| Jake's 2018 Tacoma 529 Regear is Noisy! |

|---|

| (62 BIG pics loading) |

|---|

| MARCH 9 2025 |

|---|

|

I don't have any pictures of Jake's Tacoma but I do have 2 pics of the professional Landcruiser shop down in Senoita, AZ that did remove the diffs and

deliver them way up here to me in Prescott. They seem to specialize in all Landcruisers.....take note Landcruiser guys :)

Overland Cruisers |

|---|

|

|

This is the 'go to' place.....very professional and very clean.

Senoita is located about 40 miles SE of Tucson. |

|---|

|

|

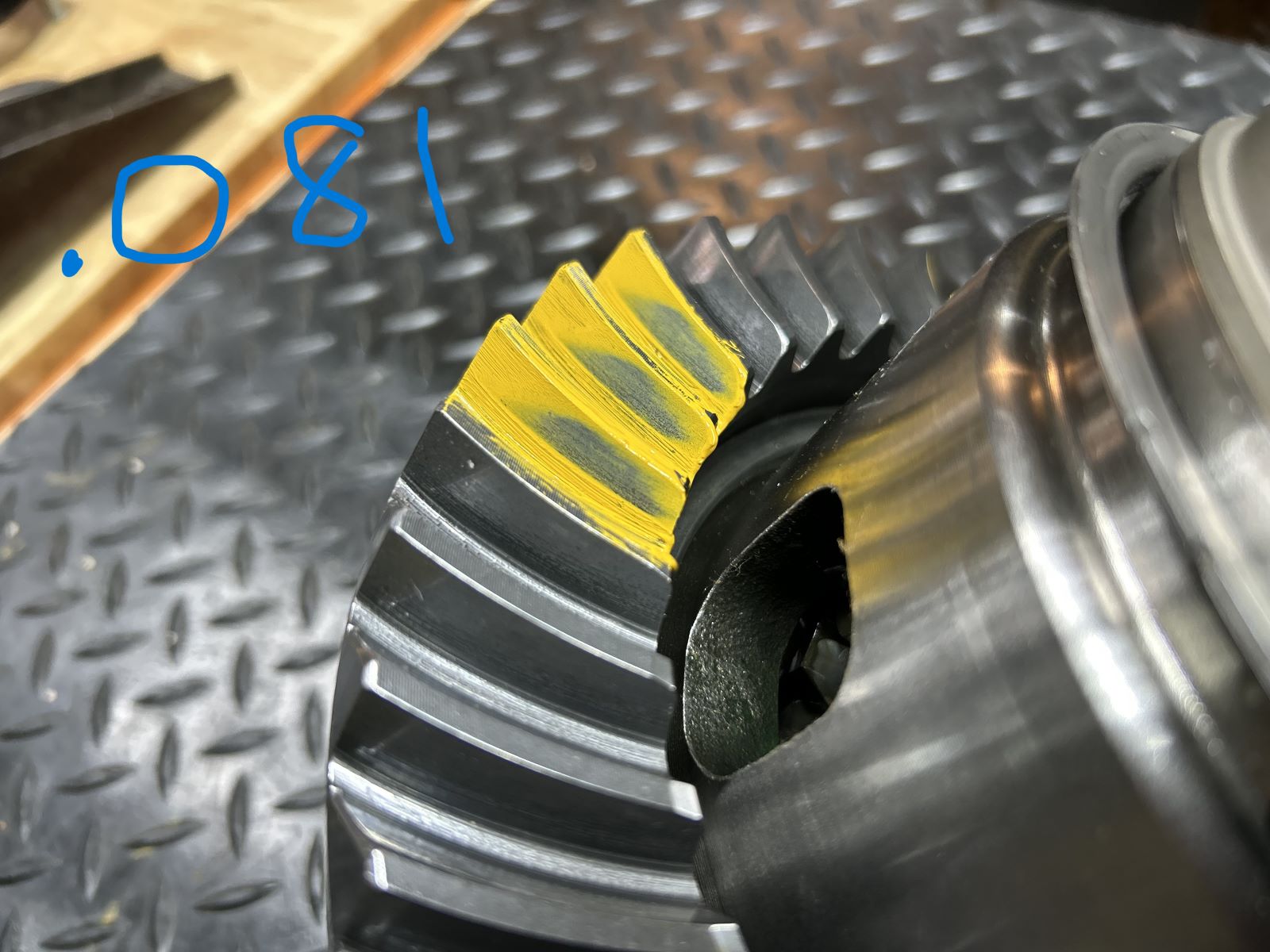

The 8.75" elocker diff is on the bench and the first thing is to perform a pattern check with yellow marking paint.

This drive pattern shows extremely deep. This would cause noise going forward.

These quality Nitro gears have too many miles on them and they are not REM super polished...

Too many miles on a gear set that has been set up too deep or too shallow will ruin the gears.

A new 529 set of polished gears is coming from Revolutiongear.com

REM super polishing means no 500 mile break-in....no excessive heat....no micro-tears/pitting on the tooth surfaces. |

|---|

|

|

|

Here's the coast......extremely deep and this also would cause loud noises on deceleration. |

|---|

|

|

2 shops worked on this......the first one in the Phoenix Valley installed the initial 529 gears.

The 2nd shop was located in Pennsylvania and supposedly replaced the gears again and the noises was still there...possibly louder than before.

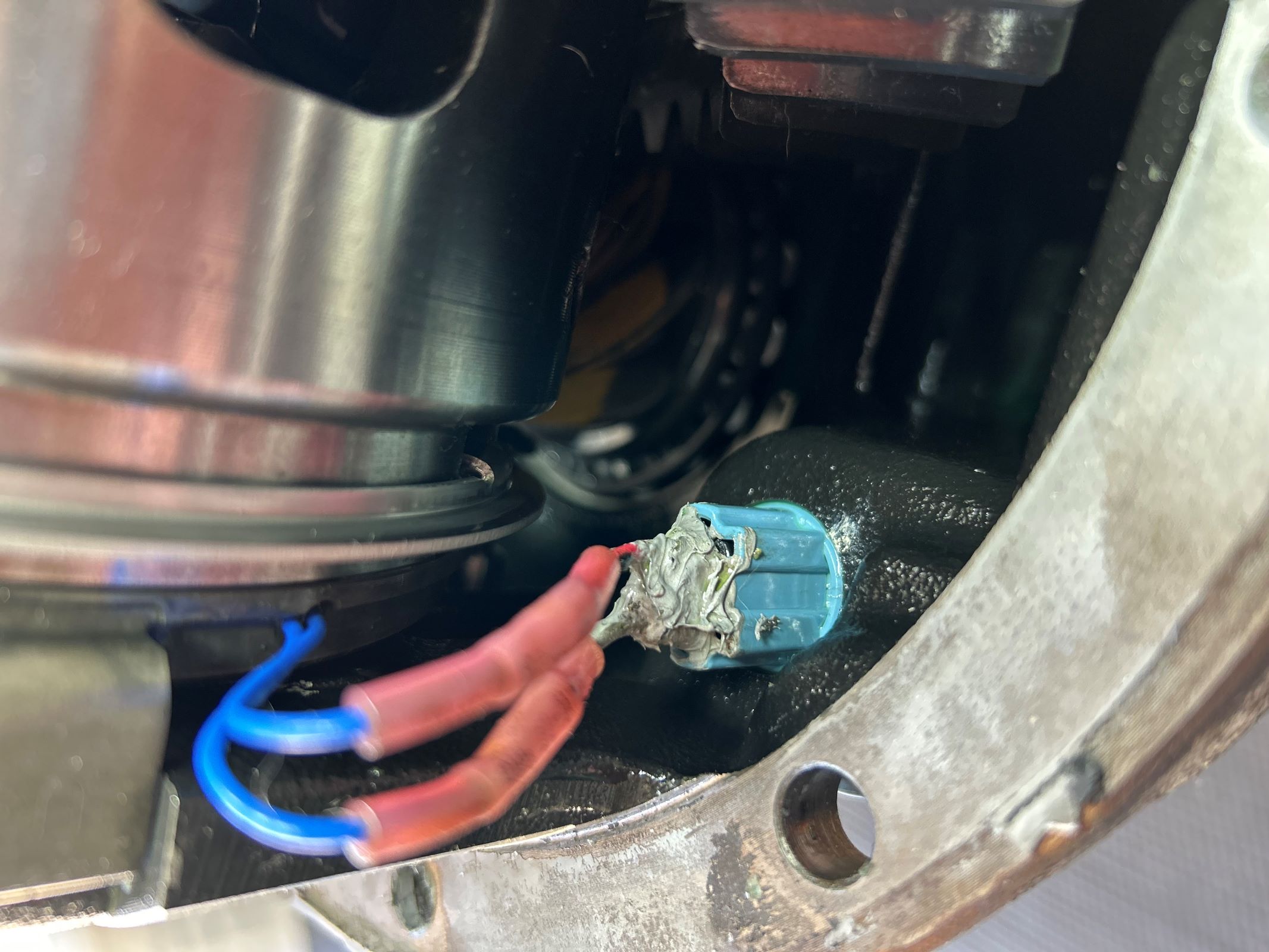

Somebody really messed up this magnetic ring harness so a new ring was ordered. These are not cheap either. |

|---|

|

|

|

Both of these connectors are considered perishable according to the Toyota FSM. Both will be replaced. |

|---|

|

|

|

No more chains wrapped around the 12 ton press to get this particular "zero clearance" carrier bearing off....the right tool for the right job. |

|---|

|

|

|

This ring is only lightly pressed in place and retains the magnetic coil. |

|---|

|

|

|

...................... |

|---|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

|

Same "zero clearance" puller is used on the other carrier bearing...then a standard 2-jawed puller can reach under it and remove it. |

|---|

|

|

|

Elocker center carrier is now ready for re-assembly..... |

|---|

|

|

....now onto the pinion end of things. I found 3 thin shims behind the big pinion bearing.

|

|---|

|

|

Those 3 shims add up to 036....there was also a 054 washer plate behind the large inner pinion race.

That adds up to a very large .090" which is way more than the typical final pinion shim. |

|---|

|

|

|

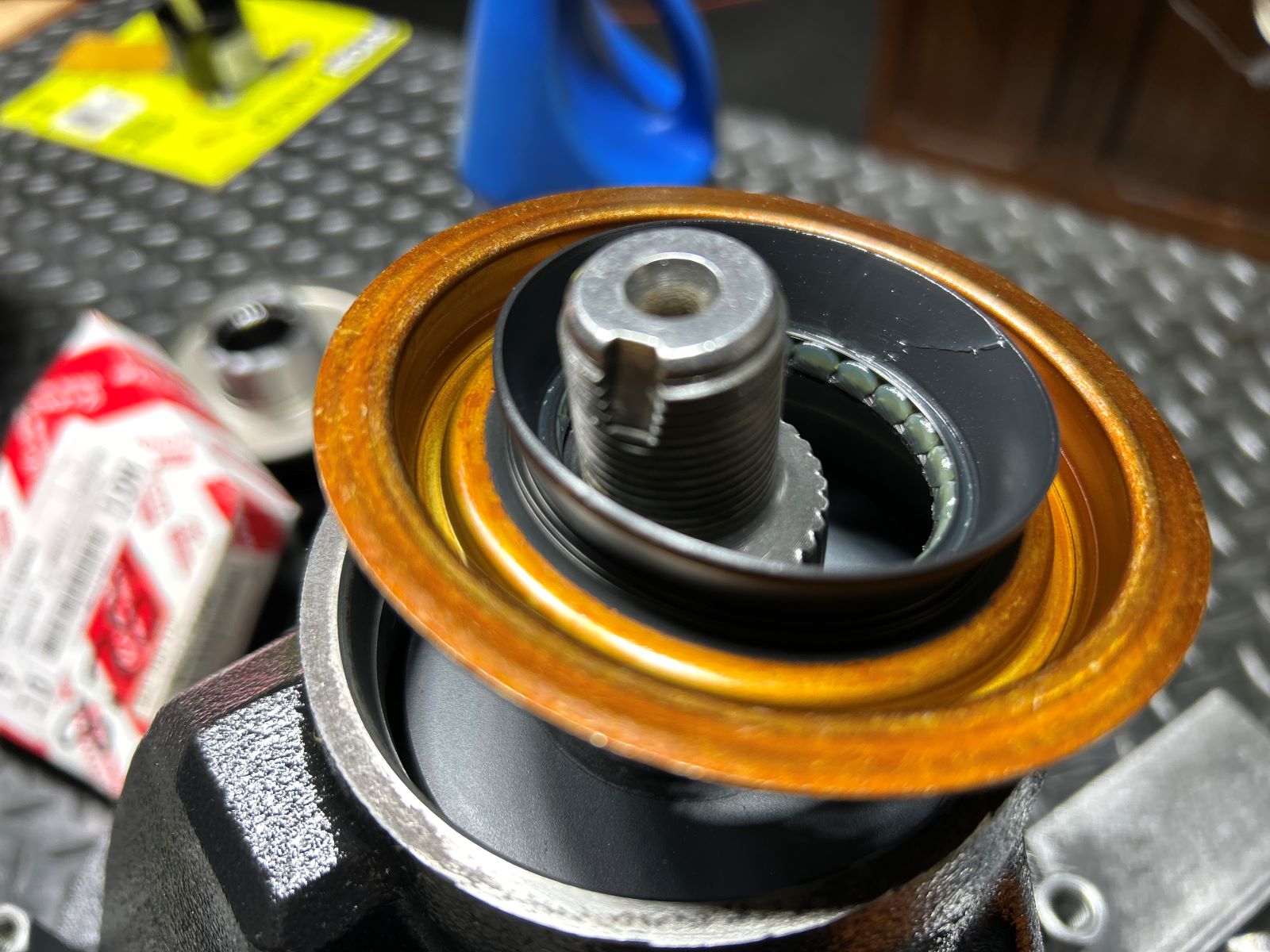

The pinion flange had a very noticable wear groove which is unusual for a 2018 model. |

|---|

|

|

|

A new flange is on order. |

|---|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

|

New flange arrived. |

|---|

|

|

|

The oil retainer near the small pinion bearing was missing so a new one is coming. |

|---|

|

|

|

Parts arrived.... |

|---|

|

|

|

All the good stuff came. Now we can re-assemble. |

|---|

|

|

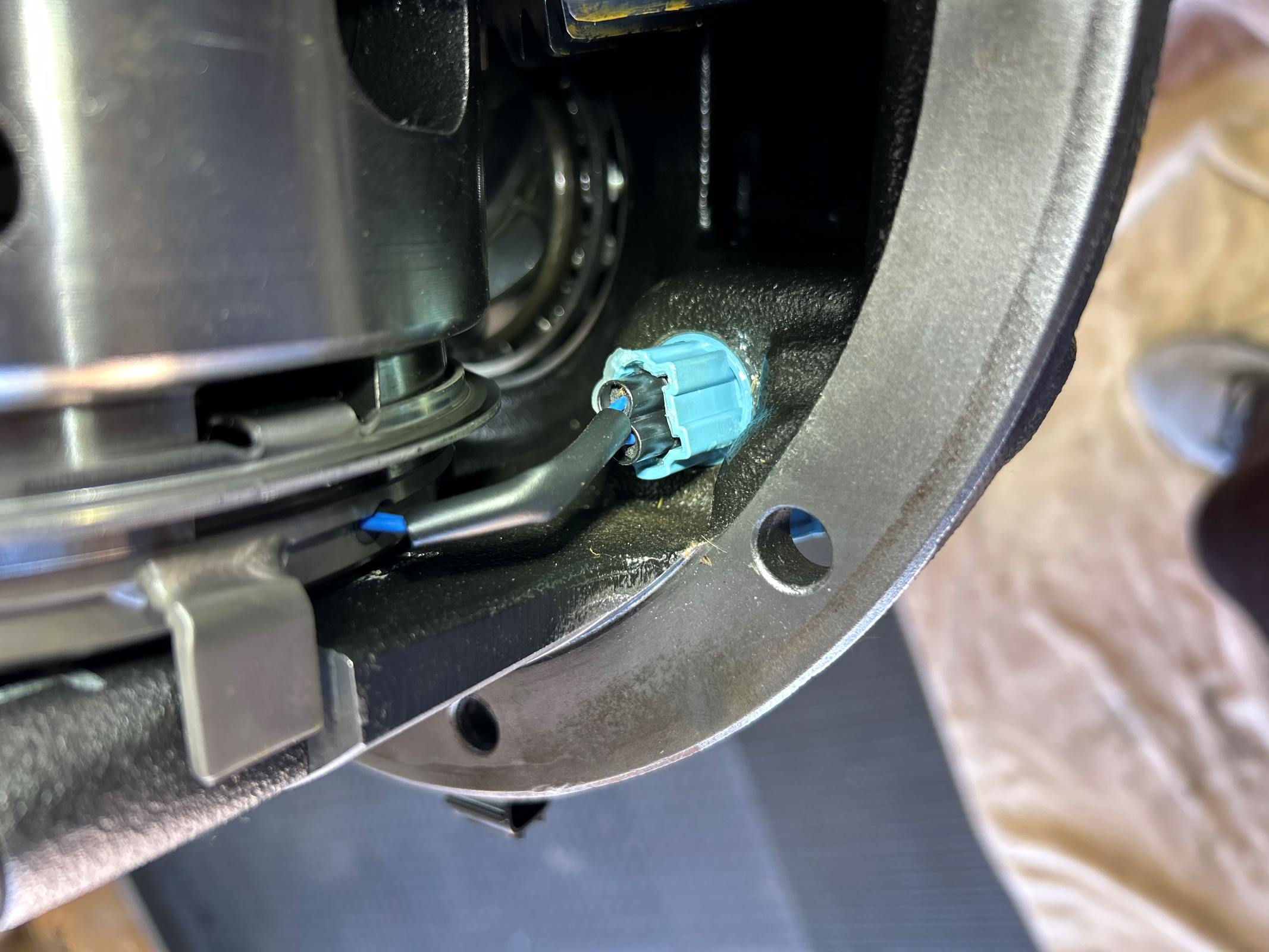

The blue connector gets replaced because the old one always gets destroyed.....

but the black seems reusable. Apparently, it should be replaced also. |

|---|

|

|

|

The super polished ring and pinion has also arrived. 92 ft/lb and red loctite on the 12 flange style bolts. |

|---|

|

|

|

The new plunger gets oiled up and slides in place perfectly. |

|---|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

|

Going back together nicely. |

|---|

|

|

|

New carrier bearing tapped in place. |

|---|

|

|

|

This center carrier is ready. |

|---|

|

|

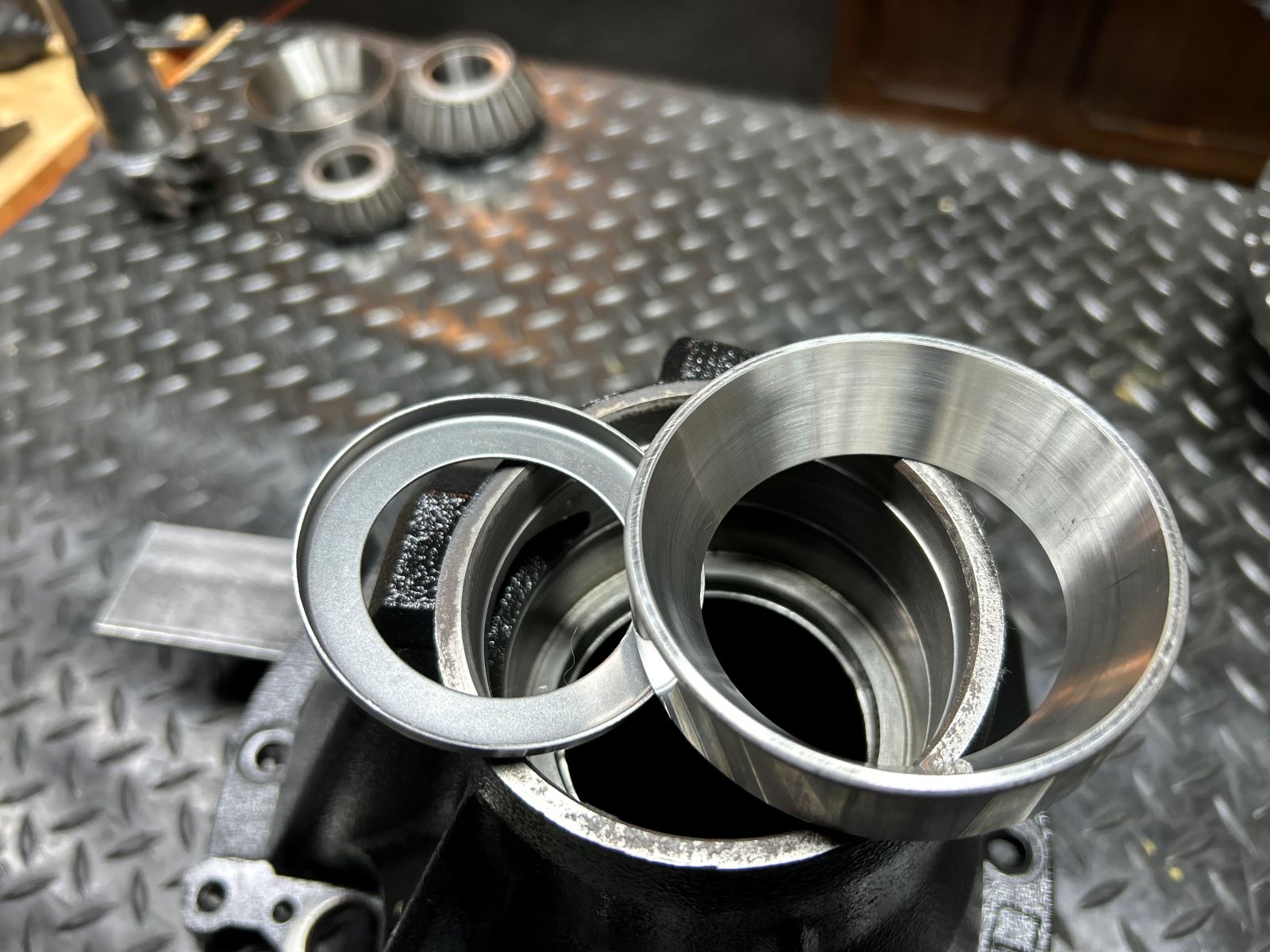

These are the 6 widgets that I use on the 8.75" to remove/install bearings.

Sure makes installs go smoother with them. |

|---|

|

|

|

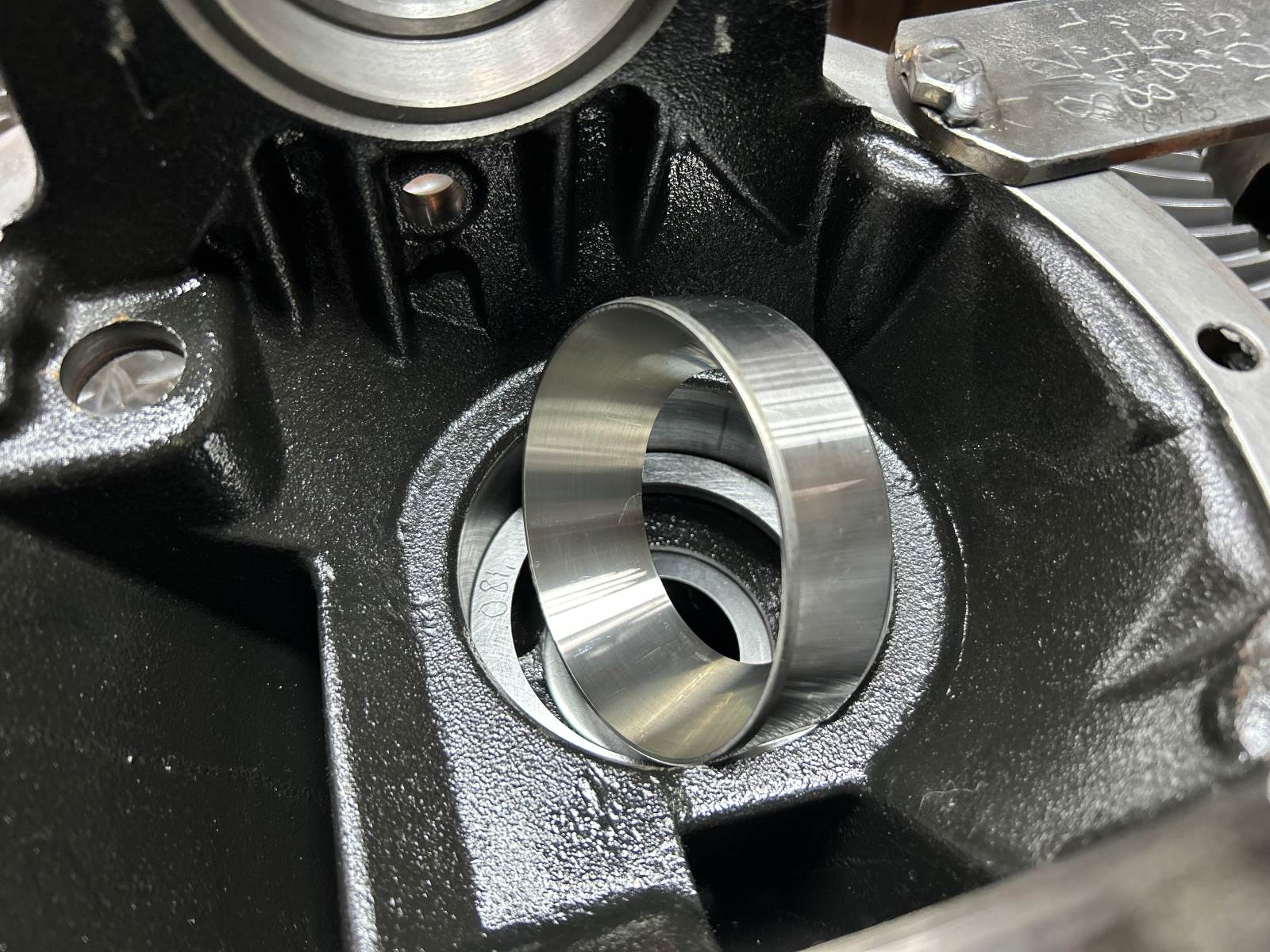

New oil retainer and race going in. |

|---|

|

|

|

It's very helpful to have a full washer plate (shim) selection....I'll start with 081 |

|---|

|

|

|

The washer plate is placed behind the large race |

|---|

|

|

|

No shims on the pinion head..... |

|---|

|

|

|

....and this monster bearing is pressed on. |

|---|

|

|

|

The pinion preload was verified at about 15 inch/pounds on well oiled bearings....now the elocker center carrier can be installed. |

|---|

|

|

|

Driveside.....081....It's deep...too much contact in the root. |

|---|

|

|

|

Driveside reversed painted....081....sometimes the reverse paint shows a different perspective. |

|---|

|

|

|

Coastside....081....nothing special to say. |

|---|

|

|

|

Coastside reverse painted....081.... |

|---|

|

|

|

081 on the pinion tooth shows shallow....contact along the top of tooth. Shallow on the pinion equates to deep on the ring gear. |

|---|

|

|

|

took 003 off.....driveside with 078.....still looks deep...excessive contact in the root. |

|---|

|

|

|

driveside reverse painted....078.... |

|---|

|

|

|

Coastside....078....nothing special. |

|---|

|

|

|

coastside reverse painted 078.... |

|---|

|

|

|

The pinion tooth is better but still shows shallow (deep on the ring gear). |

|---|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

|

Now with .0756"....driveside....this looks spot on....exact. |

|---|

|

|

|

Drive reverse painted looks nice. |

|---|

|

|

|

Coast is determined not to get any better...pattern is still on the tooth so it will be quiet. |

|---|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

|

Pinion tooth has equal balance on the root and on the top of tooth. |

|---|

|

|

|

Now to assemble the pinion....crush sleeve is placed on the pinion |

|---|

|

|

|

Slinger and then the genuine factory seal. |

|---|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

|

The trick to getting the stubborn factory crush sleeves to crush is anti-seize on the bottom of the flange nut and some on the threads. |

|---|

|

|

|

A nice, smooth 15 inch/pounds of pinion preload. |

|---|

|

|

|

DING!! and this end is done.. |

|---|

|

|

|

These 2 get installed before the center carrier goes in. |

|---|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

|

Now the center carrier goes in |

|---|

|

|

The carrier bearing washer plates might get swapped for different values.....

get the right backlash with a strong carrier bearing preload. |

|---|

|

|

|

Click! |

|---|

|

|

|

Doesn't go macro mode quite as good as I'd like it to but the I14 plus did a good job on these 63 pictures. |

|---|

|

|

|

Final assembly notes. |

|---|

|

|

|