|

|

|

|

|

|

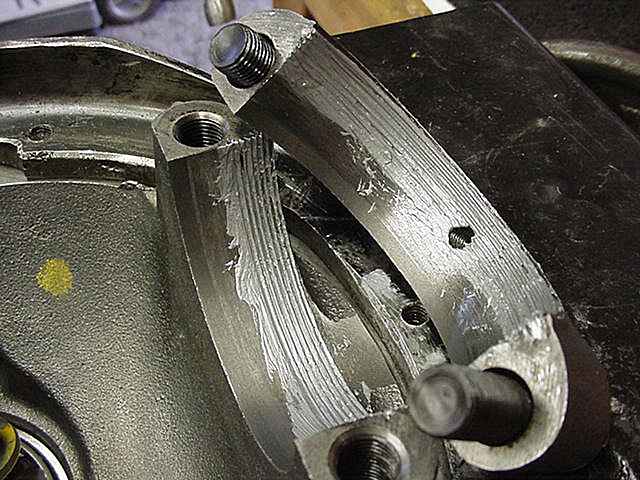

Kevin is local to me and his rear gears self-destructed. In the pic above, the old gears are not there because they are in warranty arbitration. He has tried to get them warrantied but the teeth were all evenly worn down to little nubs indicated a poor install(they were installed by a 4x4 shop here in the Phoenix area). I received this as a basket-case from Kevin....shown in the pic is the soon to be installed "cryo only" treated Yukon 529 gears as received from Bobby Long. |

|

I will be using a Yukon master kit... |

|

The new races are pressed in. |

|

I'm choosing to start with .092" for the pinion depth shim. |

|

Inner pinion bearing is pressed on with the shims. Try getting a clamshell style bearing separator in there....you won't be able to... it will require a "blue tool" like the one from RandysRingAndPinion. |

|

I'm using the usual solid collar...I started with 064 and on the 5th try at 056 I had good pinion pre-load at 12 in/lb. |

|

This Park Tool TW-1 is a must for measuring PP. |

|

The Detroit Soft Locker had to be dis-assembled and inspected for damage. |

|

... |

|

Remove these 2 "washers" on each side and it becomes a Hard Locker. Perfectly functional...just a little less "behaved" on the road sometimes. |

|

No damage...all looked good. |

|

The new ring bolts are red Loctited and torqued to 75 ft/lb. |

|

New carrier bearings are pressed on in unison. |

|

Rather shallow. |

|

shallow. |

|

.008 was added to the .092 shim-pack making for an even .100" and the drive side is nice. |

|

Coast looks great as well. Pattern is centered and not favoring the heel(outer end) as many seem to do. |

|

Whenever possible, I like to get a 3rd 'pinion' from the pinion. It agrees with me. |

|

150 ft/lbs will be applied to the carrier bearing adjusters. Anti-seize is applied in abundance to minimize thread galling. |

|

Just the right amount of muscle... |

|

These 2 pics are out of sequence but this Yukon gear is a US GEAR in disguise. |

|

Only US GEAR uses white sharpie marker....plus the fact it took .100" for the pinion shim depth is the give-a-way. |

|

The seal is carefully tapped on... |

|

Gear oil is spread on the seal to prevent dry start-up. It's a good idea to look down into the pinion hole to verify that the tiny coiled spring on the backside of the rubber seal didn't pop loose from banging the seal on too harshly. I've had it happen twice so far but I was able to suck the spring back into place with an angled pick. |

|

... |

|

Loctite and about 200 pounds. Ding the nut. |

|

.............................................................. |

|