|

Jason, out of Sacremento, recently found a small spring in his gear oil. Concerned that it might be from

the Quik-Lok (from West Coast Differential) and not having the tools to tear it down, decides to send it to me

for an inspection.

|

|

|

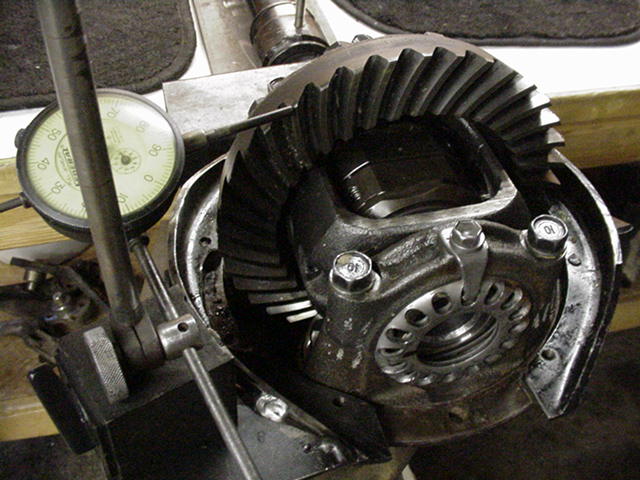

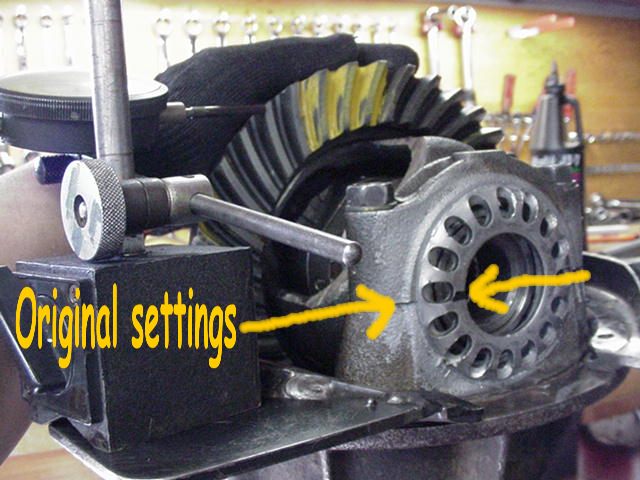

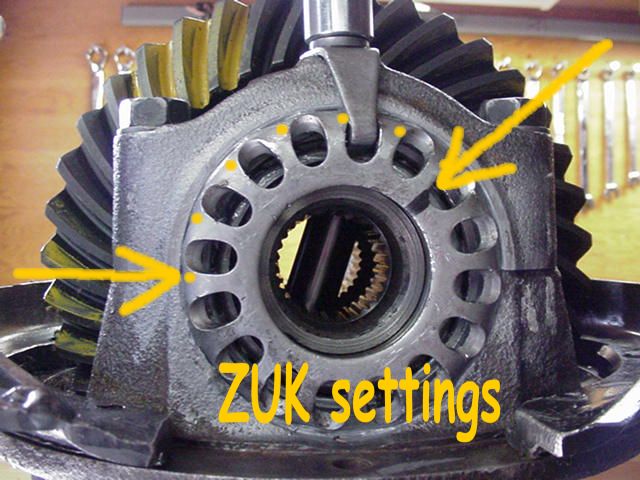

Step one is to mark both spanner rings so that when we re-assemble it, the exact

same backlash is maintained. I will also tighten up the Carrier Bearing Pre-Load when it is re-assembled.

It never fails....almost every differential that I have received has almost no CBPL.

Cranking the spanners rings does so much for over-all strength. Not enough can be said about this in

terms of strength gains.

|

|

|

This step of measuring the backlash is not mandatory.....it varied from 9~13 thou.

|

|

|

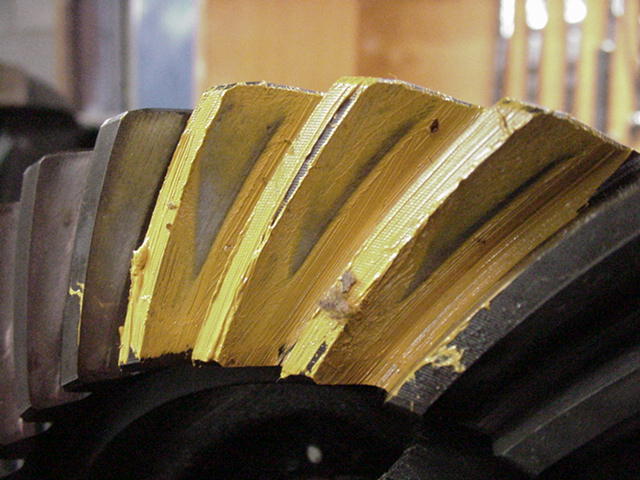

A gear commonly found in a Yukon box. A decent gear.

|

|

|

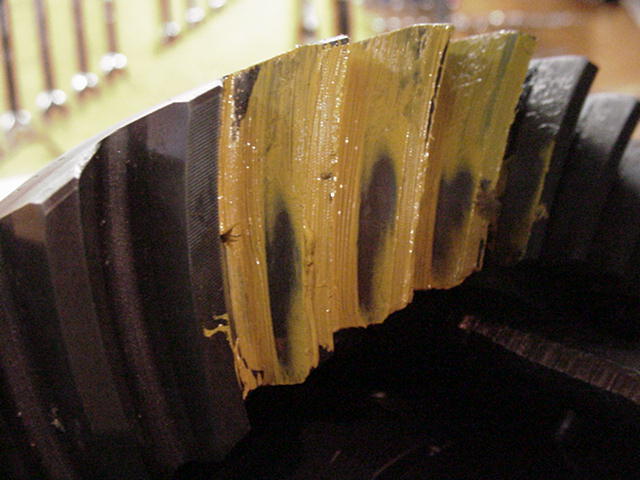

Another un-necessary step but I was more curious about the pattern....

|

|

|

coast

|

|

|

Preliminary inspection reveals busted springs.

|

|

|

I marked the ring gear before removing it.

|

|

|

The ring gear bolts had loctite on them and were properly installed...I will do the same.

|

|

|

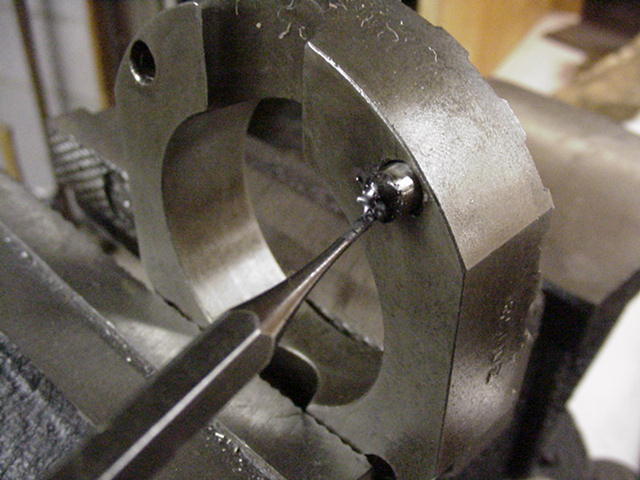

Removing the steel dowel is easy with a good punch. It only comes out one way.

|

|

|

The "power pin" then comes out smoothly...

|

|

|

Looking at all 4 springs they all looked busted.

|

|

|

|

|

|

|

|

|

2 of the busted pins could only be removed by welding something to it and pulling it out. I

used a sacrificial fine tip punch.

|

|

|

|

|

|

The next day this box arrives...

|

|

|

All this packaging for just springs and pins.

|

|

|

|

|

|

|

|

|

I will partially assemble it and check the tolerances.

|

|

|

|

|

|

I measured .015" which is ok (range is .006~.016").

|

|

|

The clutches slipped right in...

|

|

|

I jiggled the driver clutches and slipped the 4 steel pins in...

|

|

|

2 screwdrivers keep the drivers apart while the springs are inserted.

|

|

|

|

|

|

The steel dowel tapped in just fine....

|

|

|

I caved the hole in a little so the pin stays put.

|

|

|

...the cave-in.

|

|

|

I was able to spin the upper side-gear by hand. This is not right. I think they drilled the pin holes too

deep(just my guess). In any event, I updated Jason on this and it should last a year being that its used

in the front-end.

|

|

|

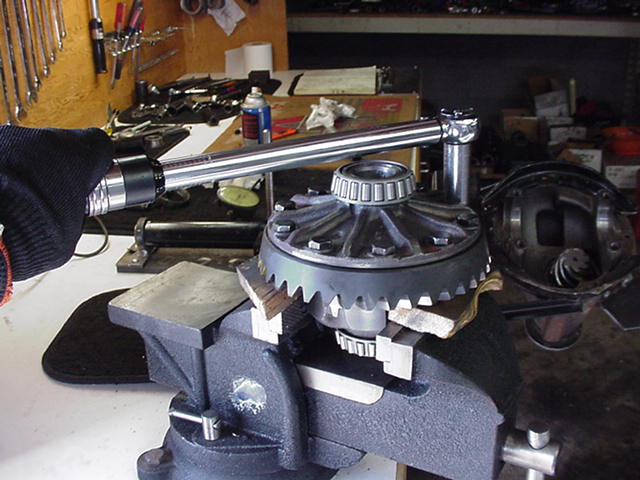

With the locker installed, it's time to Loctite the ring gear on...

|

|

|

70 foot-pounds....

|

|

|

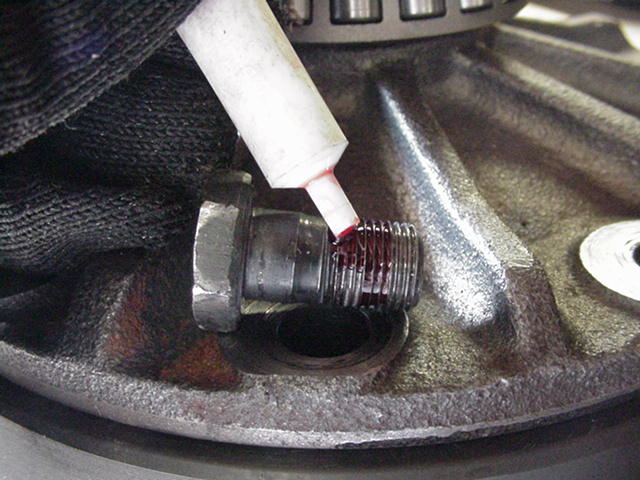

I coated the spanner threads with anti-seize. This will prevent thread damage while I'm cranking

the tension on the carrier bearings. I have the marks on the spanner so it makes it easy to duplicate

the exact original settings. The dial indicator and magnetic base are totally optional if the spanners

were marked.

|

|

|

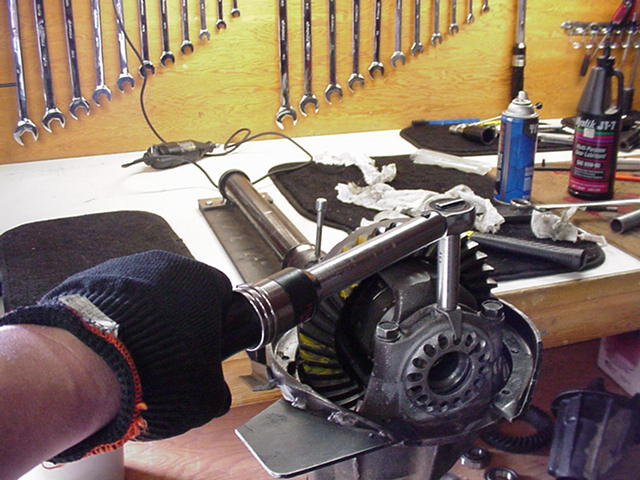

I rotate the pinion back and forth while I smack the bearing cap to allow the carrier bearings

to "self center" and equalize tensions. Not doing this might mean the backlash will shift 100 miles

down the road leading to gear noise and damage.

|

|

|

10 foot-pounds and red Loctite...

|

|

|

The spanner rings on both sides saw 6 notches each. This is something that anybody

can do on their own diffs and is the single best thing to increase over-gear strength.

|

|

|

My finger cannot generate enough push to move the ring gear back and forth. This is a

simple test for CBPL.

|

|

|

And all this time, Bullseye slept thru the gear install nearby.

|

|

|

The box on the left is the original box it was shipped to me in...I was able

to cut the other 2 boxes such that they would fit in...

|

|

|

...making for a very very strong return box.

|

|

|

|

|