traction is a good thing out here.

pre-tensioned LSD's still in stock....at least for awhile.

a good idea to add new carrier bearings at the same time.

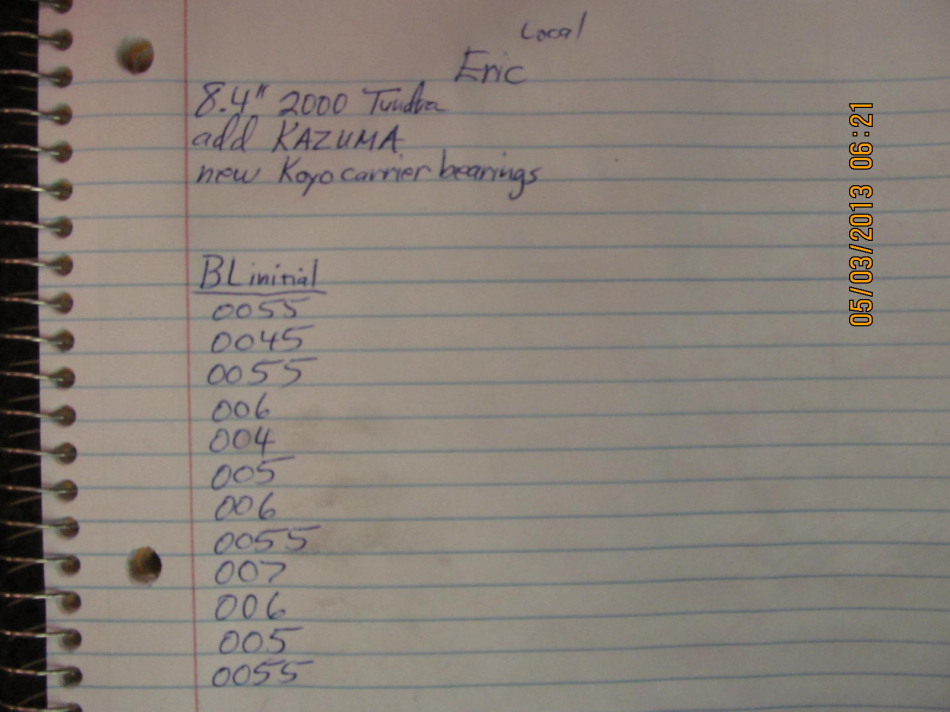

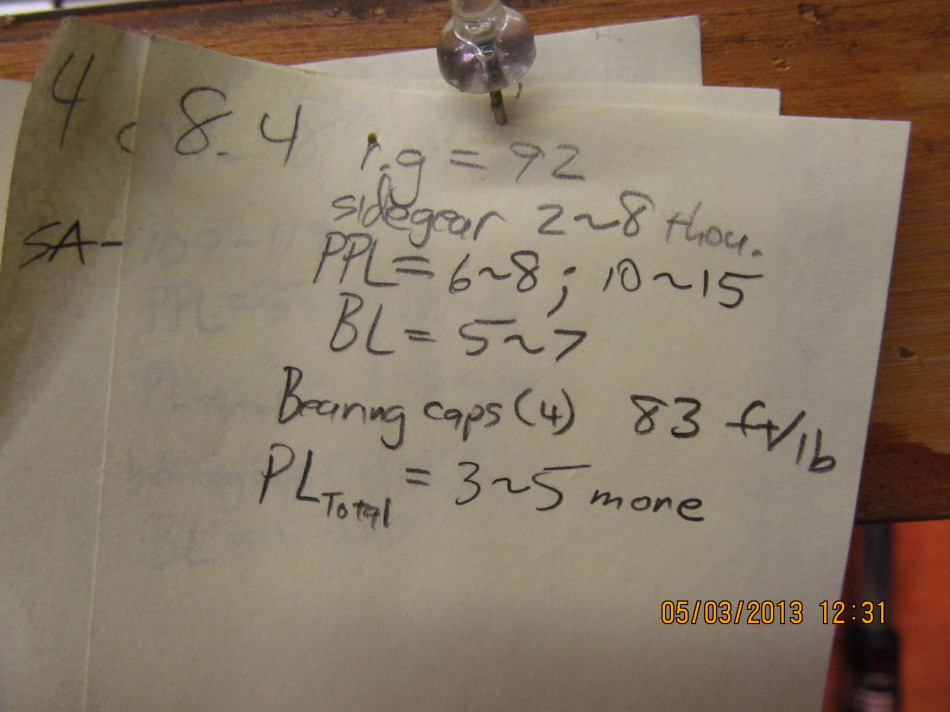

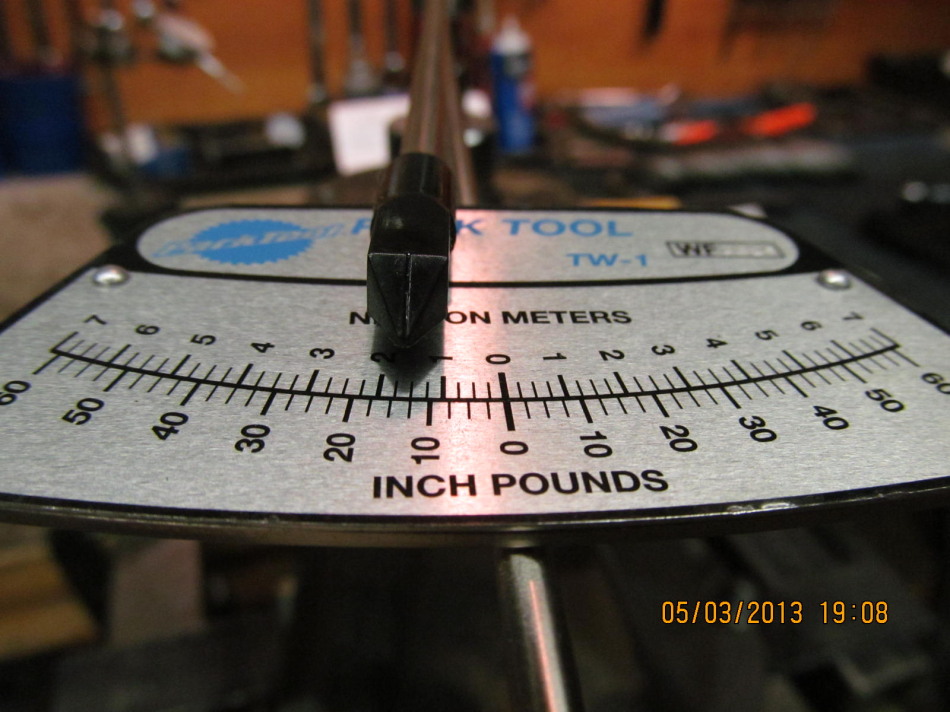

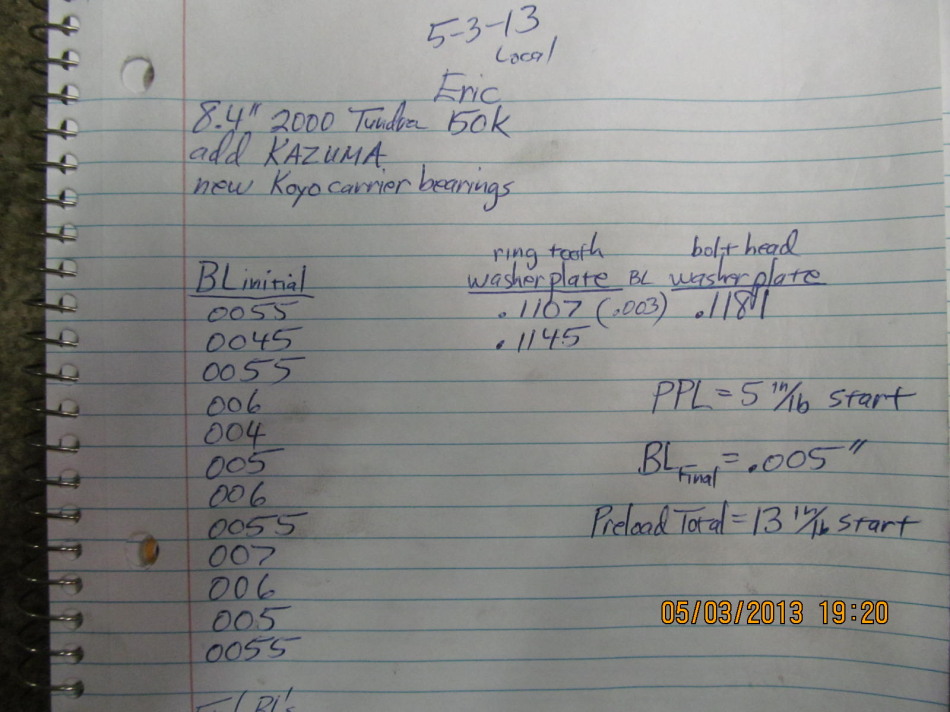

Pre-Load (CBPL) need to be adjusted/maintained. Here, the backlash is measured

and recorded on every 3rd tooth.

and it does look excellent.

not enough to remove them.

written down because I will probably add some thickness to one or both in the end.

long pinion tooth.

has paid for itself many times over.

I'm using welder gloves to cushion my hand to prevent bruising from the extreme

push required to break the bolts loose.

the low profile boltheads.

12 ring gear bolts. That's a good amount.

threads is to use the 4000 rpm bench grinder with the wire wheel attached. Makes

them look like brand new.

when I can use the tension of the press to lock it in place while I tighten the

12 bolts to 92 ft/lb.

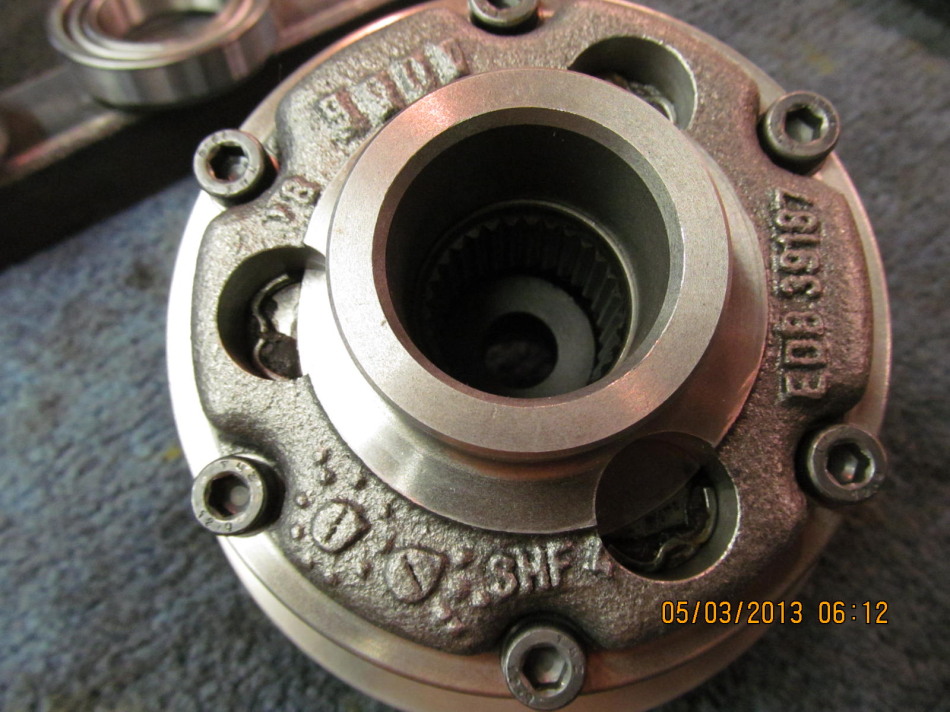

the new KOYO carrier bearings.

bearings at this point wouldn't be a bad idea.

4 or 5 inch/pounds start torque which is very good for 150k miles on the bearings.

required to tap them lightly in place.

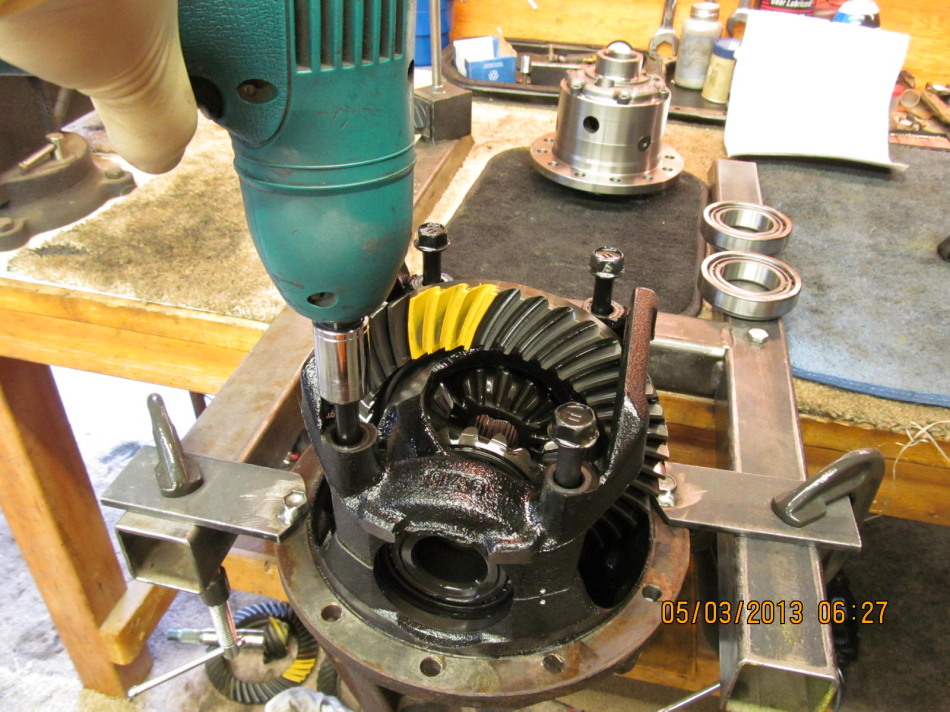

to place the brace in and snug down the 4 long bolts.

I can correct that while adding some additional CBPL at the same time.

than the oem plate. That has the effect of increasing CBPL and also

increasing the BL by about .002" more.

full seating of the washer plate.

at 13 in/lb start torque.

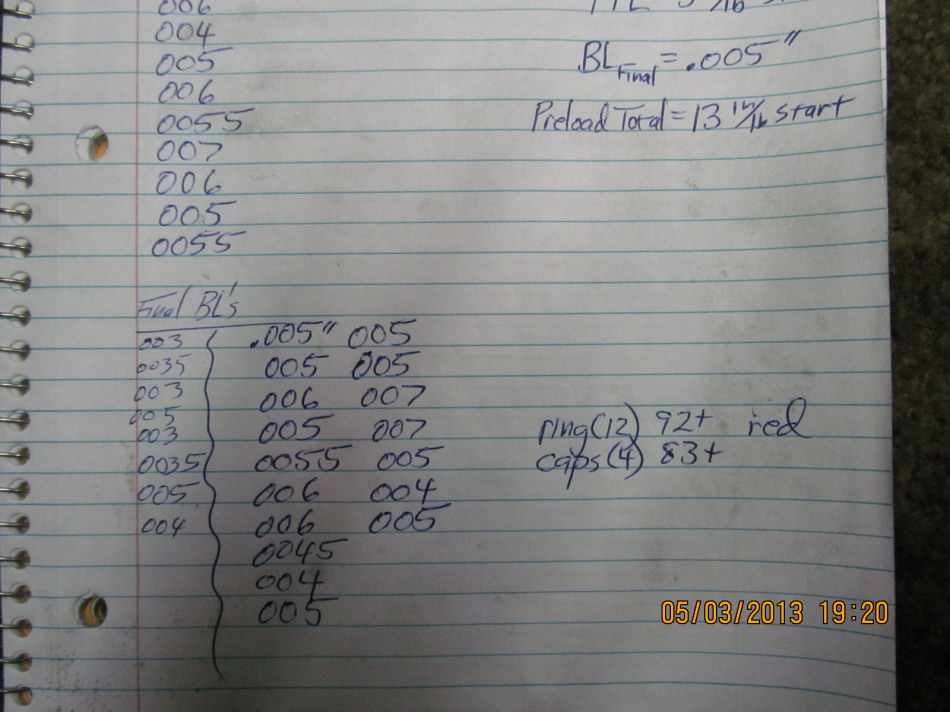

...measured on every 3rd tooth....a few that were as tight as 004 and few on

the upper side at 007. This pretty much duplicated exactly the recorded

backlash values before teardown....as verified on the notes shown below.

was not disturbed. There was nothing wrong with it. Eric did the right thing

and supplied me with new, fresh carrier bearings with the Kazuma. This should

give a very long life....and good all-around strength as the bearings are

tight and the ring gear will resist deflection.

Update----6-8-13----Eric sent me this email...cut/pasted...

"I finally got out Sunday to give the Kazuma a field test. I have to admit, it works

better than I expected :). Engagement to wheel with traction happened very quickly

with no noise, vibration , etc. and even with (traction side) wheel stuffed really hard

and opposite barely contacting the ground it delivered full power. I believe the

conservative addition of Sta Lube additive has enhanced the performance. Hopefully,

it does not accelerate the LSD clutch wear too much. I filled diff to 90% full and

drove truck for 15 miles to get things warm. Found a parking lot and did some slow

figure 8's, there was minimal chatter. I then added approx 1/4 of the additive,

buttoned her up and repeated warm up drive followed by more 8's. The chatter was

gone! Returned home topped off with Gear Oil and all is good. I can't believe

how difficult it is to find gear oil without LSD additive, thats rated for

GL5....The only local I could find ( to impatient to order online) was Coastal

brand 75W-90 Dino Oil ( not synthetic) with no LS Additive. I think I might

upgrade oil ( research pending) when I am ready to service it."