Creepy Crawlers, steel beadlock wheels(heavy), Longfield axles,

chromo hub gears, dual t-cases, full-bodied rig plus lots

of extra weight in exo tube work, winch, full size spare,

tools, spare parts and fluids. John carries a lot of tools

and spares on the trail. It's a weekend crawler that gets

trailered about 70% of the time. It's seen Sledgehammer,

Pritchett, Green Day, and a whole slew of others.

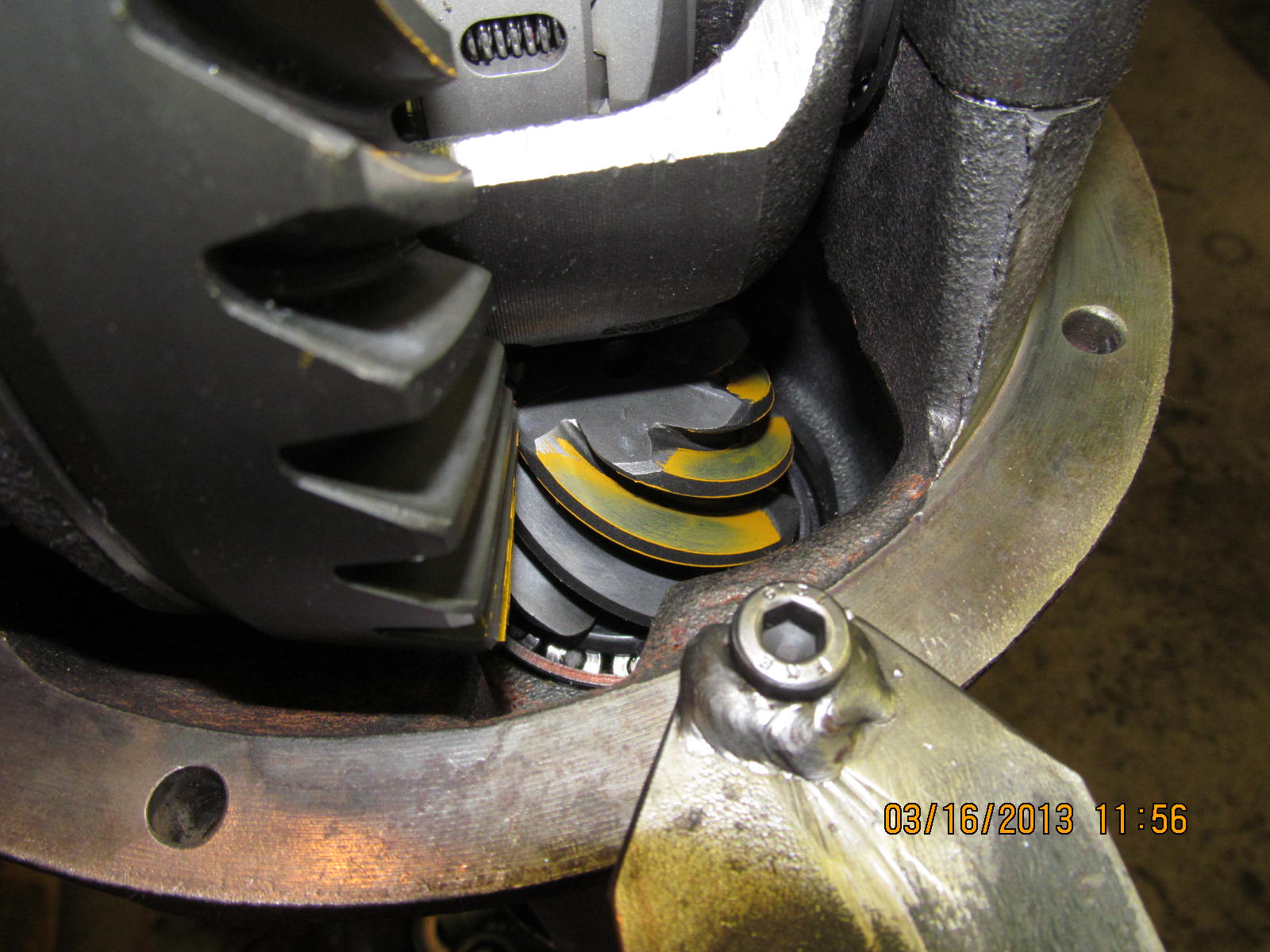

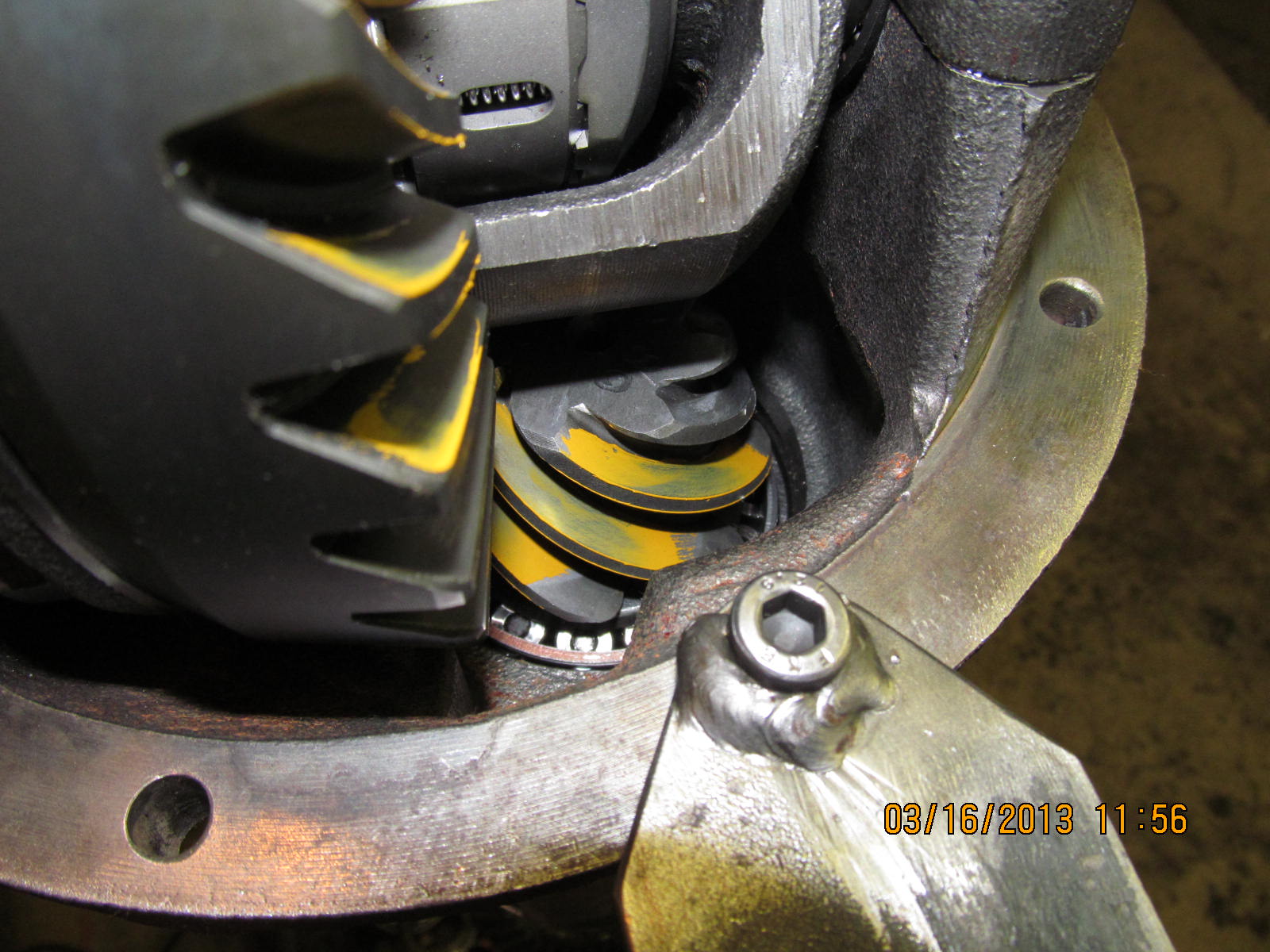

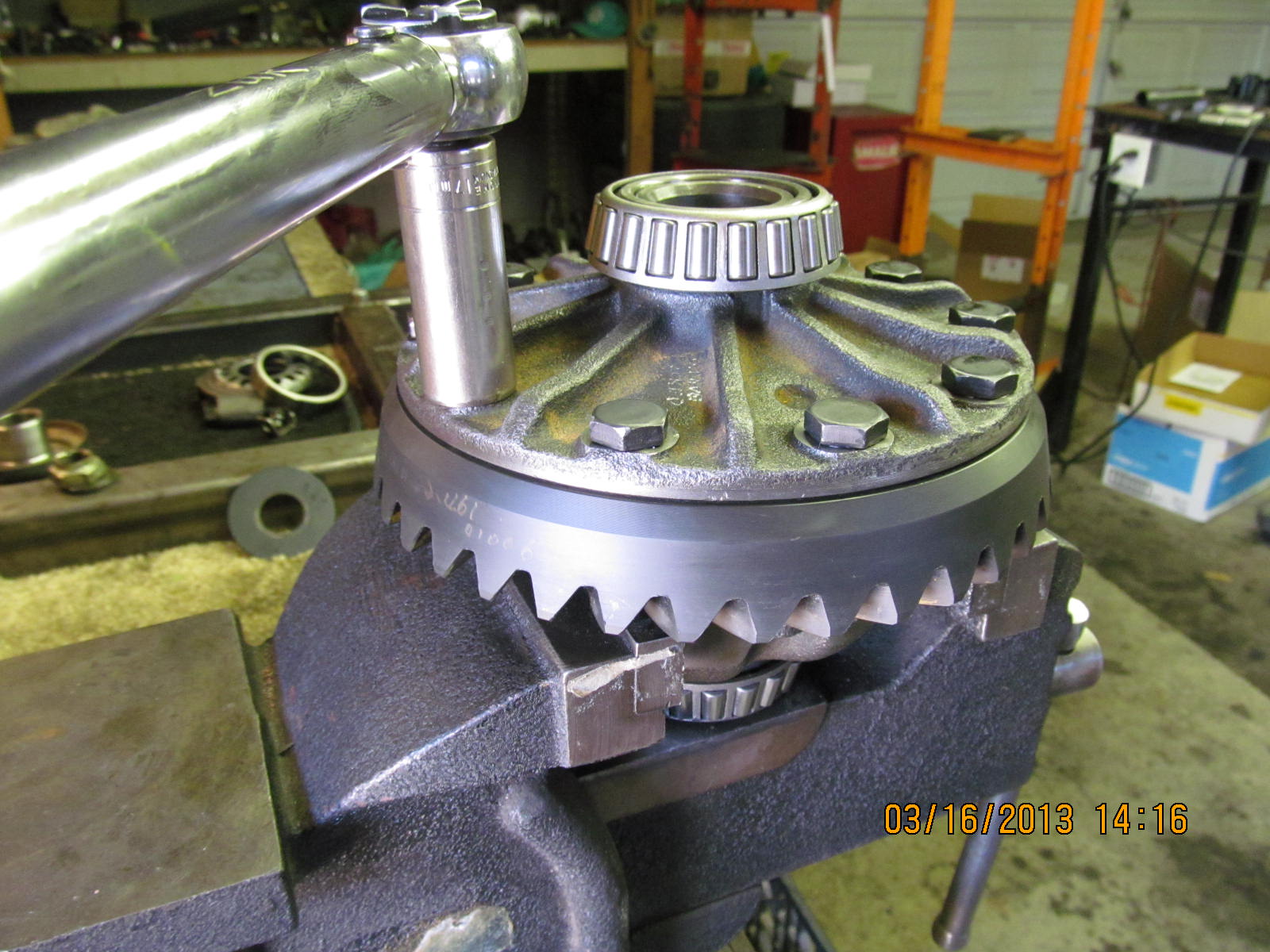

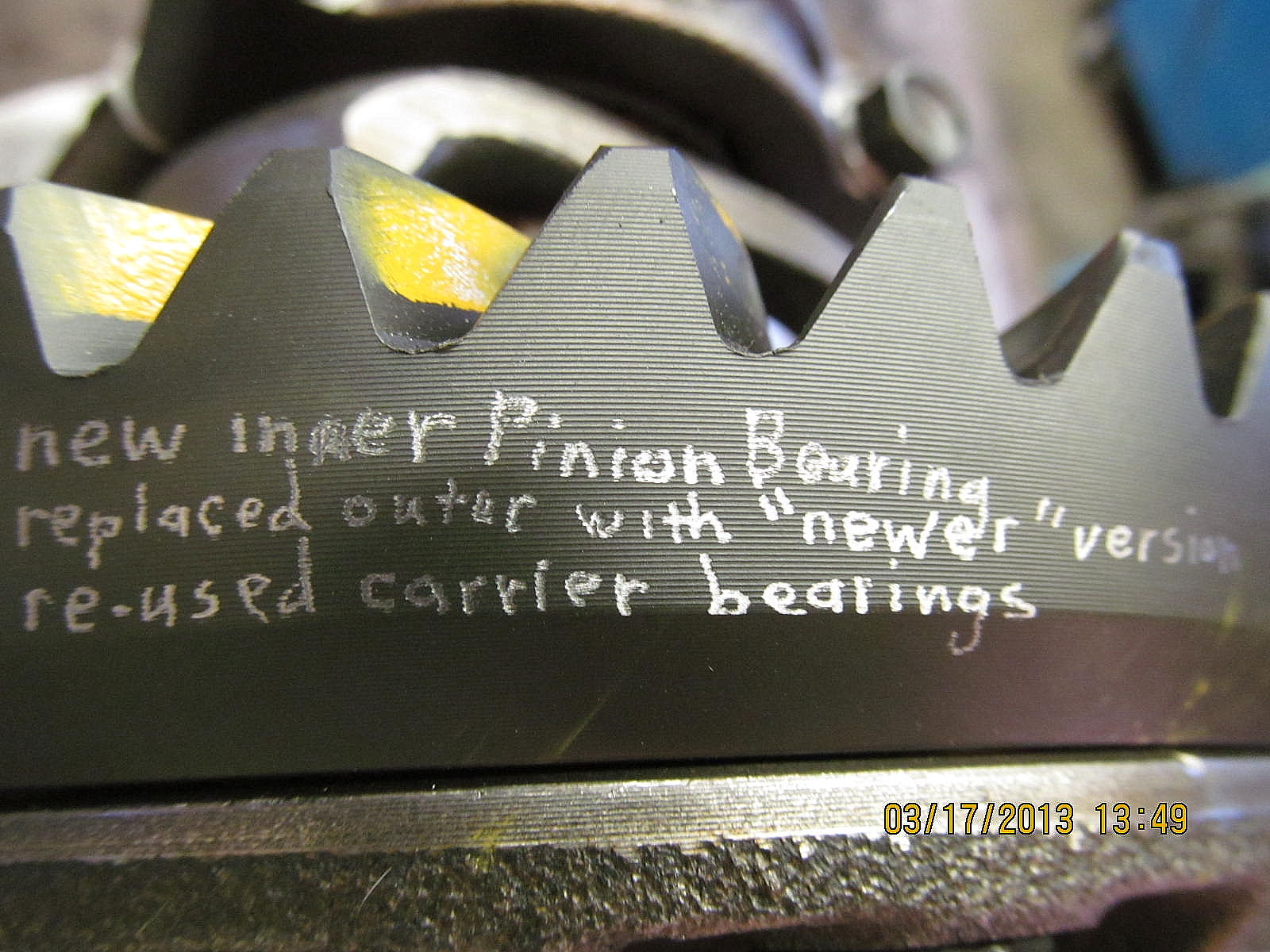

gear markings to help identify them.

characters.

torn down and cleaned up.

are ok...just will lighten up on the pre-load final values.

down on its own accord.

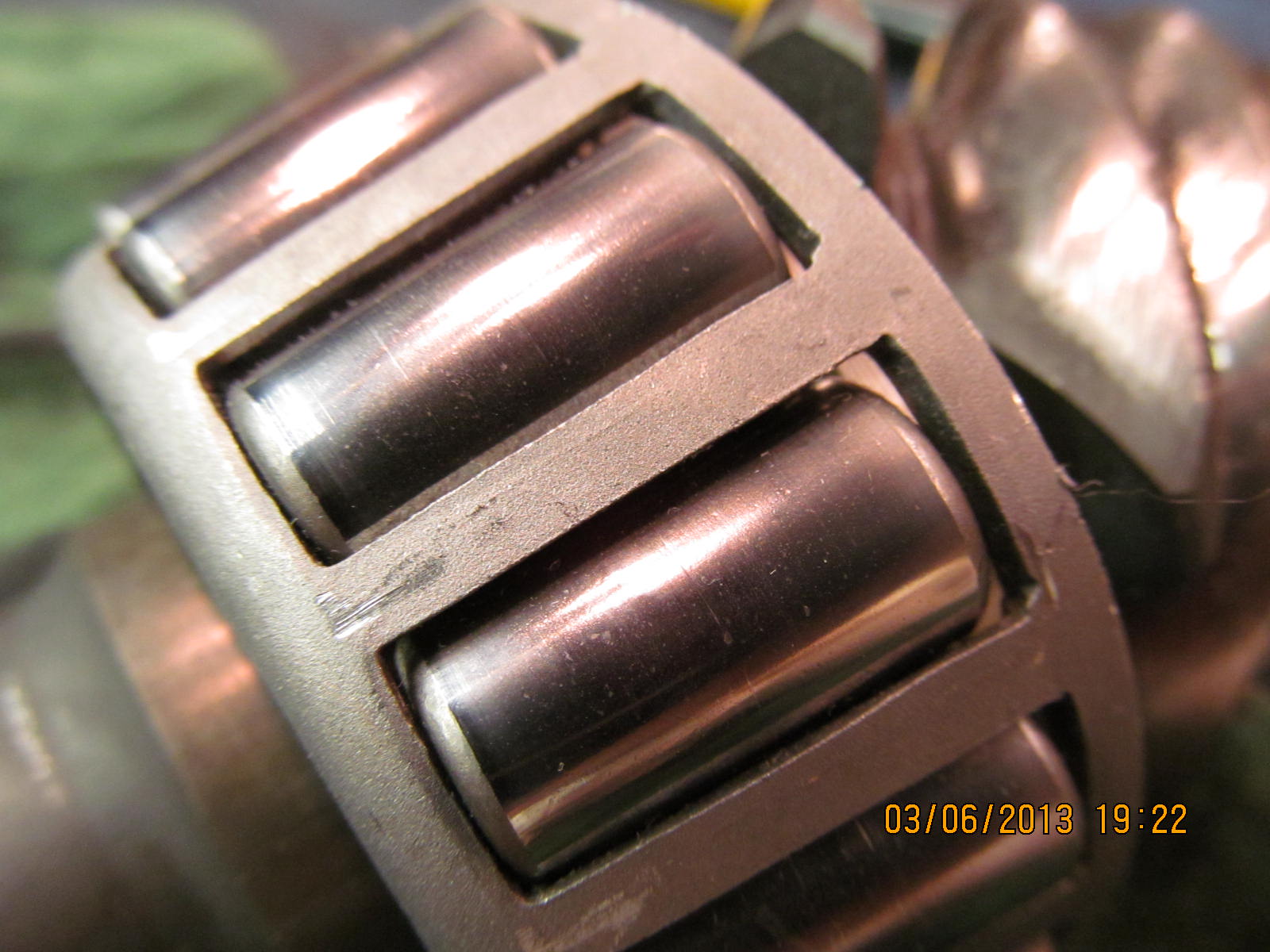

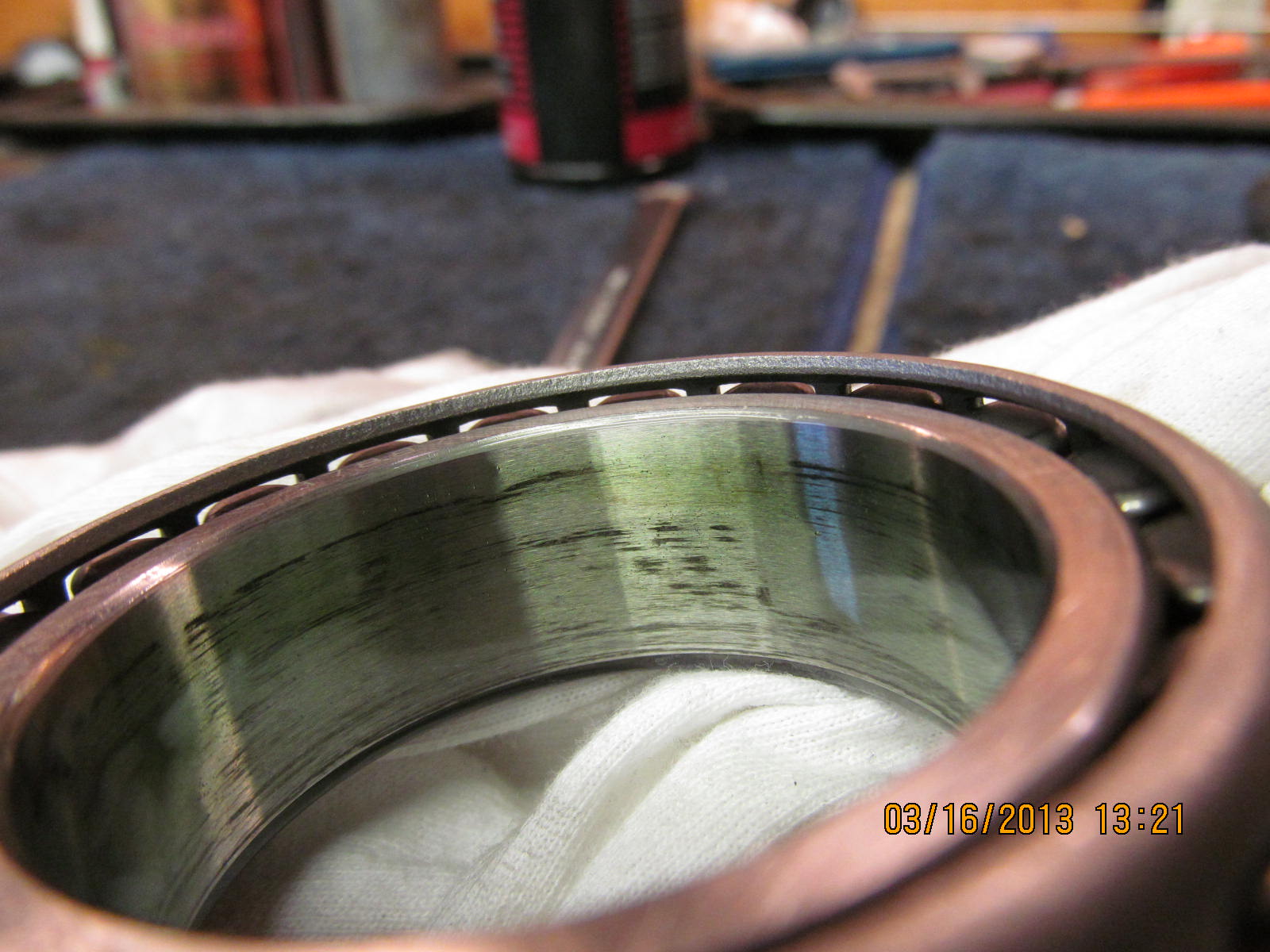

pictures...this 32307 bearing is in ok shape and because we

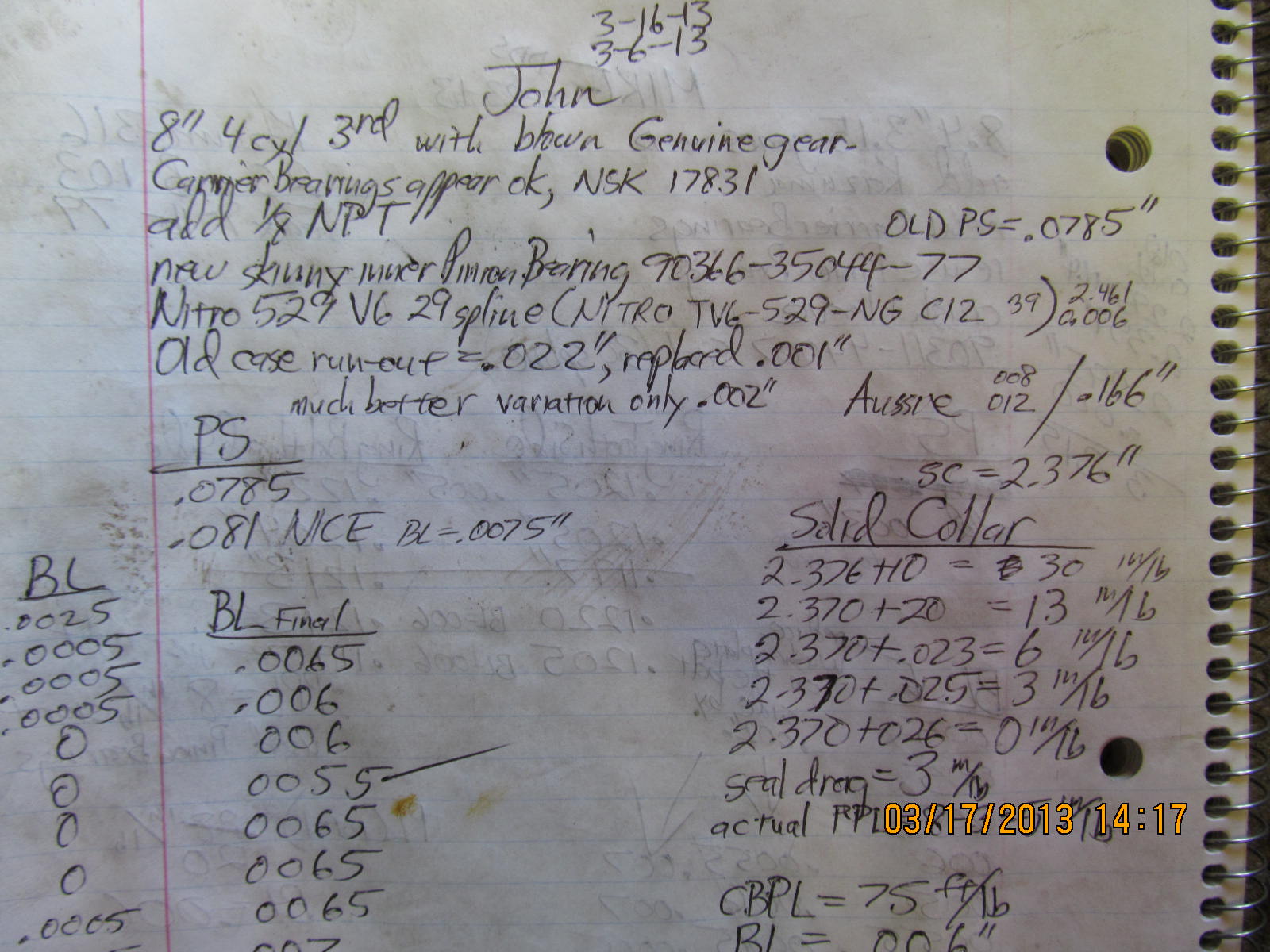

will be installing a V6 style pinion in this "4 cylinder 3rd"

means a brand new skinny bearing will be used. A skinny bearing

is what I am calling the "low profile " inner pinion bearing

that the 1986 thru 1985 trucks use in the 4 cyl 3rds....even

though those 4 cyl 3rds actually use the long pinion head V6 pinions.

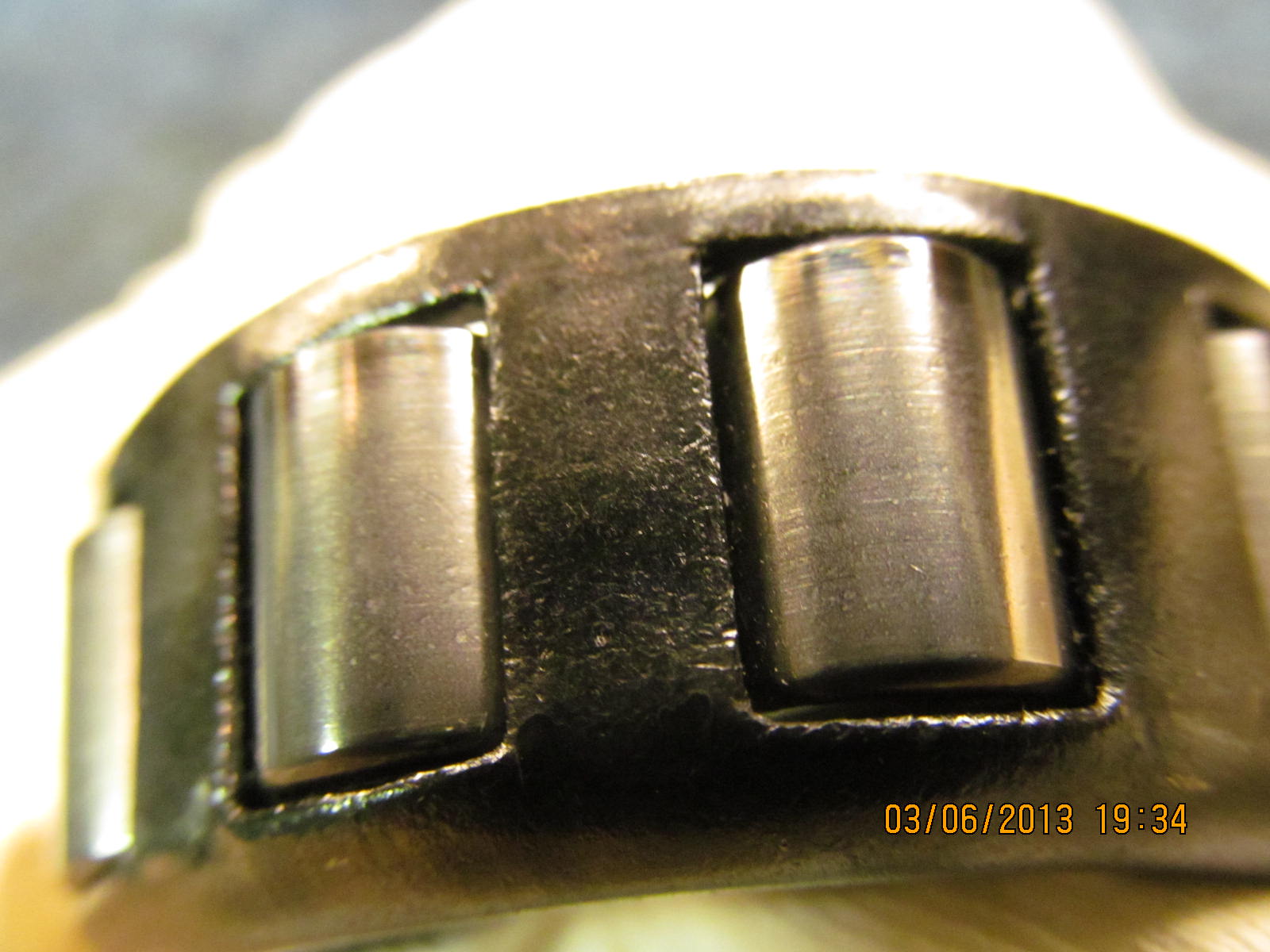

alternate bearing that is in much better shape than this one.

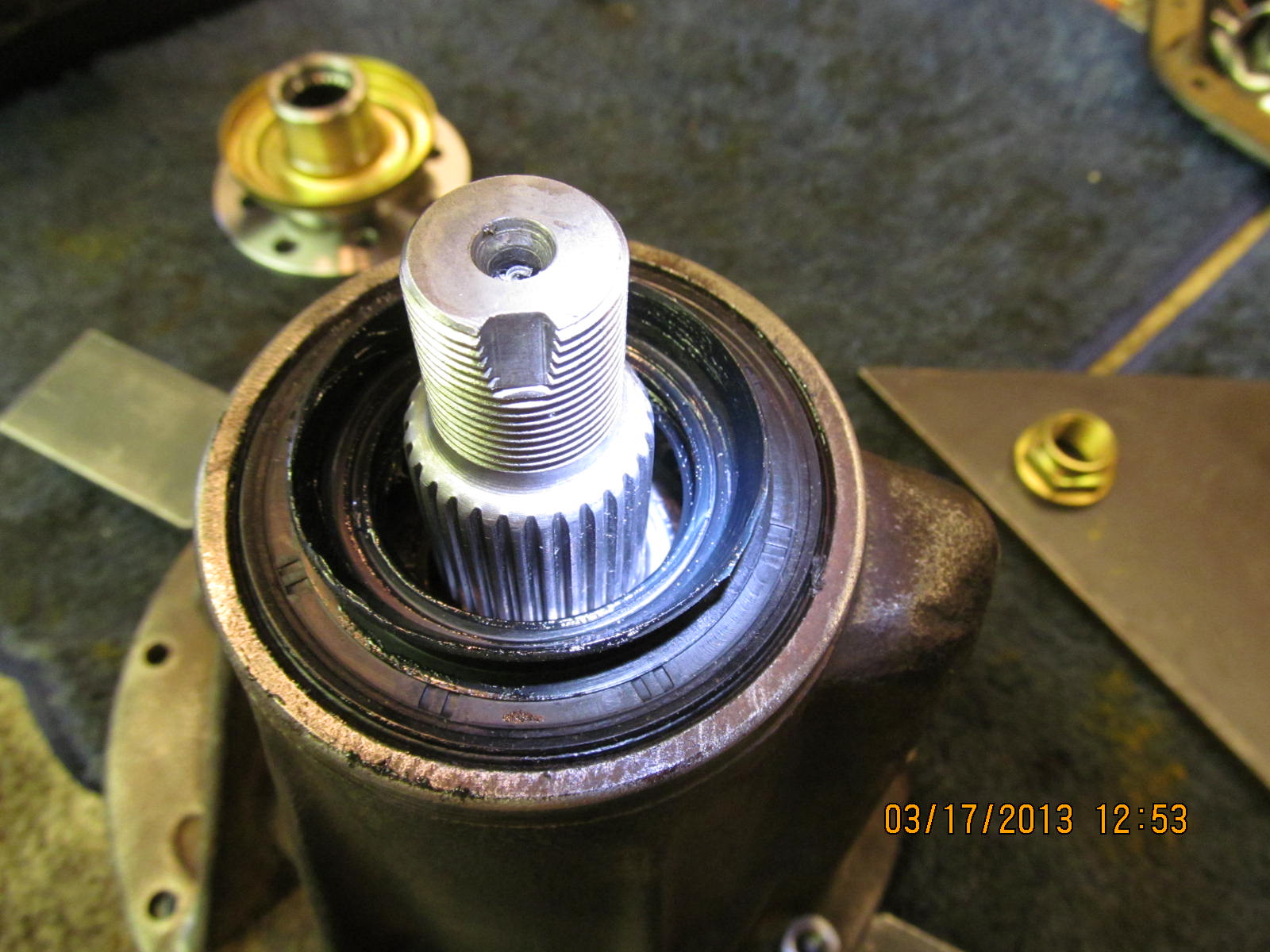

very good shape. The new 529 pinion is a 29 spliner so this 27

spliner will not be used.

matching 29 spline flange and seal and nut.

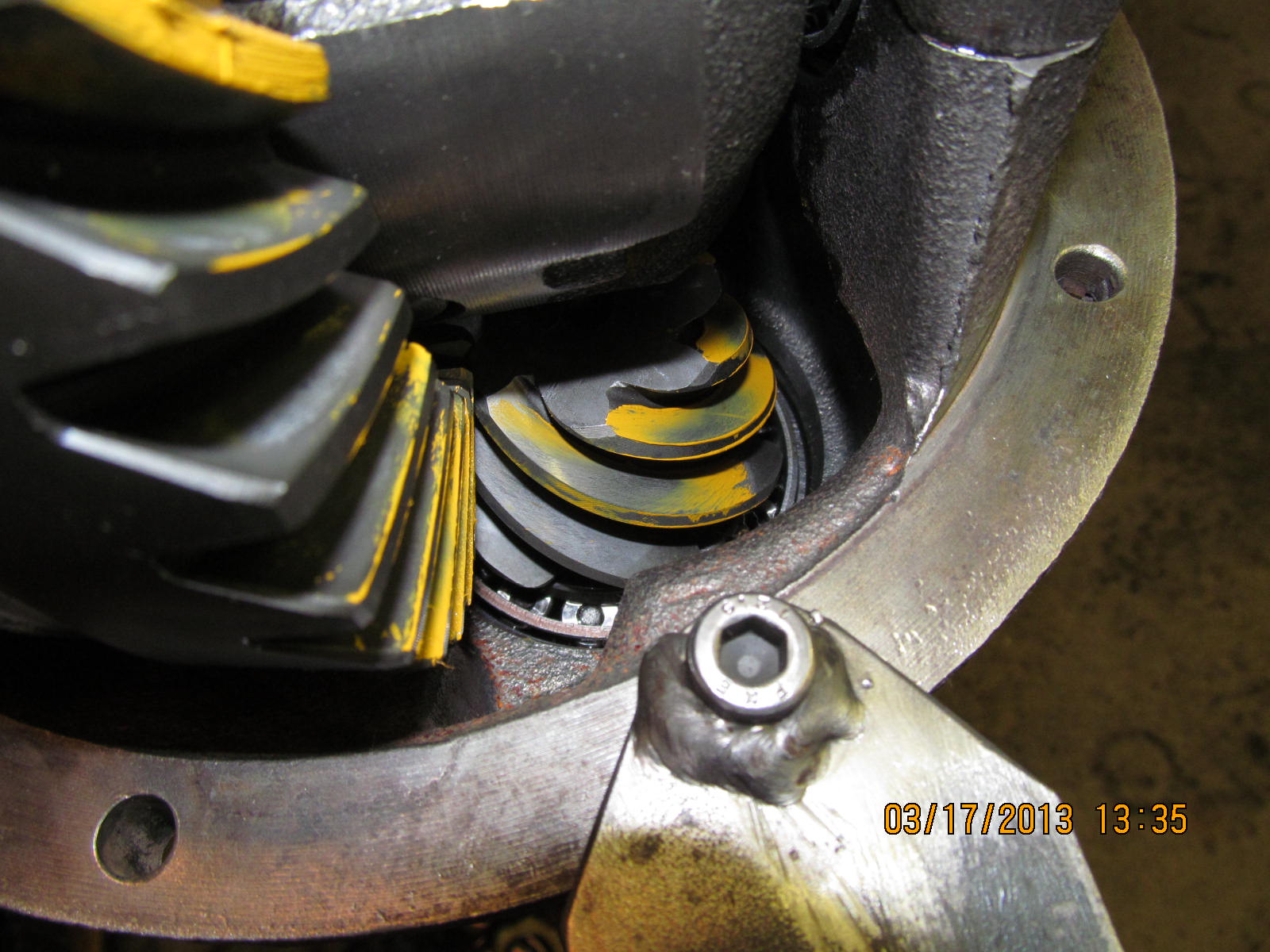

"low profile" OEM bearing to make it work out perfectly.

a used one but twice as good a shape as the original pitted one. Since

this outer bearing/race is a used one, I will factor that in when I

set the PPL.

inner bearing.

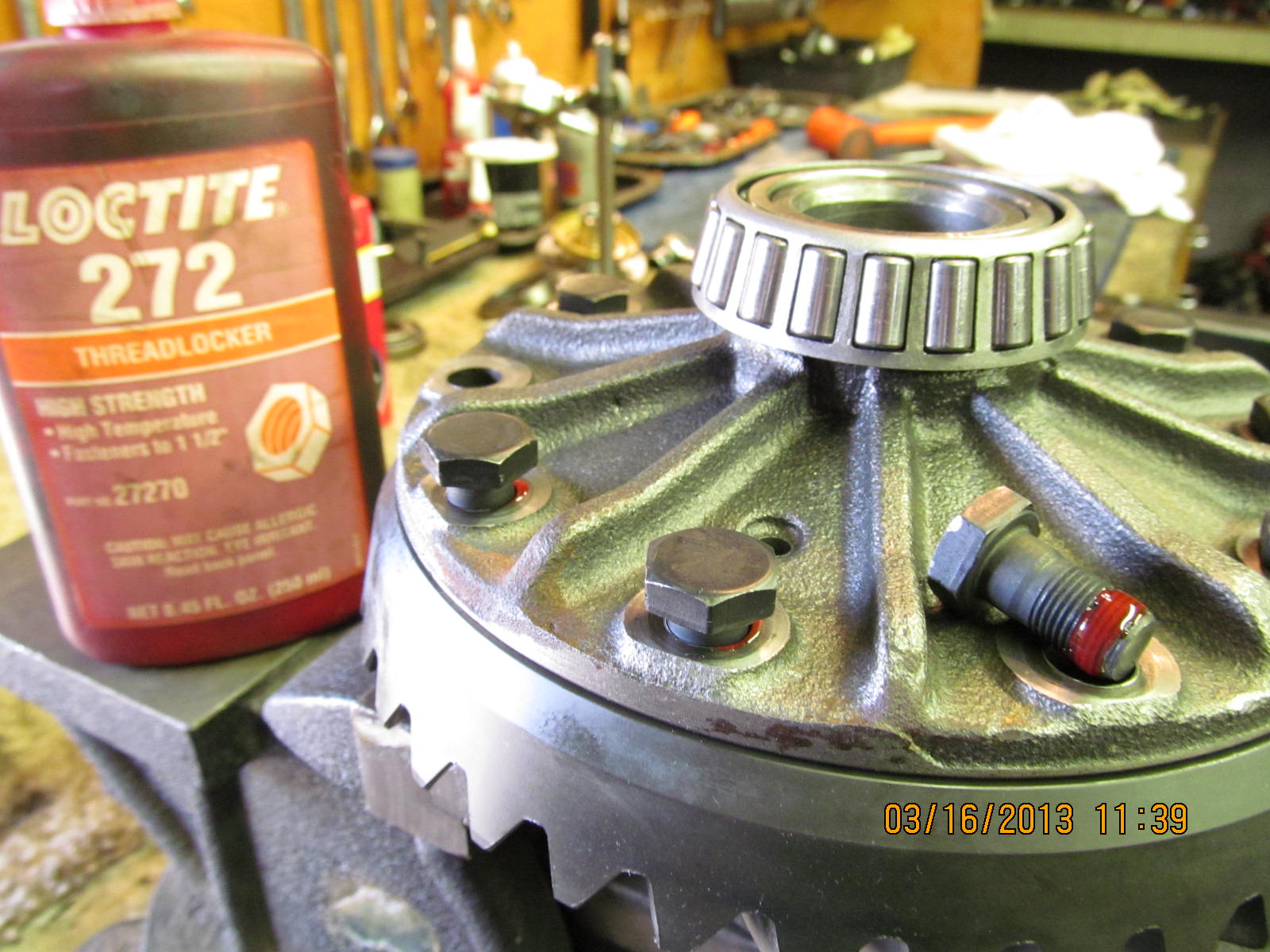

is fairly easy. Place housing over pinion...outer pinion

bearing....29 spline shop flange...tap down with lead filled

plastic hammer....start the 30mm nut and wizz it down with

the electric impact. Oil the bearings and continue the gradual

tightening of the nut until some pre-load is felt.

at this stage.

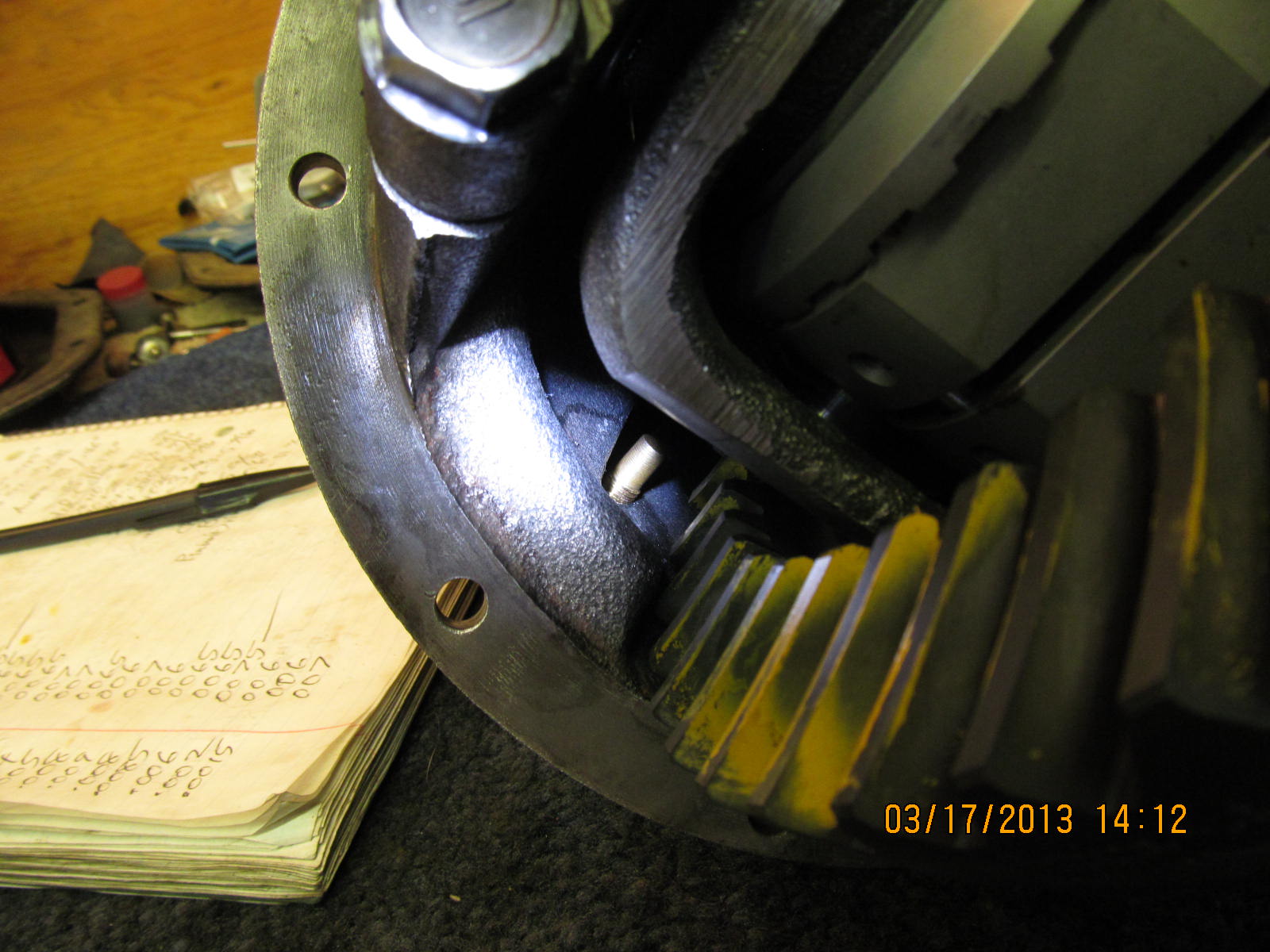

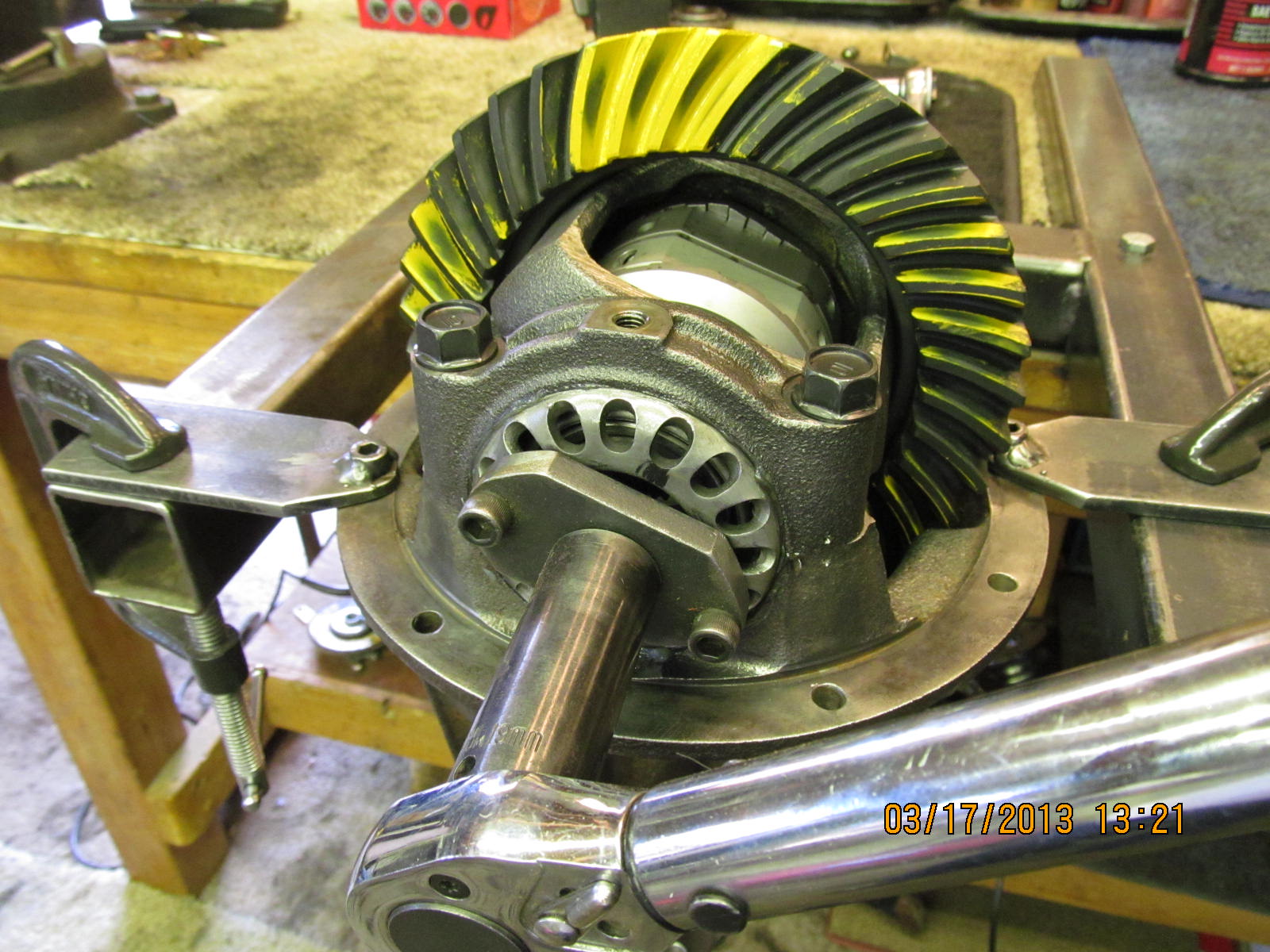

and nothing unusual was found. Ring gear also saw the file.

I was tempted to think that these Nitro Gears were

manufactured wrong but these gears are known to be

excellent gears. Logically, the case that the ring is

bolted to must have excessive run-out.

is "exact" and I can go a couple thou deeper to promote better

overall strength with no increase in noise.

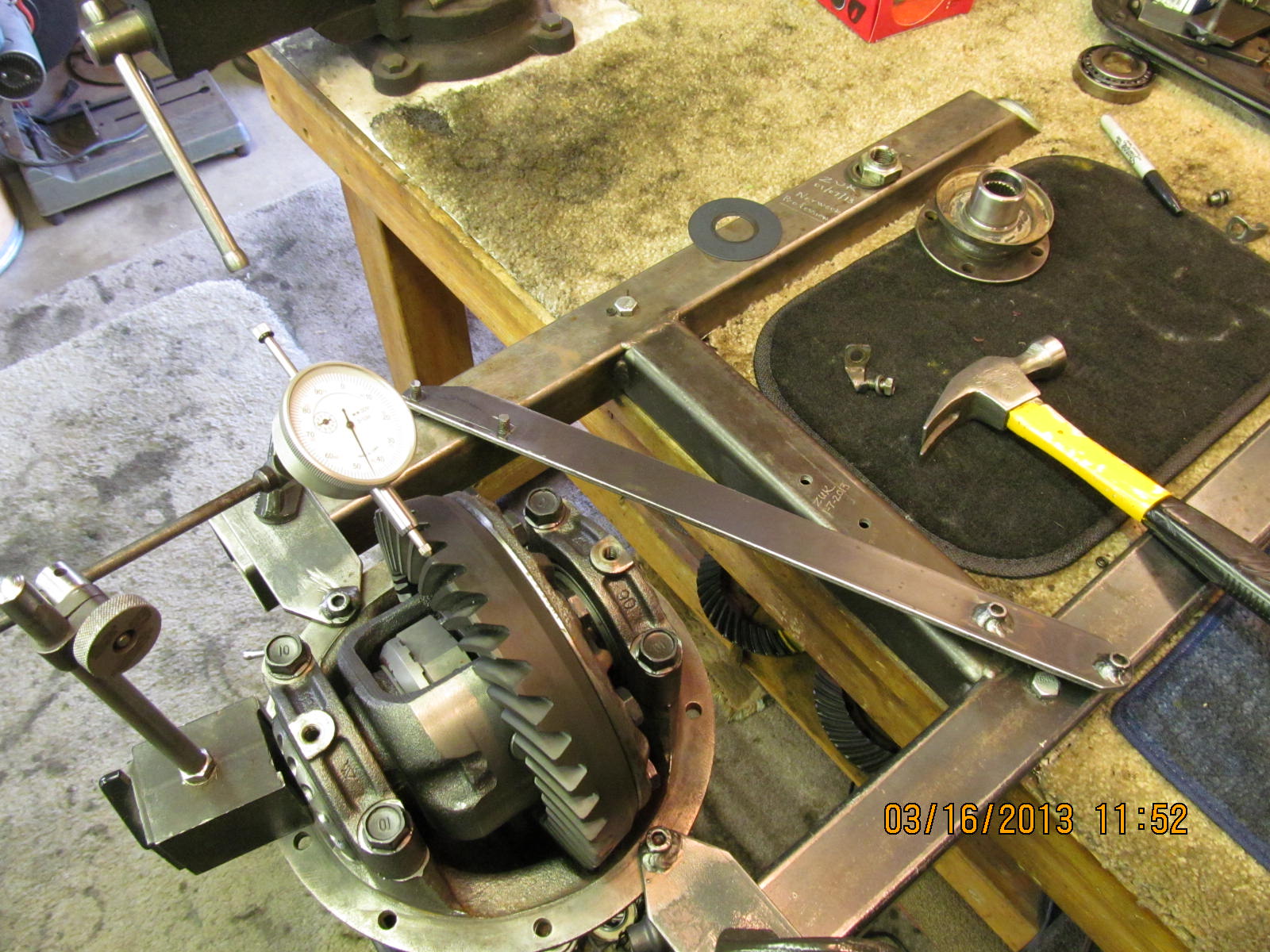

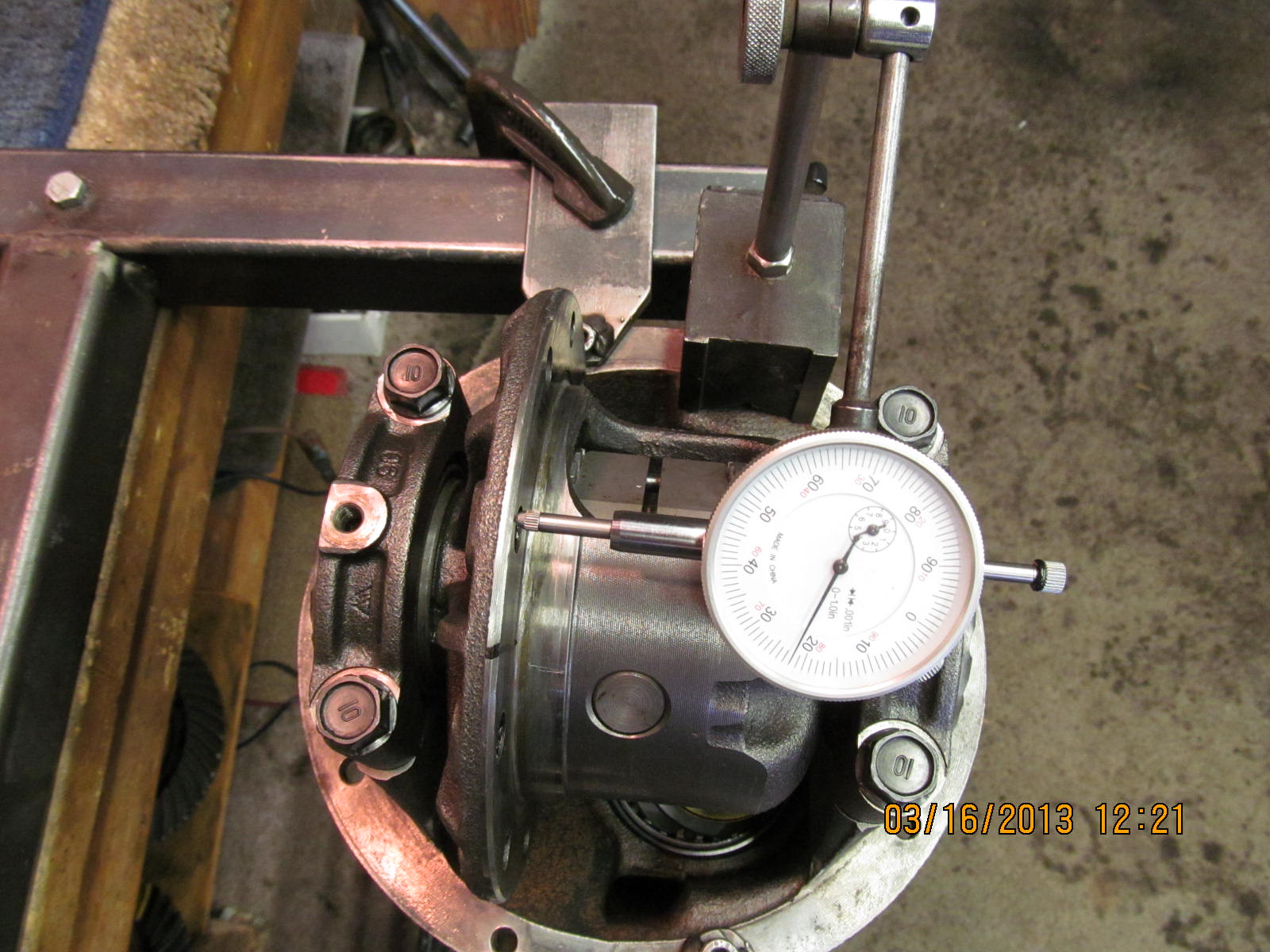

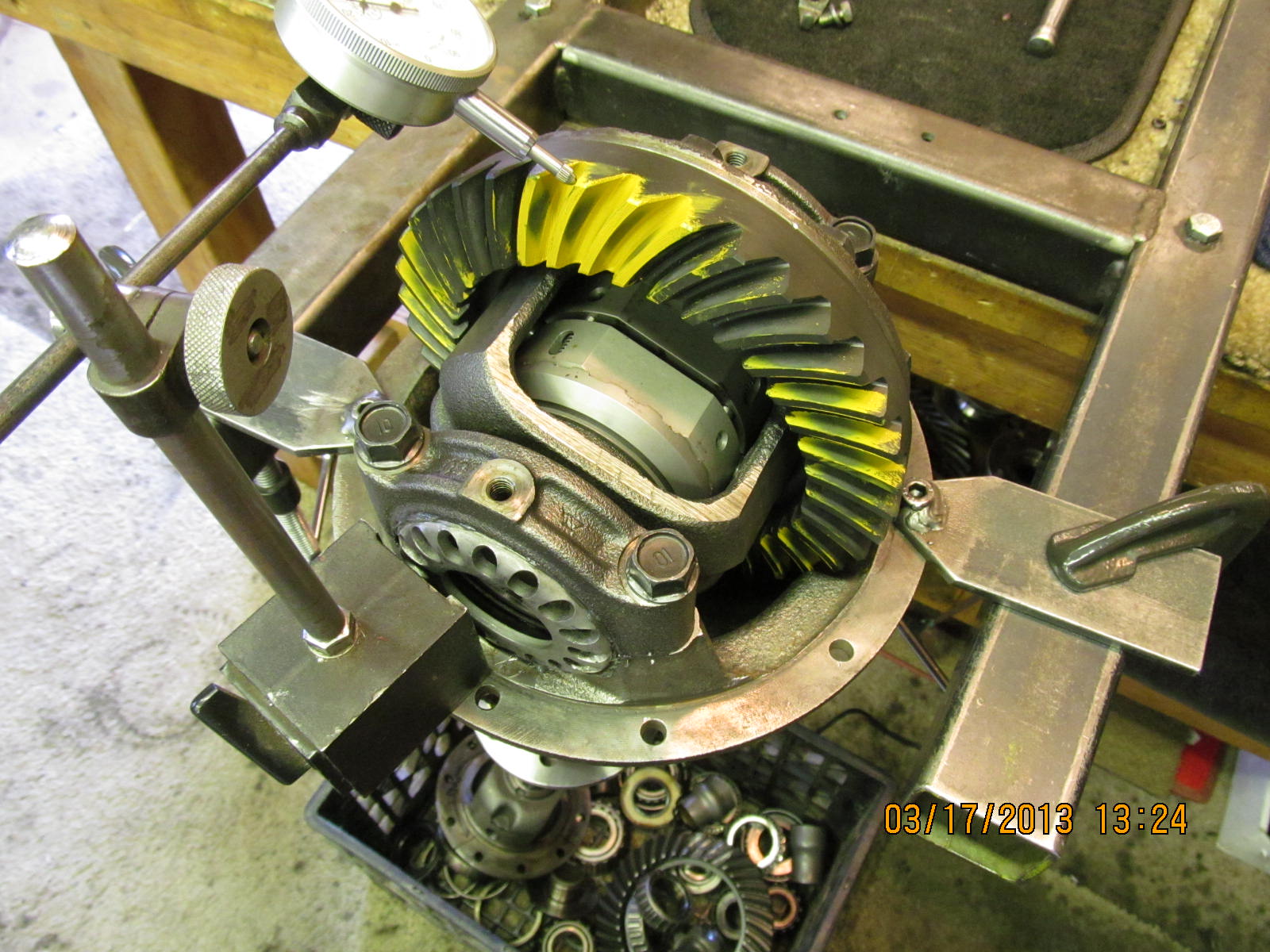

gauge on the low spot on the ring gear surface.

22 thou run-out which is about 10 times out of spec. This case

is un-usable.

(as seen in the background). It was just a small matter of

swapping the bearing over and the Lockrite also. These bearings

came off these journals fairly easy.

journals so, to play it safe, I cleaned and applied retaining compound.

out, the bearings both pressed on very tight which means God help

the next guy that has to remove them :) Consider it extra insurance

that these carrier bearings will never loosen up on the journals

like some of the other 4 cylinder cases.

the roll pin out. Easier said than done. Some of those roll pins take

some good hits to break loose. 3/16" or 7/32 diameter punch works

best.

run-out check shows only .001" variation this time.

came out pretty easy.

to spacer play. I measured about .010" on each side.

are inserted.

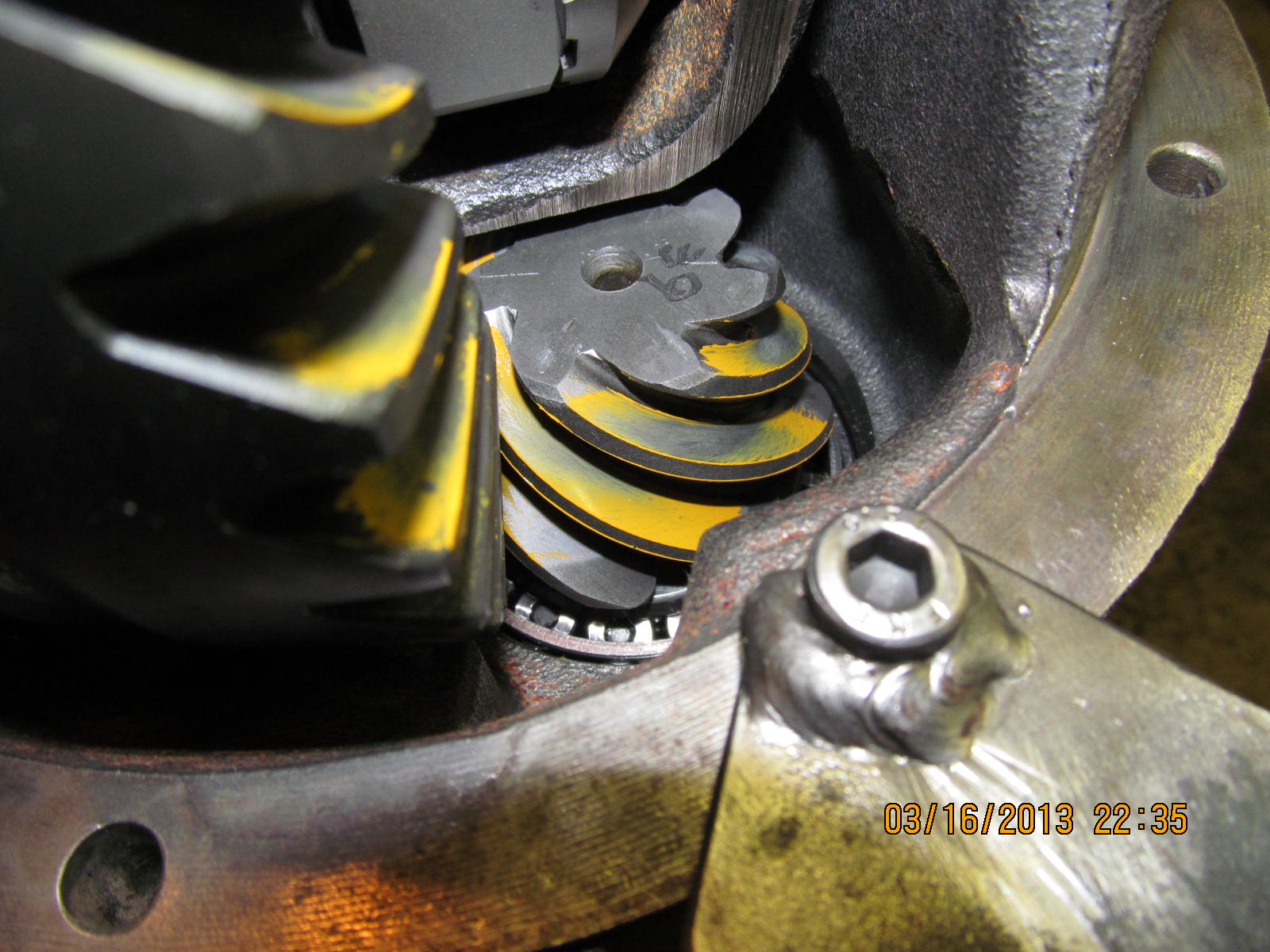

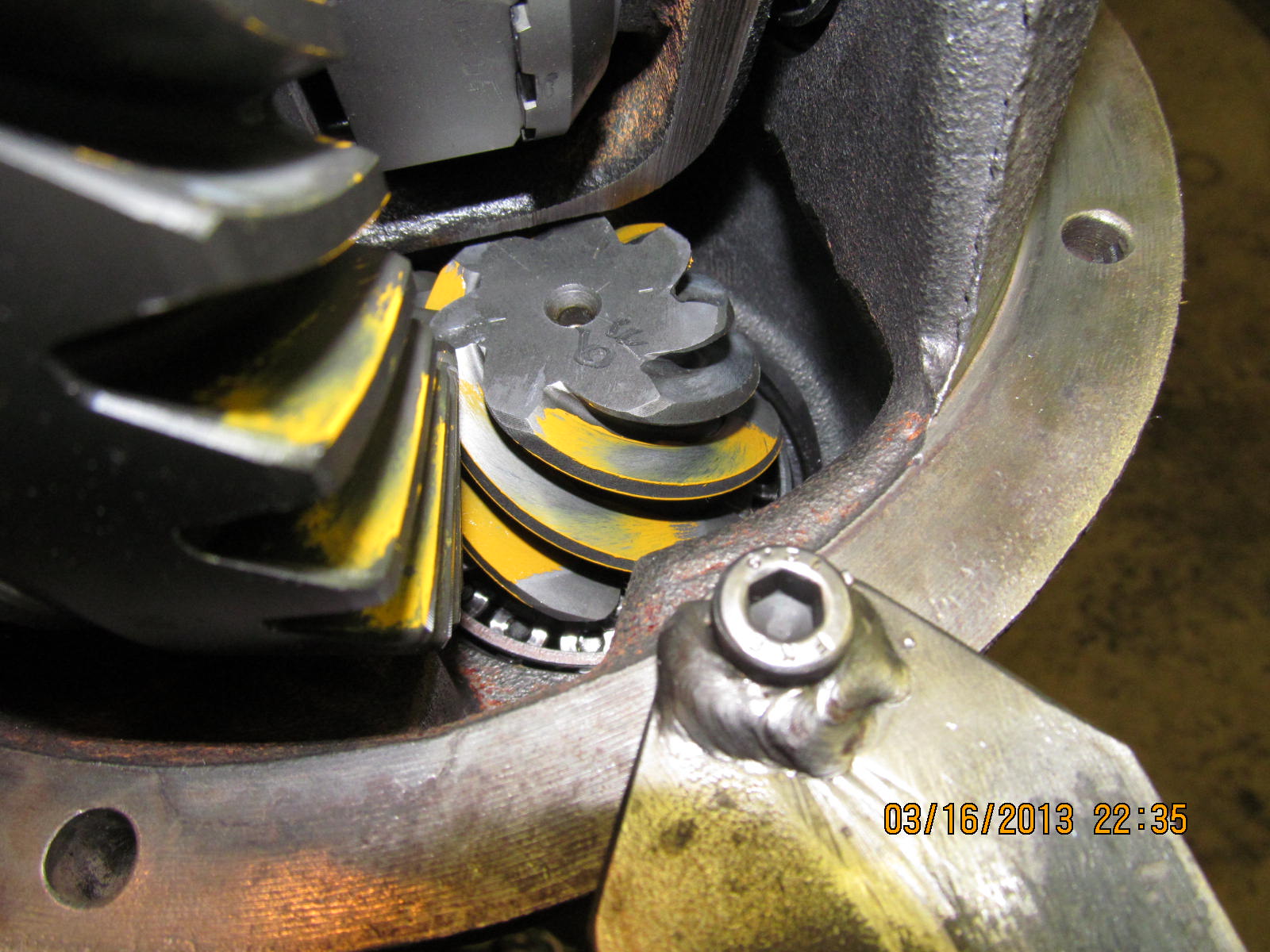

screwdriver. Notice thatI have the outside driver and coupler

marked as outside. The teeth might have developed some

wear on the leading edges and I didn't want to disturb the

wear engagement in this new case.

of the hole. The roll pin will never wander out.

and 75 ft/lb torque.

Some carrier bearing pre-load was also dialed in.

pattern once more. Using a rag to offer some resistance....

17mm wrench.

tail tucking into the root so much.

well put the solid collar in. This is the Toyota OEM solid collar.

remove them but I still wish the all-so-common 27 spline versions

would fit this snug. All you Russian guys that are using the universal

online language translators, I imagine it's hard to understand some

of the English phrases (colloquialisms) that I use :)

bearing.

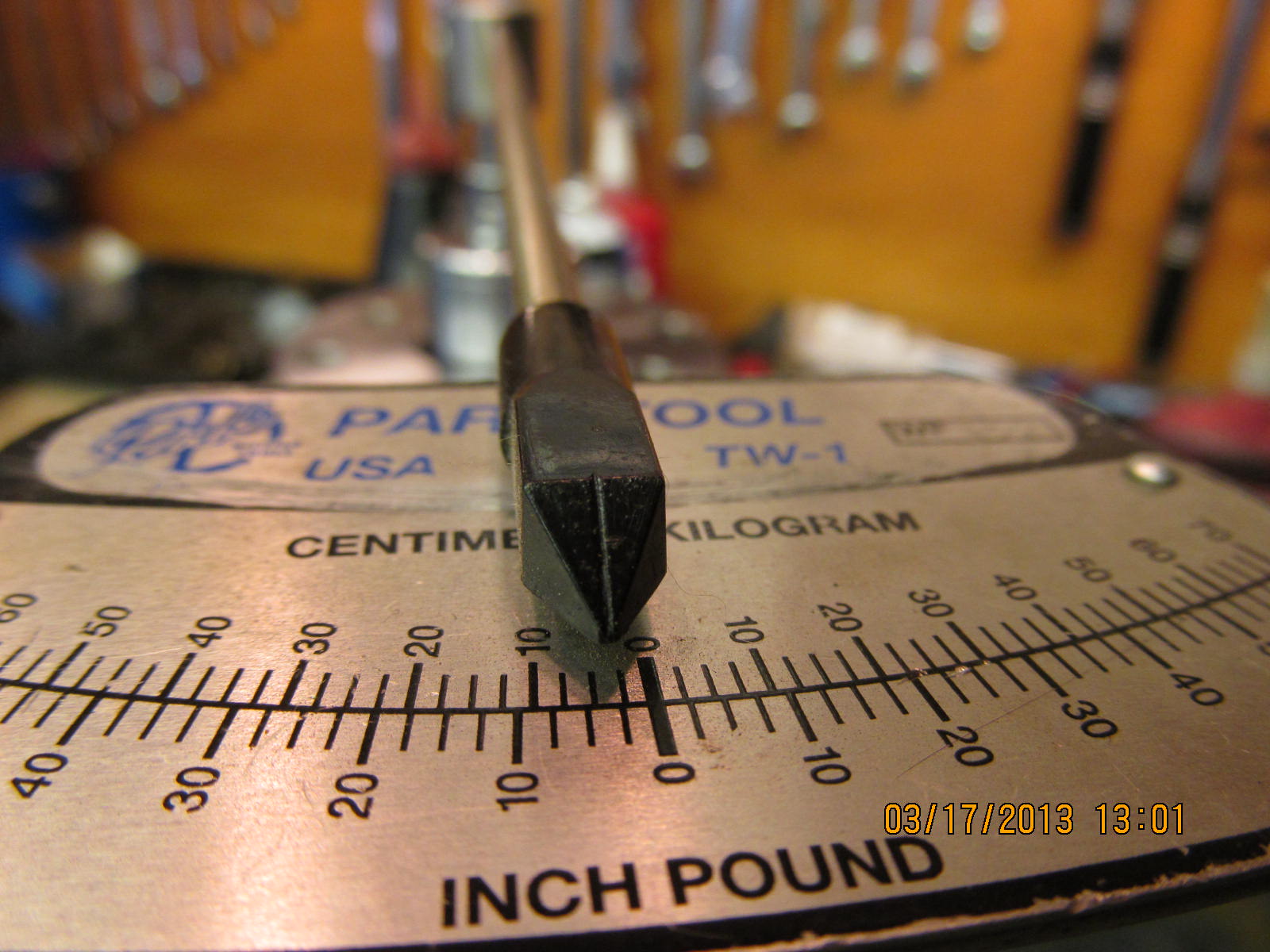

a target 5 in/lb. This one is .25mm which converts to .010".

reading....but for doing a pattern check it's still ok.

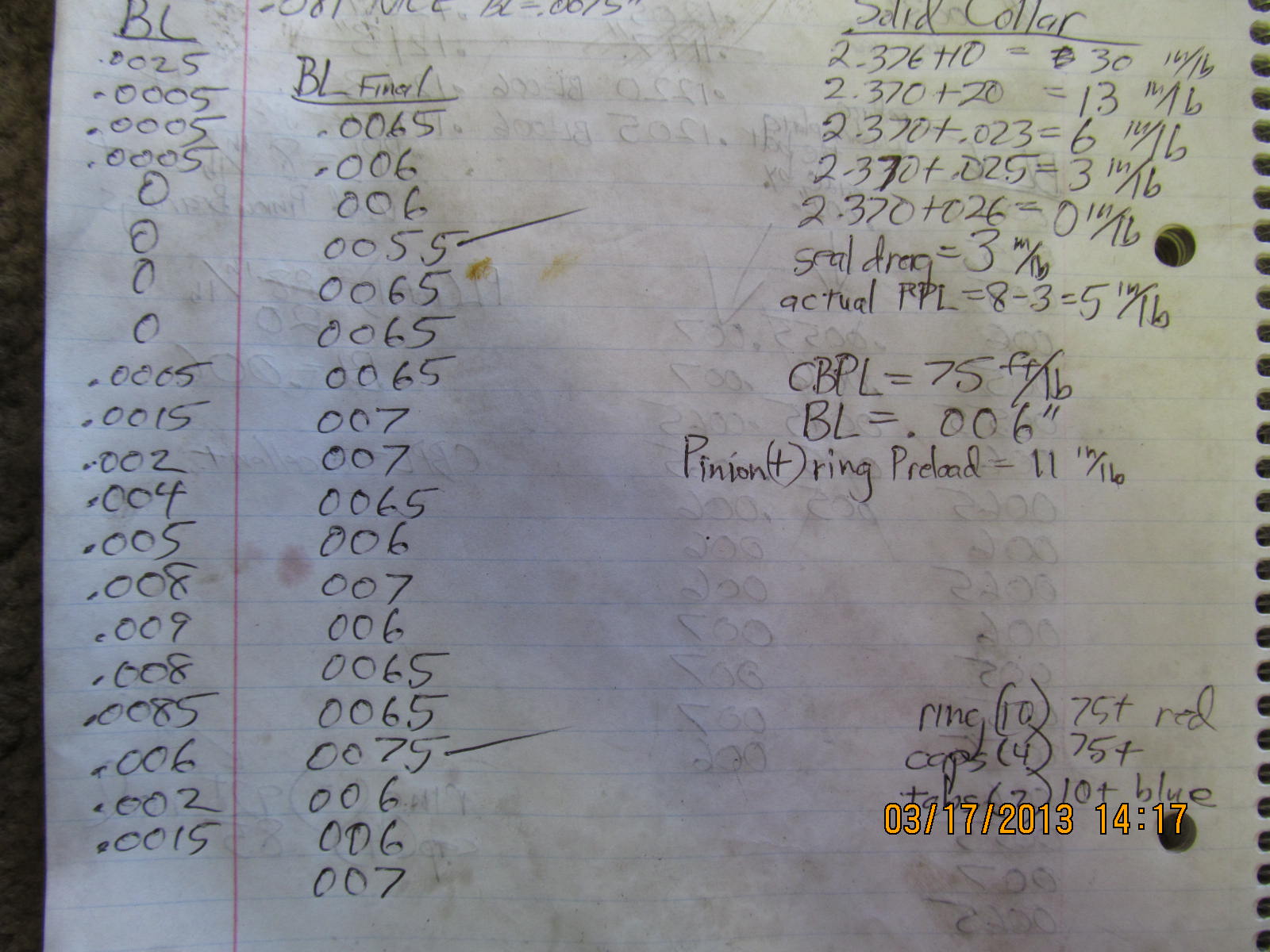

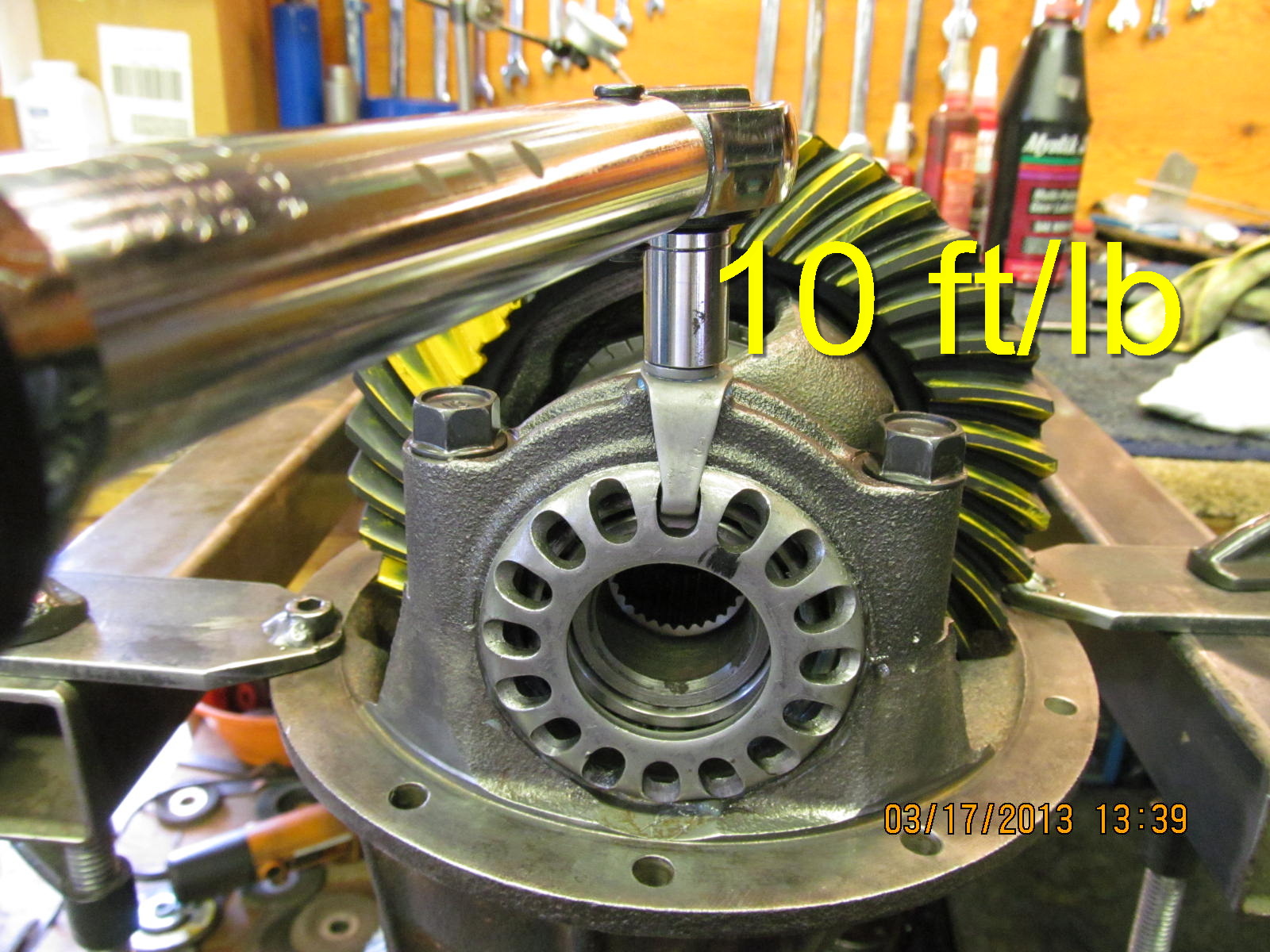

PPL just right. As my notes at the end of this link show, it took

about 5 tries to get it just right. Basically, using the electric

impact to tighten the pinion nut, I shoot for about 0~1 in/lb of

pre-load. Then I can use the 3 foot breaker bar to compress the

molecules in the collar just enough to yield a final 5 or 6 in/lb.

The outer pinion bearing is not brand new so that's the reason for

only 6 in/lb pre-load.

do want to use some silicon rtv to help tap it in place. The grease

keeps the little spring coil from popping off during the hammer

process.

don't want a dry start-up on the seal lip and, also, I want to minimize

the seal drag caused by the tight fitting rubber lips.

aluminum pucks and gently press the new 29 spline flange in place.

operation.

to the rubber lips...about 3 in/lb.

to equalize the pinion bearing tensions. Notice the black sharpie

mark on the edge of the nut. That's how much more the cheater bar

gave me...almost 1/4 turn.

to seal resistance for a grand total of 8 as shown above.

wheel adjusters.

in place til it feels just right...

place with a nice solid snap sound and no gap on either end. Then

I'm pretty sure that the threads are all aligned.

The carrier bearings are used so I don't want to get carried away

and really crank on them. I will aim for 75 ft/lb on both wheels.

point and it is now easy to tweak the carrier bearing pre-load while

guiding the backlash where I want it. On the ring gear itself, it

specified .006" for backlash.

like this.

the minimum is right at .006". Checked on every other tooth

...about 20 readings.

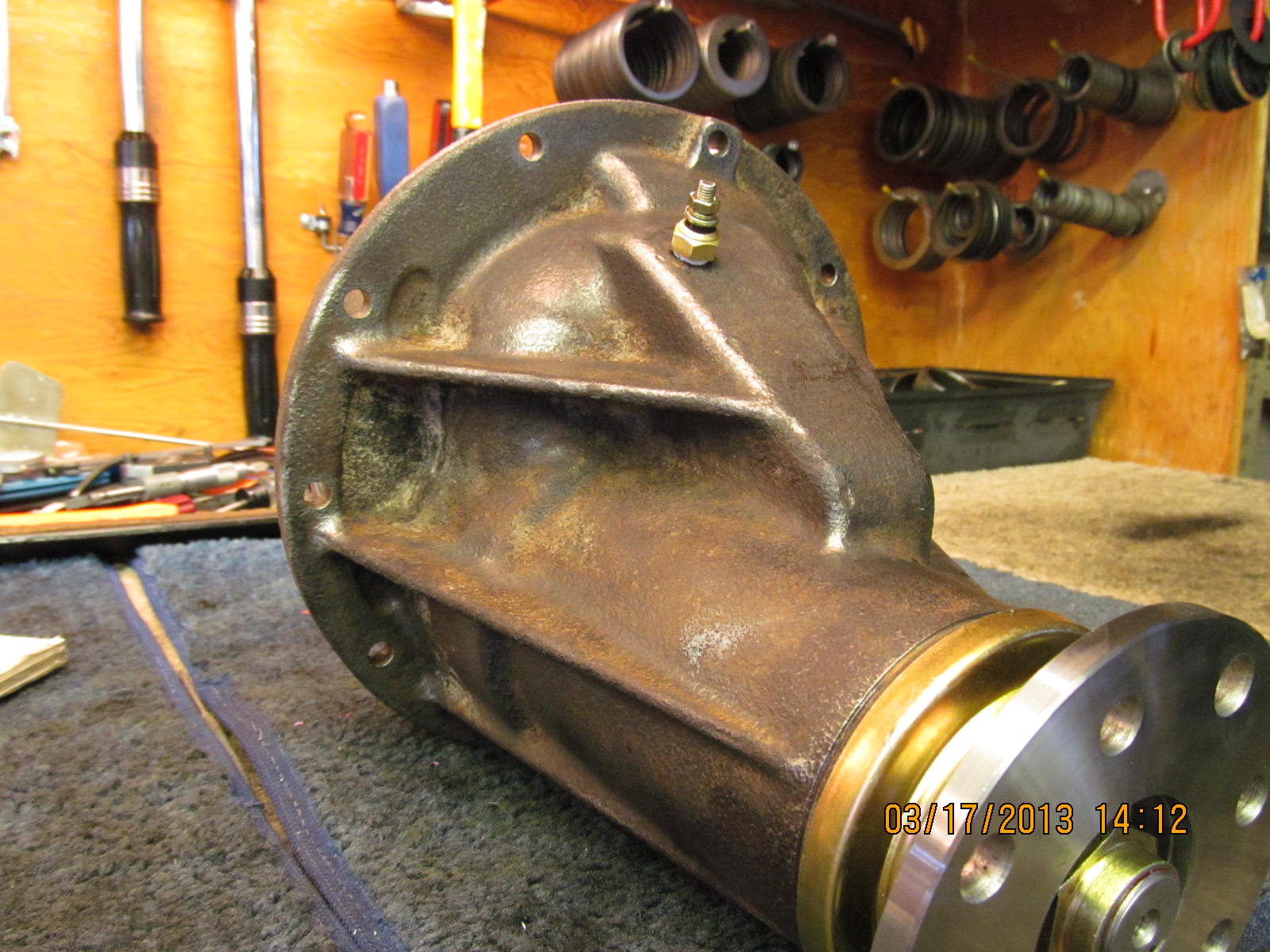

drill and tap the top of the 3rd for a 1/8 NPT sensor so that a

gauge can be used in the cab to monitor gear oil temps. Imagine

the possibilities...a cool break-in of gears....making sure the

gears don't get near 200 degrees F....highway towing.

place, a paper towel catches loose metal debri.

in would results in a loose fitting sensor.