|

Jake had someone in the Phoenix area set up his first set of rear 488 Yukon gears.

They busted shortly after but that tends to happen when one of the ring gear bolts

falls out and locks up between the ring and pinion. They admitted it was their fault and

ordered a replacement. Finally after about 4 visits and 7 weeks later, they had the rebuilt 3rd

ready for pick up. Jake didn't have much confidence in the install so he dropped it off to me for a check-up.

|

|

|

The gears installed were the cheapest possible gears they could get....Genuine :( :( :(

|

|

|

And they were the wrong ratio....456!

|

|

|

Other marks on Genuines to help identify them.

|

|

|

This one is very unique to Genuines....

|

|

|

The pinion head had this marking...

|

|

|

I checked the quality of the install....the pinion pre-load was low....about 2 or 3 inch/pounds of drag.

Just the pinion seal itself might have 2 or 3 inch/pounds so the real pre-load was probably closer to zero.

|

|

|

The pinion depth appeared to be right on...

|

|

|

good...

|

|

|

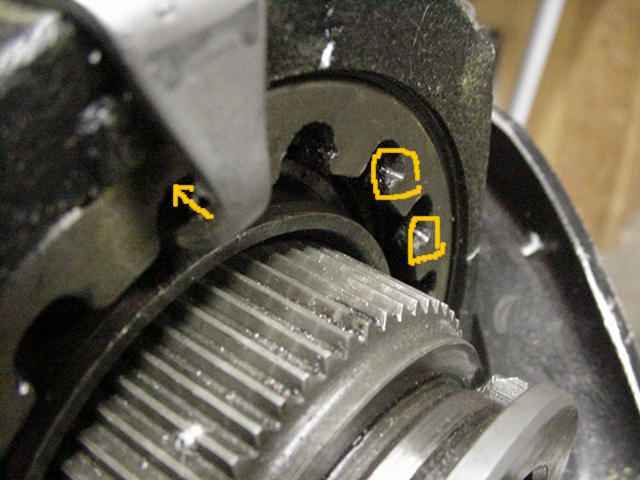

The right tool was not used to tighten the spanner rings...looks like

a hammer and screw-driver was used.

|

|

|

The locktab was not tapped in far enough to do its job.

|

|

|

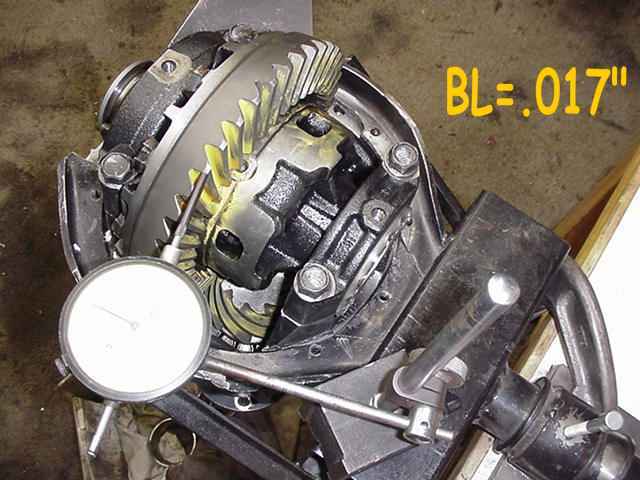

I checked the BL and it was excessive at .017"....it should have been closer to .008".

|

|

|

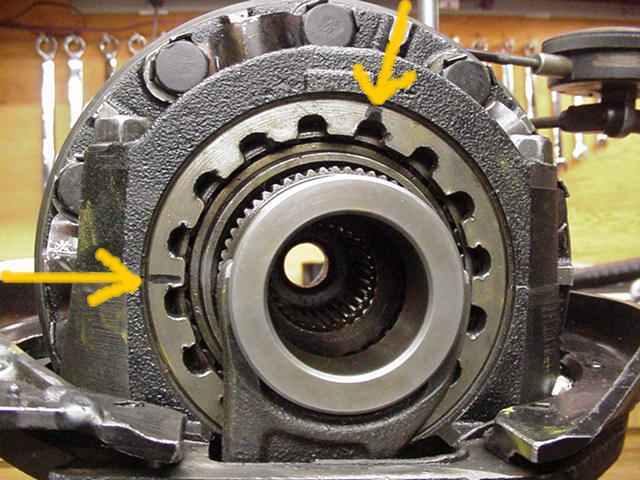

The screwdriver/hammer method does not develope enough pre-load ....I was able to tighten the

adjusters another 5 notches on both sides with minimal effort....with my homemade tool.

|

|

|

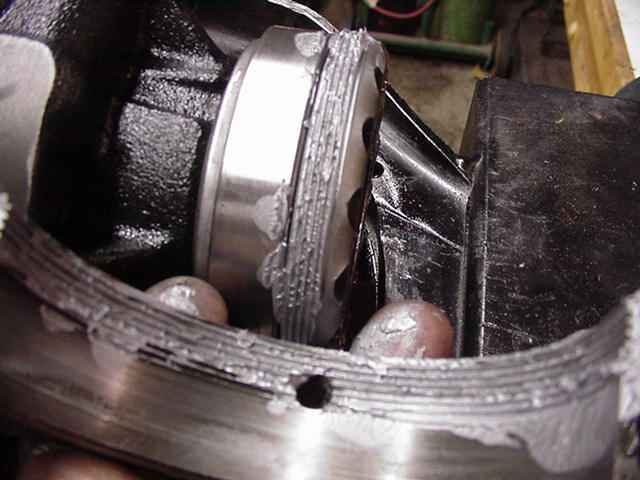

Here's the ring bolt that wiggled out and almost ruined the E-Locker case itself. The original Yukon \

ring and pinion saw some tooth damage and could not be salvaged.

|

|

|

I found plenty of grease on the pinion seal and that was good. No dry start-up issues here.

|

|

|

I'm not a big fan of crush sleeves for a rear end application. This one was beat with a hammer to help "lengthen it out" so that

it could be re-used/re-crushed :(

|

|

|

I wanted to see what shim it had....

|

|

|

.241 is a good value and the depth pattern reflects that.

|

|

|

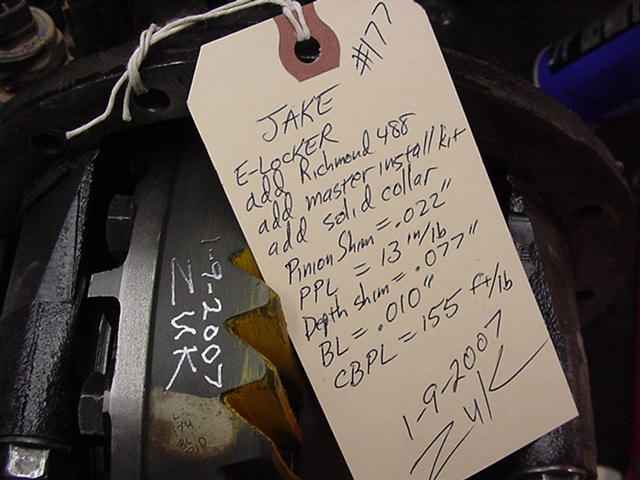

Jake found a Yukon V6 488 gearset from some friends and I had the new master kit and the solid collar. The so-called V6 gears

have a slightly longer pinion head. Same strength as the shorter pinion head gears.

|

|

|

The master kits from PORC are now packaged in black boxes. KOYO bearings are excellent.

|

|

|

Included in the kit was the usual shim assortment plus this extra thick .125" shim.

|

|

|

Original crush on left....new one on right. A superior solid collar is planned for this install.

|

|

|

On the left is one of the bolts that did not loosen up. They have 10.9 on them. I find these to be the

hardest ring gear bolts out there(this is good).

|

|

|

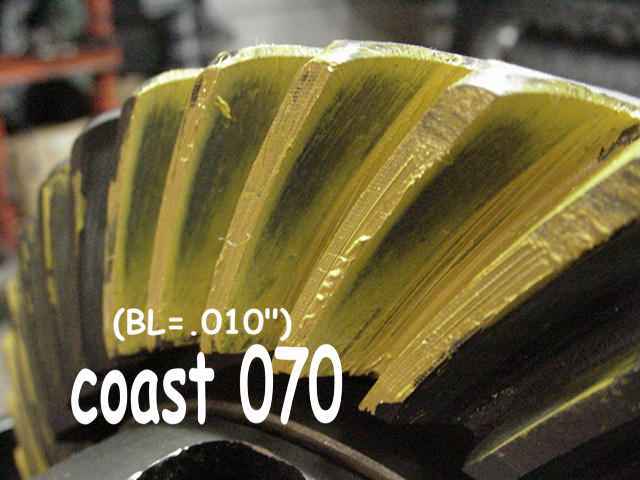

If the ring gear has markings like this "BL=010" then this identifies it as a Richmond gear.

|

|

|

Only other marking on ring...

|

|

|

The Richmond pinion had only this mark....note the way the pinion splines were cut.

|

|

|

I did not have the pricey "E-Locker master kit" but I was comfortable with using a V6 kit which has

3 of the 4 bearings that I need. The carrier bearing on the other side is a monster and rarely wears out. This one was in good shape.

One new carrier bearing is going on and ring gear surfaces are filed smooth as in this pic.

|

|

|

With the big smash mark in the case from the ring bolt, I checked the case for run-out damage. I found a couple thousands run-out

so this case is still ok.

|

|

|

A new oil retainer goes here.

|

|

|

Shown with the new outer pinion race...

|

|

|

Red loctite and 75 ft/lbs all the way around.

|

|

|

Only on Richmonds do I have to use a super fine wet/dry sandpaper to remove a surface coating of some sort.

Not doing this means the pinion bearing will press on extremely tight and, all I can say is, good luck trying

to get the bearing off later on.

|

|

|

...waiting for the bearing and yoke...

|

|

|

I use lots of anti-seize compound to protect the threads. The aluminum based version seems to lubricate the

threads the best(better than the copper).

|

|

|

First try with .070 and pattern appears shallow. Richmonds are cut at the factory to favor the toe as in this picture.

|

|

|

coast side.

|

|

|

.074 slightly shallow..

|

|

|

074 coast.

|

|

|

I did too big of a jump to 082 and now it's deep.

|

|

|

coast confirms that.

|

|

|

My machinist dad make up this V6 pinion bearing remover....sure is nice to have a good tool. I have not destroyed a bearing yet.

|

|

|

077 and this is where I want it.

|

|

|

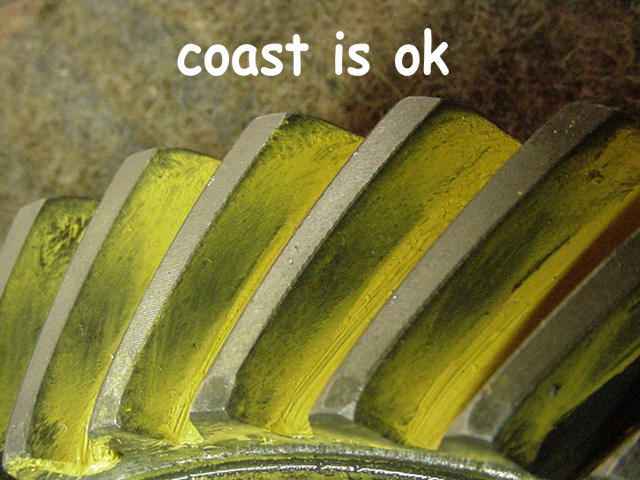

coast 077

|

|

|

Richmond wants their gears set with .010" backlash so I was very particular to set that value...and crank

the carrier bearings to 150 ft/lbs....this translates to 15 in/pounds of actual carrier bearing pre-load....

and 15 in/lb is far from excessive on carrier bearings.

|

|

|

Leverage is my specialty.

|

|

|

The threads were cleaned with starting fluid and red Loctite applied on the threads.

I feel sorry for the guy that has to re-move this

nut on down the road :)

|

|

|

Toe-tagged and ready for Jake to give it hell. :)

|

|