|

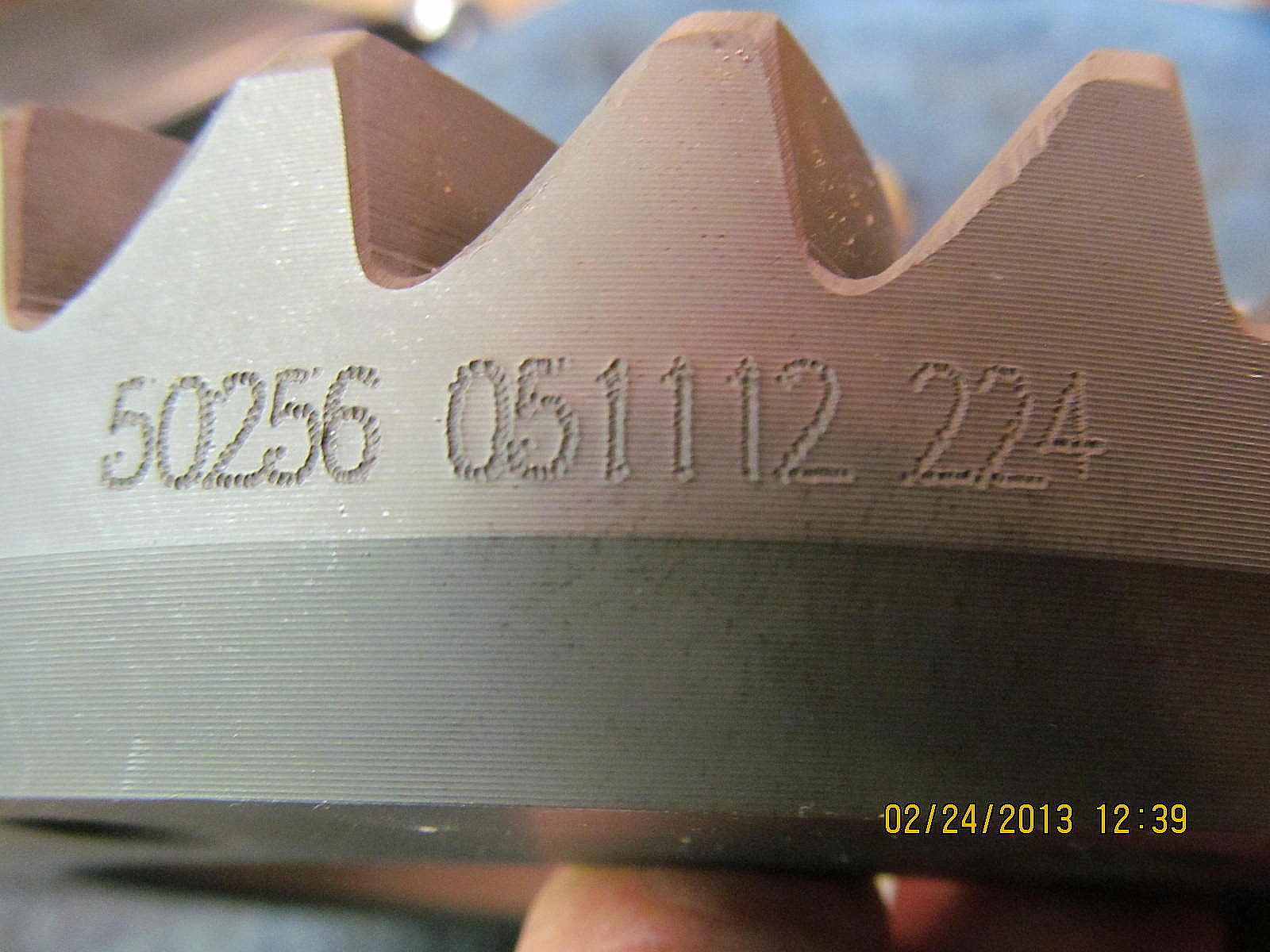

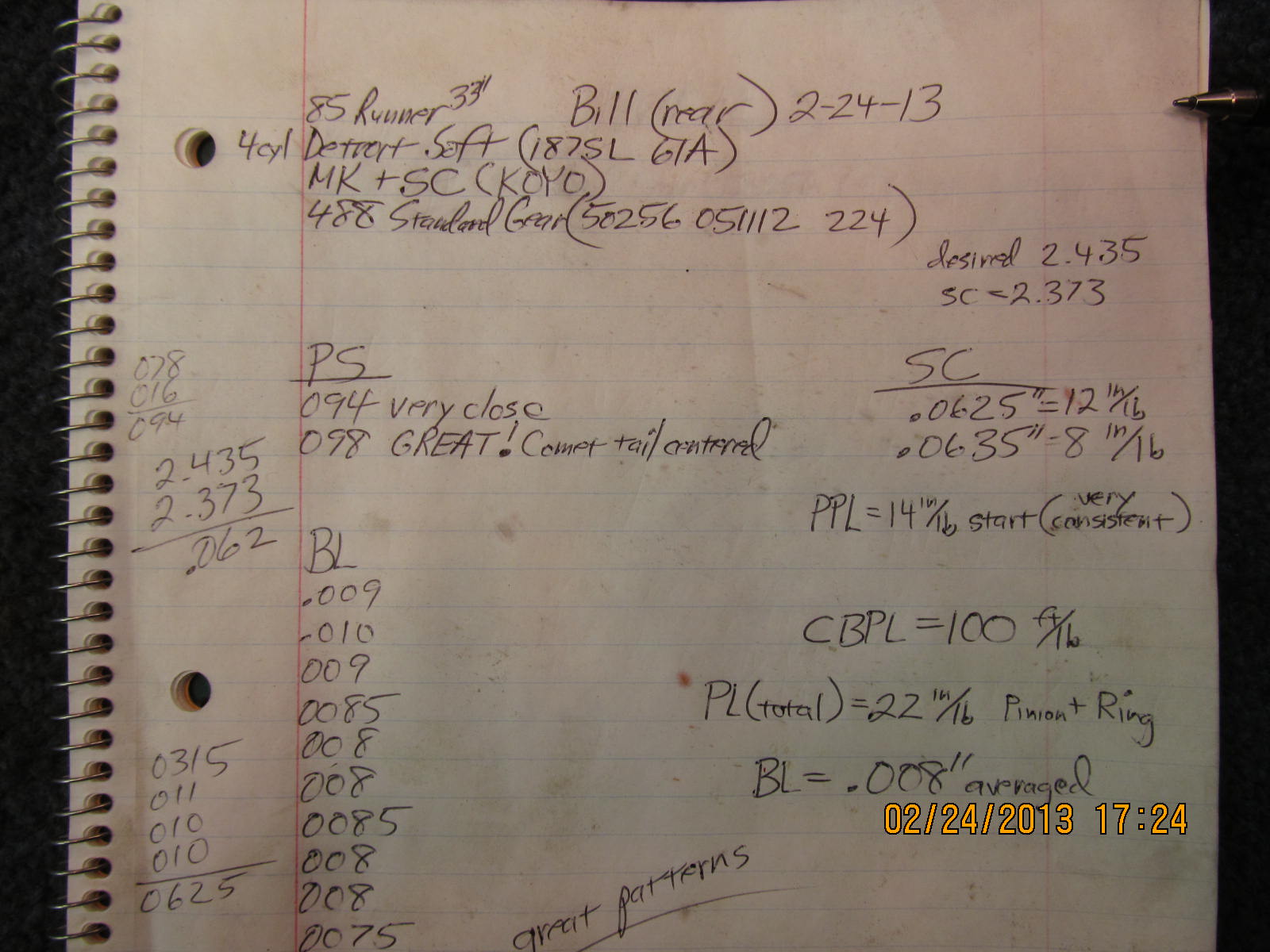

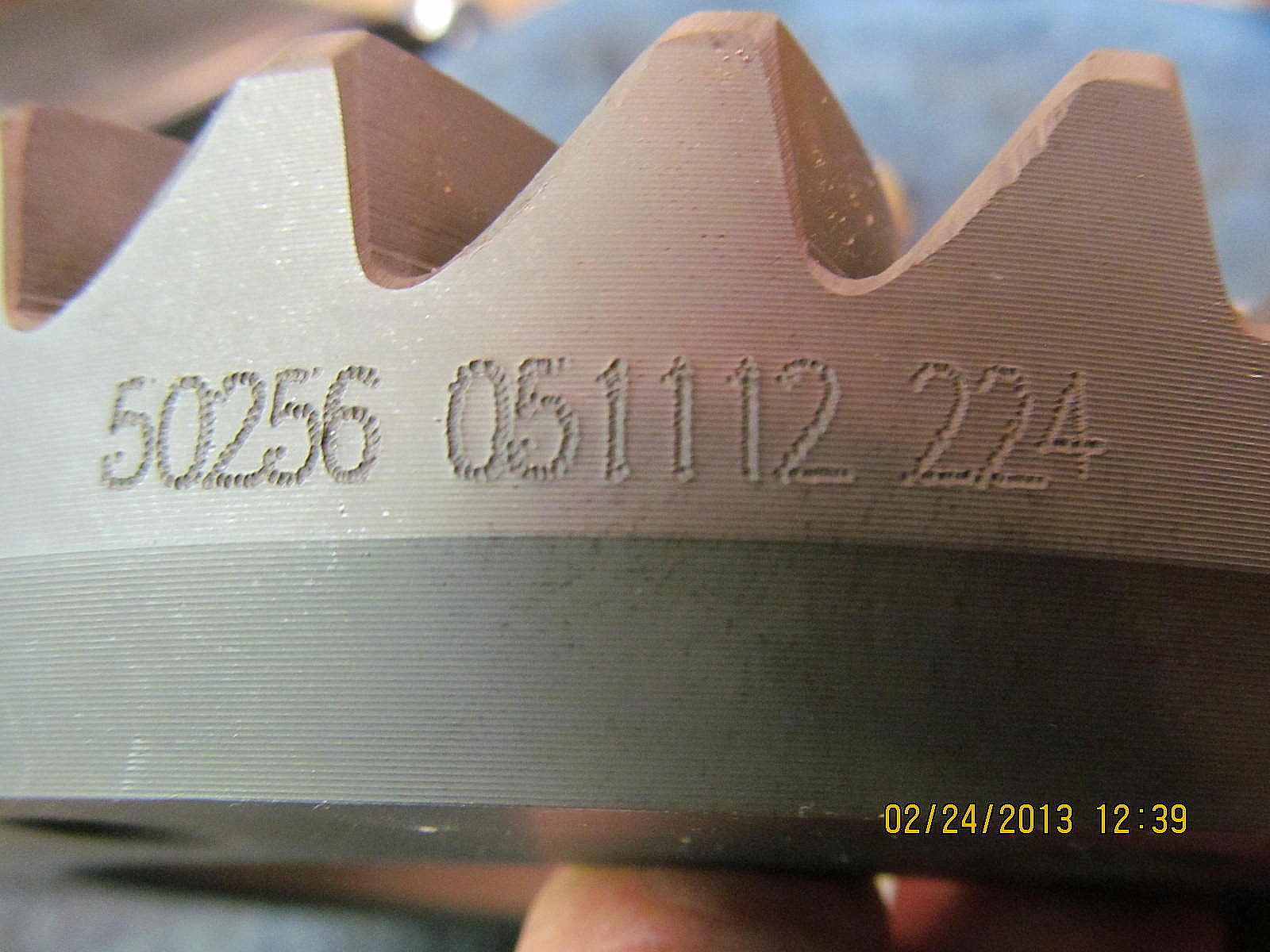

488 Standard Gears/Detroit Locker installed in KillBill's 1985 4Runner

|

|

(70 pics loading)

|

|

March 30 2014

|

|

|

Talk about procrastination......Bill(aka KillBill), located down in Tucson, contacted me about installing a 488 Standard Gear,

master kit, and Detroit Soft Locker for his 1985 4Runner with 33" tires. That was way back in February of last year(13 months

ago) and I'm finally getting around to writing it up :)

|

|

|

|

|

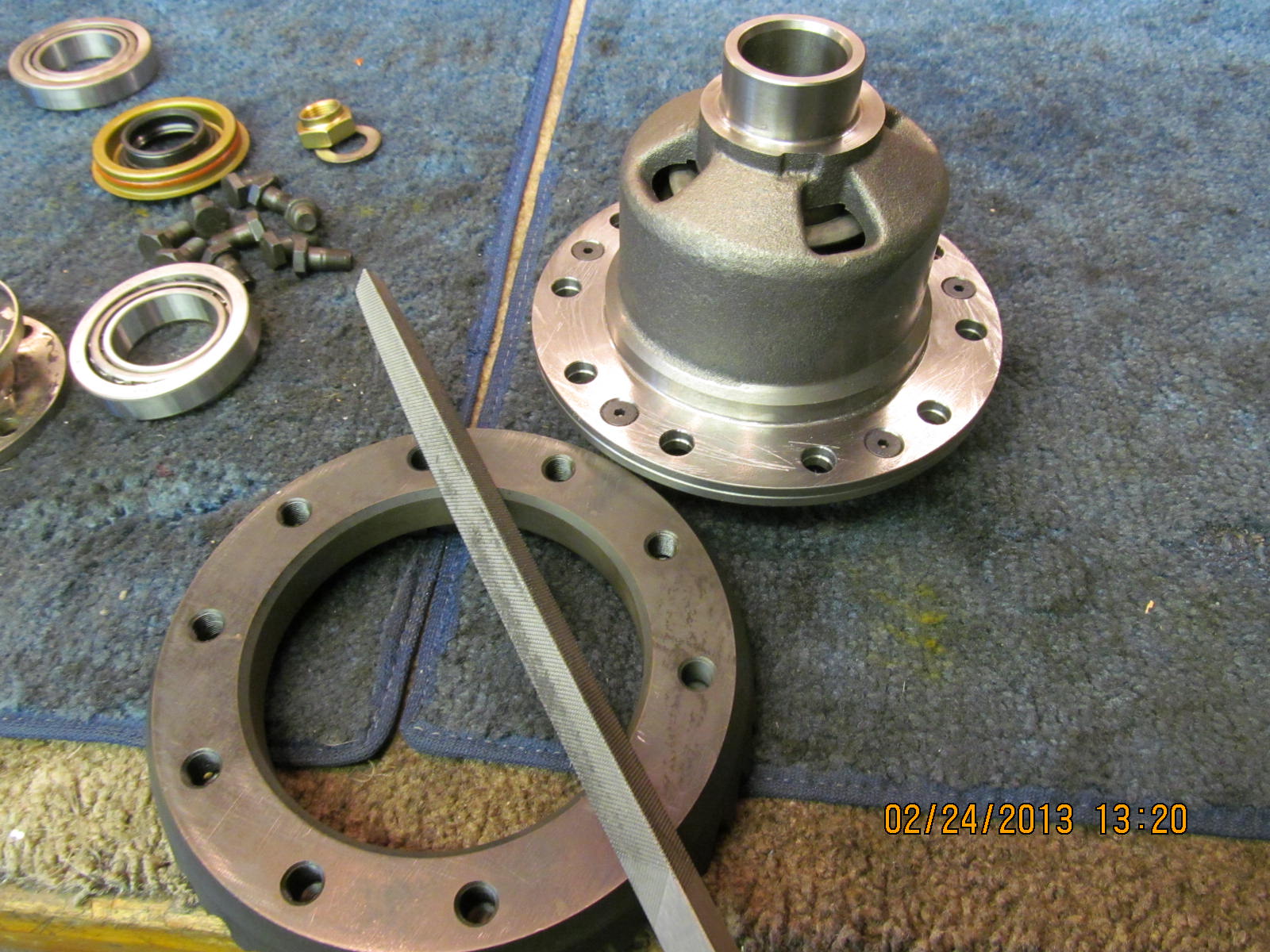

Bill supplied the Detroit Soft Locker, 488 gears, master install kit, solid collar, and Marlin Crawler Super duty pinion seal.

|

|

|

|

|

.....

|

|

|

|

|

......

|

|

|

|

There was a greyish phosphorus coating on the pinion. Best to use 1000 grit to sand it off. If not then good luck trying to remove

the big inner pinion bearing if a shim change is needed. Been there, done that.

|

|

|

|

|

.....

|

|

|

|

|

Much better. Now the bearing will press on and off with normal forces.

|

|

|

|

|

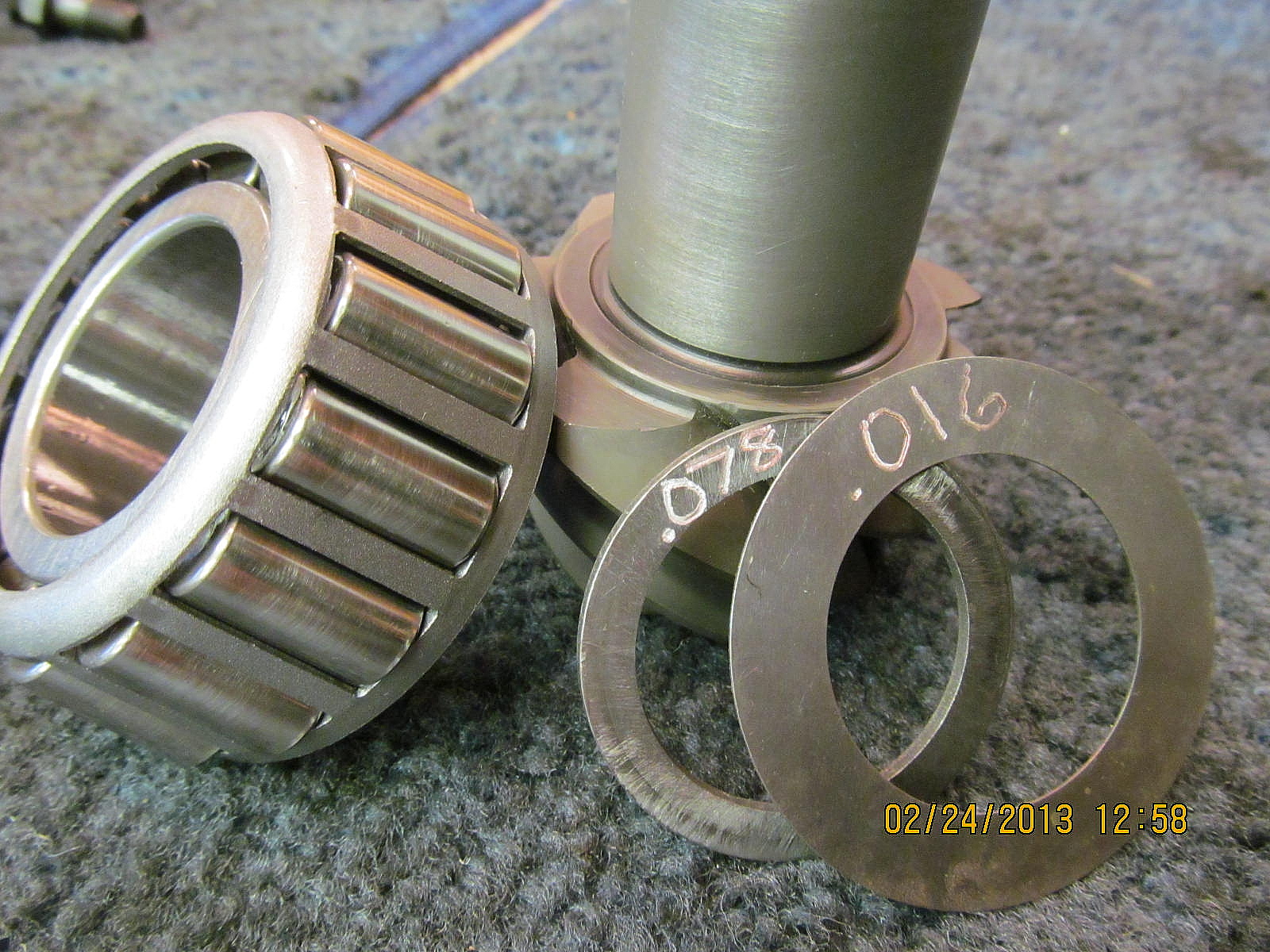

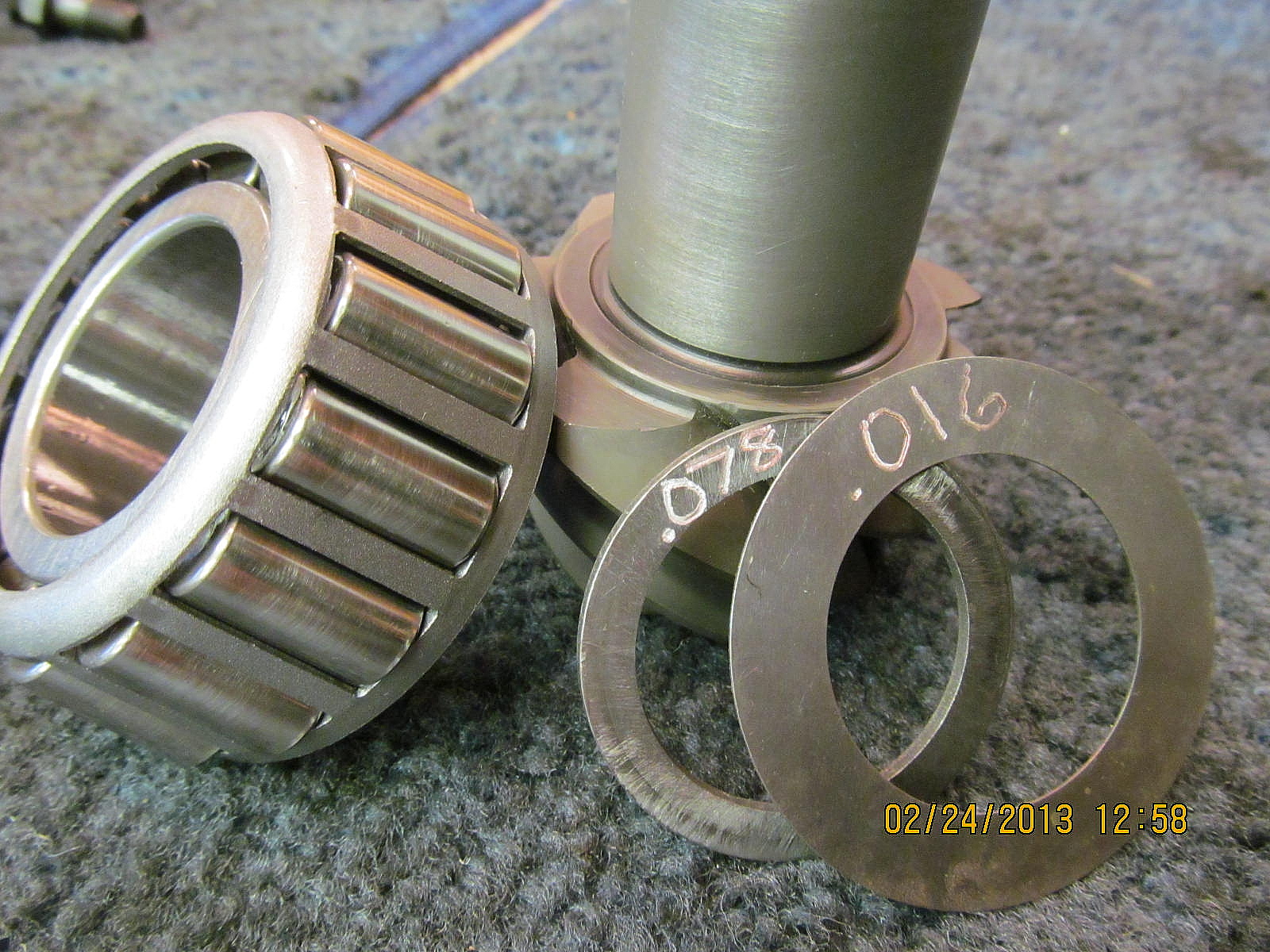

.094' will be the first value to try.

|

|

|

|

|

Pressed on with normal forces as expected.

|

|

|

|

|

The small outer race can be tapped in using a couple of old re-claimed bearing parts.

|

|

|

|

|

The larger inner race should be evenly pressed in. The soft chisel would be used as a last resort.

|

|

|

|

|

Fully seated.

|

|

|

|

|

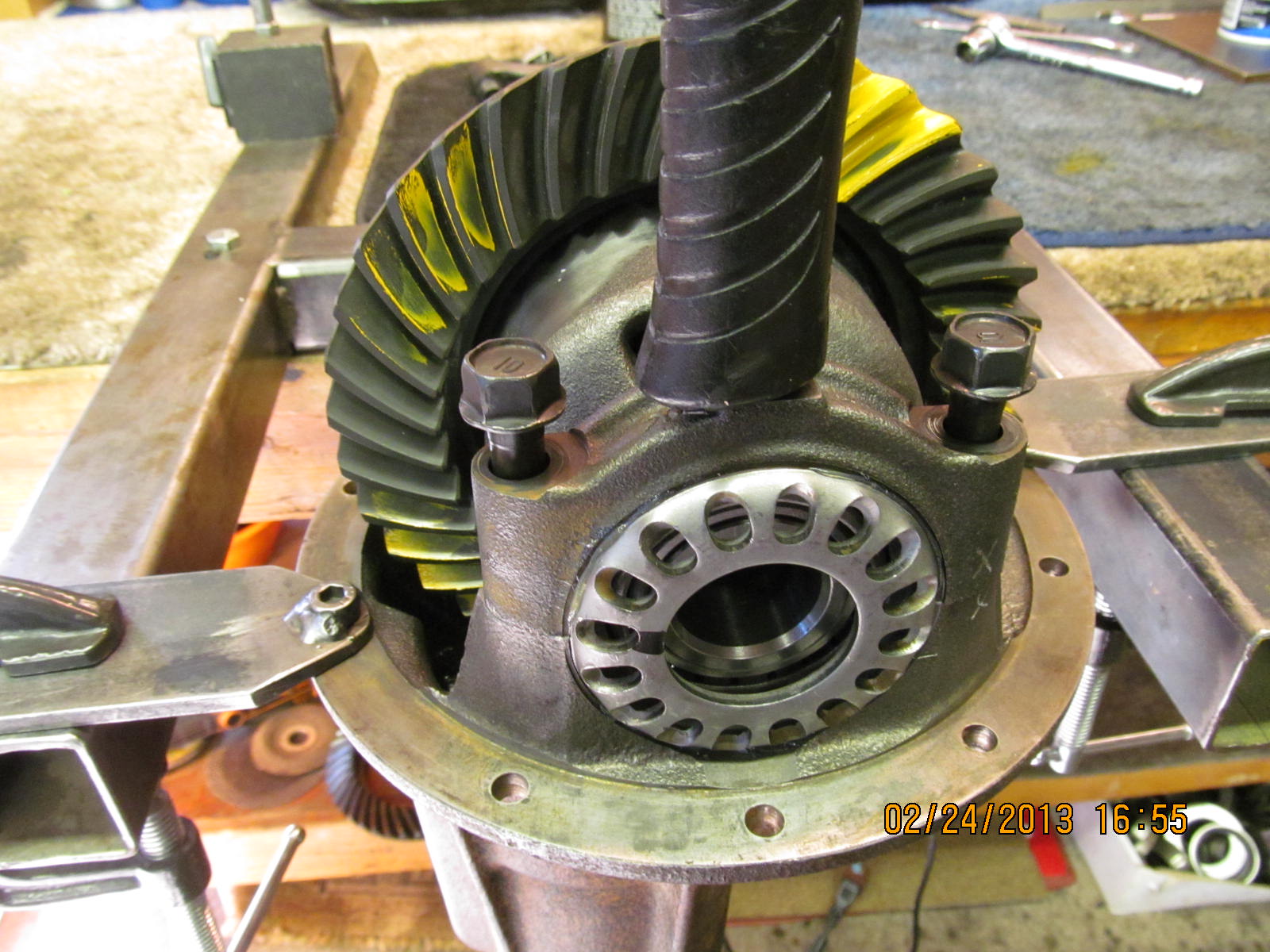

Now to install the pinion end. The solid collar will go in after we establish the pinion depth shim.

|

|

|

|

|

No need to be exact for a pattern paint. 10~20 in/lb is ok.

|

|

|

|

|

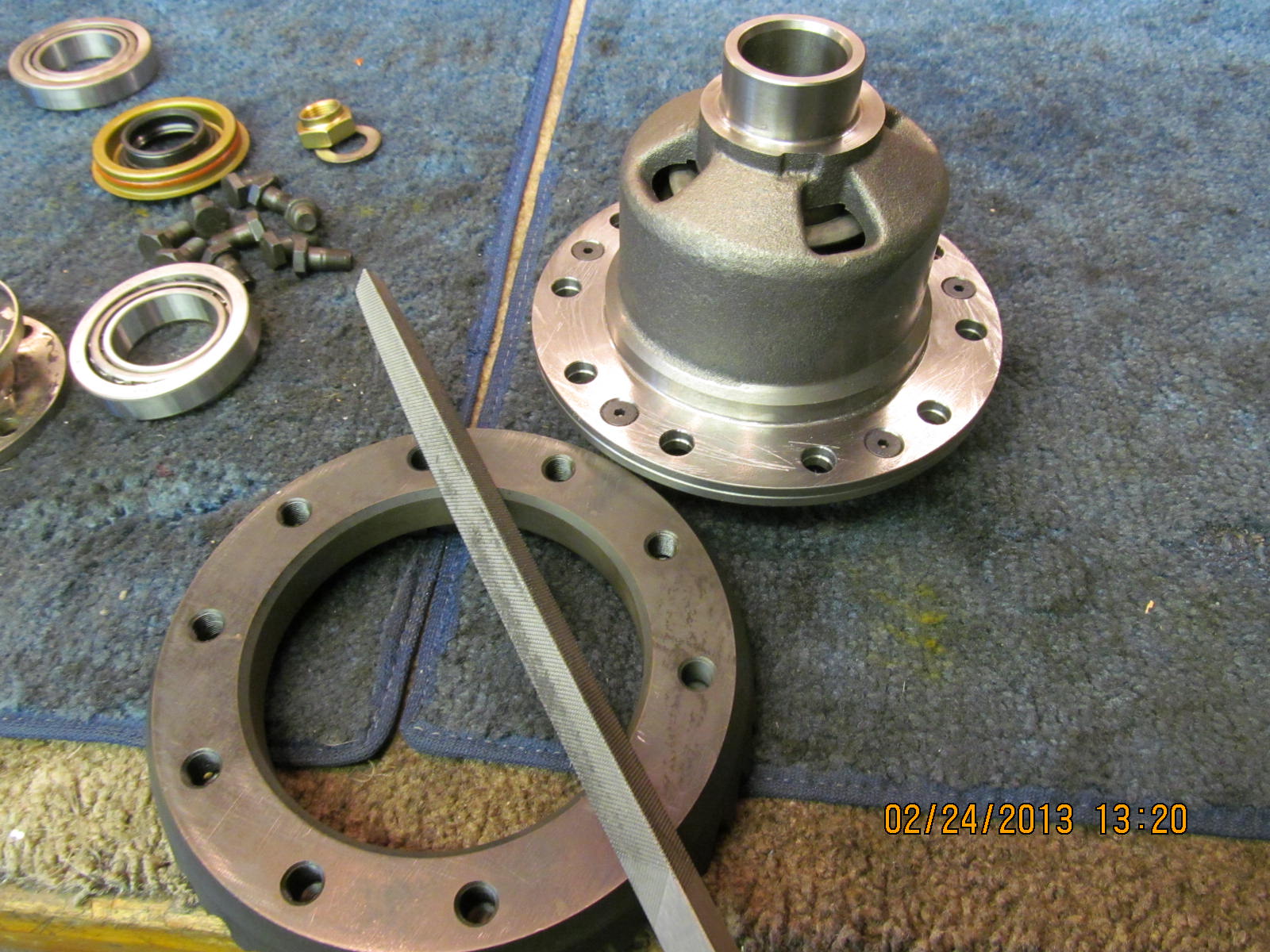

Detroit had no burrs....ring gear was aok also.

|

|

|

|

|

It was a tight fit so the 12 ton press made easy work of it.

|

|

|

|

|

The carrier bearings are pressed on at the same time.

|

|

|

|

|

....

|

|

|

|

|

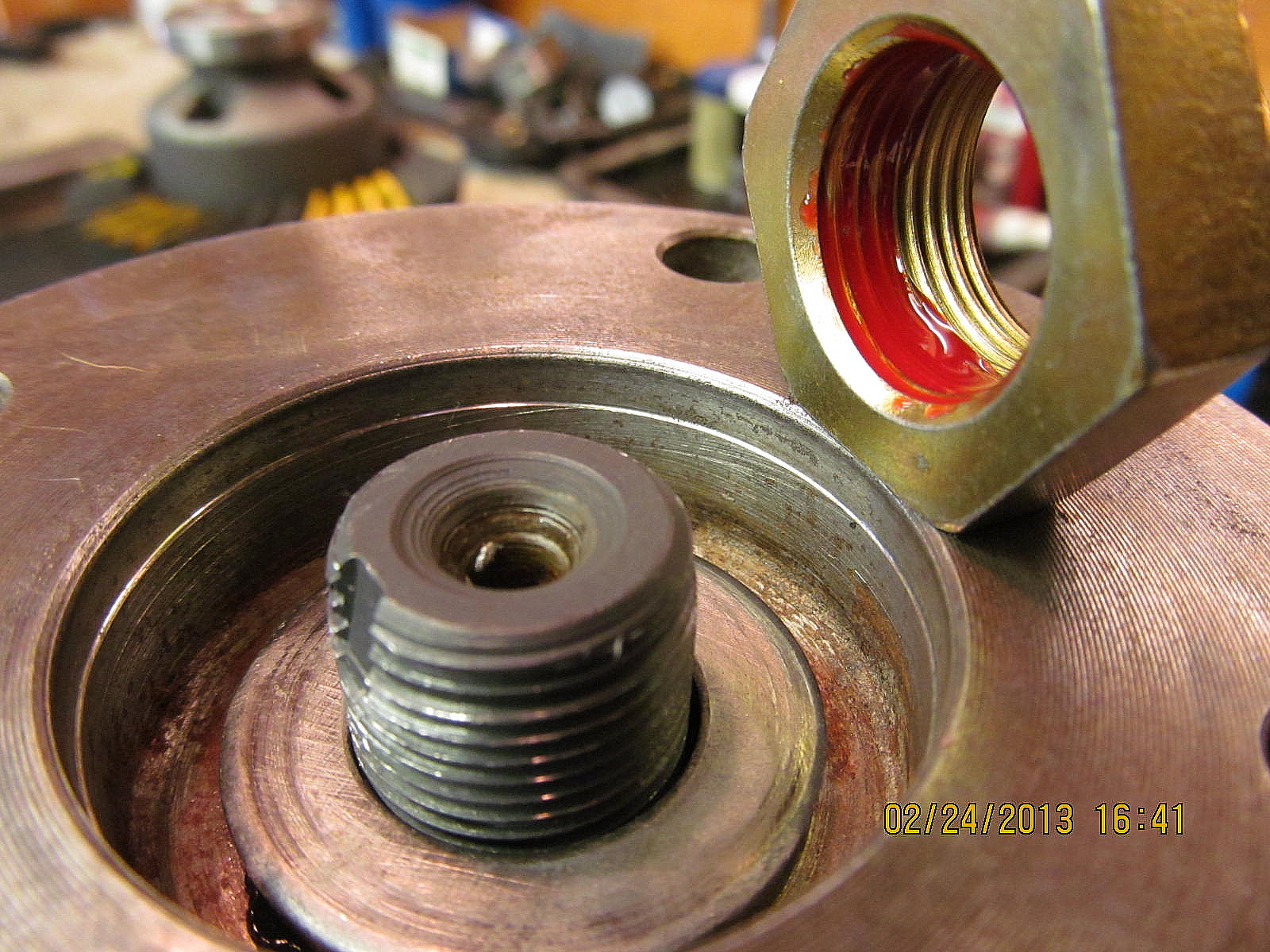

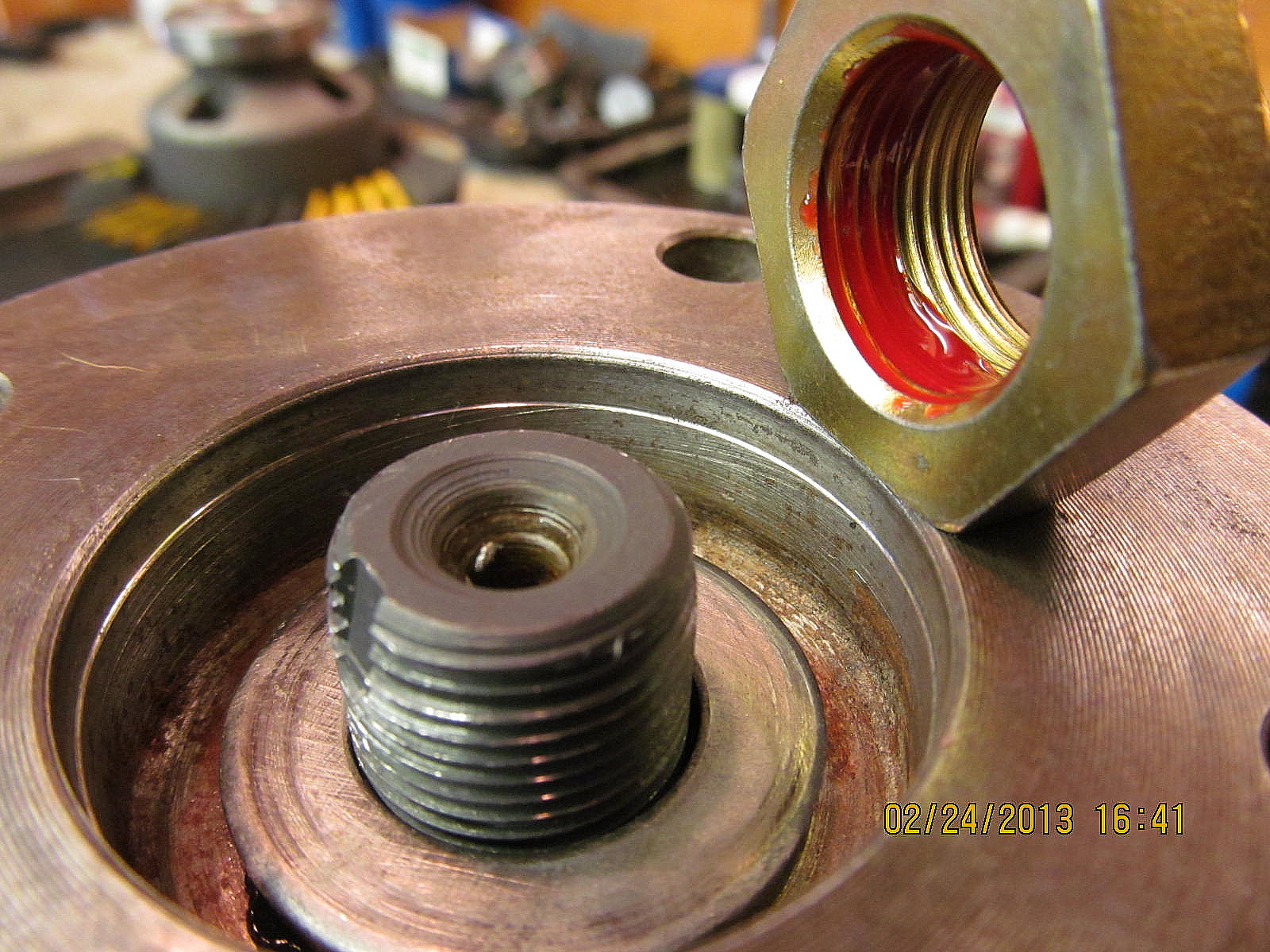

I use starting fluid to clean the oils off the threads and red loctite 272 is applied to the 10 ring gear bolts.

|

|

|

|

|

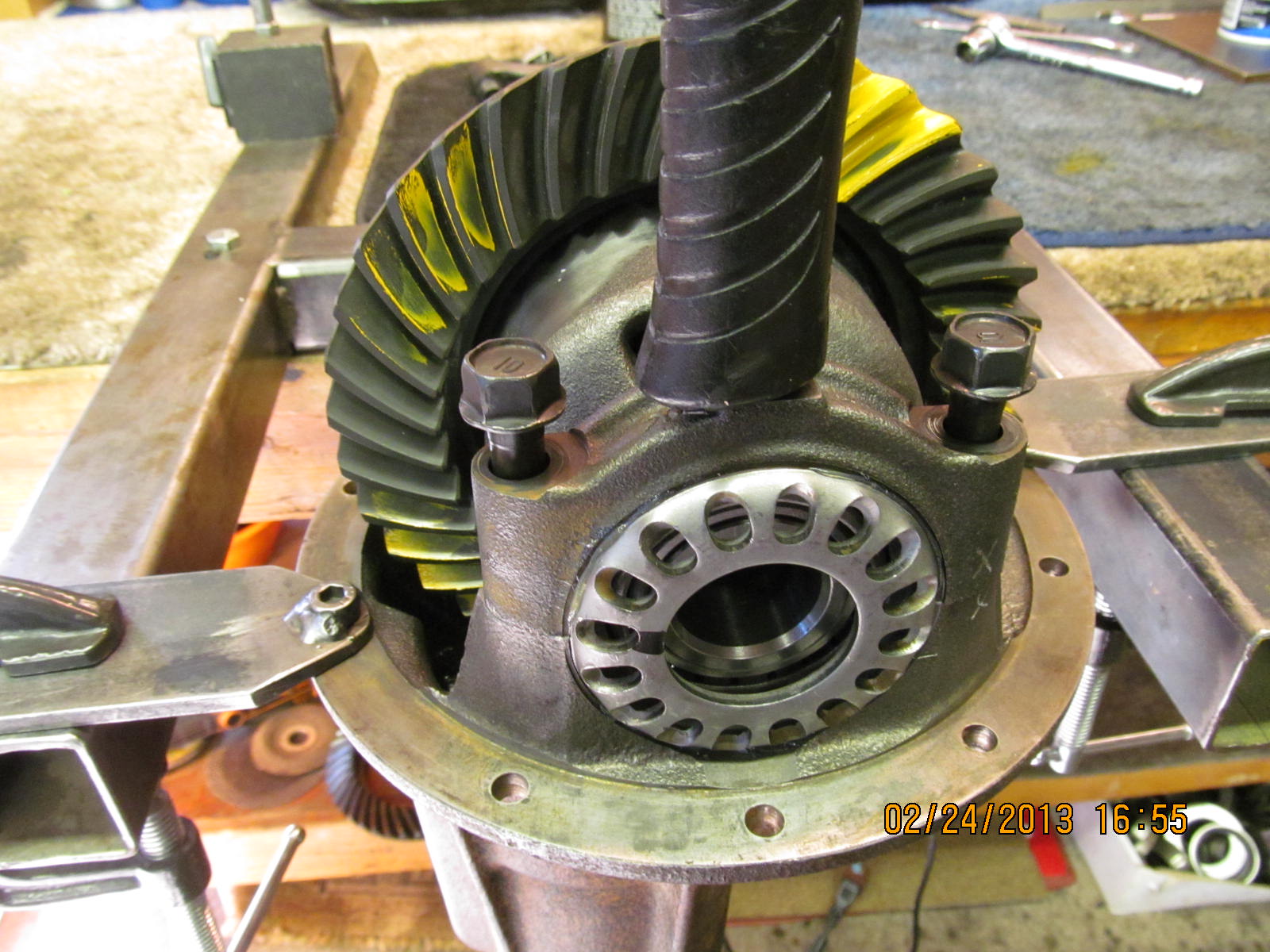

Keep the pressure on the carrier bearings and then it's easy to tighten the bolts with the Detroit "locked" in place.

|

|

|

|

THUD! I use the rubber end of the hammer to fully seat the bearing cap. Done properly, you'll never end up cross-threading

the wheel.

|

|

|

|

|

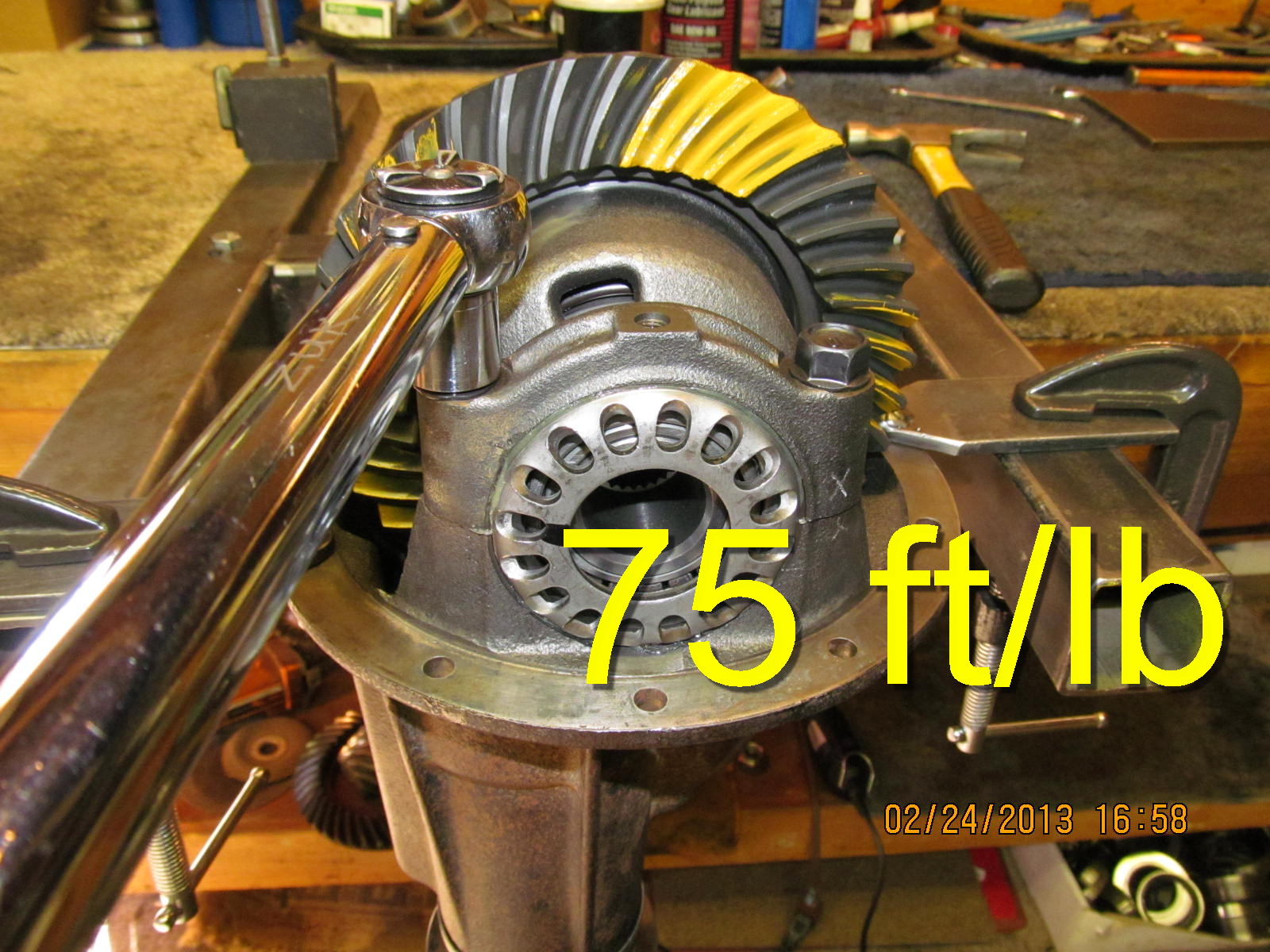

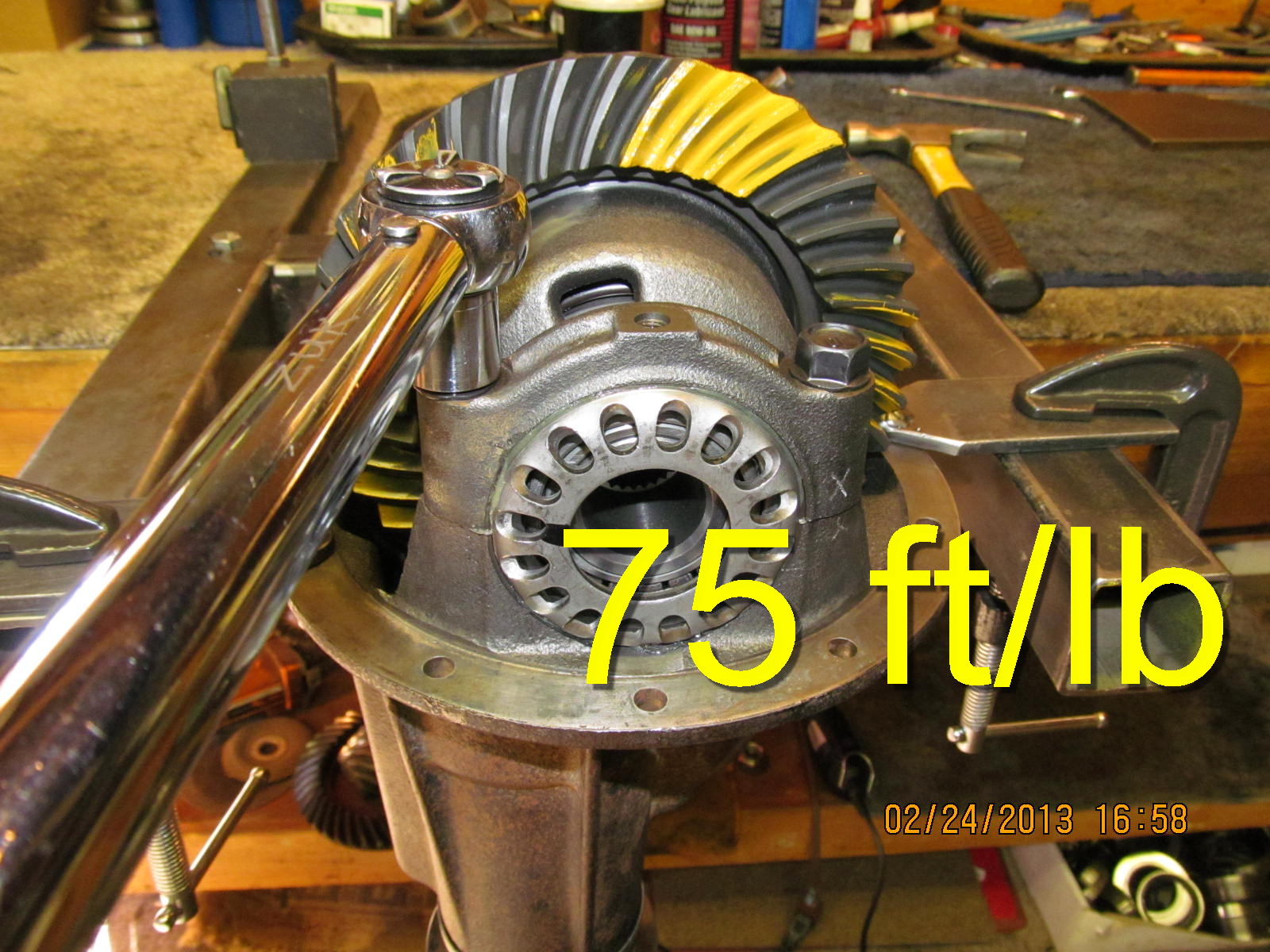

With the bearing cap bolts tightened to 75 ft/lb, the adjuster wheels should turn smooth and easy.

|

|

|

|

|

It's just a paint check so set the BL for about .006 to .009"....moderate carrier bearing preload is ok.

|

|

|

|

|

Not bad...very close. Good centering from toe to heel. Maybe a little deeper from the face to flank.

|

|

|

|

|

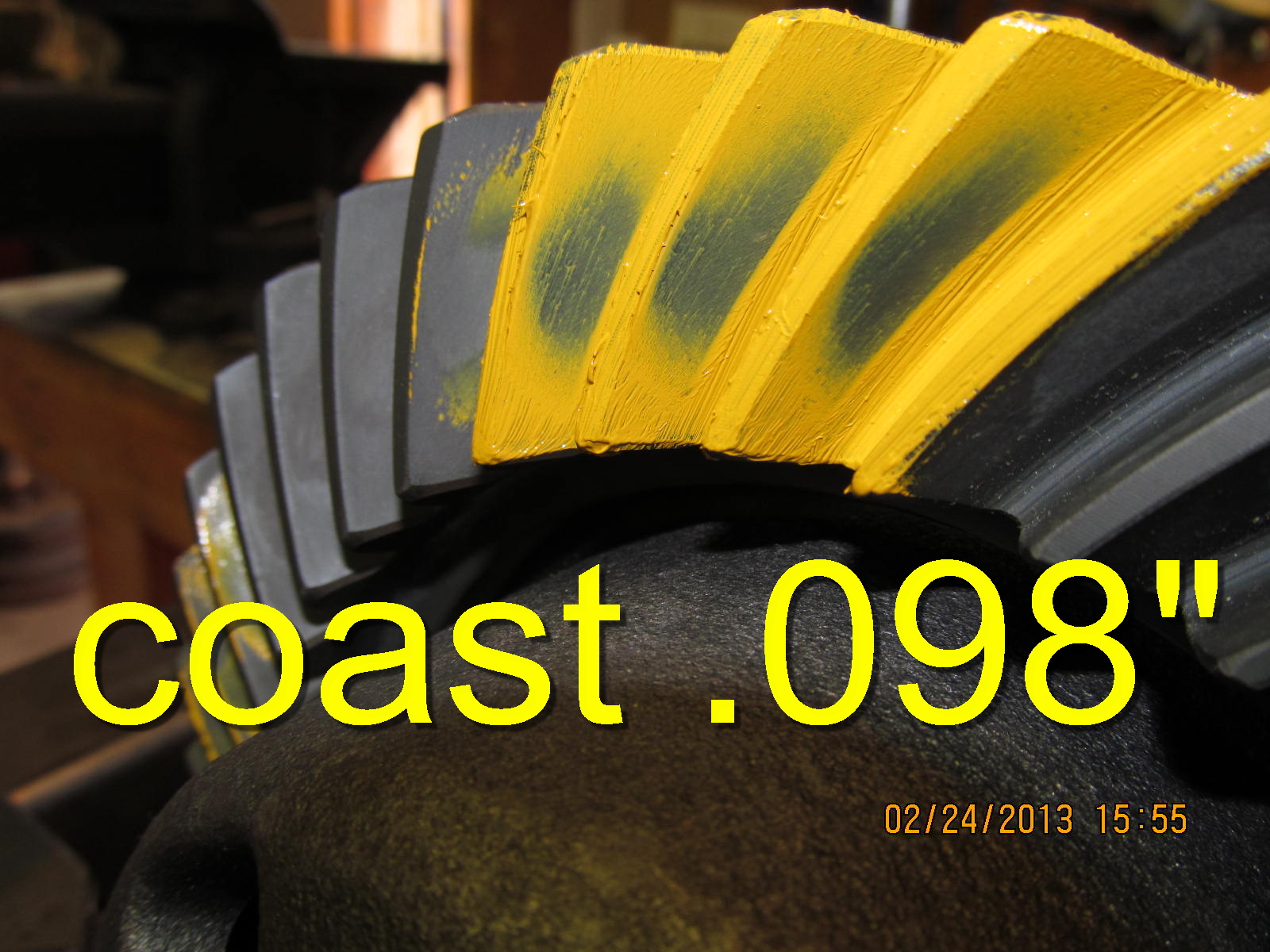

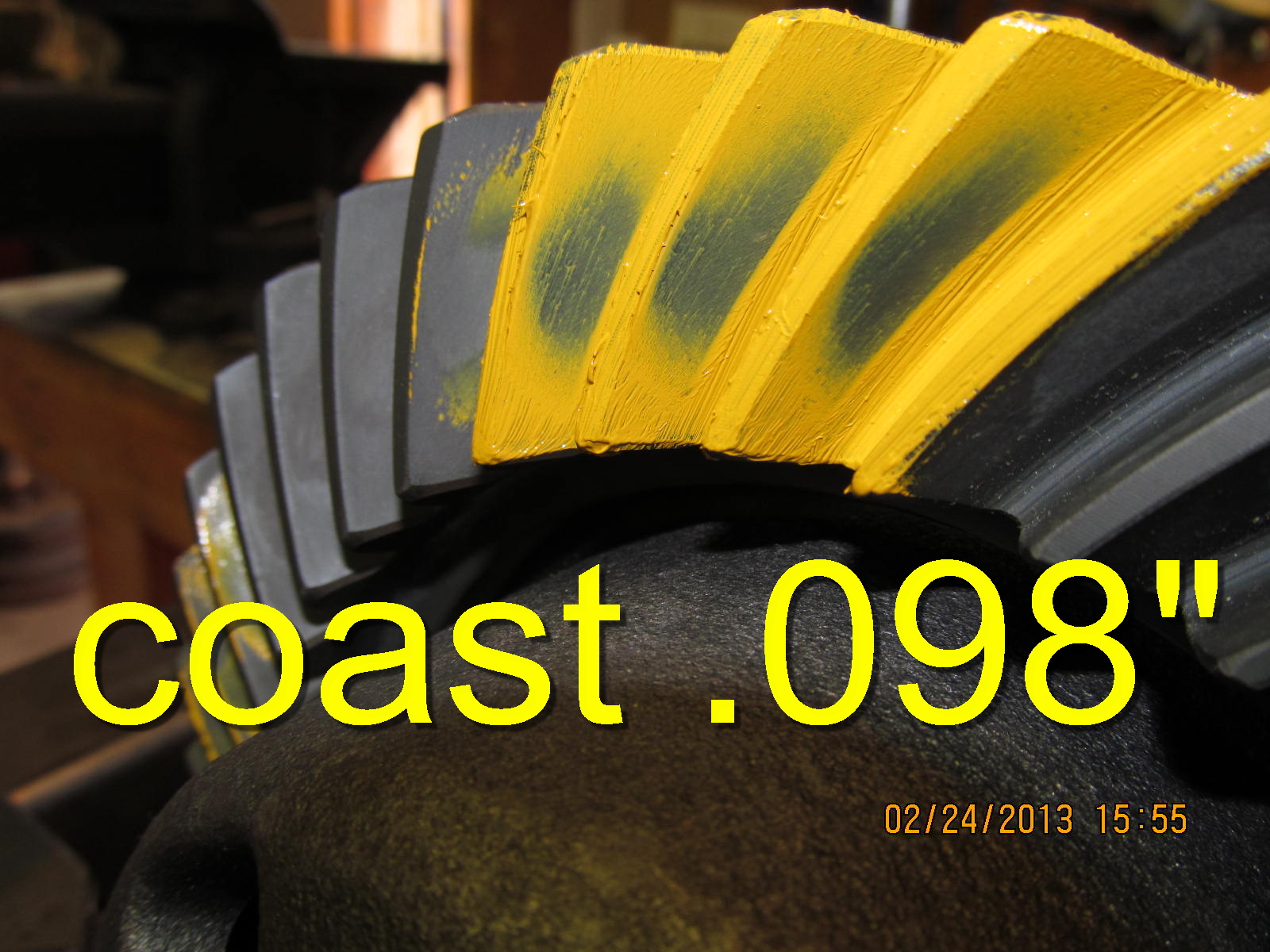

Wow, even the coast is centered from toe to heel. We have balance.

|

|

|

|

|

The comet tail on the pinion is tucked in to the root of the tooth....suggesting I could go deeper on the shim.

|

|

|

|

|

Press it out...

|

|

|

|

|

Press the inner bearing off....

|

|

|

|

|

I will replace the .016" shim with this .020" shim.

|

|

|

|

|

...and the same repetitive procedure to assemble the pinion end...

|

|

|

|

|

...same thing, set the backlash with mild to moderate carrier bearing preload.

|

|

|

|

|

Oh ya....my "slight deep" favored depth. Nice center.

|

|

|

|

|

Nice shape and solid looking pressure contact deep in the coast surface. Very well centered toe to heel.

|

|

|

|

|

Comet tail(heel end) is swinging more to center.

|

|

|

|

|

...

|

|

|

|

|

...

|

|

|

|

|

...

|

|

|

|

|

...

|

|

|

|

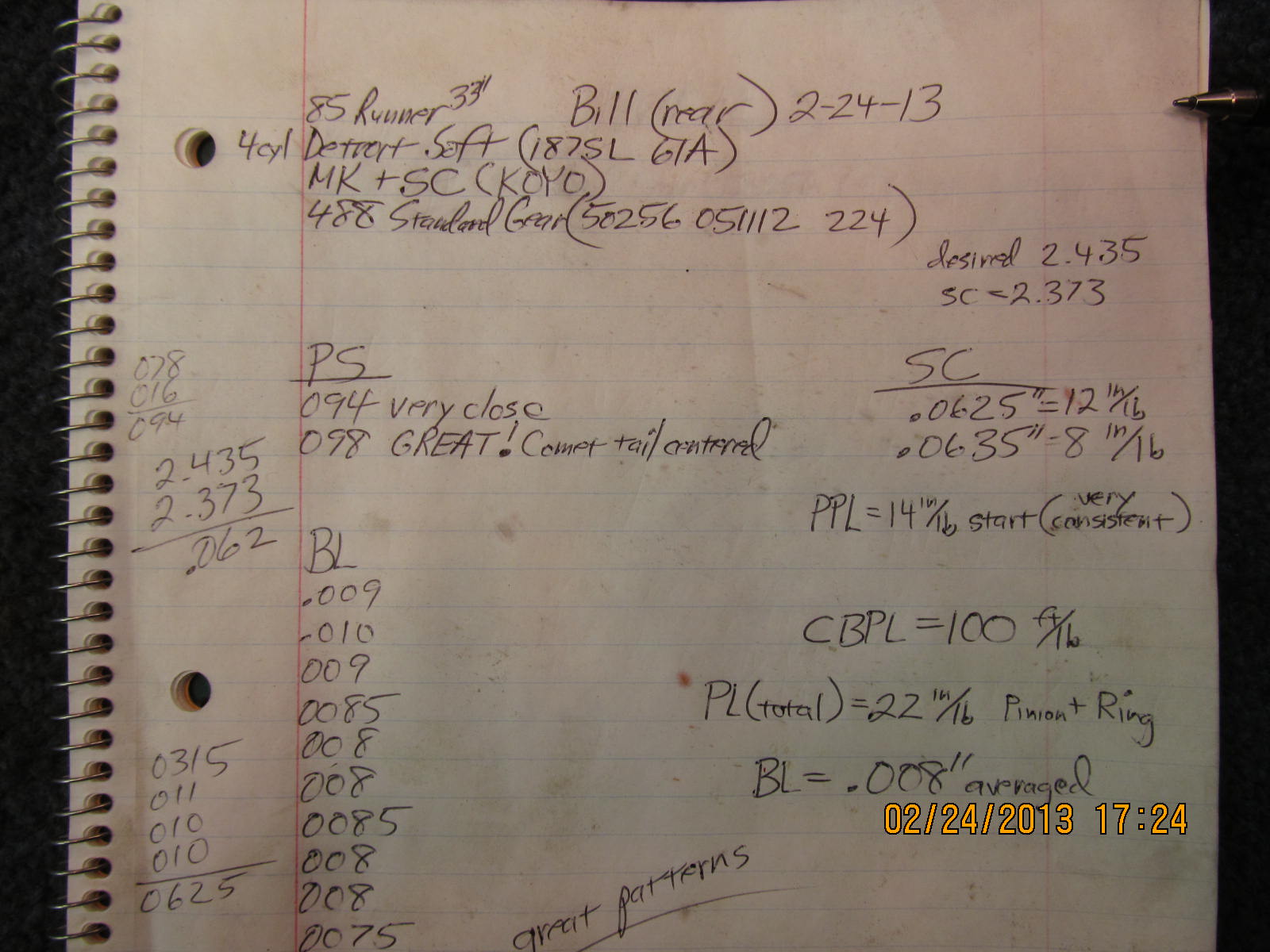

Finally, the pinion is removed and now the solid collar is installed. Approximately 2.435" is the total length when dealing with

a "4 cylinder" 3rd and a "B kit bearing" on a long pinion head V6 pinion. .0615" shim is our first try.

.0615 + 2.373" = 2.4345"

|

|

|

|

|

12 in/lb start torq....just a tad too much considering the pinion nut is only tightened to about 200 ft/lb at the moment.

|

|

|

|

|

Tear the pinion out...add .001" to the stack...and our new value is 8 in/lb start torq which is aok.

|

|

|

|

|

Now the Marlin seal can be installed.

|

|

|

|

|

It has it's own sealant which is a nice touch.

|

|

|

|

|

Pinion flange is next.

|

|

|

|

Never had a pinion nut loosen up on me....maybe the red loctite had something to do with it....or the massive amount of torq I

use....or that I ding the nut.

|

|

|

|

|

I can use the cheater bar to tighten it a bit more than the electric impact can.

|

|

|

|

|

A light tap-tap-tap while turning the pinion helps the rollers equalize their tensions.

|

|

|

|

|

The final 14 in/lb start torq is in the spec of the FSM just fine.

|

|

|

|

|

DING and the pinion end is complete.

|

|

|

|

|

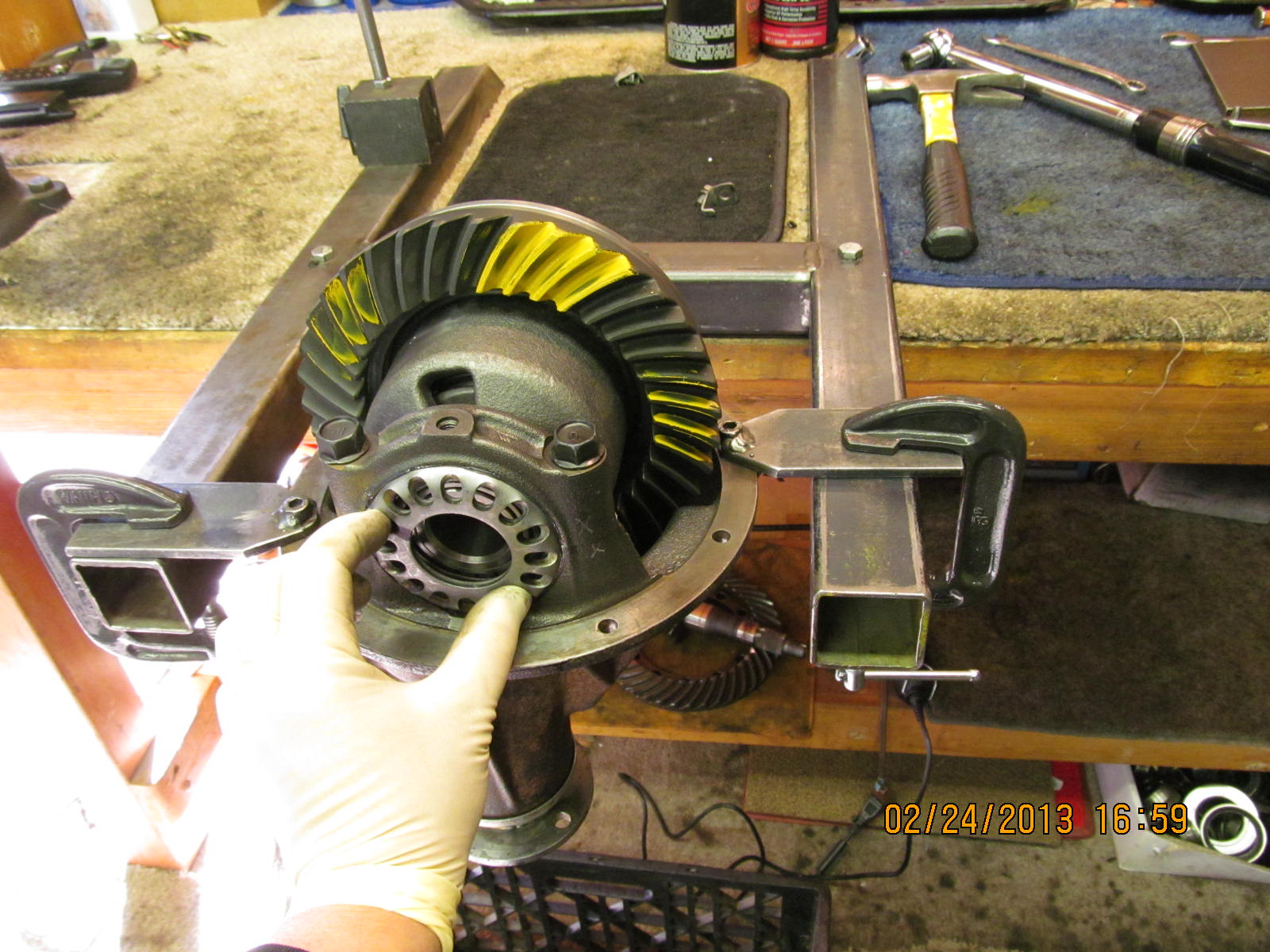

Some grease on the threads never hurts.

|

|

|

|

|

Threads are meshed properly.

|

|

|

|

|

A final 75 ft/lb on all 4 bearing cap bolts.

|

|

|

|

|

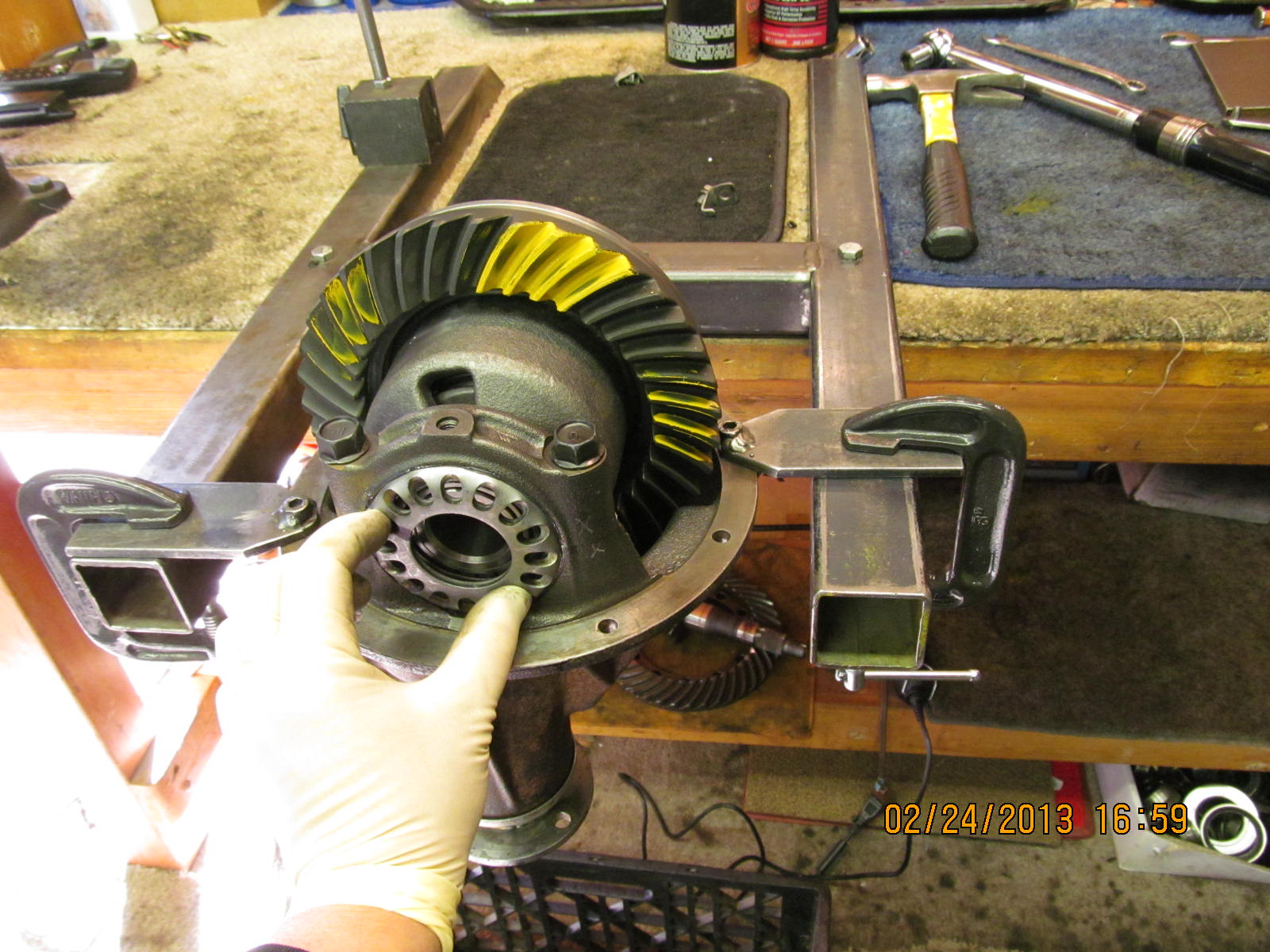

The wheels turn so nice with just finger pressure.

|

|

|

|

|

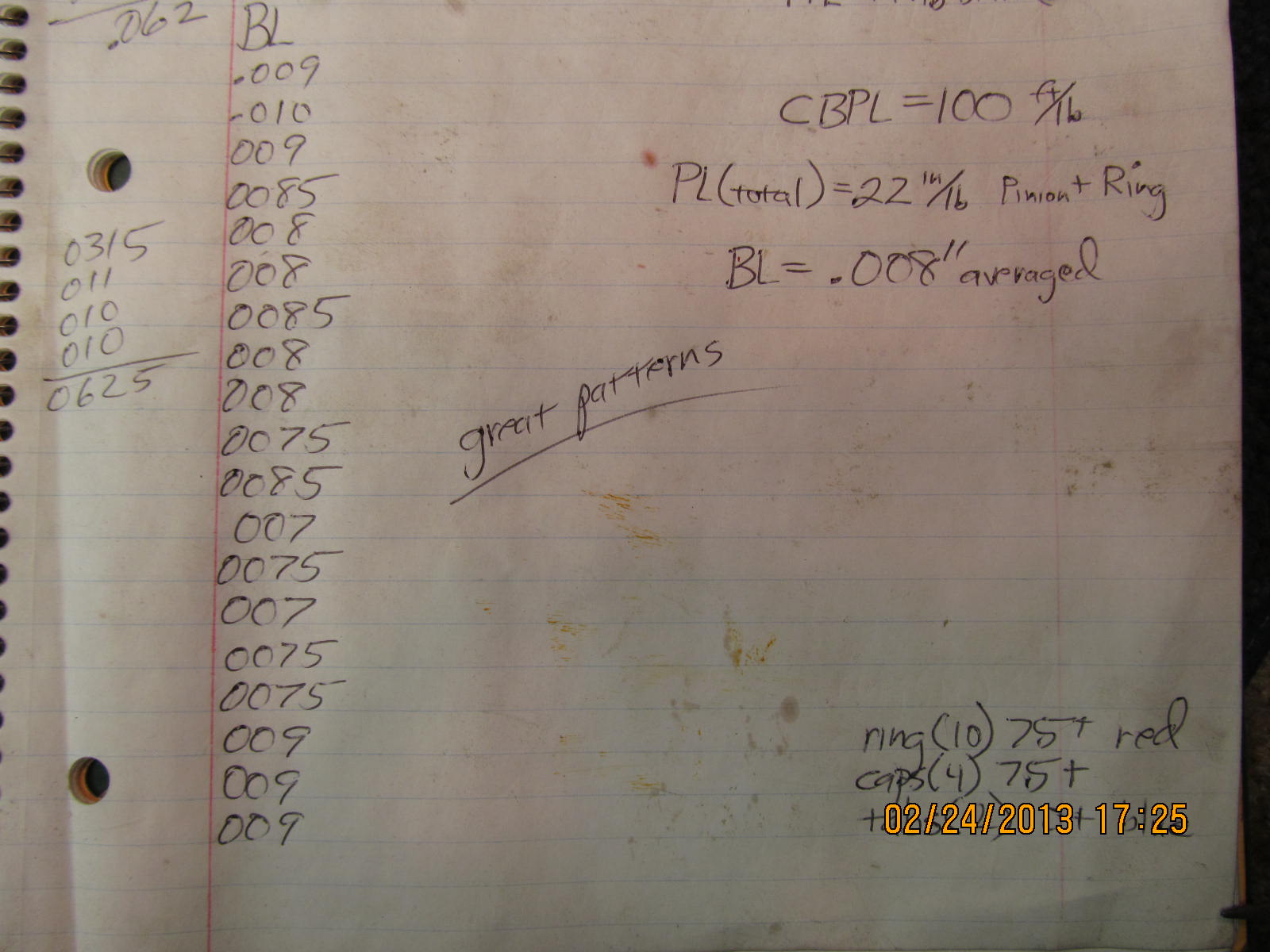

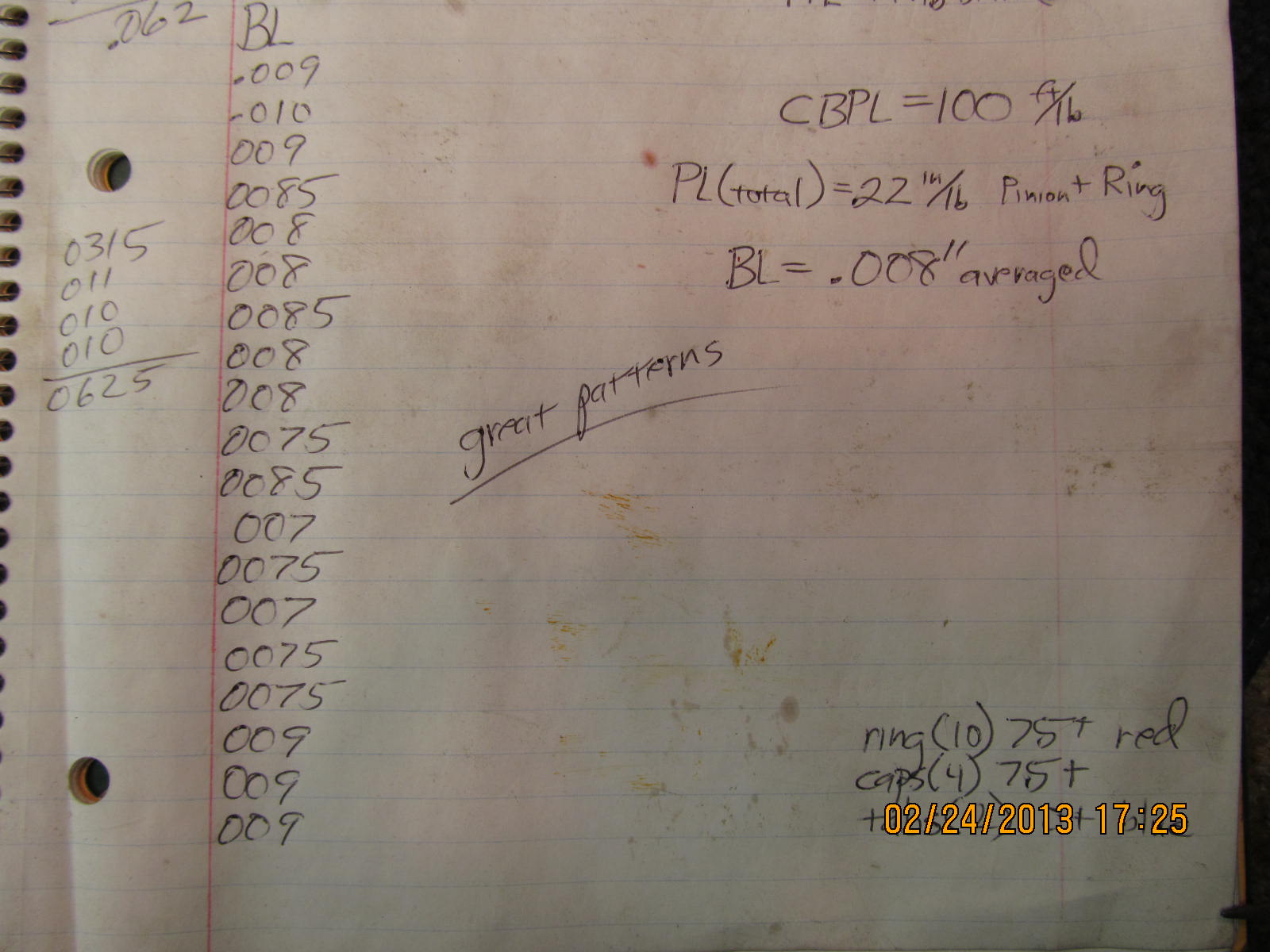

About 100 ft/lb is dialed in...while at the same time some attention is on backlash.

|

|

|

|

I measured a combined 22 in/lb for pinion plus carrier preload. Since 14 was for pinion that leaves 8 for carrier bearing

preload.

|

|

|

|

|

Backlash should be checked on every 2nd or 3rd tooth. It was averaging here about .008" which is aok.

|

|

|

|

|

Drive side----a final check. Looks excellent....well centered and slight deep.

|

|

|

|

|

Coast--- Excellent. Centered. It doesn't work out this way all the time.

|

|

|

|

|

..........................

|

|

|

|

|

With a good backlash range and good pre-load it's now time to put the lock tabs on. Blue loctite....

|

|

|

|

|

....and 10 ft/lb.

|

|

|

|

|

Some notations I put on the ring.

|

|

|

|

|

Notes taken during the install process.

|

|

|

|

|

|

|

|