|

Jeff from Austin Texas sent a Detroit SoftLocker along with

Yukon 529 gears/new bearings/solid collar.

|

|

|

The new outer pinion race is tapped in place with a soft steel chisel. Buy your

chisels at Harbor Freight and they will be soft ;)

edit---Best to stay away from all punches/chisels...

use an old race to evenly "pat down" the new race.

Using a punch could result in "oscillating" pinion

preload measurements with the torque wrench.

1-8-2011 ZUK

|

|

|

The large inner race is a bit more difficult to get a level start but

it's doable.

edit---Best to stay away from all punches/chisels...

use an old race to evenly "pat down" the new race.

Using a punch could result in "oscillating" pinion

preload measurements with the torque wrench.

1-8-2011 ZUK

|

|

|

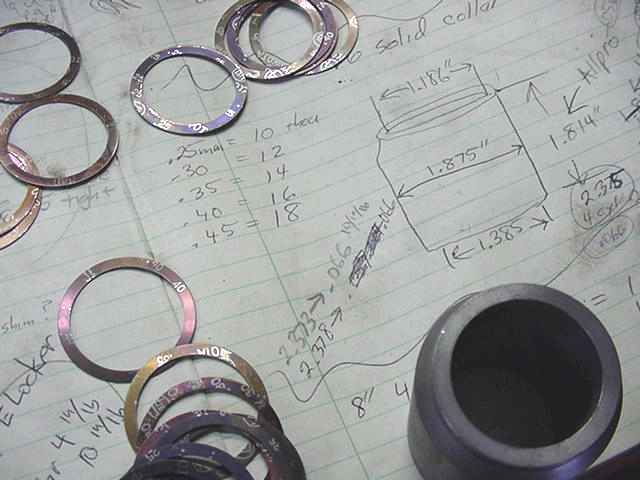

I measured the collar length, reference some numbers in my notes and figured in new bearings

and came up with a solid collar start shim of .066". Got lucky as this turned out to be the desired

end value.

|

|

|

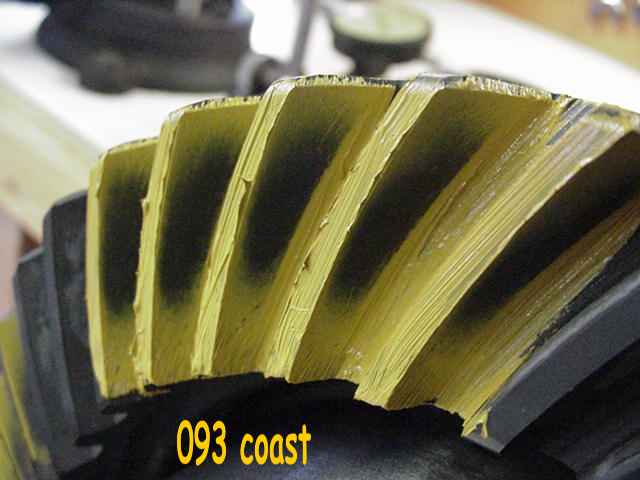

This particular brand of ring/pinion wanted to see .093" for a pinion depth value in

some of my past installs so I used my precision micrometers to arrive at that value.

Turns out I was lucky again as that is the right number for this install.

|

|

|

The wire wheel spinning at 10,000 rpm easily removes rust and paper gaskets.

|

|

|

With the pinion nut properly tightened, the PPL was a nice 9 in/lb.

|

|

|

I check for surface irregularities with a file...both the DSL and the ring.

I then tapped the ring on and used loctite with 75 ft/lbs on the bolts.

|

|

|

The new carrier bearings went on tight...no problem here.

|

|

|

With the DSL case loaded in place, it was now time to get the bearings tight

and the backlash in the ballpark. The trick is to crank the bearing tight with a spanner tool of sorts

and then spin the pinion bearings while smacking the bearing caps with a hammer. This

allows the the carrier bearings to "equalize".....and, of course, just when you think everything is perfect

and as soon as the bearing cap bolts are tightened, all of the sudden the BL has changed. Such is such.

|

|

|

MAC, from Randys, I can thank for this method of generating a paint pattern...use a rag to offer some resistance

while turning the ring gear with a 17mm wrench.

|

|

|

Beautiful.

|

|

|

YES.

|

|

|

I'm using the torque wrench set at 100 ft/lb to get the CBPL where it needs to be.

|

|

|

Backlash was verified at 8 thou.

|

|

|

Now it's time to finish the other side...I used the electric impact to remove my flange.

|

|

|

The pinon seal gets tapped on...

|

|

|

The new pinion nut sees a generous coating of the hi-strength red LocTite.

|

|

|

The nut is possibly tight.

|

|

|

The tag with all the numbers.

|

|

|

Back to Texas. :)

|

|