|

Brent sent both of his 3rds all the way from Kentucky to get a good install

....and I was not going to disappoint him! :) The rear install with the full

Detroit went well but I chose to make a link here of just his front IFS install

since I didn't have alot of them on my site anyways. Here, we are installing

a quality Yukon 7.5" IFS gearset with a new seal and crush sleeve. This Yukon

gear happened to be US GEAR stamped. The bearings

were in excellent shape so it's ok to re-use them...especially in a front end

application.

|

|

|

I marked the bearing caps and employed 2 tire irons to easily remove the

case. By

the way, there was still some very good carrier bearing pre-load (CBPL)

and it still took a couple of good grunts with the tire irons to release it.

|

|

|

I recorded the carrier bearing shim values just for the records. These shims

are available from the dealership in various thicknesses for about $10 each.

|

|

|

Bearings are good and swapping the 529 gear over is straight forward.

|

|

|

The nut gets re-used. The used crush sleeve goes to the trash.

Pinion bearings

and the original pinion shim get re-used ... the factory pinion shim

here is a full .100" thick.

|

|

|

I used the flat file on the ring gear to remove burrs as usual. Loctite and

70 ft/lbs. on the 10 ring gear bolts.

|

|

|

The new 529 pinion was placed in the carrier with no crush sleeve and the

pinion pre-load (PPL) was approximated using just the nut to set the load.

Then I loaded the case in the carrier with the help of a lead filled rubber

hammer. It took quite a few slams to get it in indicating it had nice CBPL

already. By

the way, I feel that due to the way these IFS carrier bearings are fully

captured, that

ring gear deflections are smaller than even a well set-up rear 3rd that has

the raised bearing towers. In other words, these smaller 7.5" carriers are

very "robust" for what they are.....assuming a good gear install,

of course. ;)

|

|

|

Using the "17mm wrench on the ring bolt technique" (thanks to Mac from Randys

for this), the painted pattern was spot on the first time.

|

|

|

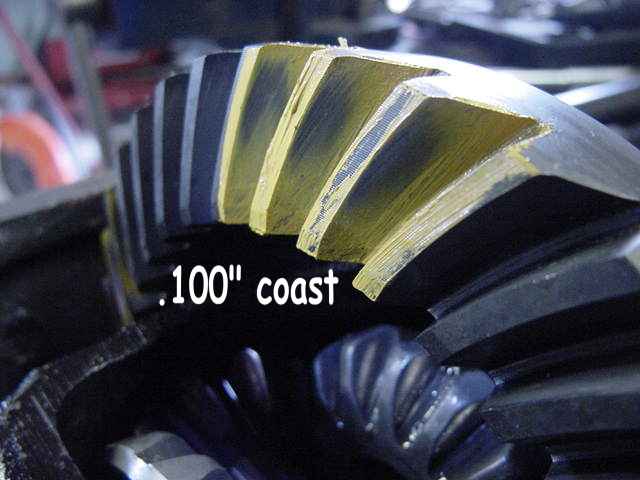

Coast side good also.

|

|

|

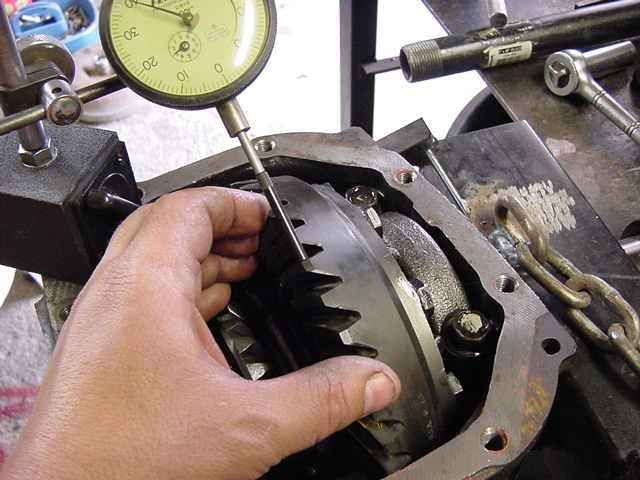

With pinion depth and backlash (.007") looking good, it was time to tear it

back down and load up the new crush sleeve. With the new seal also

in place, the PPL was set to a light 6 in/lbs due to used bearings.

|

|

|

Even though the CBPL was very good, I knew I could squeeze another 6 thou

worth of shim in there...so I found 2 thin dana44 style .003" thick shims...

one for each side. Backlash will be uneffected this way. Strength will

be maximized.

|

|

|

It took a firm hand to double check the .007" backlash but all was good.

|

|

|

Here's a pic of the other rear 3rd with the full Detroit that is also heading

to KY. This one turned out equally well. We did use new bearings in this one

with a solid collar, though.

|

|

|

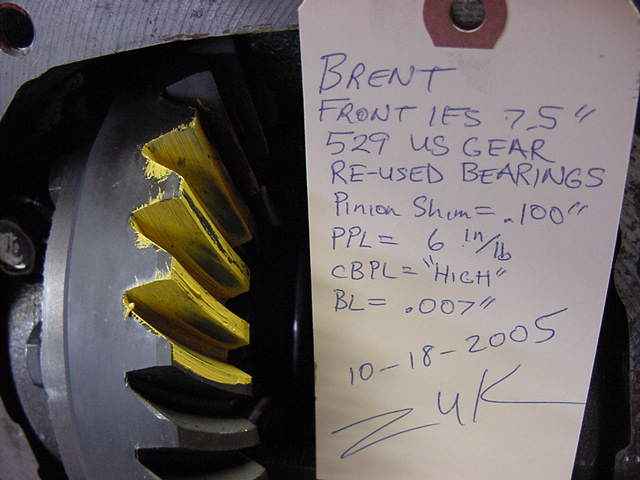

All of my builds come with some sort of tag like this one. I do this because

I would expect the same if I was having someone else do my very own diffs.

Done! ZUK

|

|