|

Jason From The Island of Kauai Gets Nitro 4.88 Gears

|

|

(61 BIG pics loading)

|

|

MAY 10 2014

|

|

|

Jasons 1993 Toyota pickup has 210,000 miles and it looks like it ran low recently on gear oil and the 488 gears are

now toast. After some email exchanges, a package from JT's arrives.

|

|

|

|

|

............

|

|

|

|

|

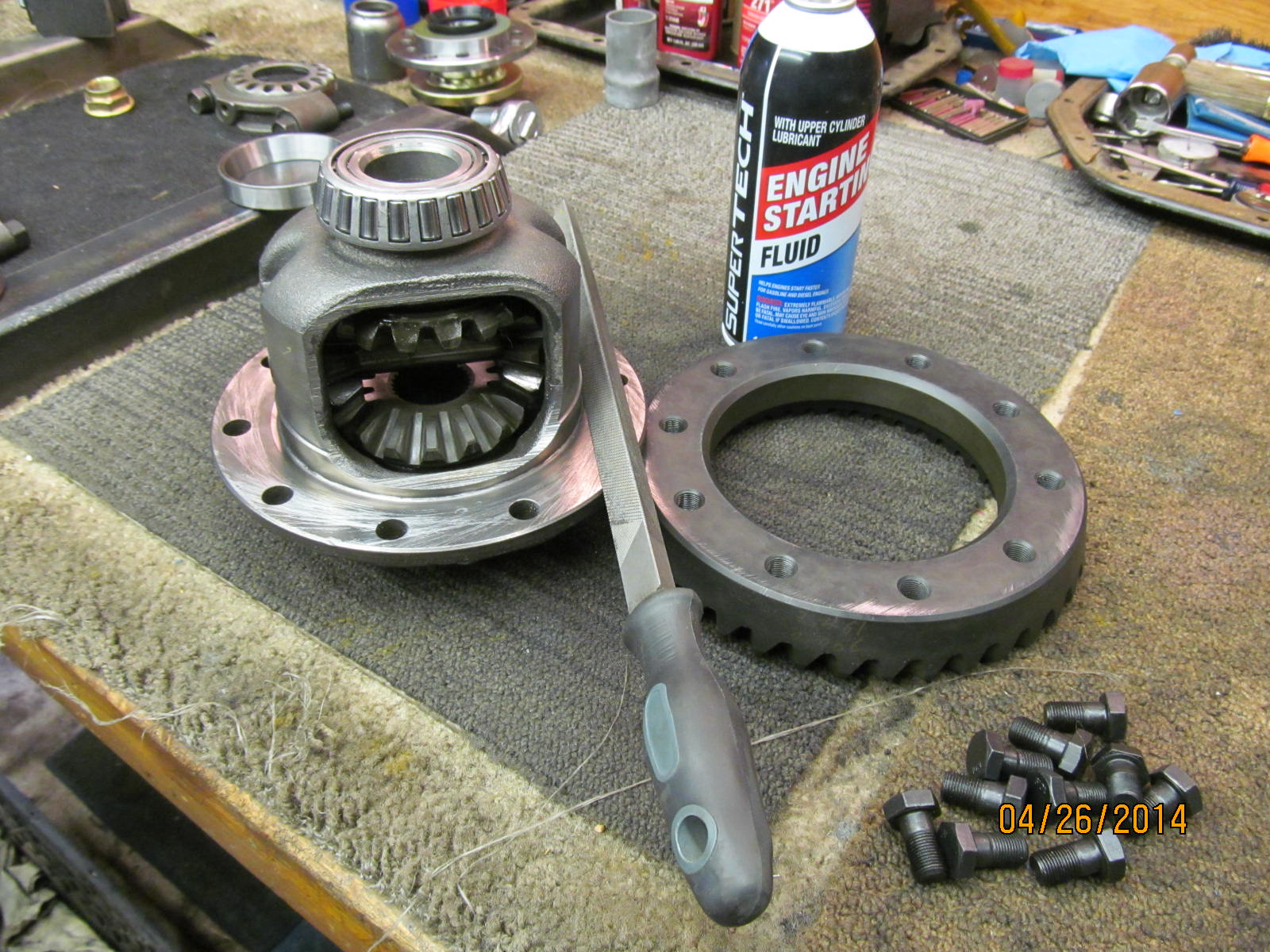

Nitro 488 29 spline ring/pinion...29 spline multi-drilled flange....master install kit.

|

|

|

|

|

...........

|

|

|

|

Because of where Jason is and the cost of sending a 65 pound 3rd to me, it was decided to use a core that I happen

to have. So, I have a solid collar, a basic core, and a basic 2 pinion differential case for this project.

|

|

|

|

The large rear pinion race is tough to press in sometimes. The trick is to get it started straight

so I use a "bubble"......

|

|

|

|

|

...and make sure the bubble placement is the same before I apply pressure from the press.

|

|

|

|

|

Save your old races. They come in handy for pushing bearings in place.

|

|

|

|

The race goes down a long way. If a chisel was being used, it's very easy to think you have the race bottomed out

when it's not.

|

|

|

|

The small front race is more straight forward....just use some old bearing parts and a hammer to tap tap

it fully in place.

|

|

|

|

|

Front(outer)race is verified in 100%.

|

|

|

|

|

.080" is the 1st choice for this Nitro gear set.

|

|

|

|

|

Press the big bearing on with the Harbor Freight press.

|

|

|

|

|

Installing the pinion assembly is a straight forward operation with the right tools.

|

|

|

|

|

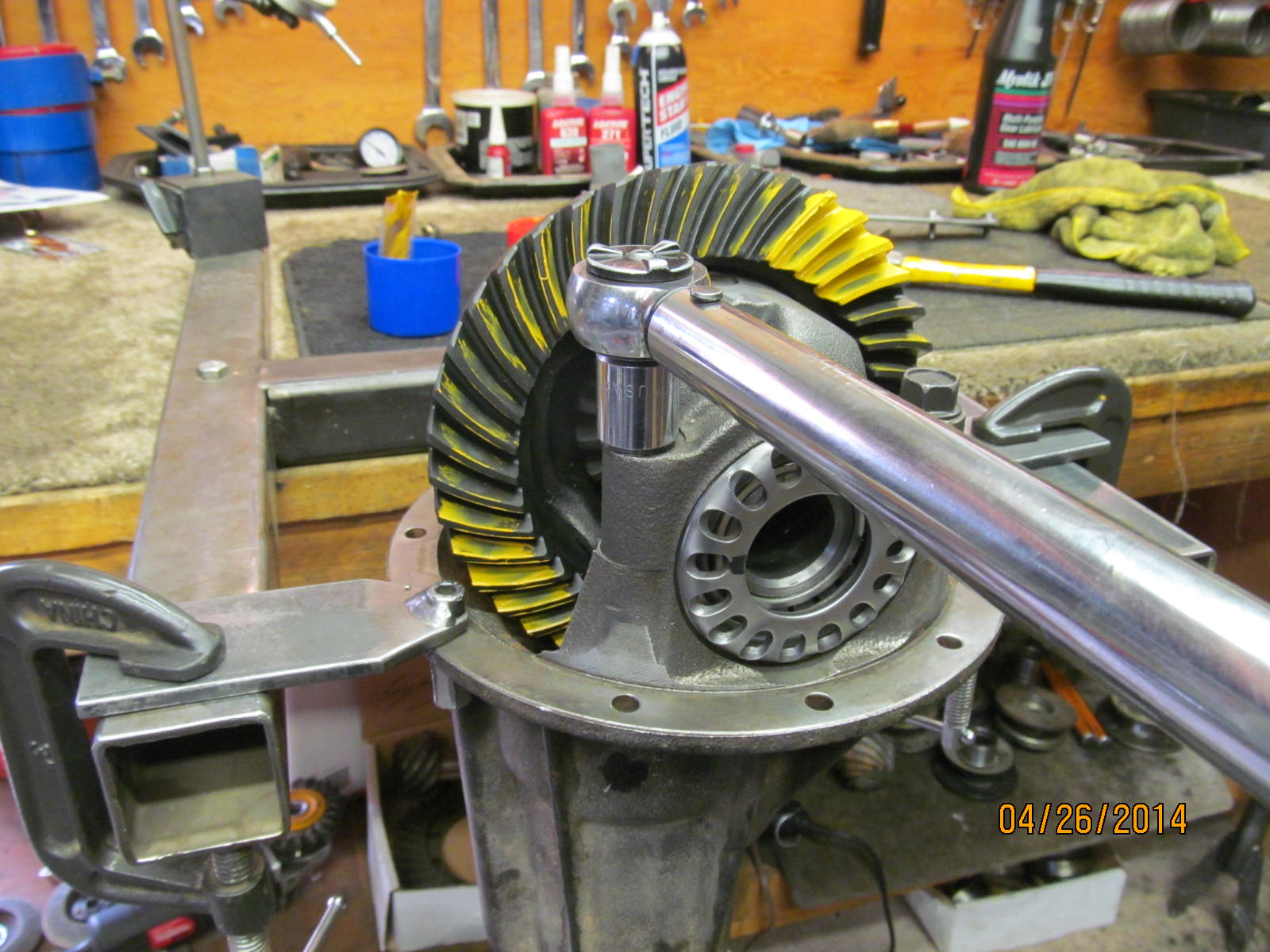

For this paint check, 18 in/lb is aok.

|

|

|

|

|

Now to prep the case end.

|

|

|

|

|

The carrier bearings did not press on as tight as I wanted so #638 retaining compound is employed on both sides.

|

|

|

|

|

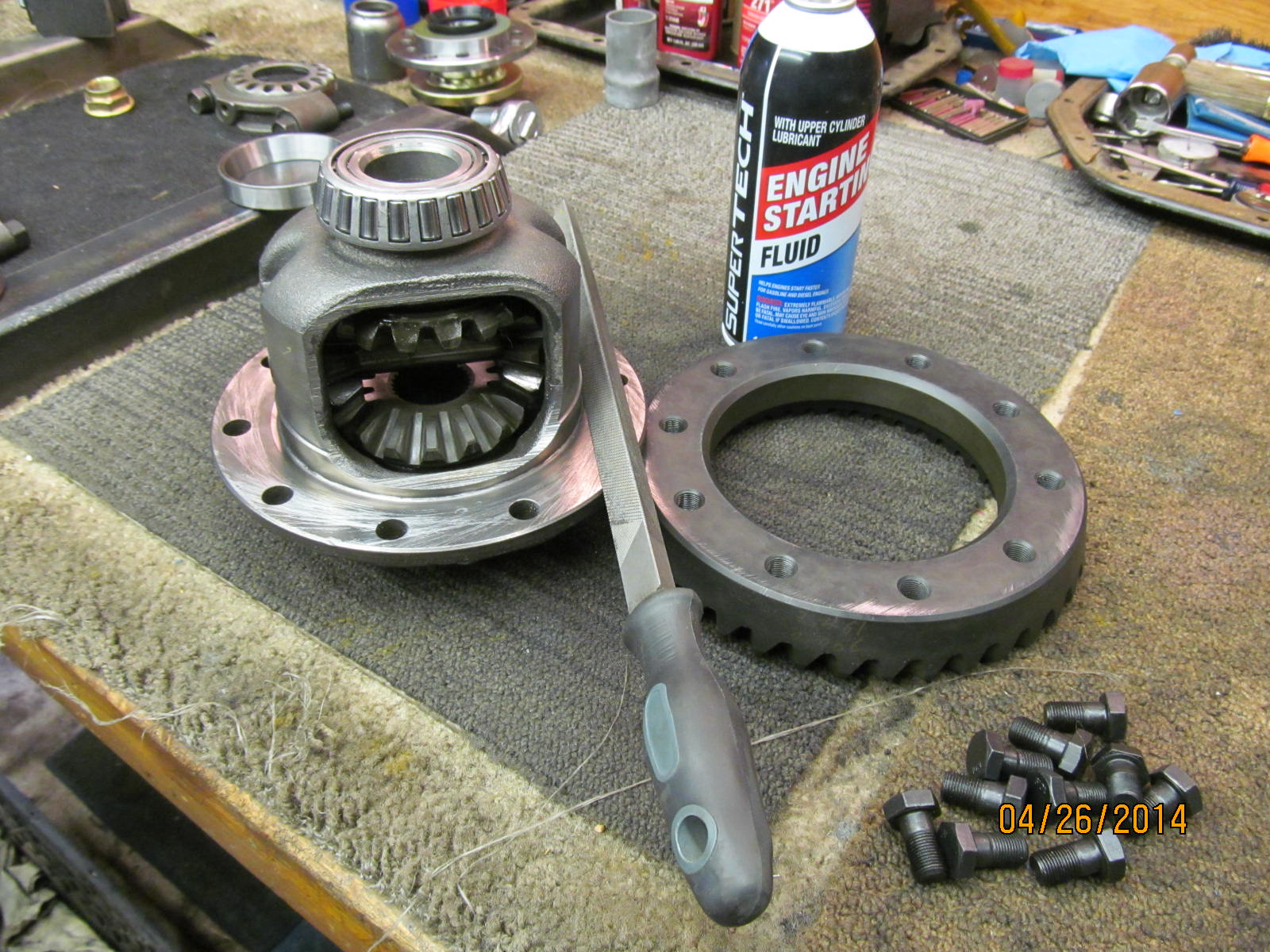

The course file found no burrs or high spots on either mating surface.

|

|

|

|

|

The ring was a tight fit but I was able to get it to seat down with the lead filled plastic hammer.

|

|

|

|

|

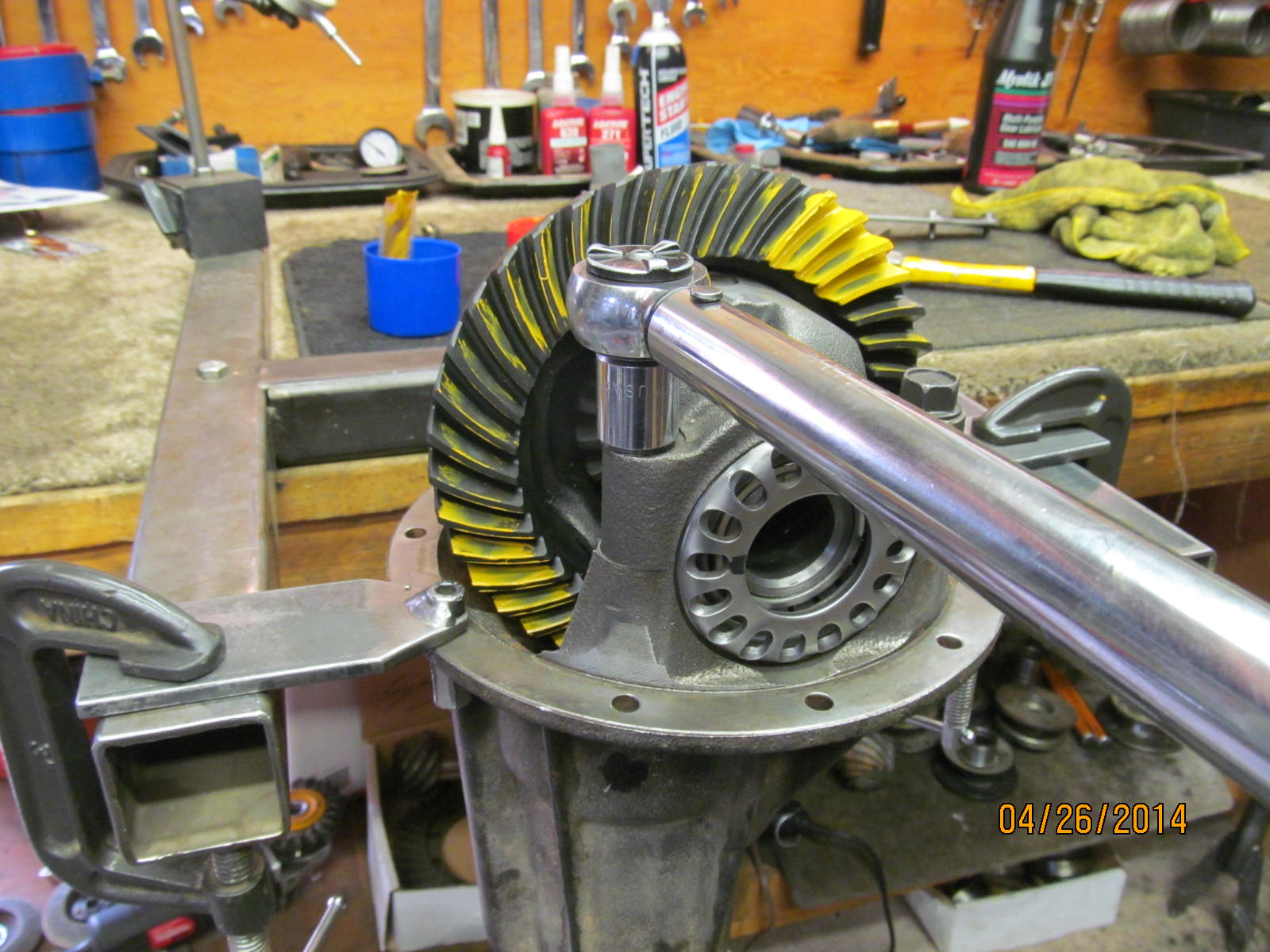

Red loctite on all 10 ring gear bolts.

|

|

|

|

|

75 ft/lbs.

|

|

|

|

|

I use extreme care when aligning the bearing caps...it's too easy to damage the threads.

|

|

|

|

|

Dial in some sort of bearing pre-load while guiding the backlash in the .008" zone.

|

|

|

|

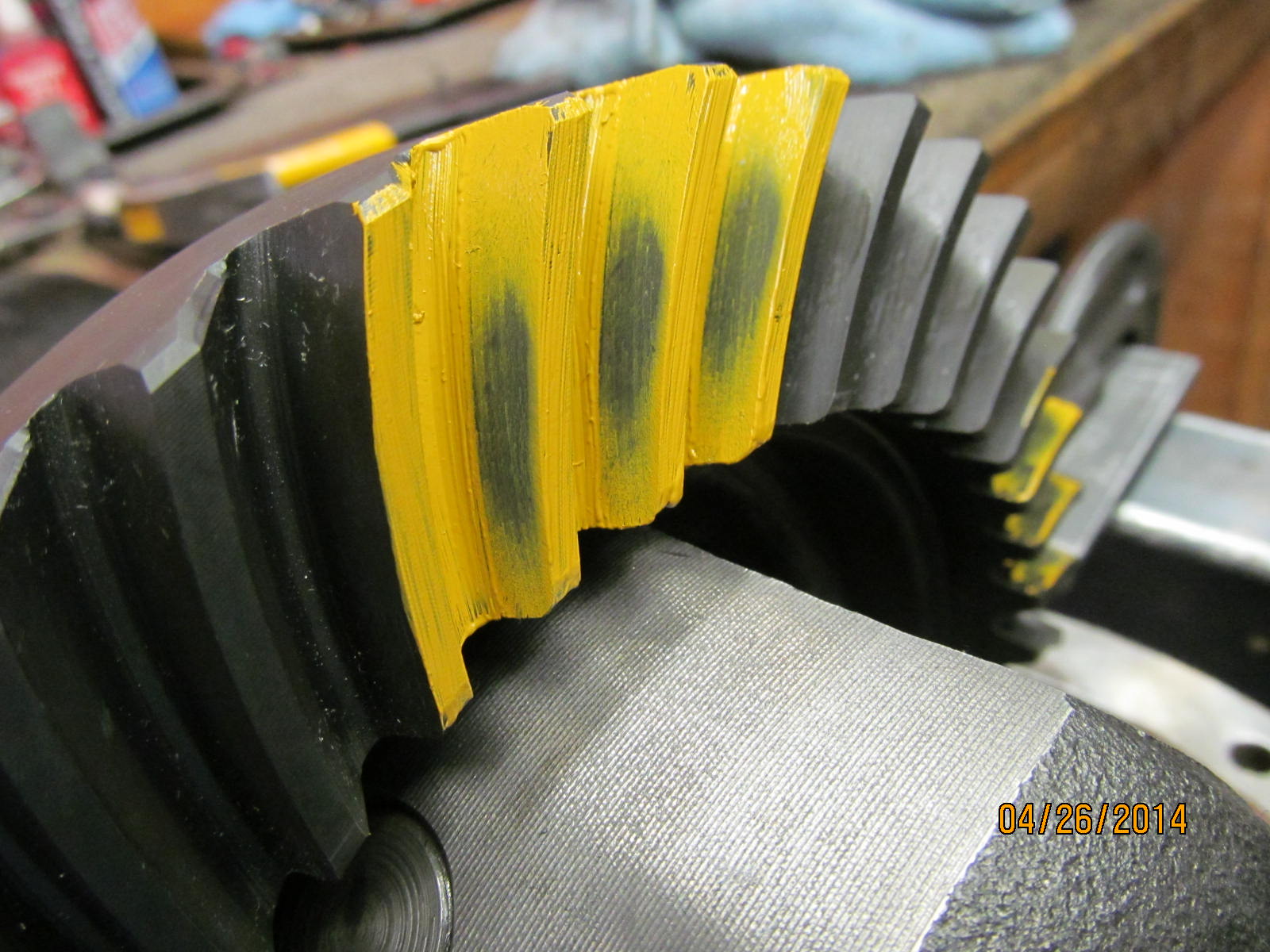

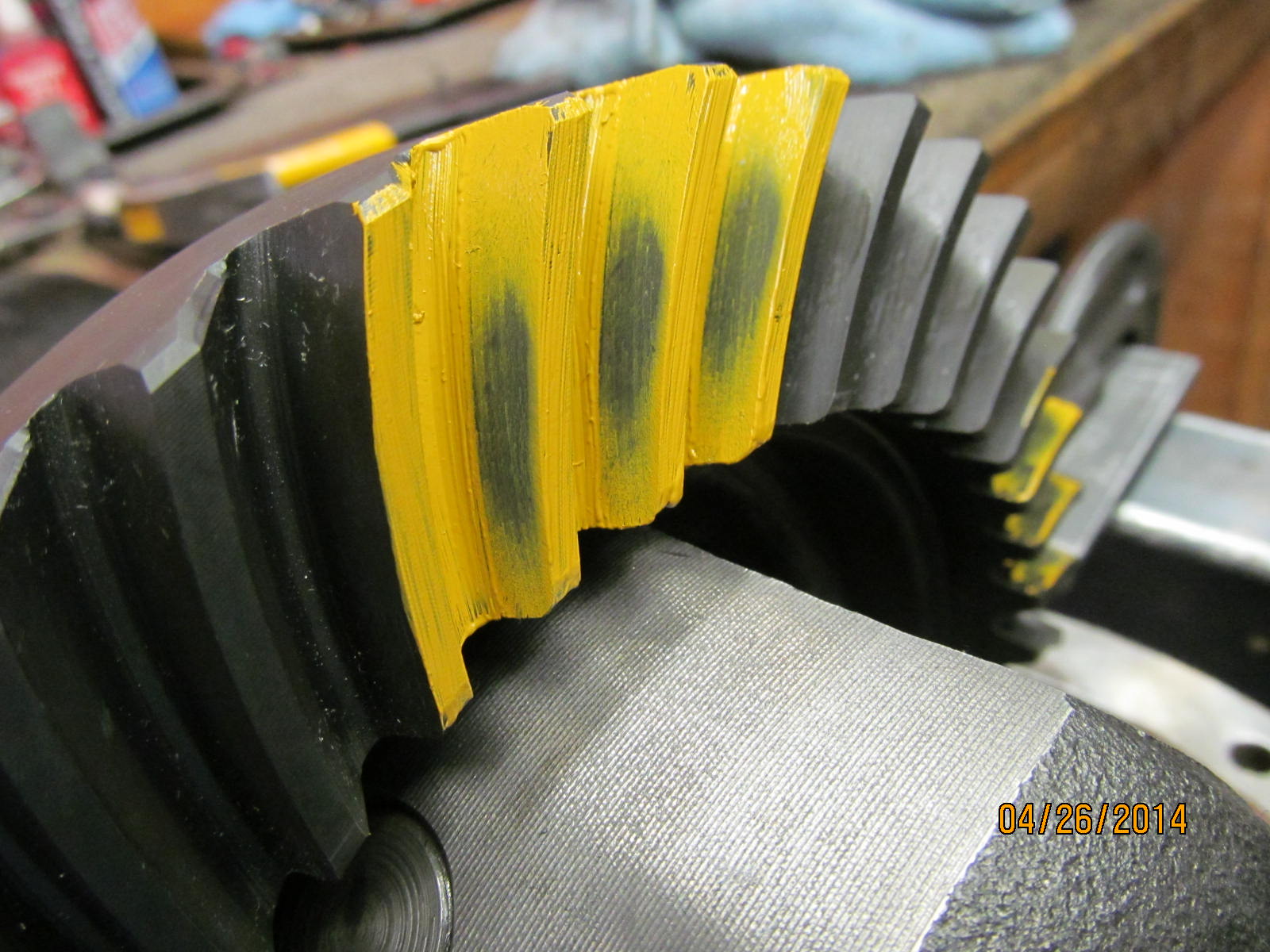

DRIVE----very near centered and appears to be "exact depth" but I think we can go for that "slight deep" look

with a little thicker shim.

|

|

|

|

|

COAST----centered.

|

|

|

|

|

.......

|

|

|

|

|

Now to push the pinion assembly out.

|

|

|

|

|

Remove the bearing...

|

|

|

|

|

...and substitute this .083" shim in place of the 080.

|

|

|

|

|

Press the bearing on.

|

|

|

|

|

Use the electric impact to gently nudge the pre-load to about 10~20 in/lb.

|

|

|

|

|

Another paint check...hmmm, didn't move hardly at all in terms of a deeper look.

|

|

|

|

|

COAST---not much change.

|

|

|

|

I didn't make a big enough change by adding only .003"....this pinion shim is .0885" and, doing

the math, is an additional .0055" deeper.

|

|

|

|

|

Now this is much better. Has the deep look...slight favoring of the toe.

|

|

|

|

|

COAST---depth looks slightly deep and favors the heel ever so lightly.

|

|

|

|

|

Not a very good pic of the pinion...again.

|

|

|

|

Now to remove the pinion again but this time to install the solid collar. On the first try, I had 7 in/lb PPL

with a .026" shim on the solid collar.

|

|

|

|

|

This is the splashguard designed for the 27 spline pinions...and this is the fatter 29 spline pinion.

|

|

|

|

By using a "half round" type of metal file, enough material can be removed in about 4 minutes to

make a proper fit.

|

|

|

|

|

90311-41009 OEM pinion seal will be used on this 29 spline pinion.

|

|

|

|

|

This homemade tool will knock the seal down evenly and fully.

|

|

|

|

Gear oil is applied to all contact surfaces to prevent a dry start-up condition and to minimize the drag

of the rubber when I check the final PPL value.

|

|

|

|

|

I used to apply a red Loctite to the pinion threads....

|

|

|

|

....but, after much thought, decided it was not needed and possibly a hindrance. I have already deformed/destroyed

one 30 mm socket because I did not use an anti-seize compound on the threads

to help reduce the spiral thread resistance.

|

|

|

|

After tightening the 30mm nut as much as the electric impact would allow, the torque wrench was employed to tweak

the ppl to its final desired value of 10 inch/pounds start torque.

|

|

|

|

|

Once the nut is dinged it will never loosen up on its own.

|

|

|

|

|

75 ft/lbs on all 4 bearing cap bolts.

|

|

|

|

Backlash is dialed in and carrier bearing preload is nudged in place by tightening the adjuster wheels 1 notch

at a time.

|

|

|

|

I am measuring 14 in/lb start torque here. That's the force required to turn both the pinion and ring gear. That

means my pinion preload is still 10 in/lb and, doing the math, the carrier bearing preload is 4.

|

|

|

|

|

The lock tabs can now be secured....blue loctite(medium strength)....

|

|

|

|

|

....and 10 inch/pounds.

|

|

|

|

|

One final paint check and the drive side looks slight deep and a slight favoring of the toe. Excellent.

|

|

|

|

|

Coast looks pretty good, too. Deepish look and favoring the heel a little.

|

|

|

|

|

....................

|

|

|

|

|

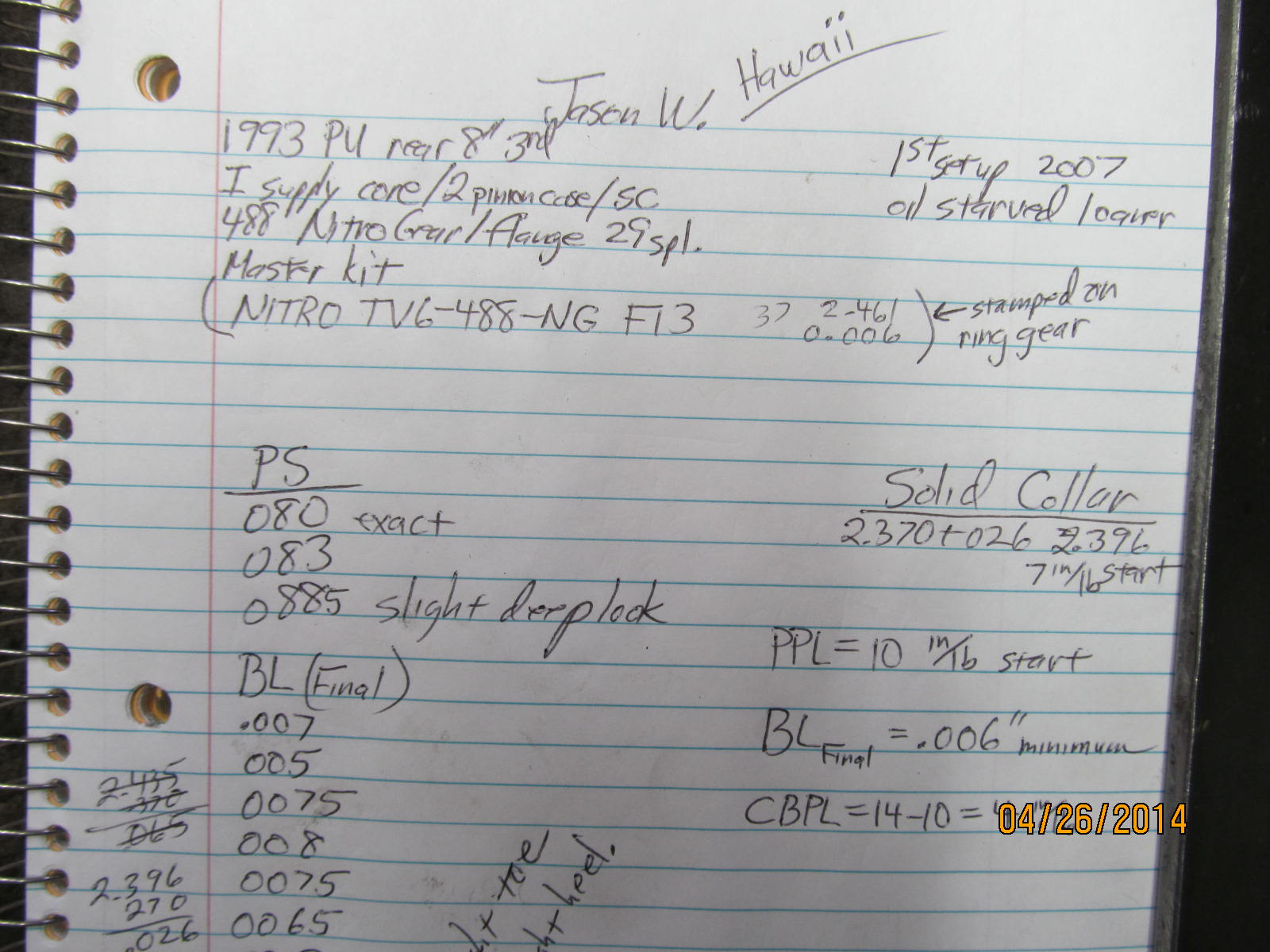

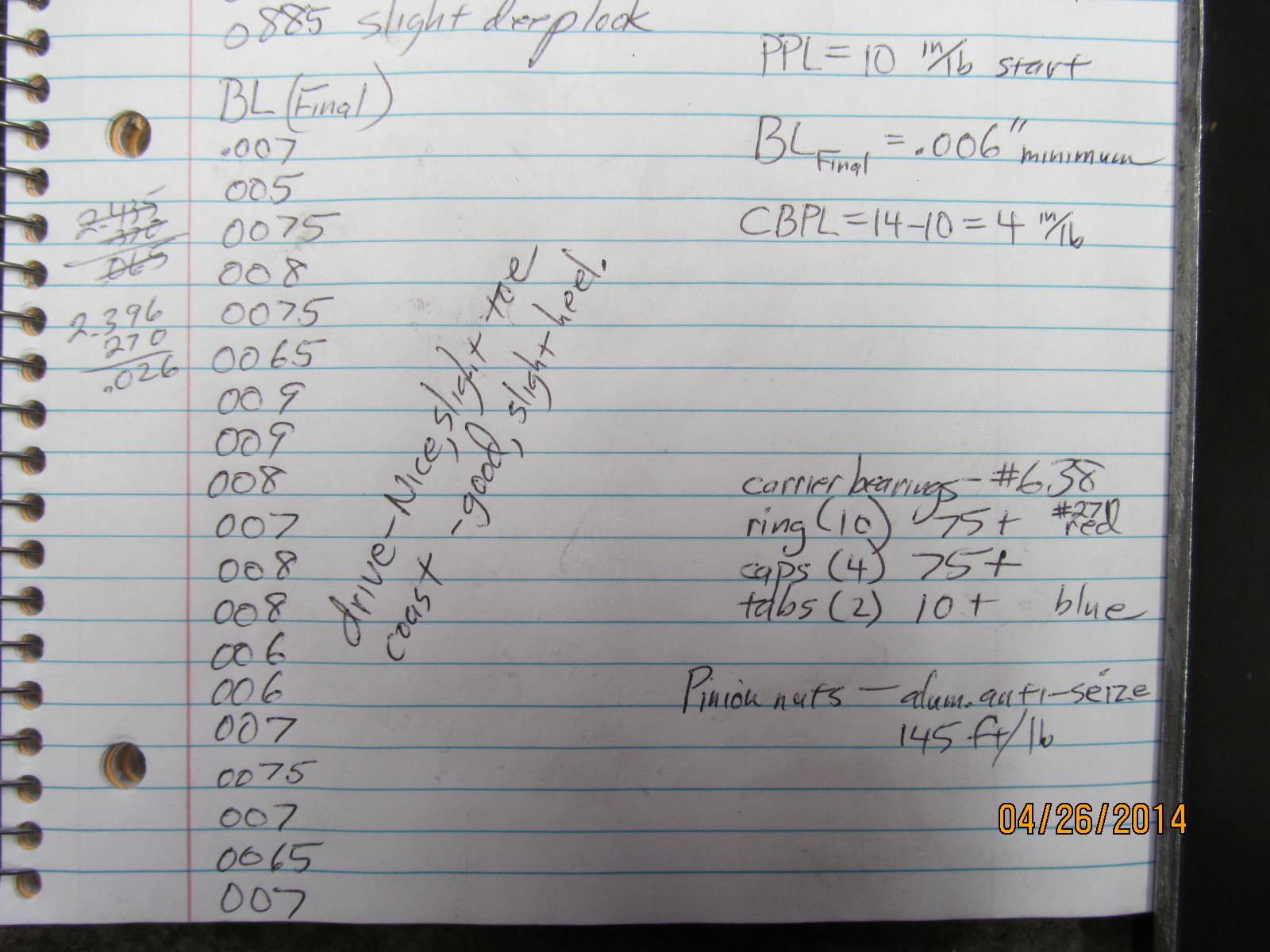

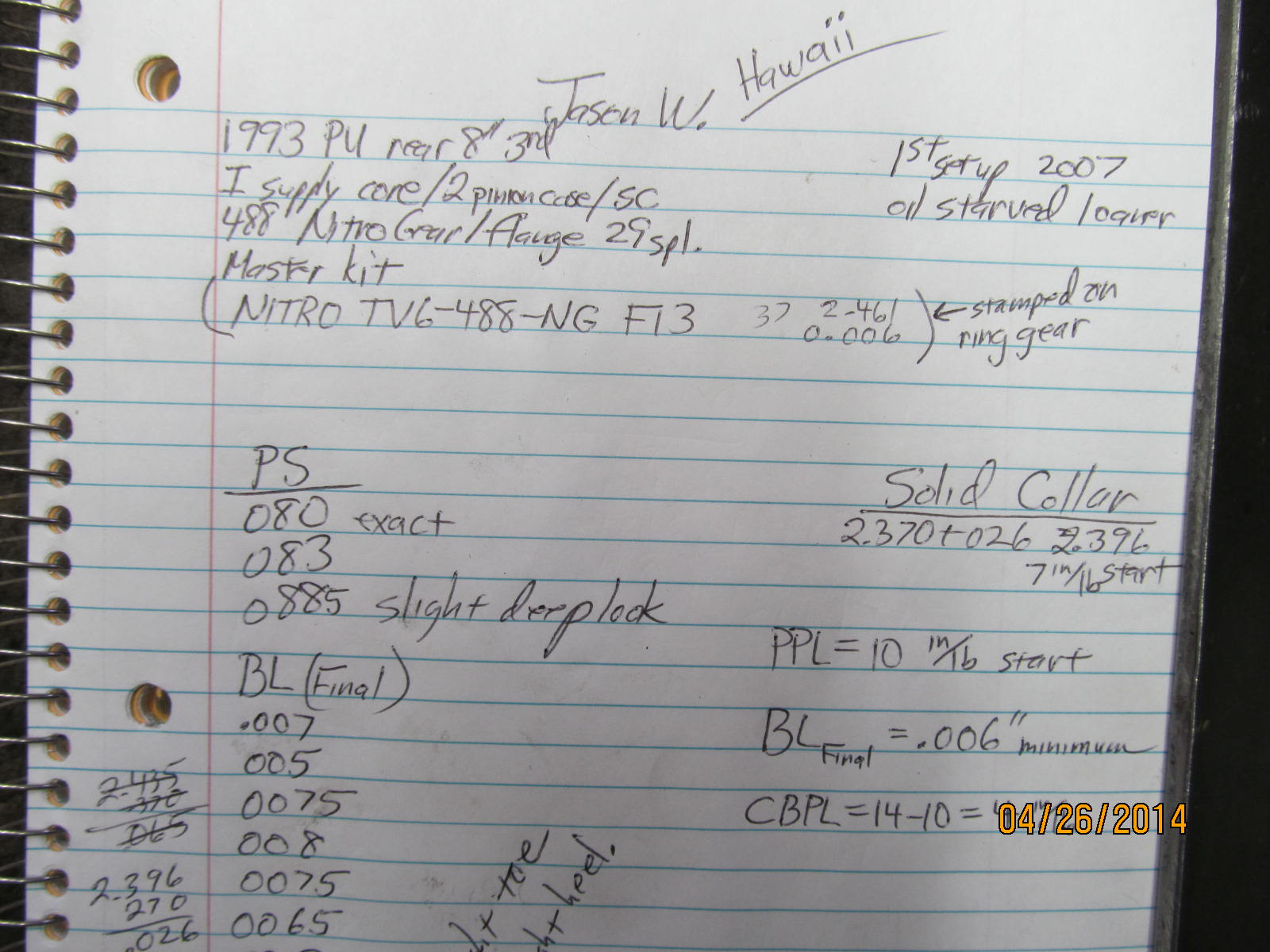

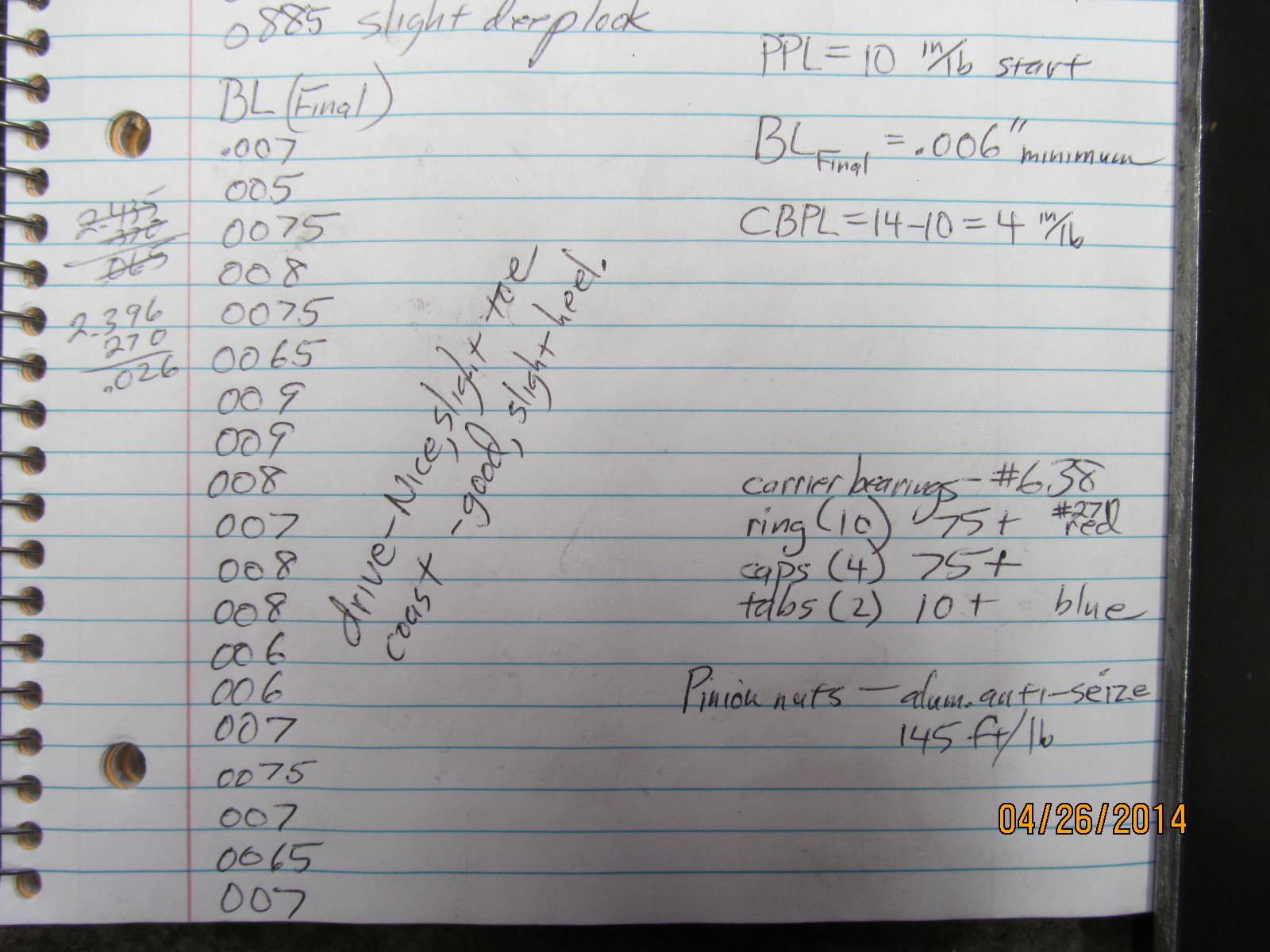

A snap shot of my assembly notes.

|

|

|

|

|

..................

|

|

|

|

And, since this was going USPS to Hawaii which has a weight limit of 70 pounds max, a light but strong

rectangular box was created. Cut in half....

|

|

|

|

|

....and slide them together to make a super duty box.

|

|

|

|