| Jason's 1987 SAS'd truck gets Nitro 529 gears/Harrop in a Marlin HP Diff Housing |

|---|

| (72 BIG pics loading) |

|---|

| AUGUST 19 2018 |

|---|

|

| Jason's lives up in Oregon where they have a lot of the white stuff in the winter time. |

|---|

|

|

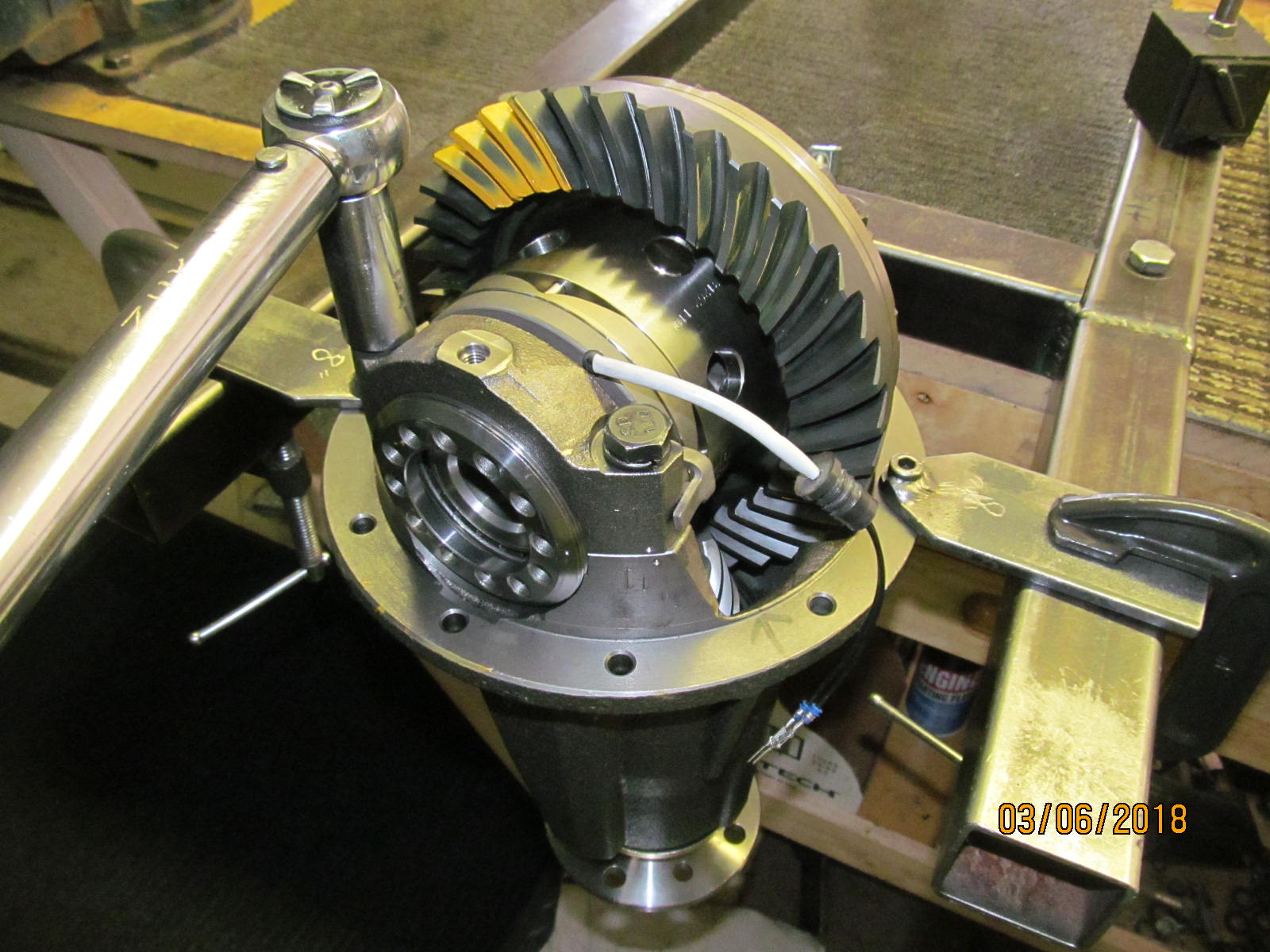

| It was time to upgrade the front to a bare High pinion 8" from Marlincrawler.com and install a set of Nitro 529 gears and Harrop electric locker. |

|---|

|

|

| Empty Marlin housing on the left...the Nitro V6 master kit.....the Harrop Elocker....529 Nitro gears and the solid collar/dual drilled flange. |

|---|

|

|

| They chamferred the circumference of the V6 wheel adjusters which was much needed. |

|---|

|

|

| Parts are unpacked and layed out. All looks to be here. |

|---|

|

|

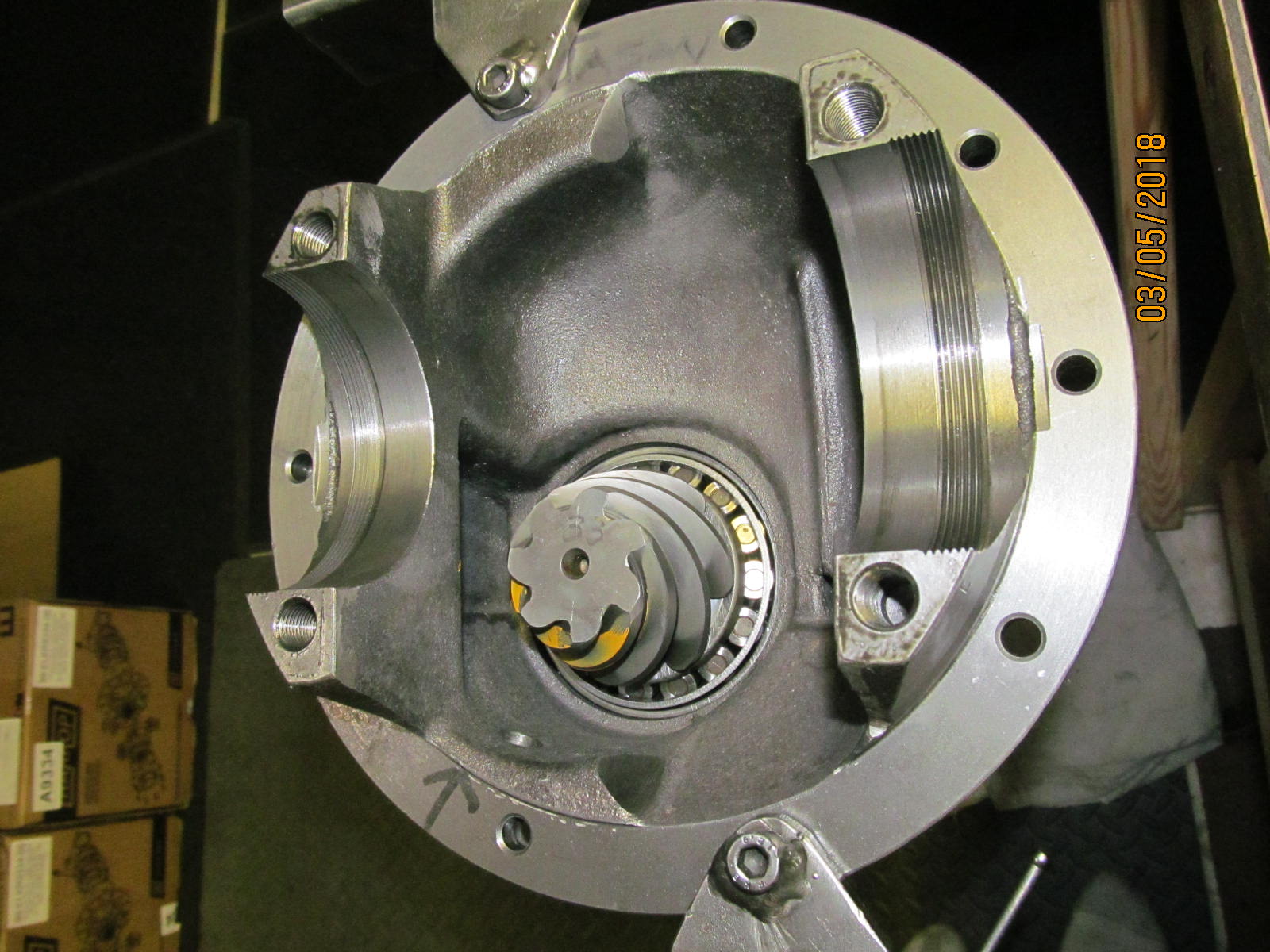

| The big inner pinion race is tapped in.....360 degree support, of course. |

|---|

|

|

| Same with the small outer race. |

|---|

|

|

| Will start with a .076" pinion shim. |

|---|

|

|

| The pinion loading station. |

|---|

|

|

Tighten the pinion nut til the estimated preload is somewheres in the neighborhood of 10~20 ft/lb.

This is only a pattern check so it's not critical. |

|---|

|

|

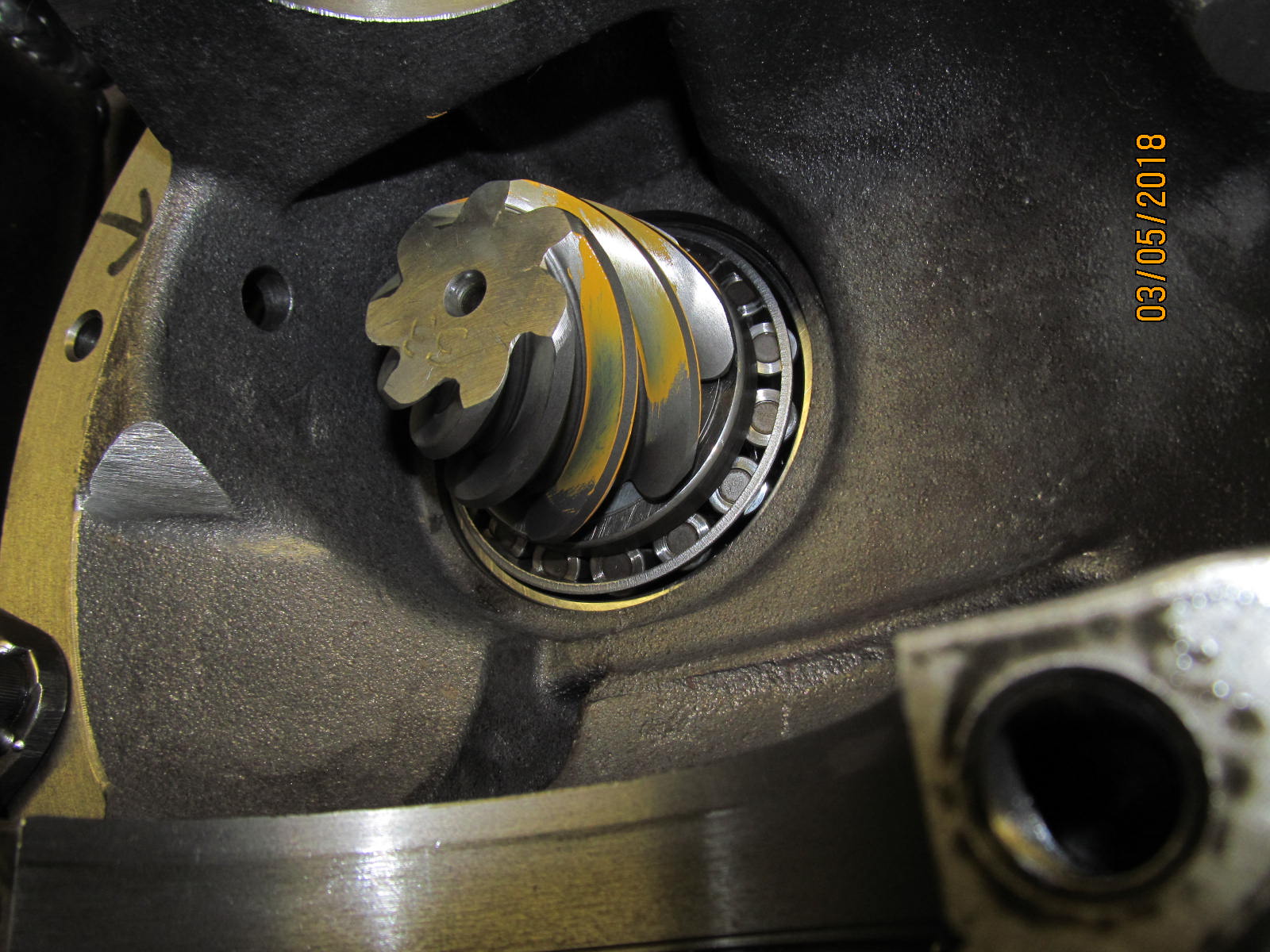

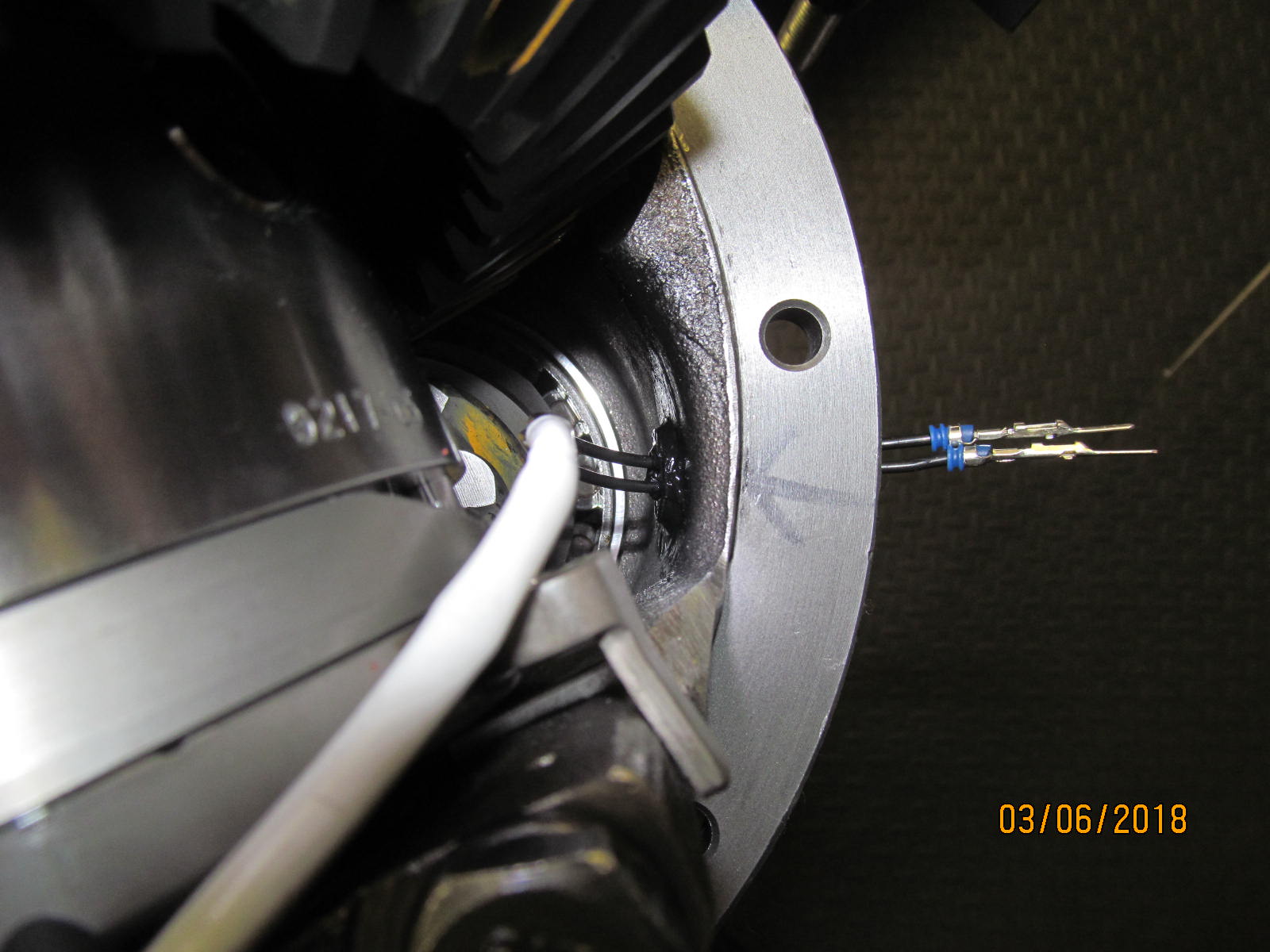

Now onto the other end. A quick check of the coil resistance of the electro-magnet.

Measuring about 4 ohms. |

|---|

|

|

| Surfaces were checked with a file and all was just fine. |

|---|

|

|

| 75 ft/lb and blue loctite. |

|---|

|

|

| The new Koyo carrier bearings were a very nice tight fit onto the journals. |

|---|

|

|

| The top bearing cap has to slide on horizontally first and then the 2 long bolts go in. |

|---|

|

|

Line the threads up...tighten the 2 bolts....and then thread the large wheel adjuster in.

Then dial in some bearing preload and backlash. |

|---|

|

|

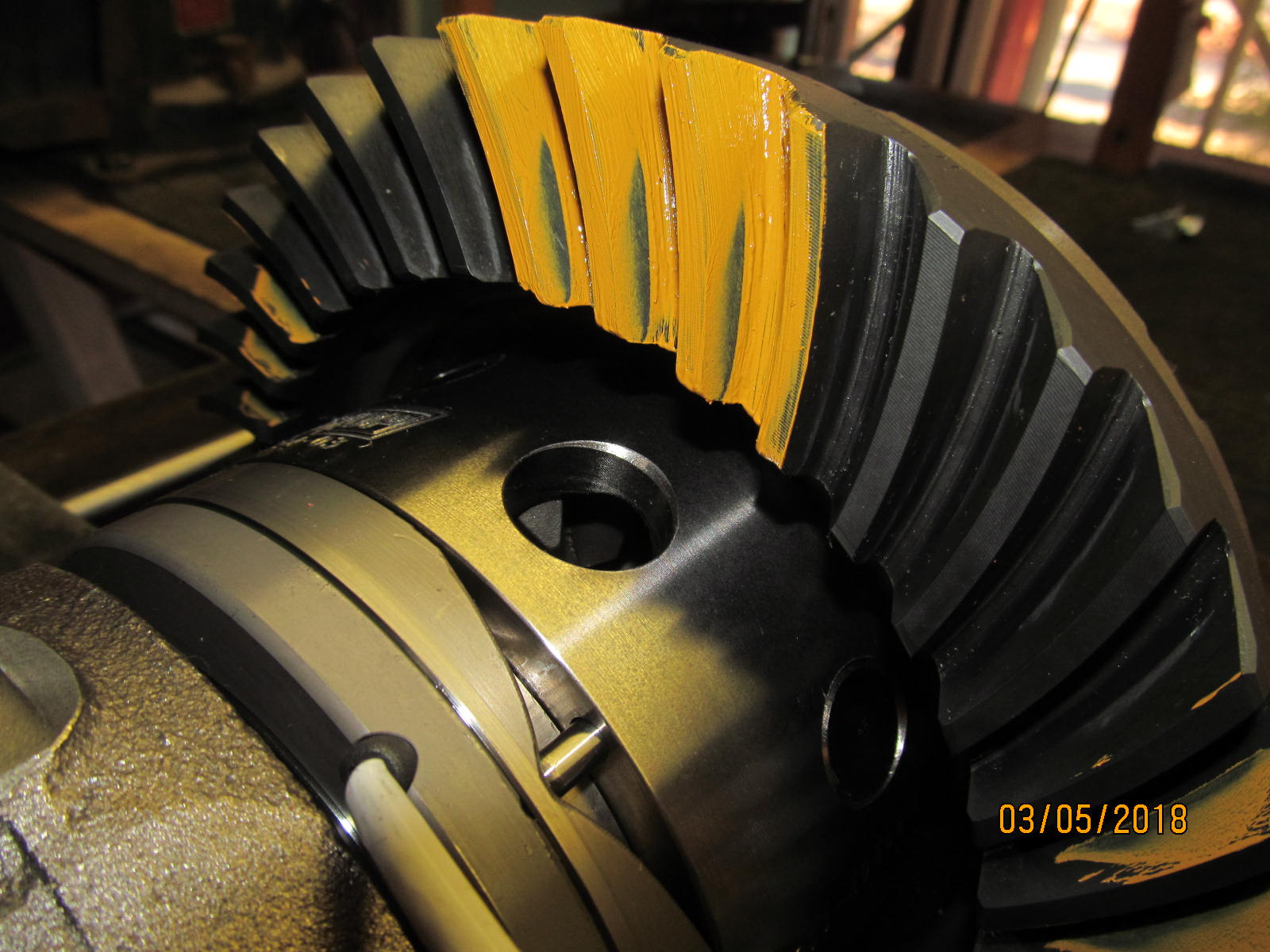

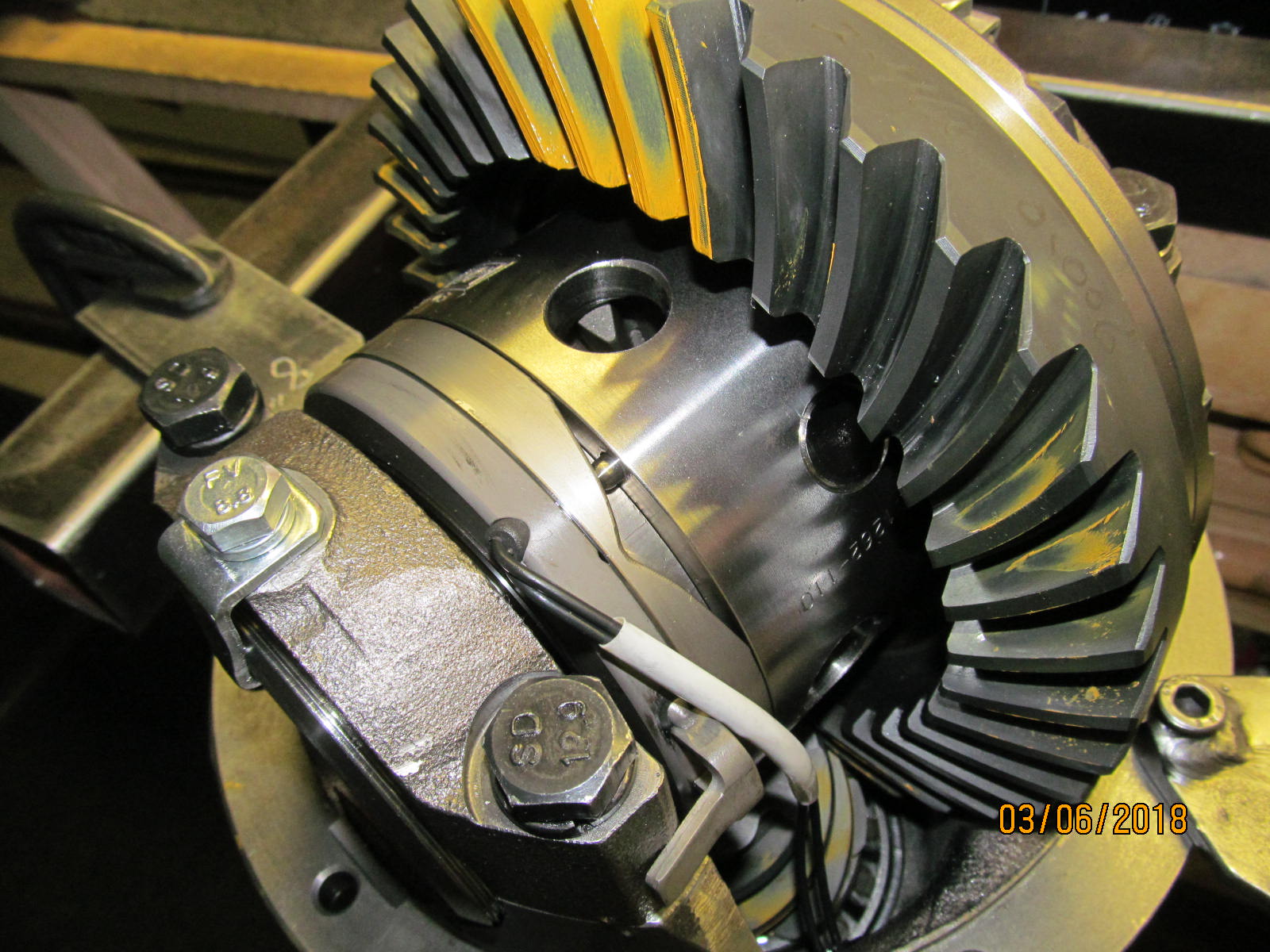

| First paint check and way too deep. This is the drive side. |

|---|

|

|

| Coast side. |

|---|

|

|

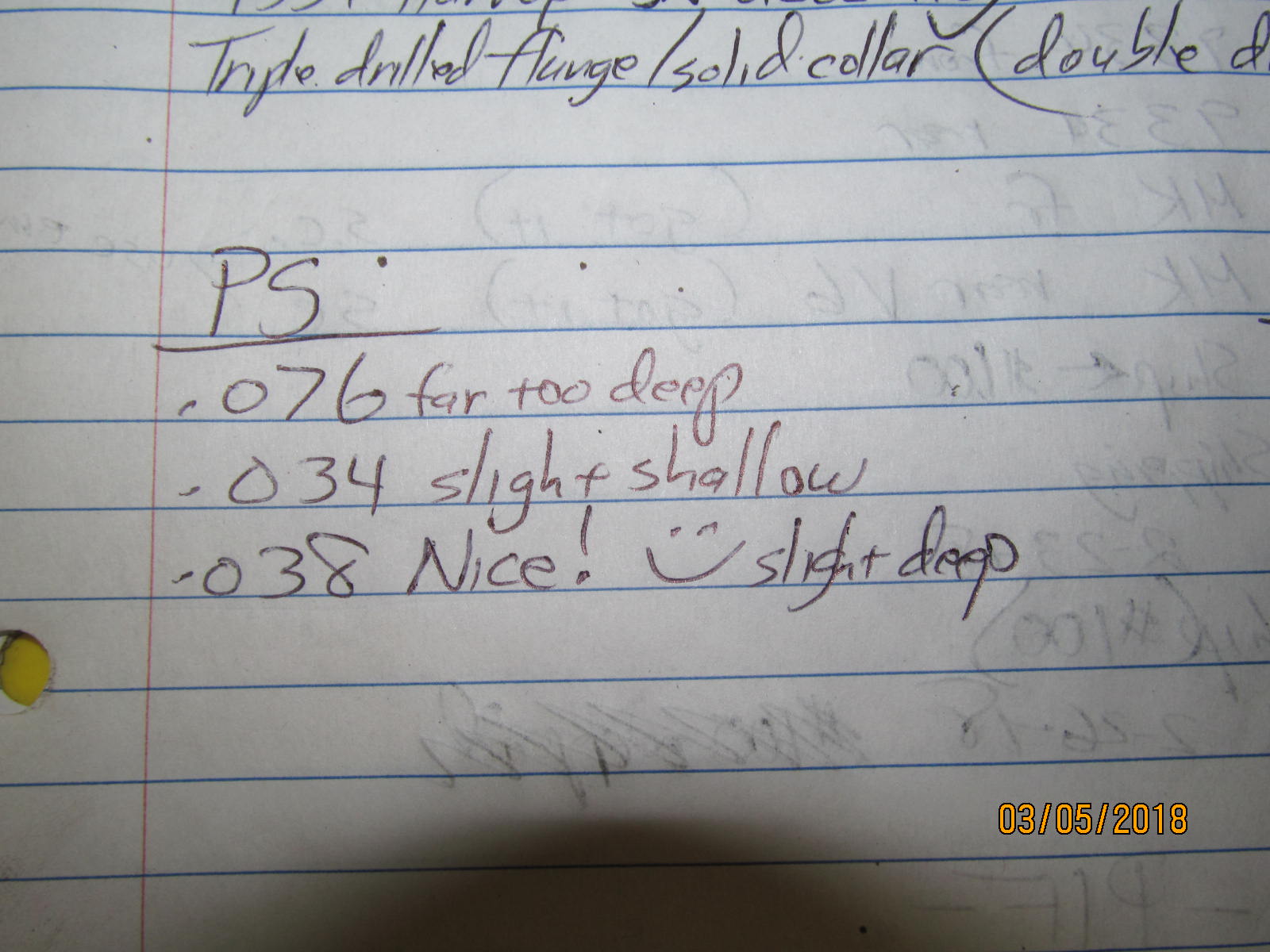

| Teardown and now trying a much thinner .034" |

|---|

|

|

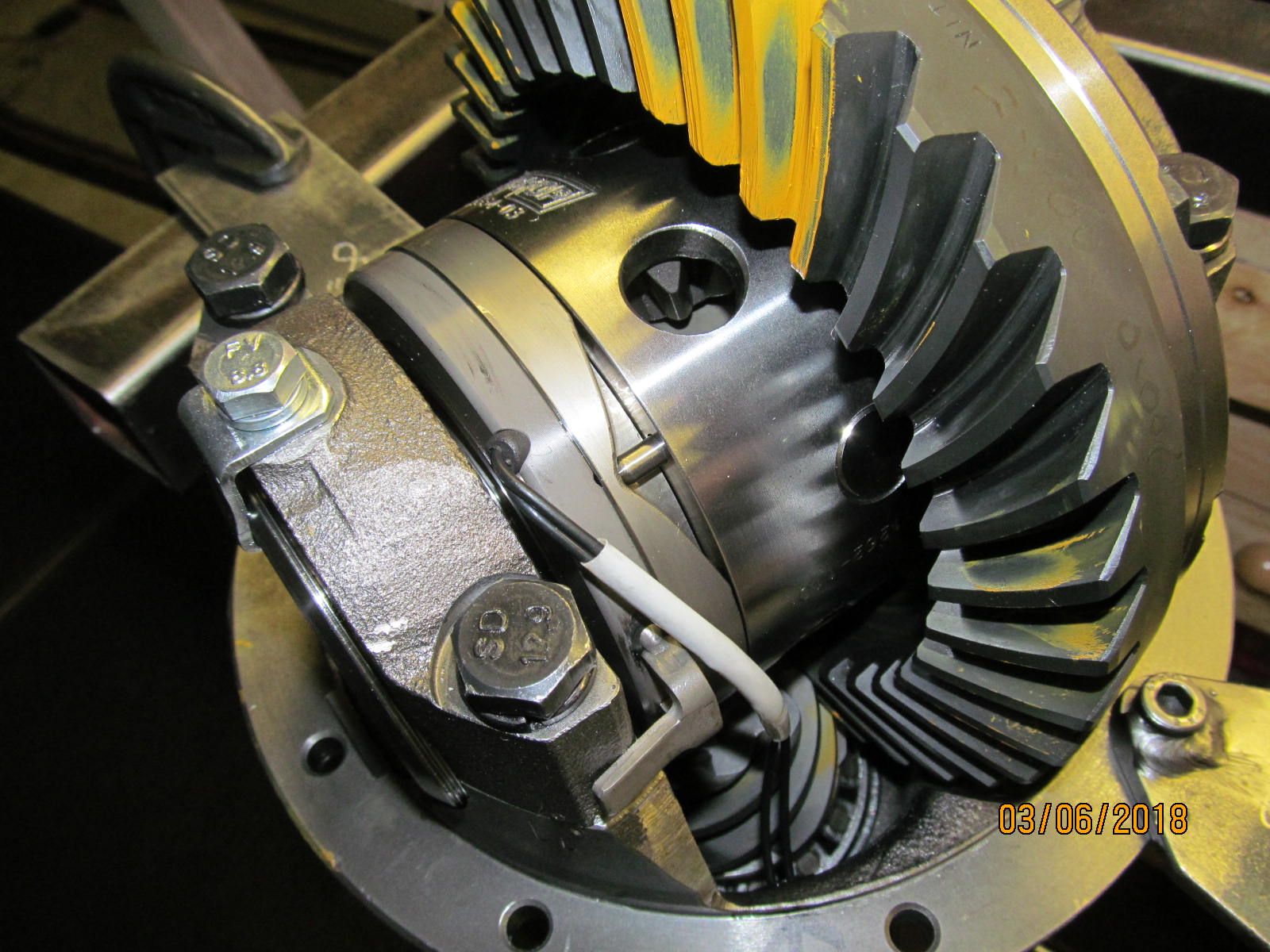

| Drive.....much better but over-shot just a little. This is slightly shallow now. |

|---|

|

|

| Coast....can't complain. |

|---|

|

|

I did notice that the 529 ring gear was so thick that the teeth were almost hitting the tunnel groove

so did some clearancing with the flapper wheel. |

|---|

|

|

| Took about 20 seconds..... |

|---|

|

|

| .................................. |

|---|

|

|

| A final look at the pinion paint shows that the comet tail is too deep into the root and that means to add more pinion shim. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| So now to increase the thickness by .004" Now trying .038". |

|---|

|

|

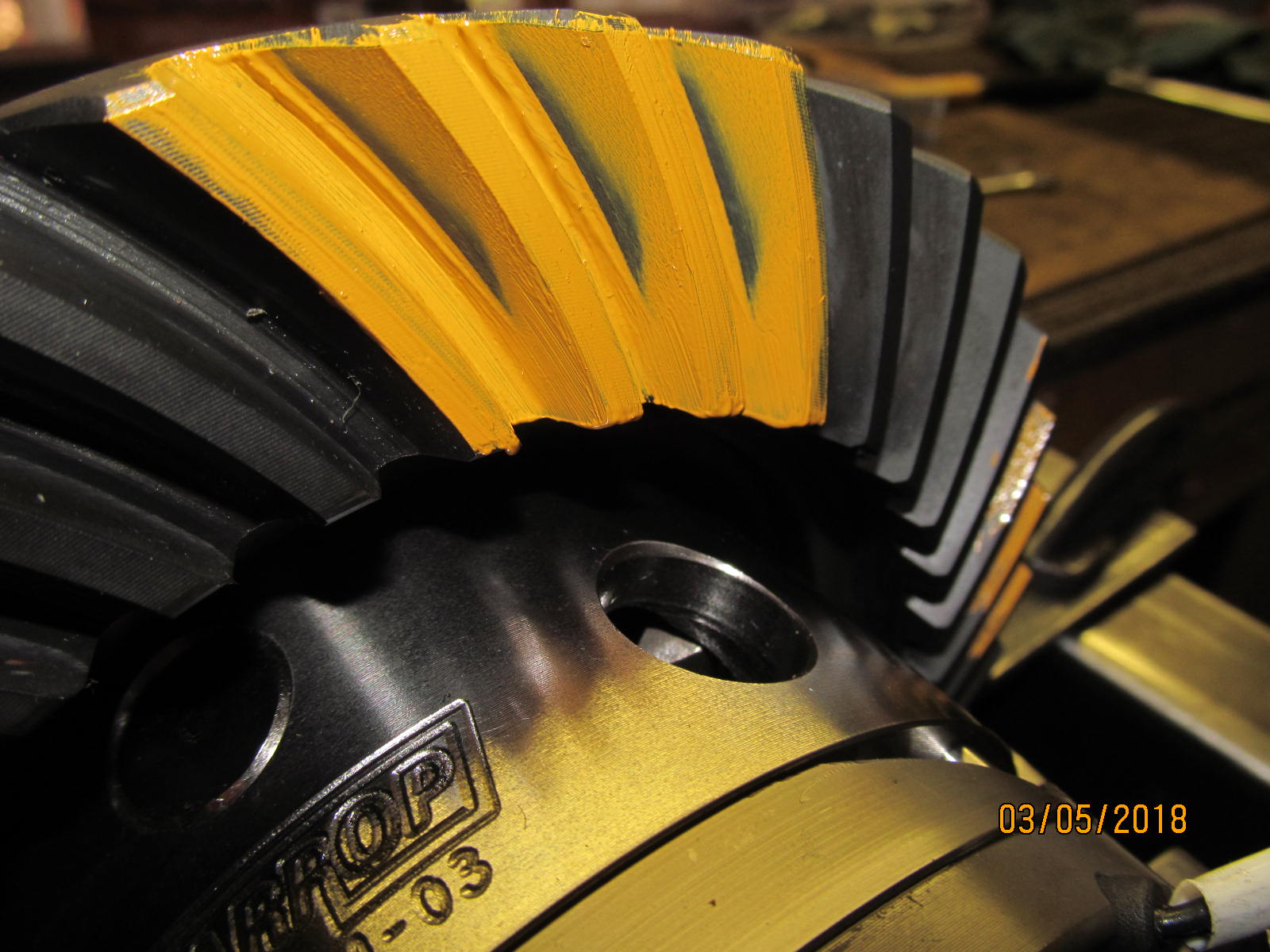

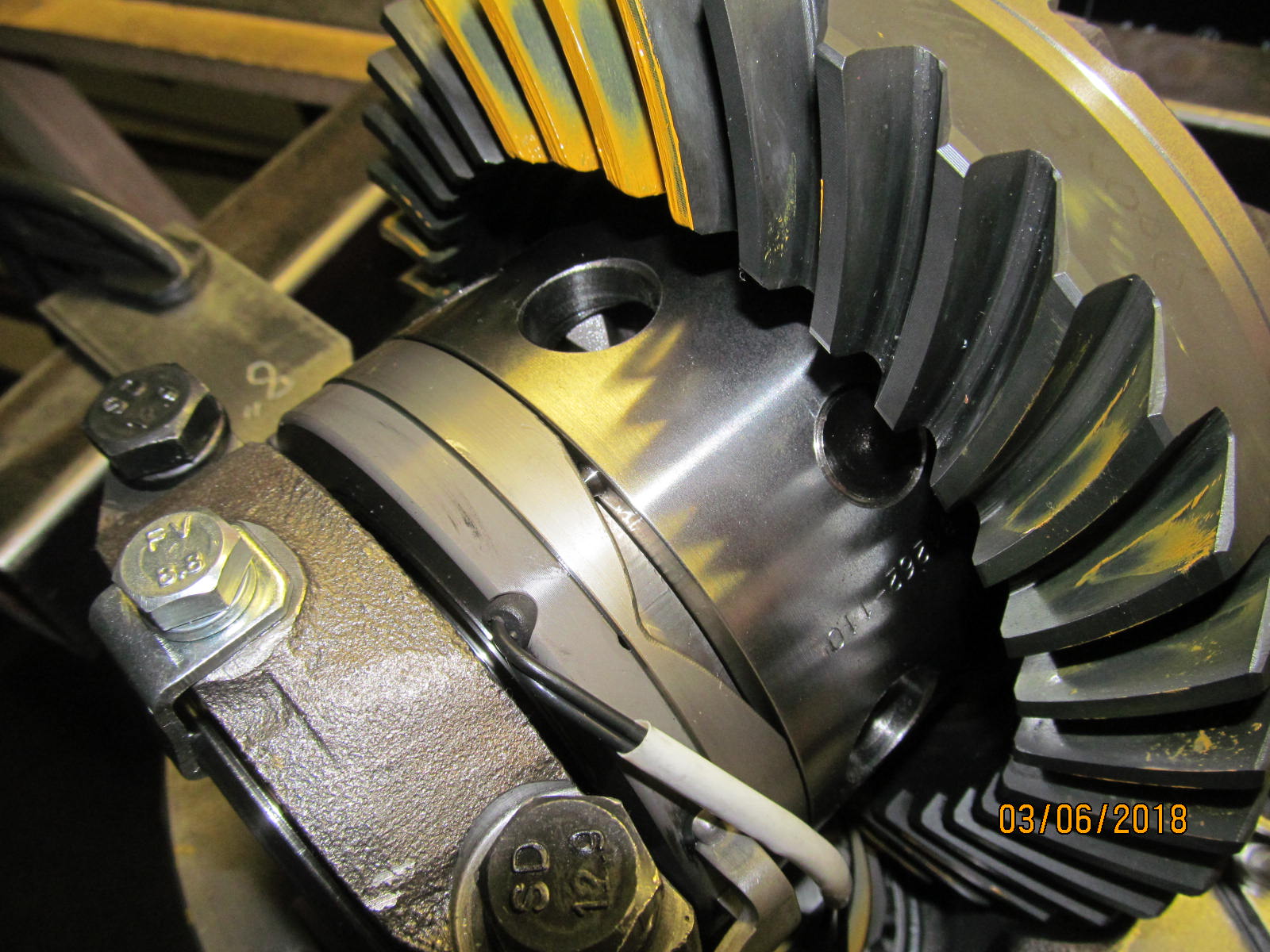

| Repaint.....Drive side....beautiful. |

|---|

|

|

| Coast....very nice indeed. |

|---|

|

|

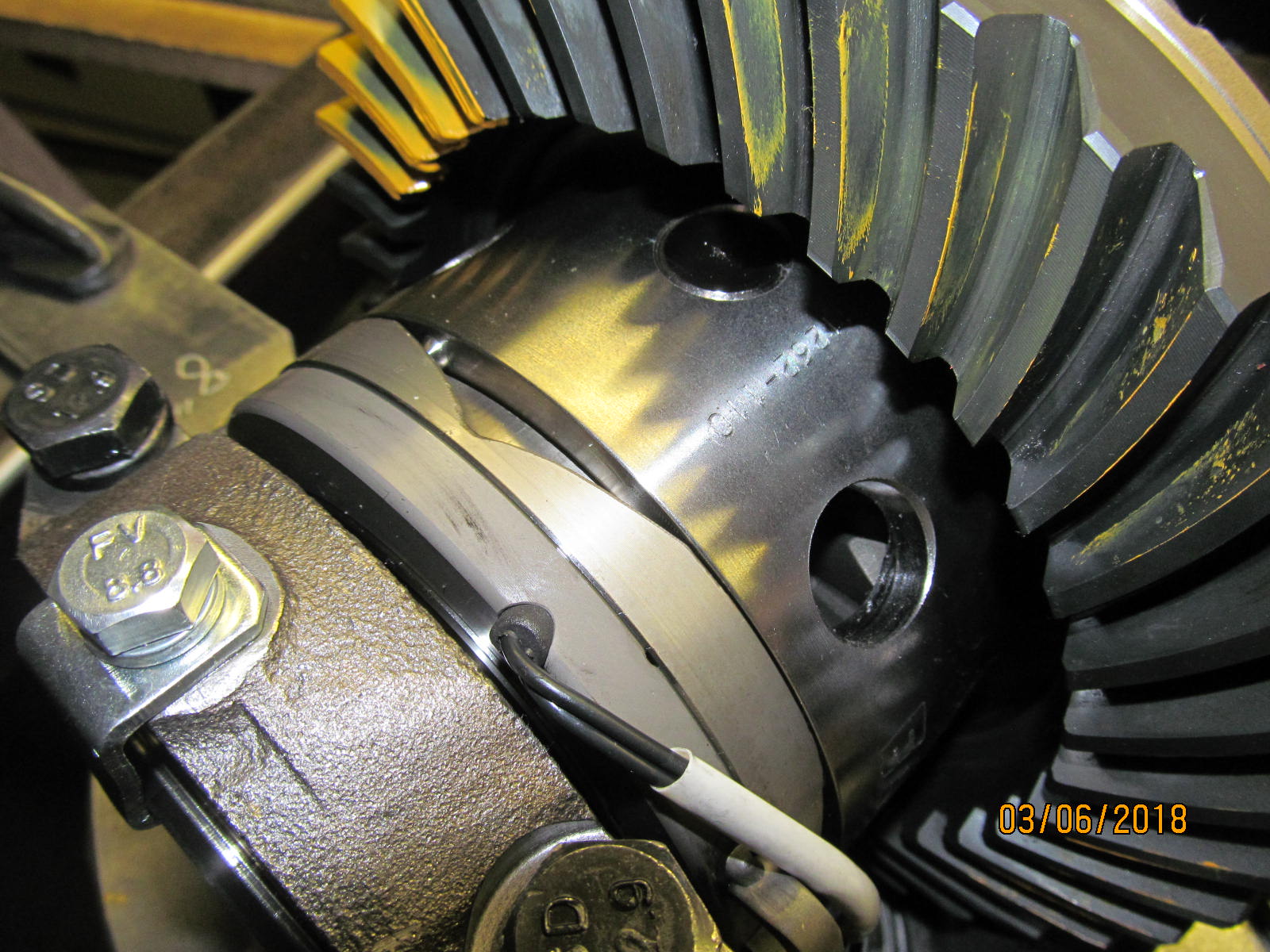

| Final confirmation....pinion tooth....comet tail is starting to feather out to the center. That means to leave it alone and button it up :) |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| //////////////////////// |

|---|

|

|

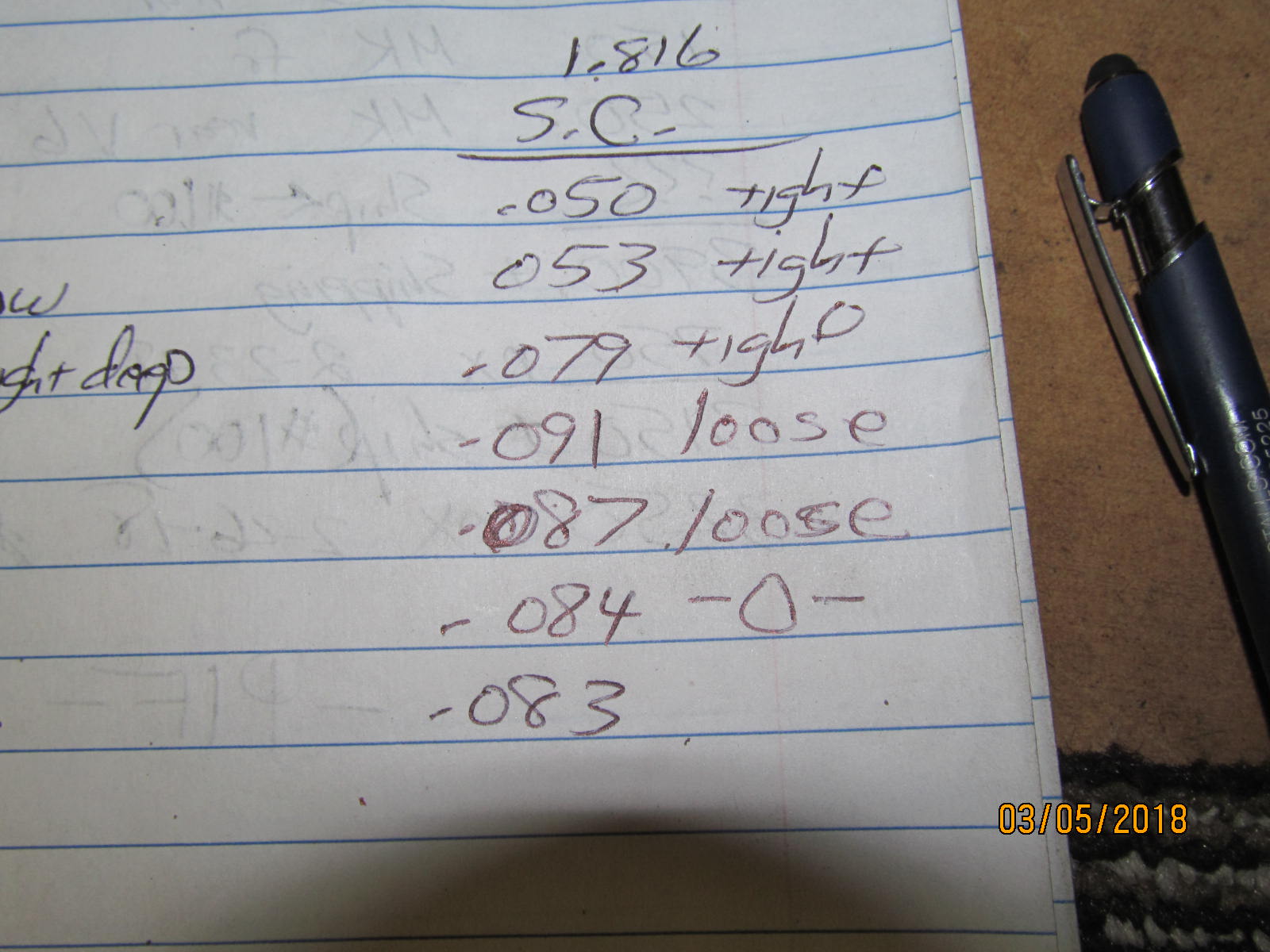

| Now to set the solid collar in place....took about 7 tries on this Hi-pinion to get it right. |

|---|

|

|

| 3 adjustments on pinion depth...... |

|---|

|

|

| 7 on the solid collar. |

|---|

|

|

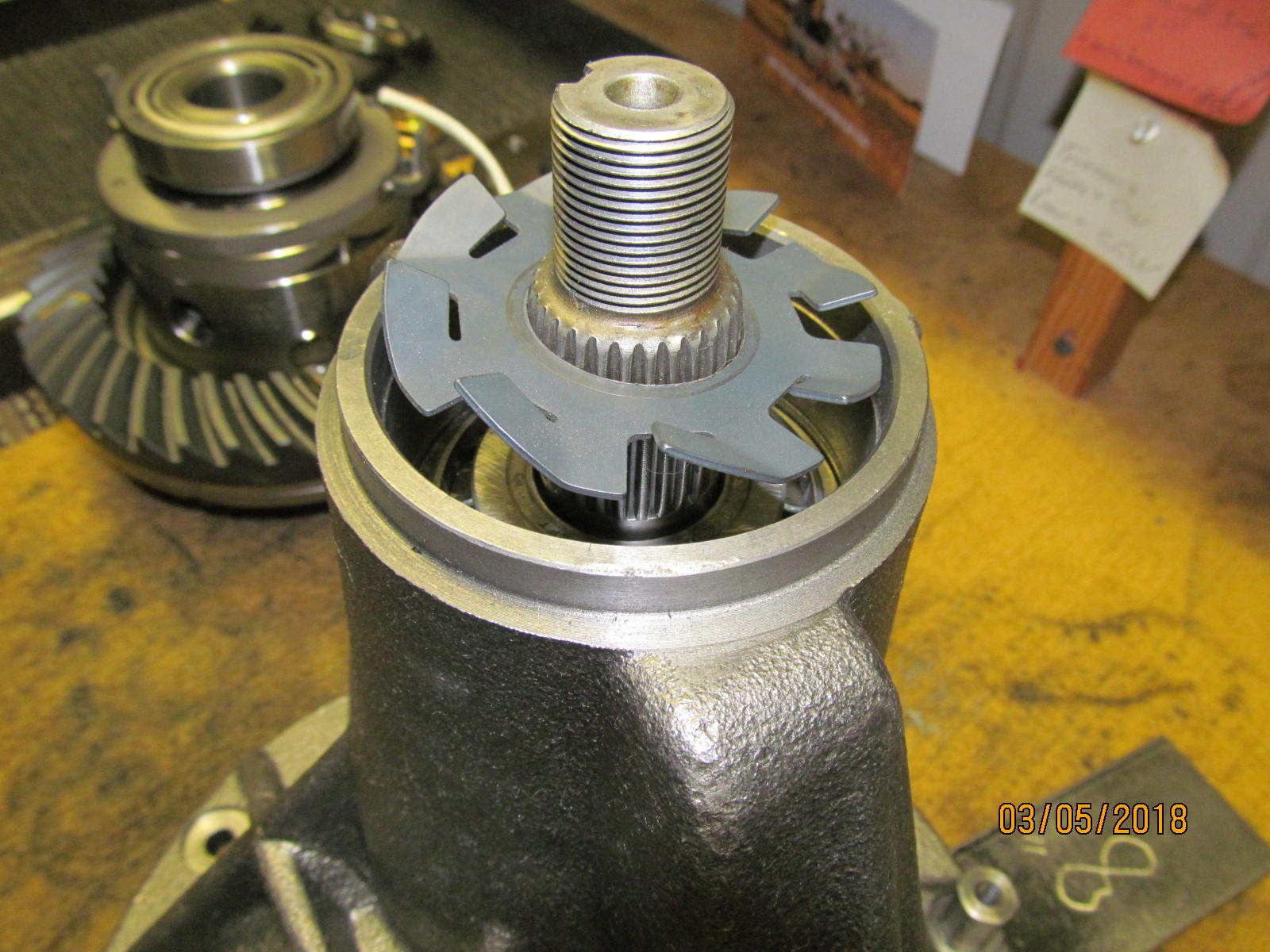

The 27 spline fanblade slinger will fit with a slight enlargement of the center hole.

A Makita 1/4" die grinder and 3 minutes did the trick. |

|---|

|

|

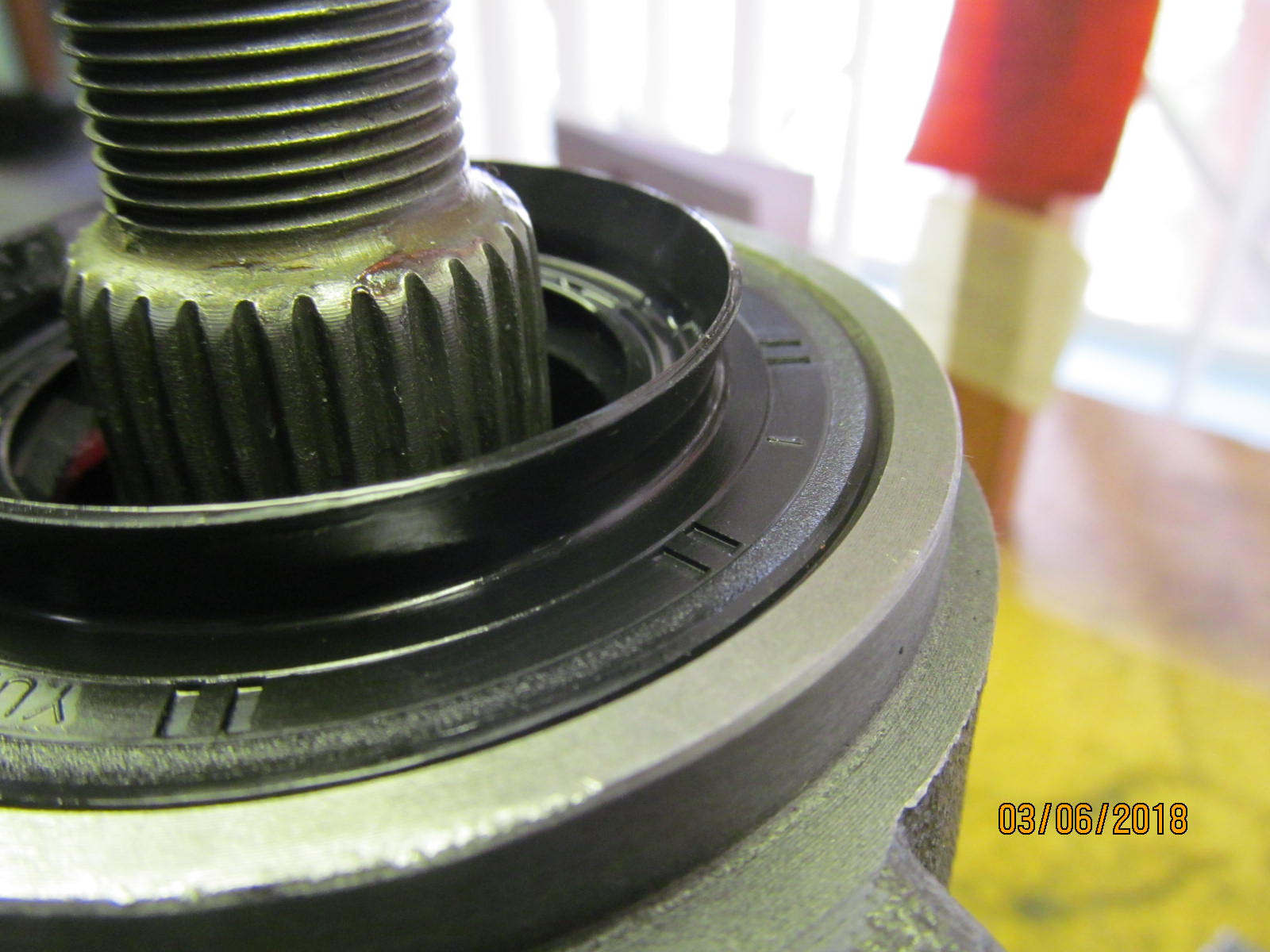

| Grease on the garter spring prevents the spring from popping off during the install process. |

|---|

|

|

| The Yukon brand seal appears to be a quality seal. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| ============================= |

|---|

|

|

| The new flange is next. |

|---|

|

|

| Anti-seize on the flat surface...not shown but also applied to the pinion threads. |

|---|

|

|

| All that anti-seize really helps in dialing in the pinion preload. |

|---|

|

|

| This side goes together like usual. |

|---|

|

|

| This side requires a little order of assembly as mentioned earlier. |

|---|

|

|

The 2 long bolts are tightened and the wheel adjuster freely threads in.

A quick final check of the locktab freeplay shows 1 mm. |

|---|

|

|

| The wheel adjuster threads in smoothly. |

|---|

|

|

| Now the 4 bolts are torqued to the 70 ft/lb spec. |

|---|

|

|

Bearing preload is set/measured at 6 in/lb (as measured from the pinion flange end).

Backlash is recorded on every other tooth for 20 measurements. |

|---|

|

|

| A small amount of rtv is applied to the rubber grommet. |

|---|

|

|

| The rubber grommet now pushes thru about 3 times easier ;) |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| 10 inch/pounds with Loctite |

|---|

|

|

3.9 ohms of resistance. There is no Harrop spec on this but it seems to be a very common number.

Ohms Law says that with 16 volts and 4 ohms that the amperage will be 4 amps.

So, the reality is, the Harrop only draws about 3.5 amps on a good day. |

|---|

|

|

| This is my Sealed Lead Acid battery that has served me well for a number of years. |

|---|

|

|

| 12 volts is applied to the 2 wires....no particular polarity. |

|---|

|

|

| The locker is not "active" until the 3 pins start to recess into the holes....the driveshaft has to turn a small amount. |

|---|

|

|

| The ring gear has to turn a small amount..... causing the pins to recess in as shown. |

|---|

|

|

| Locker fully engaged. |

|---|

|

|

| Additional turning of the ring gear causes the grey ramp ring to move with the pin. |

|---|

|

|

| Now remove the 12 volts............. |

|---|

|

|

...and the ramp ring snaps back into place due to the strong internal spring on the other side of the pin.

Locker is now unlocked. |

|---|

|

|

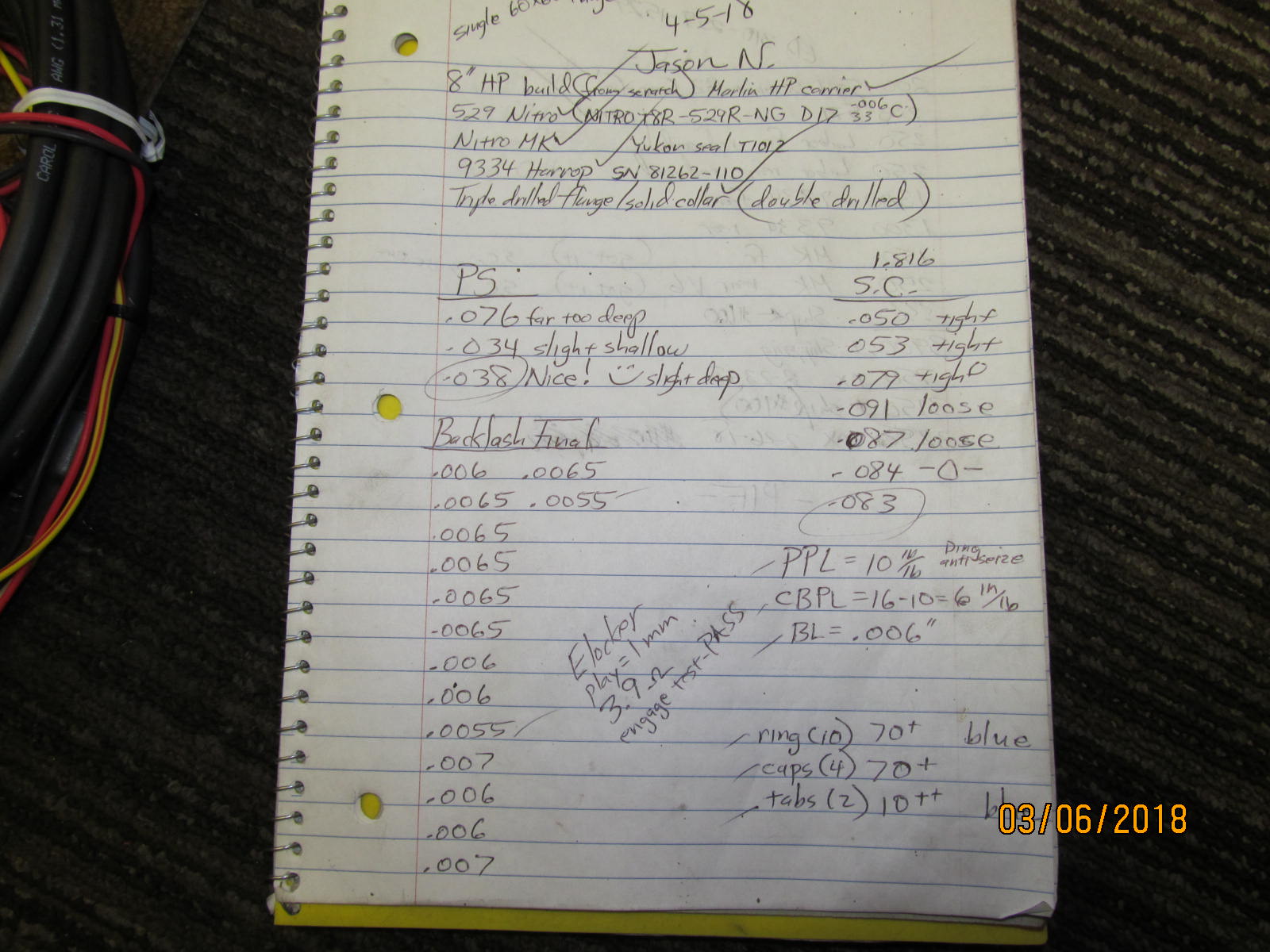

| Basic specs are inscribed. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| This is the harness. |

|---|

|

|

| The recorded notes. |

|---|

|

|

| Sure is a pretty High pinion 529 Harrop 3rd |

|---|

|

|

| :) |

|---|

|

|

|