|

Joe's Hi-pinion 8" gets a Spartan Locker

|

|

(47 BIG pics loading)

|

|

APRIL 14 2014

|

|

|

Joe is local to me. This is a small picture taken in an area called

Pyeatte Draw near Payson, Arizona. The Spartan is

going in the front 8" Hi-pinion of his 4Runner.

|

|

|

|

|

Joe brought over the Spartan and the open 2 pinion HP 3rd.

|

|

|

|

|

The first thing I do is mark the adjusters....1 ding here.

|

|

|

|

|

And 2 dings for the other side.

|

|

|

|

|

I don't have to mark the bearing cap because it has a factory brush stroke but, out of habit, I did.

|

|

|

|

|

The electric impact sure saves time :)

|

|

|

|

|

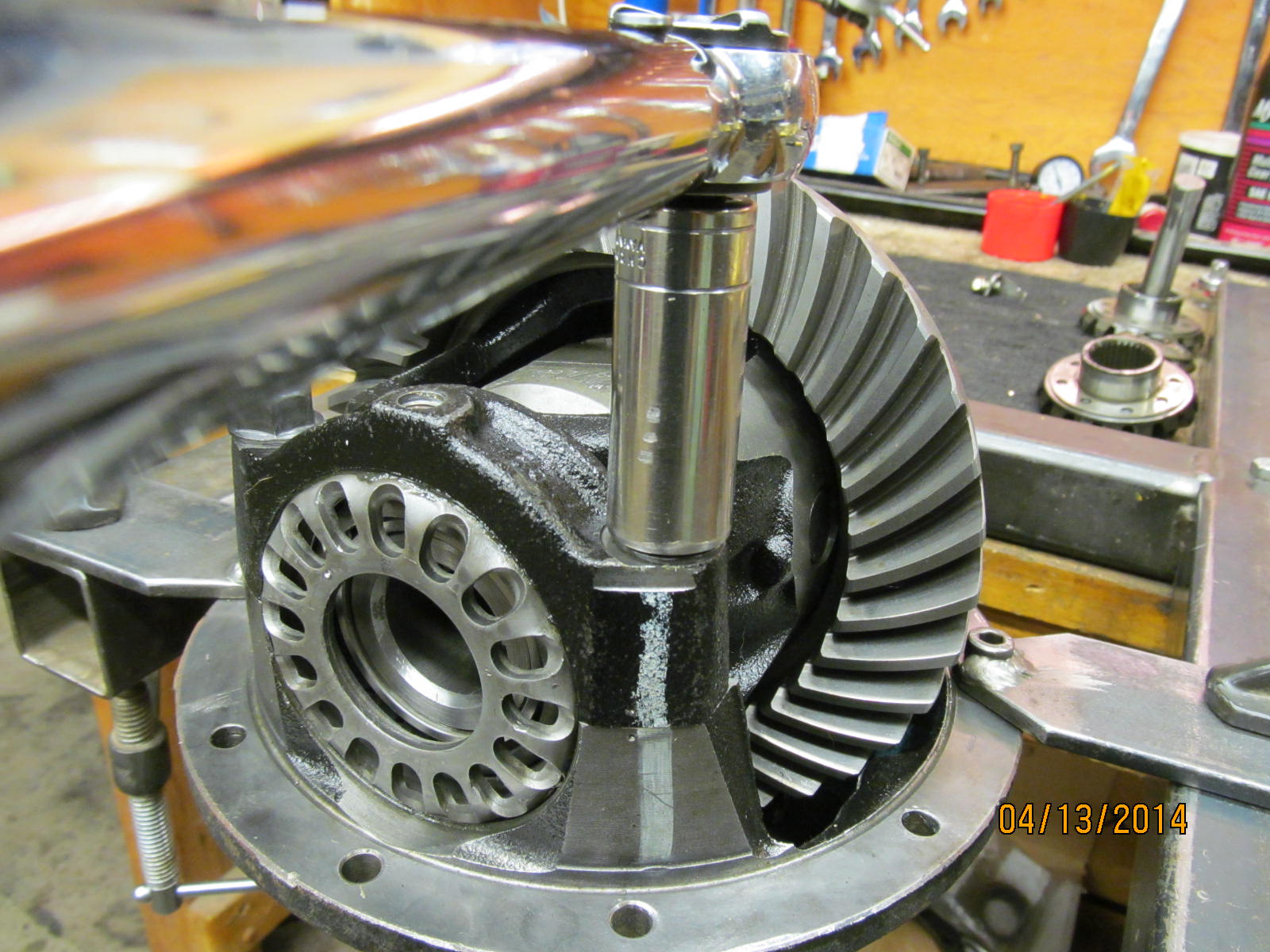

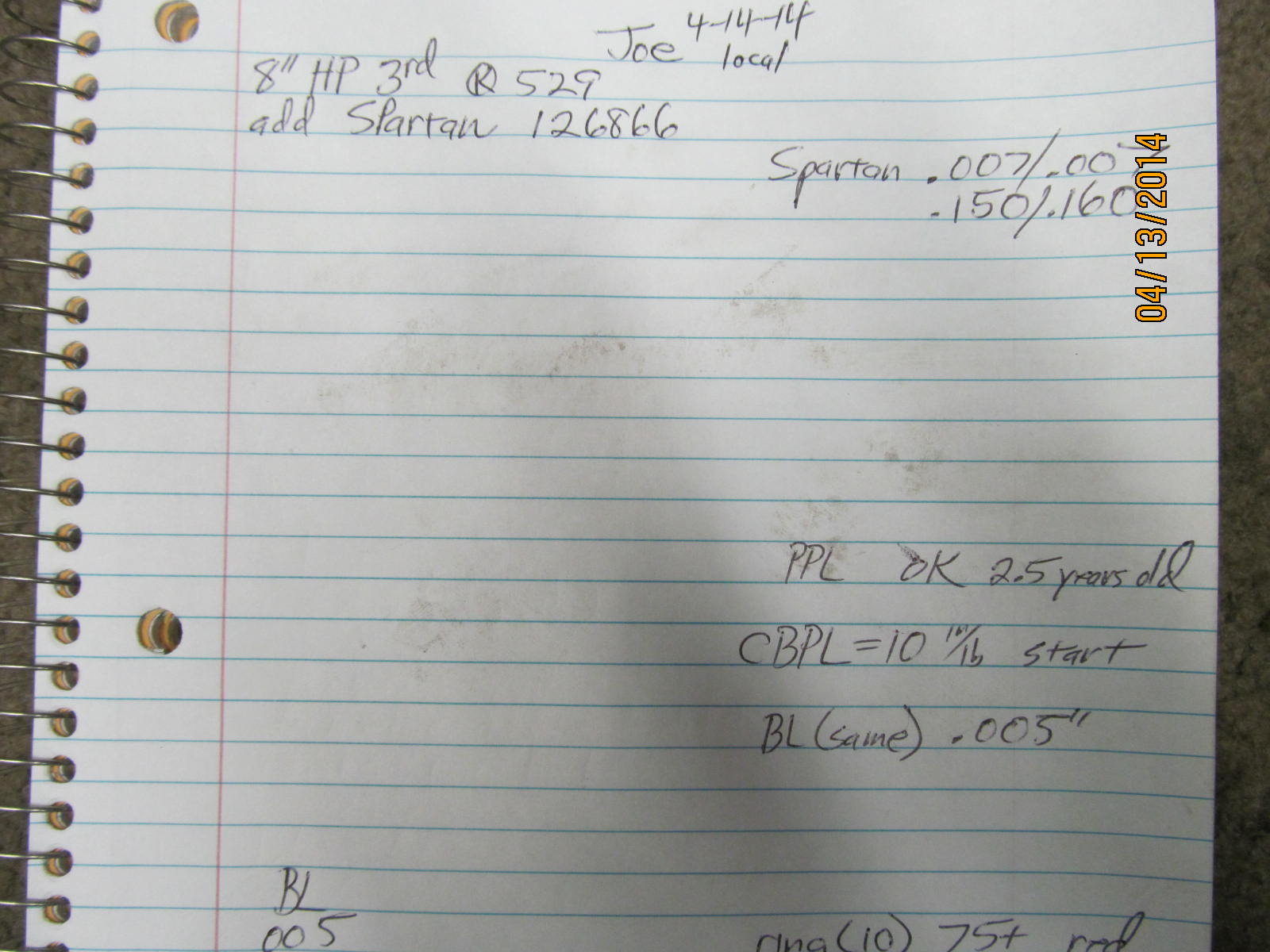

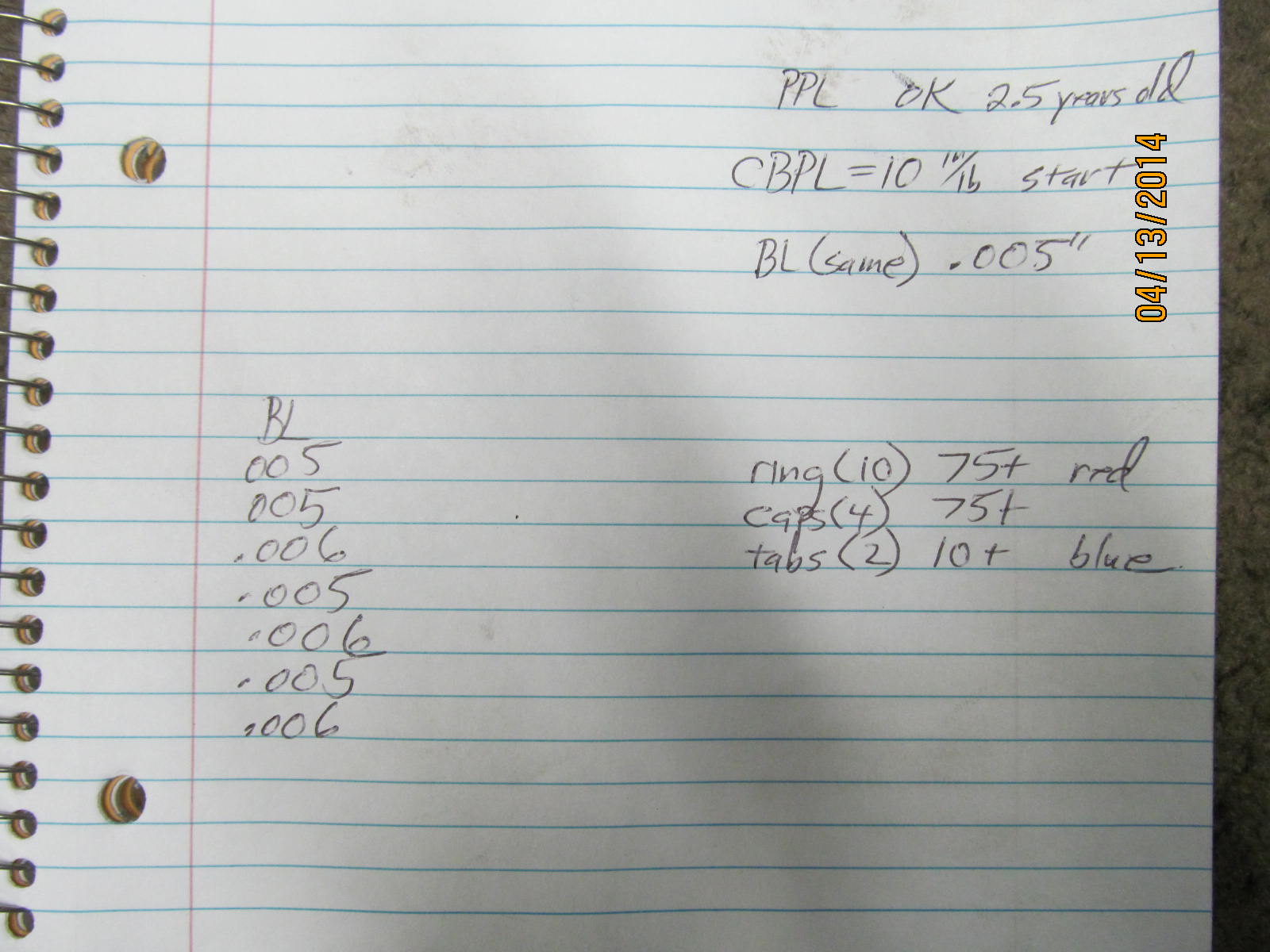

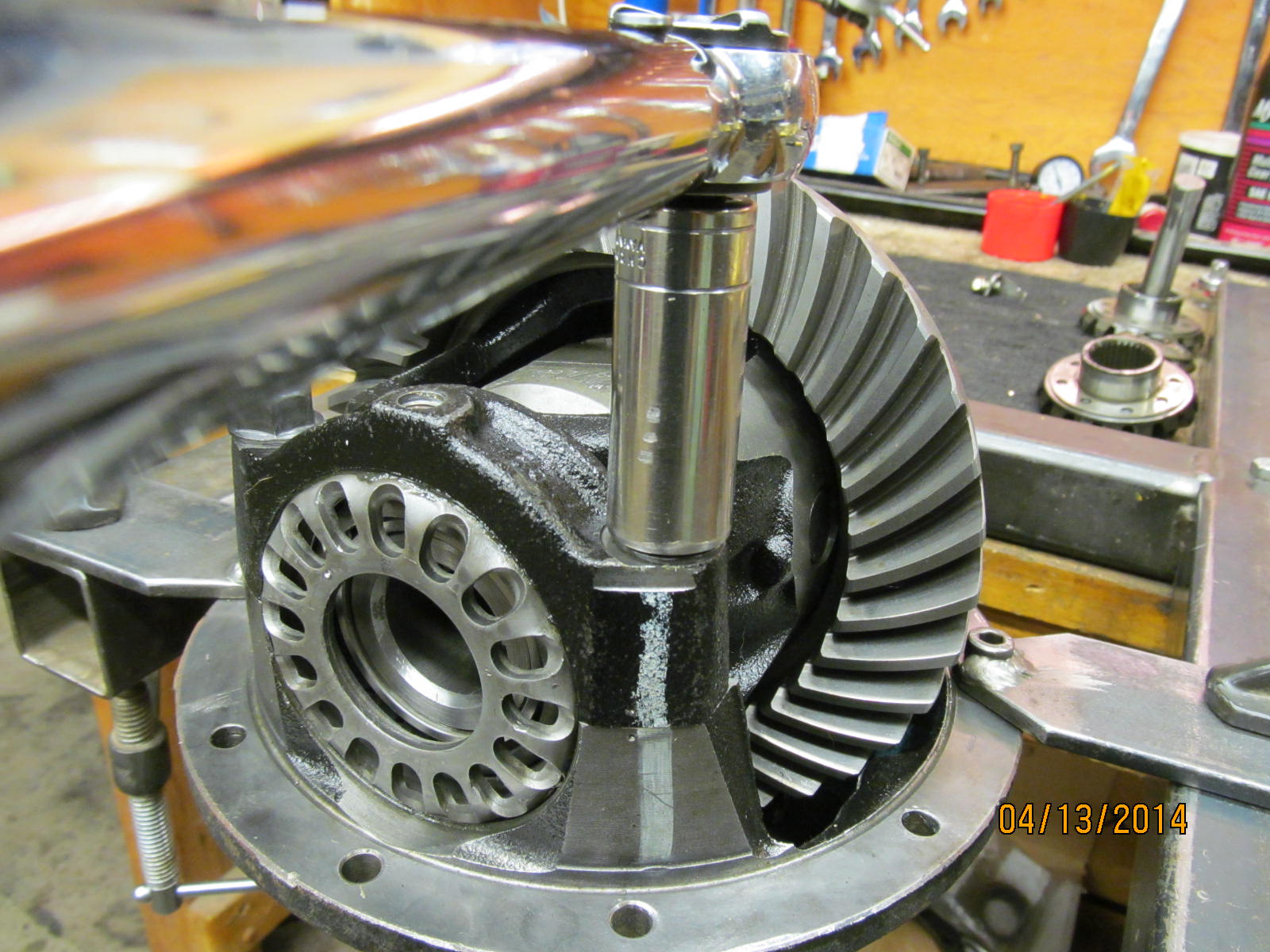

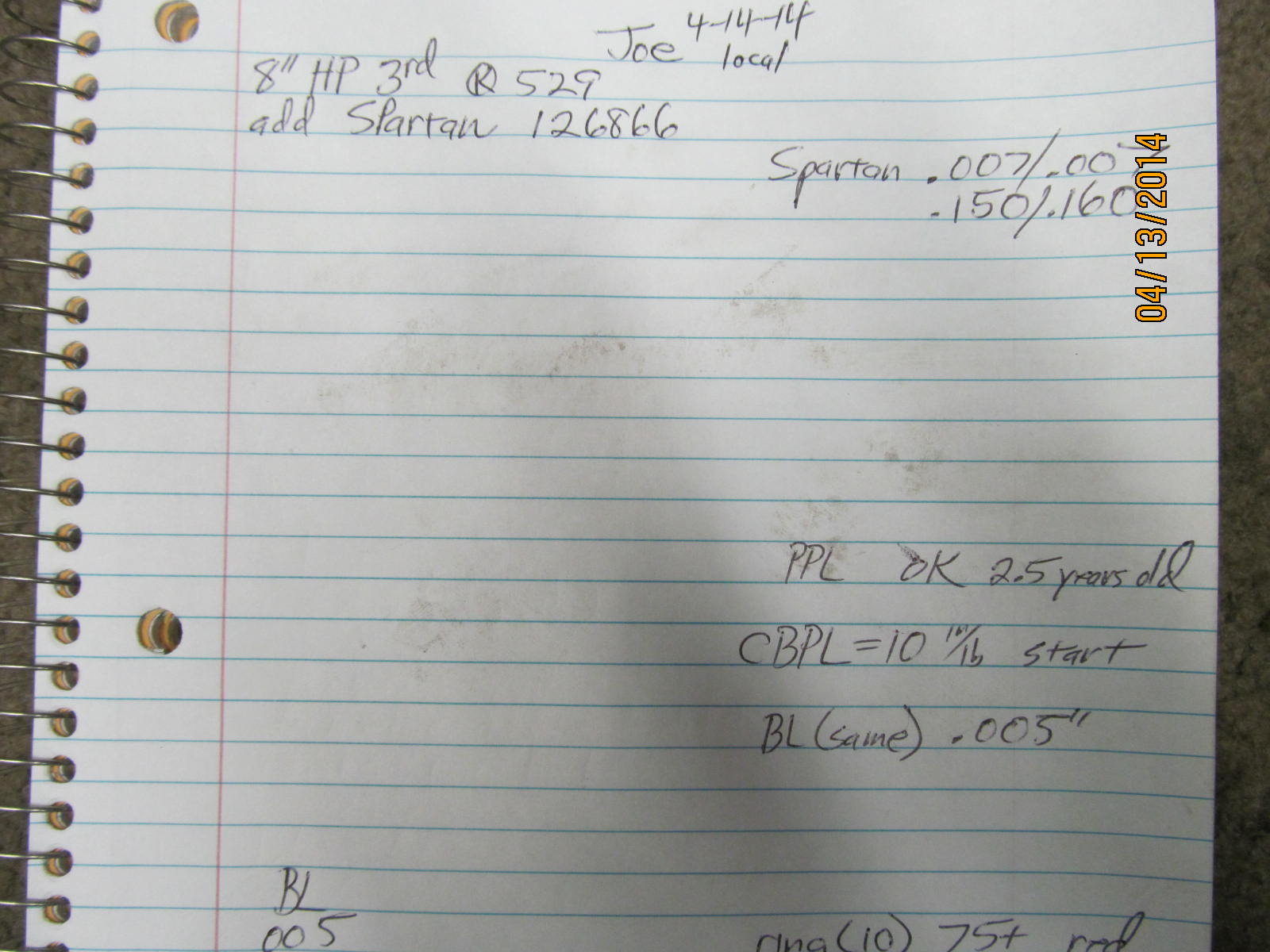

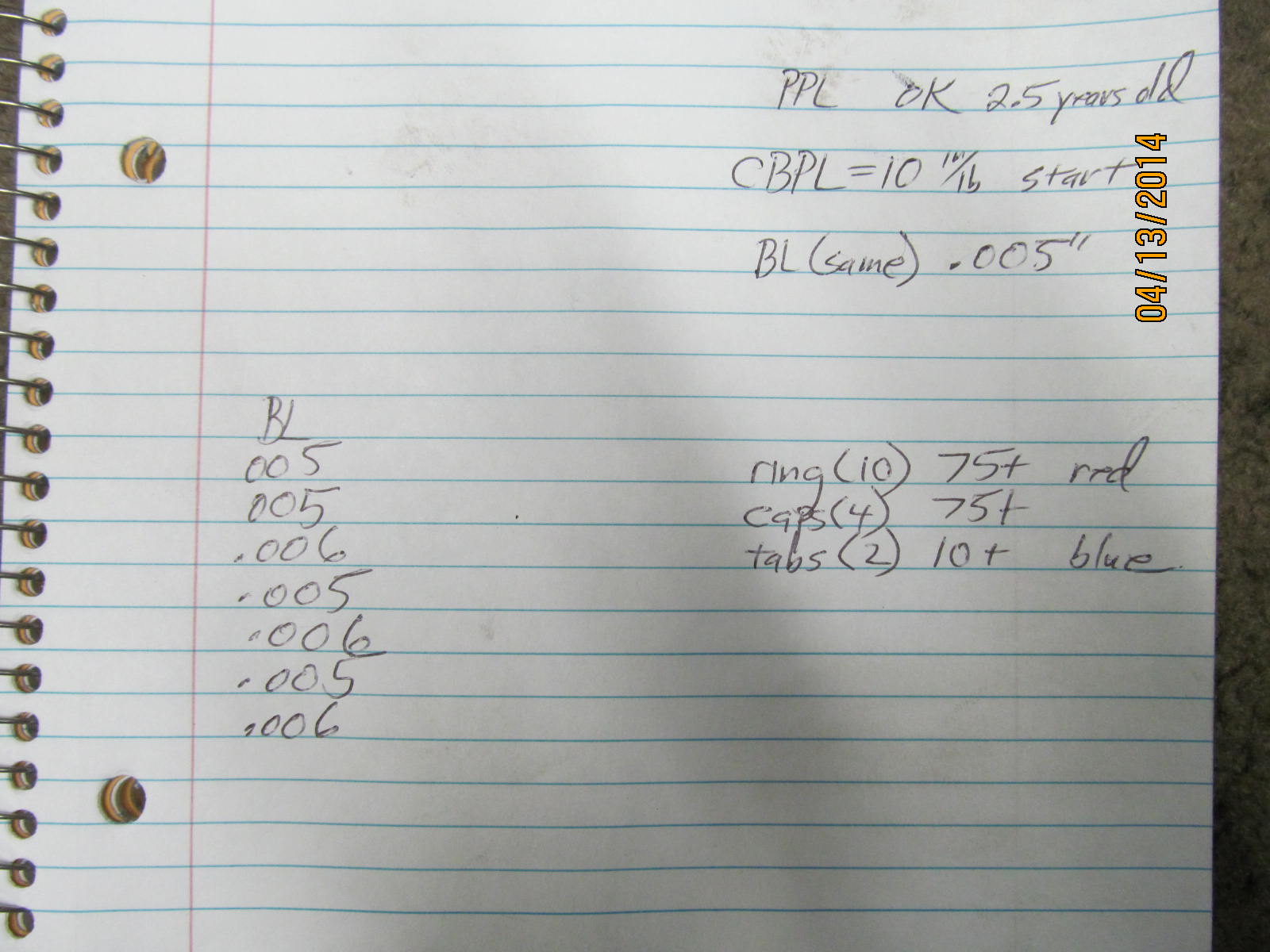

I did the gear install on this about 2.5 years ago.

|

|

|

|

|

These are the "circle K" gears that I like.

|

|

|

|

|

The cured loctite is very evident.....

|

|

|

|

|

....but the bench grinder with the wire wheel attachment sure makes them all look brand new again.

|

|

|

|

|

With the ring gear off now I can drive out the steel dowel.

|

|

|

|

|

Out comes the crosspin(power pin).

|

|

|

|

|

Remove both spiders.

|

|

|

|

|

These are the parts we will not re-use...not even the thrust washers on the sidegears seen here.

|

|

|

|

|

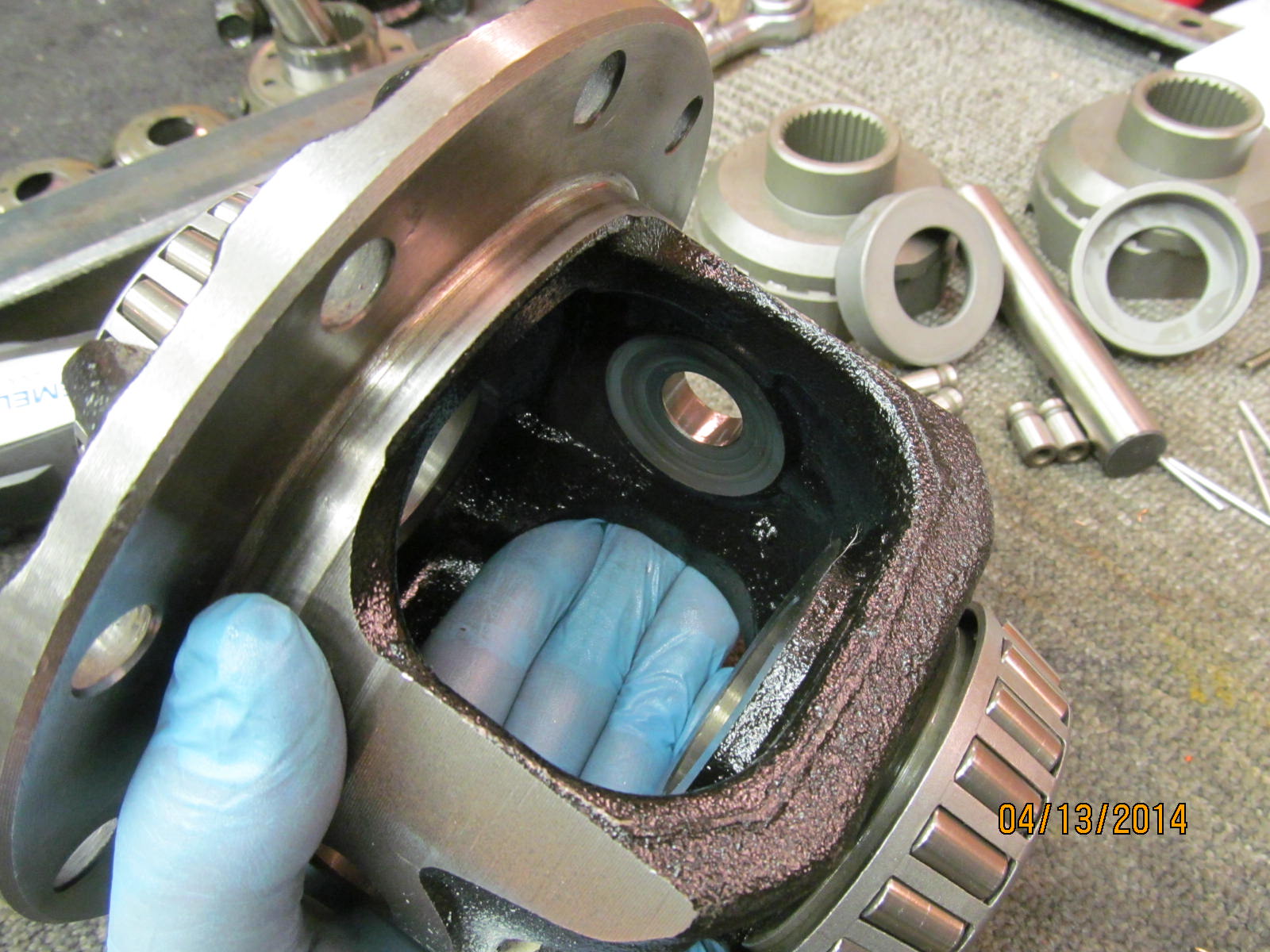

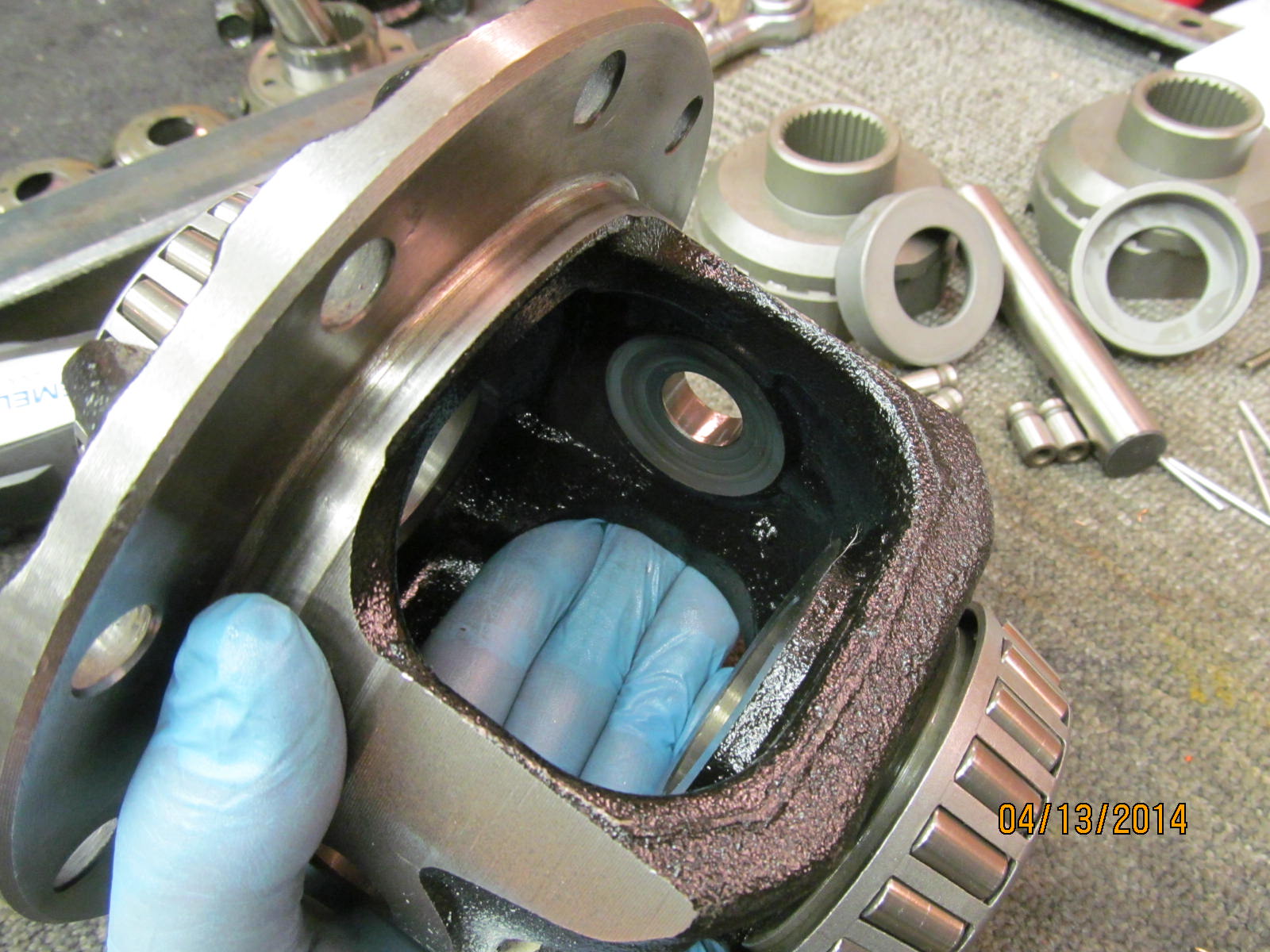

The guts have been stripped clean effectively.

|

|

|

|

|

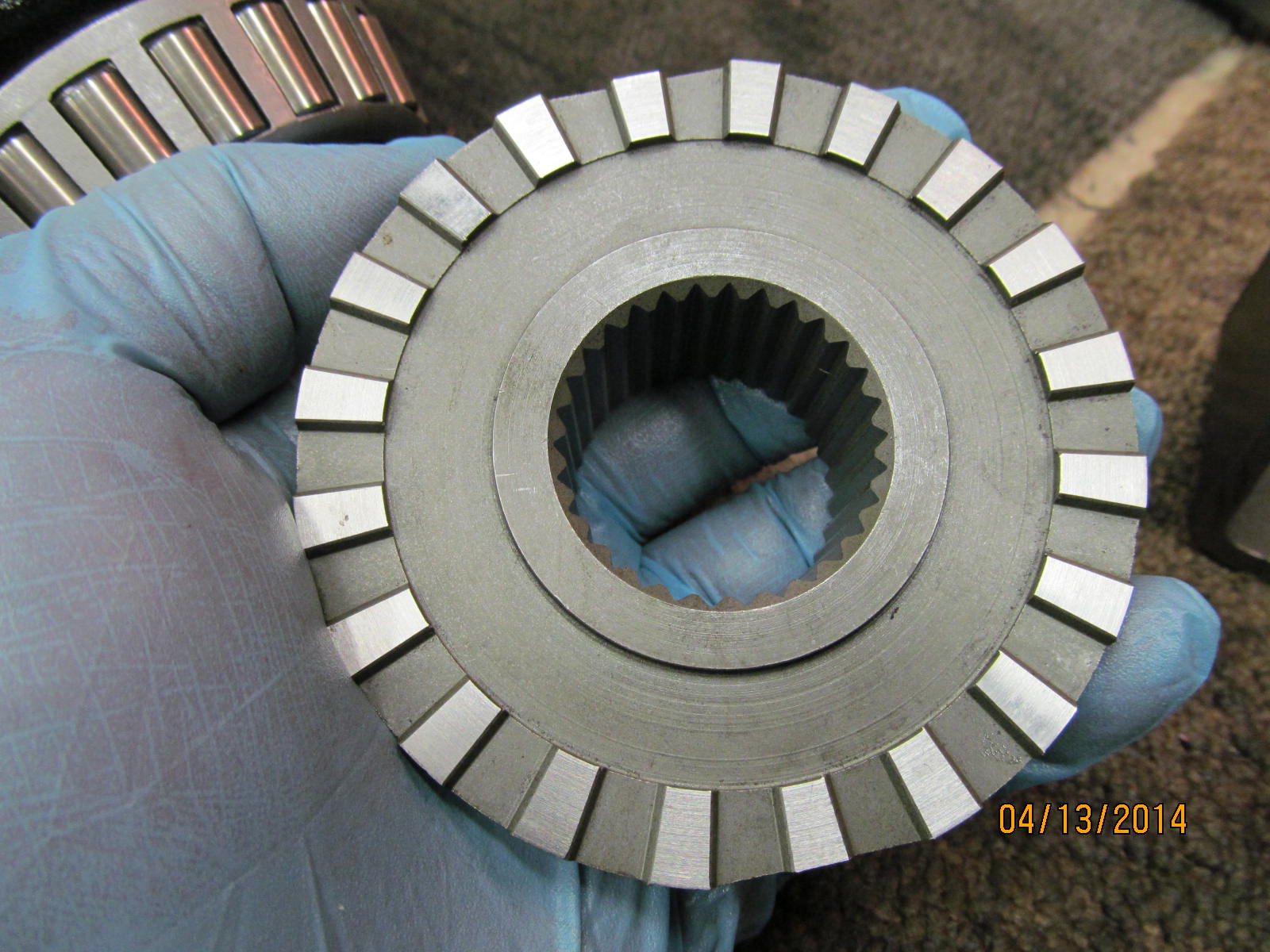

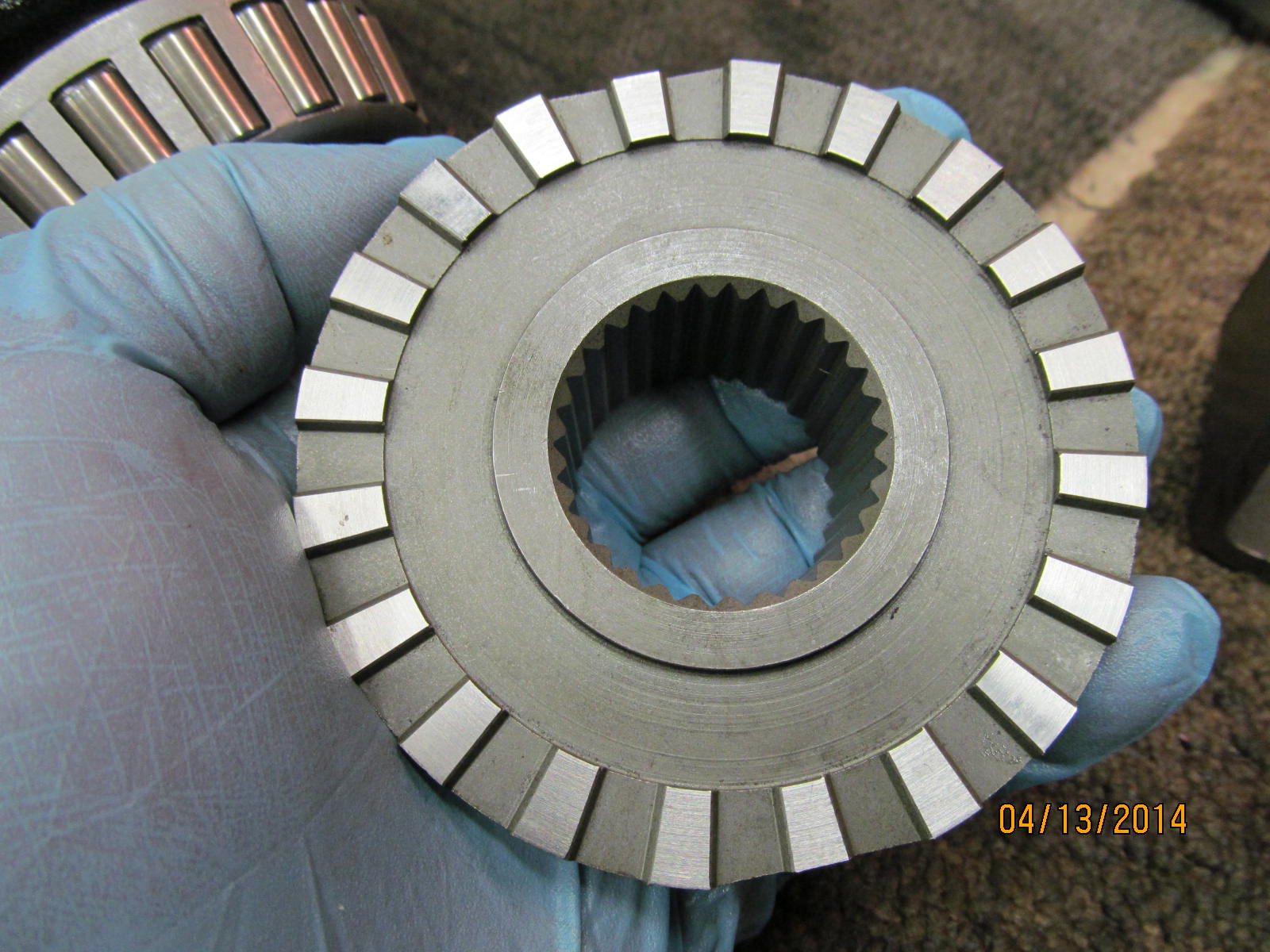

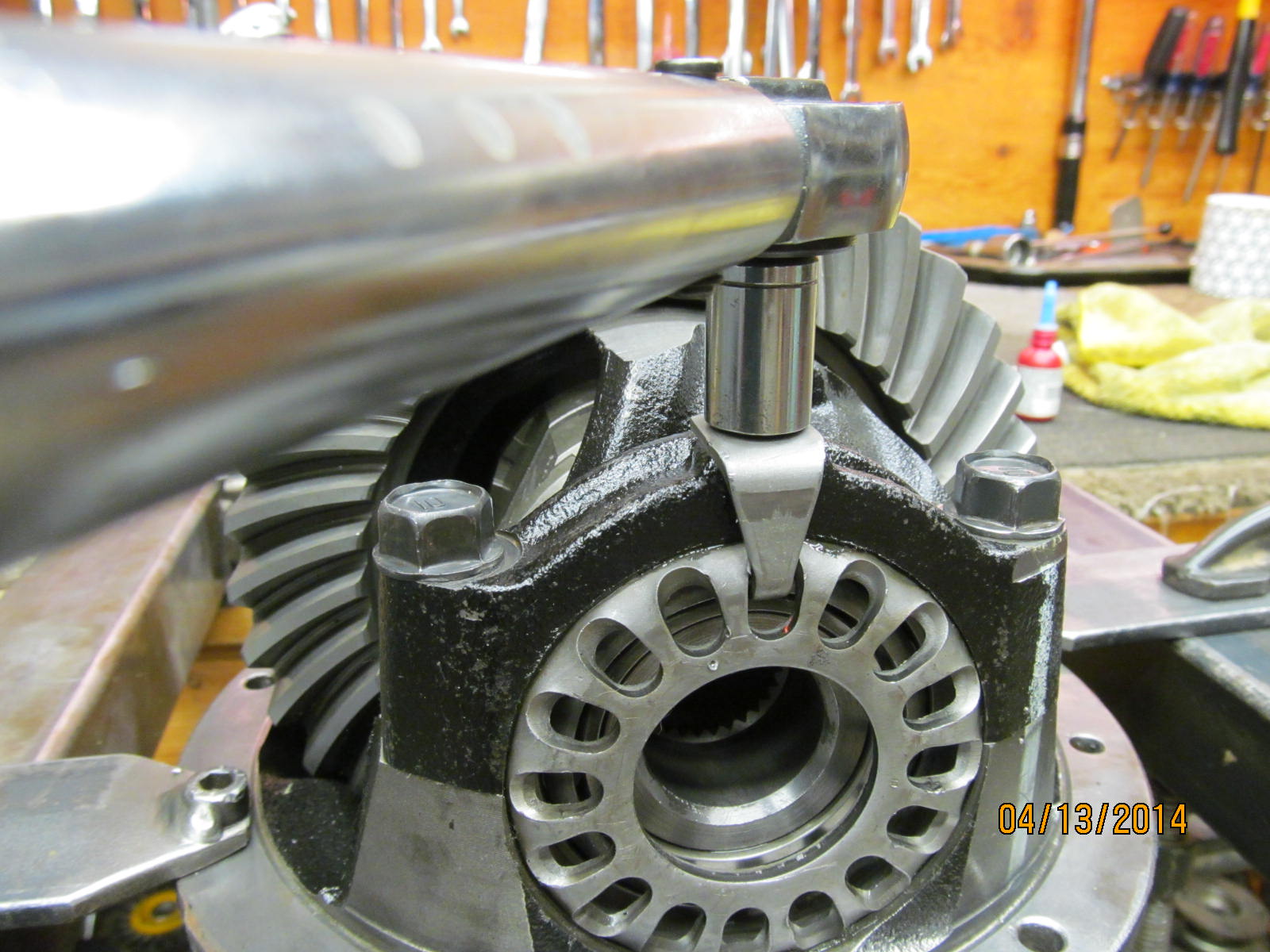

30 spline sidegear couplers....excellent piece of machine work.

|

|

|

|

|

This pre-assembly measurement is not specified in the Spartan manual....

|

|

|

|

|

...I measured .007" on this side of the power pin and .008" on the other.

|

|

|

|

|

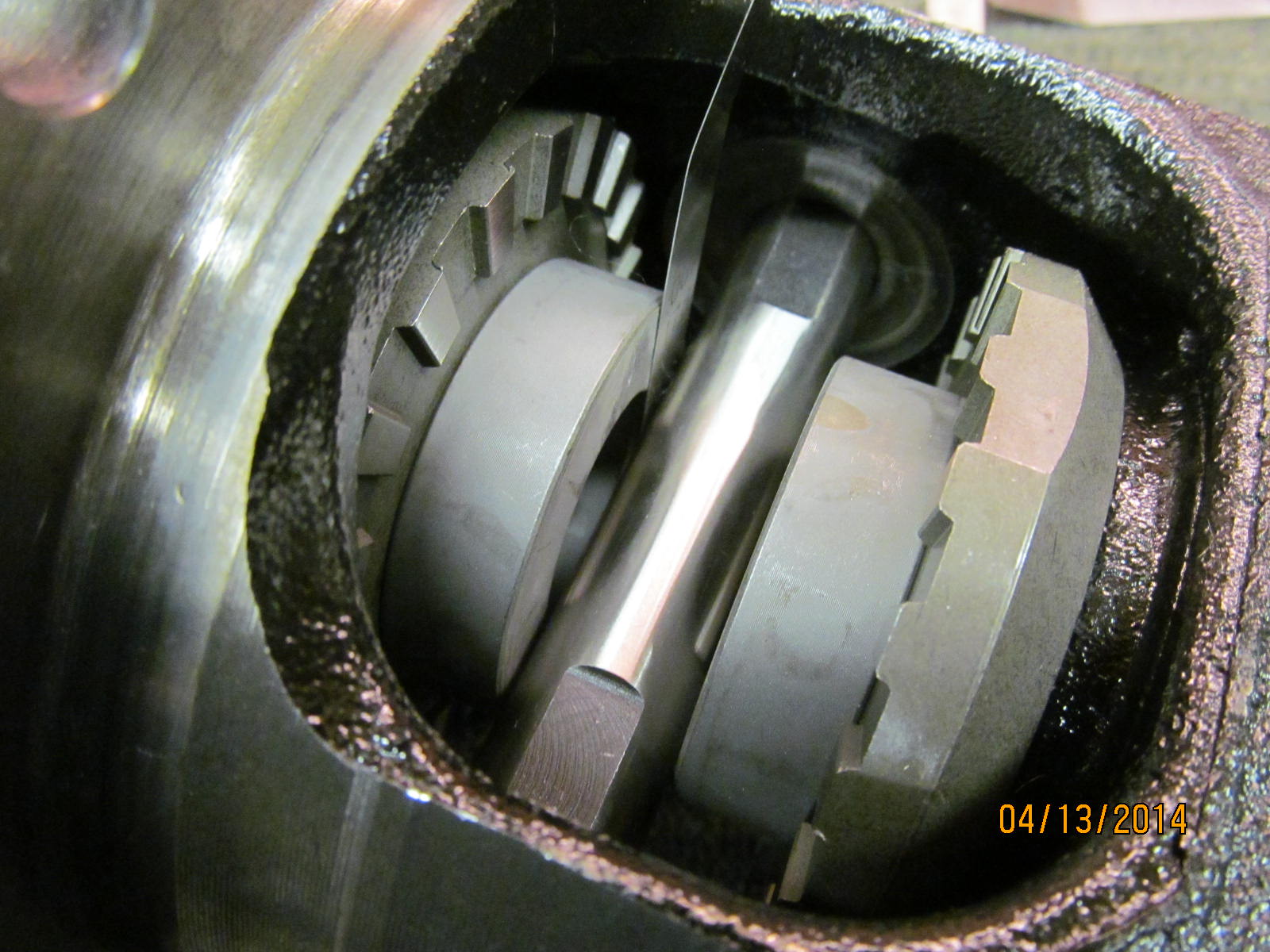

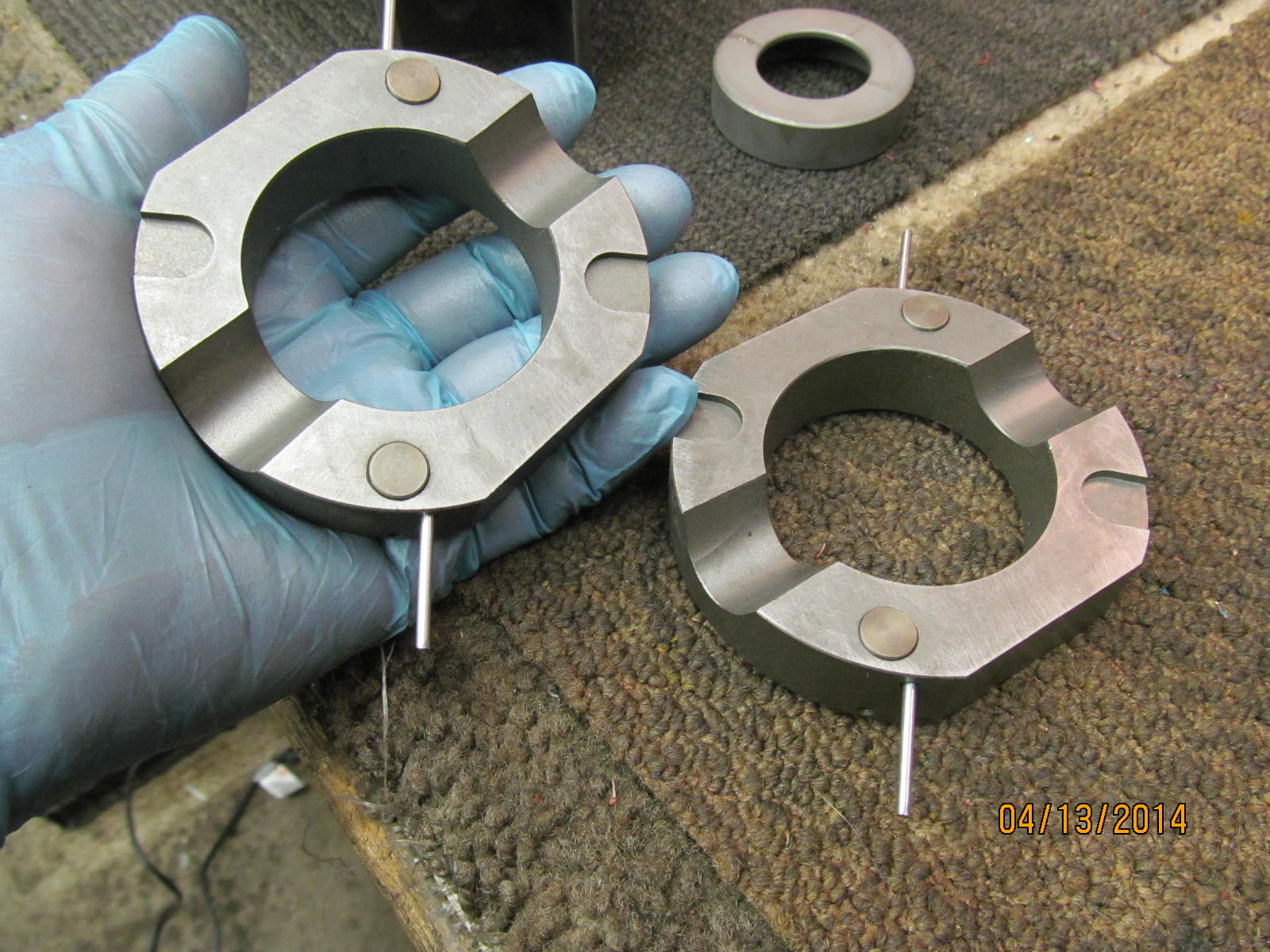

The thick pieces of wire hold the pins/springs in the 2 Spartan drivers during the assembly.

|

|

|

|

|

Put spring in pin...

|

|

|

|

|

Pushed down all the way and insert wire.

|

|

|

|

|

This makes the Spartan so easy to assemble in the open case.

|

|

|

|

|

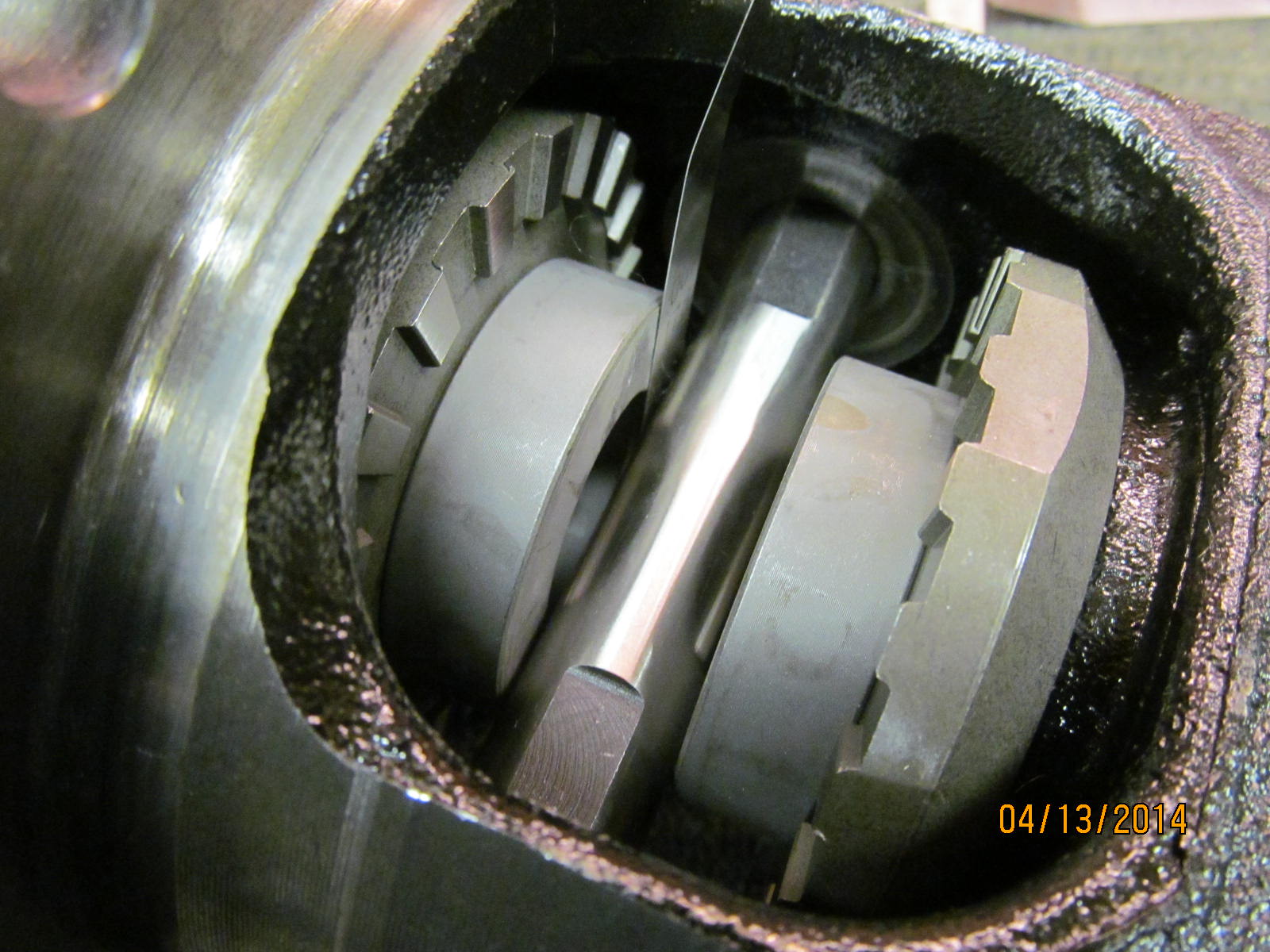

Now just wiggle everything in place.

|

|

|

|

|

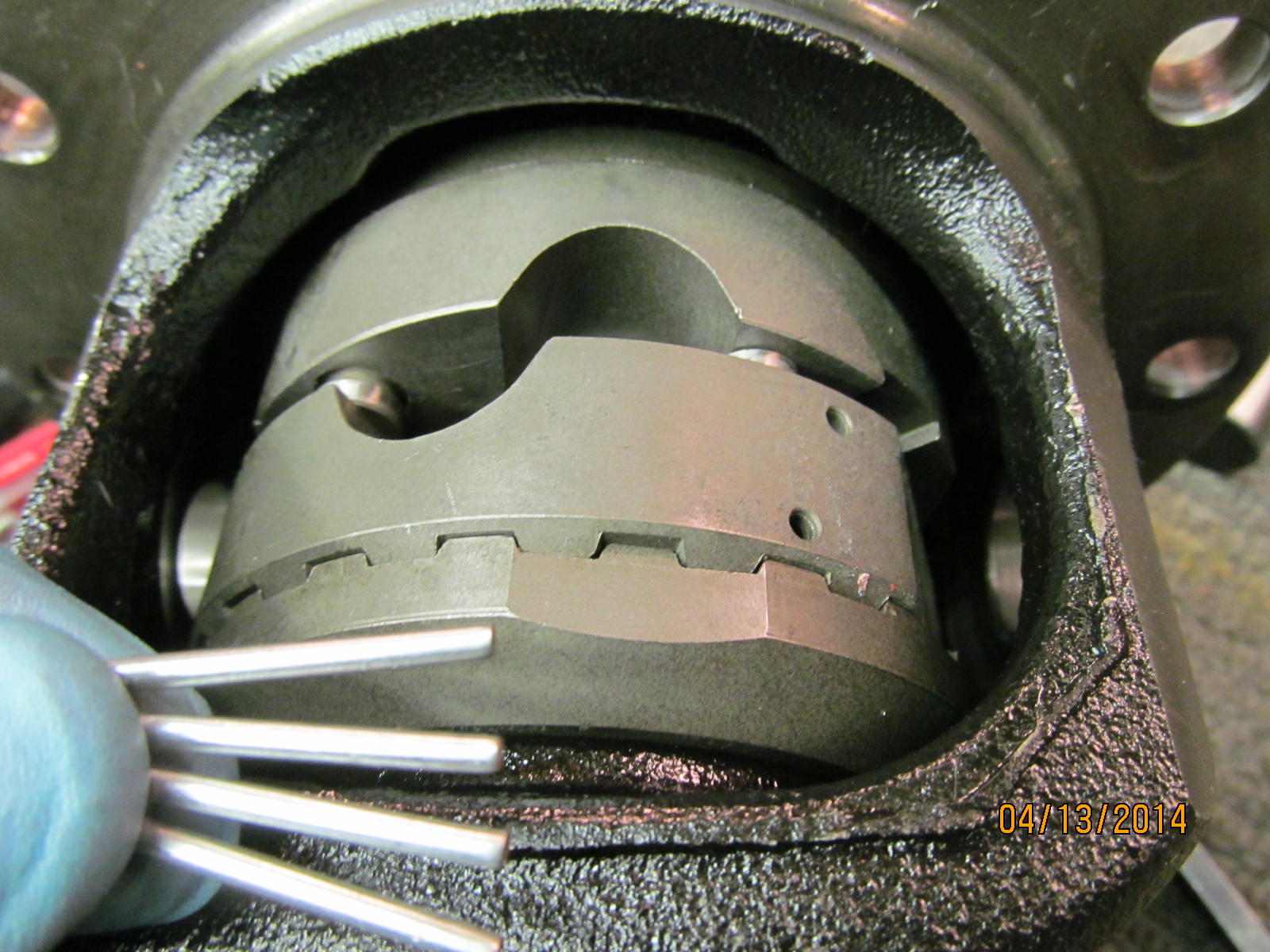

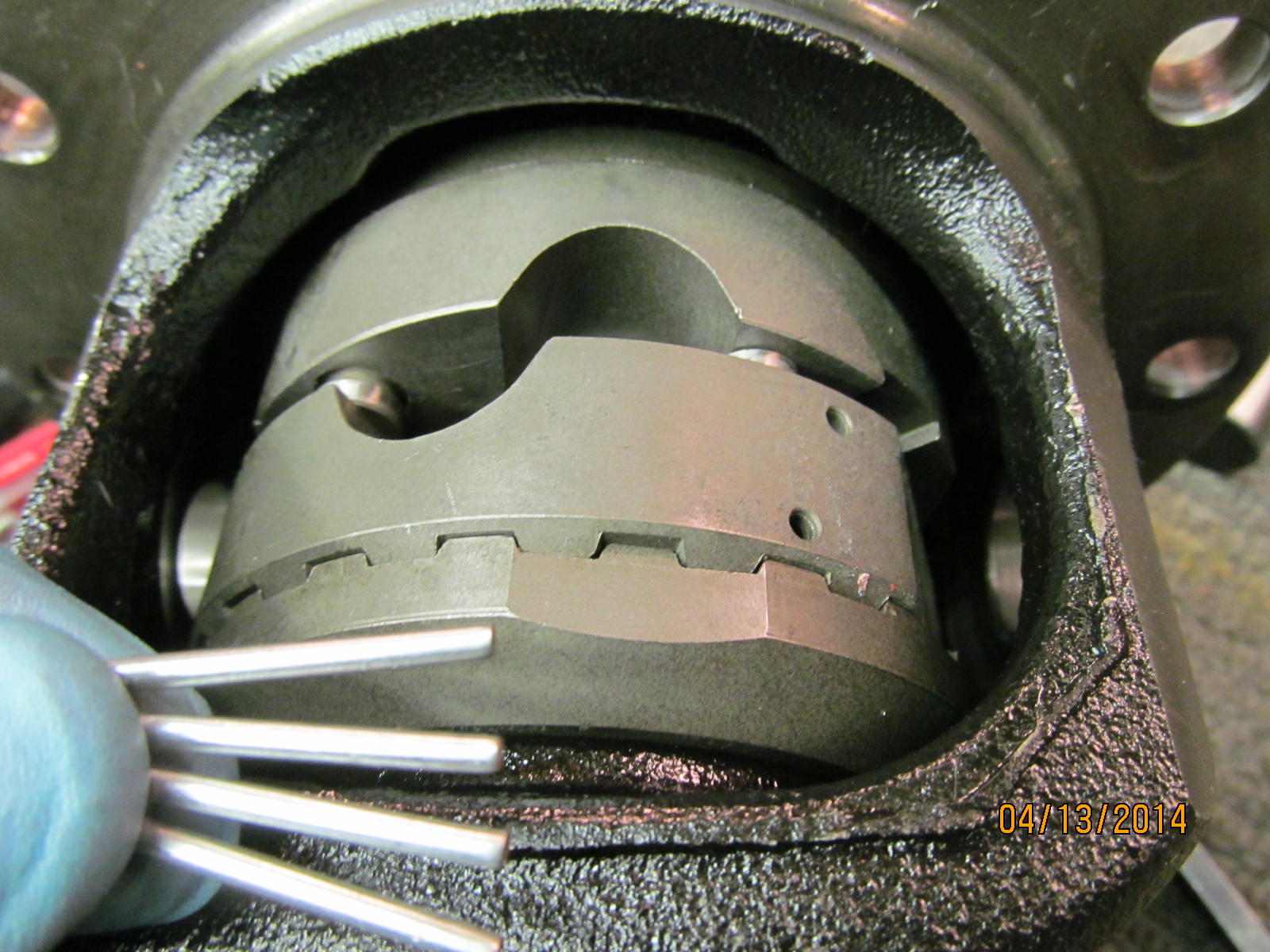

I use a couple of screwdrivers to keep the teeth in alignment....

|

|

|

|

|

...and pull out the wires.

|

|

|

|

|

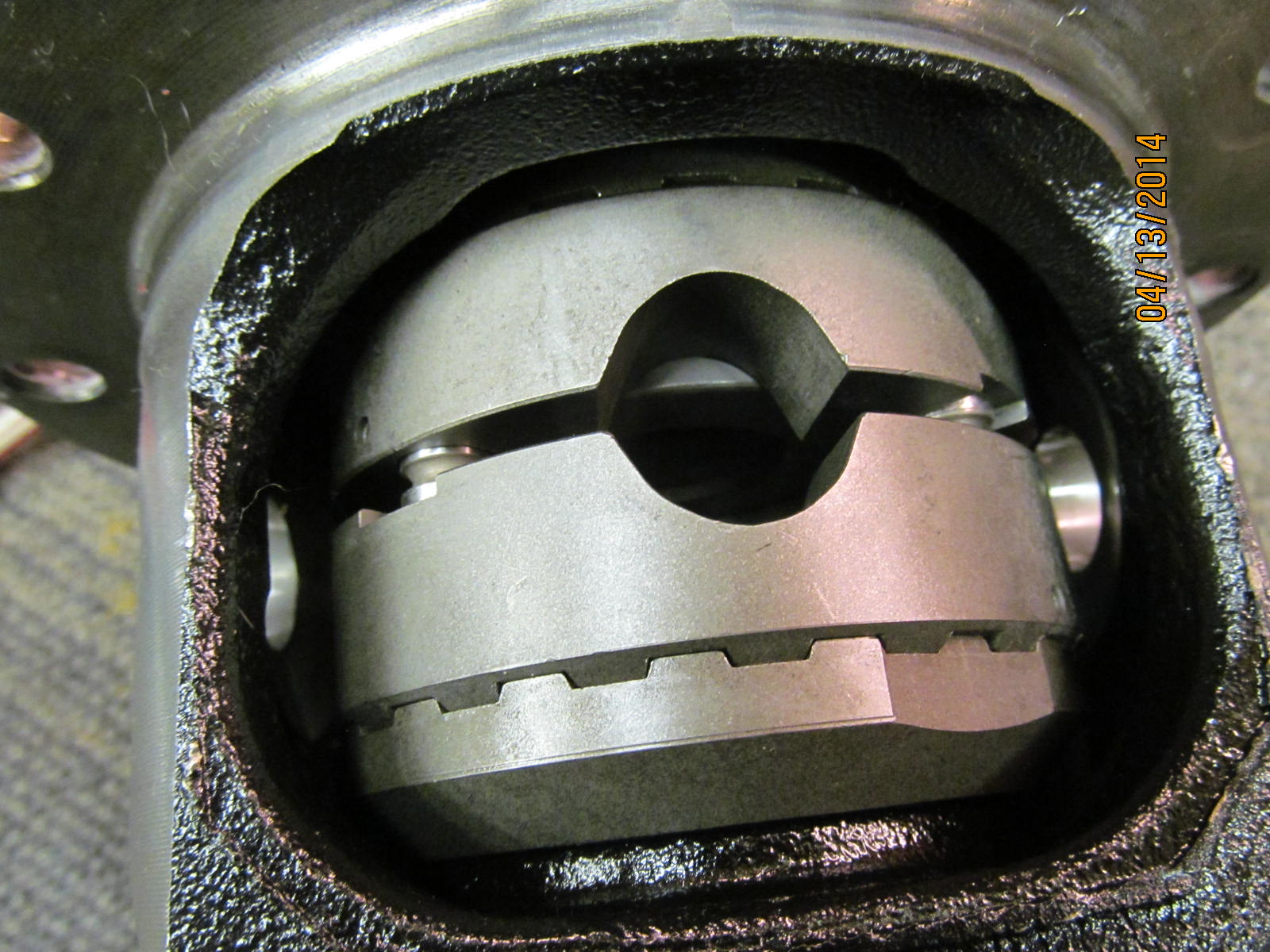

All 4 wires have been pulled out.

|

|

|

|

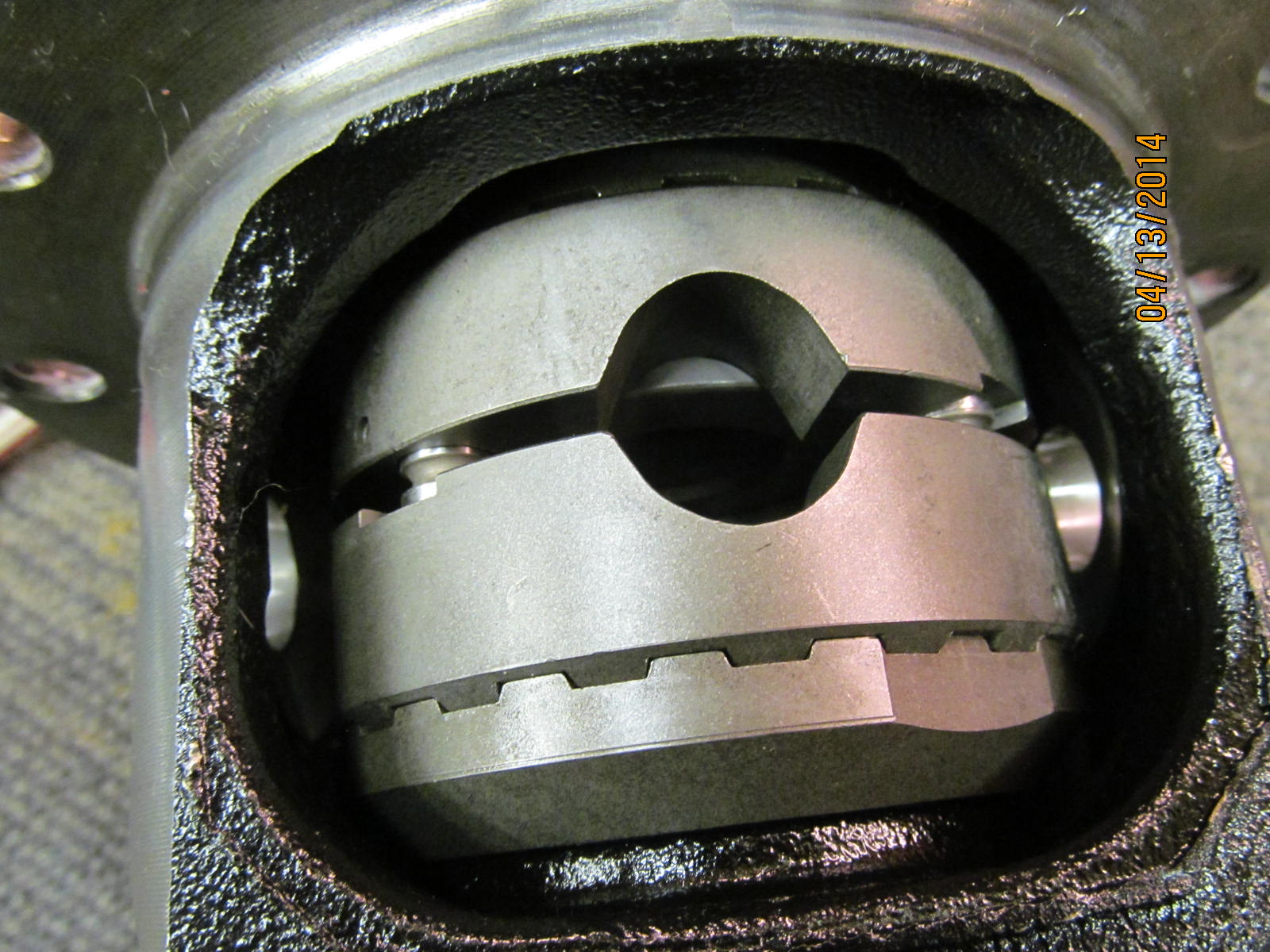

Just rotate the Spartan drivers until it snaps in place and the cam holes are directly across from each other. Those 4 tiny

springs sure have a lot of tension.

|

|

|

|

|

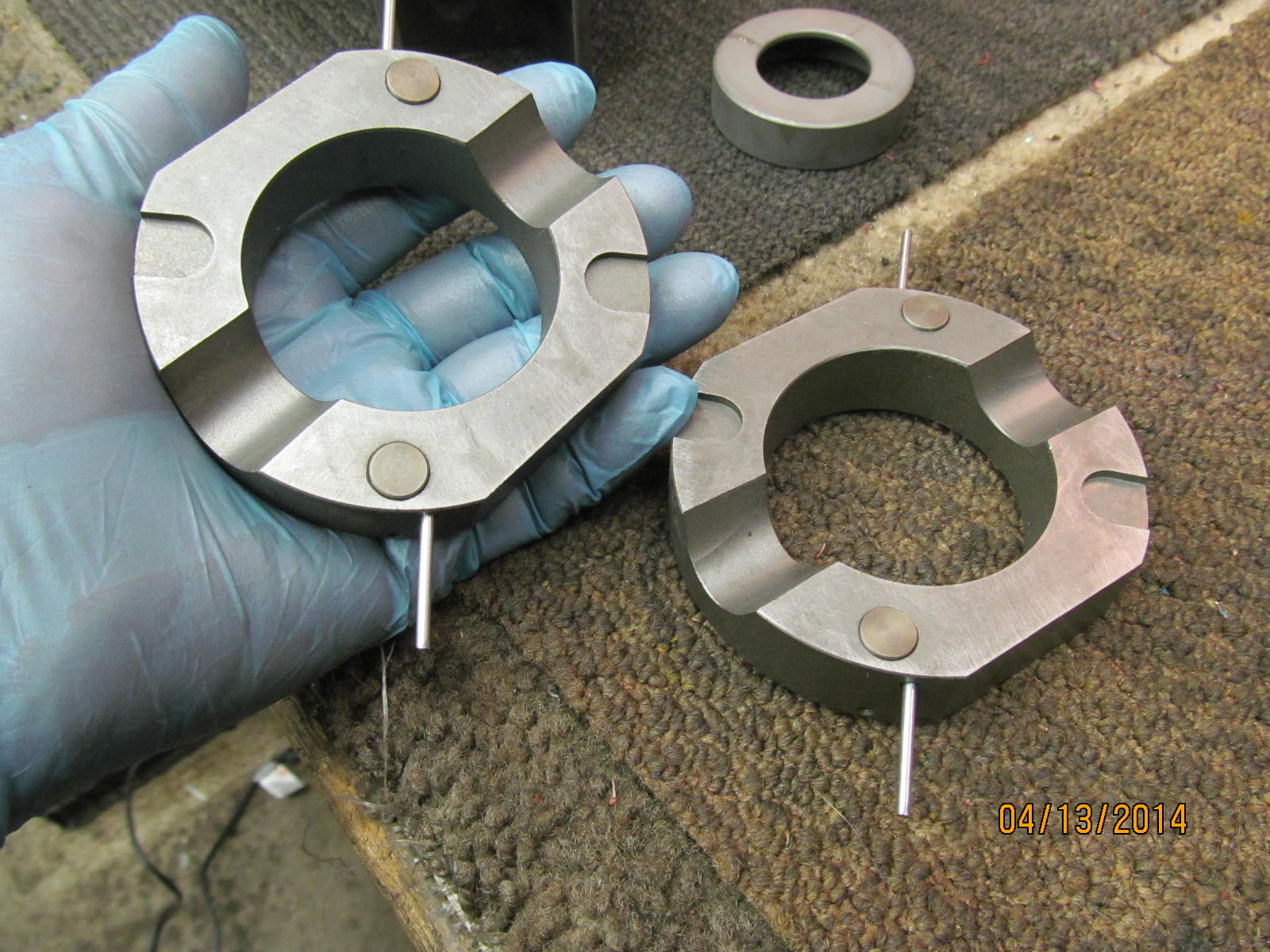

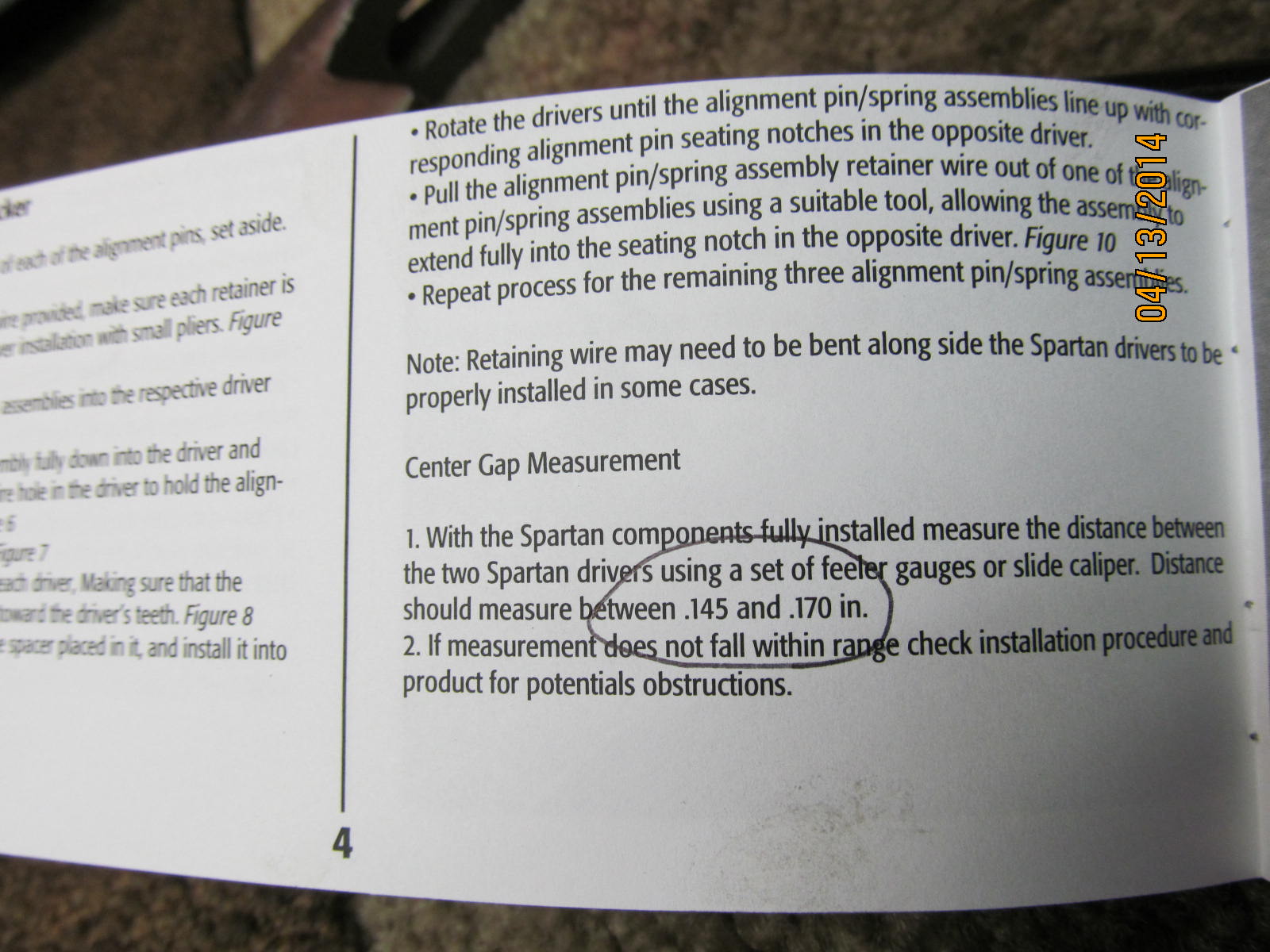

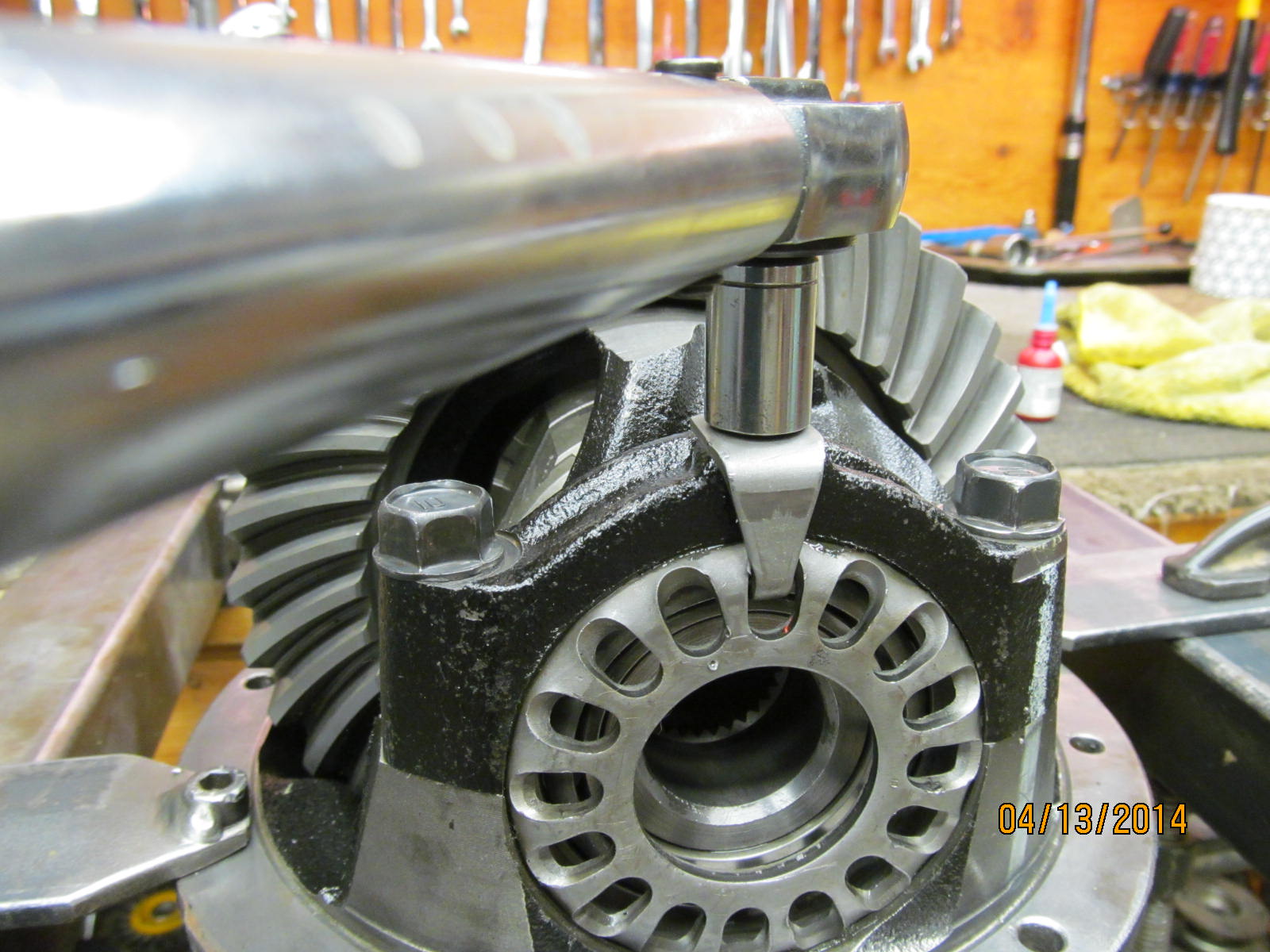

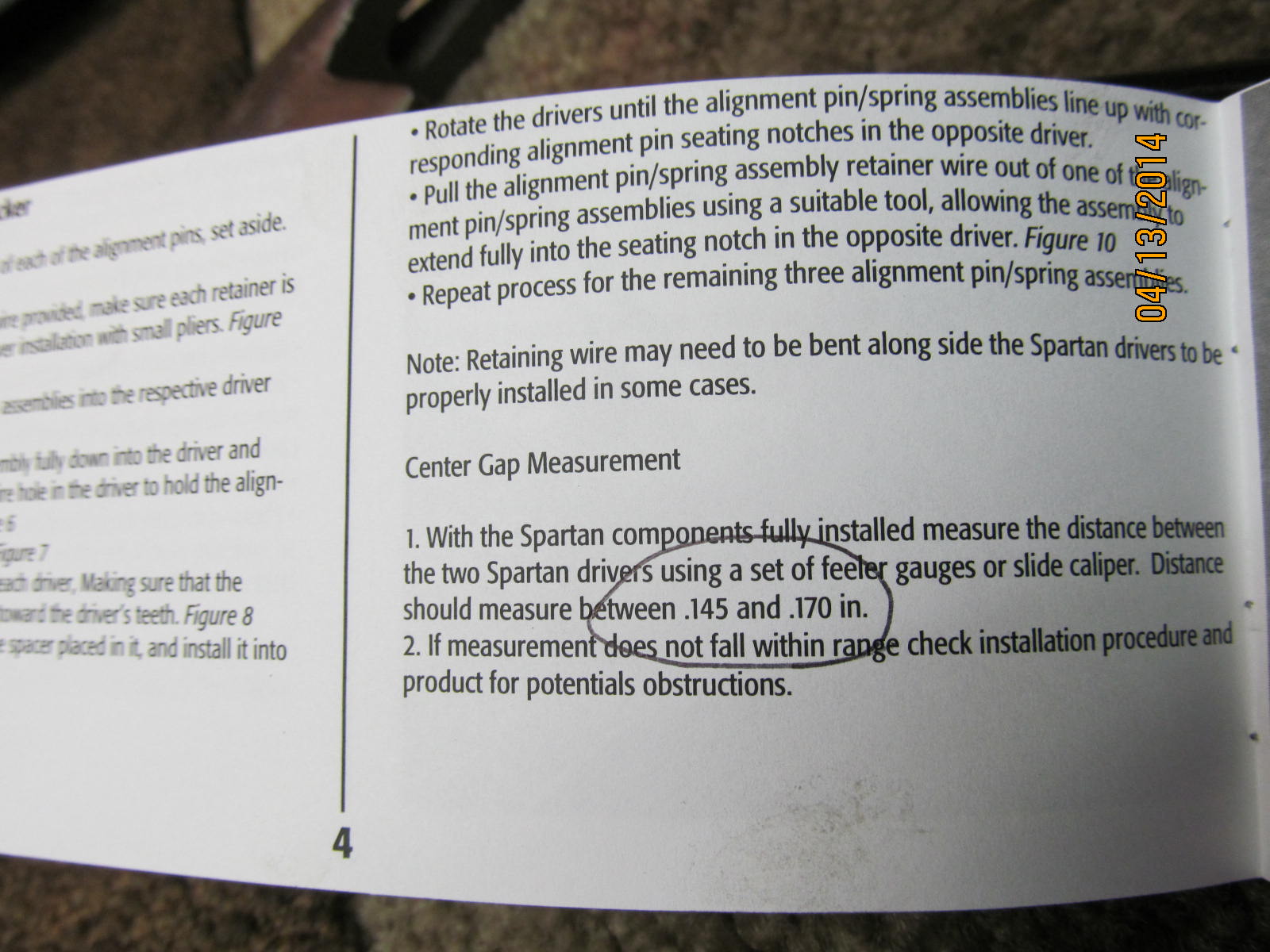

In the Spartan manual, it does mention a center gap measurement to be performed.....145 to .170" between the Spartan drivers....

|

|

|

|

|

I measured about .150" on this side and .160" on the opposite side. Pass.

|

|

|

|

|

The Spartan supplied crosspin is jiggled in place.

|

|

|

|

|

Tap the steel dowel back down the hole.

|

|

|

|

|

I like to use a pointy center punch to distort the round hole...

|

|

|

|

|

The dowel will never work its way out with this obstruction in the way :)

|

|

|

|

|

I was able to seat the ring gear with numerous hit from the rubber hammer.

|

|

|

|

|

Red Loctite #271 on all 10 ring gear bolts.

|

|

|

|

|

75 ft/lb on all ring gear bolts.

|

|

|

|

|

.....

|

|

|

|

|

75 ft/lb on the 4 long bearing cap bolts.

|

|

|

|

|

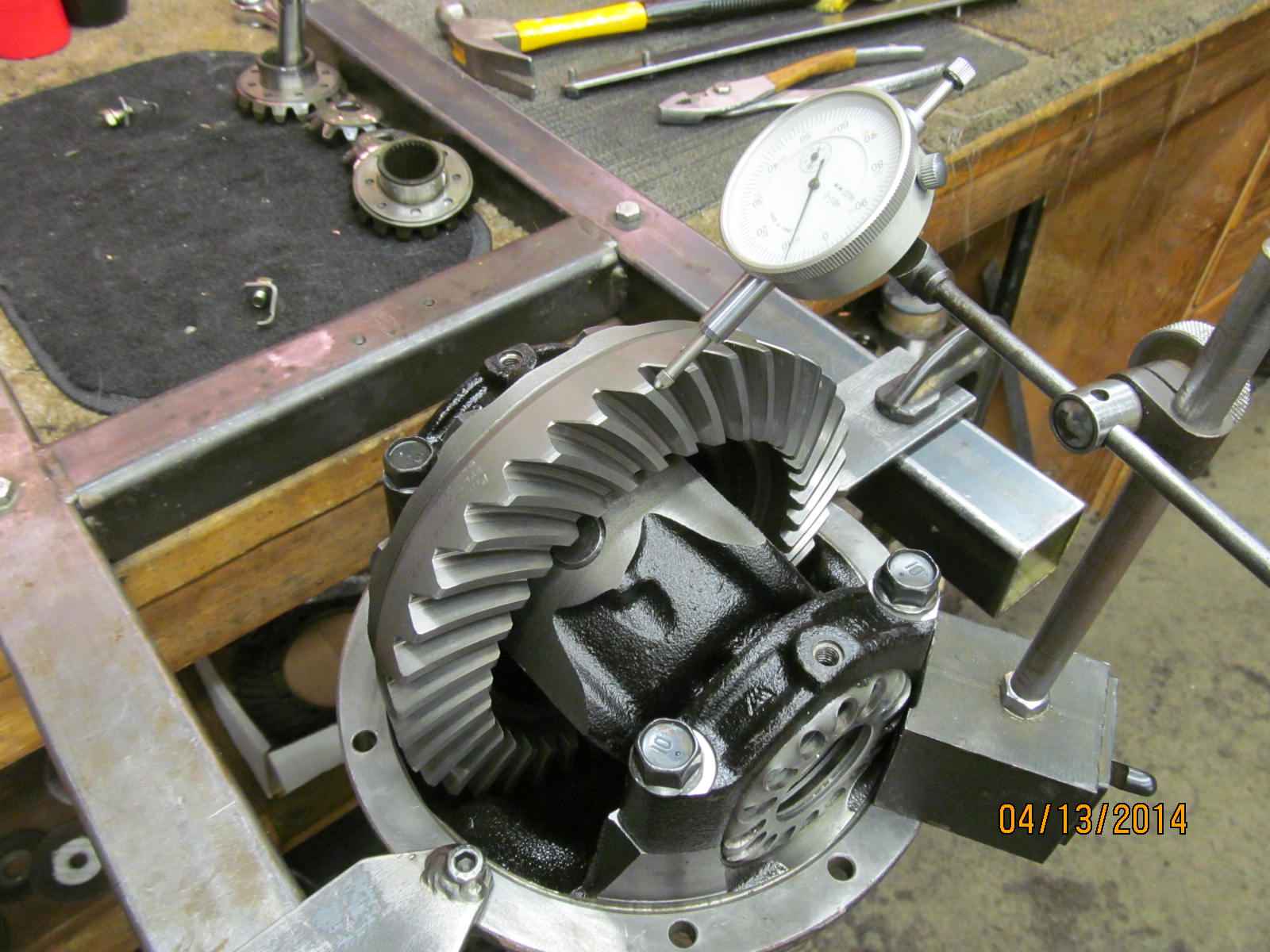

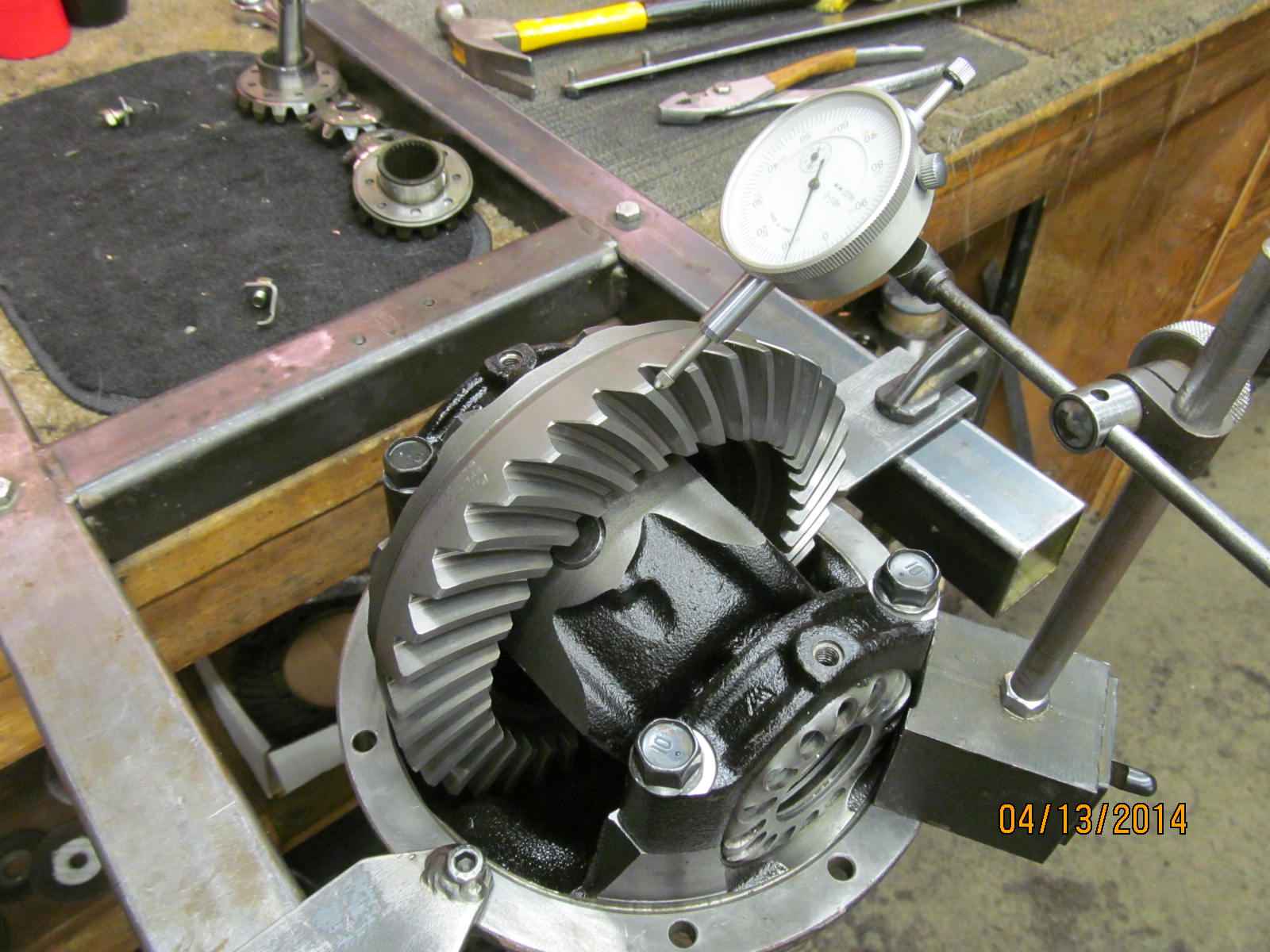

Backlash is juggled along with the carrier bearing preload.

|

|

|

|

|

blue medium strength loctite...

|

|

|

|

|

... and 10 ft/lb. Notice I elected to ease up on the CBPL and 1 less notch of "tightness".

|

|

|

|

|

This Spartan should give excellent service.

|

|

|

|

|

Pattern check----excellent drive.

|

|

|

|

|

Coast is smack in the middle and favors the root which is exceptional.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

:)

|

|

|

|