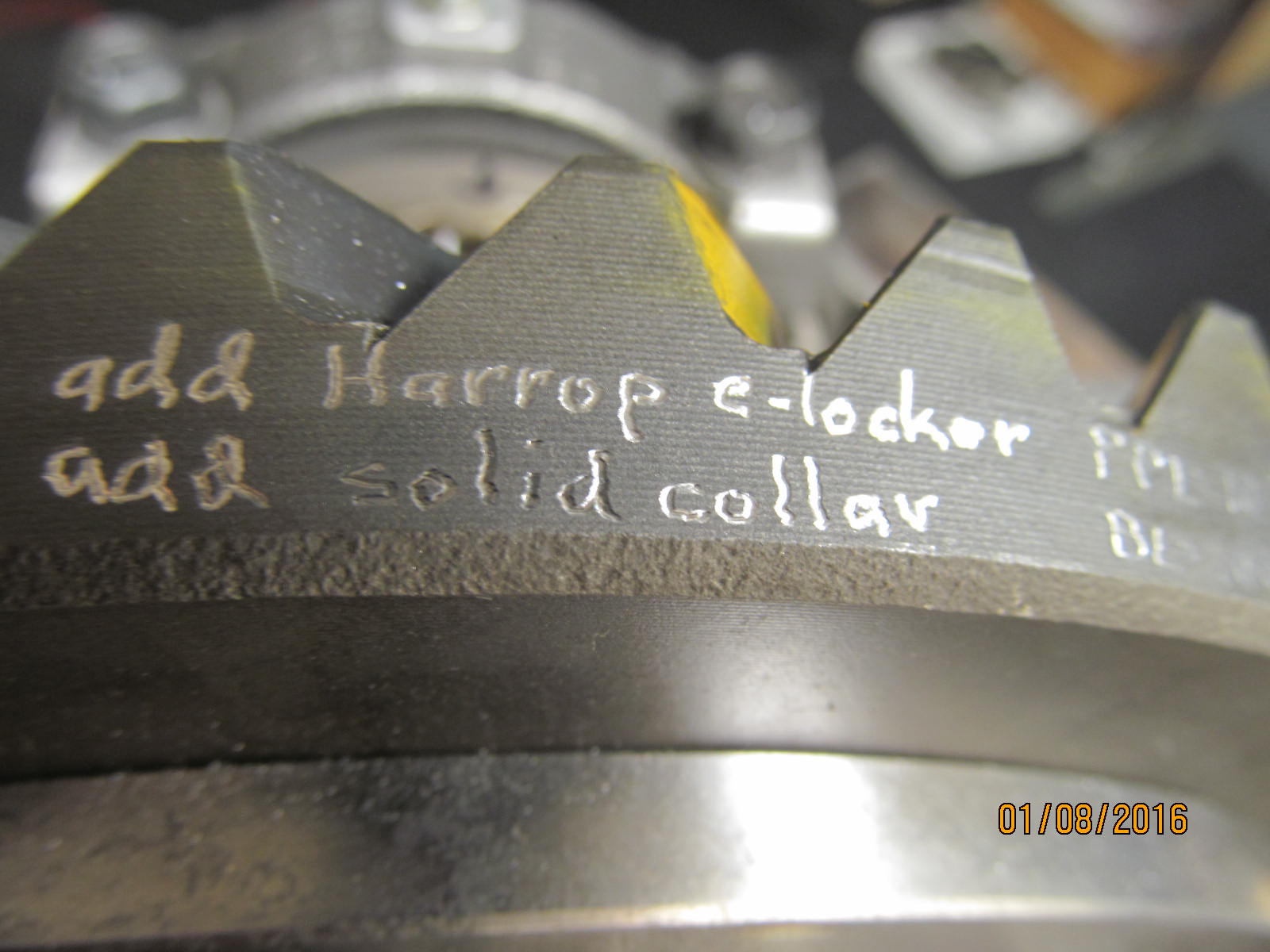

Eric had Mike from JustDifferentials send a new master install kit and solid collar.

For a Harrop install, just new carrier bearings is the norm.....but Eric figured that as long as I'm

in there now is the time to get new pinion bearings and a solid collar .

|

|

|

|

|

Also received the Harrop e-locker directly from Australia.

|

|

|

|

|

A tote arrived from Eric...

|

|

|

|

|

It is well cushioned.

|

|

|

|

|

A well wrapped open 9.5" with bubble wrap and saran plastic wrap.

|

|

|

|

|

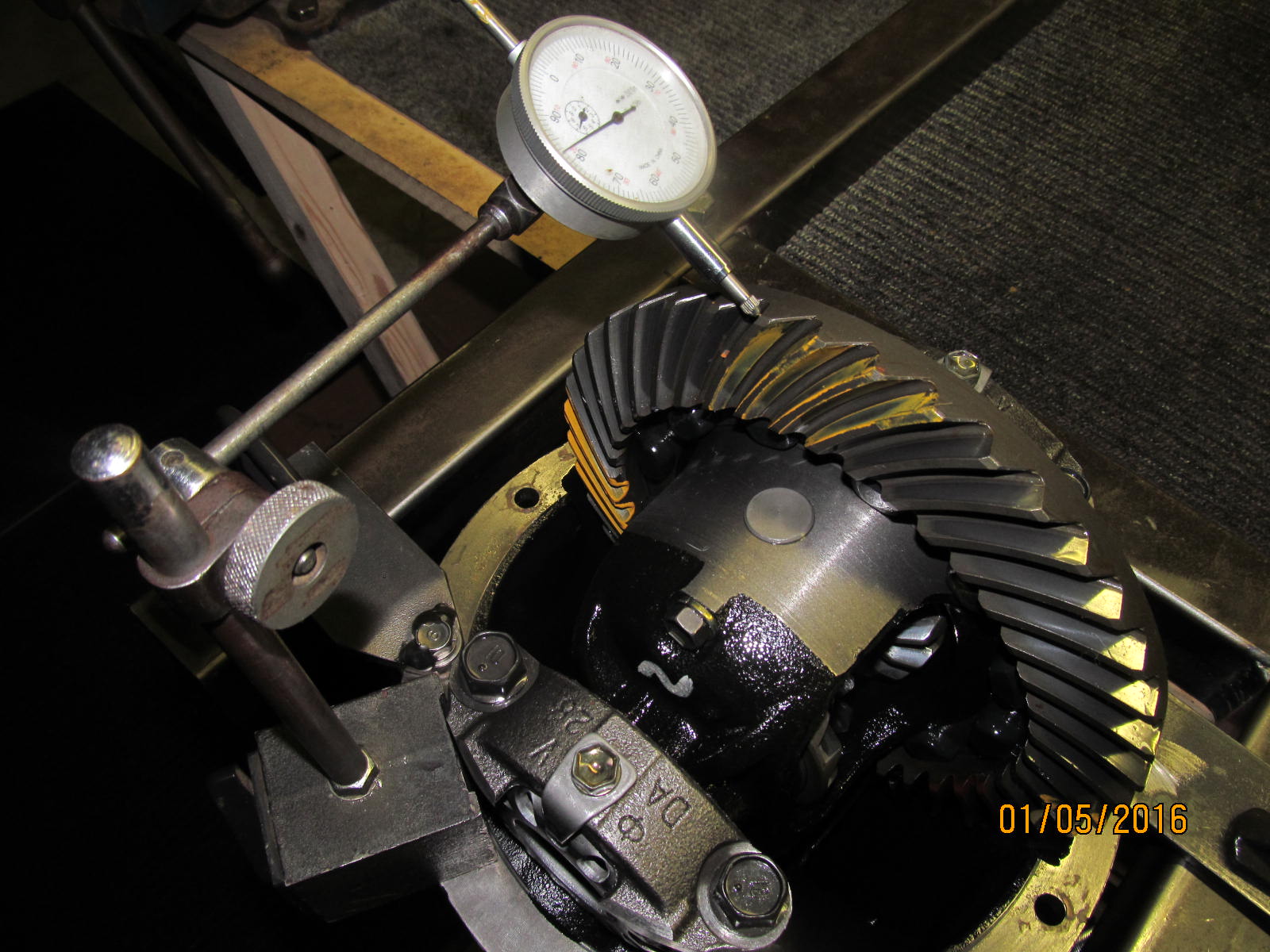

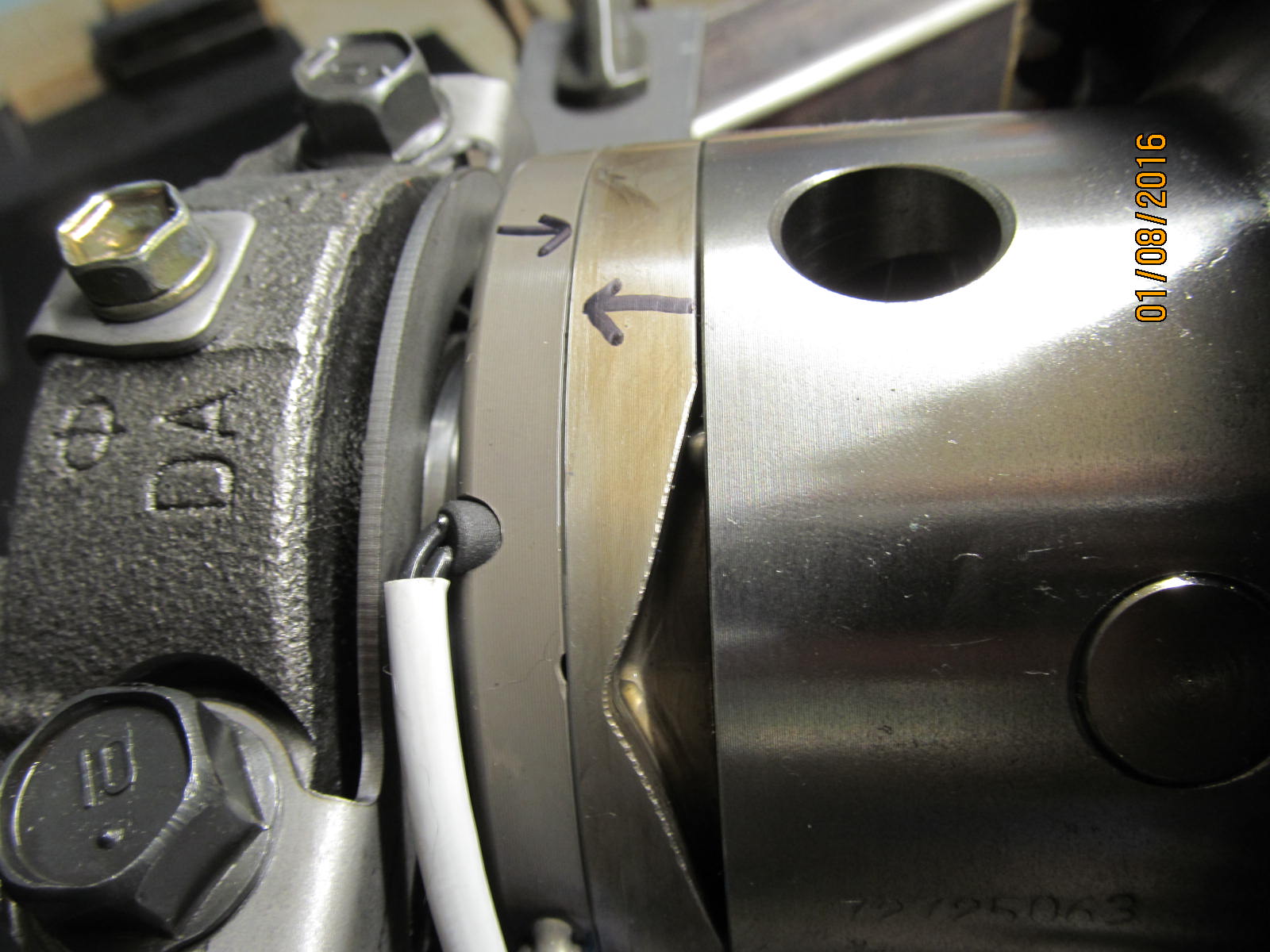

A quick pre-check of the painted pattern shows the gears are still good. Drive side.

|

|

|

|

|

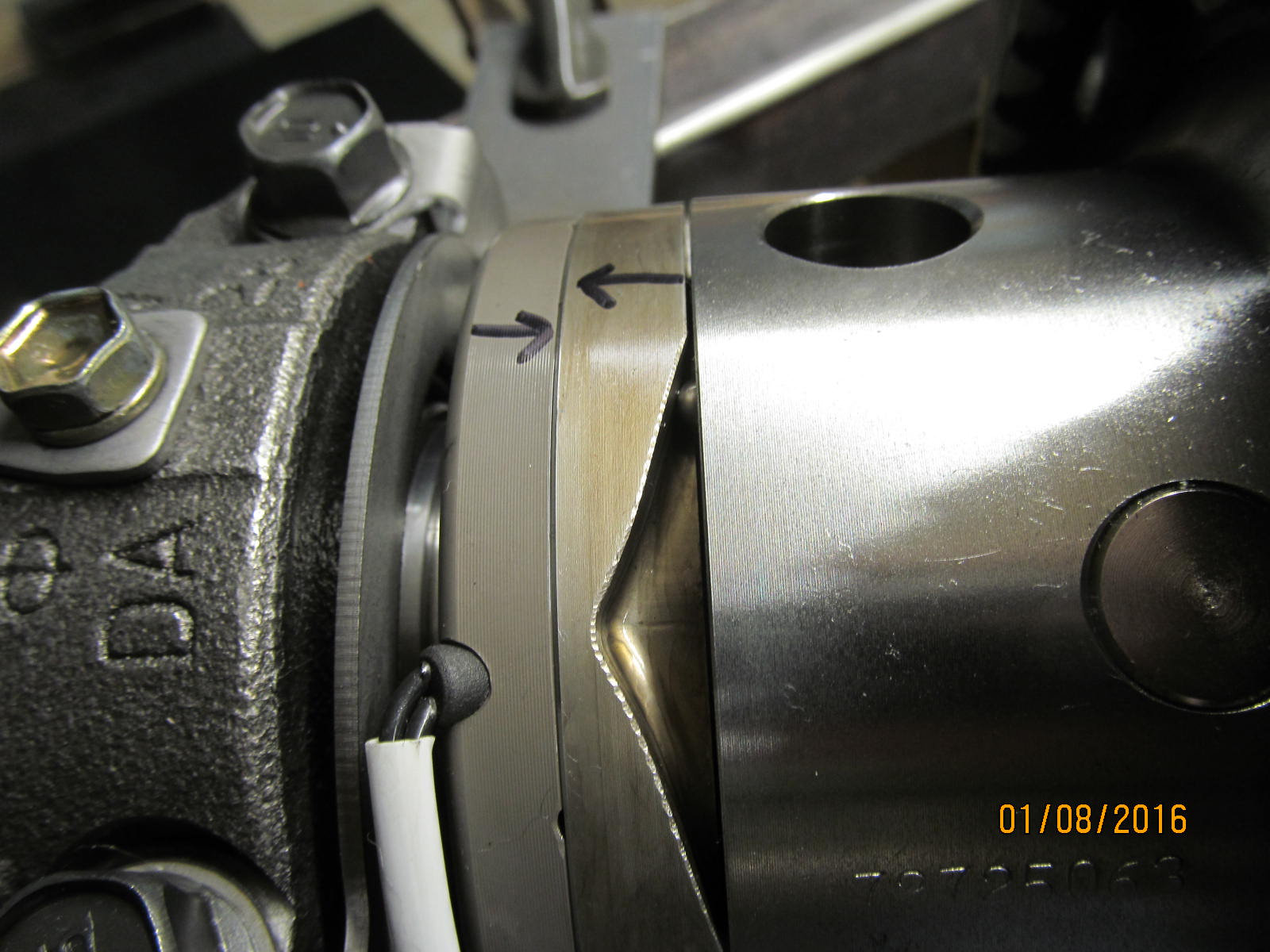

Coast side.

|

|

|

|

|

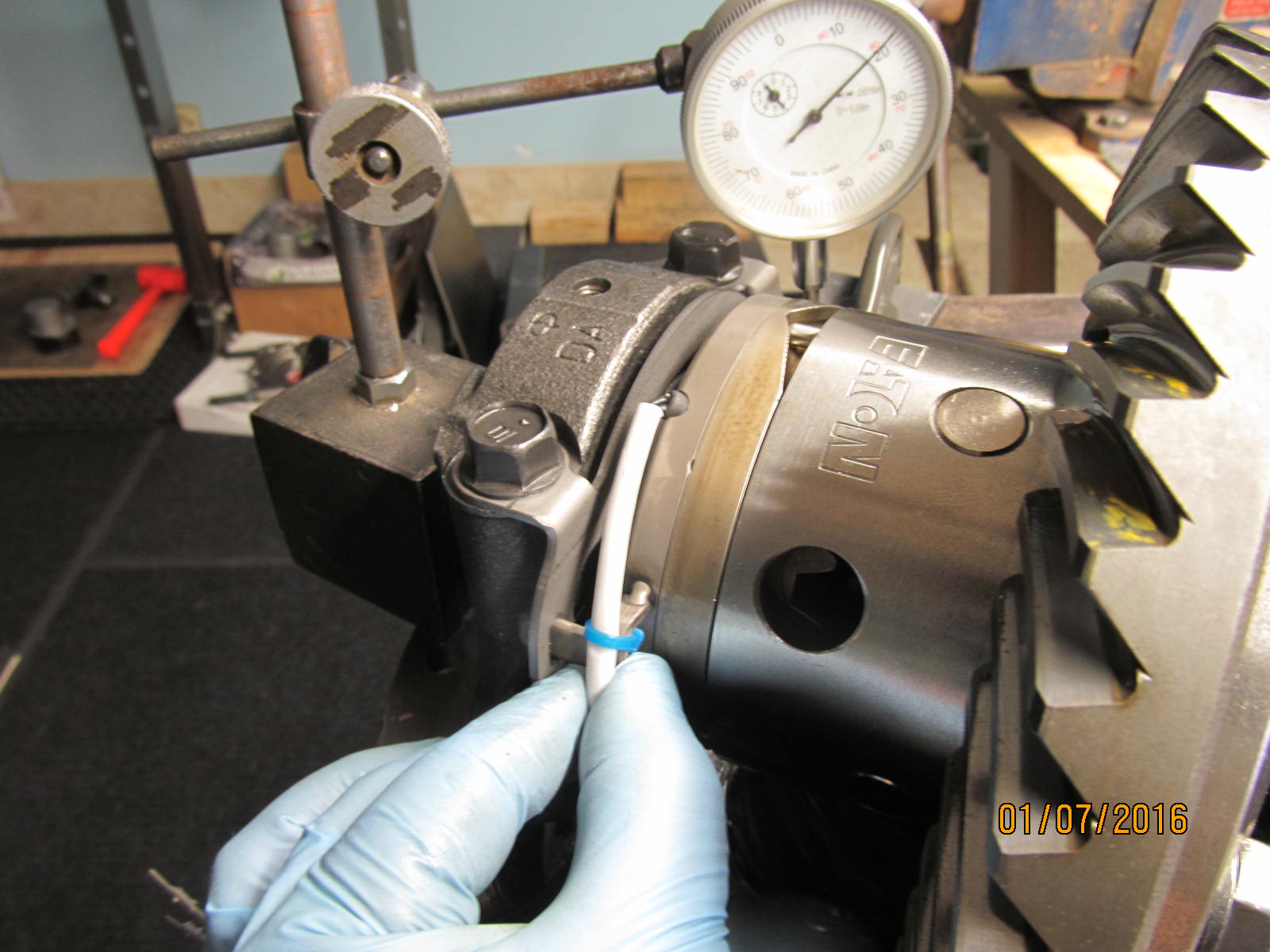

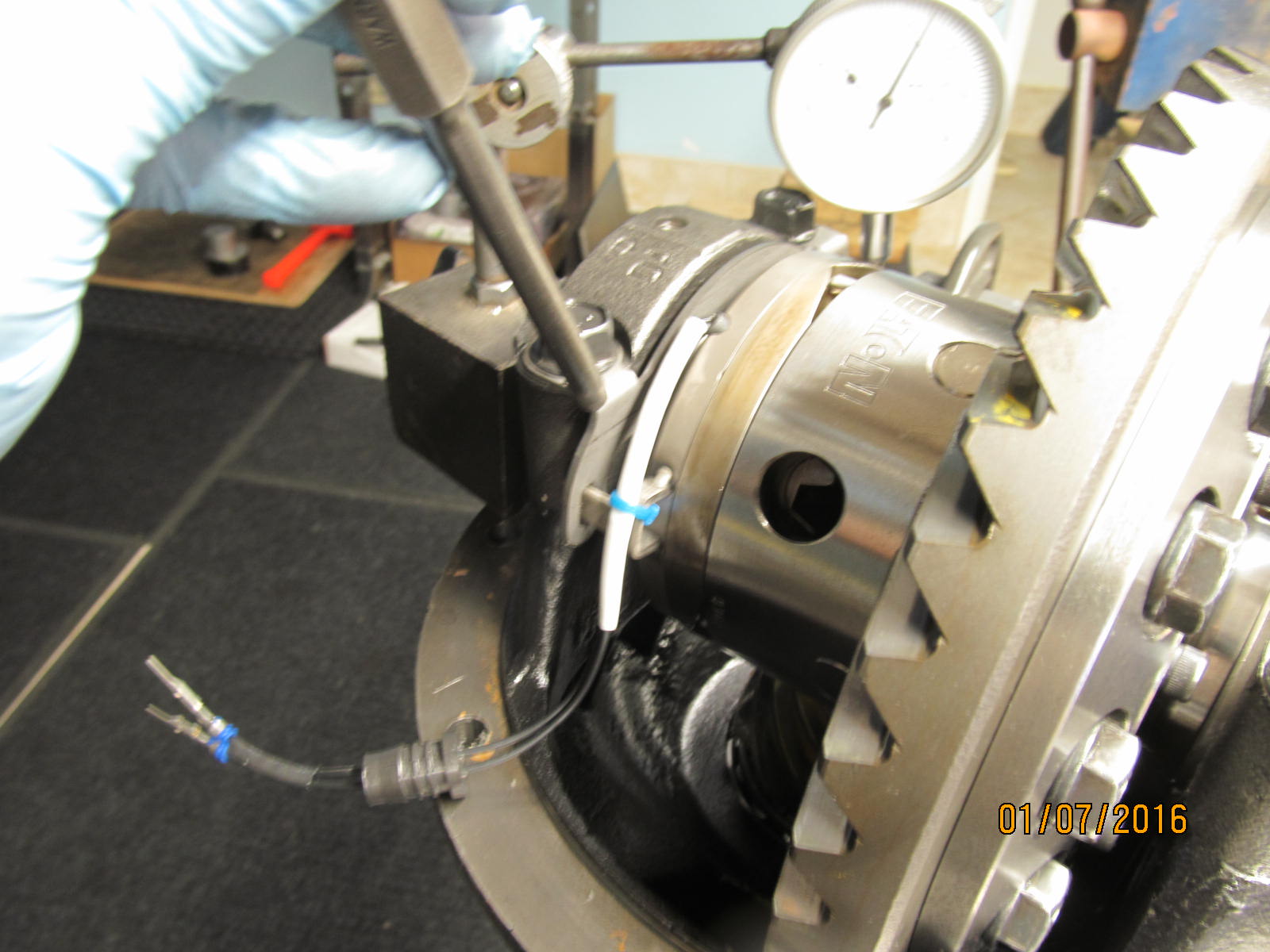

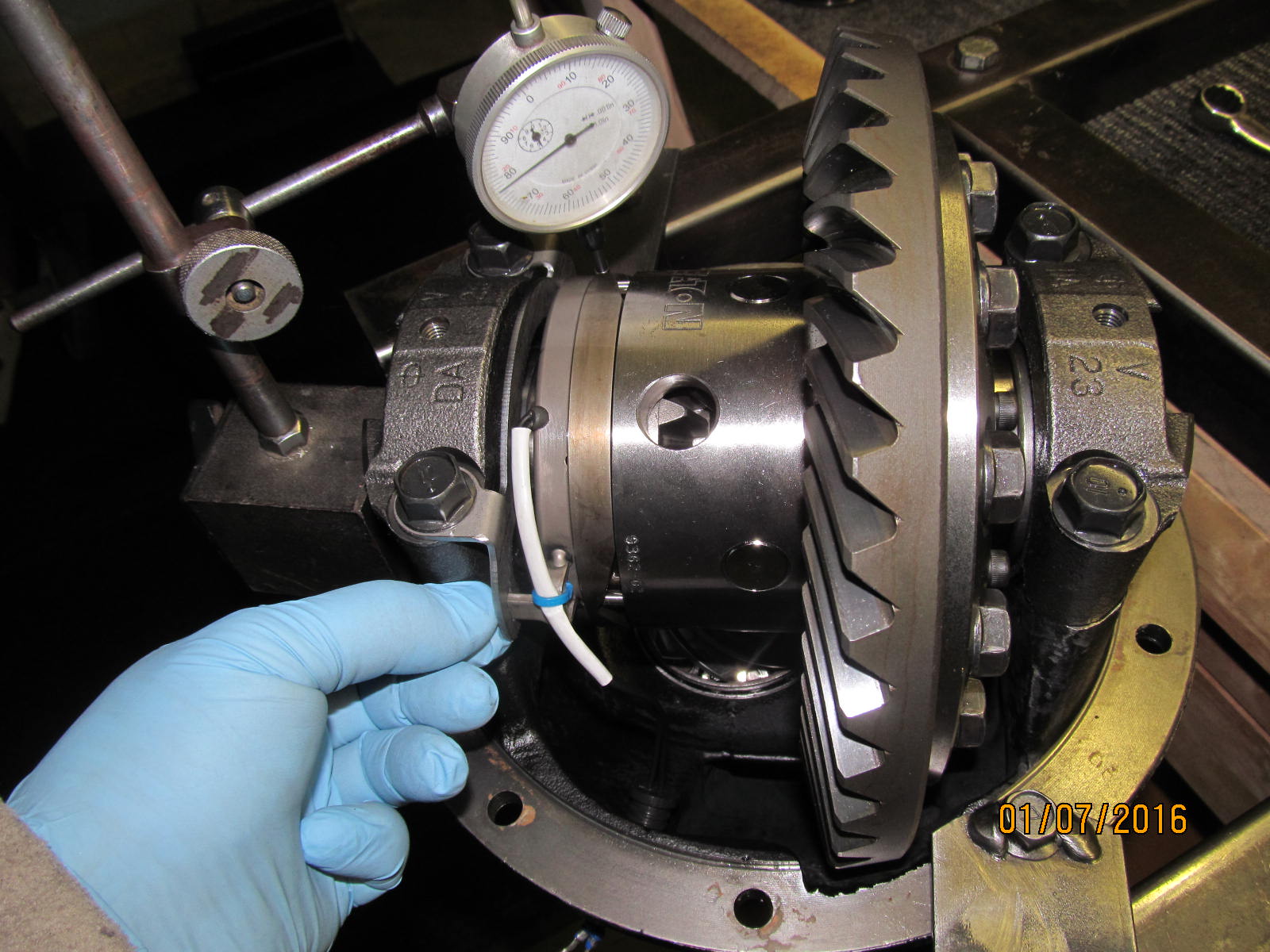

Original backlash was in the neighborhood of .005~.008"

|

|

|

|

Everything is layed out and organized....don't get over-excited like I did because there were no paper

instructions supplied. More on that in a few pictures.

|

|

|

|

|

First task....removing the ring gear for re-use. Remove the 12 ring bolts/nuts and take the cross-pin out.

|

|

|

|

|

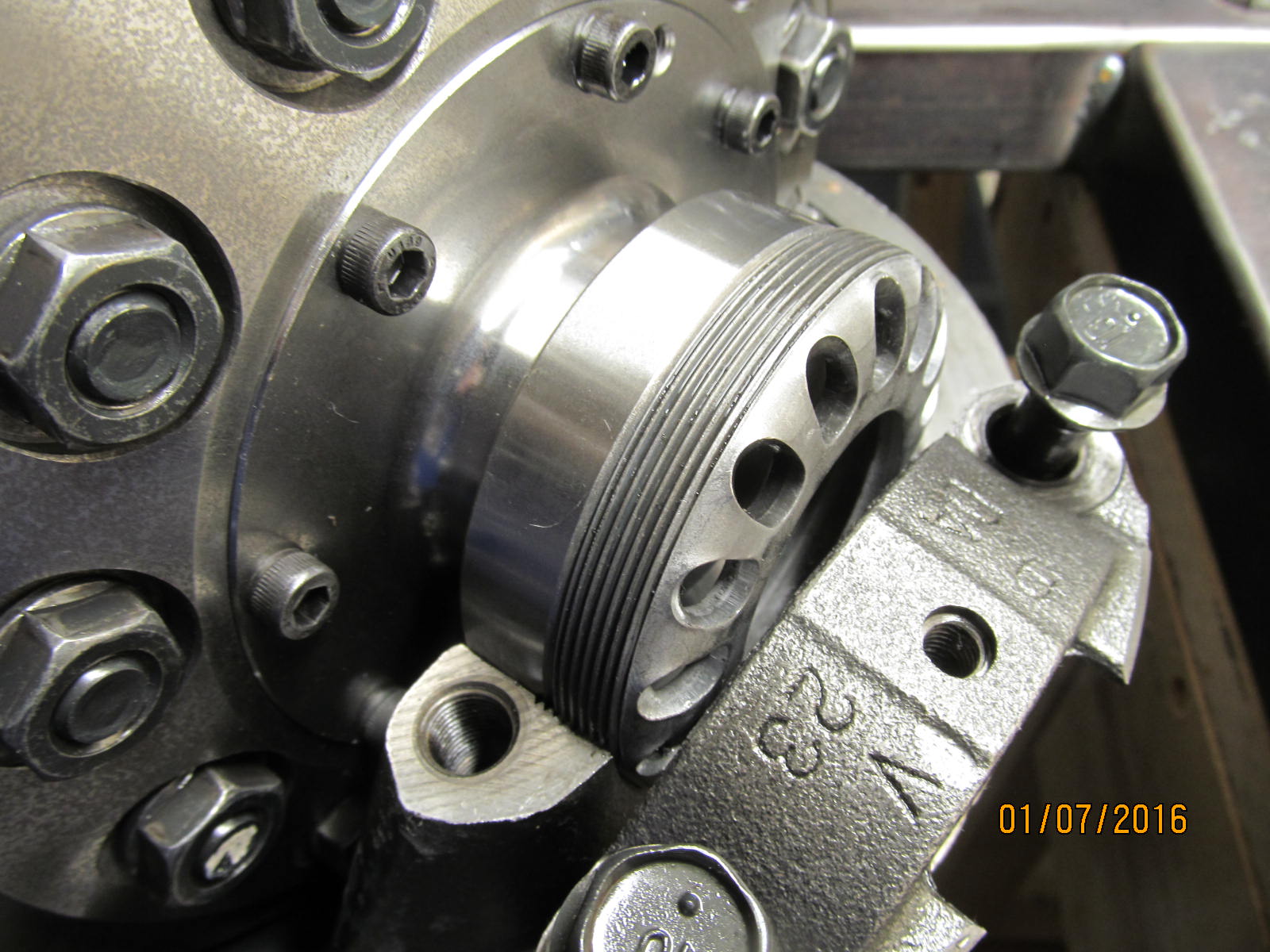

Engravings on the Harrop.

|

|

|

|

|

Nicely machined.

|

|

|

|

|

..............

|

|

|

|

|

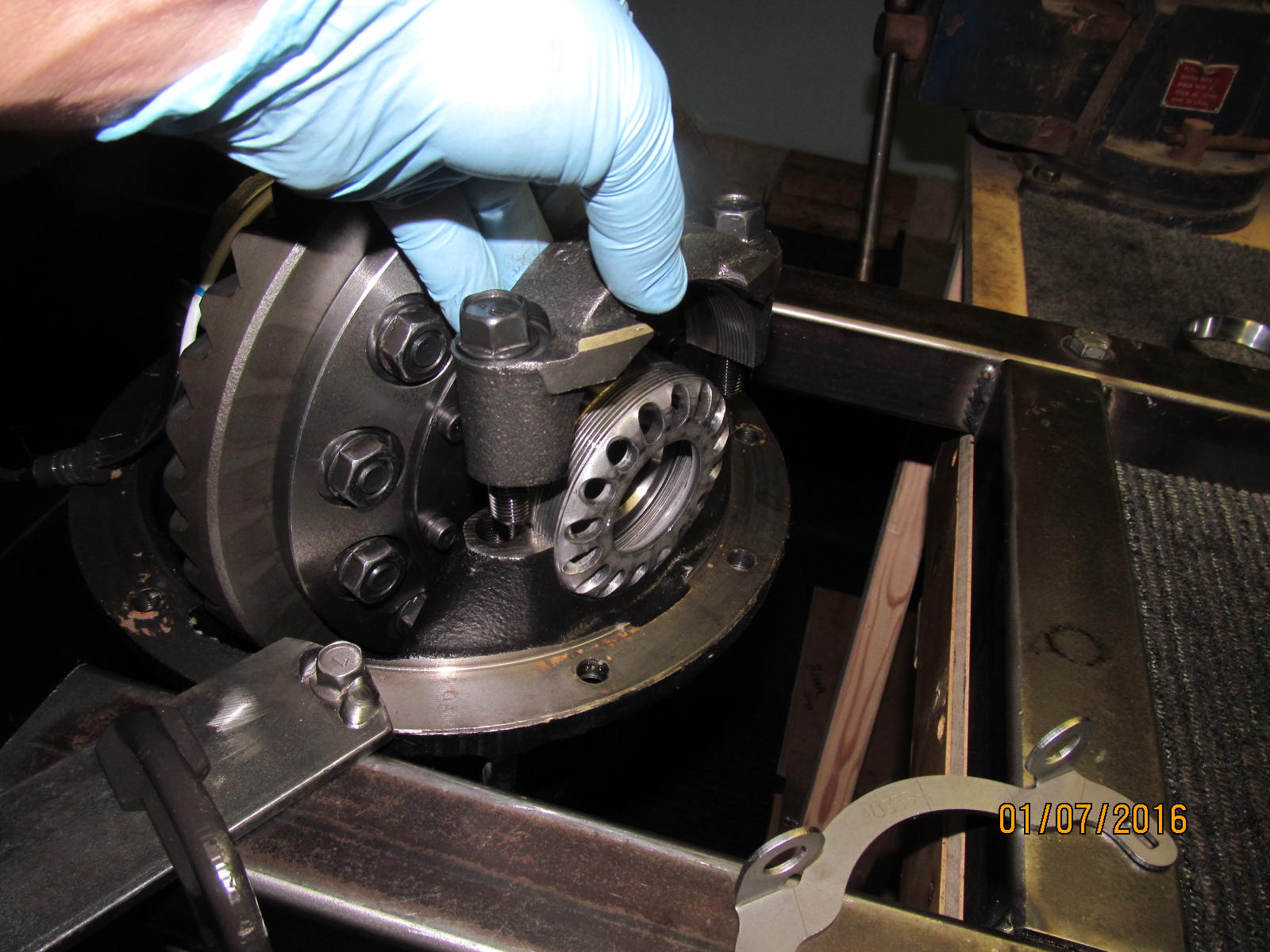

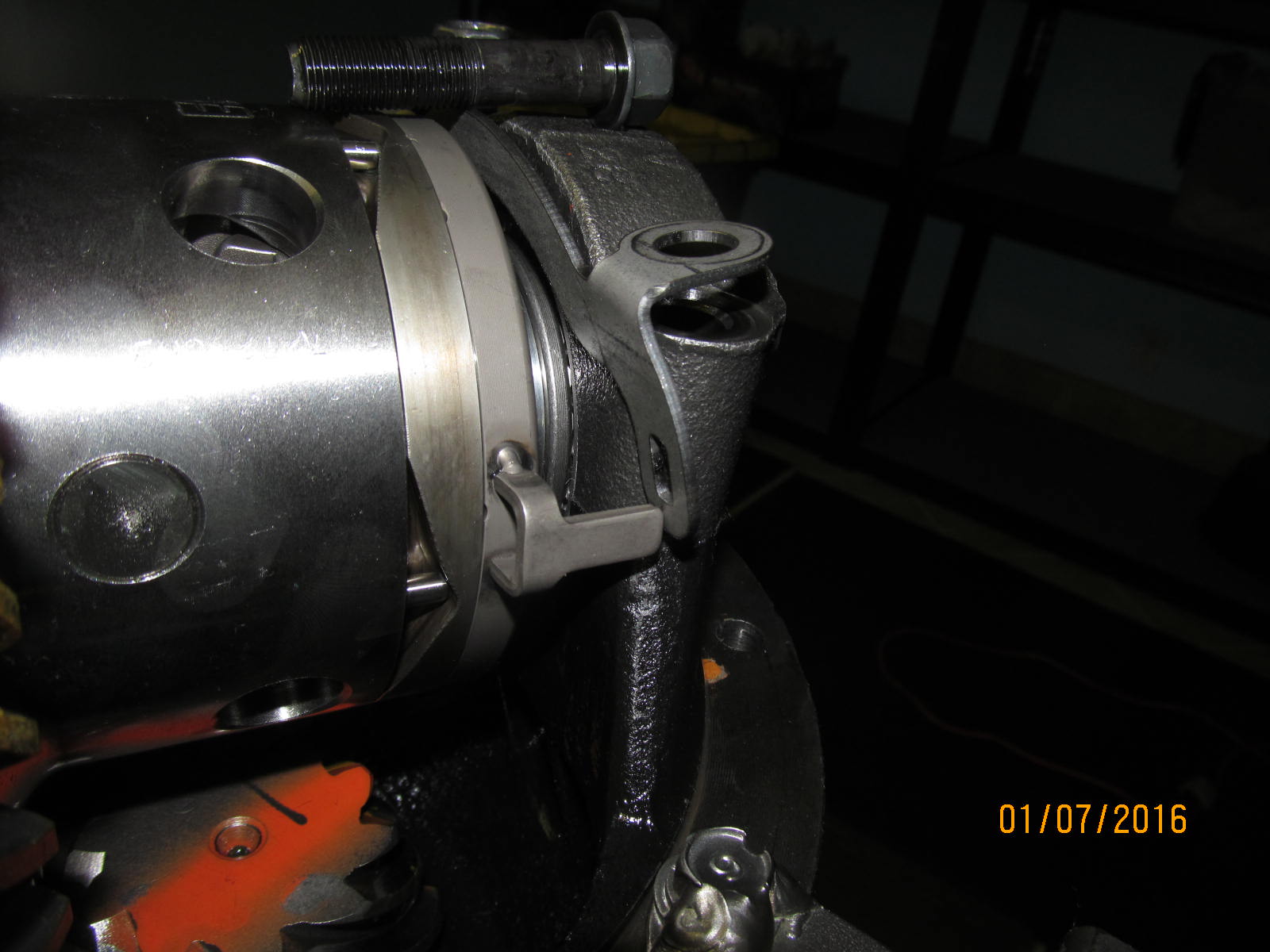

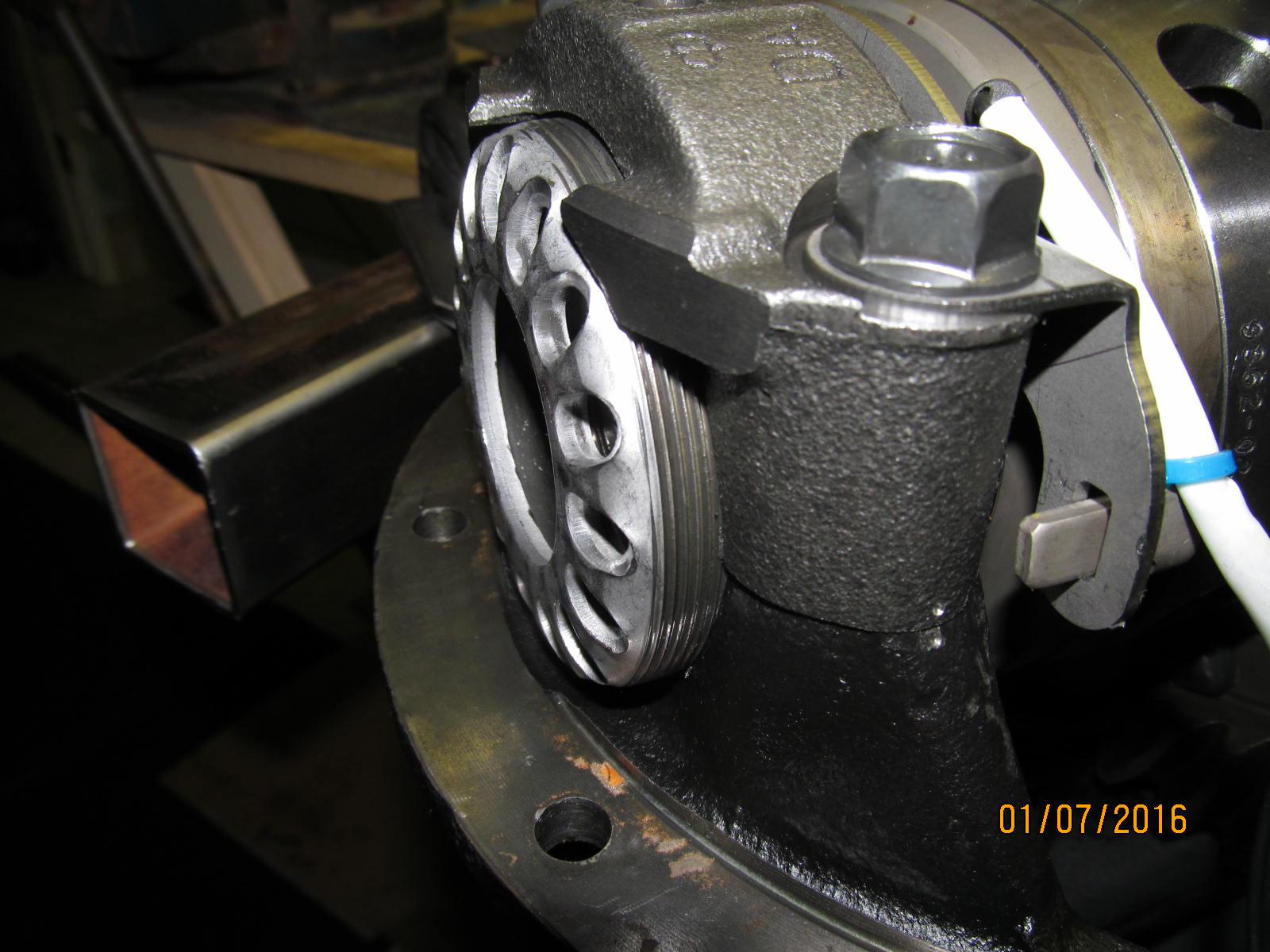

The bracket that was included with the Harrop shown located in place over the locker tabs.

|

|

|

|

|

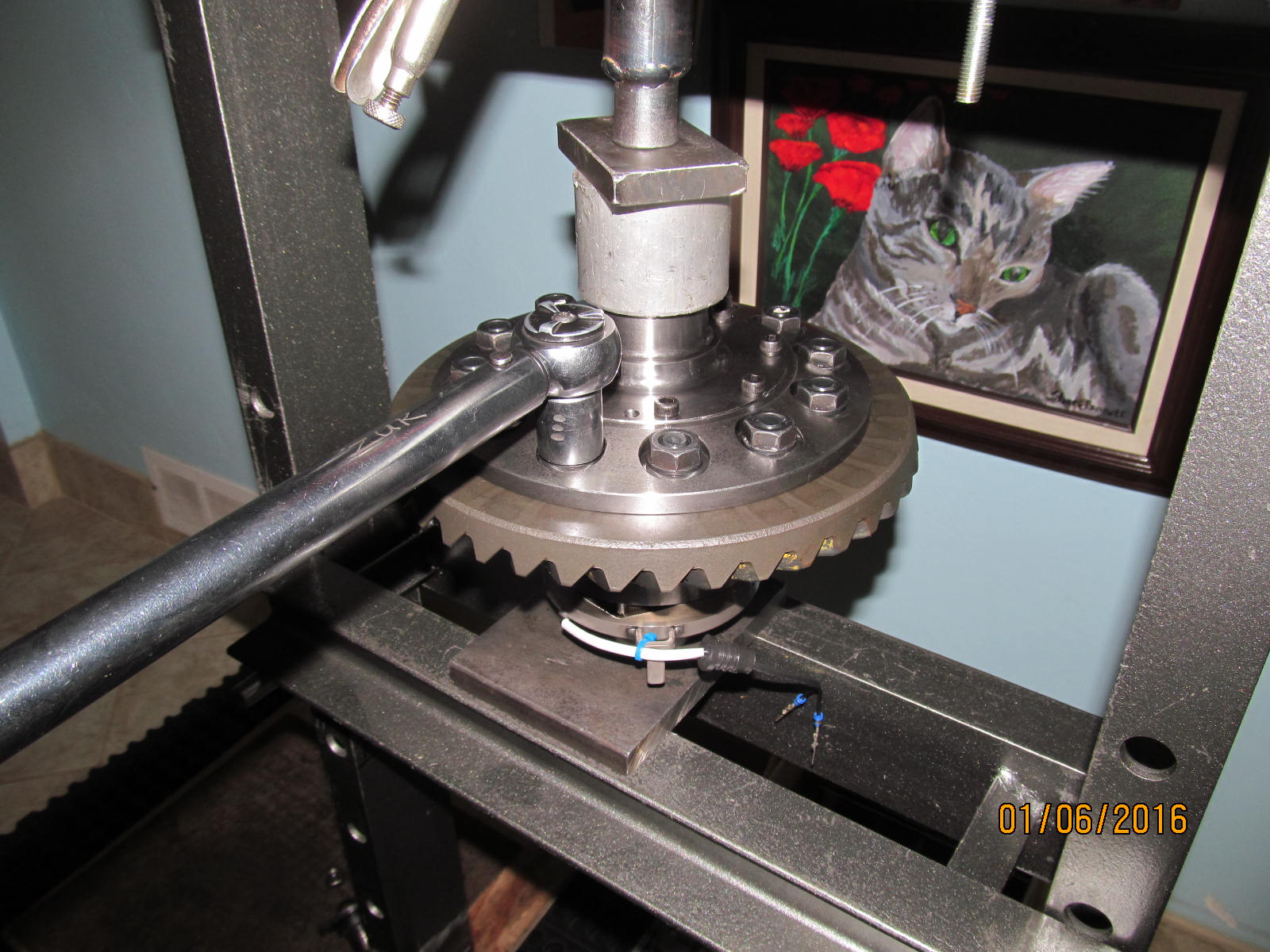

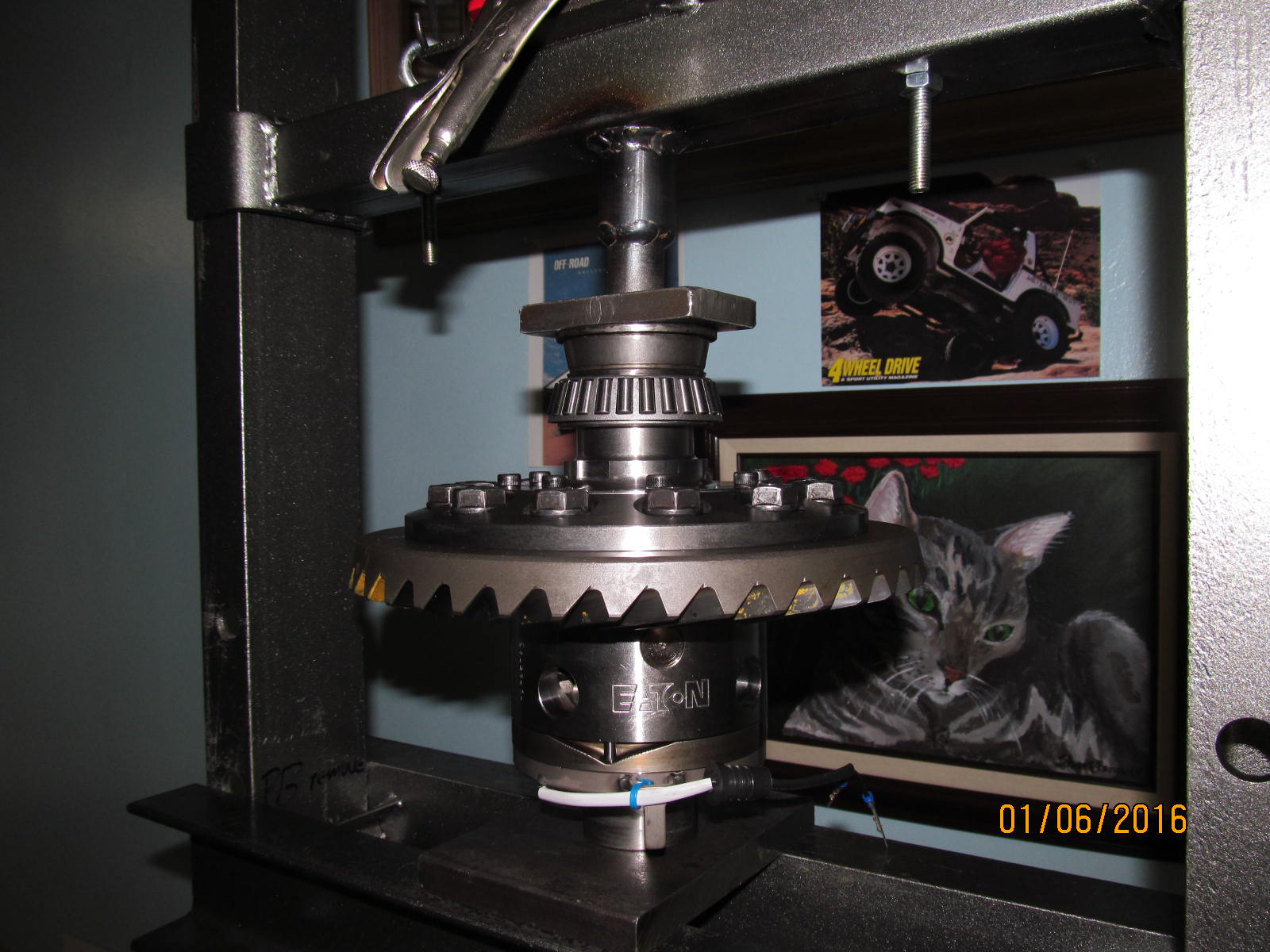

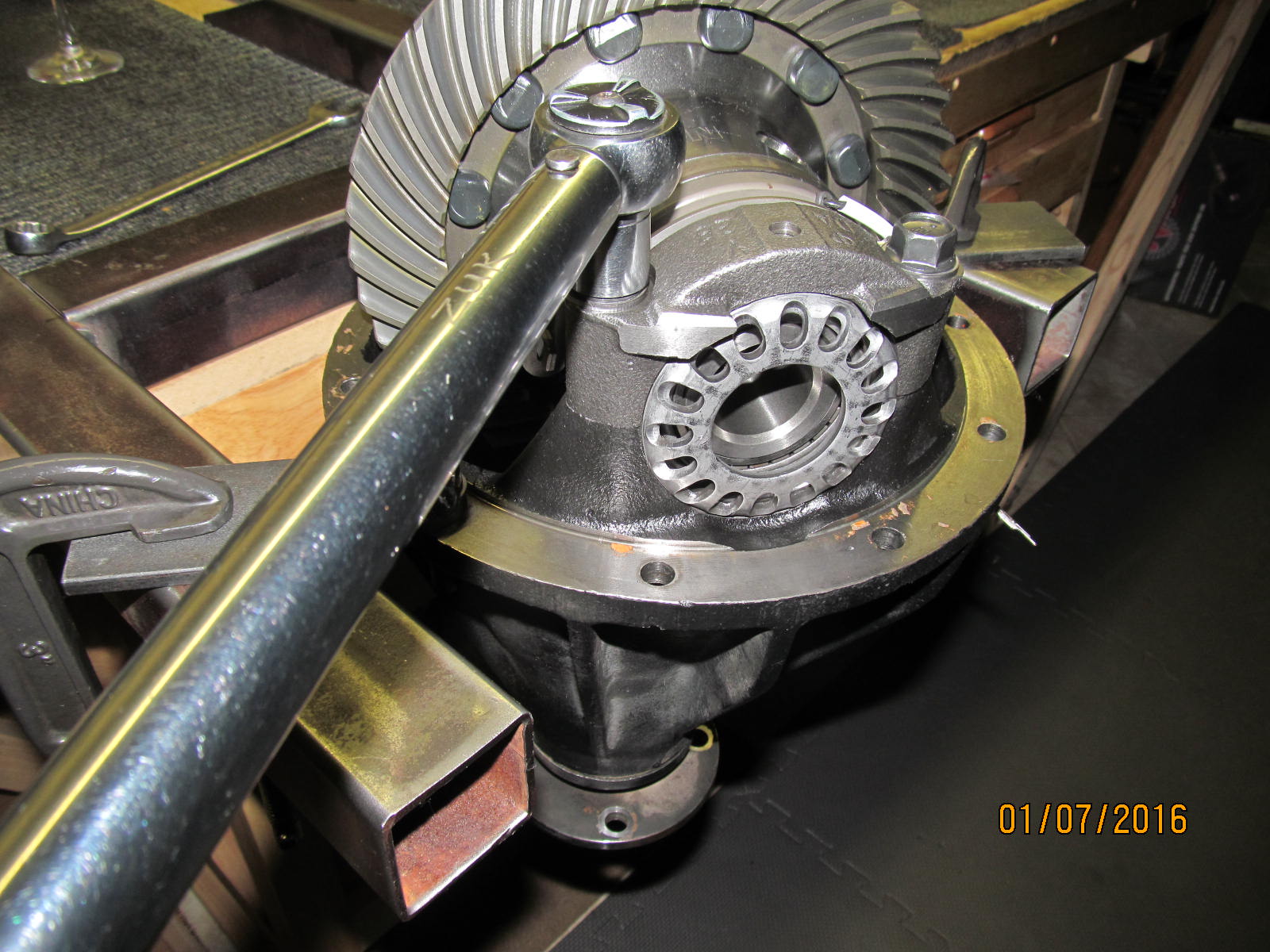

On to business, the original ring is bolted in place with 81 ft/lb on the 12 ring bolts/nuts.

|

|

|

|

New bearings from the master kit are pressed on the locker journals.

My younger sister painted that kitty portrait herself.

|

|

|

|

|

Ring and carrier bearings are on.....nothing more to do with this piece of the puzzle.

|

|

|

|

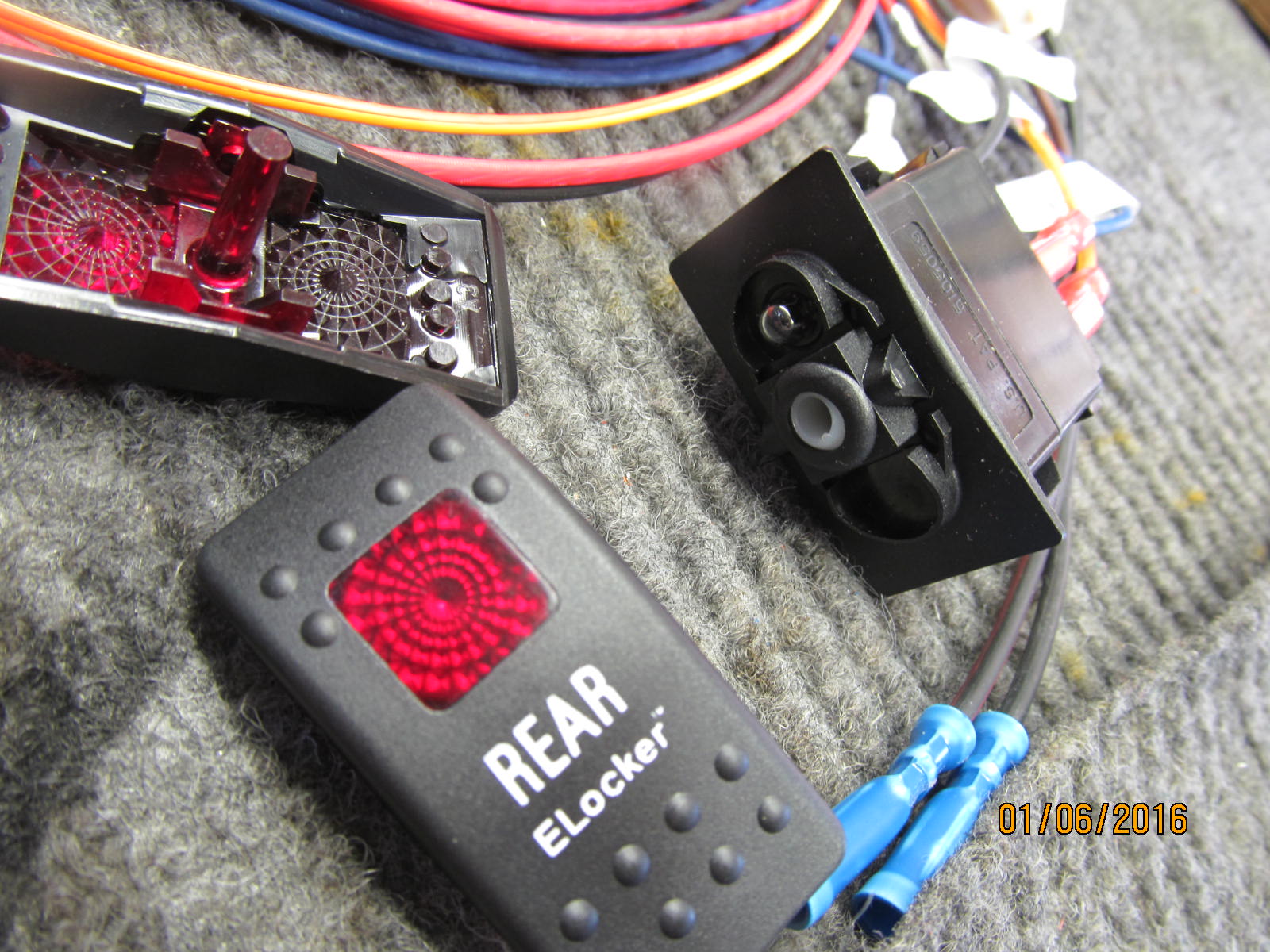

The locker stuff is layed out....at the time, I was thinking how the heck could they forget the instructions.

Actually, they included an extra "front locker" switch toggle cover as shown....no front locker

planned in this rig yet.

|

|

|

|

|

.............

|

|

|

|

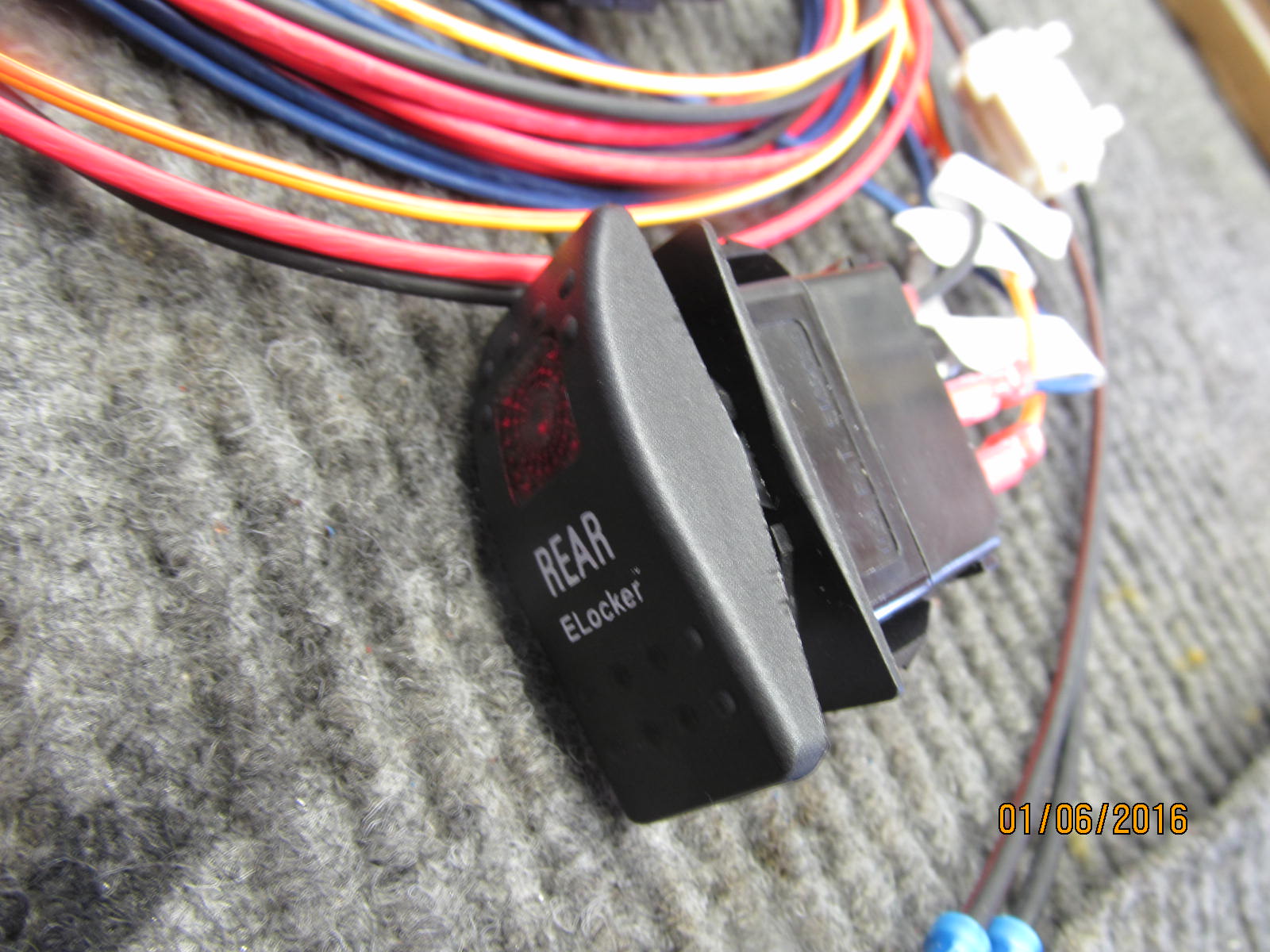

That's where the instructions are.....ok.

This is the harness piece that gets spliced into the 2 e-locker wires and routes up to the dash.

|

|

|

|

Instructions from their website.... harrop.com.au/install/elocker.pdf

Also available from my server Harrop Instructions

|

|

|

|

|

Conduit that was supplied.

|

|

|

|

|

The other part of the wiring harness.

|

|

|

|

|

..............

|

|

|

|

|

....................

|

|

|

|

|

Rear cover snaps in place nicely and makes for a good quality toggle switch.

|

|

|

|

|

This supplied bracket goes here and slides into the 2 tabs from the Harrop.

|

|

|

|

|

Cap goes in loosely in place....

|

|

|

|

|

A little bit of jiggling helps the bracket go smoothly in place.....

|

|

|

|

|

....but if I can do then anybody can do it.

|

|

|

|

|

That one stubborn tab will drop in place if you lift the Harrop case up for a moment.

|

|

|

|

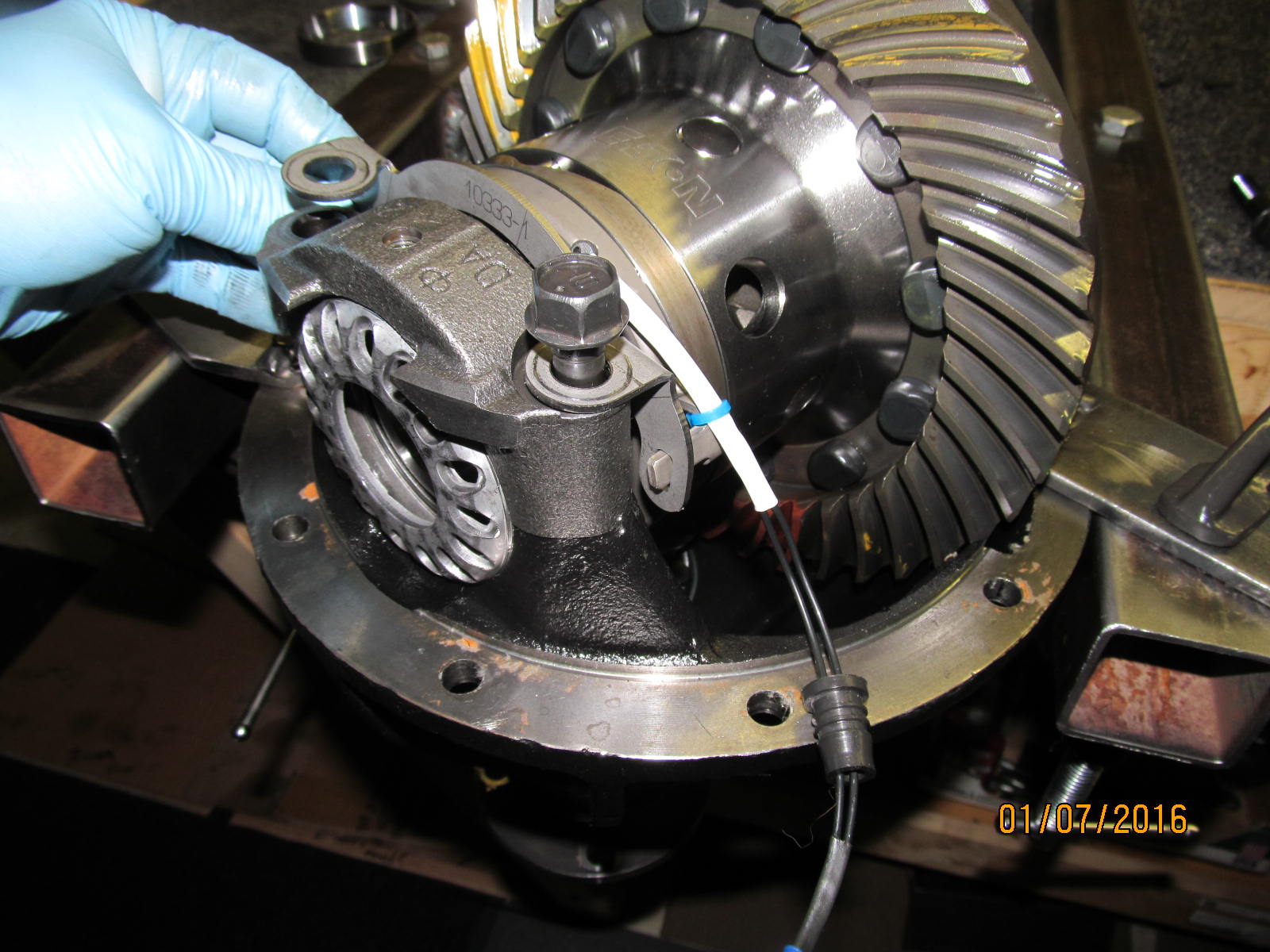

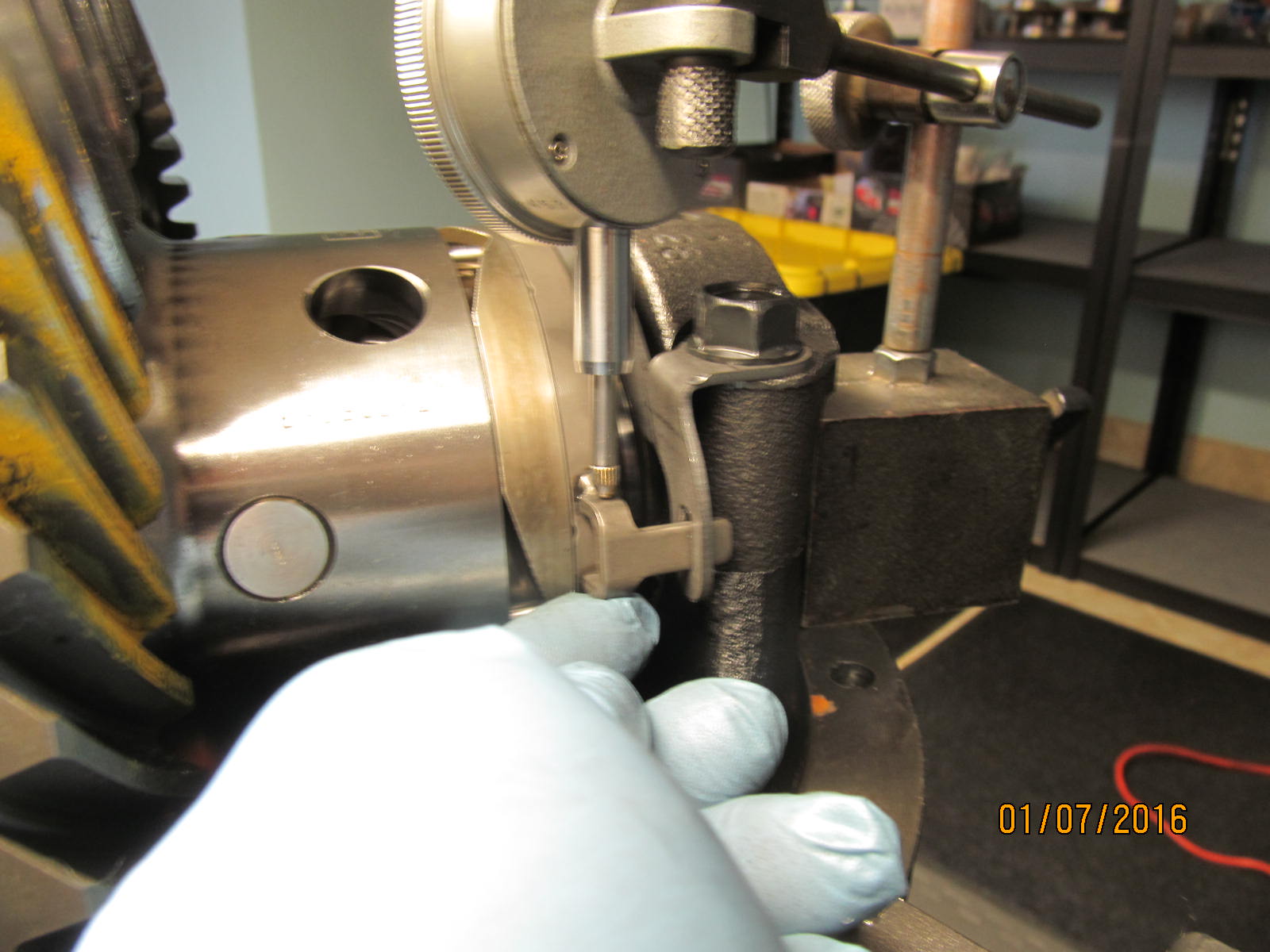

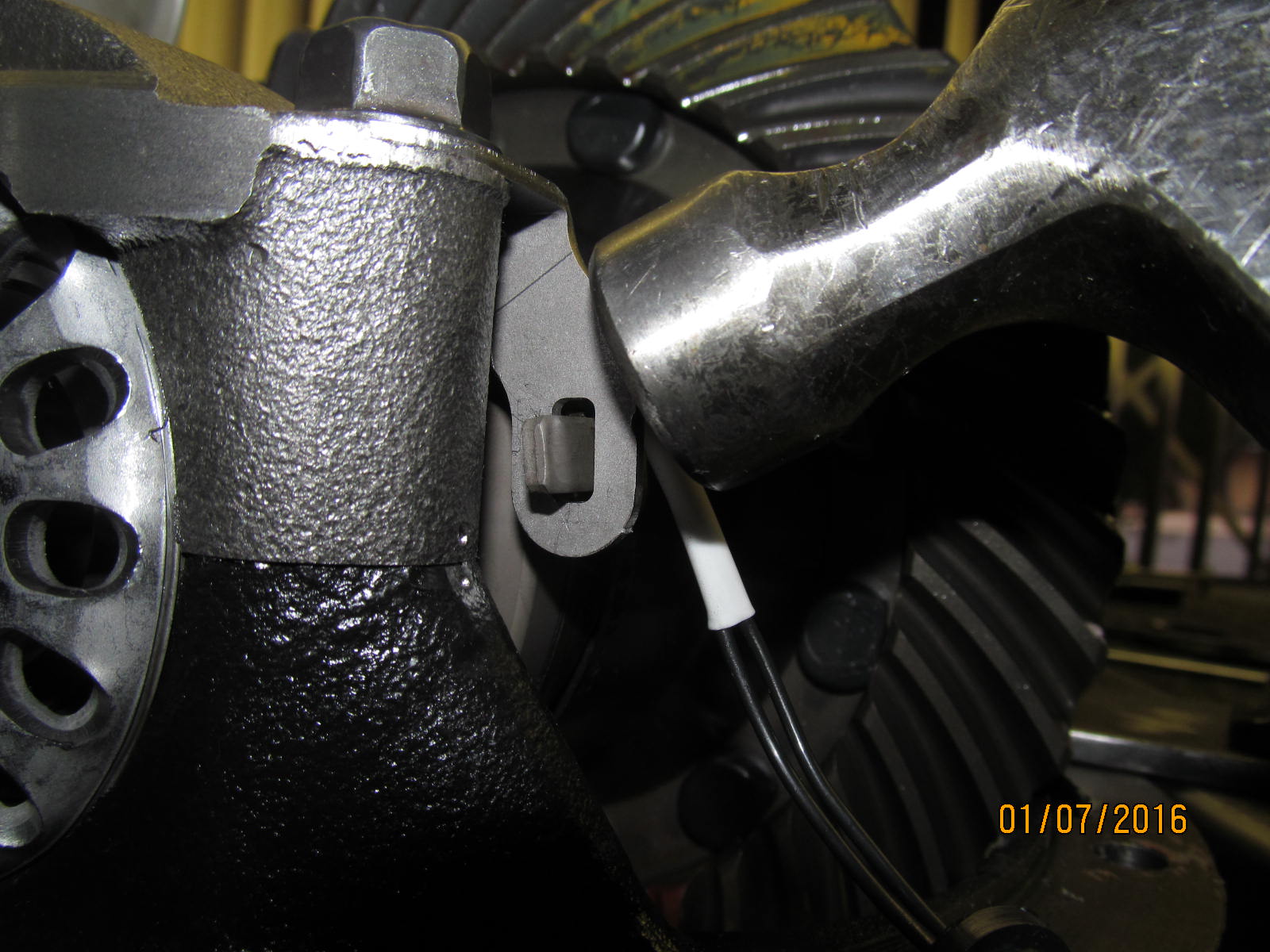

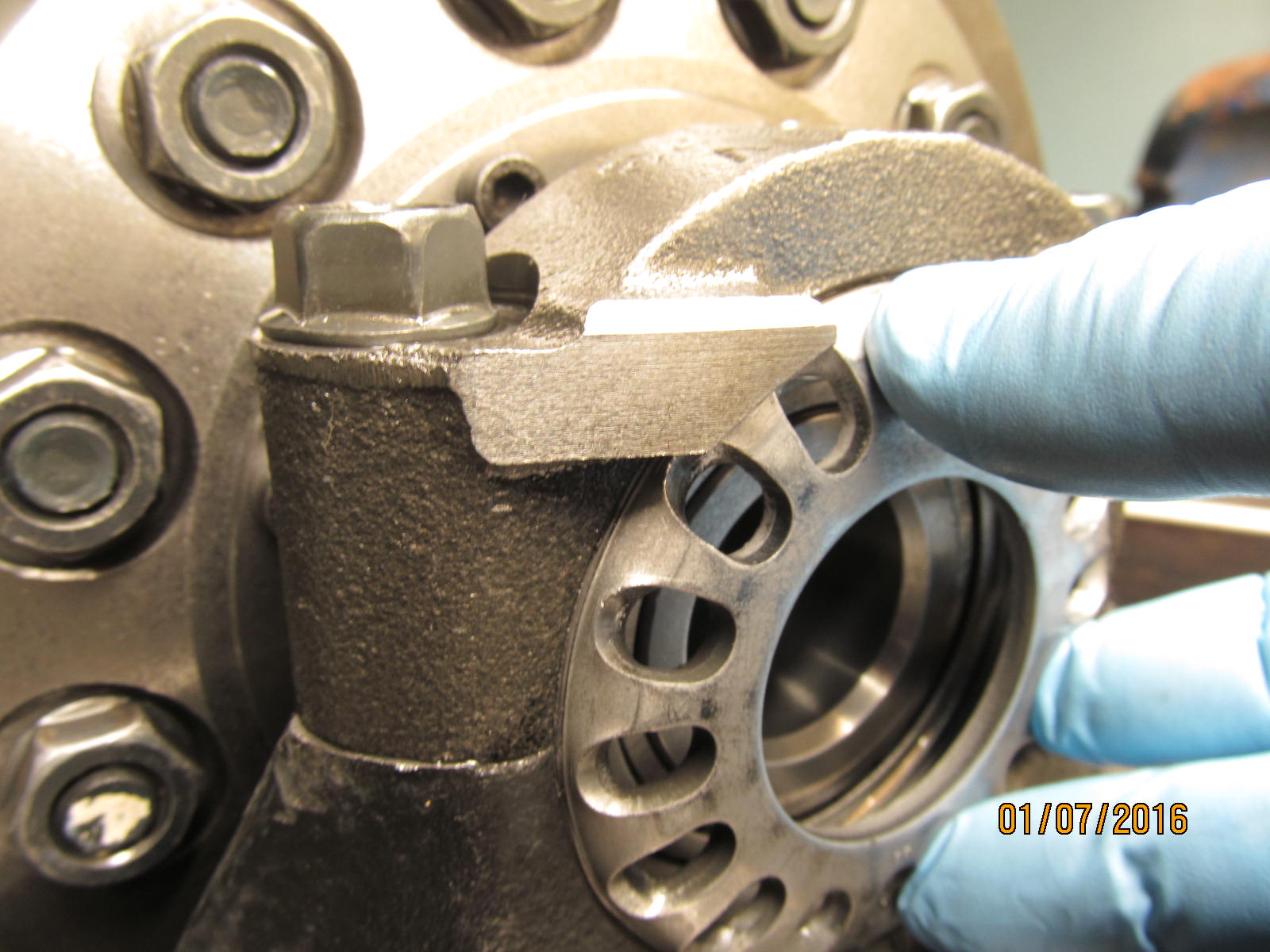

Page 6 step 21 of the online instructions talks of an approximate 2mm of radial freeplay for the

anti-rotation tabs. See those 2 welds on the tab? I did not want to stress them in any way so

light taps to the bracket allowed me to get the 2mm of play.

|

|

|

|

|

Checking radial freeplay here....

|

|

|

|

|

................

|

|

|

|

|

A light tap right here allows for plenty of play.

|

|

|

|

|

Light taps to persuade the soft steel bracket to move just a little.

|

|

|

|

|

Ready for drilling the hole for this pass-thru grommet.

|

|

|

|

|

This is the spot I chose.

|

|

|

|

|

Page 6 of the instructions talks of a 29/64 drill bit (.453")

|

|

|

|

|

Hole is drilled.

|

|

|

|

|

...............

|

|

|

|

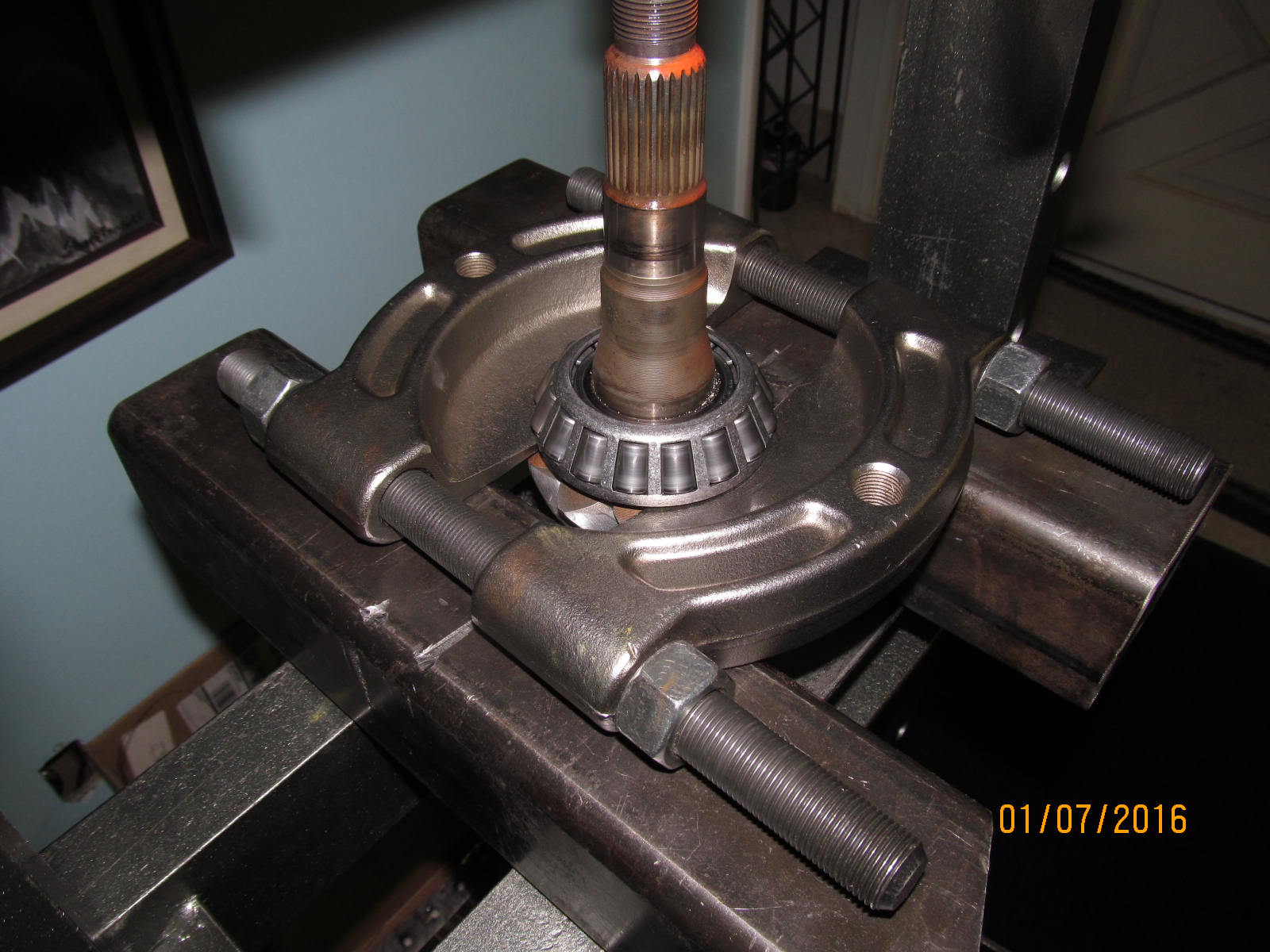

Time to put the solid collar and new pinion bearings in. This is normally

not done on a basic Harrop Install.

|

|

|

|

|

Flange was a tight fit.

|

|

|

|

|

Push the pinion out.

|

|

|

|

New large inner race is to be tapped/pressed in. The trick is to get it started straight and then it

will fall in the hole with gentle words.

|

|

|

|

|

Success....almost down all the way.

|

|

|

|

|

Using an old race, the final taps will seat it the remaining few millimeters.

|

|

|

|

|

Verified fully down.

|

|

|

|

|

The outer one is much easier.

|

|

|

|

|

Fully seated.

|

|

|

|

|

This bearing separator will remove the old pinion bearing.....

|

|

|

|

|

....with the help of the 12 ton Harbor Freight press.

|

|

|

|

|

The new bearing will be pressed on with the oem .051" shim.

|

|

|

|

|

The tubular widget I made up works superbly for this job.

|

|

|

|

|

The collar measured 2.090" and with the addition of .0465" worth of shims should put me close to the target.

|

|

|

|

|

Nope....no preload at all.

|

|

|

|

It's good to have a broad selection of collar shims. On try #2, I reduced the thickness of the shim

by .003" and that did the trick.

|

|

|

|

|

Last chance to lube up the bearings for smooth readings.

|

|

|

|

The new seal is packed with grease around the garter spring to prevent it from popping off from

shock waves caused by the hammer.

|

|

|

|

|

..............

|

|

|

|

|

Often, I use aluminum anti-seize when I anticipate that I will be really cranking down on the nut.

|

|

|

|

I use the electric impact to tighten it down 90%....then I break out the cheater bar for

the final tweaking.

|

|

|

|

|

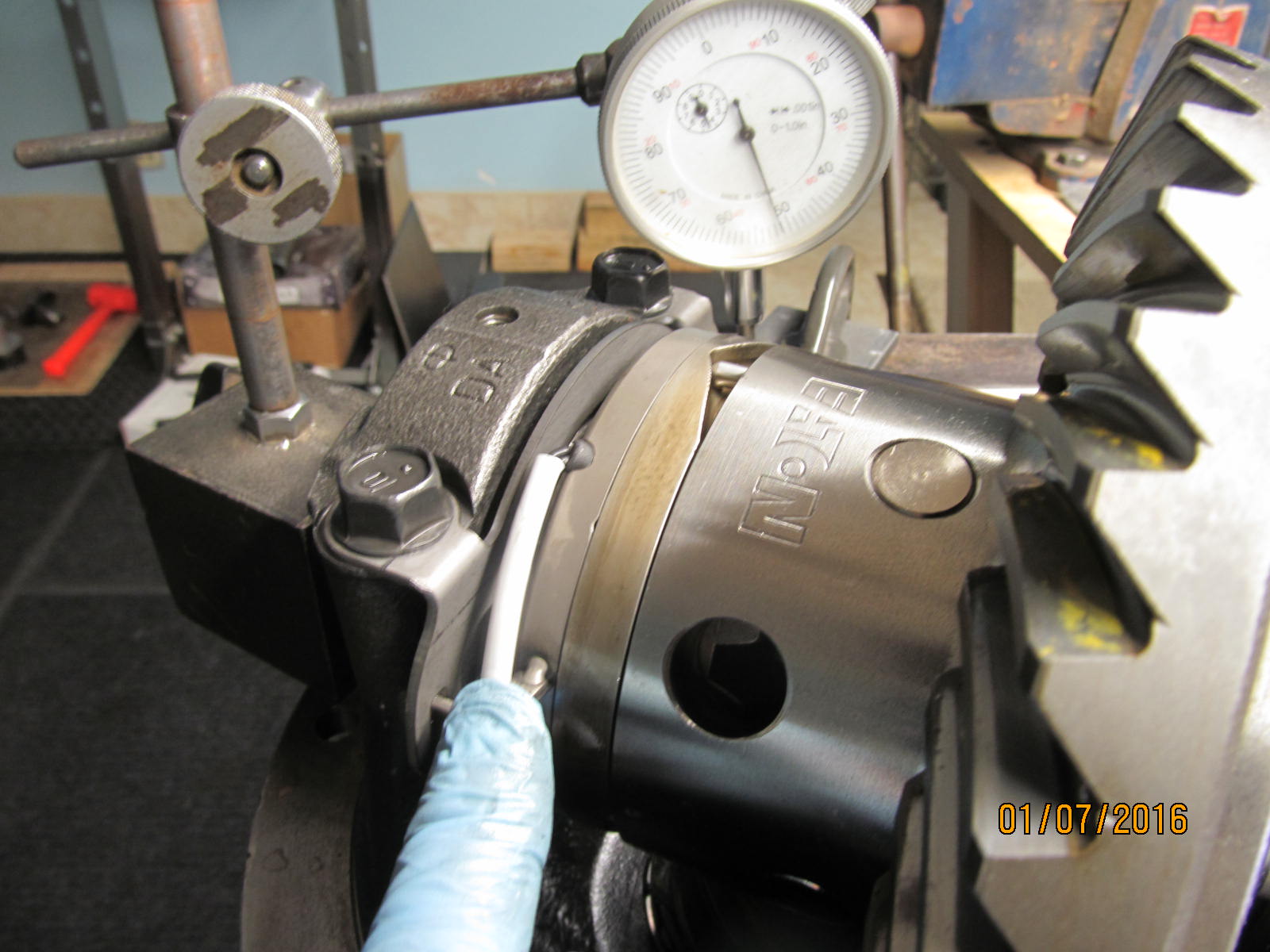

8 inch/lb.....I can get the pre-load higher by using a cheater bar.

|

|

|

|

|

That's a 150 ft/lb rated typical pendulum style torque wrench. Attached is a doubler that allows for 300 ft/lb.

|

|

|

|

|

Even with the anti-seize, I did manage to reach 300 ft/lb and the preload is right at 10 maybe a smidge more.

|

|

|

|

|

DING.

|

|

|

|

|

With the pinion end complete, now the final assembly can happen.

|

|

|

|

|

Now the rubber grommet will be pulled all the way thru....just not right now.

|

|

|

|

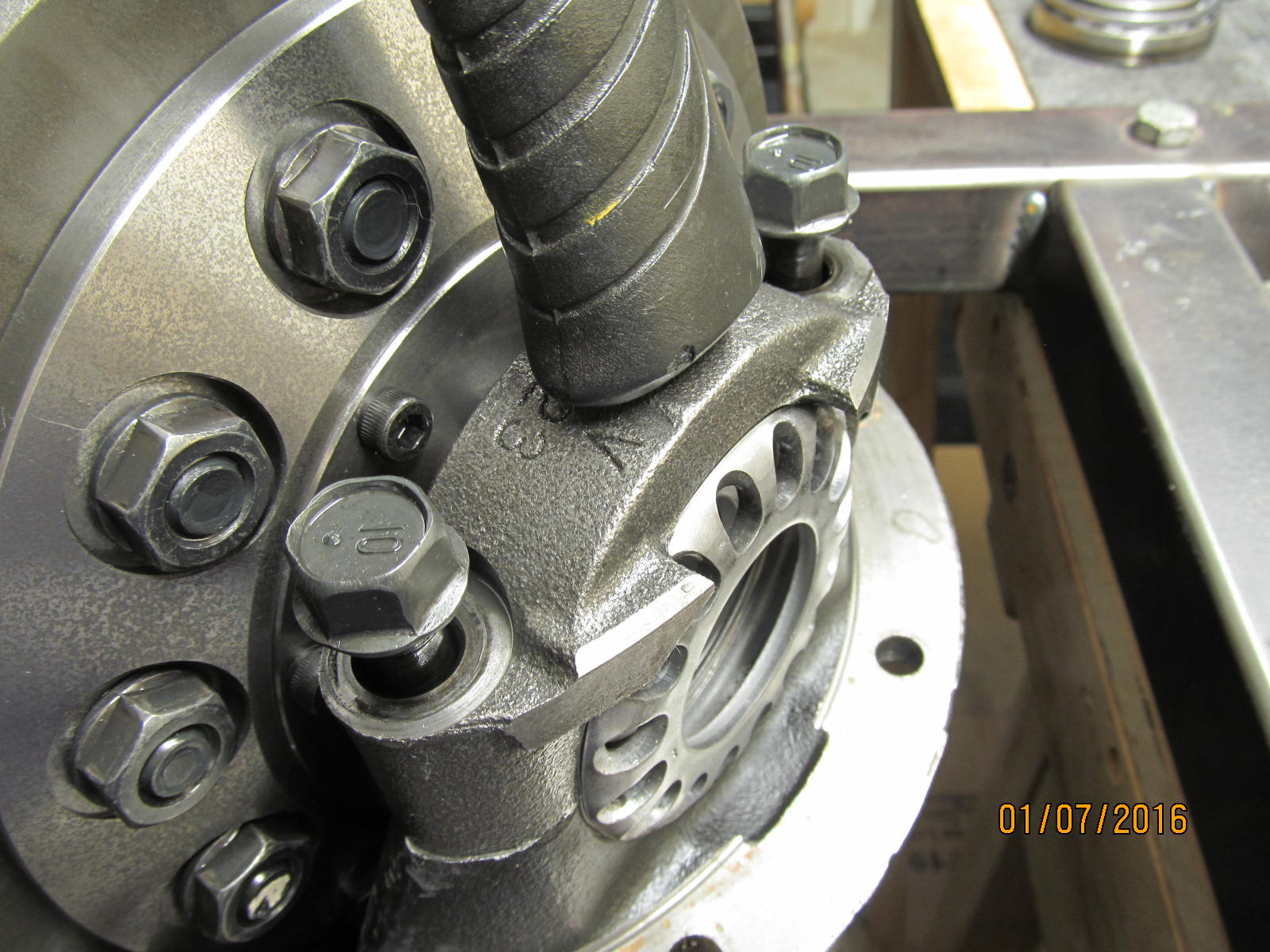

I found an easy way to get the bracket in....install bracket first like shown into the 2 tabs THEN slide

the bearing cap into place.

|

|

|

|

Drop the 2 long bolts in place. Snug the bolts down and make sure the threads are "in sync" as

shown in the pic below.

|

|

|

|

|

.............................

|

|

|

|

|

The adjusting wheel should start pretty easy.

|

|

|

|

|

The other side is business as usual. The wheel is threaded FIRST then the cap is dropped in place.

|

|

|

|

|

Use the handle side of the hammer and if it goes down with a nice, solid snap noise then all is good.

|

|

|

|

|

Both of the adjuster wheels turn smoothly with just finger power.

|

|

|

|

|

83 ft/lb on the 4 bolts per the factory repair manual.

|

|

|

|

|

The play of those tabs is verified as good.

|

|

|

|

Backlash and carrier bearing preload are both guided into the desired region. Turn the pinion

and sharp whacks in the 4 regions to equalize bearing tensions.

|

|

|

|

While laying on my back, I can measure the total preload of turning both the pinion bearings

and carrier bearings.....I measured a start torque of about 20 in/lb. I already measured

the pinion pre-load (PPL) before and it was 10......this means the other 10 must be

the carrier bearing pre-load (CBPL).

|

|

|

|

Backlash is checked on every other tooth here and recorded. Looking in the diff, you can see that

I still have to pull the rubber grommet thru.

|

|

|

|

|

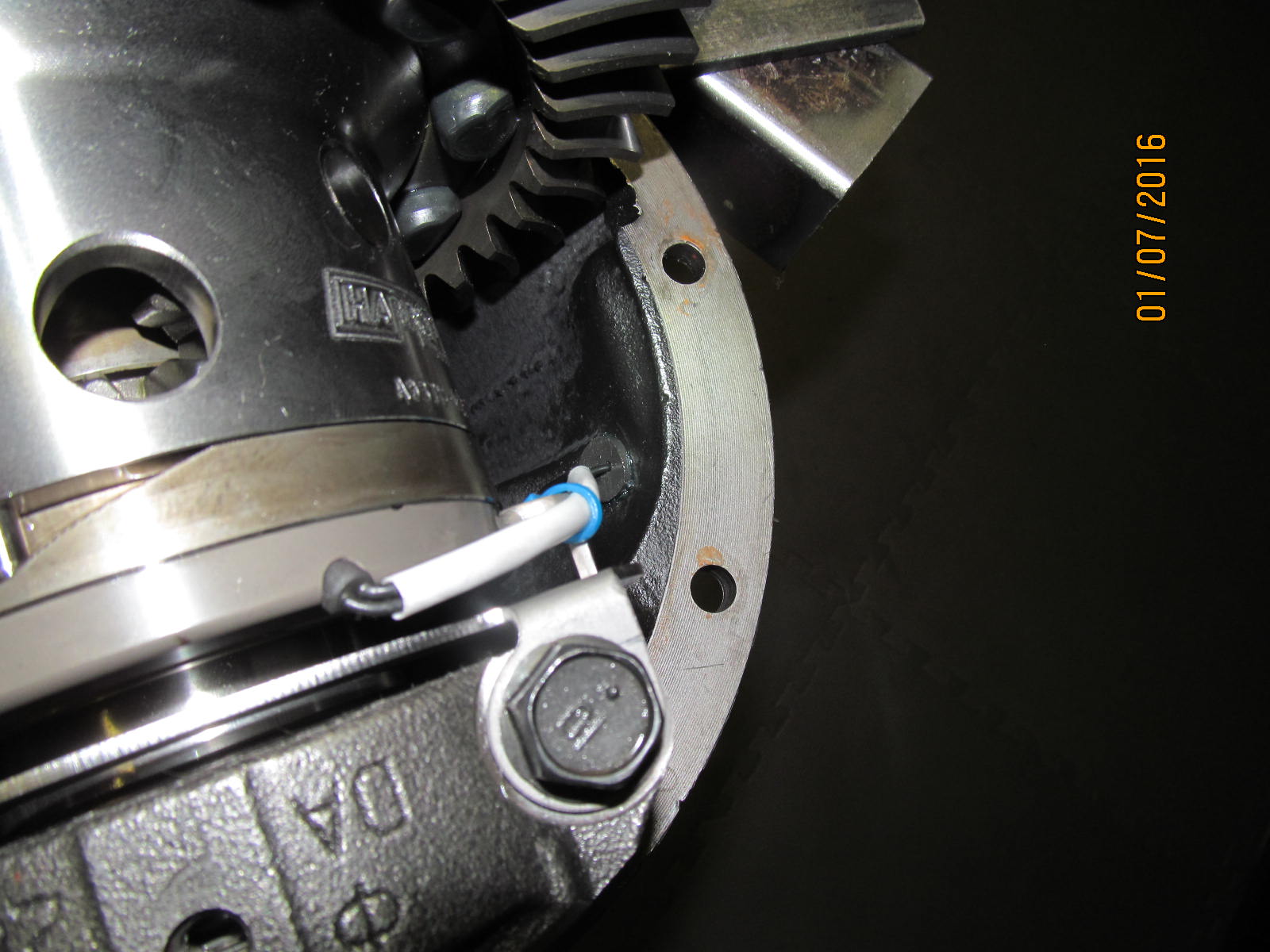

Takes a little work to coax that grommet thru.

|

|

|

|

|

Push really hard and sometimes cheat a little with the smooth end of a screwdriver....and it does go in 100%.

|

|

|

|

On the outside, there will be about 1/4" sticking out. It took some work to do it so be prepared....

and try not to tear the rubber.

|

|

|

|

|

On the 2 lockdown tab bolts, 10 ft/lb and maybe a touch more.

|

|

|

|

|

Nice drive pattern

|

|

|

|

|

Excellent coast.

|

|

|

|

|

Drive....reverse painted.

|

|

|

|

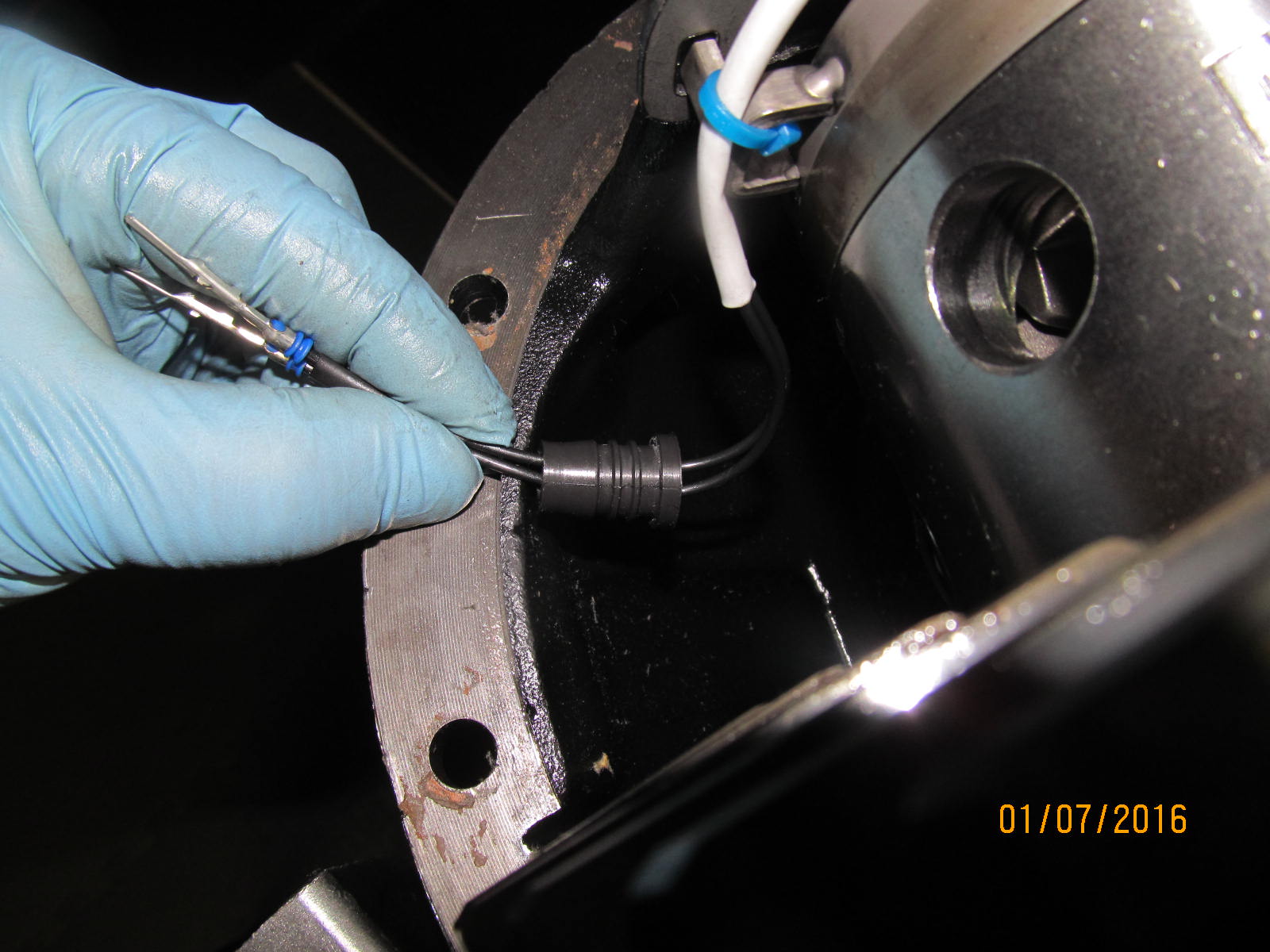

Now to test the electric locker. Place axle stub in and it spins the sidegear freely

indicating "open diff" operation.

|

|

|

|

|

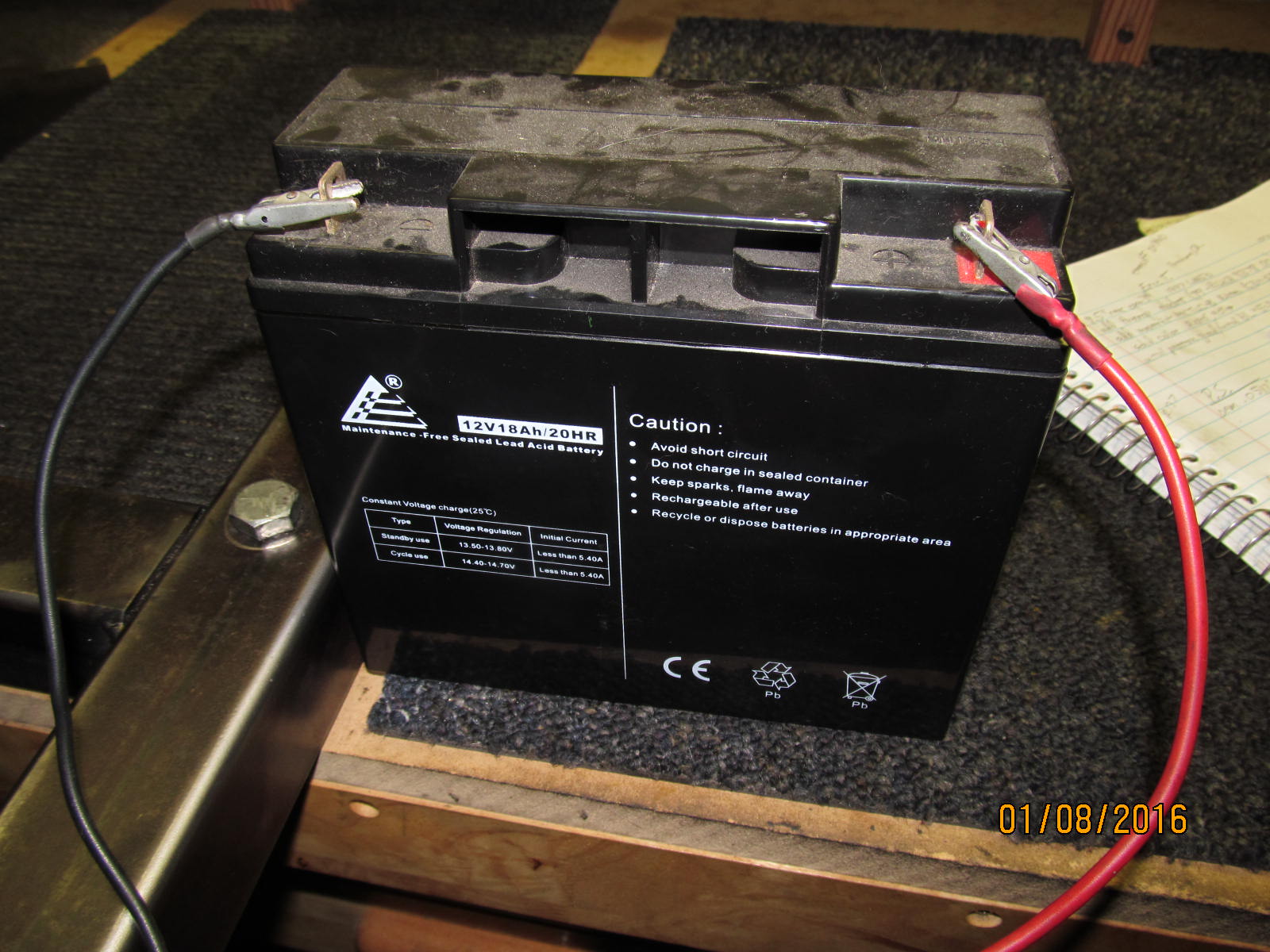

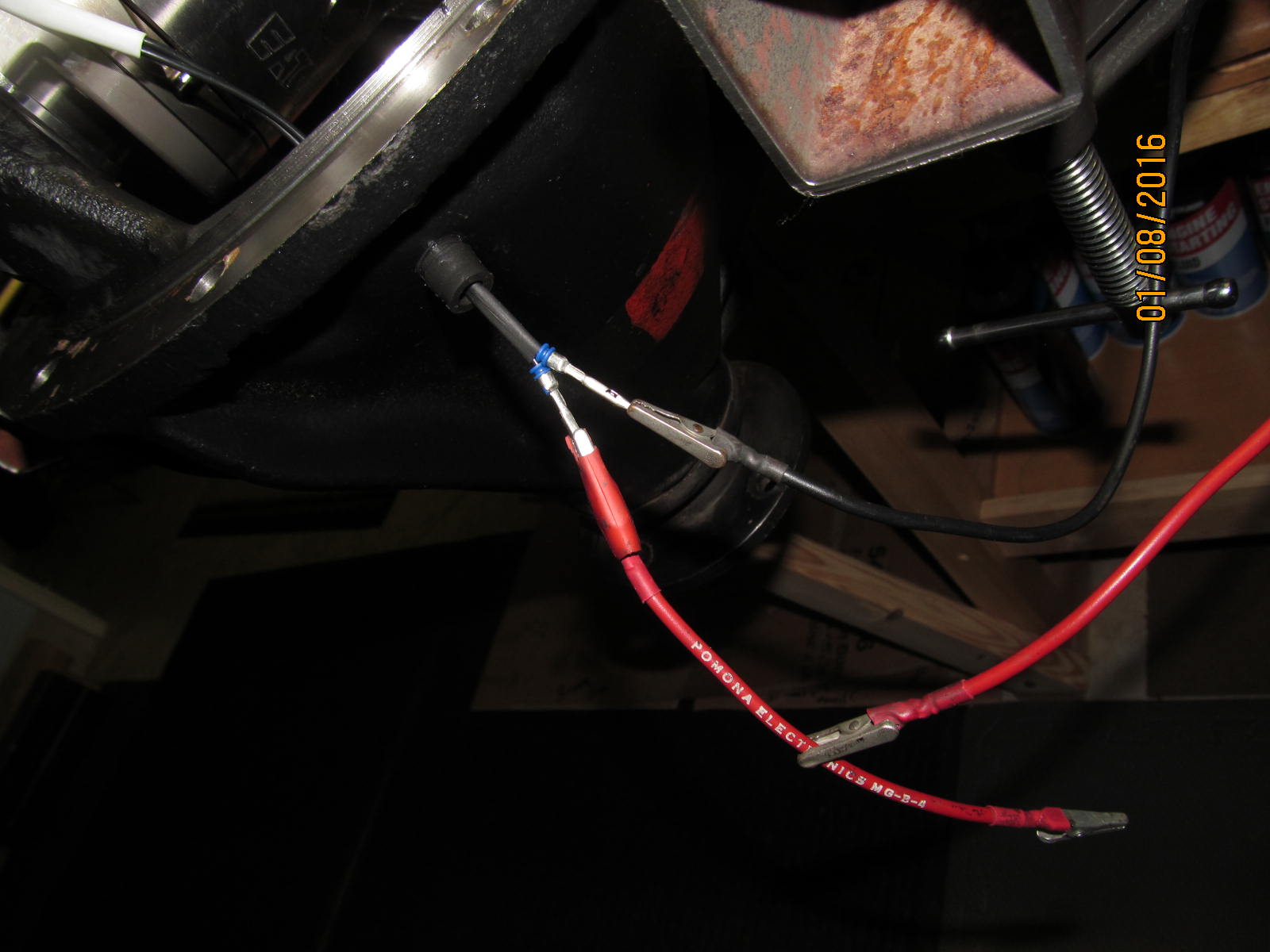

Now to find a source of 12v.....

|

|

|

|

These electric lockers have no polarity so there is no hooking them up backwards and smoking

something....Just hook them up and it will work.

|

|

|

|

|

....

|

|

|

|

|

....

|

|

|

|

|

I applied 12v....

|

|

|

|

|

As the ring gear is rotated, the pin was now allowed to retract as shown above.

|

|

|

|

|

The locker is now locked.

|

|

|

|

|

Remove the 12v and the pin snapped back into place.

|

|

|

|

|

...................

|

|

|

|

|

....................

|

|

|

|

|

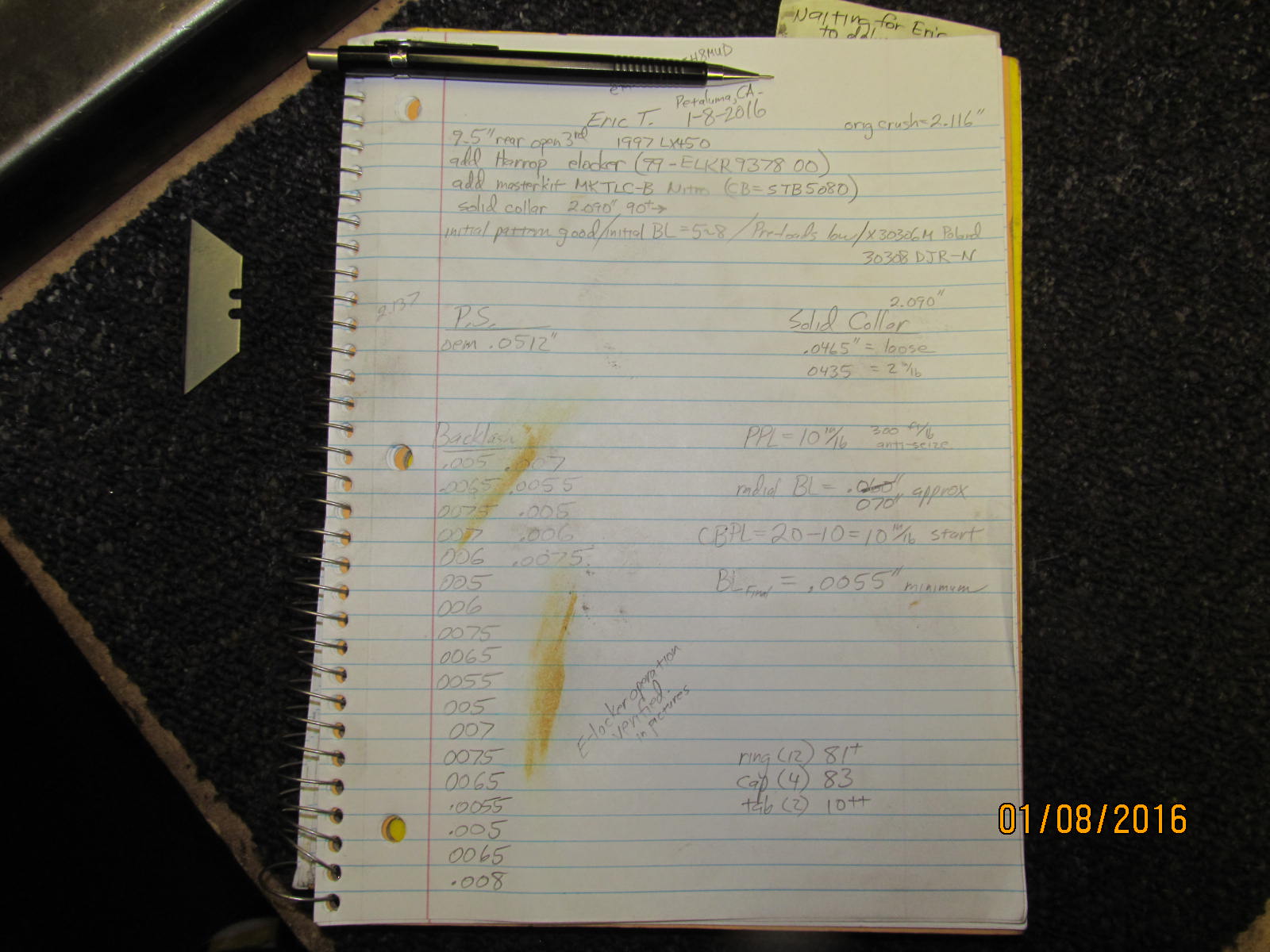

Notes taken for Erics' records...

|

|

|

|

|

Packing it back up for the trip to CA.

|

|

|

|

|

.....

|

|

|

|

Who else wants one of these Harrops installed?

Koyo carrier bearings are already included in the box.

Contact Ward Harris (National importer/authorized dealer for Harrop) at 1-800-224-7801

or email info@cruiserbrothers.com

|

|

|

|